lock LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 738 of 1007

BODY DIMENSIONS

BODY DIMENSIONS 77-1-3

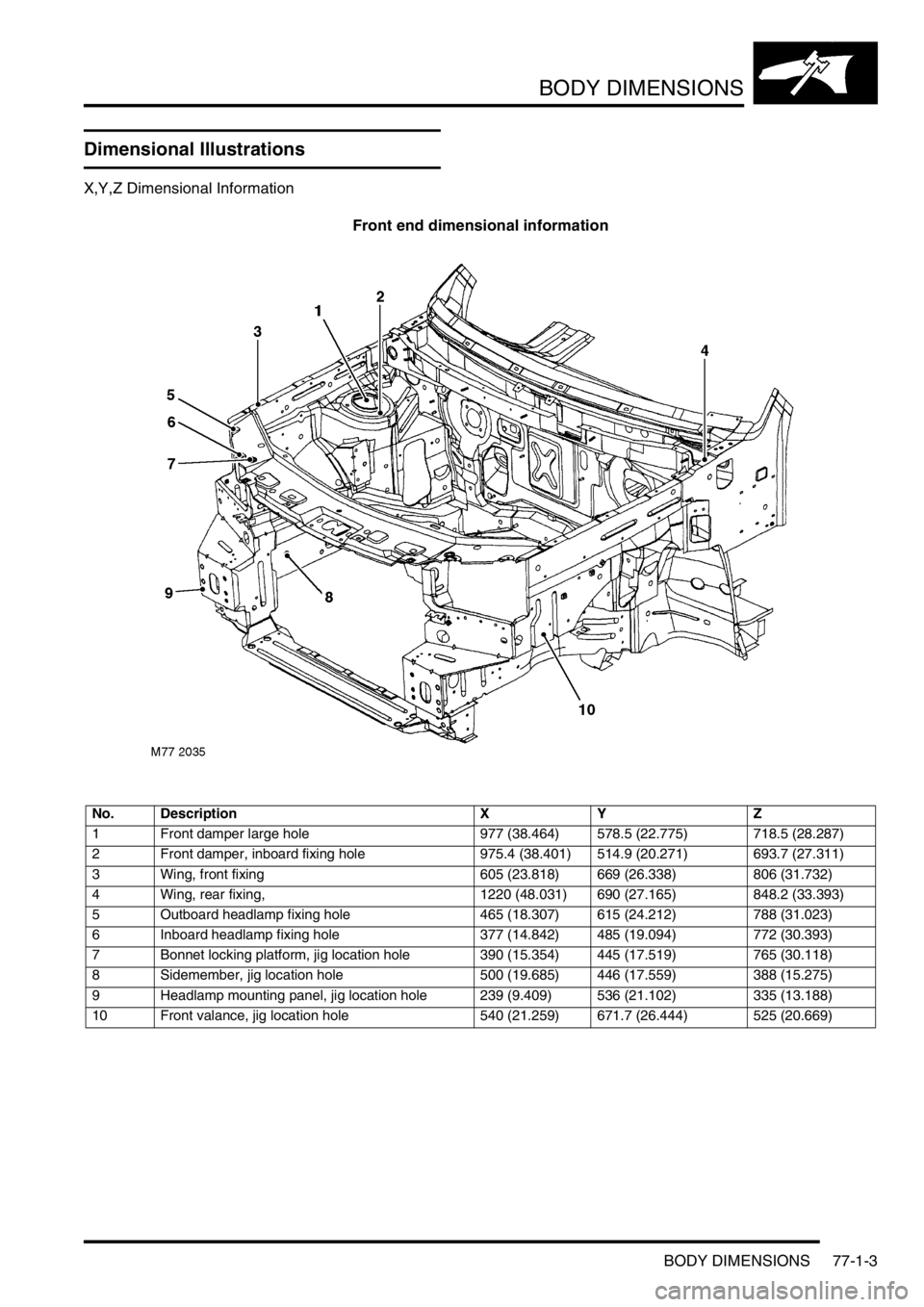

Dimensional Illustrations

X,Y,Z Dimensional Information

Front end dimensional information

No. Description X Y Z

1 Front damper large hole 977 (38.464) 578.5 (22.775) 718.5 (28.287)

2 Front damper, inboard fixing hole 975.4 (38.401) 514.9 (20.271) 693.7 (27.311)

3 Wing, front fixing 605 (23.818) 669 (26.338) 806 (31.732)

4 Wing, rear fixing, 1220 (48.031) 690 (27.165) 848.2 (33.393)

5 Outboard headlamp fixing hole 465 (18.307) 615 (24.212) 788 (31.023)

6 Inboard headlamp fixing hole 377 (14.842) 485 (19.094) 772 (30.393)

7 Bonnet locking platform, jig location hole 390 (15.354) 445 (17.519) 765 (30.118)

8 Sidemember, jig location hole 500 (19.685) 446 (17.559) 388 (15.275)

9 Headlamp mounting panel, jig location hole 239 (9.409) 536 (21.102) 335 (13.188)

10 Front valance, jig location hole 540 (21.259) 671.7 (26.444) 525 (20.669)

Page 758 of 1007

PANEL REPAIRS

REPLACEMENT PANELS 77-2-3

REPLACE ME NT PA NELS

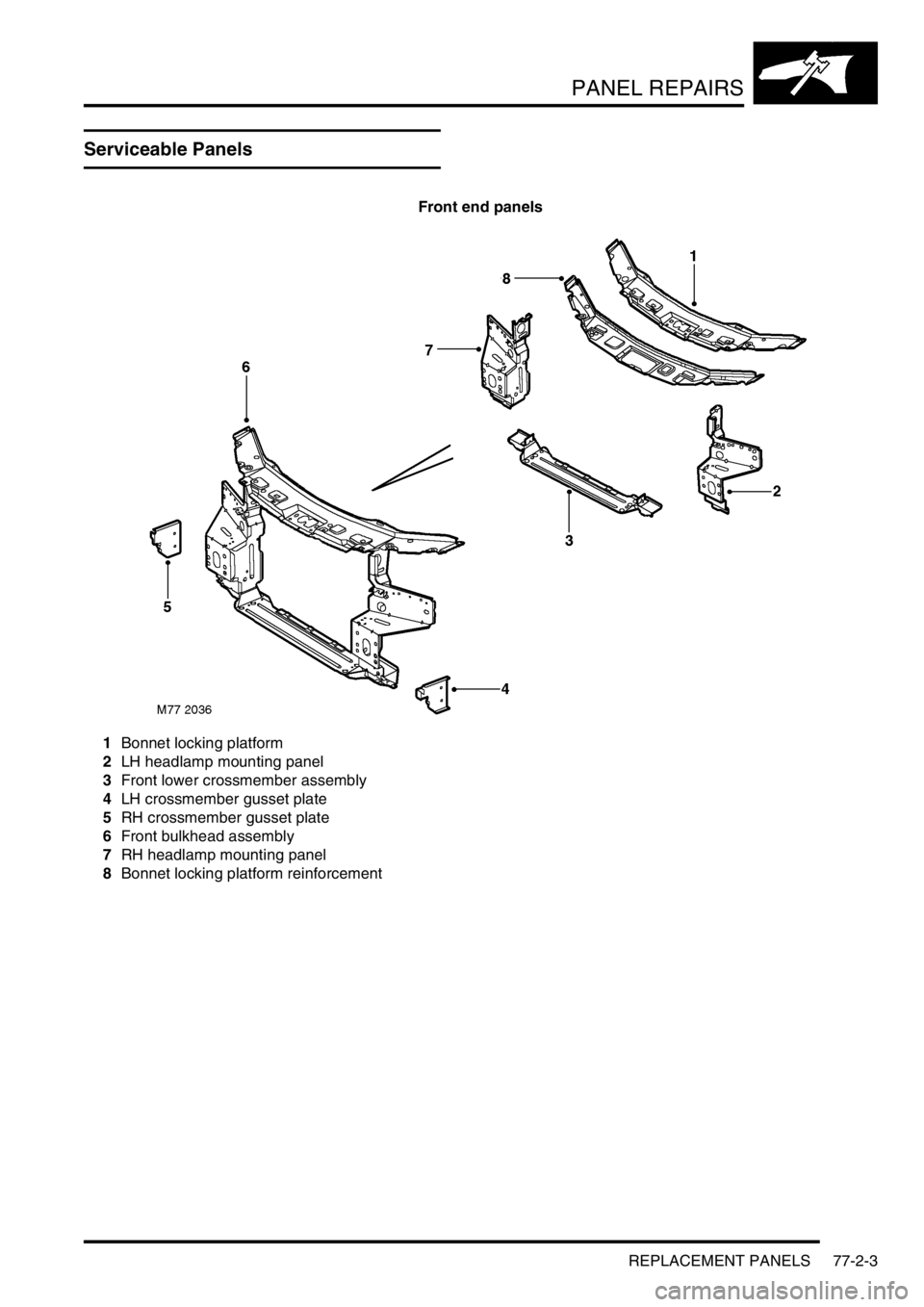

Serviceable Panels

Front end panels

1Bonnet locking platform

2LH headlamp mounting panel

3Front lower crossmember assembly

4LH crossmember gusset plate

5RH crossmember gusset plate

6Front bulkhead assembly

7RH headlamp mounting panel

8Bonnet locking platform reinforcement

Page 775 of 1007

PANEL REPAIRS

77-2-20 PROCEDURES

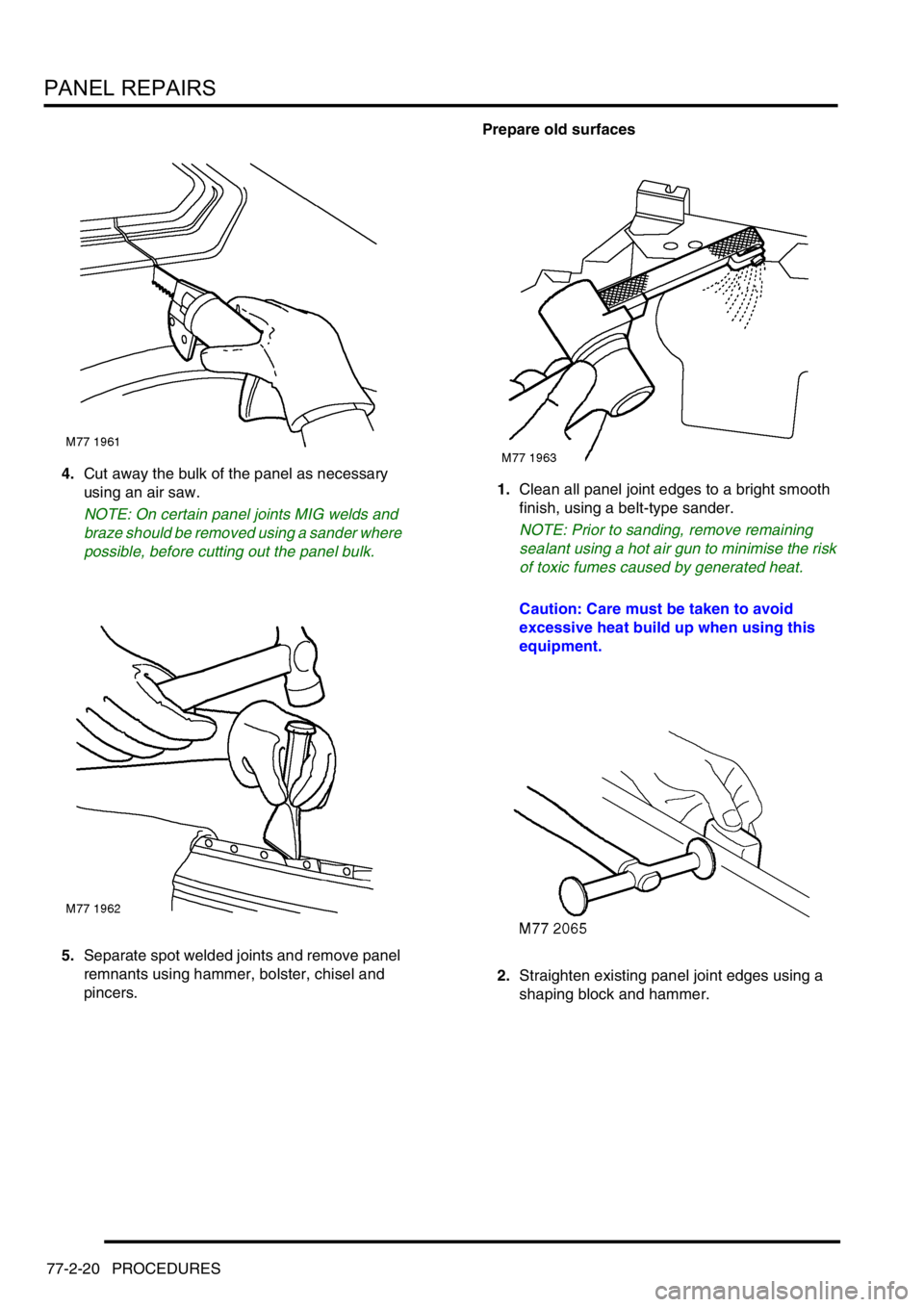

4.Cut away the bulk of the panel as necessary

using an air saw.

NOTE: On certain panel joints MIG welds and

braze should be removed using a sander where

possible, before cutting out the panel bulk.

5.Separate spot welded joints and remove panel

remnants using hammer, bolster, chisel and

pincers.Prepare old surfaces

1.Clean all panel joint edges to a bright smooth

finish, using a belt-type sander.

NOTE: Prior to sanding, remove remaining

sealant using a hot air gun to minimise the risk

of toxic fumes caused by generated heat.

Caution: Care must be taken to avoid

excessive heat build up when using this

equipment.

2.Straighten existing panel joint edges using a

shaping block and hammer.

Page 780 of 1007

PANEL REPAIRS

REPAIRS 77-2-25

REPAIRS

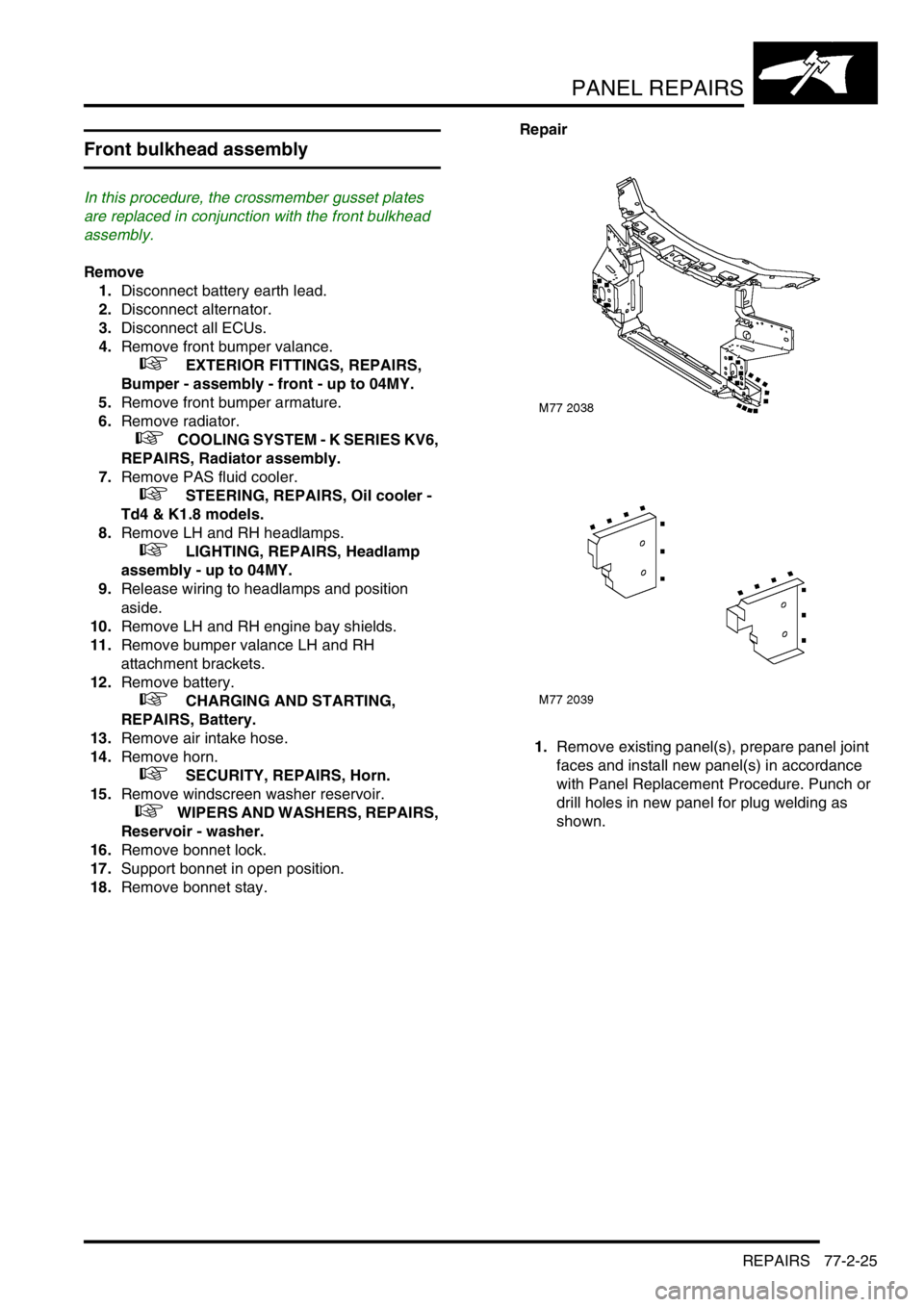

Front bulkhead assembly

In this procedure, the crossmember gusset plates

are replaced in conjunction with the front bulkhead

assembly.

Remove

1.Disconnect battery earth lead.

2.Disconnect alternator.

3.Disconnect all ECUs.

4.Remove front bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

5.Remove front bumper armature.

6.Remove radiator.

+ COOLING SYSTEM - K SERIES KV6,

REPAIRS, Radiator assembly.

7.Remove PAS fluid cooler.

+ STEERING, REPAIRS, Oil cooler -

Td4 & K1.8 models.

8.Remove LH and RH headlamps.

+ LIGHTING, REPAIRS, Headlamp

assembly - up to 04MY.

9.Release wiring to headlamps and position

aside.

10.Remove LH and RH engine bay shields.

11.Remove bumper valance LH and RH

attachment brackets.

12.Remove battery.

+ CHARGING AND STARTING,

REPAIRS, Battery.

13.Remove air intake hose.

14.Remove horn.

+ SECURITY, REPAIRS, Horn.

15.Remove windscreen washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer.

16.Remove bonnet lock.

17.Support bonnet in open position.

18.Remove bonnet stay. Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Page 781 of 1007

PANEL REPAIRS

77-2-26 REPAIRS

Refit

1.Fit bonnet stay.

2.Fit bonnet lock.

3.Fit windscreen washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer.

4.Fit horn.

+ SECURITY, REPAIRS, Horn.

5.Fit air intake hose.

6.Fit battery. Do not connect earth lead.

+ CHARGING AND STARTING,

REPAIRS, Battery.

7.Fit bumper valance LH and RH attachment

brackets.

8.Fit LH and RH engine bay shields.

9.Fit LH and RH headlamps.

+ LIGHTING, REPAIRS, Headlamp

assembly - up to 04MY. Secure headlamps

wiring.

10.Fit PAS fluid cooler.

+ STEERING, REPAIRS, Oil cooler -

Td4 & K1.8 models.

11.Fit radiator.

+ COOLING SYSTEM - K SERIES KV6,

REPAIRS, Radiator assembly.

12.Fit front bumper armature.

13.Fit front bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

14.Connect all ECUs.

15.Connect alternator.

16.Connect battery earth lead.

Page 782 of 1007

PANEL REPAIRS

REPAIRS 77-2-27

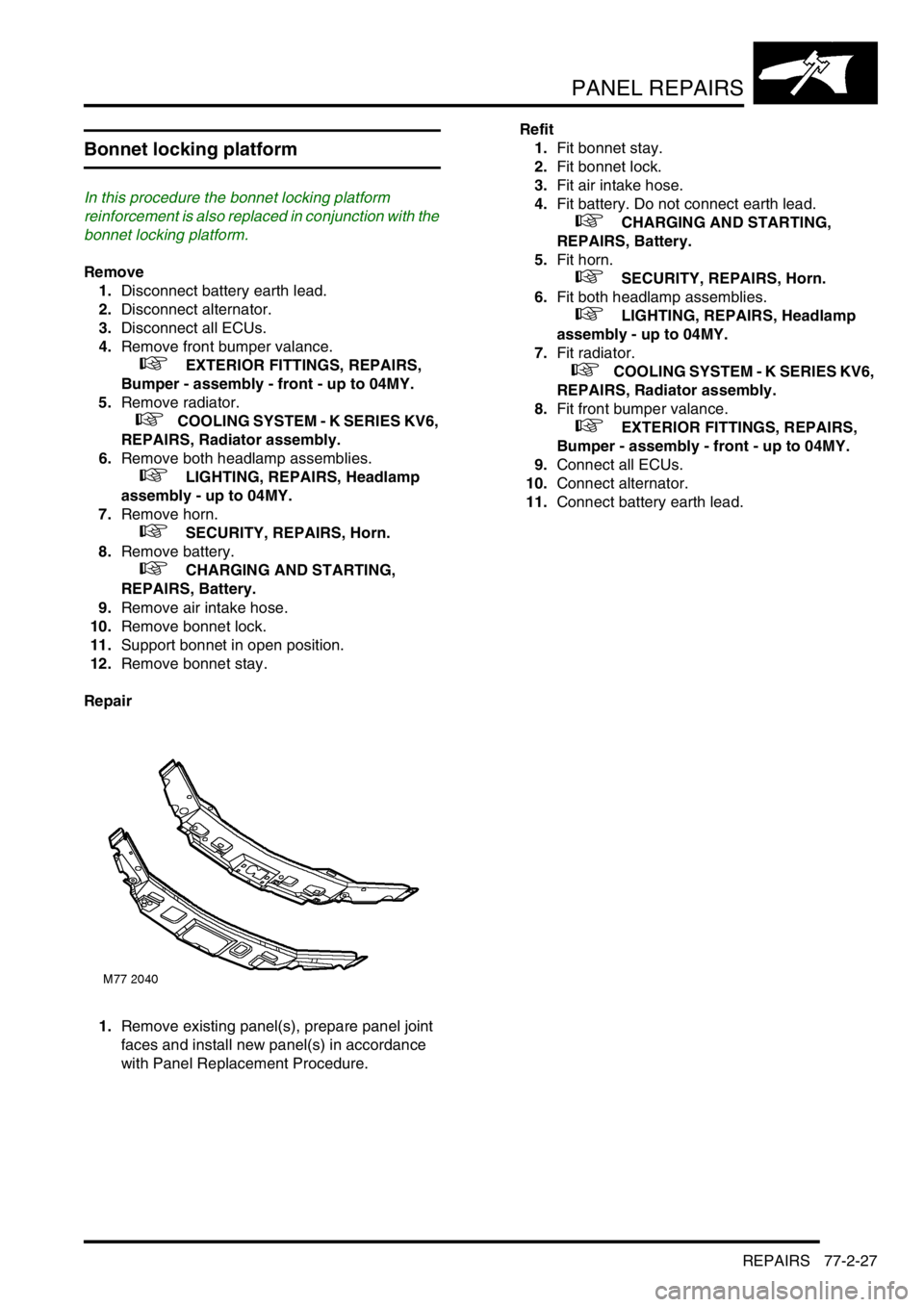

Bonnet locking platform

In this procedure the bonnet locking platform

reinforcement is also replaced in conjunction with the

bonnet locking platform.

Remove

1.Disconnect battery earth lead.

2.Disconnect alternator.

3.Disconnect all ECUs.

4.Remove front bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

5.Remove radiator.

+ COOLING SYSTEM - K SERIES KV6,

REPAIRS, Radiator assembly.

6.Remove both headlamp assemblies.

+ LIGHTING, REPAIRS, Headlamp

assembly - up to 04MY.

7.Remove horn.

+ SECURITY, REPAIRS, Horn.

8.Remove battery.

+ CHARGING AND STARTING,

REPAIRS, Battery.

9.Remove air intake hose.

10.Remove bonnet lock.

11.Support bonnet in open position.

12.Remove bonnet stay.

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Refit

1.Fit bonnet stay.

2.Fit bonnet lock.

3.Fit air intake hose.

4.Fit battery. Do not connect earth lead.

+ CHARGING AND STARTING,

REPAIRS, Battery.

5.Fit horn.

+ SECURITY, REPAIRS, Horn.

6.Fit both headlamp assemblies.

+ LIGHTING, REPAIRS, Headlamp

assembly - up to 04MY.

7.Fit radiator.

+ COOLING SYSTEM - K SERIES KV6,

REPAIRS, Radiator assembly.

8.Fit front bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

9.Connect all ECUs.

10.Connect alternator.

11.Connect battery earth lead.

Page 818 of 1007

PANEL REPAIRS

TIMES 77-2-63

TIME S

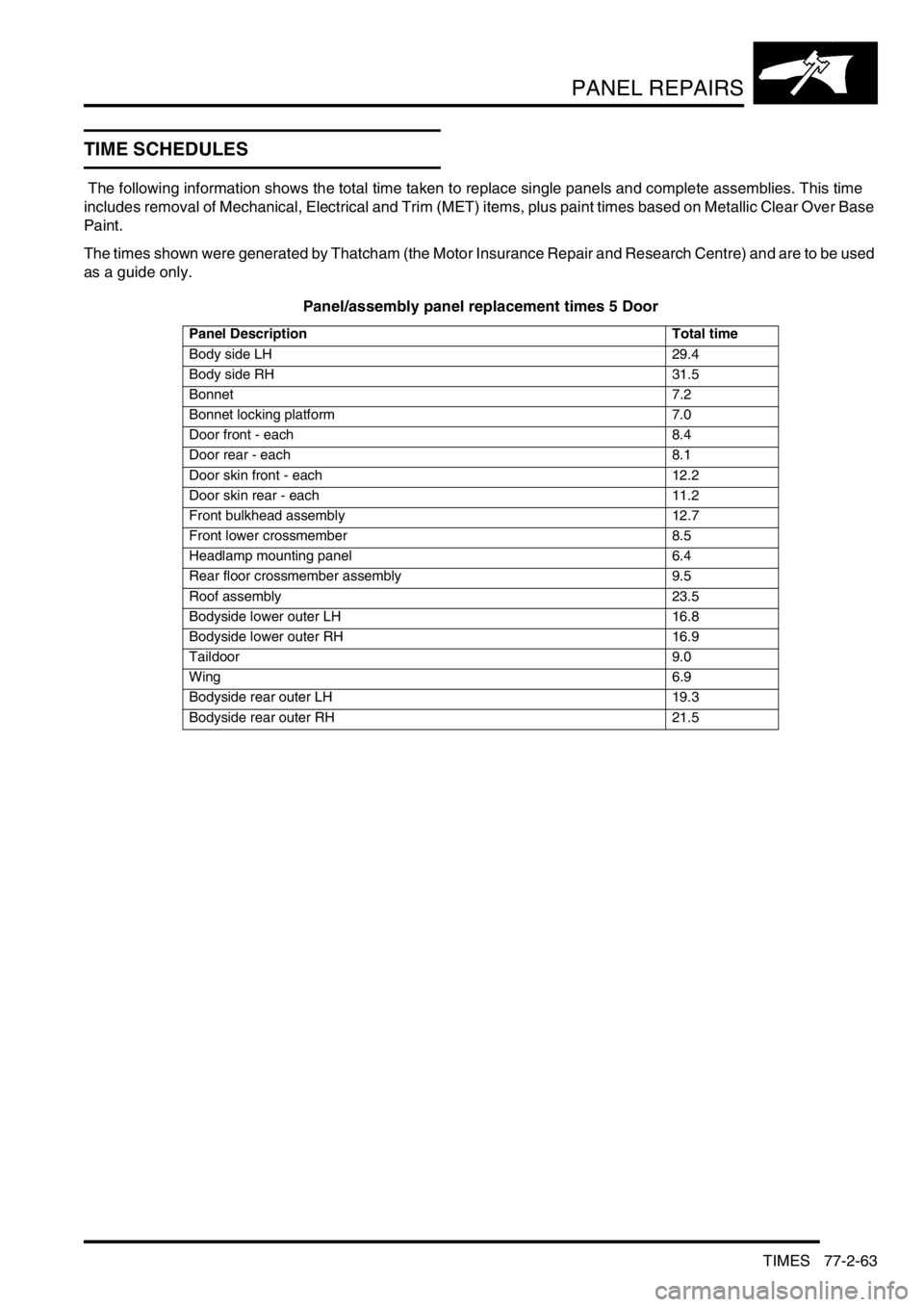

TIME SCHEDULES

The following information shows the total time taken to replace single panels and complete assemblies. This time

includes removal of Mechanical, Electrical and Trim (MET) items, plus paint times based on Metallic Clear Over Base

Paint.

The times shown were generated by Thatcham (the Motor Insurance Repair and Research Centre) and are to be used

as a guide only.

Panel/assembly panel replacement times 5 Door

Panel Description Total time

Body side LH 29.4

Body side RH 31.5

Bonnet 7.2

Bonnet locking platform 7.0

Door front - each 8.4

Door rear - each 8.1

Door skin front - each 12.2

Door skin rear - each 11.2

Front bulkhead assembly 12.7

Front lower crossmember 8.5

Headlamp mounting panel 6.4

Rear floor crossmember assembly 9.5

Roof assembly 23.5

Bodyside lower outer LH 16.8

Bodyside lower outer RH 16.9

Taildoor 9.0

Wing6.9

Bodyside rear outer LH 19.3

Bodyside rear outer RH 21.5

Page 819 of 1007

PANEL REPAIRS

77-2-64 TIMES

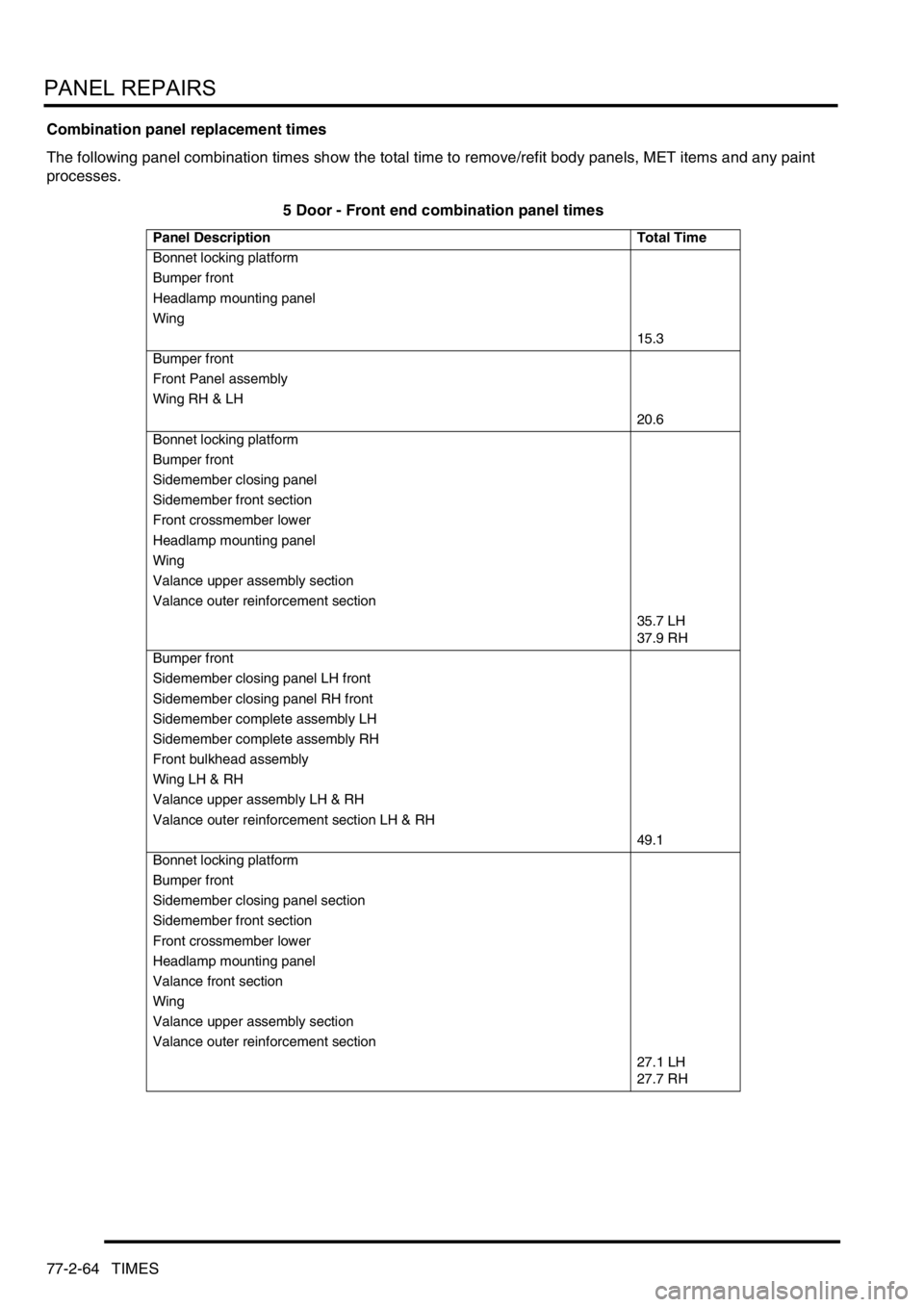

Combination panel replacement times

The following panel combination times show the total time to remove/refit body panels, MET items and any paint

processes.

5 Door - Front end combination panel times

Panel Description Total Time

Bonnet locking platform

Bumper front

Headlamp mounting panel

Wing

15.3

Bumper front

Front Panel assembly

Wing RH & LH

20.6

Bonnet locking platform

Bumper front

Sidemember closing panel

Sidemember front section

Front crossmember lower

Headlamp mounting panel

Wing

Valance upper assembly section

Valance outer reinforcement section

35.7 LH

37.9 RH

Bumper front

Sidemember closing panel LH front

Sidemember closing panel RH front

Sidemember complete assembly LH

Sidemember complete assembly RH

Front bulkhead assembly

Wing LH & RH

Valance upper assembly LH & RH

Valance outer reinforcement section LH & RH

49.1

Bonnet locking platform

Bumper front

Sidemember closing panel section

Sidemember front section

Front crossmember lower

Headlamp mounting panel

Valance front section

Wing

Valance upper assembly section

Valance outer reinforcement section

27.1 LH

27.7 RH

Page 851 of 1007

CORROSION PREVENTION AND SEALING

77-4-20 SEALING

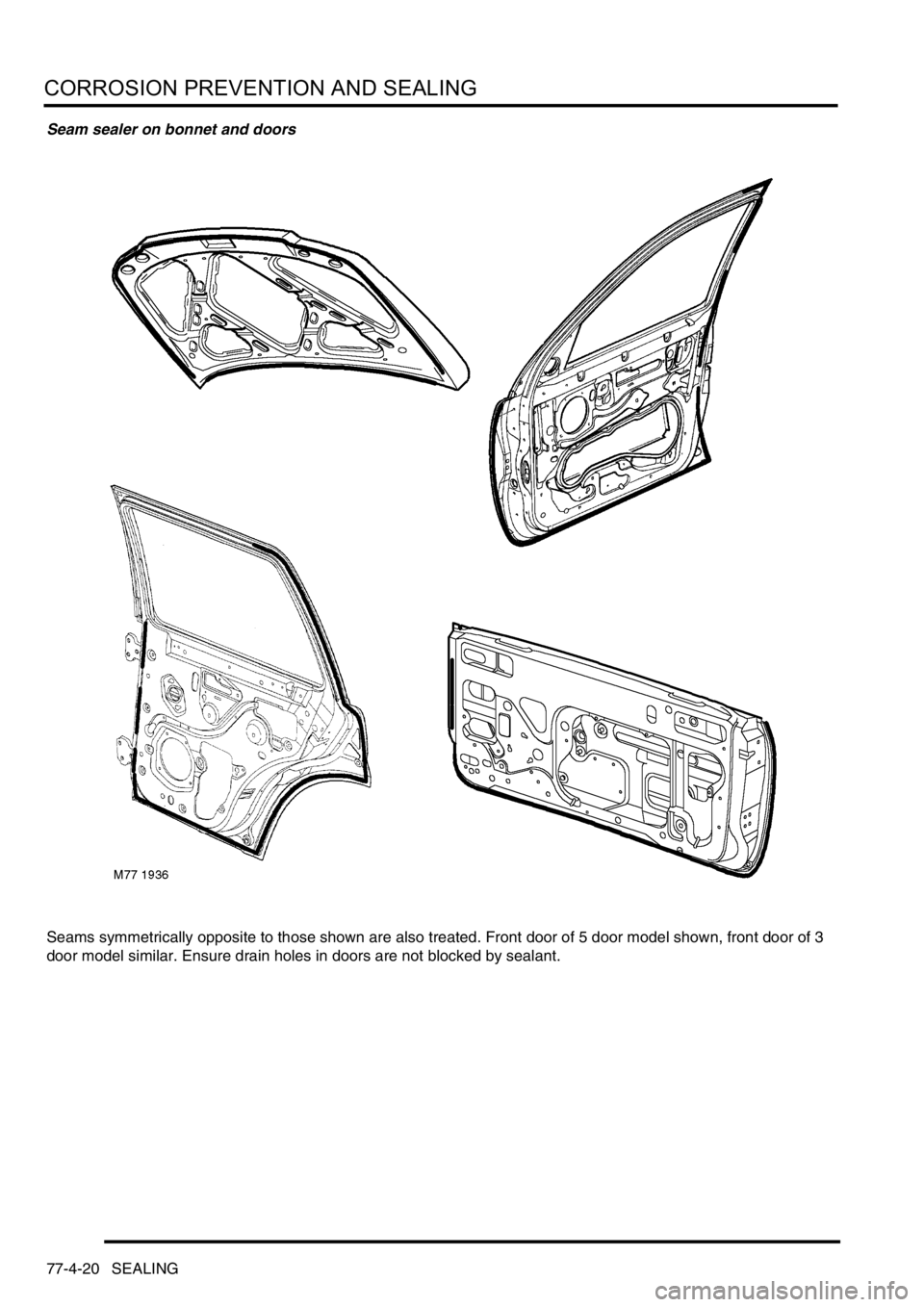

Seam sealer on bonnet and doors

Seams symmetrically opposite to those shown are also treated. Front door of 5 door model shown, front door of 3

door model similar. Ensure drain holes in doors are not blocked by sealant.

Page 859 of 1007

CORROSION PREVENTION AND SEALING

77-4-28 INTERNAL SEALING

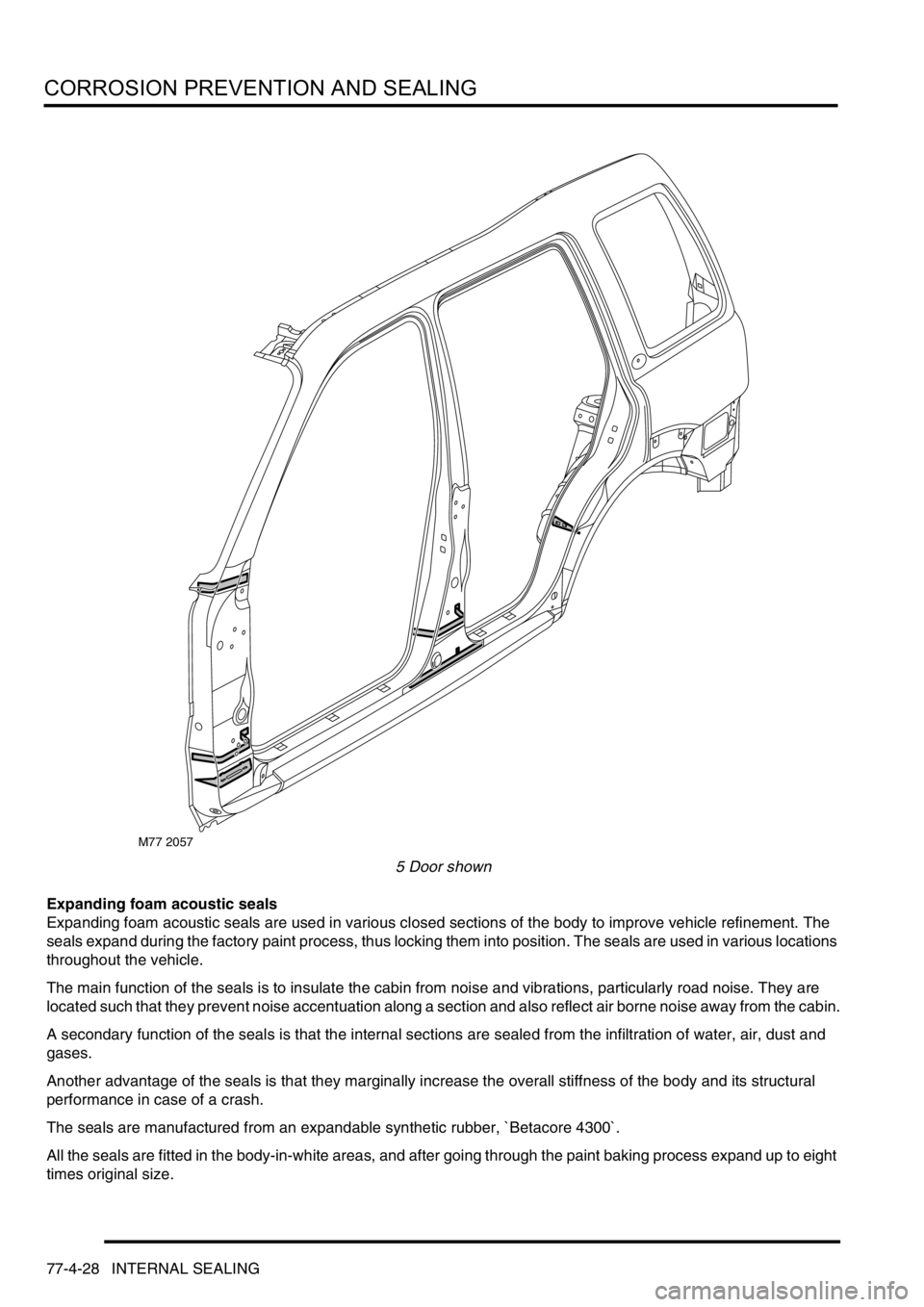

5 Door shown

Expanding foam acoustic seals

Expanding foam acoustic seals are used in various closed sections of the body to improve vehicle refinement. The

seals expand during the factory paint process, thus locking them into position. The seals are used in various locations

throughout the vehicle.

The main function of the seals is to insulate the cabin from noise and vibrations, particularly road noise. They are

located such that they prevent noise accentuation along a section and also reflect air borne noise away from the cabin.

A secondary function of the seals is that the internal sections are sealed from the infiltration of water, air, dust and

gases.

Another advantage of the seals is that they marginally increase the overall stiffness of the body and its structural

performance in case of a crash.

The seals are manufactured from an expandable synthetic rubber, `Betacore 4300`.

All the seals are fitted in the body-in-white areas, and after going through the paint baking process expand up to eight

times original size.

M77 2057