bonnet LAND ROVER FREELANDER 2001 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 452 of 1007

AUTOMATIC GEARBOX - JATCO

REPAIRS 44-17

21.Position access plate, fit bolts and tighten to 9

Nm (7 lbf.ft).

22.Clean mating faces of IRD and gearbox.

23.Lubricate and fit new 'O' ring.

24.With assistance, fit IRD.

25.Fit bolts securing IRD to gearbox and tighten

sufficiently only to pull mating faces of IRD and

gearbox together at this stage.

26.Fit IRD support bracket and tighten bolts

sufficiently only to pull mating faces together.

27.Final tighten bolts securing IRD to gearbox to

80 Nm (59 lbf.ft).

28.Final tighten bolts securing IRD support

bracket in following sequence:5 bolts securing

support bracket to IRD 50 Nm (37 lbf.ft), 2 bolts

securing support bracket to engine front

mounting bracket 50 Nm (37 lbf.ft), 3 bolts

securing support bracket to sump 45 Nm (33

lbf.ft).

29.Position lower engine steady, 'TOP' mark

uppermost. Fit bolt but do not tighten at this

stage.

30.Connect coolant hoses and secure with clips.

31.Connect breather hose to IRD housing.

32.Fit manifold heat shield and fit nut securing

heat shield to pinion housing finger tight.

33.Fit bolts securing manifold heat shield to IRD

support bracket and tighten to 9 Nm (7 lbf.ft).

34.Fit nut securing heat shield to IRD and tighten

to 45 Nm (33 lbf.ft).

35.Final tighten nut securing manifold heat shield

to IRD pinion housing to 25 Nm (18 lbf.ft).

36.Clean exhaust manifold and mating face on

cylinder head.

37.Fit exhaust manifold gasket.

38.Position exhaust manifold, fit nuts and

progressively tighten, from centre outwards to

45 Nm (33 lbf.ft).

39.Connect HO2S multiplug and secure to support

bracket.

Gearbox - KV6

$% 44.20.02.99

Remove

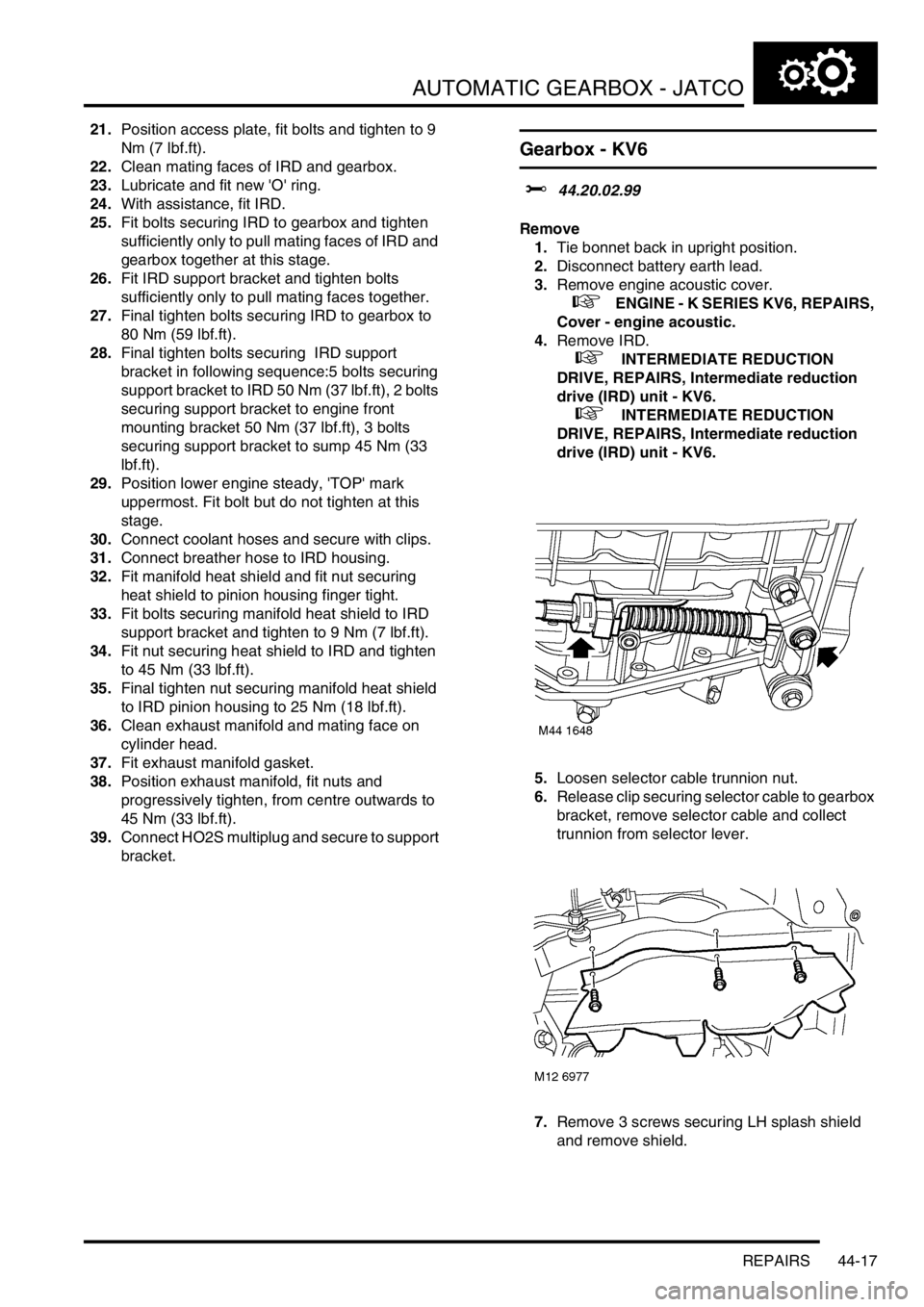

1.Tie bonnet back in upright position.

2.Disconnect battery earth lead.

3.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

4.Remove IRD.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Intermediate reduction

drive (IRD) unit - KV6.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Intermediate reduction

drive (IRD) unit - KV6.

5.Loosen selector cable trunnion nut.

6.Release clip securing selector cable to gearbox

bracket, remove selector cable and collect

trunnion from selector lever.

7.Remove 3 screws securing LH splash shield

and remove shield.

Page 458 of 1007

AUTOMATIC GEARBOX - JATCO

REPAIRS 44-23

23.Fit CKP sensor, fit bolt and tighten to 9 Nm (7

lbf.ft).

24.Position fluid cooler, tighten M12 bolts to 85 Nm

(63 lbf.ft) and M8 bolt to 25 Nm (18 lbf.ft).

25.Clean fluid cooler unions.

26.Lubricate new 'O' rings with clean transmission

fluid and fit 'O' rings to fluid cooler hoses.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

27.Connect fluid cooler hoses to gearbox and

tighten unions to 18 Nm (13 lbf.ft).

28.Clean exhaust manifold and mating face on

cylinder head.

29.Fit exhaust manifold gasket.

30.Position exhaust manifold, fit nuts and

progressively tighten, from centre outwards to

45 Nm (33 lbf.ft).

31.Connect HO2S multiplug and secure to support

bracket.

32.Position IRD cooling hose retainer, fit bolt and

tighten to 25 Nm (18 lbf.ft).

33.Align marks on drive plate to torque converter.

34.Fit bolts securing drive plate to torque converter

and tighten bolts to 45 Nm (33 lbf.ft).

35.Clean torque converter access plate.

36.Position access plate, fit bolts and tighten to 9

Nm (7 lbf.ft).

37.Clean end of drive shaft and mating splines in

gearbox.

38.Fit new circlip to LH drive shaft.

39.With assistance pull hub outwards, align drive

shaft and fit to gearbox, taking care not to

damage drive shaft oil seal.

CAUTION: Pull the drive shaft to ensure the

circlip is fully engaged and retains the shaft.

40.Fit splash shield and secure with bolts.

41.Position trunnion to selector lever, locate inner

cable through trunnion, do not tighten nut at this

stage.

42.Position selector cable to gearbox bracket and

secure with clip.

43.Adjust selector cable.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Selector cable - adjust.

44.Fit IRD.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Intermediate reduction

drive (IRD) unit - KV6.

45.Connect battery earth lead.

46.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

47.Untie and close bonnet.

Gearbox - Td4

$% 44.20.02.99

Remove

1.Disconnect battery earth lead.

2.Tie bonnet back in upright position.

3.Remove intake ducting assembly.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Ducting - intake assembly.

4.Remove fluid cooler.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Fluid cooler - Td4.

5.Remove starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - Td4.

6.Remove IRD.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Intermediate reduction

drive (IRD) unit - Td4.

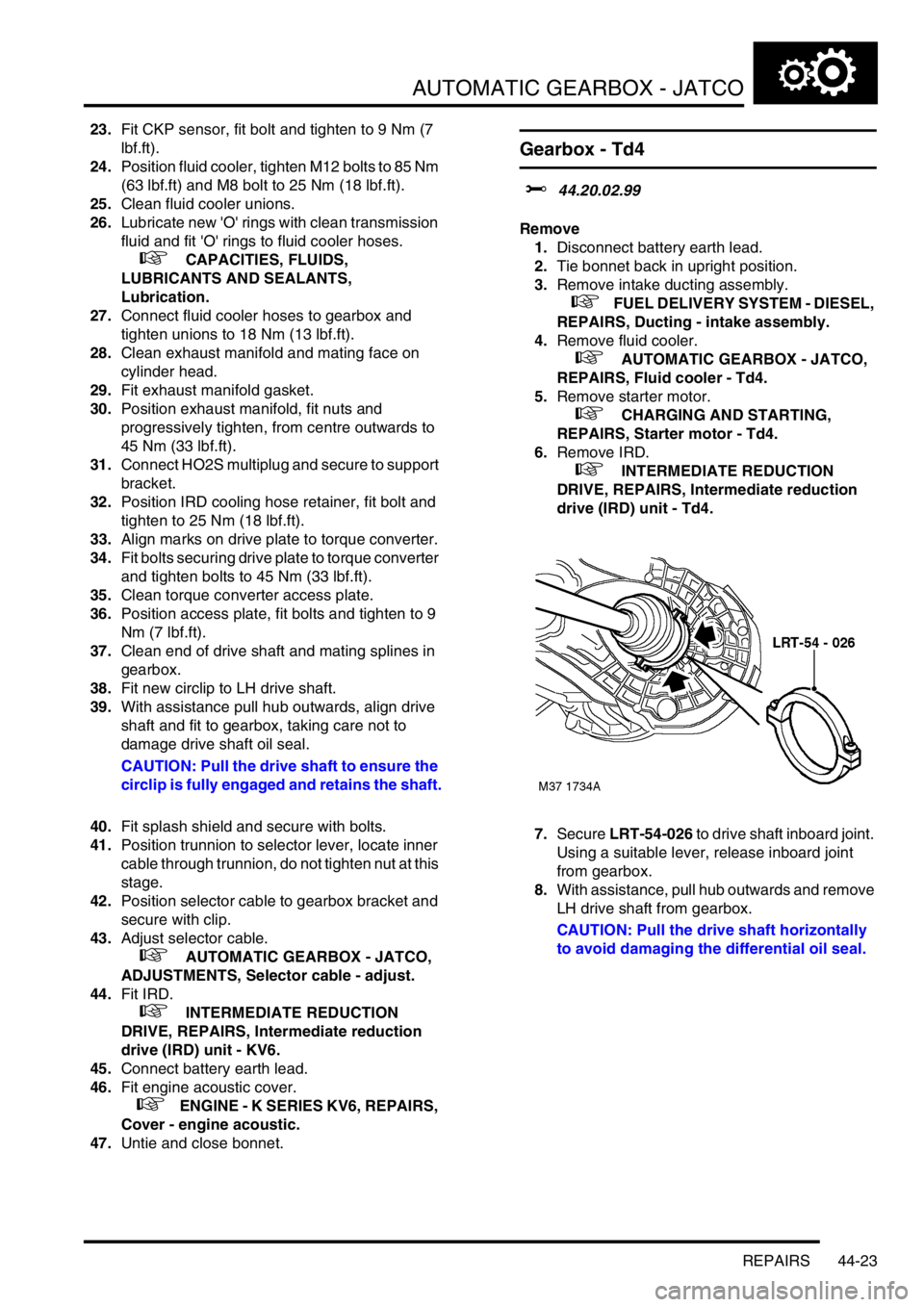

7.Secure LRT-54-026 to drive shaft inboard joint.

Using a suitable lever, release inboard joint

from gearbox.

8.With assistance, pull hub outwards and remove

LH drive shaft from gearbox.

CAUTION: Pull the drive shaft horizontally

to avoid damaging the differential oil seal.

Page 462 of 1007

AUTOMATIC GEARBOX - JATCO

REPAIRS 44-27

21.Fit new circlip to LH drive shaft.

22.With assistance, fit LH drive shaft to gearbox,

keep shaft square to prevent damage to oil seal

in gearbox.

23.Fit IRD.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Intermediate reduction

drive (IRD) unit - Td4.

24.Fit starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - Td4.

25.Fit fluid cooler.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Fluid cooler - Td4.

26.Fit intake ducting assembly.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Ducting - intake assembly.

27.Connect battery earth lead.

28.Untie and close bonnet.

Fluid pan - reseal

$% 44.24.05

Remove

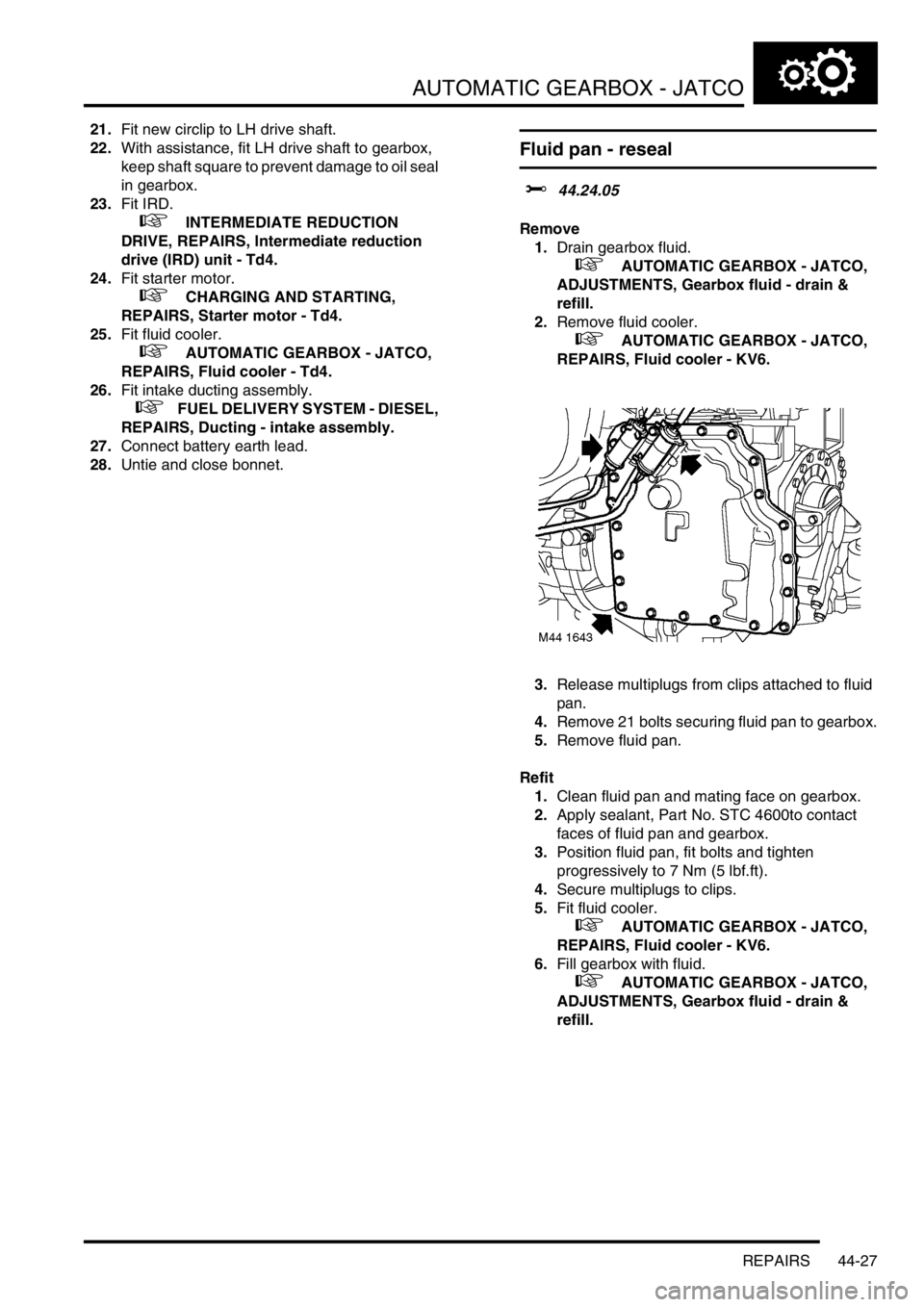

1.Drain gearbox fluid.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Gearbox fluid - drain &

refill.

2.Remove fluid cooler.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Fluid cooler - KV6.

3.Release multiplugs from clips attached to fluid

pan.

4.Remove 21 bolts securing fluid pan to gearbox.

5.Remove fluid pan.

Refit

1.Clean fluid pan and mating face on gearbox.

2.Apply sealant, Part No. STC 4600to contact

faces of fluid pan and gearbox.

3.Position fluid pan, fit bolts and tighten

progressively to 7 Nm (5 lbf.ft).

4.Secure multiplugs to clips.

5.Fit fluid cooler.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Fluid cooler - KV6.

6.Fill gearbox with fluid.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Gearbox fluid - drain &

refill.

Page 648 of 1007

EXTERIOR FITTINGS

REPAIRS 76-2-7

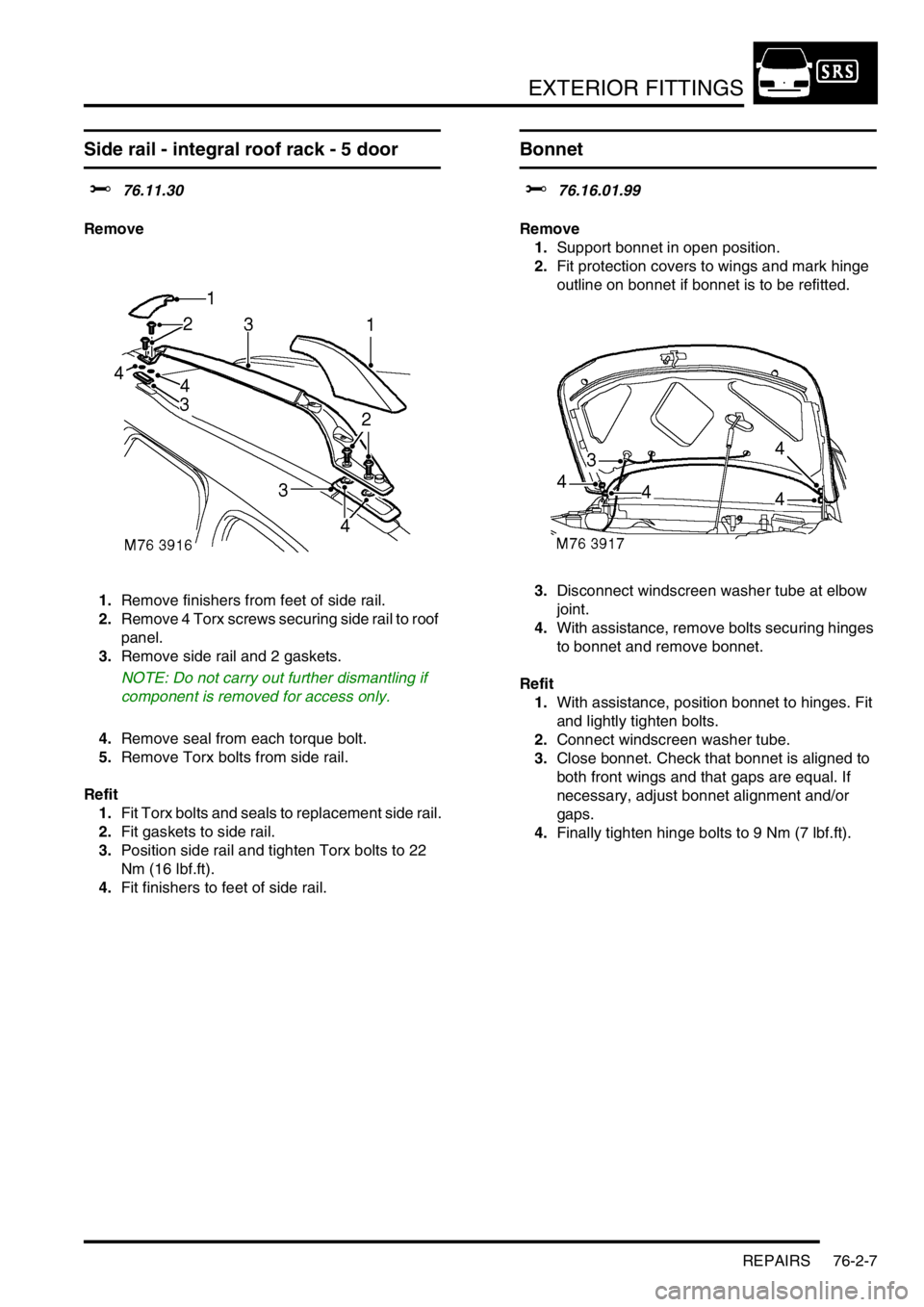

Side rail - integral roof rack - 5 door

$% 76.11.30

Remove

1.Remove finishers from feet of side rail.

2.Remove 4 Torx screws securing side rail to roof

panel.

3.Remove side rail and 2 gaskets.

NOTE: Do not carry out further dismantling if

component is removed for access only.

4.Remove seal from each torque bolt.

5.Remove Torx bolts from side rail.

Refit

1.Fit Torx bolts and seals to replacement side rail.

2.Fit gaskets to side rail.

3.Position side rail and tighten Torx bolts to 22

Nm (16 lbf.ft).

4.Fit finishers to feet of side rail.

Bonnet

$% 76.16.01.99

Remove

1.Support bonnet in open position.

2.Fit protection covers to wings and mark hinge

outline on bonnet if bonnet is to be refitted.

3.Disconnect windscreen washer tube at elbow

joint.

4.With assistance, remove bolts securing hinges

to bonnet and remove bonnet.

Refit

1.With assistance, position bonnet to hinges. Fit

and lightly tighten bolts.

2.Connect windscreen washer tube.

3.Close bonnet. Check that bonnet is aligned to

both front wings and that gaps are equal. If

necessary, adjust bonnet alignment and/or

gaps.

4.Finally tighten hinge bolts to 9 Nm (7 lbf.ft).

Page 649 of 1007

EXTERIOR FITTINGS

76-2-8 REPAIRS

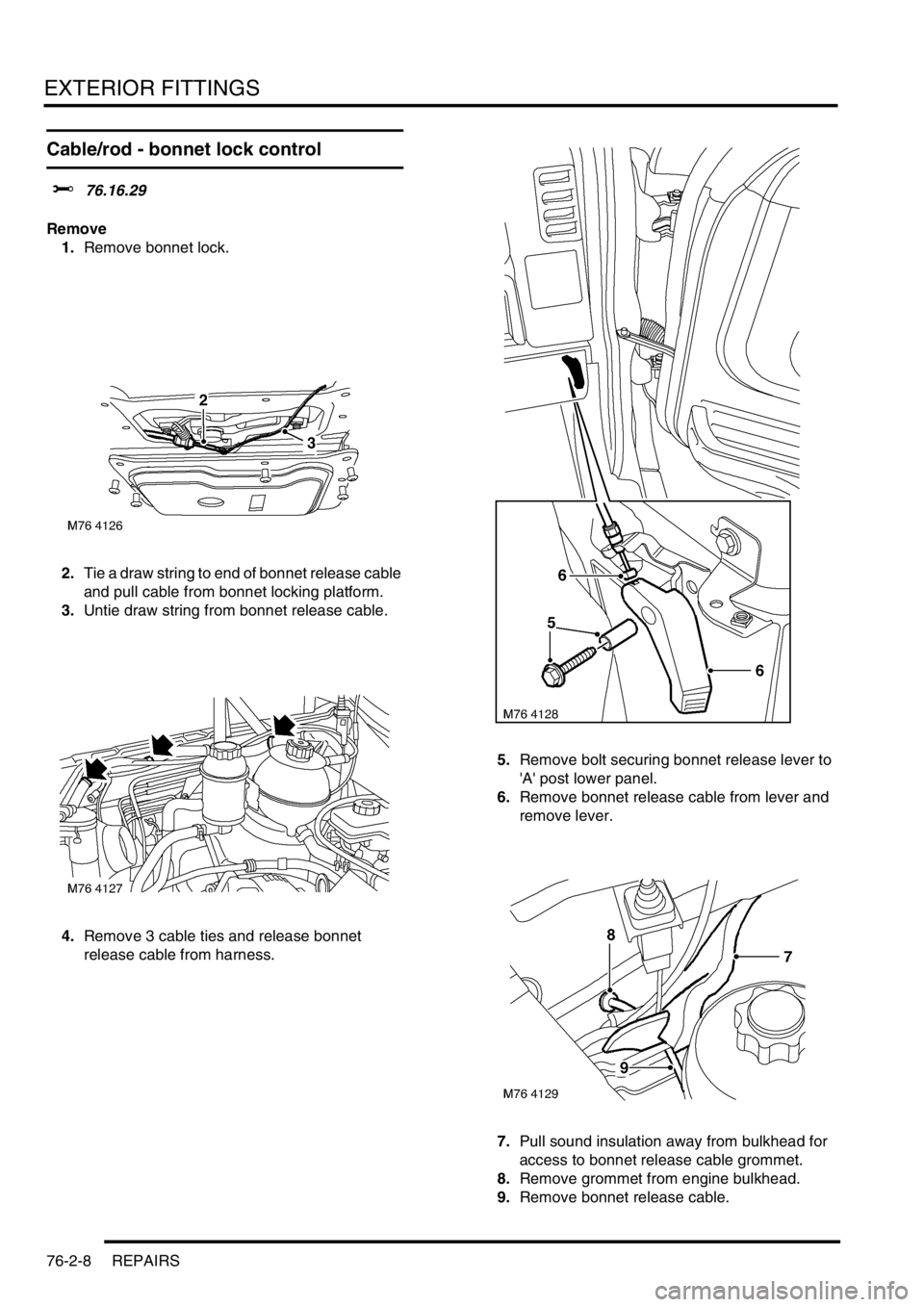

Cable/rod - bonnet lock control

$% 76.16.29

Remove

1.Remove bonnet lock.

2.Tie a draw string to end of bonnet release cable

and pull cable from bonnet locking platform.

3.Untie draw string from bonnet release cable.

4.Remove 3 cable ties and release bonnet

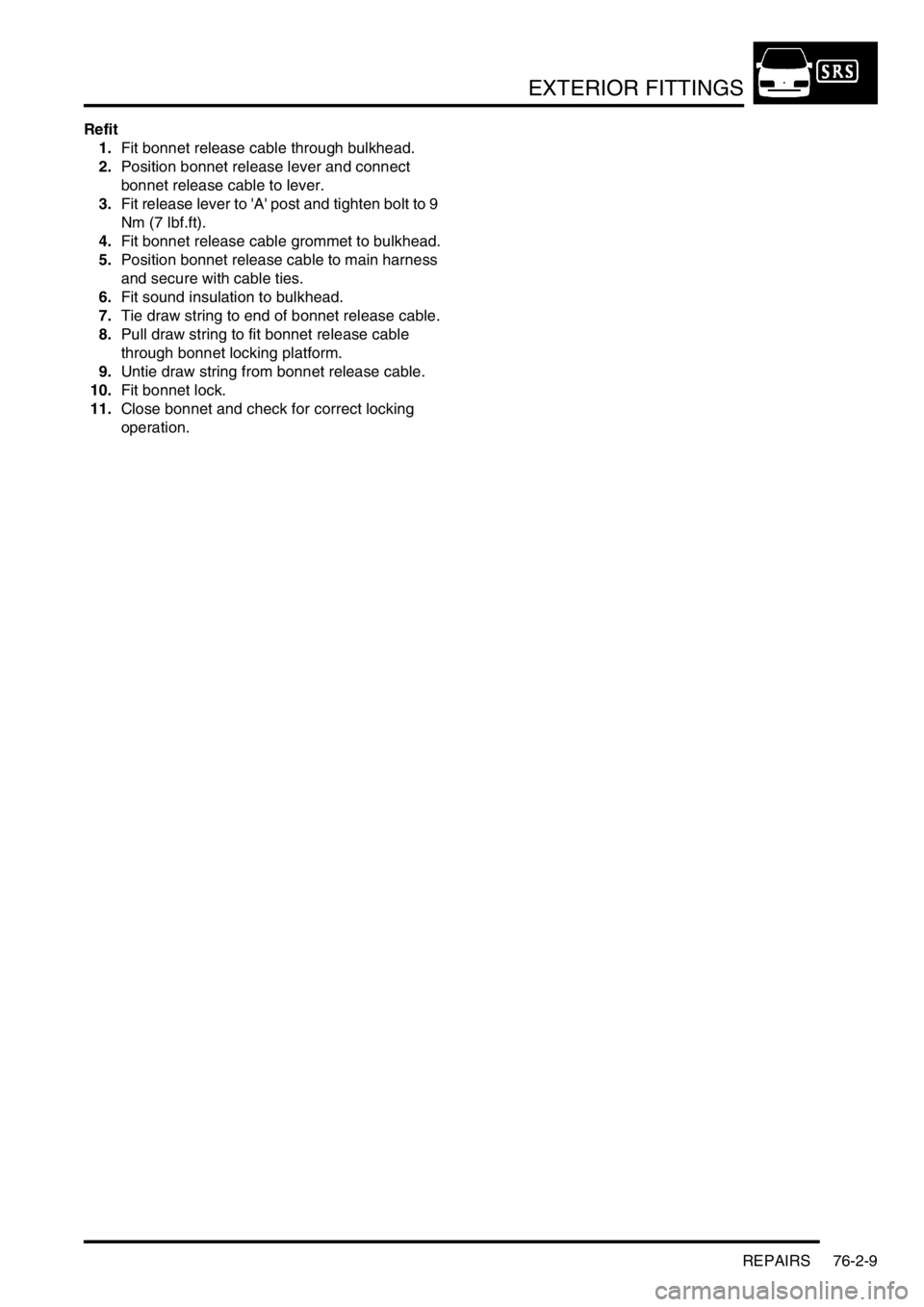

release cable from harness.5.Remove bolt securing bonnet release lever to

'A' post lower panel.

6.Remove bonnet release cable from lever and

remove lever.

7.Pull sound insulation away from bulkhead for

access to bonnet release cable grommet.

8.Remove grommet from engine bulkhead.

9.Remove bonnet release cable.

Page 650 of 1007

EXTERIOR FITTINGS

REPAIRS 76-2-9

Refit

1.Fit bonnet release cable through bulkhead.

2.Position bonnet release lever and connect

bonnet release cable to lever.

3.Fit release lever to 'A' post and tighten bolt to 9

Nm (7 lbf.ft).

4.Fit bonnet release cable grommet to bulkhead.

5.Position bonnet release cable to main harness

and secure with cable ties.

6.Fit sound insulation to bulkhead.

7.Tie draw string to end of bonnet release cable.

8.Pull draw string to fit bonnet release cable

through bonnet locking platform.

9.Untie draw string from bonnet release cable.

10.Fit bonnet lock.

11.Close bonnet and check for correct locking

operation.

Page 651 of 1007

EXTERIOR FITTINGS

76-2-10 REPAIRS

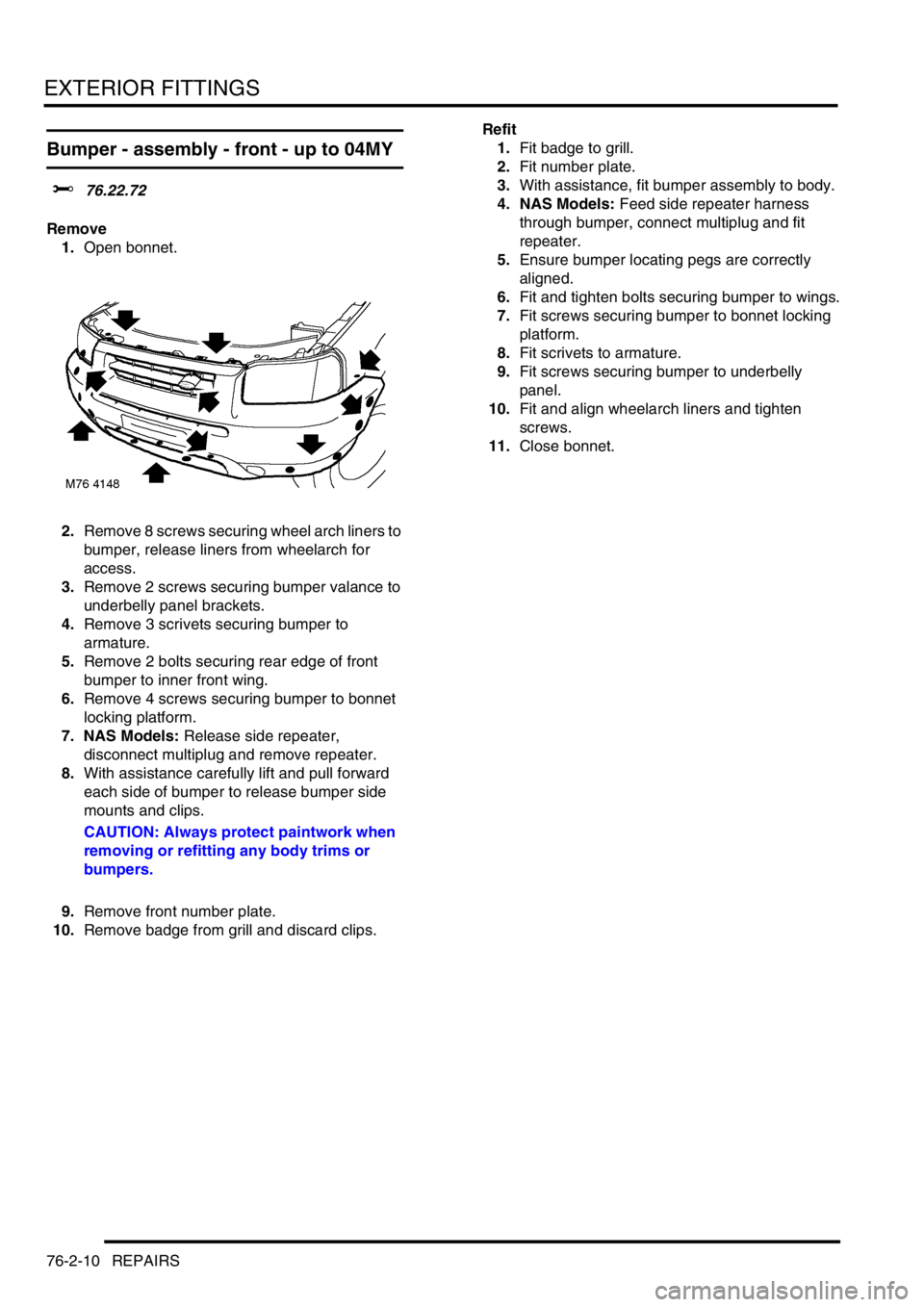

Bumper - assembly - front - up to 04MY

$% 76.22.72

Remove

1.Open bonnet.

2.Remove 8 screws securing wheel arch liners to

bumper, release liners from wheelarch for

access.

3.Remove 2 screws securing bumper valance to

underbelly panel brackets.

4.Remove 3 scrivets securing bumper to

armature.

5.Remove 2 bolts securing rear edge of front

bumper to inner front wing.

6.Remove 4 screws securing bumper to bonnet

locking platform.

7. NAS Models: Release side repeater,

disconnect multiplug and remove repeater.

8.With assistance carefully lift and pull forward

each side of bumper to release bumper side

mounts and clips.

CAUTION: Always protect paintwork when

removing or refitting any body trims or

bumpers.

9.Remove front number plate.

10.Remove badge from grill and discard clips.Refit

1.Fit badge to grill.

2.Fit number plate.

3.With assistance, fit bumper assembly to body.

4. NAS Models: Feed side repeater harness

through bumper, connect multiplug and fit

repeater.

5.Ensure bumper locating pegs are correctly

aligned.

6.Fit and tighten bolts securing bumper to wings.

7.Fit screws securing bumper to bonnet locking

platform.

8.Fit scrivets to armature.

9.Fit screws securing bumper to underbelly

panel.

10.Fit and align wheelarch liners and tighten

screws.

11.Close bonnet.

Page 652 of 1007

EXTERIOR FITTINGS

REPAIRS 76-2-11

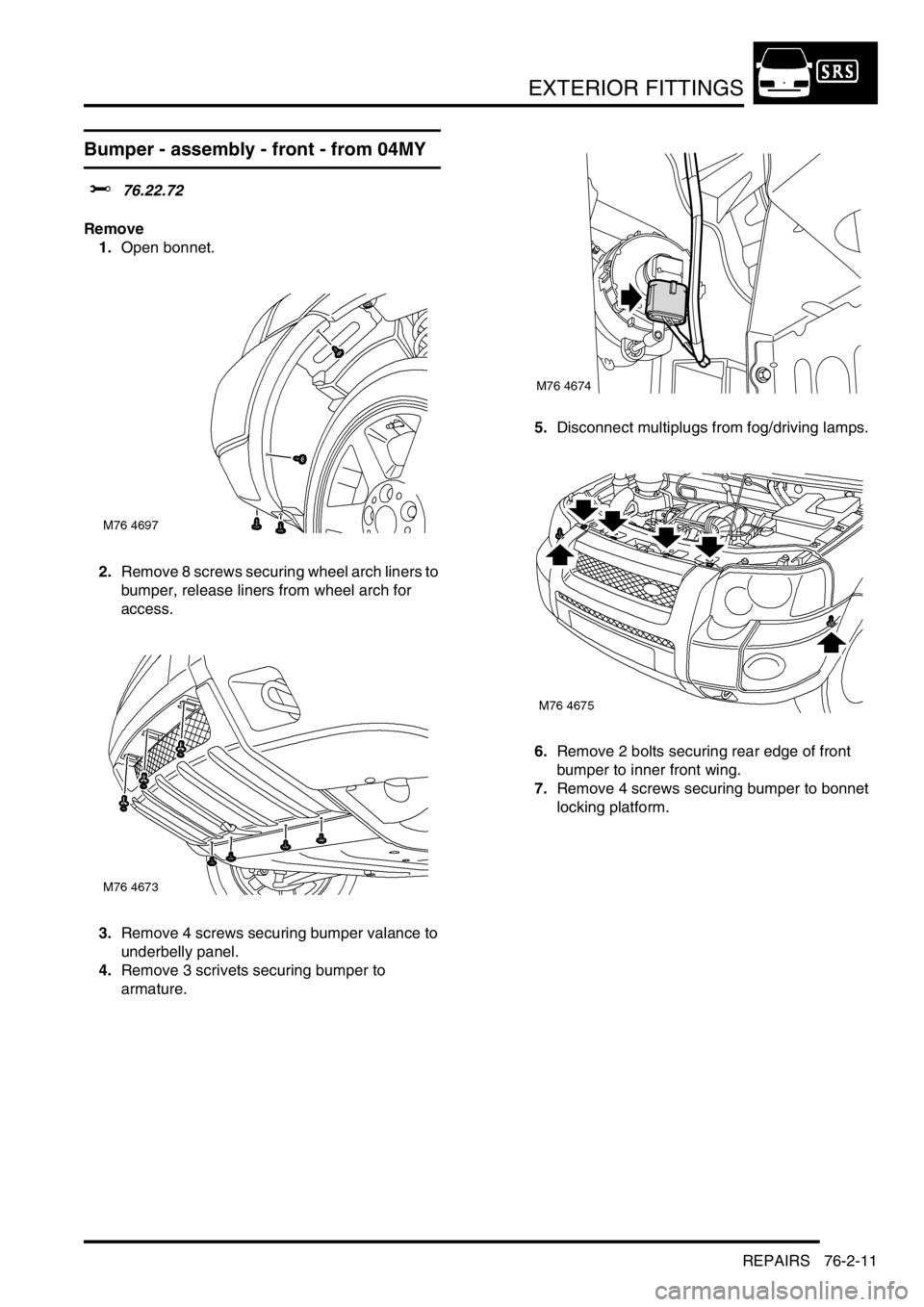

Bumper - assembly - front - from 04MY

$% 76.22.72

Remove

1.Open bonnet.

2.Remove 8 screws securing wheel arch liners to

bumper, release liners from wheel arch for

access.

3.Remove 4 screws securing bumper valance to

underbelly panel.

4.Remove 3 scrivets securing bumper to

armature.5.Disconnect multiplugs from fog/driving lamps.

6.Remove 2 bolts securing rear edge of front

bumper to inner front wing.

7.Remove 4 screws securing bumper to bonnet

locking platform.

M76 4674

Page 653 of 1007

EXTERIOR FITTINGS

76-2-12 REPAIRS

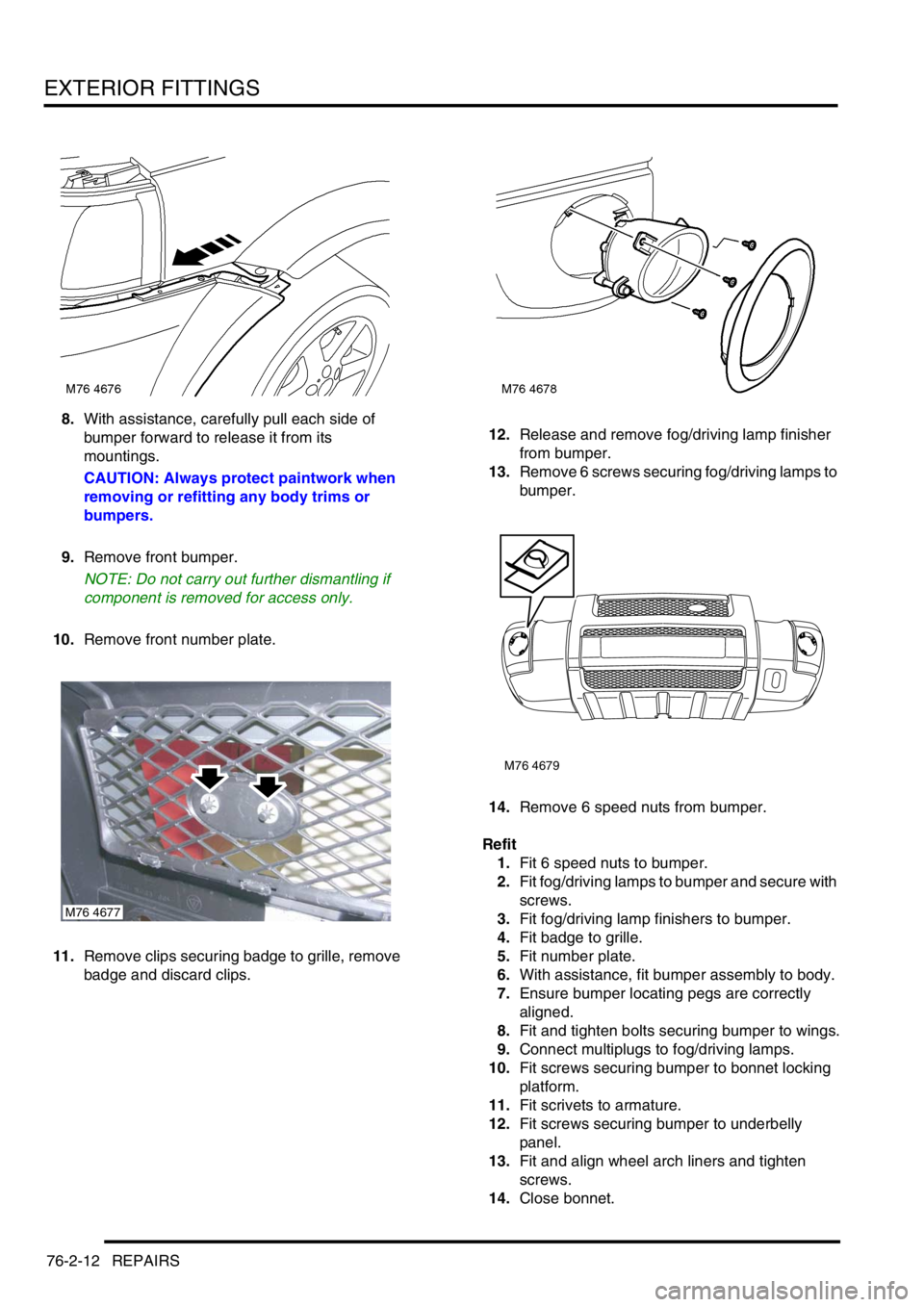

8.With assistance, carefully pull each side of

bumper forward to release it from its

mountings.

CAUTION: Always protect paintwork when

removing or refitting any body trims or

bumpers.

9.Remove front bumper.

NOTE: Do not carry out further dismantling if

component is removed for access only.

10.Remove front number plate.

11.Remove clips securing badge to grille, remove

badge and discard clips.12.Release and remove fog/driving lamp finisher

from bumper.

13.Remove 6 screws securing fog/driving lamps to

bumper.

14.Remove 6 speed nuts from bumper.

Refit

1.Fit 6 speed nuts to bumper.

2.Fit fog/driving lamps to bumper and secure with

screws.

3.Fit fog/driving lamp finishers to bumper.

4.Fit badge to grille.

5.Fit number plate.

6.With assistance, fit bumper assembly to body.

7.Ensure bumper locating pegs are correctly

aligned.

8.Fit and tighten bolts securing bumper to wings.

9.Connect multiplugs to fog/driving lamps.

10.Fit screws securing bumper to bonnet locking

platform.

11.Fit scrivets to armature.

12.Fit screws securing bumper to underbelly

panel.

13.Fit and align wheel arch liners and tighten

screws.

14.Close bonnet.

M76 4677

M76 4679

Page 692 of 1007

SCREENS

REPAIRS 76-4-1

SCREENS REPAIRS

Windscreen

$% 76.81.01

The following equipment is required: Cutting wire

and handles, Windscreen repair kit, Sealer applicator

gun and Suction cups

Wear protective gloves when handling glass,

solvents and primers.

Wear suitable eye protection when removing and

refitting glass.

Remove

1.Remove air intake panel.

+ HEATING AND VENTILATION,

REPAIRS, Plenum - air intake.

2.Remove sun visors and sun visor retaining

clips.

3.Remove 'A' post upper trim casings.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim finisher - 'A' post - upper -

renew.

4.Remove retaining stud from front of headlining.

5.Remove interior mirror.

6.Fit protection to bonnet and areas around

screen.

7.Cover heater ducts with masking tape.

8.Cover interior of vehicle with protective sheet.

9.Make knife cut in sealant at bottom of 'A' post.

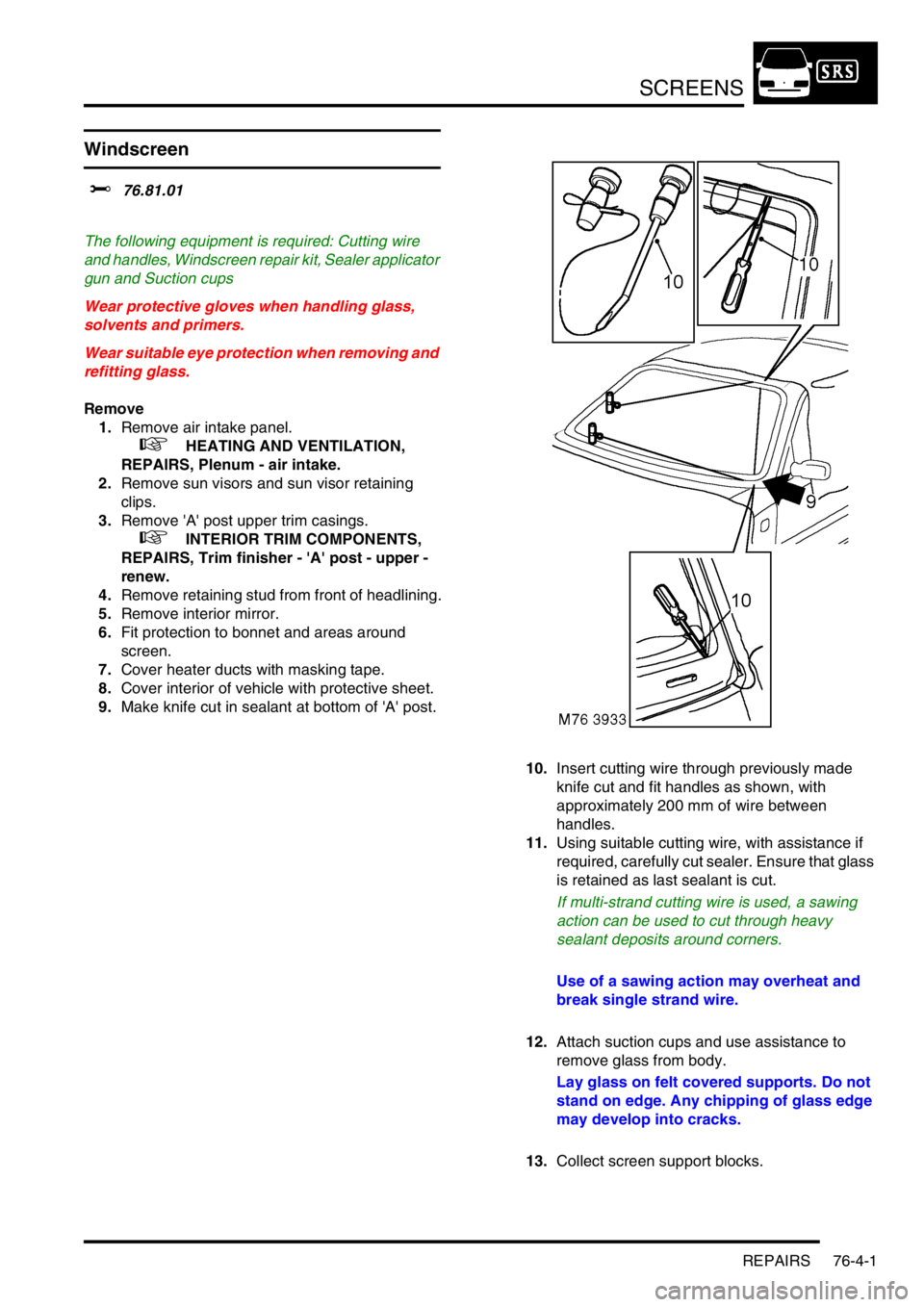

10.Insert cutting wire through previously made

knife cut and fit handles as shown, with

approximately 200 mm of wire between

handles.

11.Using suitable cutting wire, with assistance if

required, carefully cut sealer. Ensure that glass

is retained as last sealant is cut.

If multi-strand cutting wire is used, a sawing

action can be used to cut through heavy

sealant deposits around corners.

Use of a sawing action may overheat and

break single strand wire.

12.Attach suction cups and use assistance to

remove glass from body.

Lay glass on felt covered supports. Do not

stand on edge. Any chipping of glass edge

may develop into cracks.

13.Collect screen support blocks.