engine oil LAND ROVER FREELANDER 2001 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 110 of 1007

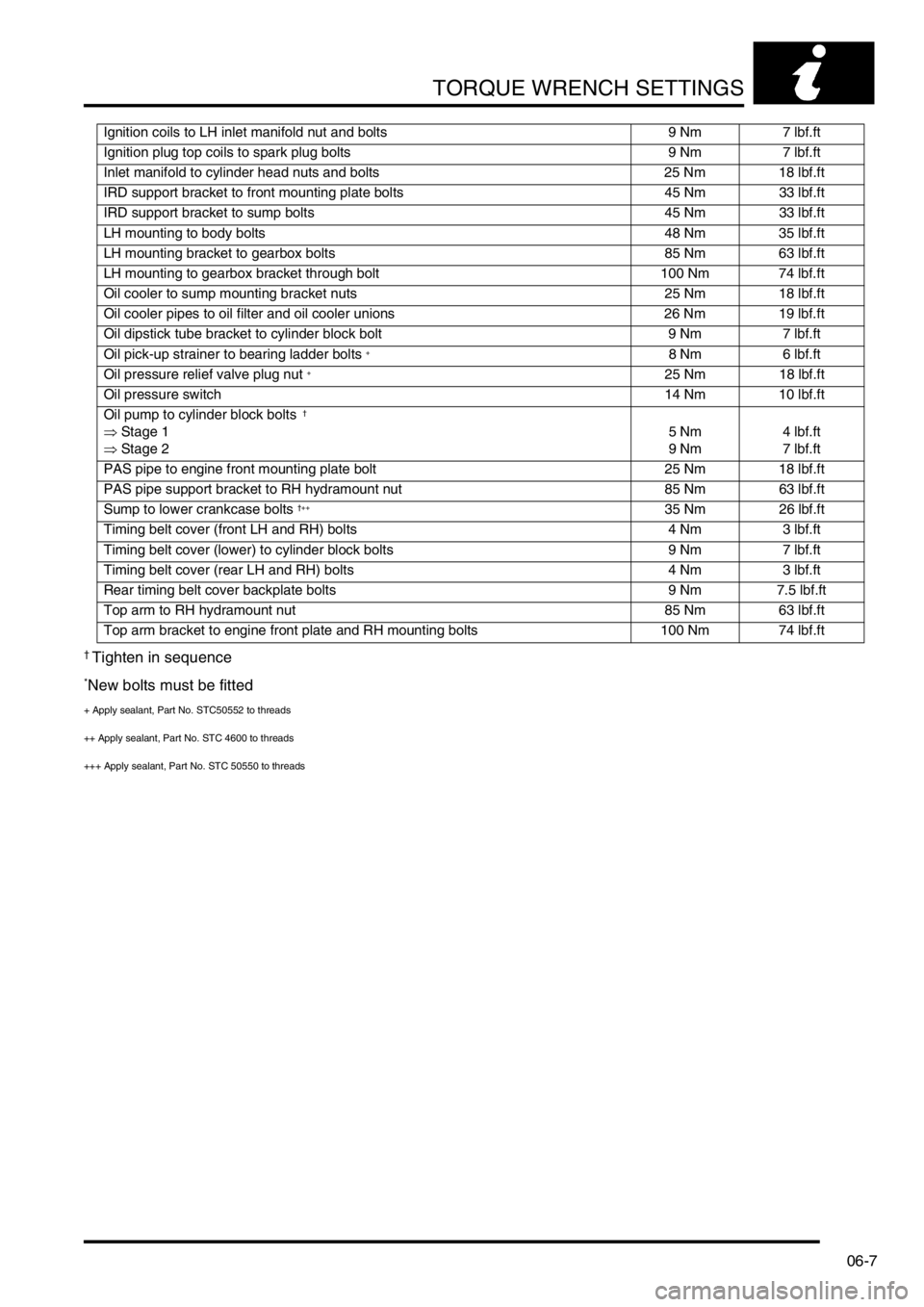

TORQUE WRENCH SETTINGS

06-7

† Tighten in sequence

*New bolts must be fitted

+ Apply sealant, Part No. STC50552 to threads

++ Apply sealant, Part No. STC 4600 to threads

+++ Apply sealant, Part No. STC 50550 to threads

Ignition coils to LH inlet manifold nut and bolts 9 Nm 7 lbf.ft

Ignition plug top coils to spark plug bolts 9 Nm 7 lbf.ft

Inlet manifold to cylinder head nuts and bolts 25 Nm 18 lbf.ft

IRD support bracket to front mounting plate bolts 45 Nm 33 lbf.ft

IRD support bracket to sump bolts 45 Nm 33 lbf.ft

LH mounting to body bolts 48 Nm 35 lbf.ft

LH mounting bracket to gearbox bolts 85 Nm 63 lbf.ft

LH mounting to gearbox bracket through bolt 100 Nm 74 lbf.ft

Oil cooler to sump mounting bracket nuts 25 Nm 18 lbf.ft

Oil cooler pipes to oil filter and oil cooler unions 26 Nm 19 lbf.ft

Oil dipstick tube bracket to cylinder block bolt 9 Nm 7 lbf.ft

Oil pick-up strainer to bearing ladder bolts

+8 Nm 6 lbf.ft

Oil pressure relief valve plug nut

+25 Nm 18 lbf.ft

Oil pressure switch 14 Nm 10 lbf.ft

Oil pump to cylinder block bolts

†

⇒ Stage 1

⇒ Stage 25 Nm

9 Nm4 lbf.ft

7 lbf.ft

PAS pipe to engine front mounting plate bolt 25 Nm 18 lbf.ft

PAS pipe support bracket to RH hydramount nut 85 Nm 63 lbf.ft

Sump to lower crankcase bolts

†++35 Nm 26 lbf.ft

Timing belt cover (front LH and RH) bolts 4 Nm 3 lbf.ft

Timing belt cover (lower) to cylinder block bolts 9 Nm 7 lbf.ft

Timing belt cover (rear LH and RH) bolts 4 Nm 3 lbf.ft

Rear timing belt cover backplate bolts 9 Nm 7.5 lbf.ft

Top arm to RH hydramount nut 85 Nm 63 lbf.ft

Top arm bracket to engine front plate and RH mounting bolts 100 Nm 74 lbf.ft

Page 113 of 1007

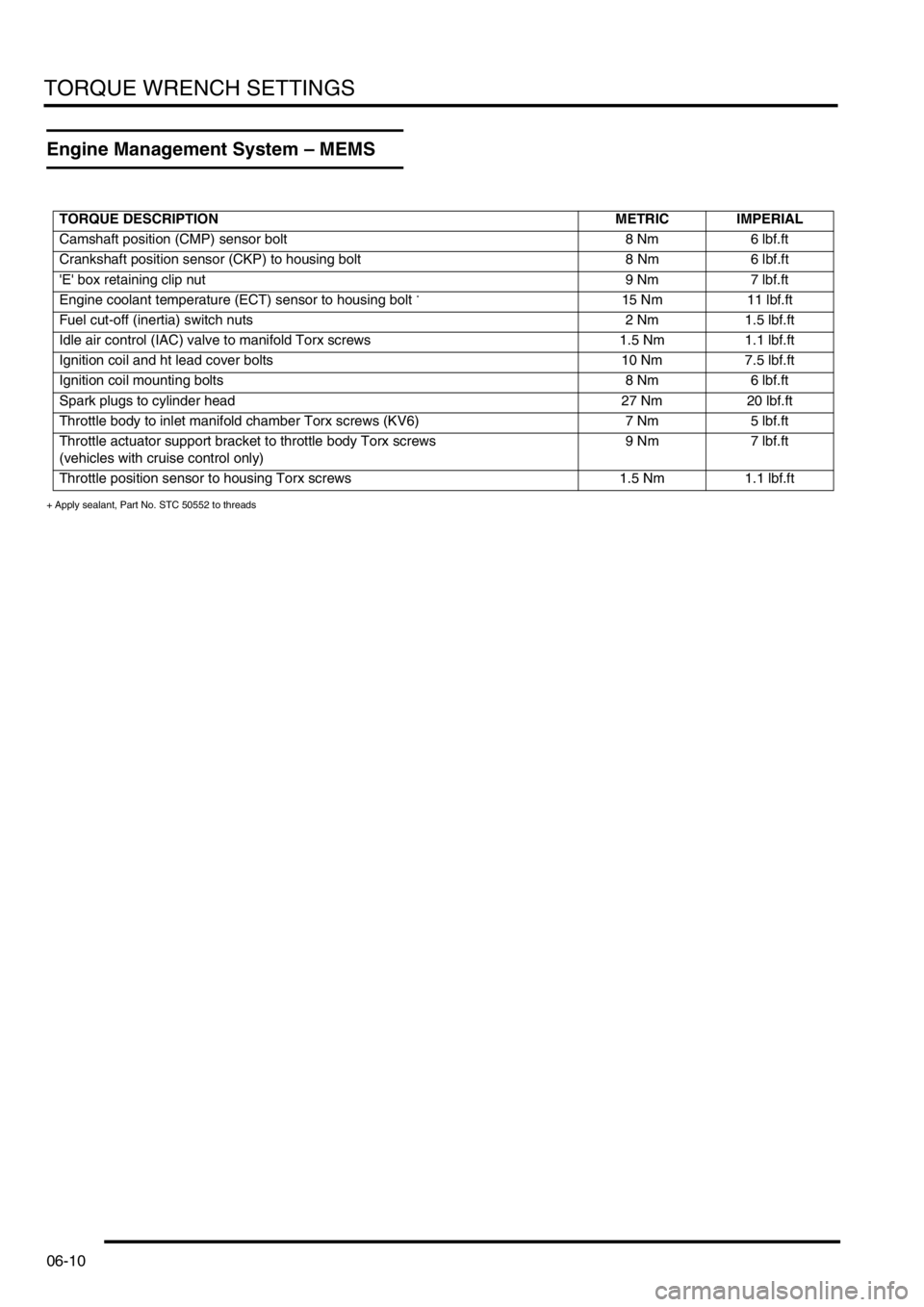

TORQUE WRENCH SETTINGS

06-10

Engine Management System – MEMS

+ Apply sealant, Part No. STC 50552 to threads

TORQUE DESCRIPTION METRIC IMPERIAL

Camshaft position (CMP) sensor bolt 8 Nm 6 lbf.ft

Crankshaft position sensor (CKP) to housing bolt 8 Nm 6 lbf.ft

'E' box retaining clip nut 9 Nm 7 lbf.ft

Engine coolant temperature (ECT) sensor to housing bolt

*15 Nm 11 lbf.ft

Fuel cut-off (inertia) switch nuts 2 Nm 1.5 lbf.ft

Idle air control (IAC) valve to manifold Torx screws 1.5 Nm 1.1 lbf.ft

Ignition coil and ht lead cover bolts 10 Nm 7.5 lbf.ft

Ignition coil mounting bolts 8 Nm 6 lbf.ft

Spark plugs to cylinder head 27 Nm 20 lbf.ft

Throttle body to inlet manifold chamber Torx screws (KV6) 7 Nm 5 lbf.ft

Throttle actuator support bracket to throttle body Torx screws

(vehicles with cruise control only)9 Nm 7 lbf.ft

Throttle position sensor to housing Torx screws 1.5 Nm 1.1 lbf.ft

Page 114 of 1007

TORQUE WRENCH SETTINGS

06-11

Engine Management System – Siemens

TORQUE DESCRIPTION METRIC IMPERIAL

Camshaft position (CMP) sensor 8 Nm 6 lbf.ft

CMP sensor mounting bracket bolt 8 Nm 6 lbf.ft

Crankshaft position (CKP) sensor bolt 9 Nm 6.5 lbf.ft

Engine Coolant temperature (ECT) sensor 17 Nm 12.5 lbf.ft

'E' box cover Allen screws 2 Nm 1.5 lbf.ft

'E' box mounting nut 9 Nm 7 lbf.ft

Plug top coils to LH inlet manifold nut and bolt 9 Nm 6.5 lbf.ft

Plug top coils to RH camshaft cover bolts 9 Nm 6.5 lbf.ft

Spark plugs25 Nm 18 lbf.ft

Throttle body to inlet manifold chamber Torx screws (KV6) 7 Nm 5 lbf.ft

Throttle pedal assembly to bulkhead nuts 25 Nm 18 lbf.ft

Throttle position (TP) sensor screws 1.5 Nm 1.1 lbf.ft

Page 116 of 1007

TORQUE WRENCH SETTINGS

06-13

Fuel delivery system – Petrol

1 Tighten in sequence using the procedure defined in 'Repairs' section.

+ ENGINE MANAGEMENT SYSTEM - SIEMENS, REPAIRS, Sensor - combined - manifold absolute

pressure/Intake air temperature (MAP/IAT).

TORQUE DESCRIPTION METRIC IMPERIAL

Air cleaner to battery tray bolts 9 Nm 7 lbf.ft

Fuel filler neck to body nuts and bolt 9 Nm 7 lbf.ft

Fuel pump/sender unit to tank locking ring 35 Nm 26 lbf.ft

Fuel rail to inlet manifold bolt 8 Nm 6 lbf.ft

Fuel tank to body bolts 40 Nm 29 lbf.ft

Heated Oxygen (HO

2S) Sensor 40 Nm 29 lbf.ft

Ignition coils to LH inlet manifold nuts and bolts - KV6 - Up to 03 Model Year 9 Nm 7 lbf.ft

Inertia (fuel cut-off) switch 2 Nm 1.5 lbf.ft

Intake Air Control Valve (IACV) to throttle body Allen screws 6 Nm 4.5 lbf.ft

Subframe to body bolts 190 Nm 140 lbf.ft

Throttle housing to inlet manifold bolts

1 (K1.8)

⇒1st. stage4 Nm 3 lbf.ft

⇒2nd. stage9 Nm 7 lbf.ft

Throttle body to inlet manifold chamber Torx screws (KV6) 8 Nm 6 lbf.ft

Throttle actuator support bracket to throttle body Torx screws (vehicles with cruise

control only)9 Nm 7 lbf.ft

Throttle position sensor to housing Torx screws 1.5 Nm 1.1 lbf.ft

VIS motor to inlet manifold chamber screws (KV6 only) 8 Nm 6 lbf.ft

Page 131 of 1007

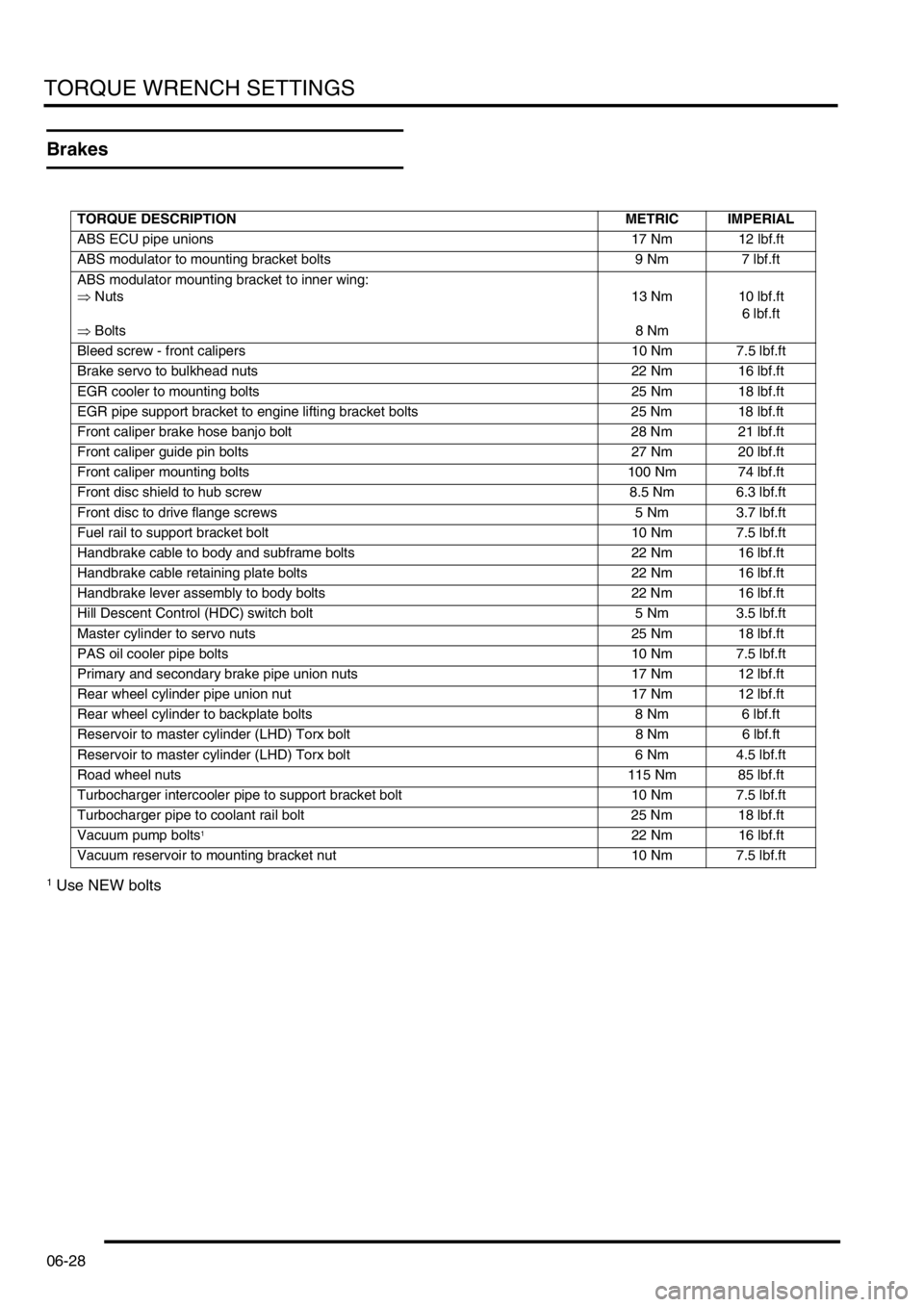

TORQUE WRENCH SETTINGS

06-28

Brakes

1 Use NEW bolts

TORQUE DESCRIPTION METRIC IMPERIAL

ABS ECU pipe unions 17 Nm 12 lbf.ft

ABS modulator to mounting bracket bolts 9 Nm 7 lbf.ft

ABS modulator mounting bracket to inner wing:

⇒ Nuts

⇒ Bolts13 Nm

8 Nm10 lbf.ft

6 lbf.ft

Bleed screw - front calipers 10 Nm 7.5 lbf.ft

Brake servo to bulkhead nuts 22 Nm 16 lbf.ft

EGR cooler to mounting bolts 25 Nm 18 lbf.ft

EGR pipe support bracket to engine lifting bracket bolts 25 Nm 18 lbf.ft

Front caliper brake hose banjo bolt 28 Nm 21 lbf.ft

Front caliper guide pin bolts 27 Nm 20 lbf.ft

Front caliper mounting bolts 100 Nm 74 lbf.ft

Front disc shield to hub screw 8.5 Nm 6.3 lbf.ft

Front disc to drive flange screws 5 Nm 3.7 lbf.ft

Fuel rail to support bracket bolt 10 Nm 7.5 lbf.ft

Handbrake cable to body and subframe bolts 22 Nm 16 lbf.ft

Handbrake cable retaining plate bolts 22 Nm 16 lbf.ft

Handbrake lever assembly to body bolts 22 Nm 16 lbf.ft

Hill Descent Control (HDC) switch bolt 5 Nm 3.5 lbf.ft

Master cylinder to servo nuts 25 Nm 18 lbf.ft

PAS oil cooler pipe bolts 10 Nm 7.5 lbf.ft

Primary and secondary brake pipe union nuts 17 Nm 12 lbf.ft

Rear wheel cylinder pipe union nut 17 Nm 12 lbf.ft

Rear wheel cylinder to backplate bolts 8 Nm 6 lbf.ft

Reservoir to master cylinder (LHD) Torx bolt 8 Nm 6 lbf.ft

Reservoir to master cylinder (LHD) Torx bolt 6 Nm 4.5 lbf.ft

Road wheel nuts 115 Nm 85 lbf.ft

Turbocharger intercooler pipe to support bracket bolt 10 Nm 7.5 lbf.ft

Turbocharger pipe to coolant rail bolt 25 Nm 18 lbf.ft

Vacuum pump bolts

122 Nm 16 lbf.ft

Vacuum reservoir to mounting bracket nut 10 Nm 7.5 lbf.ft

Page 144 of 1007

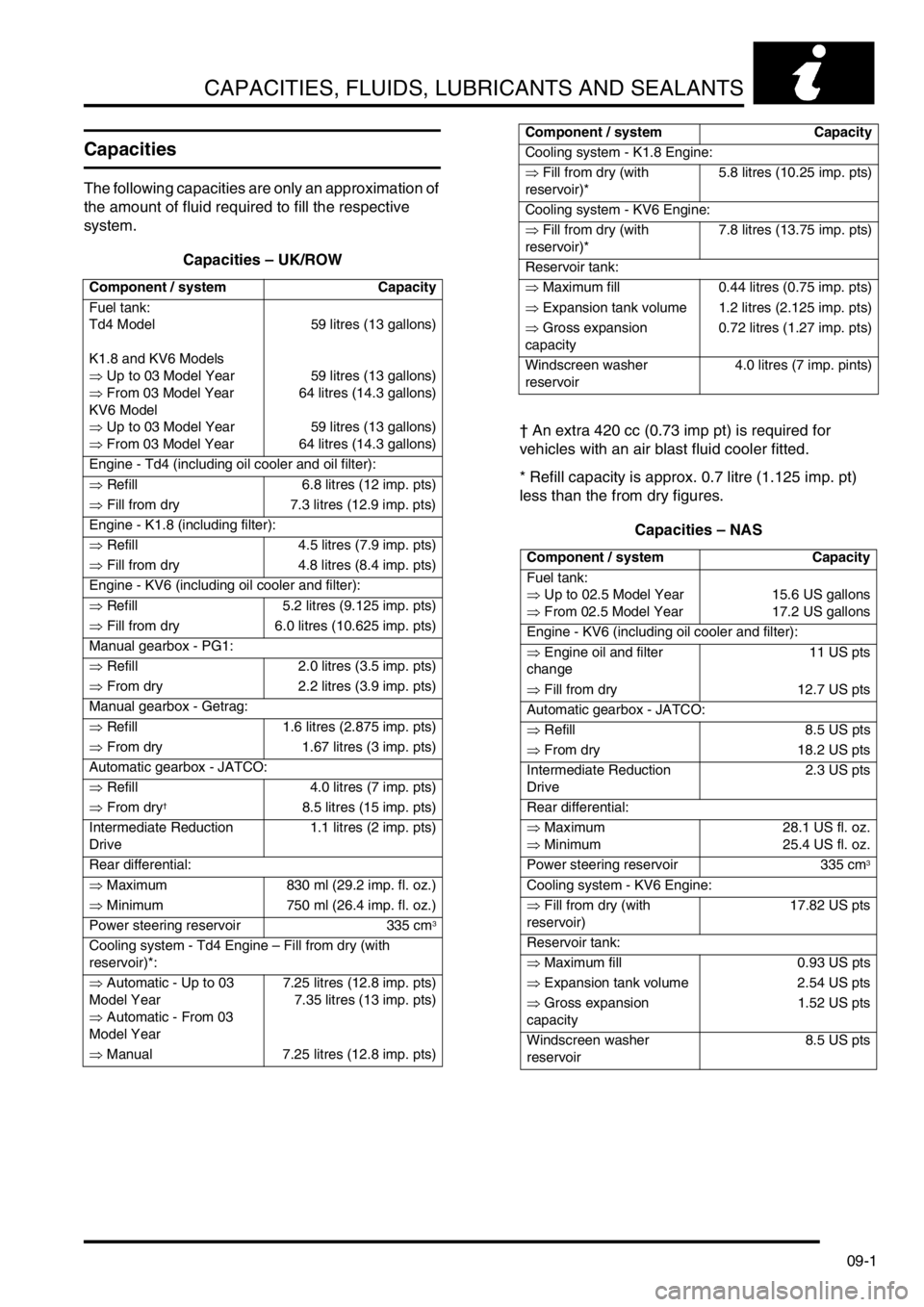

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS

09-1

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS

Capacities

The following capacities are only an approximation of

the amount of fluid required to fill the respective

system.

Capacities – UK/ROW

† An extra 420 cc (0.73 imp pt) is required for

vehicles with an air blast fluid cooler fitted.

* Refill capacity is approx. 0.7 litre (1.125 imp. pt)

less than the from dry figures.

Capacities – NAS

Component / system Capacity

Fuel tank:

Td4 Model

K1.8 and KV6 Models

⇒ Up to 03 Model Year

⇒ From 03 Model Year

KV6 Model

⇒ Up to 03 Model Year

⇒ From 03 Model Year59 litres (13 gallons)

59 litres (13 gallons)

64 litres (14.3 gallons)

59 litres (13 gallons)

64 litres (14.3 gallons)

Engine - Td4 (including oil cooler and oil filter):

⇒ Refill 6.8 litres (12 imp. pts)

⇒ Fill from dry 7.3 litres (12.9 imp. pts)

Engine - K1.8 (including filter):

⇒ Refill 4.5 litres (7.9 imp. pts)

⇒ Fill from dry 4.8 litres (8.4 imp. pts)

Engine - KV6 (including oil cooler and filter):

⇒ Refill 5.2 litres (9.125 imp. pts)

⇒ Fill from dry 6.0 litres (10.625 imp. pts)

Manual gearbox - PG1:

⇒ Refill 2.0 litres (3.5 imp. pts)

⇒ From dry 2.2 litres (3.9 imp. pts)

Manual gearbox - Getrag:

⇒ Refill 1.6 litres (2.875 imp. pts)

⇒ From dry 1.67 litres (3 imp. pts)

Automatic gearbox - JATCO:

⇒ Refill 4.0 litres (7 imp. pts)

⇒ From dry

†8.5 litres (15 imp. pts)

Intermediate Reduction

Drive1.1 litres (2 imp. pts)

Rear differential:

⇒ Maximum 830 ml (29.2 imp. fl. oz.)

⇒ Minimum 750 ml (26.4 imp. fl. oz.)

Power steering reservoir 335 cm

3

Cooling system - Td4 Engine – Fill from dry (with

reservoir)*:

⇒ Automatic - Up to 03

Model Year

⇒ Automatic - From 03

Model Year7.25 litres (12.8 imp. pts)

7.35 litres (13 imp. pts)

⇒ Manual 7.25 litres (12.8 imp. pts)

Cooling system - K1.8 Engine:

⇒ Fill from dry (with

reservoir)*5.8 litres (10.25 imp. pts)

Cooling system - KV6 Engine:

⇒ Fill from dry (with

reservoir)*7.8 litres (13.75 imp. pts)

Reservoir tank:

⇒ Maximum fill 0.44 litres (0.75 imp. pts)

⇒ Expansion tank volume 1.2 litres (2.125 imp. pts)

⇒ Gross expansion

capacity0.72 litres (1.27 imp. pts)

Windscreen washer

reservoir 4.0 litres (7 imp. pints)

Component / system Capacity

Fuel tank:

⇒ Up to 02.5 Model Year

⇒ From 02.5 Model Year15.6 US gallons

17.2 US gallons

Engine - KV6 (including oil cooler and filter):

⇒ Engine oil and filter

change11 US pts

⇒ Fill from dry 12.7 US pts

Automatic gearbox - JATCO:

⇒ Refill 8.5 US pts

⇒ From dry 18.2 US pts

Intermediate Reduction

Drive2.3 US pts

Rear differential:

⇒ Maximum

⇒ Minimum28.1 US fl. oz.

25.4 US fl. oz.

Power steering reservoir 335 cm

3

Cooling system - KV6 Engine:

⇒ Fill from dry (with

reservoir)17.82 US pts

Reservoir tank:

⇒ Maximum fill 0.93 US pts

⇒ Expansion tank volume 2.54 US pts

⇒ Gross expansion

capacity1.52 US pts

Windscreen washer

reservoir 8.5 US pts Component / system Capacity

Page 145 of 1007

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS

09-2

Fluids

Fuel

Always use the following recommended fuels:

Petrol engines

Use unleaded petrol with a minimum octane rating of

95 RON to ENN 228 specification.

In an emergency (and only if the correct fuel is

unavailable), lower octane rated fuel can be used for

very limited periods of moderate, low speed

motoring, provided engine 'knocking' does not occur.

Fuels of 90 RON is used in certain markets; 90 RON

fuel can be used regularly ONLY if the engine has

been tuned specifically to suit low octane fuel.

Certain markets use fuel containing a 23% Ethanol

additive.

K1.8 and KV6 engines are also available for use with

a low octane leaded fuel specification in some

markets.

Diesel engines

Use a good quality diesel fuel or automotive gas oil

(AGO) conforming to EN 590 specification.

It is important that the sulphur content of diesel fuel

does not exceed 0.3%.

Ensure the fuel filter element is changed at the

recommended intervals.

+ MAINTENANCE, MAINTENANCE, Fuel

Filter - Diesel.

Brake Fluid

Use only DOT 4 brake fluid. DO NOT use brake fluid

of a different specification.

PAS fluid

Use Texaco 9226 fluid.Anti-freeze solutions

The overall anti-freeze concentration should not fall,

by volume, below 50% to ensure that the anti-

corrosion properties of the coolant are maintained.

Anti-freeze concentrations greater than 60% are not

recommended as cooling efficiency will be impaired.

Use Havoline Extended Life Coolant (XLC), or any

ethylene glycol based anti-freeze (containing no

methanol) with only Organic Acid Technology (OAT)

corrosion inhibitors, to protect the cooling system.

CAUTION: No other anti-freeze should be used

with Havoline Extended Life Coolant.

The cooling system should be drained, flushed and

refilled with the correct amount of anti-freeze

solution at the intervals given on the Service

Maintenance Check Sheet.

After filling with anti-freeze solution, attach a warning

label to a prominent position on the vehicle stating

the type of anti-freeze contained in the cooling

system to ensure that the correct type is used for

topping-up.

The following recommended quantities of anti-freeze

will provide frost protection to -36 °C (-33 °F):

Engine – Td4

Engine – K1.8

Engine – KV6

Concentration 50%

Amount of anti-freeze 3.75 litres

(6.625 imp. pts)

Concentration 50%

Amount of anti-freeze 2.9 litres

(5.125 imp. pts)

Concentration 50%

Amount of anti-freeze 3.9 litres

(6.875 imp. pts, )

Page 146 of 1007

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS

09-3

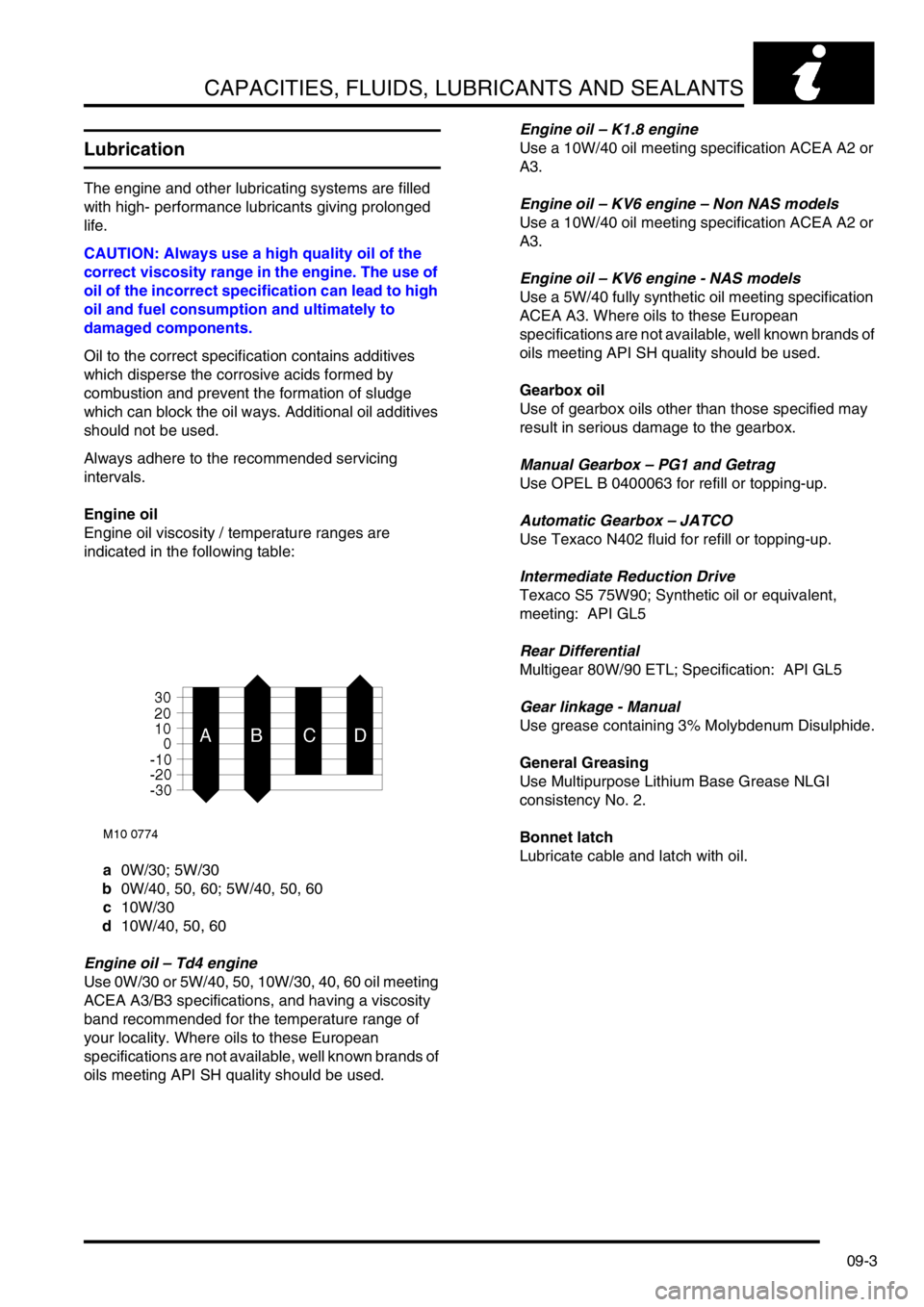

Lubrication

The engine and other lubricating systems are filled

with high- performance lubricants giving prolonged

life.

CAUTION: Always use a high quality oil of the

correct viscosity range in the engine. The use of

oil of the incorrect specification can lead to high

oil and fuel consumption and ultimately to

damaged components.

Oil to the correct specification contains additives

which disperse the corrosive acids formed by

combustion and prevent the formation of sludge

which can block the oil ways. Additional oil additives

should not be used.

Always adhere to the recommended servicing

intervals.

Engine oil

Engine oil viscosity / temperature ranges are

indicated in the following table:

a0W/30; 5W/30

b0W/40, 50, 60; 5W/40, 50, 60

c10W/30

d10W/40, 50, 60

Engine oil – Td4 engine

Use 0W/30 or 5W/40, 50, 10W/30, 40, 60 oil meeting

ACEA A3/B3 specifications, and having a viscosity

band recommended for the temperature range of

your locality. Where oils to these European

specifications are not available, well known brands of

oils meeting API SH quality should be used.Engine oil – K1.8 engine

Use a 10W/40 oil meeting specification ACEA A2 or

A3.

Engine oil – KV6 engine – Non NAS models

Use a 10W/40 oil meeting specification ACEA A2 or

A3.

Engine oil – KV6 engine - NAS models

Use a 5W/40 fully synthetic oil meeting specification

ACEA A3. Where oils to these European

specifications are not available, well known brands of

oils meeting API SH quality should be used.

Gearbox oil

Use of gearbox oils other than those specified may

result in serious damage to the gearbox.

Manual Gearbox – PG1 and Getrag

Use OPEL B 0400063 for refill or topping-up.

Automatic Gearbox – JATCO

Use Texaco N402 fluid for refill or topping-up.

Intermediate Reduction Drive

Texaco S5 75W90; Synthetic oil or equivalent,

meeting: API GL5

Rear Differential

Multigear 80W/90 ETL; Specification: API GL5

Gear linkage - Manual

Use grease containing 3% Molybdenum Disulphide.

General Greasing

Use Multipurpose Lithium Base Grease NLGI

consistency No. 2.

Bonnet latch

Lubricate cable and latch with oil.

Page 147 of 1007

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS

09-4

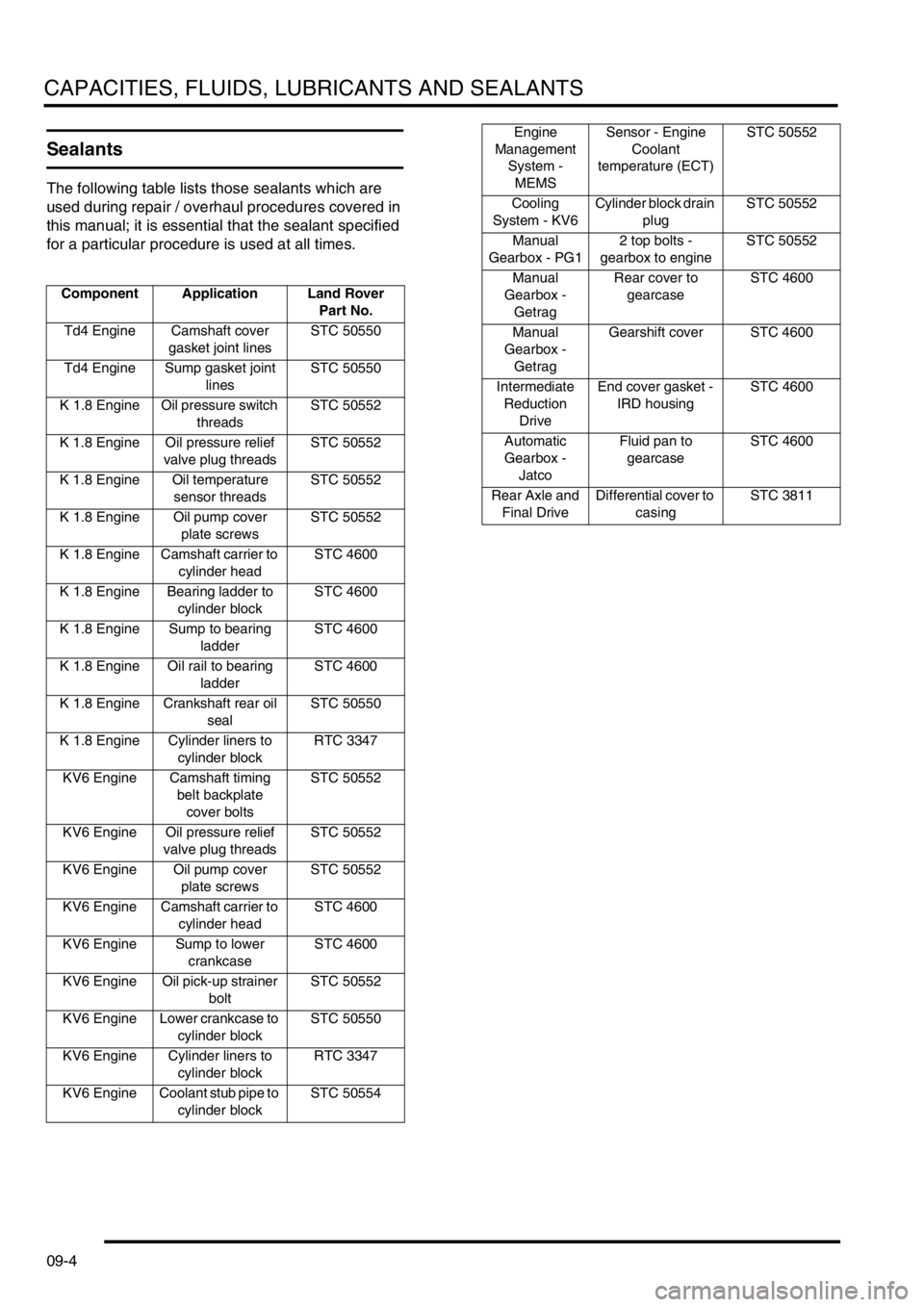

Sealants

The following table lists those sealants which are

used during repair / overhaul procedures covered in

this manual; it is essential that the sealant specified

for a particular procedure is used at all times.

Component Application Land Rover

Part No.

Td4 Engine Camshaft cover

gasket joint linesSTC 50550

Td4 Engine Sump gasket joint

linesSTC 50550

K 1.8 Engine Oil pressure switch

threadsSTC 50552

K 1.8 Engine Oil pressure relief

valve plug threadsSTC 50552

K 1.8 Engine Oil temperature

sensor threadsSTC 50552

K 1.8 Engine Oil pump cover

plate screwsSTC 50552

K 1.8 Engine Camshaft carrier to

cylinder headSTC 4600

K 1.8 Engine Bearing ladder to

cylinder blockSTC 4600

K 1.8 Engine Sump to bearing

ladderSTC 4600

K 1.8 Engine Oil rail to bearing

ladderSTC 4600

K 1.8 Engine Crankshaft rear oil

seal STC 50550

K 1.8 Engine Cylinder liners to

cylinder blockRTC 3347

KV6 Engine Camshaft timing

belt backplate

cover boltsSTC 50552

KV6 Engine Oil pressure relief

valve plug threadsSTC 50552

KV6 Engine Oil pump cover

plate screwsSTC 50552

KV6 Engine Camshaft carrier to

cylinder headSTC 4600

KV6 Engine Sump to lower

crankcaseSTC 4600

KV6 Engine Oil pick-up strainer

boltSTC 50552

KV6 Engine Lower crankcase to

cylinder blockSTC 50550

KV6 Engine Cylinder liners to

cylinder blockRTC 3347

KV6 Engine Coolant stub pipe to

cylinder blockSTC 50554

Engine

Management

System -

MEMSSensor - Engine

Coolant

temperature (ECT)STC 50552

Cooling

System - KV6Cylinder block drain

plugSTC 50552

Manual

Gearbox - PG12 top bolts -

gearbox to engineSTC 50552

Manual

Gearbox -

GetragRear cover to

gearcaseSTC 4600

Manual

Gearbox -

GetragGearshift cover STC 4600

Intermediate

Reduction

DriveEnd cover gasket -

IRD housingSTC 4600

Automatic

Gearbox -

JatcoFluid pan to

gearcaseSTC 4600

Rear Axle and

Final DriveDifferential cover to

casingSTC 3811

Page 148 of 1007

MAINTENANCE

MAINTENANCE 10-1

MAINTENANCE MAINTENANCE

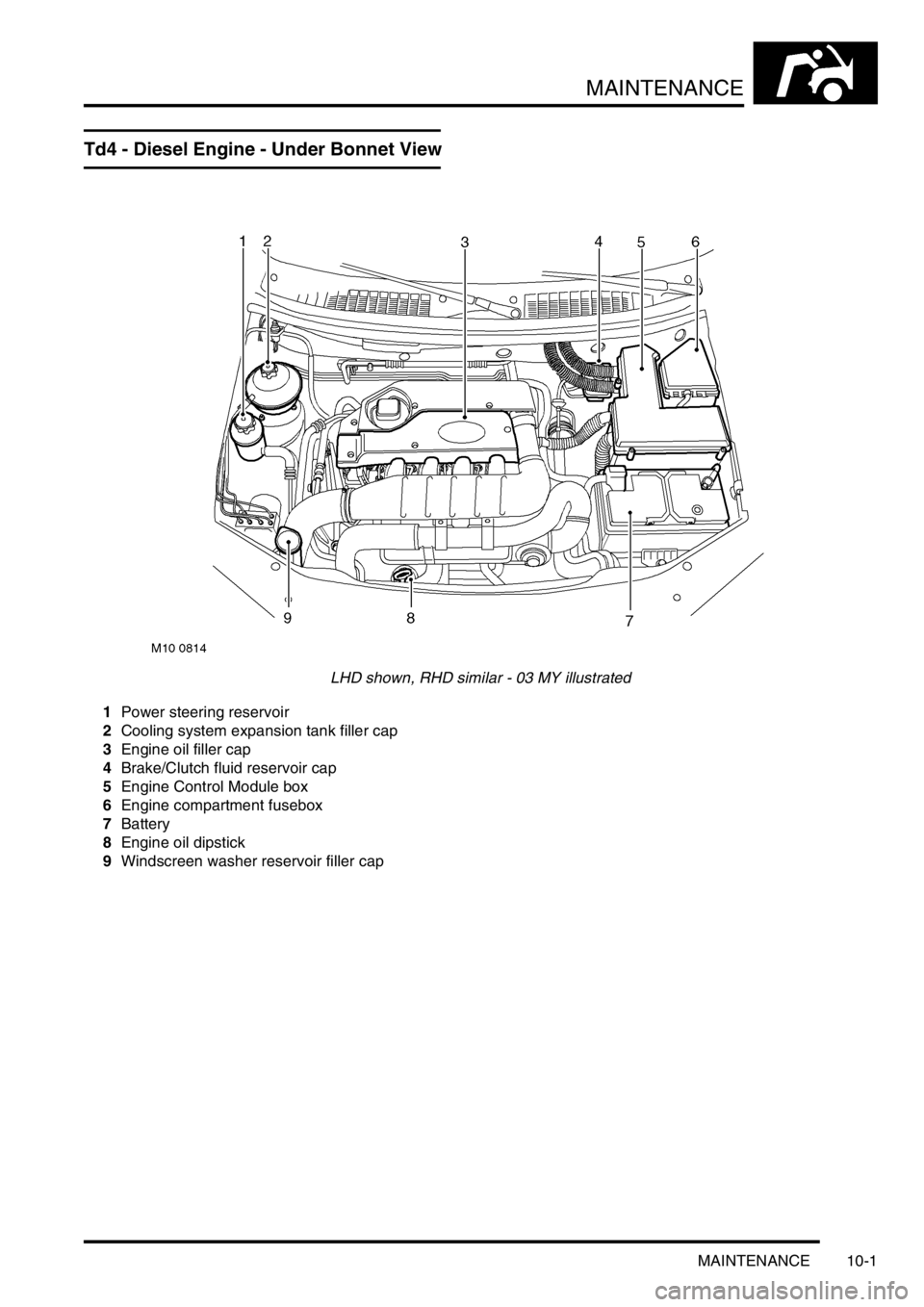

Td4 - Diesel Engine - Under Bonnet View

LHD shown, RHD similar - 03 MY illustrated

1Power steering reservoir

2Cooling system expansion tank filler cap

3Engine oil filler cap

4Brake/Clutch fluid reservoir cap

5Engine Control Module box

6Engine compartment fusebox

7Battery

8Engine oil dipstick

9Windscreen washer reservoir filler cap