fuel LAND ROVER FREELANDER 2001 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 79 of 1007

GENERAL DATA

04-16

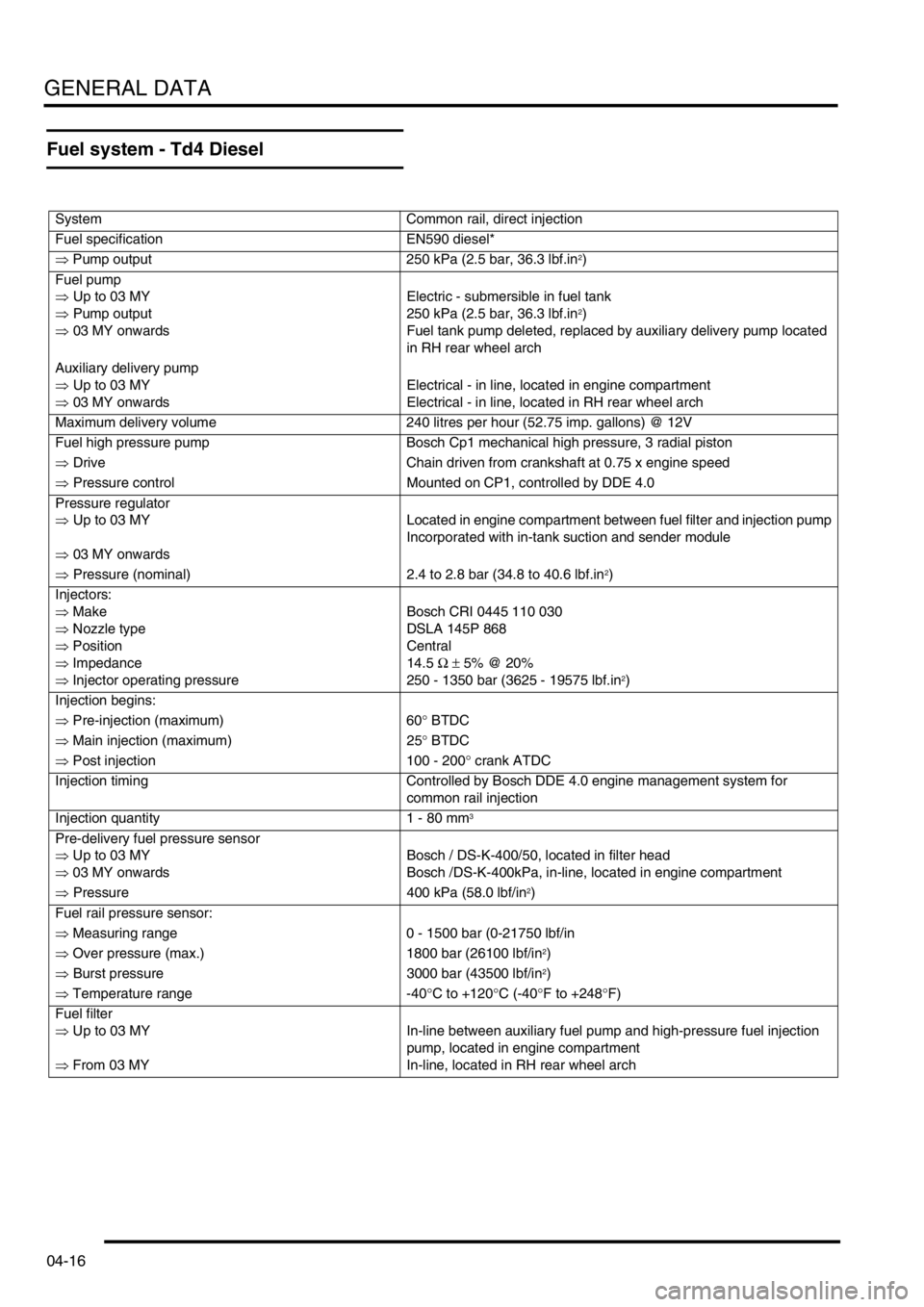

Fuel system - Td4 Diesel

System Common rail, direct injection

Fuel specification EN590 diesel*

⇒ Pump output 250 kPa (2.5 bar, 36.3 lbf.in

2)

Fuel pump

⇒ Up to 03 MY

⇒ Pump output

⇒ 03 MY onwardsElectric - submersible in fuel tank

250 kPa (2.5 bar, 36.3 lbf.in

2)

Fuel tank pump deleted, replaced by auxiliary delivery pump located

in RH rear wheel arch

Auxiliary delivery pump

⇒ Up to 03 MY

⇒ 03 MY onwardsElectrical - in line, located in engine compartment

Electrical - in line, located in RH rear wheel arch

Maximum delivery volume 240 litres per hour (52.75 imp. gallons) @ 12V

Fuel high pressure pump Bosch Cp1 mechanical high pressure, 3 radial piston

⇒ Drive Chain driven from crankshaft at 0.75 x engine speed

⇒ Pressure control Mounted on CP1, controlled by DDE 4.0

Pressure regulator

⇒ Up to 03 MY

⇒ 03 MY onwardsLocated in engine compartment between fuel filter and injection pump

Incorporated with in-tank suction and sender module

⇒ Pressure (nominal) 2.4 to 2.8 bar (34.8 to 40.6 lbf.in

2)

Injectors:

⇒ Make

⇒ Nozzle type

⇒ Position

⇒ Impedance

⇒ Injector operating pressureBosch CRI 0445 110 030

DSLA 145P 868

Central

14.5 Ω ± 5% @ 20%

250 - 1350 bar (3625 - 19575 lbf.in

2)

Injection begins:

⇒ Pre-injection (maximum) 60° BTDC

⇒ Main injection (maximum) 25° BTDC

⇒ Post injection 100 - 200° crank ATDC

Injection timing Controlled by Bosch DDE 4.0 engine management system for

common rail injection

Injection quantity 1 - 80 mm

3

Pre-delivery fuel pressure sensor

⇒ Up to 03 MY

⇒ 03 MY onwardsBosch / DS-K-400/50, located in filter head

Bosch /DS-K-400kPa, in-line, located in engine compartment

⇒ Pressure 400 kPa (58.0 lbf/in

2)

Fuel rail pressure sensor:

⇒ Measuring range 0 - 1500 bar (0-21750 lbf/in

⇒ Over pressure (max.) 1800 bar (26100 lbf/in

2)

⇒ Burst pressure 3000 bar (43500 lbf/in

2)

⇒ Temperature range -40°C to +120°C (-40°F to +248°F)

Fuel filter

⇒ Up to 03 MY

⇒ From 03 MYIn-line between auxiliary fuel pump and high-pressure fuel injection

pump, located in engine compartment

In-line, located in RH rear wheel arch

Page 80 of 1007

GENERAL DATA

04-17

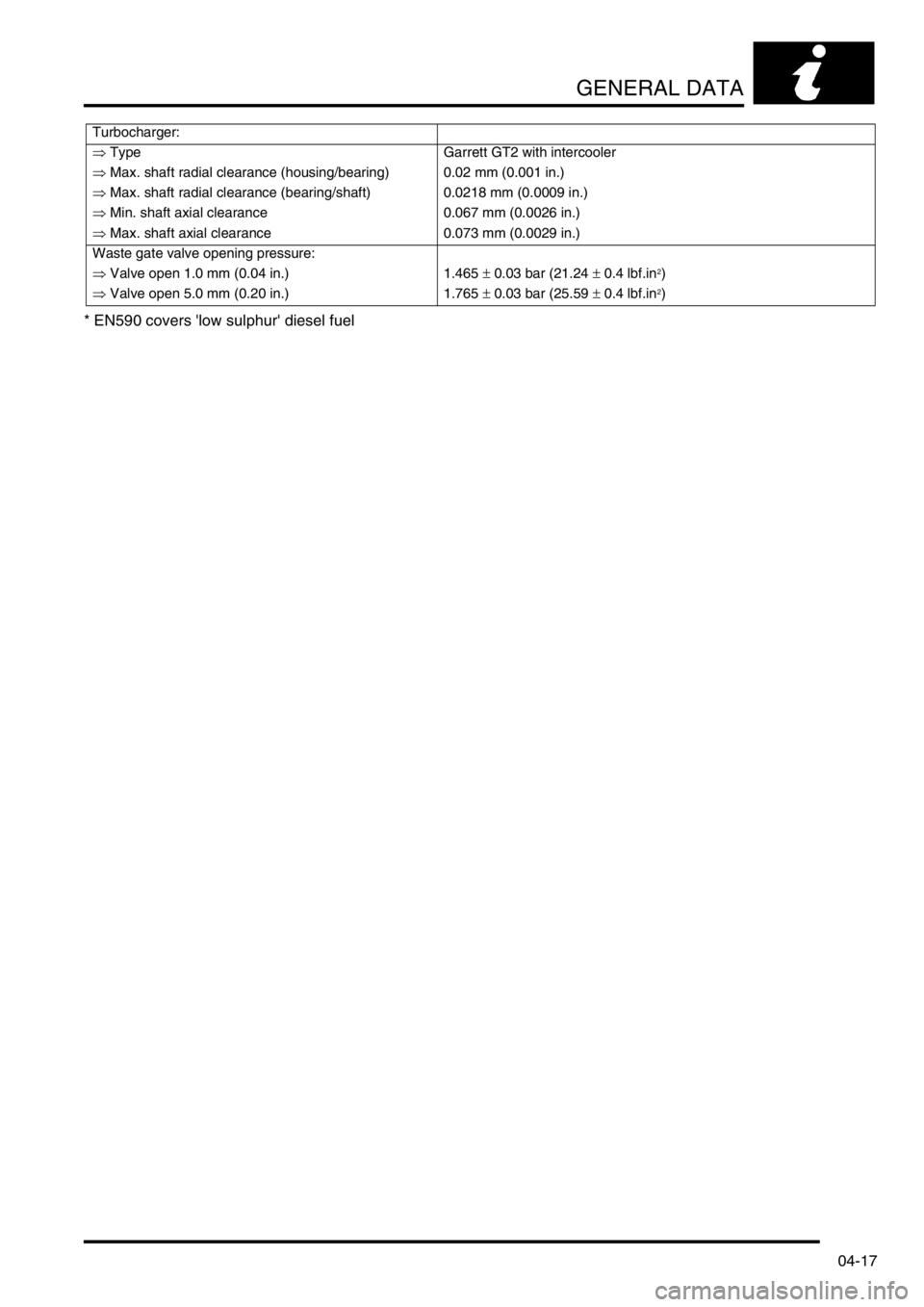

* EN590 covers 'low sulphur' diesel fuel

Turbocharger:

⇒ Type Garrett GT2 with intercooler

⇒ Max. shaft radial clearance (housing/bearing) 0.02 mm (0.001 in.)

⇒ Max. shaft radial clearance (bearing/shaft) 0.0218 mm (0.0009 in.)

⇒ Min. shaft axial clearance 0.067 mm (0.0026 in.)

⇒ Max. shaft axial clearance 0.073 mm (0.0029 in.)

Waste gate valve opening pressure:

⇒ Valve open 1.0 mm (0.04 in.) 1.465 ± 0.03 bar (21.24 ± 0.4 lbf.in

2)

⇒ Valve open 5.0 mm (0.20 in.) 1.765 ± 0.03 bar (25.59 ± 0.4 lbf.in

2)

Page 81 of 1007

GENERAL DATA

04-18

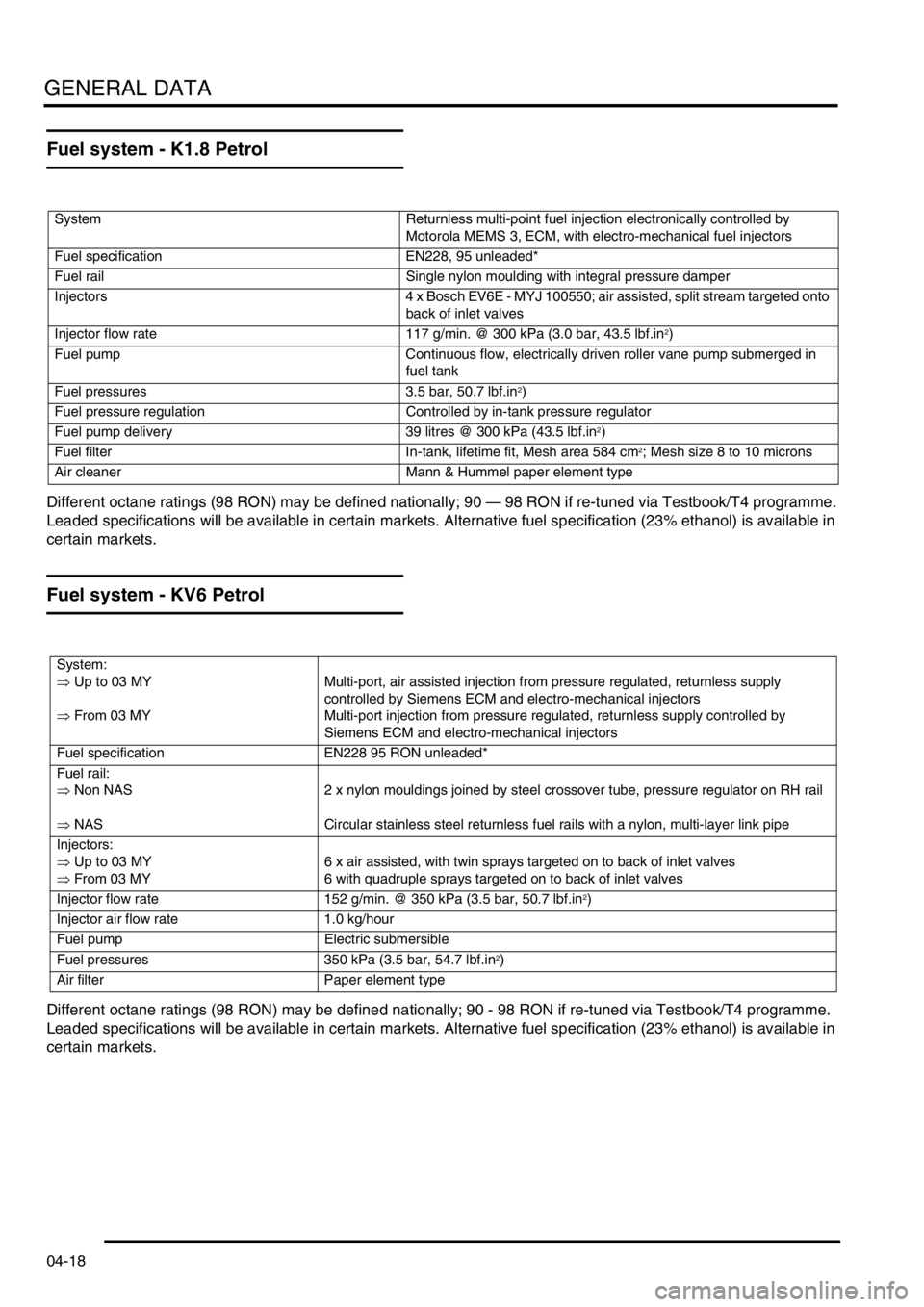

Fuel system - K1.8 Petrol

Different octane ratings (98 RON) may be defined nationally; 90 — 98 RON if re-tuned via Testbook/T4 programme.

Leaded specifications will be available in certain markets. Alternative fuel specification (23% ethanol) is available in

certain markets.

Fuel system - KV6 Petrol

Different octane ratings (98 RON) may be defined nationally; 90 - 98 RON if re-tuned via Testbook/T4 programme.

Leaded specifications will be available in certain markets. Alternative fuel specification (23% ethanol) is available in

certain markets.

System Returnless multi-point fuel injection electronically controlled by

Motorola MEMS 3, ECM, with electro-mechanical fuel injectors

Fuel specification EN228, 95 unleaded*

Fuel rail Single nylon moulding with integral pressure damper

Injectors 4 x Bosch EV6E - MYJ 100550; air assisted, split stream targeted onto

back of inlet valves

Injector flow rate 117 g/min. @ 300 kPa (3.0 bar, 43.5 lbf.in

2)

Fuel pump Continuous flow, electrically driven roller vane pump submerged in

fuel tank

Fuel pressures 3.5 bar, 50.7 lbf.in

2)

Fuel pressure regulation Controlled by in-tank pressure regulator

Fuel pump delivery 39 litres @ 300 kPa (43.5 lbf.in

2)

Fuel filter In-tank, lifetime fit, Mesh area 584 cm

2; Mesh size 8 to 10 microns

Air cleaner Mann & Hummel paper element type

System:

⇒ Up to 03 MY

⇒ From 03 MYMulti-port, air assisted injection from pressure regulated, returnless supply

controlled by Siemens ECM and electro-mechanical injectors

Multi-port injection from pressure regulated, returnless supply controlled by

Siemens ECM and electro-mechanical injectors

Fuel specification EN228 95 RON unleaded*

Fuel rail:

⇒ Non NAS

⇒ NAS2 x nylon mouldings joined by steel crossover tube, pressure regulator on RH rail

Circular stainless steel returnless fuel rails with a nylon, multi-layer link pipe

Injectors:

⇒ Up to 03 MY

⇒ From 03 MY6 x air assisted, with twin sprays targeted on to back of inlet valves

6 with quadruple sprays targeted on to back of inlet valves

Injector flow rate 152 g/min. @ 350 kPa (3.5 bar, 50.7 lbf.in

2)

Injector air flow rate 1.0 kg/hour

Fuel pump Electric submersible

Fuel pressures 350 kPa (3.5 bar, 54.7 lbf.in

2)

Air filter Paper element type

Page 99 of 1007

GENERAL DATA

04-36

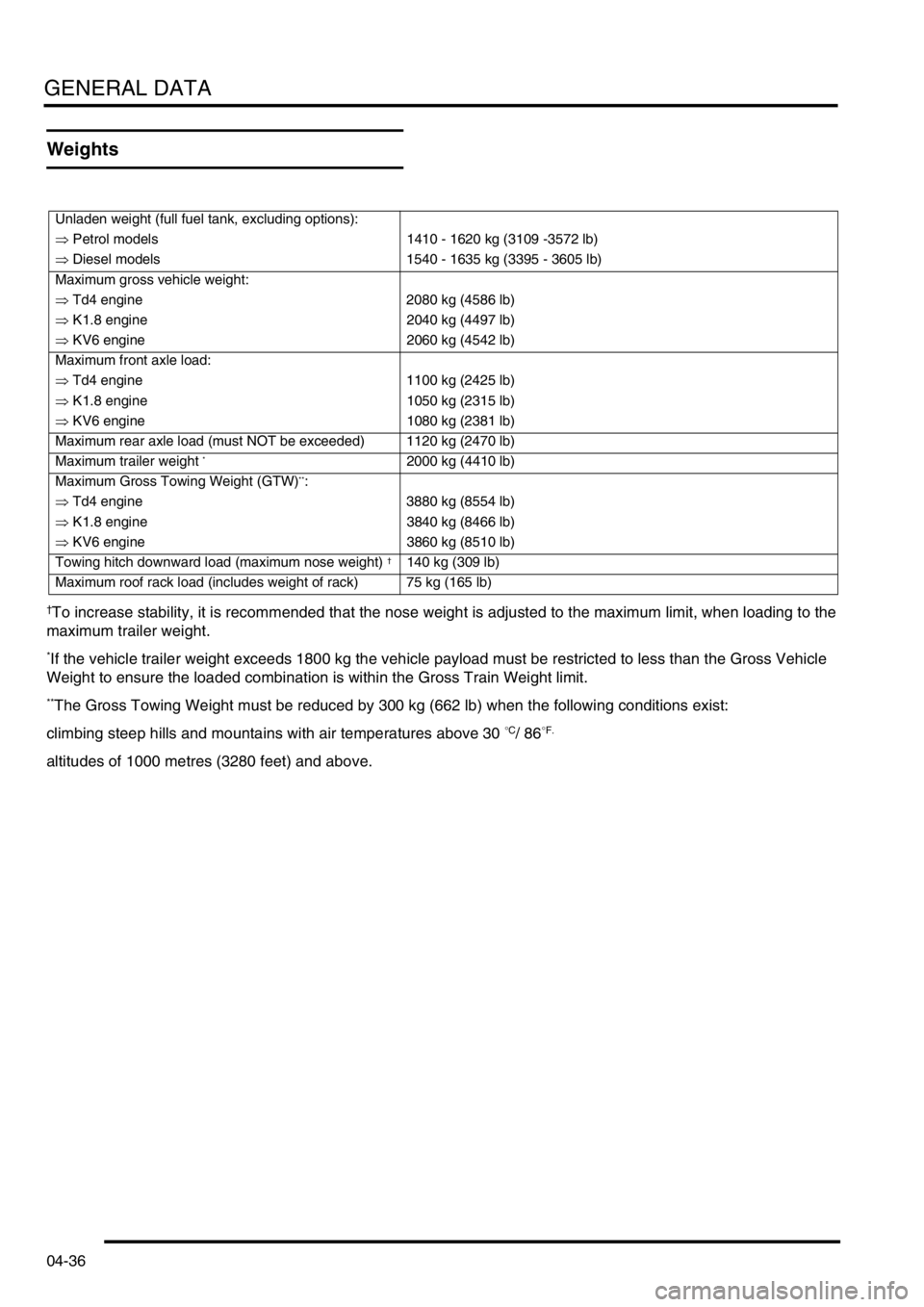

Weights

†To increase stability, it is recommended that the nose weight is adjusted to the maximum limit, when loading to the

maximum trailer weight.

*If the vehicle trailer weight exceeds 1800 kg the vehicle payload must be restricted to less than the Gross Vehicle

Weight to ensure the loaded combination is within the Gross Train Weight limit.

**The Gross Towing Weight must be reduced by 300 kg (662 lb) when the following conditions exist:

climbing steep hills and mountains with air temperatures above 30

°C/ 86°F.

altitudes of 1000 metres (3280 feet) and above.

Unladen weight (full fuel tank, excluding options):

⇒ Petrol models 1410 - 1620 kg (3109 -3572 lb)

⇒ Diesel models 1540 - 1635 kg (3395 - 3605 lb)

Maximum gross vehicle weight:

⇒ Td4 engine 2080 kg (4586 lb)

⇒ K1.8 engine 2040 kg (4497 lb)

⇒ KV6 engine 2060 kg (4542 lb)

Maximum front axle load:

⇒ Td4 engine 1100 kg (2425 lb)

⇒ K1.8 engine 1050 kg (2315 lb)

⇒ KV6 engine 1080 kg (2381 lb)

Maximum rear axle load (must NOT be exceeded) 1120 kg (2470 lb)

Maximum trailer weight

*2000 kg (4410 lb)

Maximum Gross Towing Weight (GTW)

**:

⇒ Td4 engine 3880 kg (8554 lb)

⇒ K1.8 engine 3840 kg (8466 lb)

⇒ KV6 engine 3860 kg (8510 lb)

Towing hitch downward load (maximum nose weight)

†140 kg (309 lb)

Maximum roof rack load (includes weight of rack) 75 kg (165 lb)

Page 105 of 1007

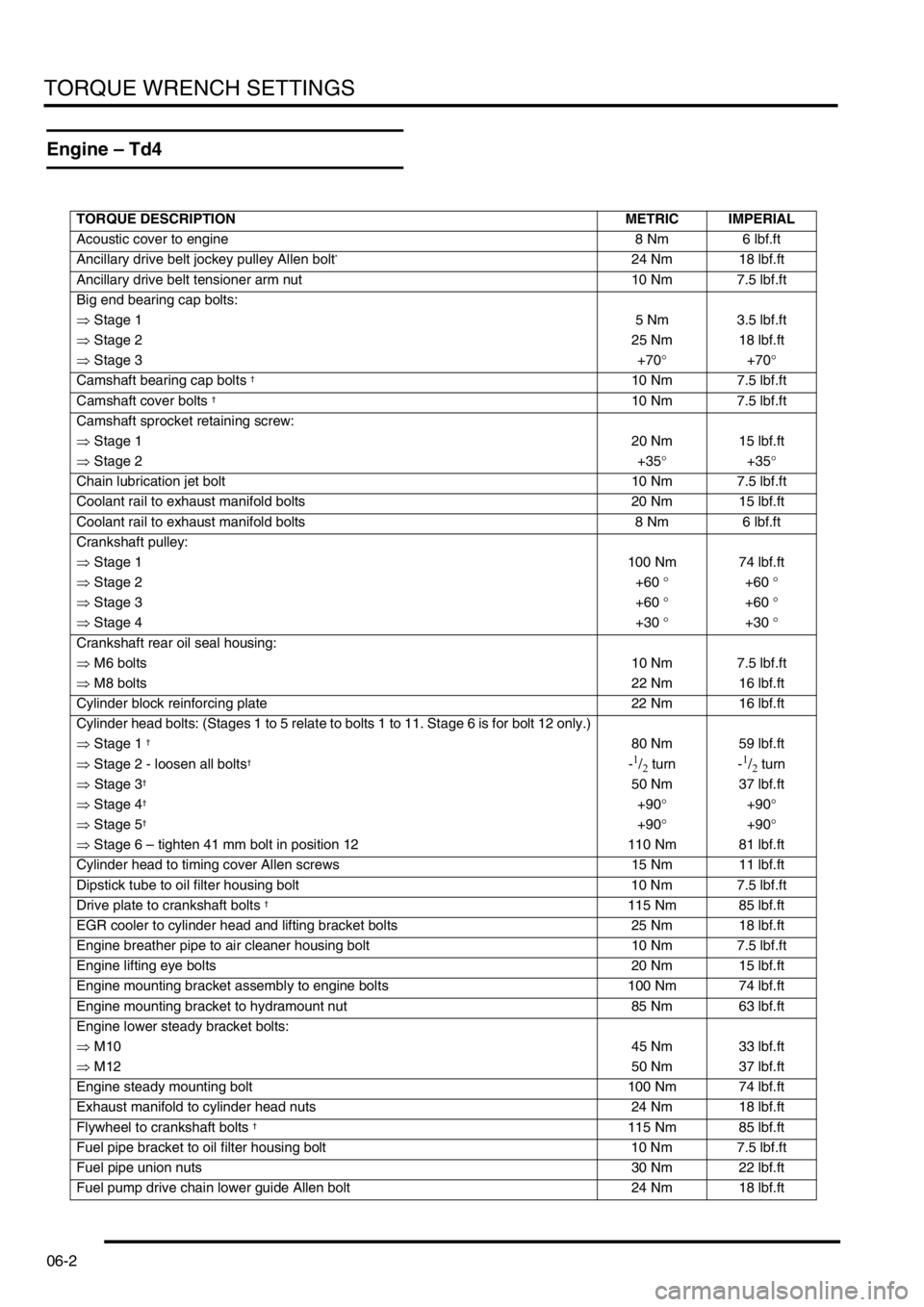

TORQUE WRENCH SETTINGS

06-2

Engine – Td4

TORQUE DESCRIPTION METRIC IMPERIAL

Acoustic cover to engine 8 Nm 6 lbf.ft

Ancillary drive belt jockey pulley Allen bolt

*24 Nm 18 lbf.ft

Ancillary drive belt tensioner arm nut 10 Nm 7.5 lbf.ft

Big end bearing cap bolts:

⇒ Stage 15 Nm 3.5 lbf.ft

⇒ Stage 225 Nm 18 lbf.ft

⇒ Stage 3+70°+70°

Camshaft bearing cap bolts

† 10 Nm 7.5 lbf.ft

Camshaft cover bolts

† 10 Nm 7.5 lbf.ft

Camshaft sprocket retaining screw:

⇒ Stage 120 Nm 15 lbf.ft

⇒ Stage 2+35°+35°

Chain lubrication jet bolt 10 Nm 7.5 lbf.ft

Coolant rail to exhaust manifold bolts 20 Nm 15 lbf.ft

Coolant rail to exhaust manifold bolts 8 Nm 6 lbf.ft

Crankshaft pulley:

⇒ Stage 1100 Nm 74 lbf.ft

⇒ Stage 2+60 °+60 °

⇒ Stage 3+60 °+60 °

⇒ Stage 4+30 °+30 °

Crankshaft rear oil seal housing:

⇒ M6 bolts10 Nm 7.5 lbf.ft

⇒ M8 bolts22 Nm 16 lbf.ft

Cylinder block reinforcing plate 22 Nm 16 lbf.ft

Cylinder head bolts: (Stages 1 to 5 relate to bolts 1 to 11. Stage 6 is for bolt 12 only.)

⇒ Stage 1

†80 Nm 59 lbf.ft

⇒ Stage 2 - loosen all bolts

†-1/2 turn -1/2 turn

⇒ Stage 3

†50 Nm 37 lbf.ft

⇒ Stage 4

†+90°+90°

⇒ Stage 5

†+90°+90°

⇒ Stage 6 – tighten 41 mm bolt in position 12 110 Nm 81 lbf.ft

Cylinder head to timing cover Allen screws 15 Nm 11 lbf.ft

Dipstick tube to oil filter housing bolt 10 Nm 7.5 lbf.ft

Drive plate to crankshaft bolts

† 115 Nm 85 lbf.ft

EGR cooler to cylinder head and lifting bracket bolts 25 Nm 18 lbf.ft

Engine breather pipe to air cleaner housing bolt 10 Nm 7.5 lbf.ft

Engine lifting eye bolts 20 Nm 15 lbf.ft

Engine mounting bracket assembly to engine bolts 100 Nm 74 lbf.ft

Engine mounting bracket to hydramount nut 85 Nm 63 lbf.ft

Engine lower steady bracket bolts:

⇒ M1045 Nm 33 lbf.ft

⇒ M1250 Nm 37 lbf.ft

Engine steady mounting bolt 100 Nm 74 lbf.ft

Exhaust manifold to cylinder head nuts 24 Nm 18 lbf.ft

Flywheel to crankshaft bolts

† 115 Nm 85 lbf.ft

Fuel pipe bracket to oil filter housing bolt 10 Nm 7.5 lbf.ft

Fuel pipe union nuts 30 Nm 22 lbf.ft

Fuel pump drive chain lower guide Allen bolt 24 Nm 18 lbf.ft

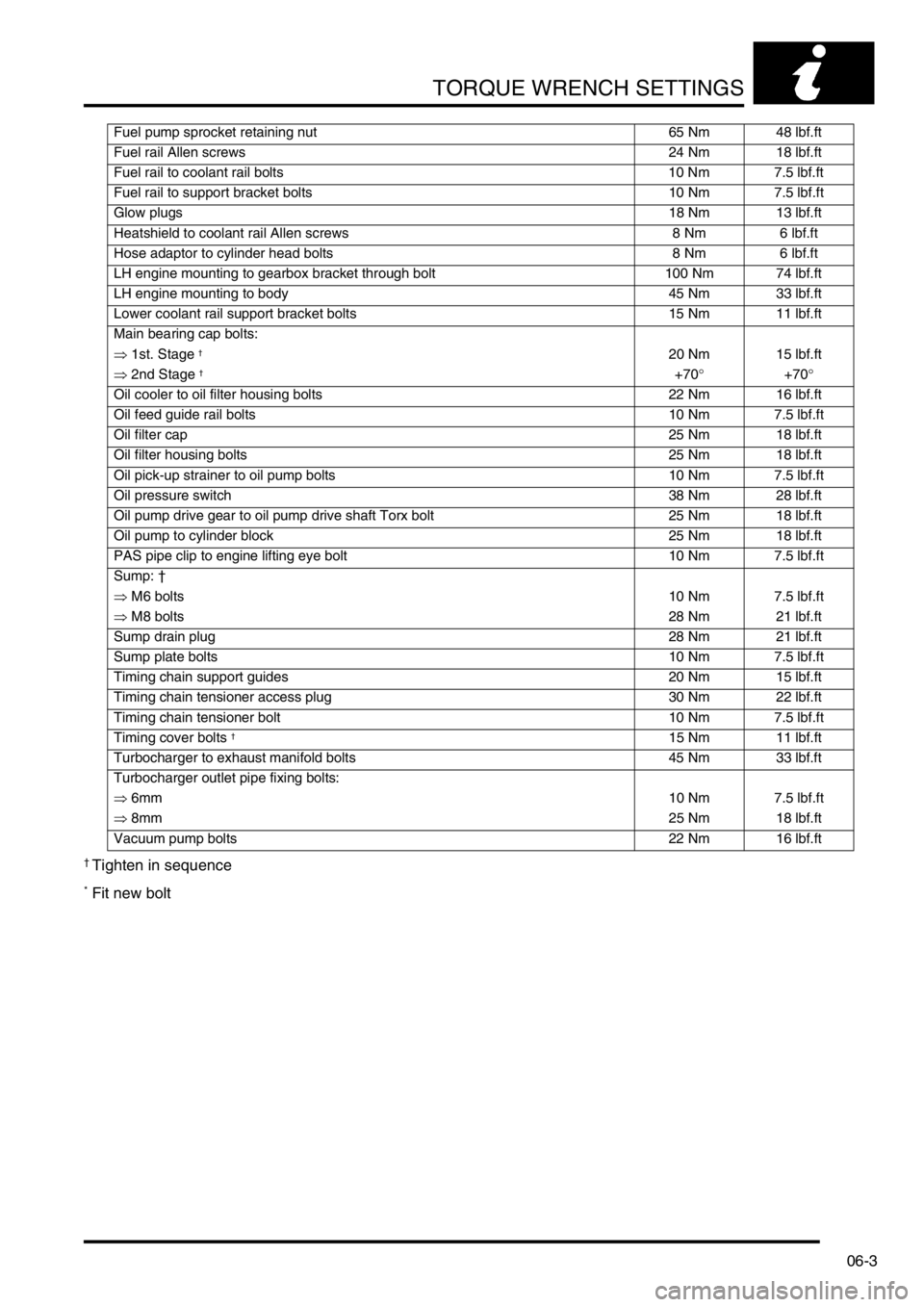

Page 106 of 1007

TORQUE WRENCH SETTINGS

06-3

† Tighten in sequence

* Fit new bolt

Fuel pump sprocket retaining nut 65 Nm 48 lbf.ft

Fuel rail Allen screws 24 Nm 18 lbf.ft

Fuel rail to coolant rail bolts 10 Nm 7.5 lbf.ft

Fuel rail to support bracket bolts 10 Nm 7.5 lbf.ft

Glow plugs18 Nm 13 lbf.ft

Heatshield to coolant rail Allen screws 8 Nm 6 lbf.ft

Hose adaptor to cylinder head bolts 8 Nm 6 lbf.ft

LH engine mounting to gearbox bracket through bolt 100 Nm 74 lbf.ft

LH engine mounting to body 45 Nm 33 lbf.ft

Lower coolant rail support bracket bolts 15 Nm 11 lbf.ft

Main bearing cap bolts:

⇒ 1st. Stage

† 20 Nm 15 lbf.ft

⇒ 2nd Stage

† +70°+70°

Oil cooler to oil filter housing bolts 22 Nm 16 lbf.ft

Oil feed guide rail bolts 10 Nm 7.5 lbf.ft

Oil filter cap25 Nm 18 lbf.ft

Oil filter housing bolts 25 Nm 18 lbf.ft

Oil pick-up strainer to oil pump bolts 10 Nm 7.5 lbf.ft

Oil pressure switch 38 Nm 28 lbf.ft

Oil pump drive gear to oil pump drive shaft Torx bolt 25 Nm 18 lbf.ft

Oil pump to cylinder block 25 Nm 18 lbf.ft

PAS pipe clip to engine lifting eye bolt 10 Nm 7.5 lbf.ft

Sump: †

⇒ M6 bolts10 Nm 7.5 lbf.ft

⇒ M8 bolts28 Nm 21 lbf.ft

Sump drain plug28 Nm 21 lbf.ft

Sump plate bolts10 Nm 7.5 lbf.ft

Timing chain support guides 20 Nm 15 lbf.ft

Timing chain tensioner access plug 30 Nm 22 lbf.ft

Timing chain tensioner bolt 10 Nm 7.5 lbf.ft

Timing cover bolts

† 15 Nm 11 lbf.ft

Turbocharger to exhaust manifold bolts 45 Nm 33 lbf.ft

Turbocharger outlet pipe fixing bolts:

⇒ 6mm10 Nm 7.5 lbf.ft

⇒ 8mm25 Nm 18 lbf.ft

Vacuum pump bolts 22 Nm 16 lbf.ft

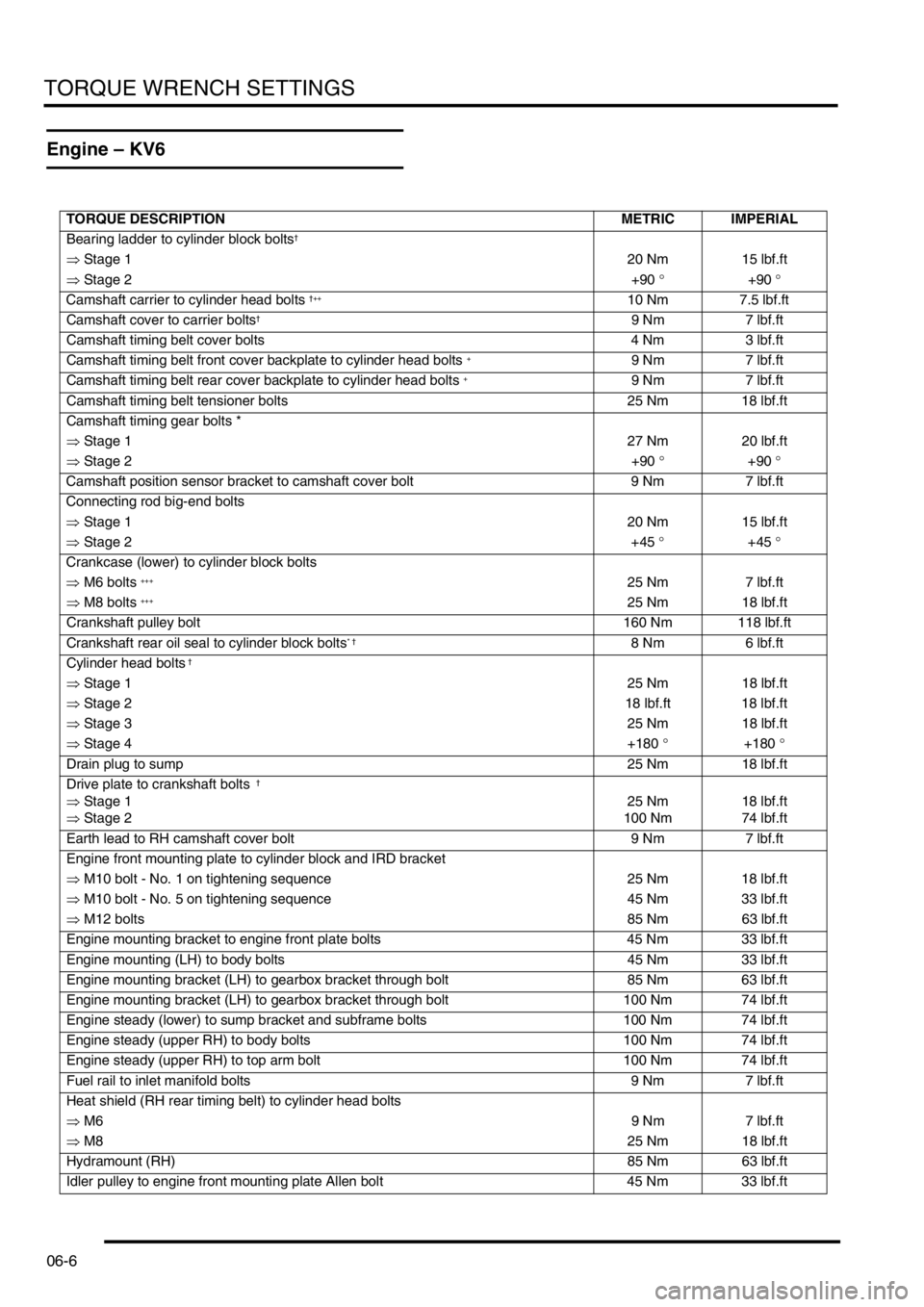

Page 109 of 1007

TORQUE WRENCH SETTINGS

06-6

Engine – KV6

TORQUE DESCRIPTION METRIC IMPERIAL

Bearing ladder to cylinder block bolts

†

⇒ Stage 120 Nm 15 lbf.ft

⇒ Stage 2+90 °+90 °

Camshaft carrier to cylinder head bolts

†++10 Nm 7.5 lbf.ft

Camshaft cover to carrier bolts

†9 Nm 7 lbf.ft

Camshaft timing belt cover bolts 4 Nm 3 lbf.ft

Camshaft timing belt front cover backplate to cylinder head bolts

+9 Nm 7 lbf.ft

Camshaft timing belt rear cover backplate to cylinder head bolts

+9 Nm 7 lbf.ft

Camshaft timing belt tensioner bolts 25 Nm 18 lbf.ft

Camshaft timing gear bolts *

⇒ Stage 127 Nm 20 lbf.ft

⇒ Stage 2+90 °+90 °

Camshaft position sensor bracket to camshaft cover bolt 9 Nm 7 lbf.ft

Connecting rod big-end bolts

⇒ Stage 120 Nm 15 lbf.ft

⇒ Stage 2+45 °+45 °

Crankcase (lower) to cylinder block bolts

⇒ M6 bolts

+++25 Nm 7 lbf.ft

⇒ M8 bolts

+++25 Nm 18 lbf.ft

Crankshaft pulley bolt 160 Nm 118 lbf.ft

Crankshaft rear oil seal to cylinder block bolts

* † 8 Nm 6 lbf.ft

Cylinder head bolts

†

⇒ Stage 125 Nm 18 lbf.ft

⇒ Stage 218 lbf.ft 18 lbf.ft

⇒ Stage 325 Nm 18 lbf.ft

⇒ Stage 4+180 °+180 °

Drain plug to sump 25 Nm 18 lbf.ft

Drive plate to crankshaft bolts

†

⇒ Stage 1

⇒ Stage 225 Nm

100 Nm18 lbf.ft

74 lbf.ft

Earth lead to RH camshaft cover bolt 9 Nm 7 lbf.ft

Engine front mounting plate to cylinder block and IRD bracket

⇒ M10 bolt - No. 1 on tightening sequence 25 Nm 18 lbf.ft

⇒ M10 bolt - No. 5 on tightening sequence 45 Nm 33 lbf.ft

⇒ M12 bolts85 Nm 63 lbf.ft

Engine mounting bracket to engine front plate bolts 45 Nm 33 lbf.ft

Engine mounting (LH) to body bolts 45 Nm 33 lbf.ft

Engine mounting bracket (LH) to gearbox bracket through bolt 85 Nm 63 lbf.ft

Engine mounting bracket (LH) to gearbox bracket through bolt 100 Nm 74 lbf.ft

Engine steady (lower) to sump bracket and subframe bolts 100 Nm 74 lbf.ft

Engine steady (upper RH) to body bolts 100 Nm 74 lbf.ft

Engine steady (upper RH) to top arm bolt 100 Nm 74 lbf.ft

Fuel rail to inlet manifold bolts 9 Nm 7 lbf.ft

Heat shield (RH rear timing belt) to cylinder head bolts

⇒ M69 Nm 7 lbf.ft

⇒ M825 Nm 18 lbf.ft

Hydramount (RH)85 Nm 63 lbf.ft

Idler pulley to engine front mounting plate Allen bolt 45 Nm 33 lbf.ft

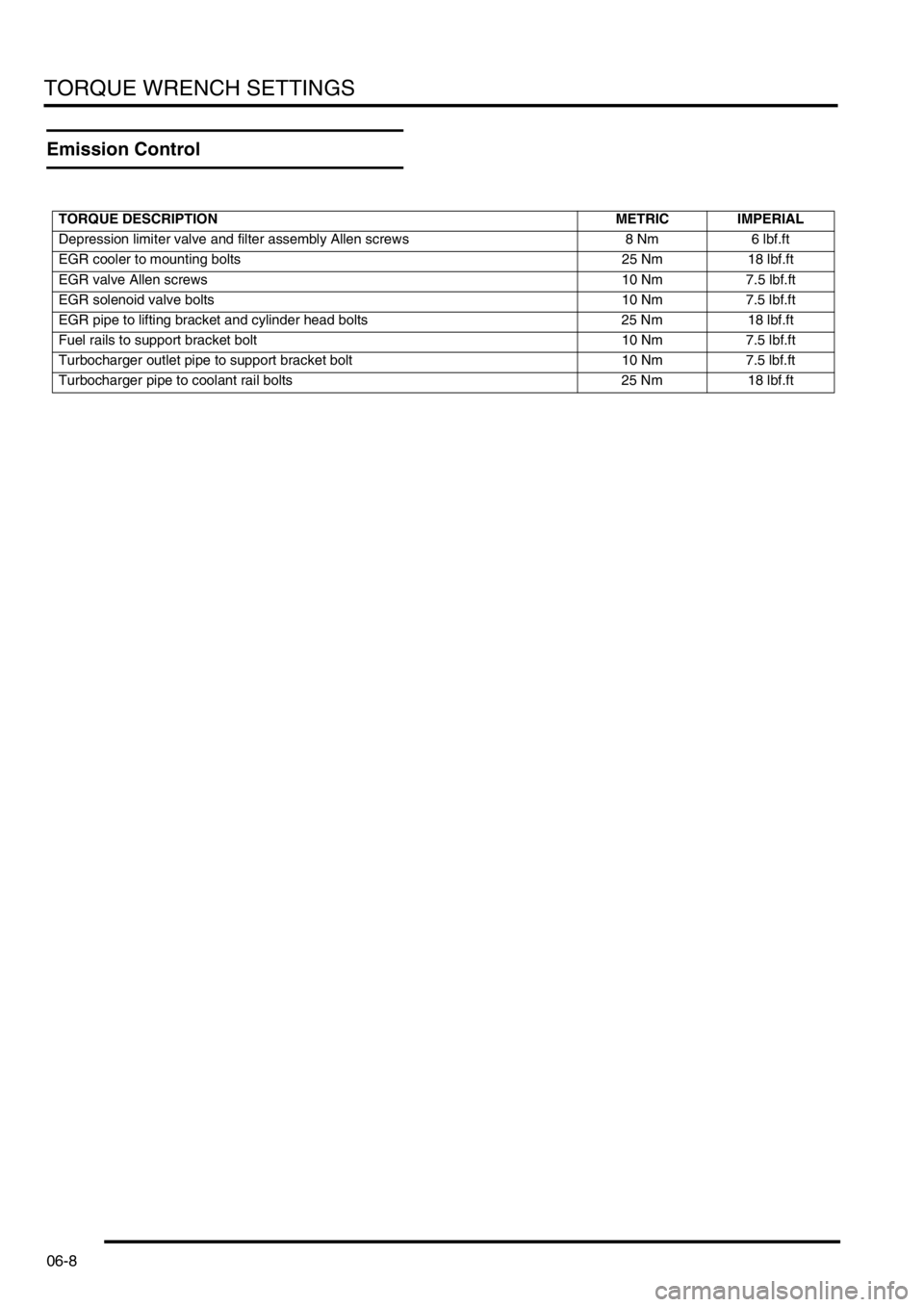

Page 111 of 1007

TORQUE WRENCH SETTINGS

06-8

Emission Control

TORQUE DESCRIPTION METRIC IMPERIAL

Depression limiter valve and filter assembly Allen screws 8 Nm 6 lbf.ft

EGR cooler to mounting bolts 25 Nm 18 lbf.ft

EGR valve Allen screws 10 Nm 7.5 lbf.ft

EGR solenoid valve bolts 10 Nm 7.5 lbf.ft

EGR pipe to lifting bracket and cylinder head bolts 25 Nm 18 lbf.ft

Fuel rails to support bracket bolt 10 Nm 7.5 lbf.ft

Turbocharger outlet pipe to support bracket bolt 10 Nm 7.5 lbf.ft

Turbocharger pipe to coolant rail bolts 25 Nm 18 lbf.ft

Page 113 of 1007

TORQUE WRENCH SETTINGS

06-10

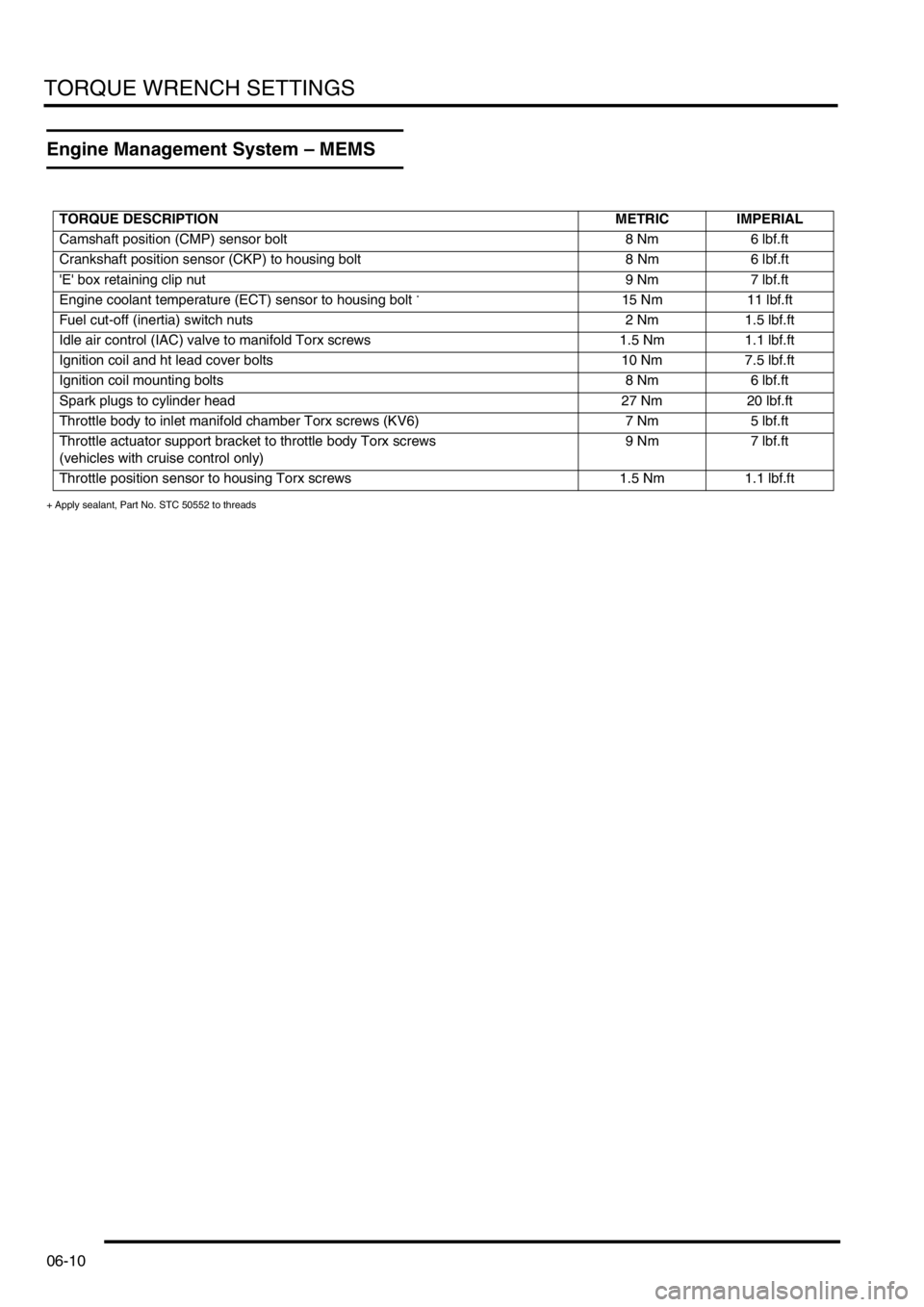

Engine Management System – MEMS

+ Apply sealant, Part No. STC 50552 to threads

TORQUE DESCRIPTION METRIC IMPERIAL

Camshaft position (CMP) sensor bolt 8 Nm 6 lbf.ft

Crankshaft position sensor (CKP) to housing bolt 8 Nm 6 lbf.ft

'E' box retaining clip nut 9 Nm 7 lbf.ft

Engine coolant temperature (ECT) sensor to housing bolt

*15 Nm 11 lbf.ft

Fuel cut-off (inertia) switch nuts 2 Nm 1.5 lbf.ft

Idle air control (IAC) valve to manifold Torx screws 1.5 Nm 1.1 lbf.ft

Ignition coil and ht lead cover bolts 10 Nm 7.5 lbf.ft

Ignition coil mounting bolts 8 Nm 6 lbf.ft

Spark plugs to cylinder head 27 Nm 20 lbf.ft

Throttle body to inlet manifold chamber Torx screws (KV6) 7 Nm 5 lbf.ft

Throttle actuator support bracket to throttle body Torx screws

(vehicles with cruise control only)9 Nm 7 lbf.ft

Throttle position sensor to housing Torx screws 1.5 Nm 1.1 lbf.ft

Page 115 of 1007

TORQUE WRENCH SETTINGS

06-12

Fuel Delivery System – Diesel

TORQUE DESCRIPTION METRIC IMPERIAL

Air cleaner cover Allen screws 8 Nm 6 lbf.ft

Condenser to radiator bolts 3 Nm 2.2 lbf.ft

Filler neck to body nuts and bolt 9 Nm 6.5 lbf.ft

Fuel cooler to mounting bracket bolts 10 Nm 7 lbf.ft

Fuel cooler matrix to bonnet locking platform nuts 10 Nm 7 lbf.ft

Fuel cut-off (inertia) switch to bracket nuts 2 Nm 1.5 lbf.ft

Fuel injector clamp nuts 10 Nm 7 lbf.ft

Fuel injector pipe union nuts 20 Nm 15 lbf.ft

Fuel injection pump nuts 24 Nm 18 lbf.ft

Fuel injection pump sprocket nut 65 Nm 48 lbf.ft

Fuel injector studs 10 Nm 7 lbf.ft

Fuel pressure regulator Torx screws 9 Nm 6.5 lbf.ft

Fuel pressure sensor 38 Nm 28 lbf.ft

Fuel pump/sender unit to tank locking ring 35 Nm 26 lbf.ft

Fuel rails to support bracket bolt 10 Nm 7.5 lbf.ft

Fuel rail Allen screws 24 Nm 18 lbf.ft

Fuel tank to body bolts 45 Nm 33 lbf.ft

Glow plugs20 Nm 15 lbf.ft

High pressure fuel pipe union nuts 20 Nm 15 lbf.ft

Intercooler to radiator bolts 3 Nm 2.2 lbf.ft

Low pressure fuel rail bolts 10 Nm 7 lbf.ft

Timing case access plug 30 Nm 22 lbf.ft

Turbocharger boost control solenoid valve mounting bracket to turbocharger bolts 10 Nm 7 lbf.ft

Turbocharger boost control solenoid valve to mounting rubber nuts 5 Nm 3.7 lbf.ft

Turbocharger boost pressure sensor to inlet manifold bolt 8 Nm 6 lbf.ft

Turbocharger oil drain pipe bracket bolts 20 Nm 15 lbf.ft

Turbocharger oil drain pipe flange bolts 8 Nm 6 lbf.ft

Turbocharger oil feed pipe banjo bolts 22 Nm 16 lbf.ft

Turbocharger outlet pipe to bracket bolts:

⇒ 6 mm10 Nm 7 lbf.ft

⇒ 8 mm20 Nm 15 lbf.ft

Turbocharger to exhaust manifold bolts 50 Nm 37 lbf.ft