Oil pump LAND ROVER FREELANDER 2001 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 264 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-87

Refit

1.Fit oil pump gasket.

+ ENGINE - K SERIES KV6,

OVERHAUL, Oil pump - Overhaul.

2.Fit engine sump.

+ ENGINE - K SERIES KV6,

OVERHAUL, Sump - engine oil.

3.Fit crankshaft rear oil seal.

+ ENGINE - K SERIES KV6,

OVERHAUL, Crankshaft rear oil seal.

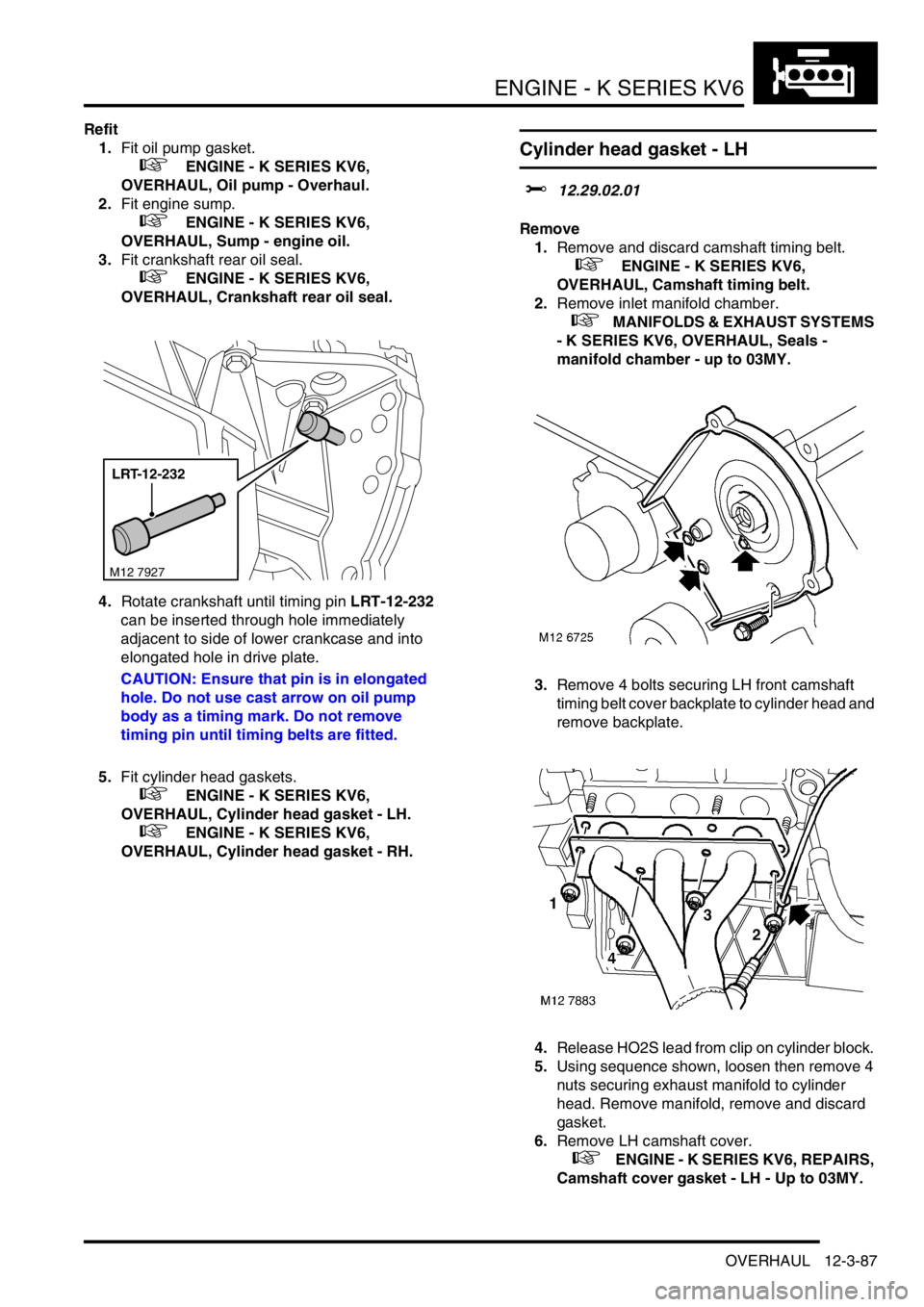

4.Rotate crankshaft until timing pin LRT-12-232

can be inserted through hole immediately

adjacent to side of lower crankcase and into

elongated hole in drive plate.

CAUTION: Ensure that pin is in elongated

hole. Do not use cast arrow on oil pump

body as a timing mark. Do not remove

timing pin until timing belts are fitted.

5.Fit cylinder head gaskets.

+ ENGINE - K SERIES KV6,

OVERHAUL, Cylinder head gasket - LH.

+ ENGINE - K SERIES KV6,

OVERHAUL, Cylinder head gasket - RH.

Cylinder head gasket - LH

$% 12.29.02.01

Remove

1.Remove and discard camshaft timing belt.

+ ENGINE - K SERIES KV6,

OVERHAUL, Camshaft timing belt.

2.Remove inlet manifold chamber.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, OVERHAUL, Seals -

manifold chamber - up to 03MY.

3.Remove 4 bolts securing LH front camshaft

timing belt cover backplate to cylinder head and

remove backplate.

4.Release HO2S lead from clip on cylinder block.

5.Using sequence shown, loosen then remove 4

nuts securing exhaust manifold to cylinder

head. Remove manifold, remove and discard

gasket.

6.Remove LH camshaft cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft cover gasket - LH - Up to 03MY.

LRT-12-232

M12 7927

Page 281 of 1007

ENGINE - K SERIES KV6

12-3-104 OVERHAUL

Oil pump - Overhaul

$% 12.60.32

Remove

1.Remove oil pump gasket.

+ ENGINE - K SERIES KV6, REPAIRS,

Gasket - oil pump.

Disassembly

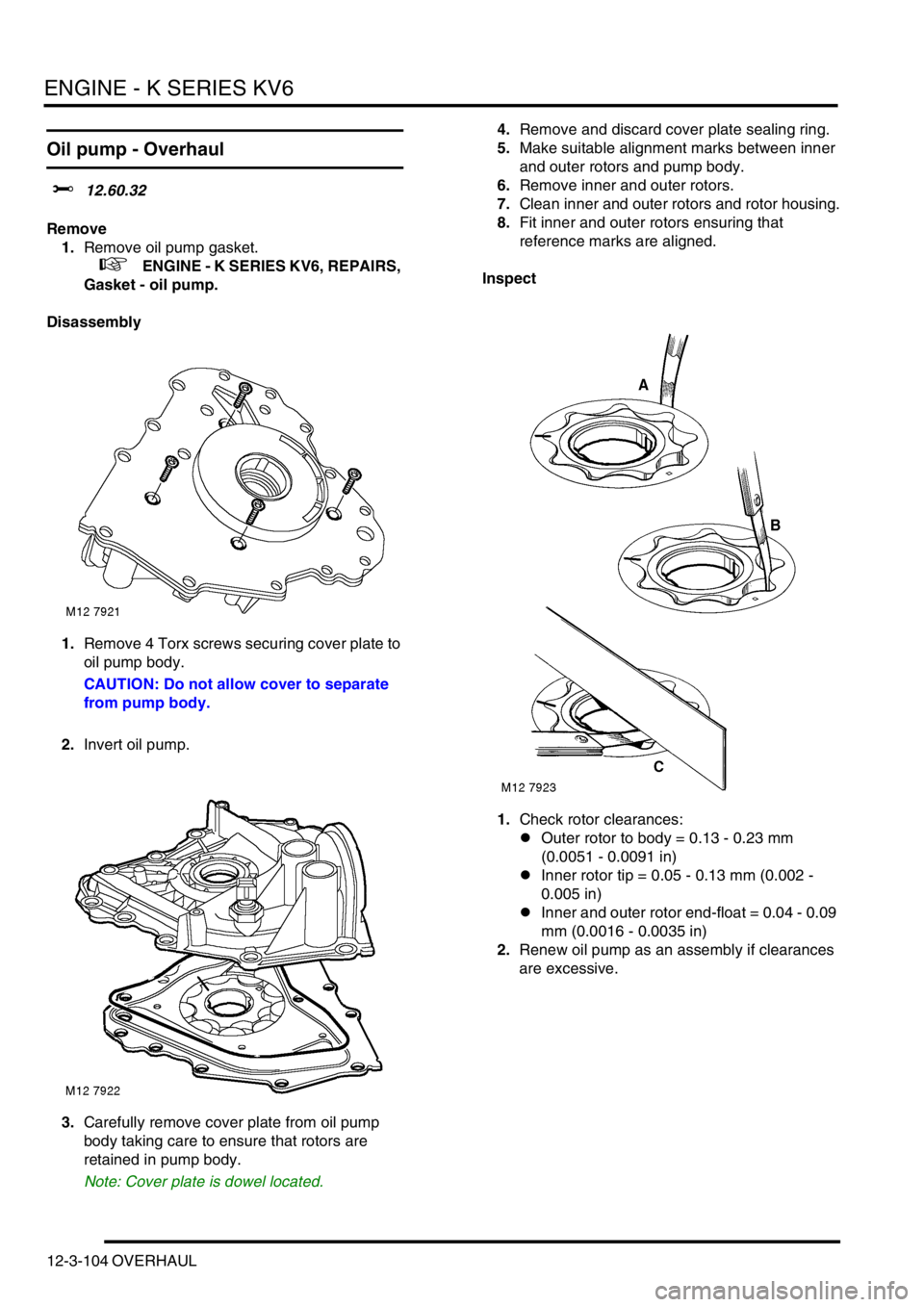

1.Remove 4 Torx screws securing cover plate to

oil pump body.

CAUTION: Do not allow cover to separate

from pump body.

2.Invert oil pump.

3.Carefully remove cover plate from oil pump

body taking care to ensure that rotors are

retained in pump body.

Note: Cover plate is dowel located.4.Remove and discard cover plate sealing ring.

5.Make suitable alignment marks between inner

and outer rotors and pump body.

6.Remove inner and outer rotors.

7.Clean inner and outer rotors and rotor housing.

8.Fit inner and outer rotors ensuring that

reference marks are aligned.

Inspect

1.Check rotor clearances:

lOuter rotor to body = 0.13 - 0.23 mm

(0.0051 - 0.0091 in)

lInner rotor tip = 0.05 - 0.13 mm (0.002 -

0.005 in)

lInner and outer rotor end-float = 0.04 - 0.09

mm (0.0016 - 0.0035 in)

2.Renew oil pump as an assembly if clearances

are excessive.

Page 282 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-105

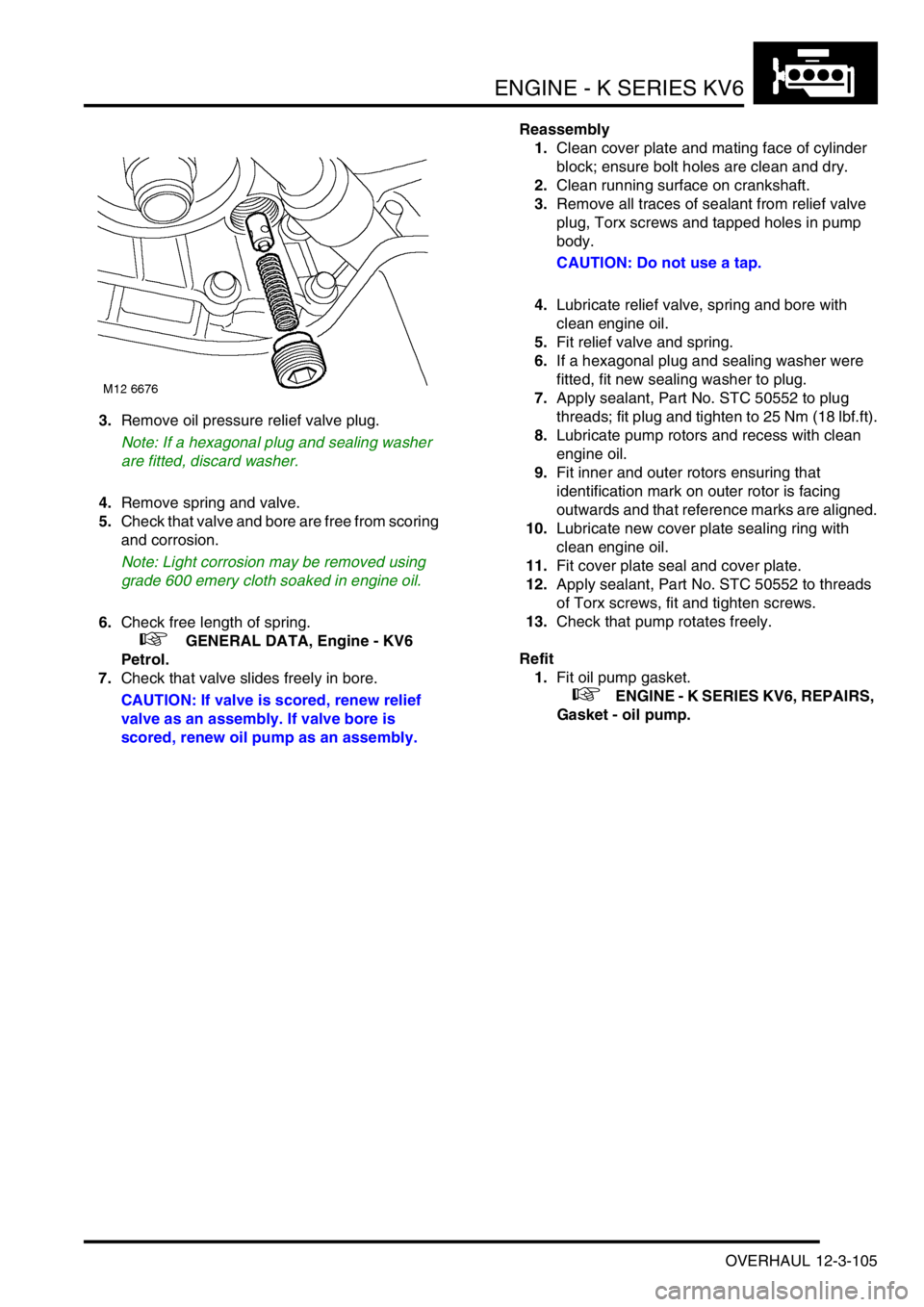

3.Remove oil pressure relief valve plug.

Note: If a hexagonal plug and sealing washer

are fitted, discard washer.

4.Remove spring and valve.

5.Check that valve and bore are free from scoring

and corrosion.

Note: Light corrosion may be removed using

grade 600 emery cloth soaked in engine oil.

6.Check free length of spring.

+ GENERAL DATA, Engine - KV6

Petrol.

7.Check that valve slides freely in bore.

CAUTION: If valve is scored, renew relief

valve as an assembly. If valve bore is

scored, renew oil pump as an assembly.Reassembly

1.Clean cover plate and mating face of cylinder

block; ensure bolt holes are clean and dry.

2.Clean running surface on crankshaft.

3.Remove all traces of sealant from relief valve

plug, Torx screws and tapped holes in pump

body.

CAUTION: Do not use a tap.

4.Lubricate relief valve, spring and bore with

clean engine oil.

5.Fit relief valve and spring.

6.If a hexagonal plug and sealing washer were

fitted, fit new sealing washer to plug.

7.Apply sealant, Part No. STC 50552 to plug

threads; fit plug and tighten to 25 Nm (18 lbf.ft).

8.Lubricate pump rotors and recess with clean

engine oil.

9.Fit inner and outer rotors ensuring that

identification mark on outer rotor is facing

outwards and that reference marks are aligned.

10.Lubricate new cover plate sealing ring with

clean engine oil.

11.Fit cover plate seal and cover plate.

12.Apply sealant, Part No. STC 50552 to threads

of Torx screws, fit and tighten screws.

13.Check that pump rotates freely.

Refit

1.Fit oil pump gasket.

+ ENGINE - K SERIES KV6, REPAIRS,

Gasket - oil pump.

Page 286 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-109

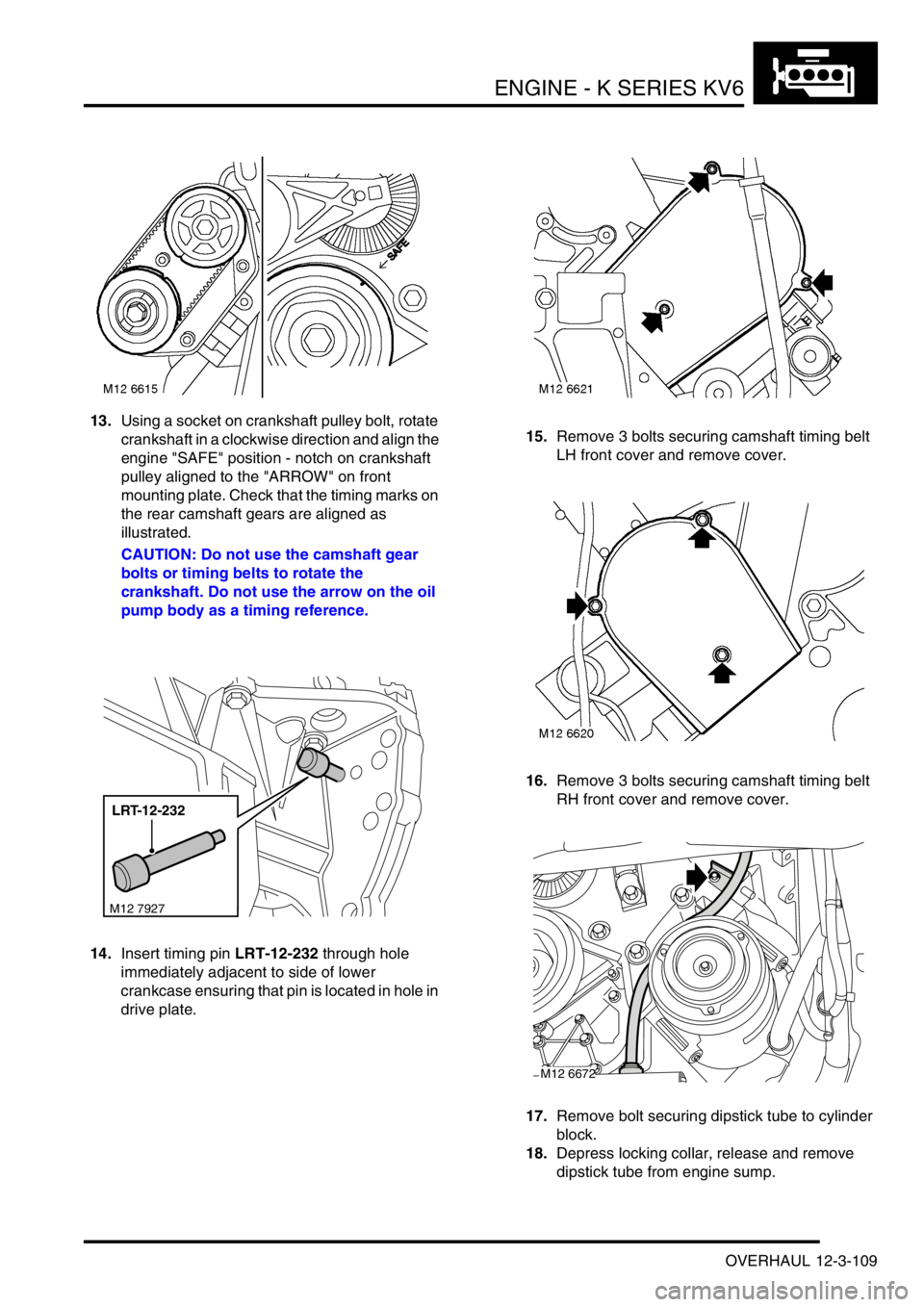

13.Using a socket on crankshaft pulley bolt, rotate

crankshaft in a clockwise direction and align the

engine "SAFE" position - notch on crankshaft

pulley aligned to the "ARROW" on front

mounting plate. Check that the timing marks on

the rear camshaft gears are aligned as

illustrated.

CAUTION: Do not use the camshaft gear

bolts or timing belts to rotate the

crankshaft. Do not use the arrow on the oil

pump body as a timing reference.

14.Insert timing pin LRT-12-232 through hole

immediately adjacent to side of lower

crankcase ensuring that pin is located in hole in

drive plate.15.Remove 3 bolts securing camshaft timing belt

LH front cover and remove cover.

16.Remove 3 bolts securing camshaft timing belt

RH front cover and remove cover.

17.Remove bolt securing dipstick tube to cylinder

block.

18.Depress locking collar, release and remove

dipstick tube from engine sump.

LRT-12-232

M12 7927

M12 6672

Page 288 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-111

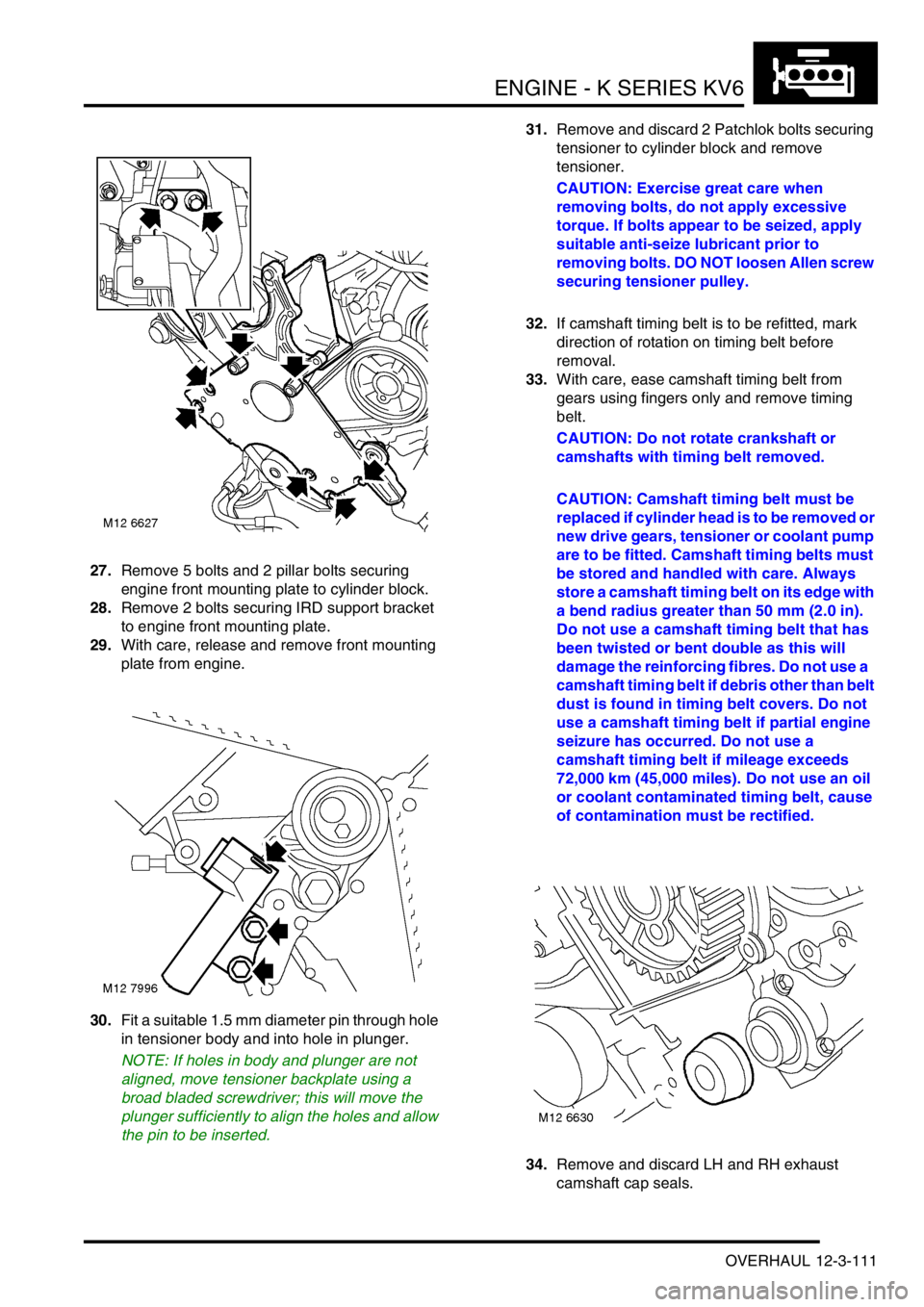

27.Remove 5 bolts and 2 pillar bolts securing

engine front mounting plate to cylinder block.

28.Remove 2 bolts securing IRD support bracket

to engine front mounting plate.

29.With care, release and remove front mounting

plate from engine.

30.Fit a suitable 1.5 mm diameter pin through hole

in tensioner body and into hole in plunger.

NOTE: If holes in body and plunger are not

aligned, move tensioner backplate using a

broad bladed screwdriver; this will move the

plunger sufficiently to align the holes and allow

the pin to be inserted.31.Remove and discard 2 Patchlok bolts securing

tensioner to cylinder block and remove

tensioner.

CAUTION: Exercise great care when

removing bolts, do not apply excessive

torque. If bolts appear to be seized, apply

suitable anti-seize lubricant prior to

removing bolts. DO NOT loosen Allen screw

securing tensioner pulley.

32.If camshaft timing belt is to be refitted, mark

direction of rotation on timing belt before

removal.

33.With care, ease camshaft timing belt from

gears using fingers only and remove timing

belt.

CAUTION: Do not rotate crankshaft or

camshafts with timing belt removed.

CAUTION: Camshaft timing belt must be

replaced if cylinder head is to be removed or

new drive gears, tensioner or coolant pump

are to be fitted. Camshaft timing belts must

be stored and handled with care. Always

store a camshaft timing belt on its edge with

a bend radius greater than 50 mm (2.0 in).

Do not use a camshaft timing belt that has

been twisted or bent double as this will

damage the reinforcing fibres. Do not use a

camshaft timing belt if debris other than belt

dust is found in timing belt covers. Do not

use a camshaft timing belt if partial engine

seizure has occurred. Do not use a

camshaft timing belt if mileage exceeds

72,000 km (45,000 miles). Do not use an oil

or coolant contaminated timing belt, cause

of contamination must be rectified.

34.Remove and discard LH and RH exhaust

camshaft cap seals.

Page 289 of 1007

ENGINE - K SERIES KV6

12-3-112 OVERHAUL

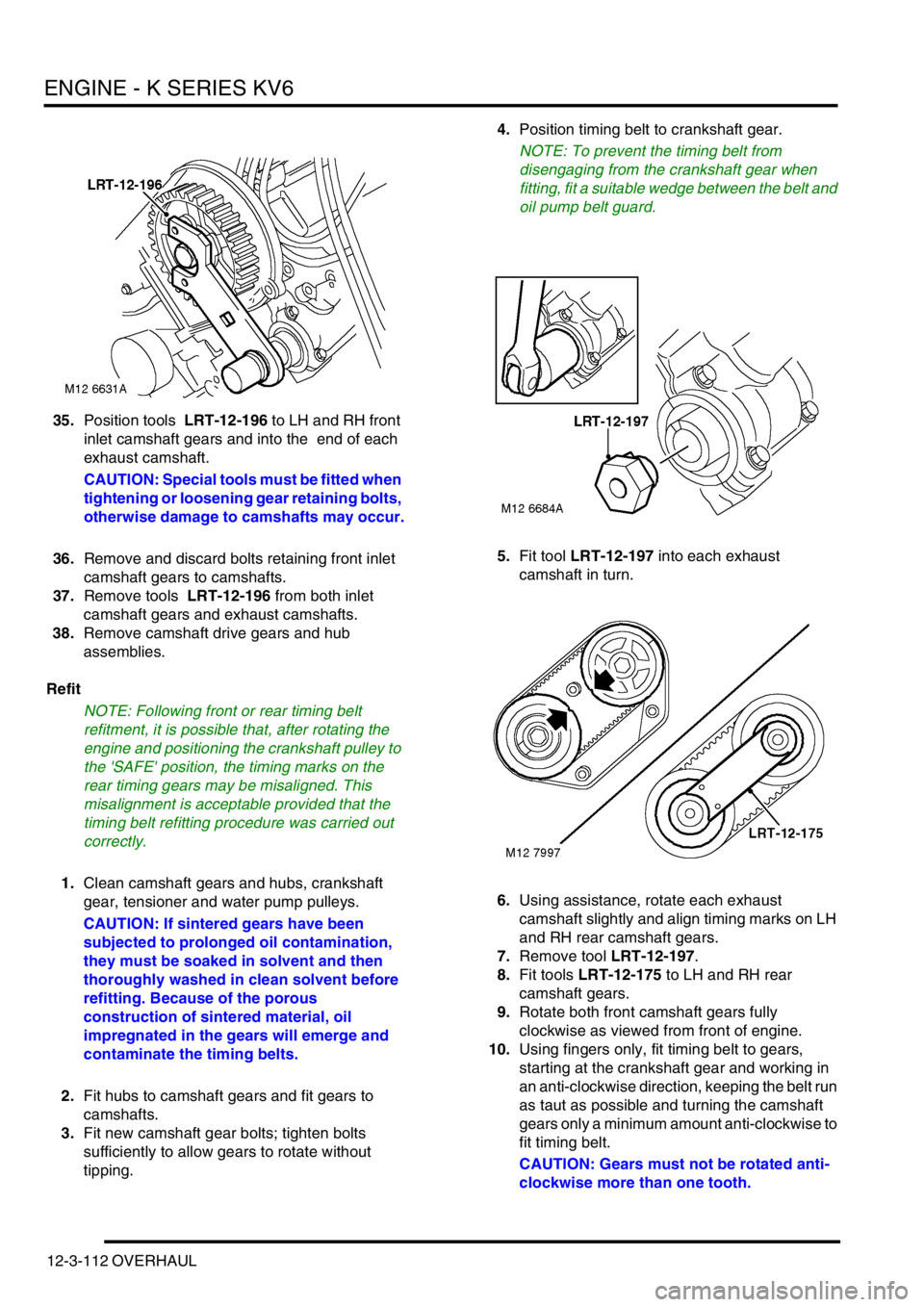

35.Position tools LRT-12-196 to LH and RH front

inlet camshaft gears and into the end of each

exhaust camshaft.

CAUTION: Special tools must be fitted when

tightening or loosening gear retaining bolts,

otherwise damage to camshafts may occur.

36.Remove and discard bolts retaining front inlet

camshaft gears to camshafts.

37.Remove tools LRT-12-196 from both inlet

camshaft gears and exhaust camshafts.

38.Remove camshaft drive gears and hub

assemblies.

Refit

NOTE: Following front or rear timing belt

refitment, it is possible that, after rotating the

engine and positioning the crankshaft pulley to

the 'SAFE' position, the timing marks on the

rear timing gears may be misaligned. This

misalignment is acceptable provided that the

timing belt refitting procedure was carried out

correctly.

1.Clean camshaft gears and hubs, crankshaft

gear, tensioner and water pump pulleys.

CAUTION: If sintered gears have been

subjected to prolonged oil contamination,

they must be soaked in solvent and then

thoroughly washed in clean solvent before

refitting. Because of the porous

construction of sintered material, oil

impregnated in the gears will emerge and

contaminate the timing belts.

2.Fit hubs to camshaft gears and fit gears to

camshafts.

3.Fit new camshaft gear bolts; tighten bolts

sufficiently to allow gears to rotate without

tipping.4.Position timing belt to crankshaft gear.

NOTE: To prevent the timing belt from

disengaging from the crankshaft gear when

fitting, fit a suitable wedge between the belt and

oil pump belt guard.

5.Fit tool LRT-12-197 into each exhaust

camshaft in turn.

6.Using assistance, rotate each exhaust

camshaft slightly and align timing marks on LH

and RH rear camshaft gears.

7.Remove tool LRT-12-197.

8.Fit tools LRT-12-175 to LH and RH rear

camshaft gears.

9.Rotate both front camshaft gears fully

clockwise as viewed from front of engine.

10.Using fingers only, fit timing belt to gears,

starting at the crankshaft gear and working in

an anti-clockwise direction, keeping the belt run

as taut as possible and turning the camshaft

gears only a minimum amount anti-clockwise to

fit timing belt.

CAUTION: Gears must not be rotated anti-

clockwise more than one tooth.

Page 290 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-113

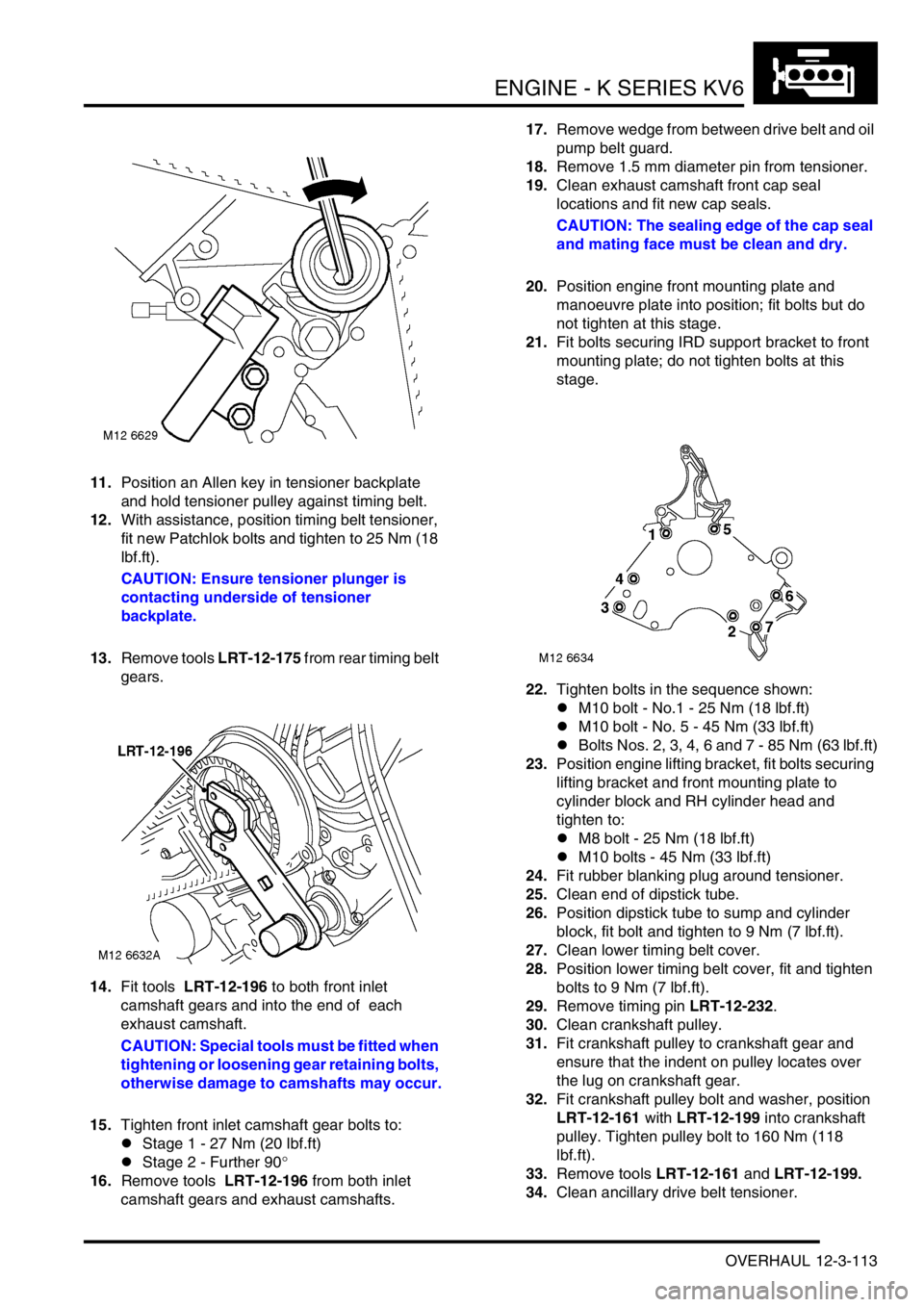

11.Position an Allen key in tensioner backplate

and hold tensioner pulley against timing belt.

12.With assistance, position timing belt tensioner,

fit new Patchlok bolts and tighten to 25 Nm (18

lbf.ft).

CAUTION: Ensure tensioner plunger is

contacting underside of tensioner

backplate.

13.Remove tools LRT-12-175 from rear timing belt

gears.

14.Fit tools LRT-12-196 to both front inlet

camshaft gears and into the end of each

exhaust camshaft.

CAUTION: Special tools must be fitted when

tightening or loosening gear retaining bolts,

otherwise damage to camshafts may occur.

15.Tighten front inlet camshaft gear bolts to:

lStage 1 - 27 Nm (20 lbf.ft)

lStage 2 - Further 90°

16.Remove tools LRT-12-196 from both inlet

camshaft gears and exhaust camshafts.17.Remove wedge from between drive belt and oil

pump belt guard.

18.Remove 1.5 mm diameter pin from tensioner.

19.Clean exhaust camshaft front cap seal

locations and fit new cap seals.

CAUTION: The sealing edge of the cap seal

and mating face must be clean and dry.

20.Position engine front mounting plate and

manoeuvre plate into position; fit bolts but do

not tighten at this stage.

21.Fit bolts securing IRD support bracket to front

mounting plate; do not tighten bolts at this

stage.

22.Tighten bolts in the sequence shown:

lM10 bolt - No.1 - 25 Nm (18 lbf.ft)

lM10 bolt - No. 5 - 45 Nm (33 lbf.ft)

lBolts Nos. 2, 3, 4, 6 and 7 - 85 Nm (63 lbf.ft)

23.Position engine lifting bracket, fit bolts securing

lifting bracket and front mounting plate to

cylinder block and RH cylinder head and

tighten to:

lM8 bolt - 25 Nm (18 lbf.ft)

lM10 bolts - 45 Nm (33 lbf.ft)

24.Fit rubber blanking plug around tensioner.

25.Clean end of dipstick tube.

26.Position dipstick tube to sump and cylinder

block, fit bolt and tighten to 9 Nm (7 lbf.ft).

27.Clean lower timing belt cover.

28.Position lower timing belt cover, fit and tighten

bolts to 9 Nm (7 lbf.ft).

29.Remove timing pin LRT-12-232.

30.Clean crankshaft pulley.

31.Fit crankshaft pulley to crankshaft gear and

ensure that the indent on pulley locates over

the lug on crankshaft gear.

32.Fit crankshaft pulley bolt and washer, position

LRT-12-161 with LRT-12-199 into crankshaft

pulley. Tighten pulley bolt to 160 Nm (118

lbf.ft).

33.Remove tools LRT-12-161 and LRT-12-199.

34.Clean ancillary drive belt tensioner.

Page 326 of 1007

FUEL DELIVERY SYSTEM - PETROL

ADJUSTMENTS 19-2-5

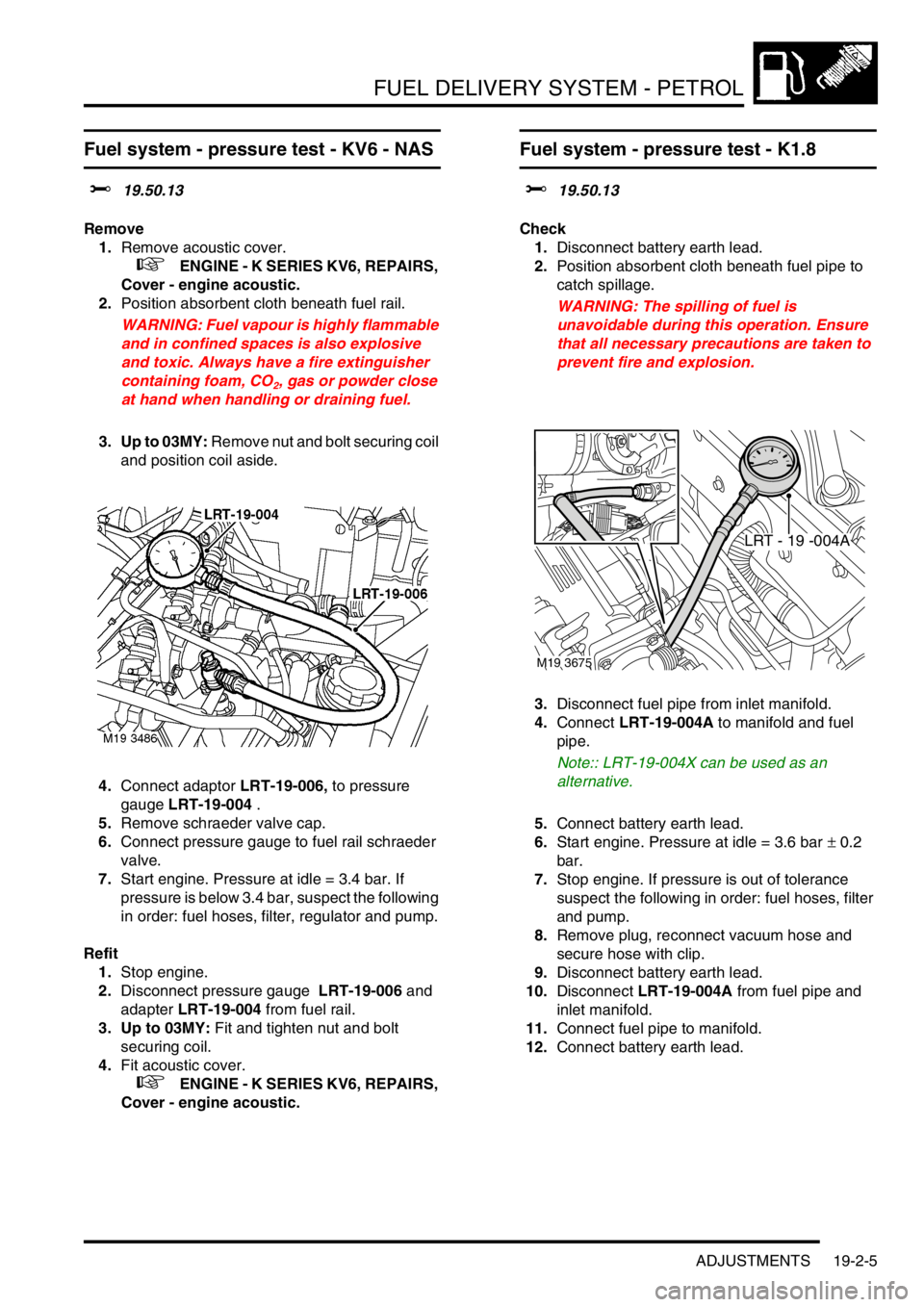

Fuel system - pressure test - KV6 - NAS

$% 19.50.13

Remove

1.Remove acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2.Position absorbent cloth beneath fuel rail.

WARNING: Fuel vapour is highly flammable

and in confined spaces is also explosive

and toxic. Always have a fire extinguisher

containing foam, CO

2, gas or powder close

at hand when handling or draining fuel.

3. Up to 03MY: Remove nut and bolt securing coil

and position coil aside.

4.Connect adaptor LRT-19-006, to pressure

gauge LRT-19-004 .

5.Remove schraeder valve cap.

6.Connect pressure gauge to fuel rail schraeder

valve.

7.Start engine. Pressure at idle = 3.4 bar. If

pressure is below 3.4 bar, suspect the following

in order: fuel hoses, filter, regulator and pump.

Refit

1.Stop engine.

2.Disconnect pressure gauge LRT-19-006 and

adapter LRT-19-004 from fuel rail.

3. Up to 03MY: Fit and tighten nut and bolt

securing coil.

4.Fit acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

Fuel system - pressure test - K1.8

$% 19.50.13

Check

1.Disconnect battery earth lead.

2.Position absorbent cloth beneath fuel pipe to

catch spillage.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

3.Disconnect fuel pipe from inlet manifold.

4.Connect LRT-19-004A to manifold and fuel

pipe.

Note:: LRT-19-004X can be used as an

alternative.

5.Connect battery earth lead.

6.Start engine. Pressure at idle = 3.6 bar ± 0.2

bar.

7.Stop engine. If pressure is out of tolerance

suspect the following in order: fuel hoses, filter

and pump.

8.Remove plug, reconnect vacuum hose and

secure hose with clip.

9.Disconnect battery earth lead.

10.Disconnect LRT-19-004A from fuel pipe and

inlet manifold.

11.Connect fuel pipe to manifold.

12.Connect battery earth lead.

LRT - 19 -004A

M19 3675

Page 357 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-36 REPAIRS

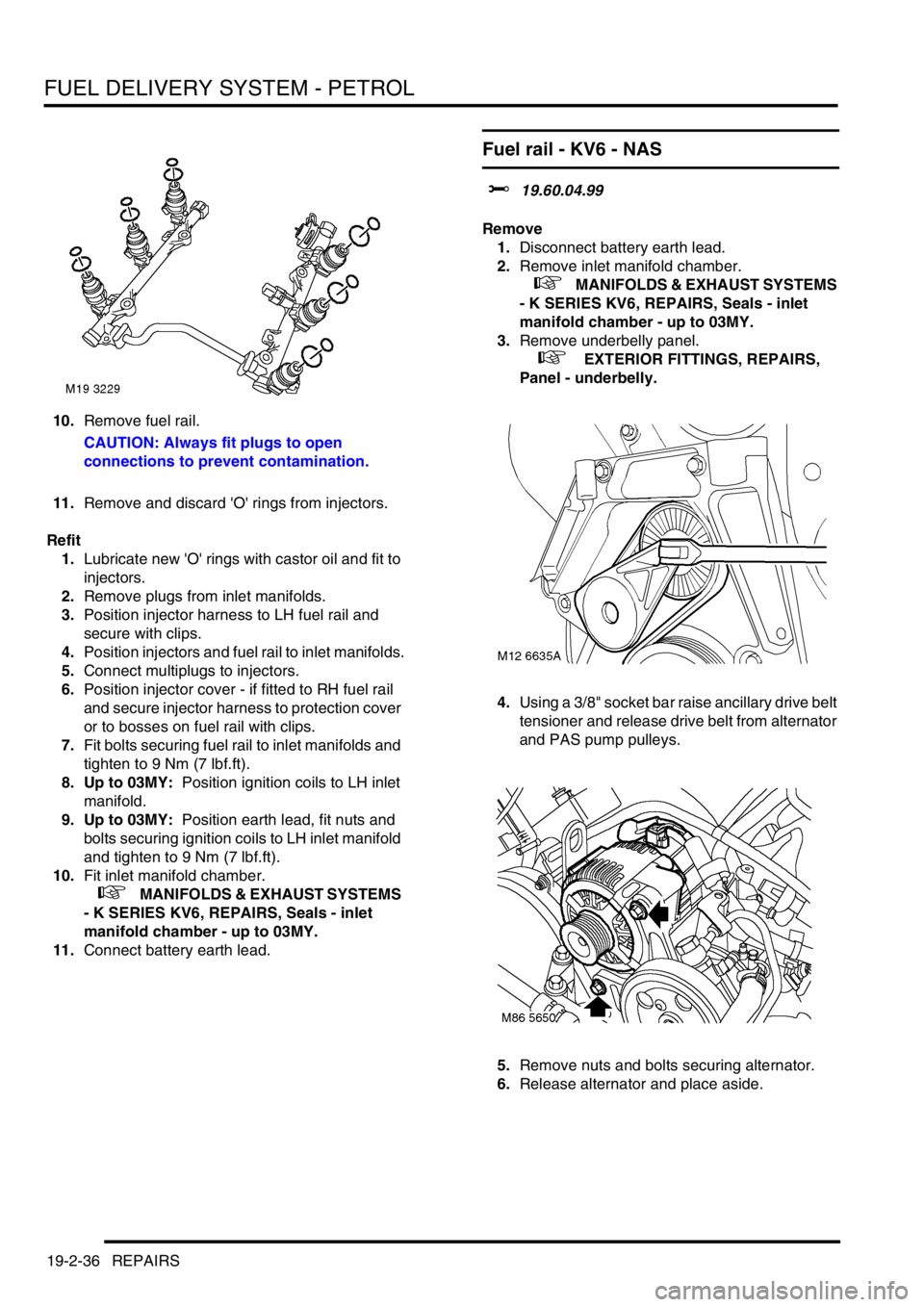

10.Remove fuel rail.

CAUTION: Always fit plugs to open

connections to prevent contamination.

11.Remove and discard 'O' rings from injectors.

Refit

1.Lubricate new 'O' rings with castor oil and fit to

injectors.

2.Remove plugs from inlet manifolds.

3.Position injector harness to LH fuel rail and

secure with clips.

4.Position injectors and fuel rail to inlet manifolds.

5.Connect multiplugs to injectors.

6.Position injector cover - if fitted to RH fuel rail

and secure injector harness to protection cover

or to bosses on fuel rail with clips.

7.Fit bolts securing fuel rail to inlet manifolds and

tighten to 9 Nm (7 lbf.ft).

8. Up to 03MY: Position ignition coils to LH inlet

manifold.

9. Up to 03MY: Position earth lead, fit nuts and

bolts securing ignition coils to LH inlet manifold

and tighten to 9 Nm (7 lbf.ft).

10.Fit inlet manifold chamber.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Seals - inlet

manifold chamber - up to 03MY.

11.Connect battery earth lead.

Fuel rail - KV6 - NAS

$% 19.60.04.99

Remove

1.Disconnect battery earth lead.

2.Remove inlet manifold chamber.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Seals - inlet

manifold chamber - up to 03MY.

3.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

4.Using a 3/8" socket bar raise ancillary drive belt

tensioner and release drive belt from alternator

and PAS pump pulleys.

5.Remove nuts and bolts securing alternator.

6.Release alternator and place aside.

Page 446 of 1007

AUTOMATIC GEARBOX - JATCO

REPAIRS 44-11

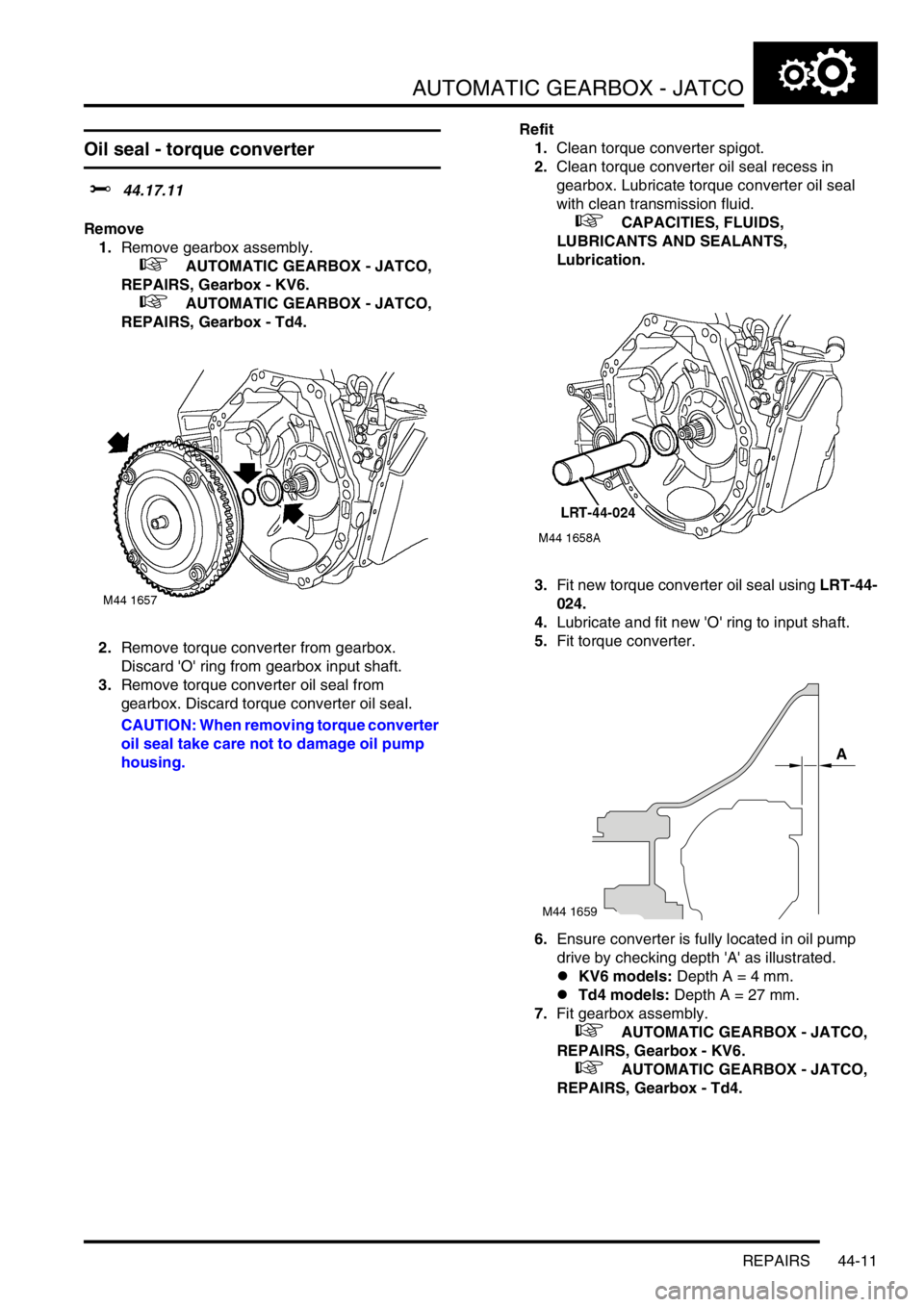

Oil seal - torque converter

$% 44.17.11

Remove

1.Remove gearbox assembly.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Gearbox - KV6.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Gearbox - Td4.

2.Remove torque converter from gearbox.

Discard 'O' ring from gearbox input shaft.

3.Remove torque converter oil seal from

gearbox. Discard torque converter oil seal.

CAUTION: When removing torque converter

oil seal take care not to damage oil pump

housing.Refit

1.Clean torque converter spigot.

2.Clean torque converter oil seal recess in

gearbox. Lubricate torque converter oil seal

with clean transmission fluid.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

3.Fit new torque converter oil seal using LRT-44-

024.

4.Lubricate and fit new 'O' ring to input shaft.

5.Fit torque converter.

6.Ensure converter is fully located in oil pump

drive by checking depth 'A' as illustrated.

lKV6 models: Depth A = 4 mm.

lTd4 models: Depth A = 27 mm.

7.Fit gearbox assembly.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Gearbox - KV6.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Gearbox - Td4.

M44 1659

A