ECU LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 733 of 1007

HOOD

76-7-8 REPAIRS

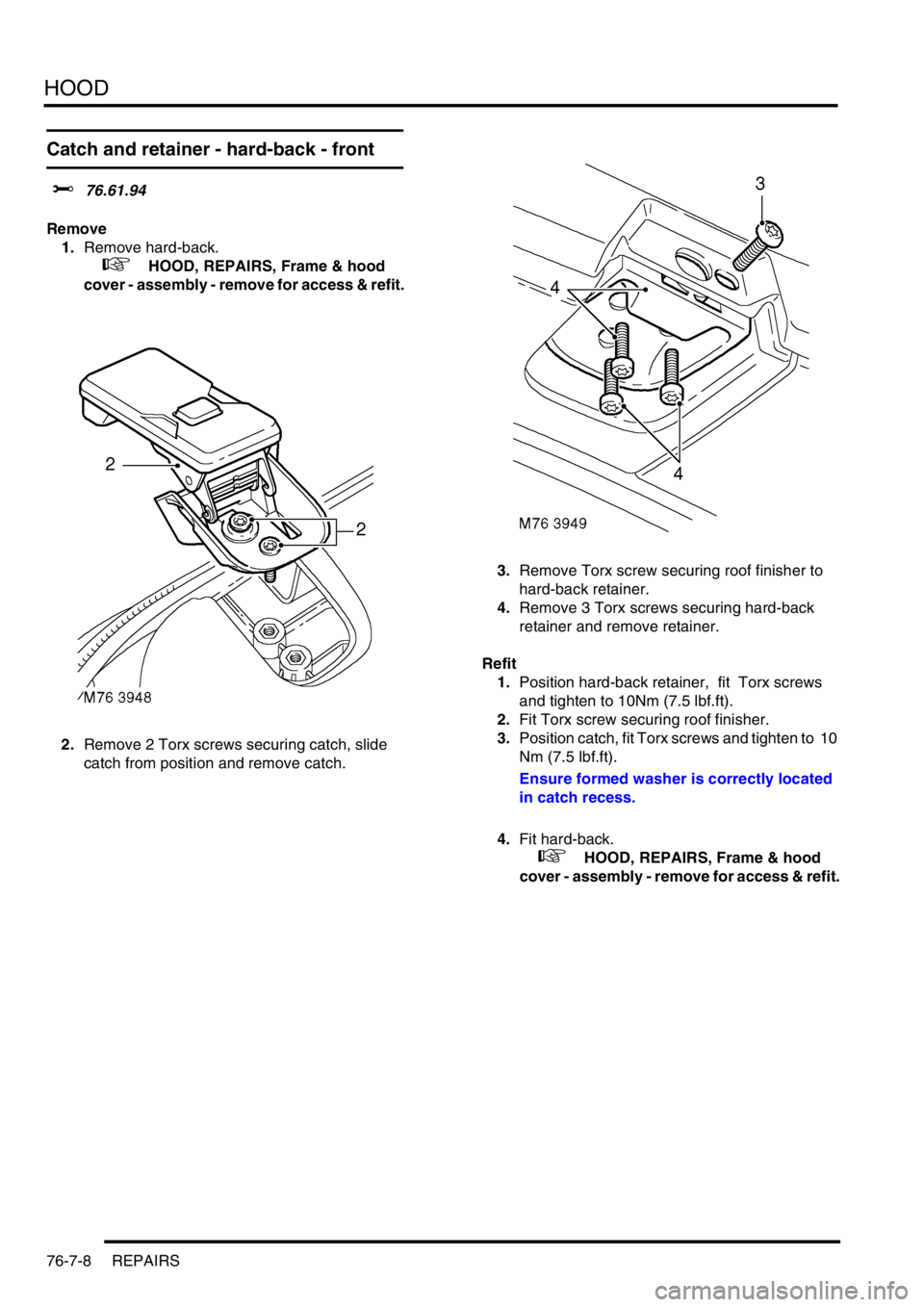

Catch and retainer - hard-back - front

$% 76.61.94

Remove

1.Remove hard-back.

+ HOOD, REPAIRS, Frame & hood

cover - assembly - remove for access & refit.

2.Remove 2 Torx screws securing catch, slide

catch from position and remove catch. 3.Remove Torx screw securing roof finisher to

hard-back retainer.

4.Remove 3 Torx screws securing hard-back

retainer and remove retainer.

Refit

1.Position hard-back retainer, fit Torx screws

and tighten to 10Nm (7.5 lbf.ft).

2.Fit Torx screw securing roof finisher.

3.Position catch, fit Torx screws and tighten to 10

Nm (7.5 lbf.ft).

Ensure formed washer is correctly located

in catch recess.

4.Fit hard-back.

+ HOOD, REPAIRS, Frame & hood

cover - assembly - remove for access & refit.

Page 734 of 1007

HOOD

REPAIRS 76-7-9

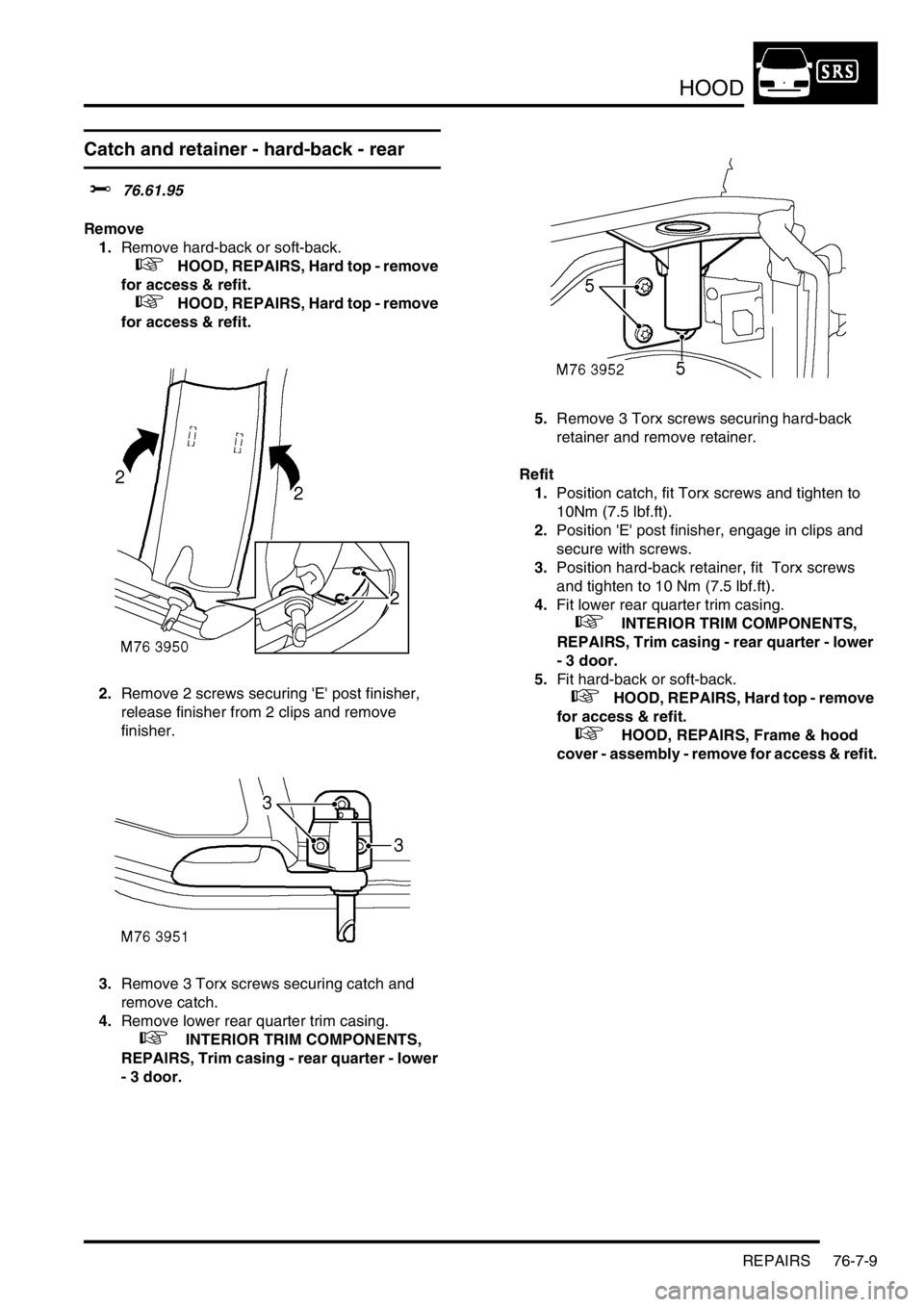

Catch and retainer - hard-back - rear

$% 76.61.95

Remove

1.Remove hard-back or soft-back.

+ HOOD, REPAIRS, Hard top - remove

for access & refit.

+ HOOD, REPAIRS, Hard top - remove

for access & refit.

2.Remove 2 screws securing 'E' post finisher,

release finisher from 2 clips and remove

finisher.

3.Remove 3 Torx screws securing catch and

remove catch.

4.Remove lower rear quarter trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 3 door.5.Remove 3 Torx screws securing hard-back

retainer and remove retainer.

Refit

1.Position catch, fit Torx screws and tighten to

10Nm (7.5 lbf.ft).

2.Position 'E' post finisher, engage in clips and

secure with screws.

3.Position hard-back retainer, fit Torx screws

and tighten to 10 Nm (7.5 lbf.ft).

4.Fit lower rear quarter trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 3 door.

5.Fit hard-back or soft-back.

+ HOOD, REPAIRS, Hard top - remove

for access & refit.

+ HOOD, REPAIRS, Frame & hood

cover - assembly - remove for access & refit.

Page 770 of 1007

PANEL REPAIRS

WELDING PROCEDURES 77-2-15

WE LDING PROCEDURE S

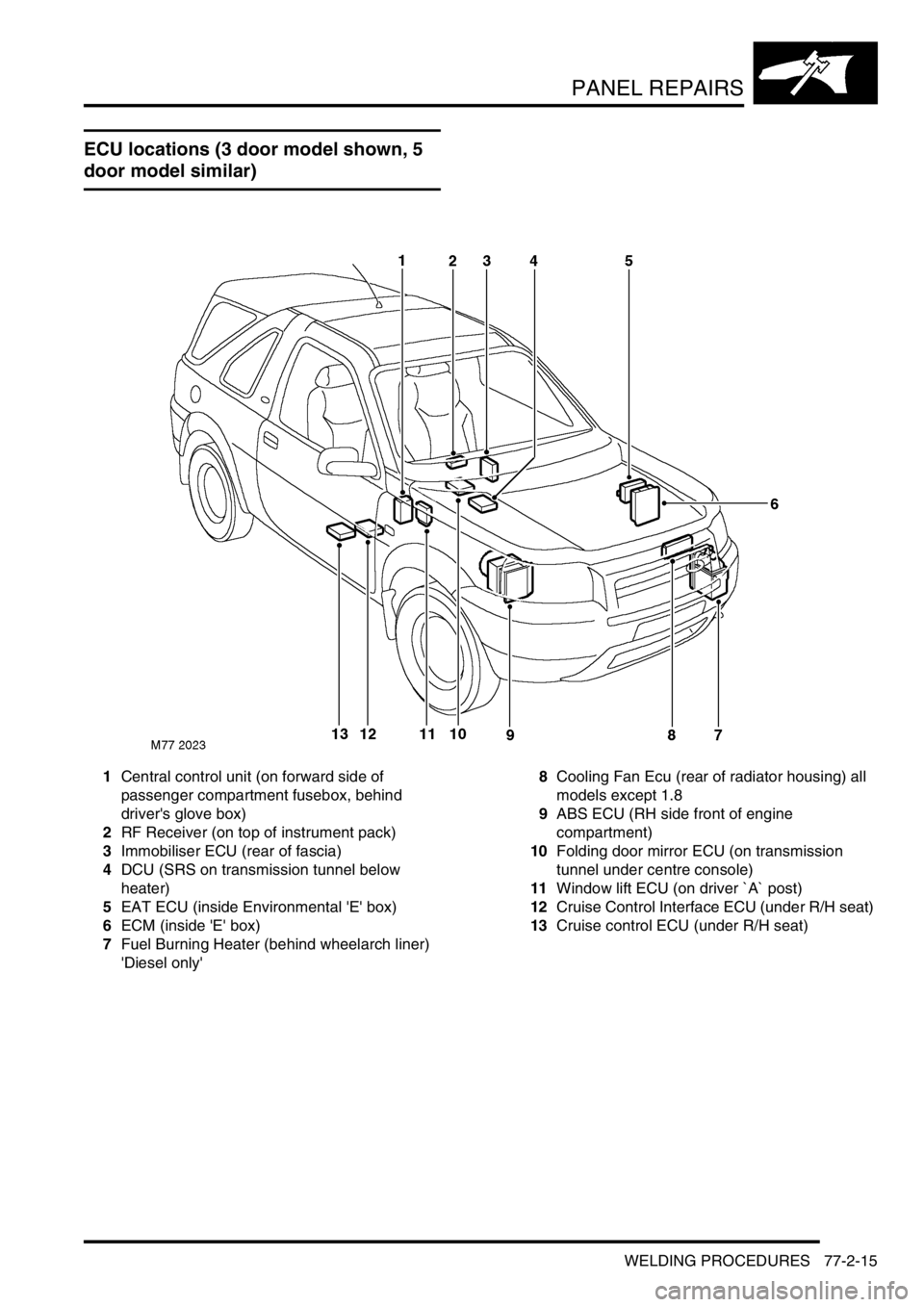

ECU locations (3 door model shown, 5

door model similar)

1Central control unit (on forward side of

passenger compartment fusebox, behind

driver's glove box)

2RF Receiver (on top of instrument pack)

3Immobiliser ECU (rear of fascia)

4DCU (SRS on transmission tunnel below

heater)

5EAT ECU (inside Environmental 'E' box)

6ECM (inside 'E' box)

7Fuel Burning Heater (behind wheelarch liner)

'Diesel only'8Cooling Fan Ecu (rear of radiator housing) all

models except 1.8

9ABS ECU (RH side front of engine

compartment)

10Folding door mirror ECU (on transmission

tunnel under centre console)

11Window lift ECU (on driver `A` post)

12Cruise Control Interface ECU (under R/H seat)

13Cruise control ECU (under R/H seat)

Page 771 of 1007

PANEL REPAIRS

77-2-16 WELDING PROCEDURES

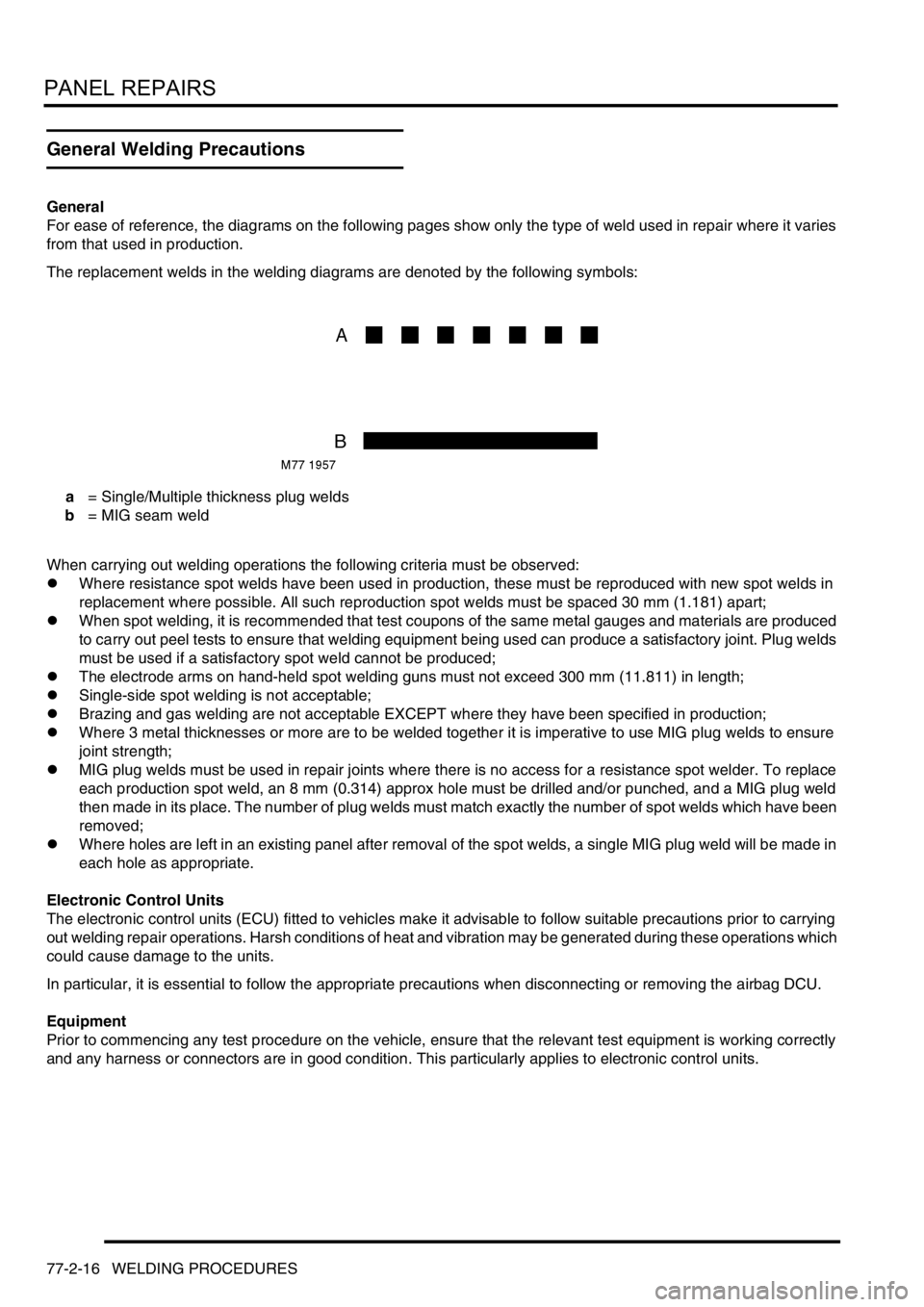

General Welding Precautions

General

For ease of reference, the diagrams on the following pages show only the type of weld used in repair where it varies

from that used in production.

The replacement welds in the welding diagrams are denoted by the following symbols:

a = Single/Multiple thickness plug welds

b = MIG seam weld

When carrying out welding operations the following criteria must be observed:

lWhere resistance spot welds have been used in production, these must be reproduced with new spot welds in

replacement where possible. All such reproduction spot welds must be spaced 30 mm (1.181) apart;

lWhen spot welding, it is recommended that test coupons of the same metal gauges and materials are produced

to carry out peel tests to ensure that welding equipment being used can produce a satisfactory joint. Plug welds

must be used if a satisfactory spot weld cannot be produced;

lThe electrode arms on hand-held spot welding guns must not exceed 300 mm (11.811) in length;

lSingle-side spot welding is not acceptable;

lBrazing and gas welding are not acceptable EXCEPT where they have been specified in production;

lWhere 3 metal thicknesses or more are to be welded together it is imperative to use MIG plug welds to ensure

joint strength;

lMIG plug welds must be used in repair joints where there is no access for a resistance spot welder. To replace

each production spot weld, an 8 mm (0.314) approx hole must be drilled and/or punched, and a MIG plug weld

then made in its place. The number of plug welds must match exactly the number of spot welds which have been

removed;

lWhere holes are left in an existing panel after removal of the spot welds, a single MIG plug weld will be made in

each hole as appropriate.

Electronic Control Units

The electronic control units (ECU) fitted to vehicles make it advisable to follow suitable precautions prior to carrying

out welding repair operations. Harsh conditions of heat and vibration may be generated during these operations which

could cause damage to the units.

In particular, it is essential to follow the appropriate precautions when disconnecting or removing the airbag DCU.

Equipment

Prior to commencing any test procedure on the vehicle, ensure that the relevant test equipment is working correctly

and any harness or connectors are in good condition. This particularly applies to electronic control units.

Page 780 of 1007

PANEL REPAIRS

REPAIRS 77-2-25

REPAIRS

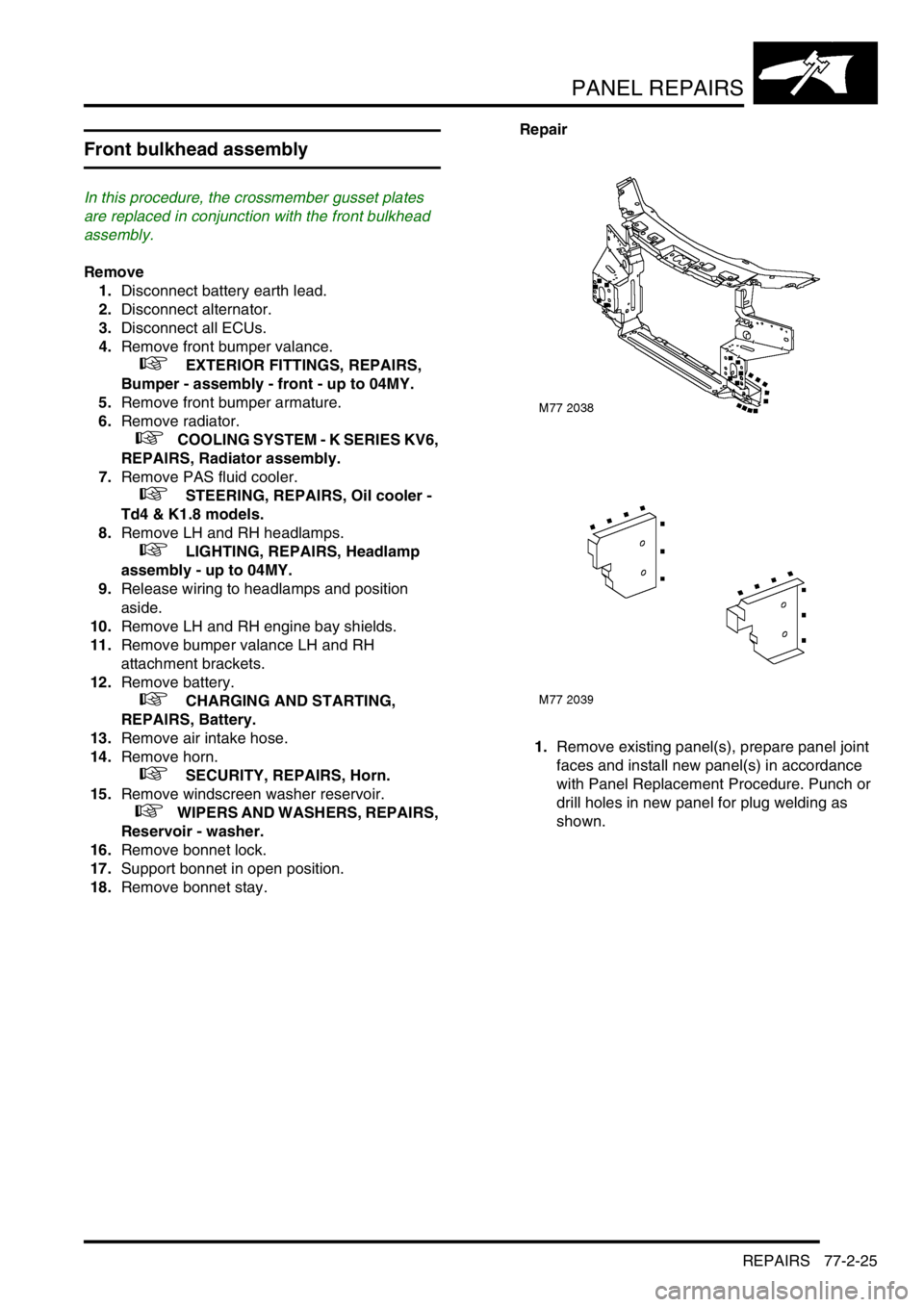

Front bulkhead assembly

In this procedure, the crossmember gusset plates

are replaced in conjunction with the front bulkhead

assembly.

Remove

1.Disconnect battery earth lead.

2.Disconnect alternator.

3.Disconnect all ECUs.

4.Remove front bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

5.Remove front bumper armature.

6.Remove radiator.

+ COOLING SYSTEM - K SERIES KV6,

REPAIRS, Radiator assembly.

7.Remove PAS fluid cooler.

+ STEERING, REPAIRS, Oil cooler -

Td4 & K1.8 models.

8.Remove LH and RH headlamps.

+ LIGHTING, REPAIRS, Headlamp

assembly - up to 04MY.

9.Release wiring to headlamps and position

aside.

10.Remove LH and RH engine bay shields.

11.Remove bumper valance LH and RH

attachment brackets.

12.Remove battery.

+ CHARGING AND STARTING,

REPAIRS, Battery.

13.Remove air intake hose.

14.Remove horn.

+ SECURITY, REPAIRS, Horn.

15.Remove windscreen washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer.

16.Remove bonnet lock.

17.Support bonnet in open position.

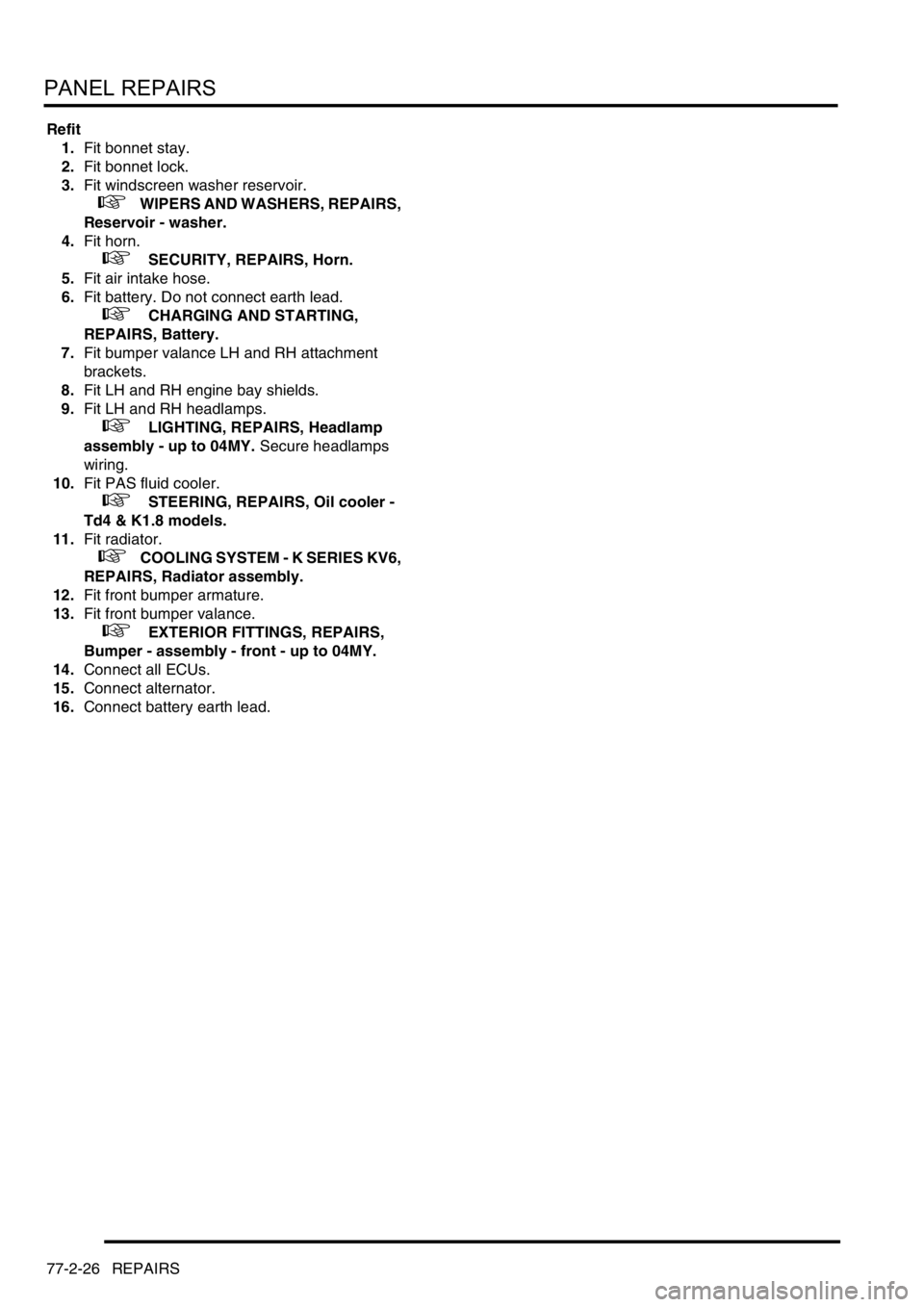

18.Remove bonnet stay. Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Page 781 of 1007

PANEL REPAIRS

77-2-26 REPAIRS

Refit

1.Fit bonnet stay.

2.Fit bonnet lock.

3.Fit windscreen washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer.

4.Fit horn.

+ SECURITY, REPAIRS, Horn.

5.Fit air intake hose.

6.Fit battery. Do not connect earth lead.

+ CHARGING AND STARTING,

REPAIRS, Battery.

7.Fit bumper valance LH and RH attachment

brackets.

8.Fit LH and RH engine bay shields.

9.Fit LH and RH headlamps.

+ LIGHTING, REPAIRS, Headlamp

assembly - up to 04MY. Secure headlamps

wiring.

10.Fit PAS fluid cooler.

+ STEERING, REPAIRS, Oil cooler -

Td4 & K1.8 models.

11.Fit radiator.

+ COOLING SYSTEM - K SERIES KV6,

REPAIRS, Radiator assembly.

12.Fit front bumper armature.

13.Fit front bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

14.Connect all ECUs.

15.Connect alternator.

16.Connect battery earth lead.

Page 782 of 1007

PANEL REPAIRS

REPAIRS 77-2-27

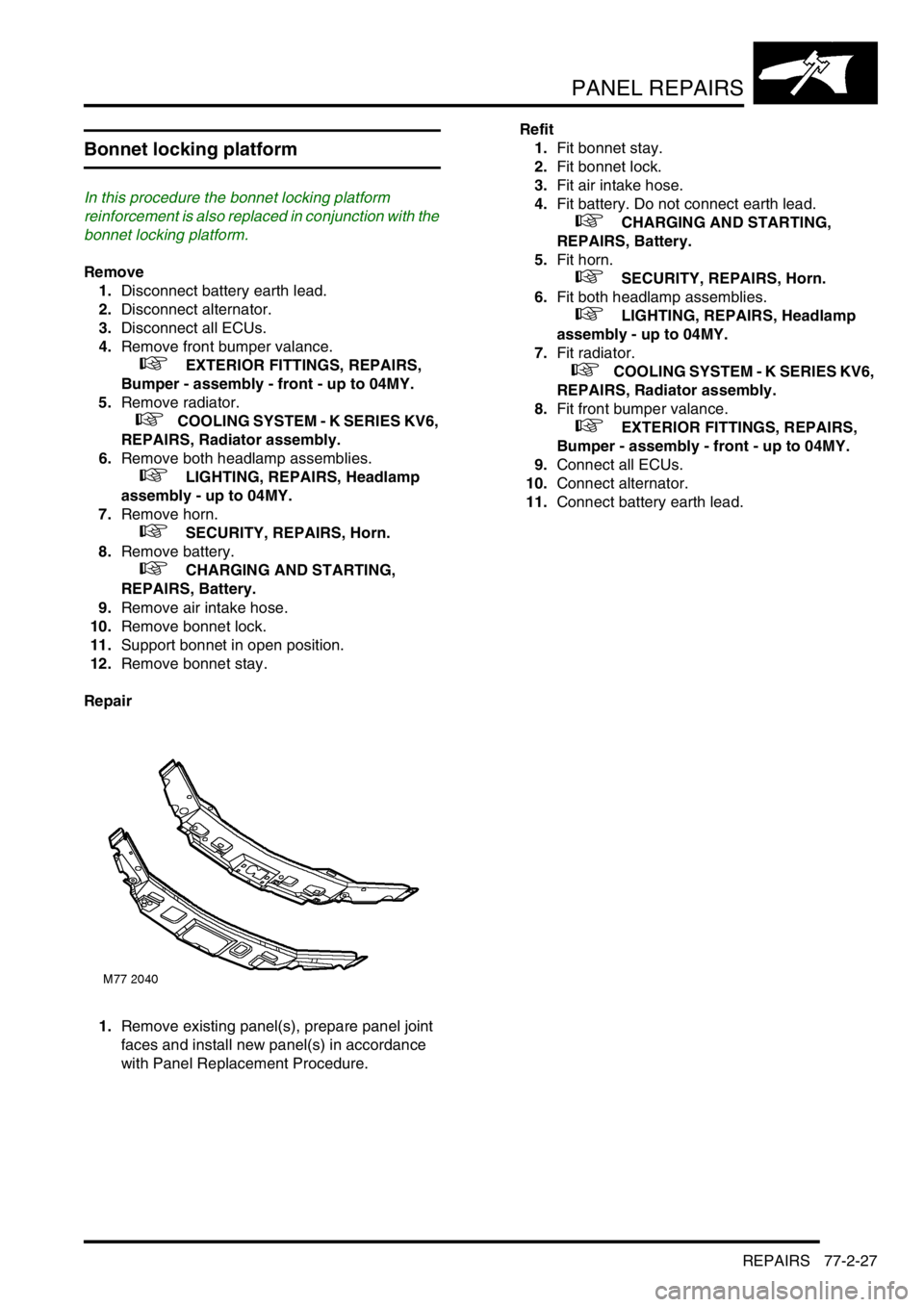

Bonnet locking platform

In this procedure the bonnet locking platform

reinforcement is also replaced in conjunction with the

bonnet locking platform.

Remove

1.Disconnect battery earth lead.

2.Disconnect alternator.

3.Disconnect all ECUs.

4.Remove front bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

5.Remove radiator.

+ COOLING SYSTEM - K SERIES KV6,

REPAIRS, Radiator assembly.

6.Remove both headlamp assemblies.

+ LIGHTING, REPAIRS, Headlamp

assembly - up to 04MY.

7.Remove horn.

+ SECURITY, REPAIRS, Horn.

8.Remove battery.

+ CHARGING AND STARTING,

REPAIRS, Battery.

9.Remove air intake hose.

10.Remove bonnet lock.

11.Support bonnet in open position.

12.Remove bonnet stay.

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Refit

1.Fit bonnet stay.

2.Fit bonnet lock.

3.Fit air intake hose.

4.Fit battery. Do not connect earth lead.

+ CHARGING AND STARTING,

REPAIRS, Battery.

5.Fit horn.

+ SECURITY, REPAIRS, Horn.

6.Fit both headlamp assemblies.

+ LIGHTING, REPAIRS, Headlamp

assembly - up to 04MY.

7.Fit radiator.

+ COOLING SYSTEM - K SERIES KV6,

REPAIRS, Radiator assembly.

8.Fit front bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

9.Connect all ECUs.

10.Connect alternator.

11.Connect battery earth lead.

Page 783 of 1007

PANEL REPAIRS

77-2-28 REPAIRS

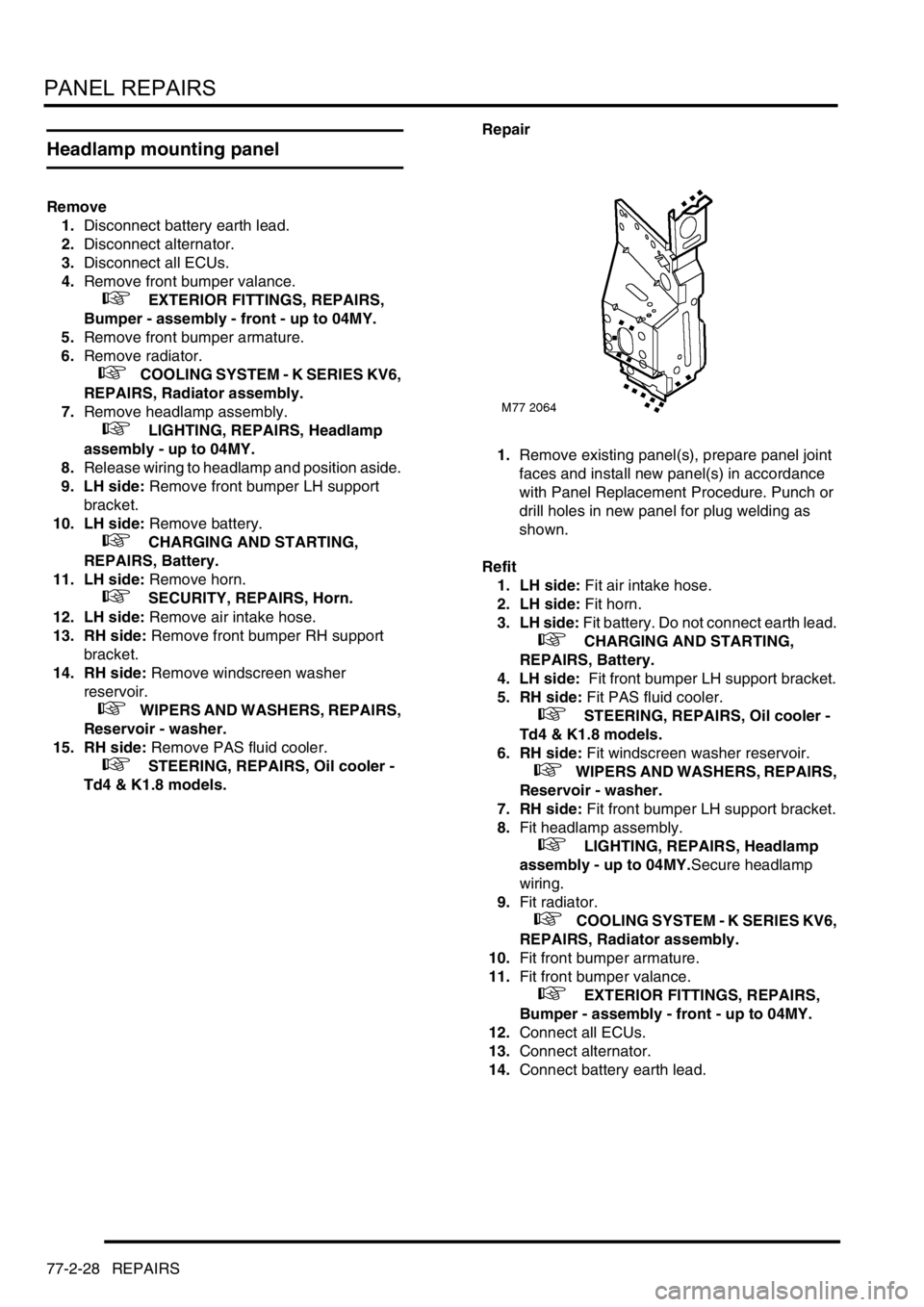

Headlamp mounting panel

Remove

1.Disconnect battery earth lead.

2.Disconnect alternator.

3.Disconnect all ECUs.

4.Remove front bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

5.Remove front bumper armature.

6.Remove radiator.

+ COOLING SYSTEM - K SERIES KV6,

REPAIRS, Radiator assembly.

7.Remove headlamp assembly.

+ LIGHTING, REPAIRS, Headlamp

assembly - up to 04MY.

8.Release wiring to headlamp and position aside.

9. LH side: Remove front bumper LH support

bracket.

10. LH side: Remove battery.

+ CHARGING AND STARTING,

REPAIRS, Battery.

11. LH side: Remove horn.

+ SECURITY, REPAIRS, Horn.

12. LH side: Remove air intake hose.

13. RH side: Remove front bumper RH support

bracket.

14. RH side: Remove windscreen washer

reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer.

15. RH side: Remove PAS fluid cooler.

+ STEERING, REPAIRS, Oil cooler -

Td4 & K1.8 models.Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1. LH side: Fit air intake hose.

2. LH side: Fit horn.

3. LH side: Fit battery. Do not connect earth lead.

+ CHARGING AND STARTING,

REPAIRS, Battery.

4. LH side: Fit front bumper LH support bracket.

5. RH side: Fit PAS fluid cooler.

+ STEERING, REPAIRS, Oil cooler -

Td4 & K1.8 models.

6. RH side: Fit windscreen washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer.

7. RH side: Fit front bumper LH support bracket.

8.Fit headlamp assembly.

+ LIGHTING, REPAIRS, Headlamp

assembly - up to 04MY.Secure headlamp

wiring.

9.Fit radiator.

+ COOLING SYSTEM - K SERIES KV6,

REPAIRS, Radiator assembly.

10.Fit front bumper armature.

11.Fit front bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

12.Connect all ECUs.

13.Connect alternator.

14.Connect battery earth lead.

Page 784 of 1007

PANEL REPAIRS

REPAIRS 77-2-29

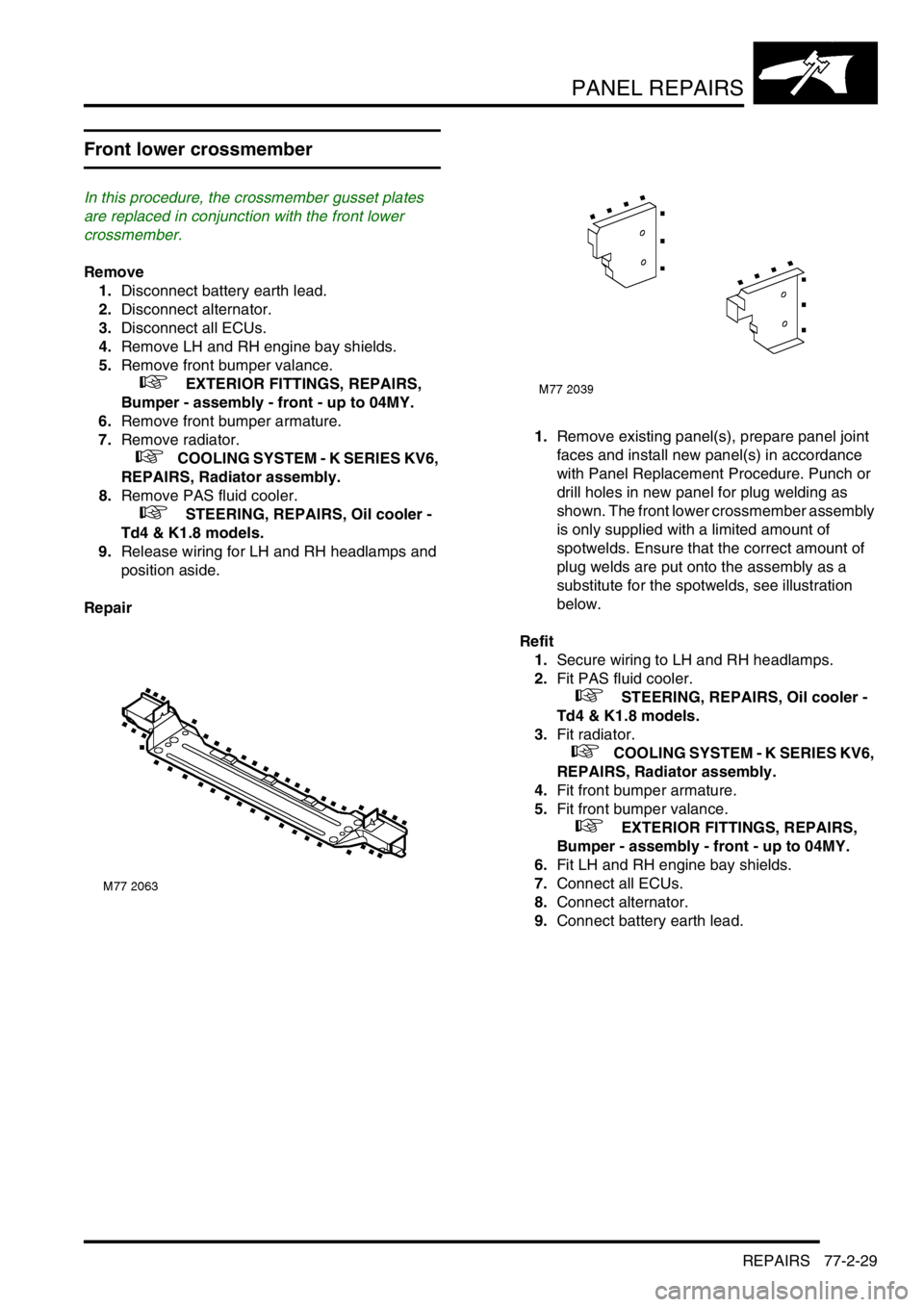

Front lower crossmember

In this procedure, the crossmember gusset plates

are replaced in conjunction with the front lower

crossmember.

Remove

1.Disconnect battery earth lead.

2.Disconnect alternator.

3.Disconnect all ECUs.

4.Remove LH and RH engine bay shields.

5.Remove front bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

6.Remove front bumper armature.

7.Remove radiator.

+ COOLING SYSTEM - K SERIES KV6,

REPAIRS, Radiator assembly.

8.Remove PAS fluid cooler.

+ STEERING, REPAIRS, Oil cooler -

Td4 & K1.8 models.

9.Release wiring for LH and RH headlamps and

position aside.

Repair1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown. The front lower crossmember assembly

is only supplied with a limited amount of

spotwelds. Ensure that the correct amount of

plug welds are put onto the assembly as a

substitute for the spotwelds, see illustration

below.

Refit

1.Secure wiring to LH and RH headlamps.

2.Fit PAS fluid cooler.

+ STEERING, REPAIRS, Oil cooler -

Td4 & K1.8 models.

3.Fit radiator.

+ COOLING SYSTEM - K SERIES KV6,

REPAIRS, Radiator assembly.

4.Fit front bumper armature.

5.Fit front bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

6.Fit LH and RH engine bay shields.

7.Connect all ECUs.

8.Connect alternator.

9.Connect battery earth lead.

Page 785 of 1007

PANEL REPAIRS

77-2-30 REPAIRS

Front sidemember (complete)

In this procedure, the front sidemember closing

panel and the related crossmember to sidemember

gusset plate are replaced in conjunction with the front

sidemember.

Remove

1.Disconnect battery earth lead.

2.Disconnect alternator.

3.Disconnect all ECUs.

4.Remove road wheel(s).

5.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

6.Remove front bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

7.Remove front bumper armature.

8.Remove radiator.

+ COOLING SYSTEM - K SERIES KV6,

REPAIRS, Radiator assembly.

9.Remove PAS fluid cooler.

+ STEERING, REPAIRS, Oil cooler -

Td4 & K1.8 models.

10.Remove headlamp.

+ LIGHTING, REPAIRS, Headlamp

assembly - up to 04MY.

11.Release wiring to headlamp and position aside.

12.Remove engine bay shield.

13.Remove front wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - front wheel arch.

14.Remove front suspension rear beam.

15.Remove engine and gearbox.

+ ENGINE - K SERIES KV6, REPAIRS,

Engine and automatic gearbox - up to 03MY.

16.Remove PAS rack.

+ STEERING, REPAIRS, Power

steering rack.

17.Remove fascia.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Fascia - up to 04MY.

18. LH side: Remove front bumper LH support

bracket.

19. LH side: Remove LH engine mounting from

body.

20. LH side: Remove battery.

+ CHARGING AND STARTING,

REPAIRS, Battery.

21. LH side: Remove air intake hose.

22. LH side: Remove horn.

+ SECURITY, REPAIRS, Horn.

23. RH side: Remove front bumper RH support

bracket.24. RH side: Remove RH engine mounting from

body.

25. RH side: Remove windscreen washer

reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer.

26. Driver's side: Remove passenger

compartment fuse box.

27. Driver's side: Remove brake pedal box and

brake servo.

28. Driver's side: Remove clutch pedal box.

29.Remove treadplate from front door aperture.

Release front carpet and position aside.

30.Remove insulation pads from engine bulkhead.