wheel LAND ROVER FREELANDER 2001 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 250 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-73

Camshaft rear timing belt - RH cylinder

head

$% 12.65.57

Remove

1.Disconnect battery earth lead.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Remove RH front road wheel.

4.Remove 3 bolts securing RH splash shield to

body and remove shield.

5.Remove RH rear timing belt cover.

+ ENGINE - K SERIES KV6, REPAIRS,

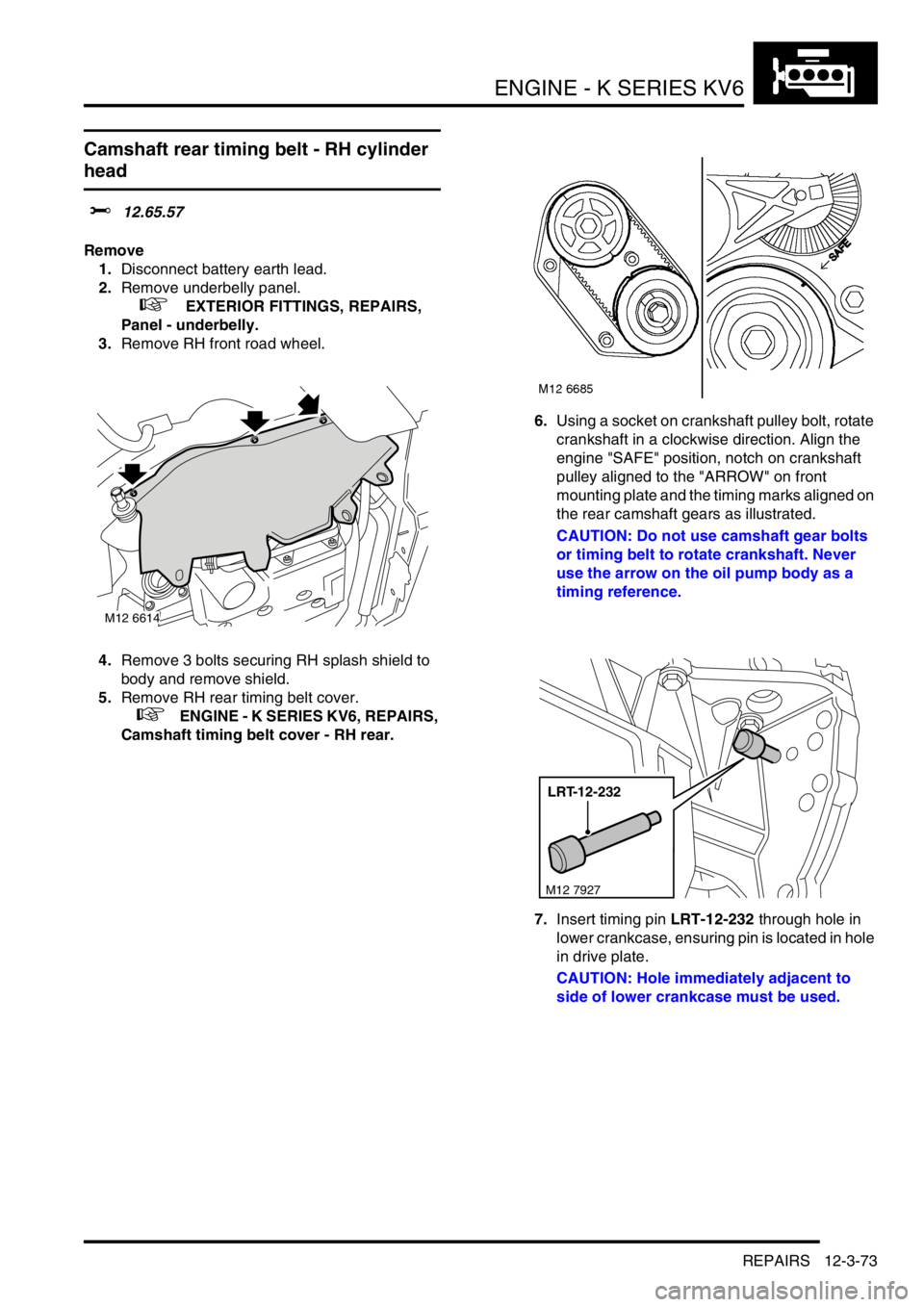

Camshaft timing belt cover - RH rear.6.Using a socket on crankshaft pulley bolt, rotate

crankshaft in a clockwise direction. Align the

engine "SAFE" position, notch on crankshaft

pulley aligned to the "ARROW" on front

mounting plate and the timing marks aligned on

the rear camshaft gears as illustrated.

CAUTION: Do not use camshaft gear bolts

or timing belt to rotate crankshaft. Never

use the arrow on the oil pump body as a

timing reference.

7.Insert timing pin LRT-12-232 through hole in

lower crankcase, ensuring pin is located in hole

in drive plate.

CAUTION: Hole immediately adjacent to

side of lower crankcase must be used.

M12 6614

LRT-12-232

M12 7927

Page 253 of 1007

ENGINE - K SERIES KV6

12-3-76 REPAIRS

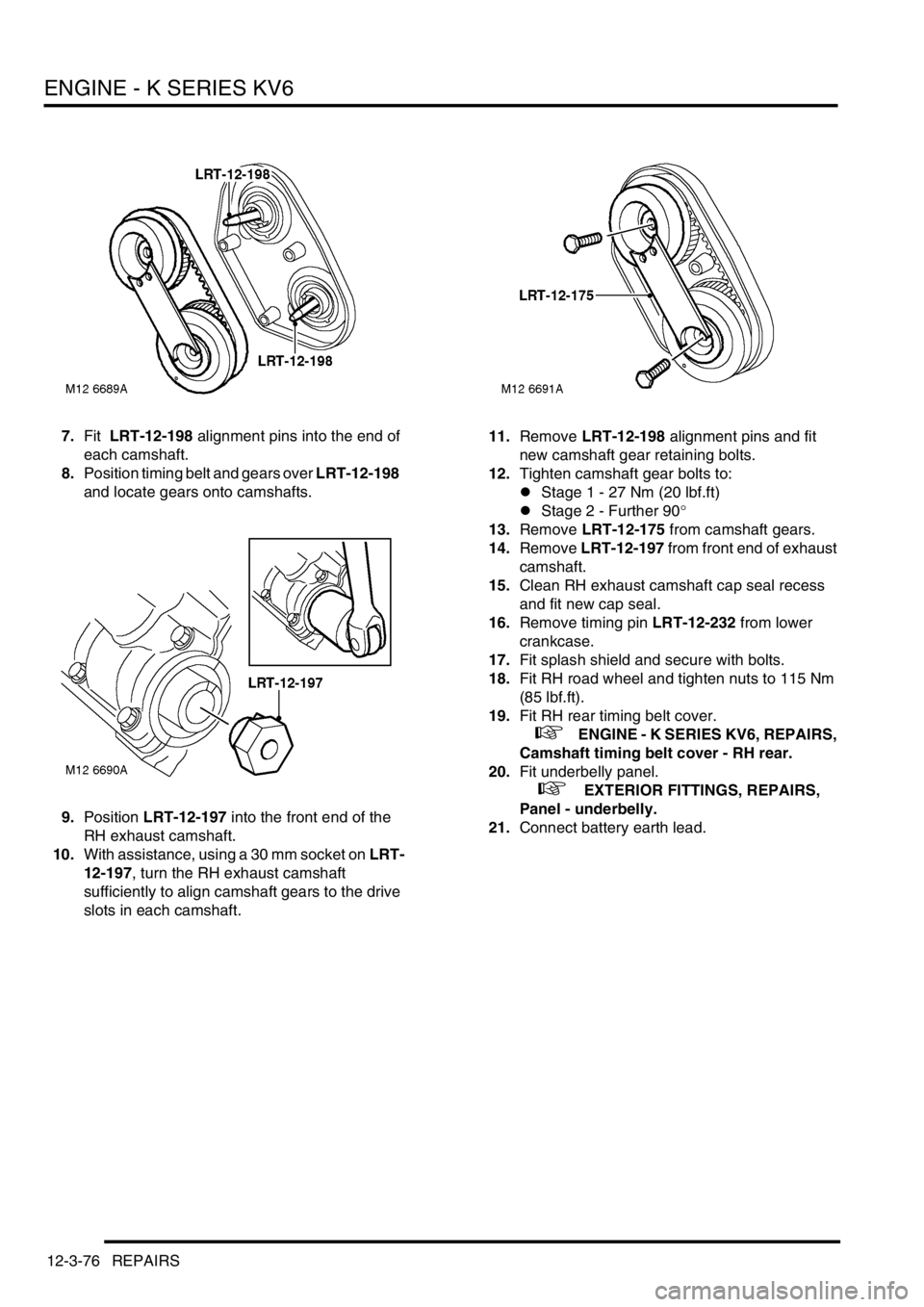

7.Fit LRT-12-198 alignment pins into the end of

each camshaft.

8.Position timing belt and gears over LRT-12-198

and locate gears onto camshafts.

9.Position LRT-12-197 into the front end of the

RH exhaust camshaft.

10.With assistance, using a 30 mm socket on LRT-

12-197, turn the RH exhaust camshaft

sufficiently to align camshaft gears to the drive

slots in each camshaft.11.Remove LRT-12-198 alignment pins and fit

new camshaft gear retaining bolts.

12.Tighten camshaft gear bolts to:

lStage 1 - 27 Nm (20 lbf.ft)

lStage 2 - Further 90°

13.Remove LRT-12-175 from camshaft gears.

14.Remove LRT-12-197 from front end of exhaust

camshaft.

15.Clean RH exhaust camshaft cap seal recess

and fit new cap seal.

16.Remove timing pin LRT-12-232 from lower

crankcase.

17.Fit splash shield and secure with bolts.

18.Fit RH road wheel and tighten nuts to 115 Nm

(85 lbf.ft).

19.Fit RH rear timing belt cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft timing belt cover - RH rear.

20.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

21.Connect battery earth lead.

Page 292 of 1007

EMISSION CONTROL

ADJUSTMENTS 17-1-1

EMISS ION CONTROL ADJUST ME NTS

Evaporative loss control system

(EVAPS) - leak test - NAS

$% 17.90.02.01

The following procedure allows a fuel leak, indicated

by the Malfunction Indicator Lamp (MIL), to be

accurately located. It must only be carried out once it

has been established that there are no obvious faults

with any of the system components.

Check

1.Check components in fuel and EVAP system

for obvious damage. Ensure all connections

are properly secured.

2.The system must be checked using a EVAPS

Diagnostic Testing Station LRA-19-004.

3.Disconnect vent pipe from purge valve and

connect adapter LRA-19-004/1.

NOTE: The reason for inserting the adapter into

the purge valve is that there is currently no

service port fitted to Freelander.

4.Remove RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

5.Release clip and disconnect hose from

charcoal canister.

CAUTION: Before disconnecting any part of

the fuel system, it is imperative that all dust,

dirt and debris is removed from around

components to prevent ingress of foreign

matter into fuel system.

6.Block charcoal canister port with bung,

included in LRA-19-004.

7.Connect LRA-19-004 to service port fitted on

purge valve.

8.Carry out procedures given in the operating

instructions, these are supplied with LRA-19-

004.Adjust

1.If a leak has been detected, replace component

as necessary and repeat leak test to validate

repair.

2.Remove bung from charcoal canister.

3.Connect hose to charcoal canister and secure

with clip.

4.Fit rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

5.Disconnect adaptor LRA-19-004/1 from purge

valve.

6.Connect hose to purge valve.

Page 296 of 1007

EMISSION CONTROL

REPAIRS 17-1-5

Charcoal canister - NAS

$% 17.15.13

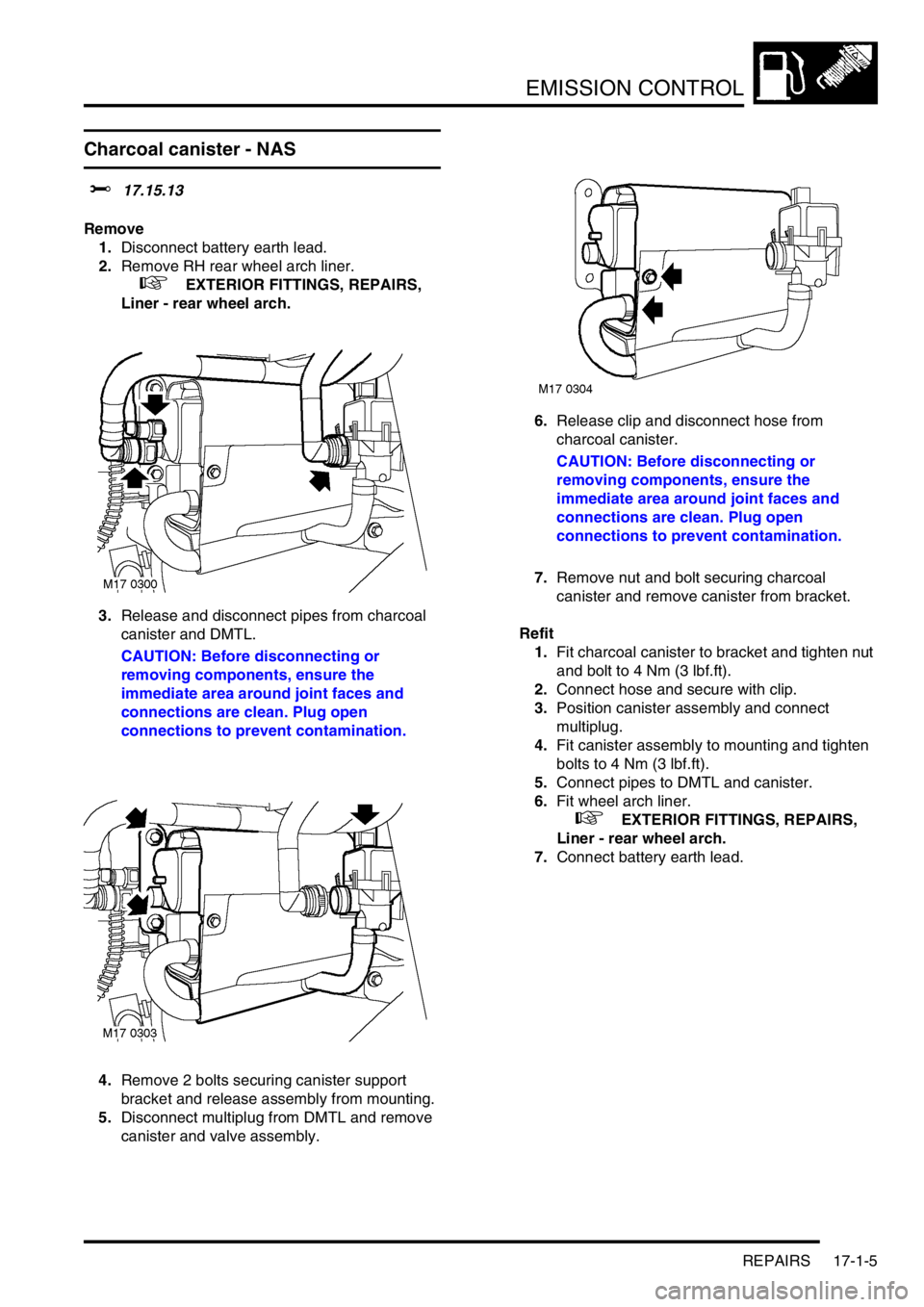

Remove

1.Disconnect battery earth lead.

2.Remove RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

3.Release and disconnect pipes from charcoal

canister and DMTL.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

4.Remove 2 bolts securing canister support

bracket and release assembly from mounting.

5.Disconnect multiplug from DMTL and remove

canister and valve assembly.6.Release clip and disconnect hose from

charcoal canister.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

7.Remove nut and bolt securing charcoal

canister and remove canister from bracket.

Refit

1.Fit charcoal canister to bracket and tighten nut

and bolt to 4 Nm (3 lbf.ft).

2.Connect hose and secure with clip.

3.Position canister assembly and connect

multiplug.

4.Fit canister assembly to mounting and tighten

bolts to 4 Nm (3 lbf.ft).

5.Connect pipes to DMTL and canister.

6.Fit wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

7.Connect battery earth lead.

Page 302 of 1007

EMISSION CONTROL

REPAIRS 17-1-11

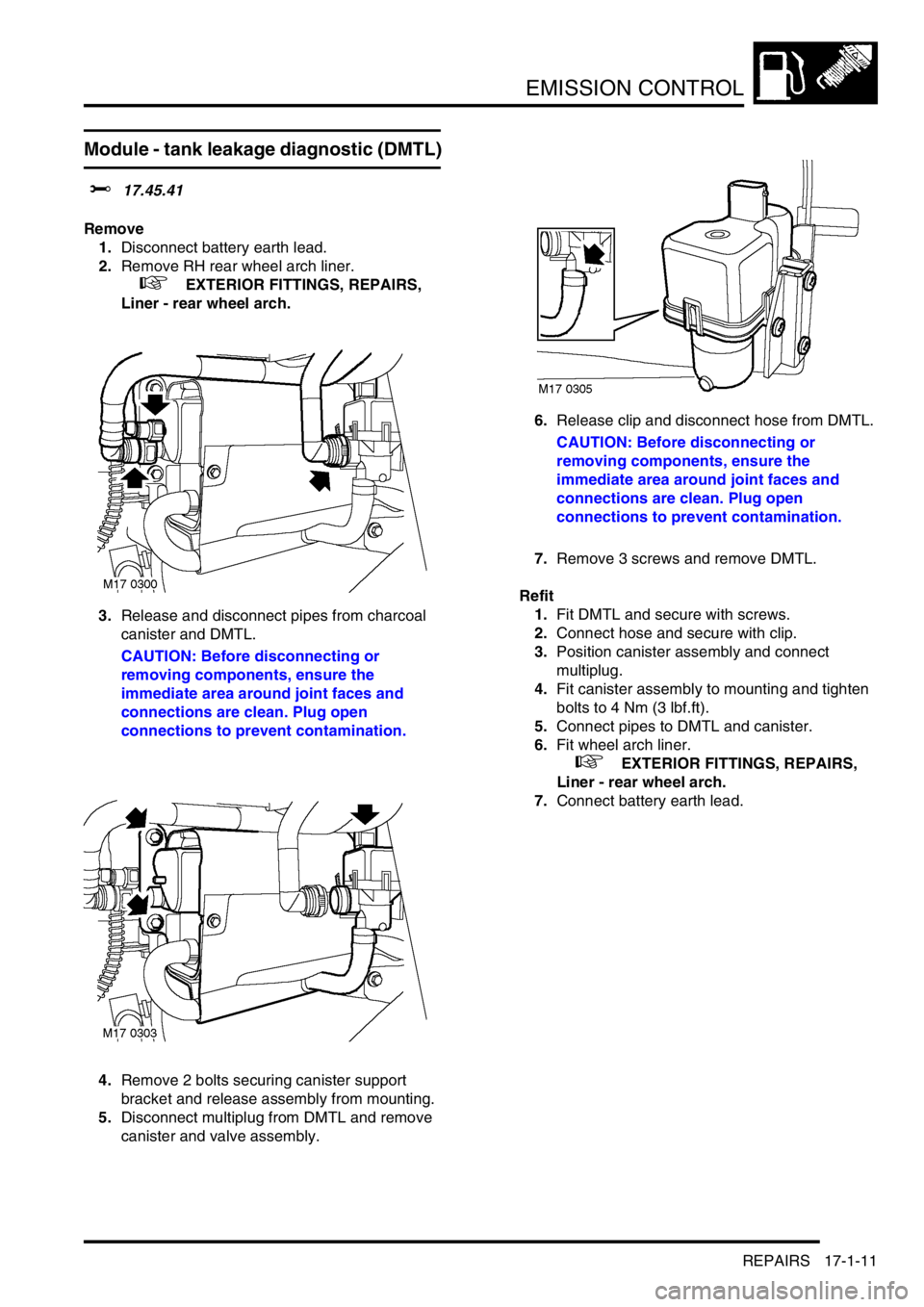

Module - tank leakage diagnostic (DMTL)

$% 17.45.41

Remove

1.Disconnect battery earth lead.

2.Remove RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

3.Release and disconnect pipes from charcoal

canister and DMTL.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

4.Remove 2 bolts securing canister support

bracket and release assembly from mounting.

5.Disconnect multiplug from DMTL and remove

canister and valve assembly.6.Release clip and disconnect hose from DMTL.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

7.Remove 3 screws and remove DMTL.

Refit

1.Fit DMTL and secure with screws.

2.Connect hose and secure with clip.

3.Position canister assembly and connect

multiplug.

4.Fit canister assembly to mounting and tighten

bolts to 4 Nm (3 lbf.ft).

5.Connect pipes to DMTL and canister.

6.Fit wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

7.Connect battery earth lead.

Page 303 of 1007

EMISSION CONTROL

17-1-12 REPAIRS

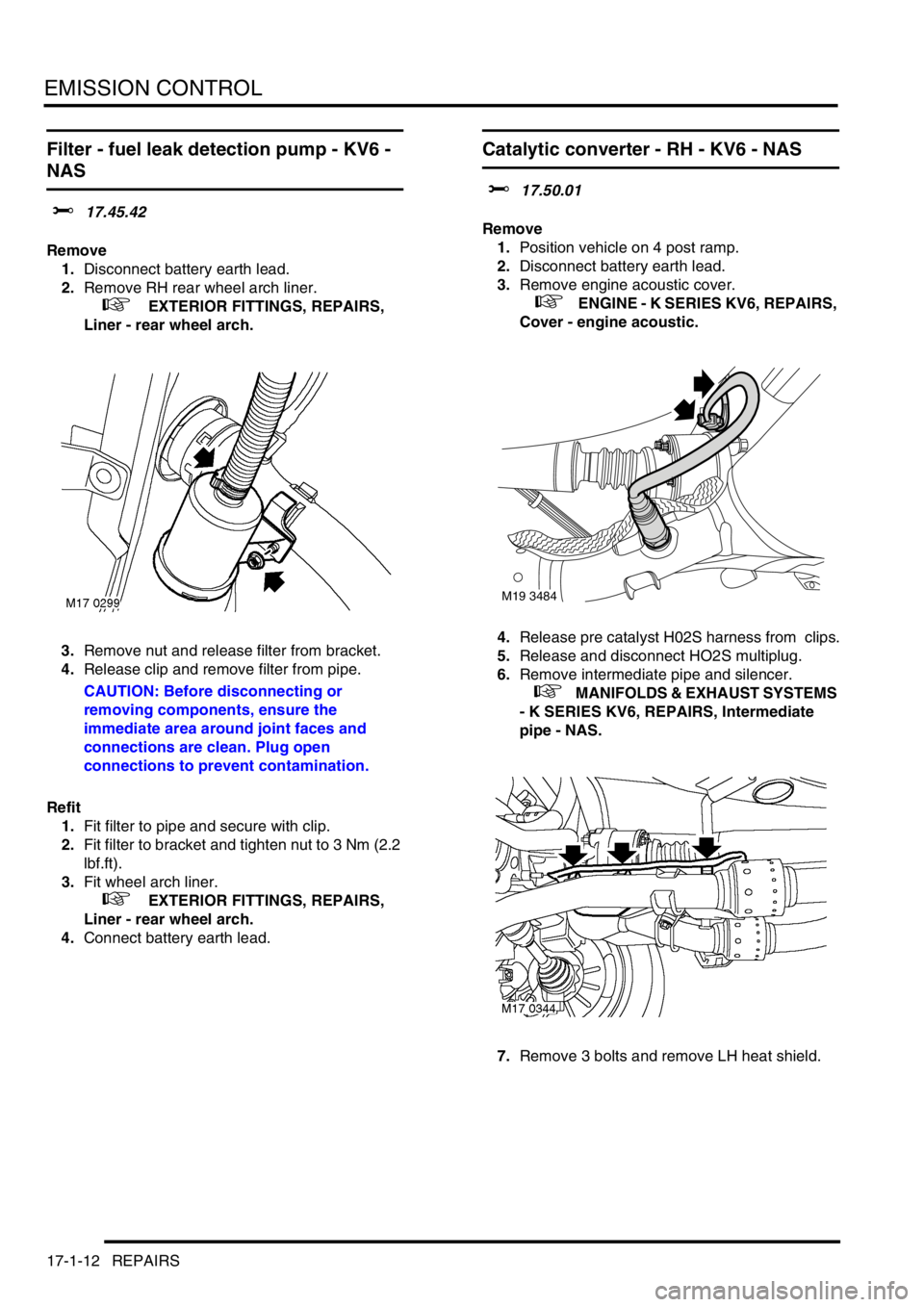

Filter - fuel leak detection pump - KV6 -

NAS

$% 17.45.42

Remove

1.Disconnect battery earth lead.

2.Remove RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

3.Remove nut and release filter from bracket.

4.Release clip and remove filter from pipe.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

Refit

1.Fit filter to pipe and secure with clip.

2.Fit filter to bracket and tighten nut to 3 Nm (2.2

lbf.ft).

3.Fit wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

4.Connect battery earth lead.

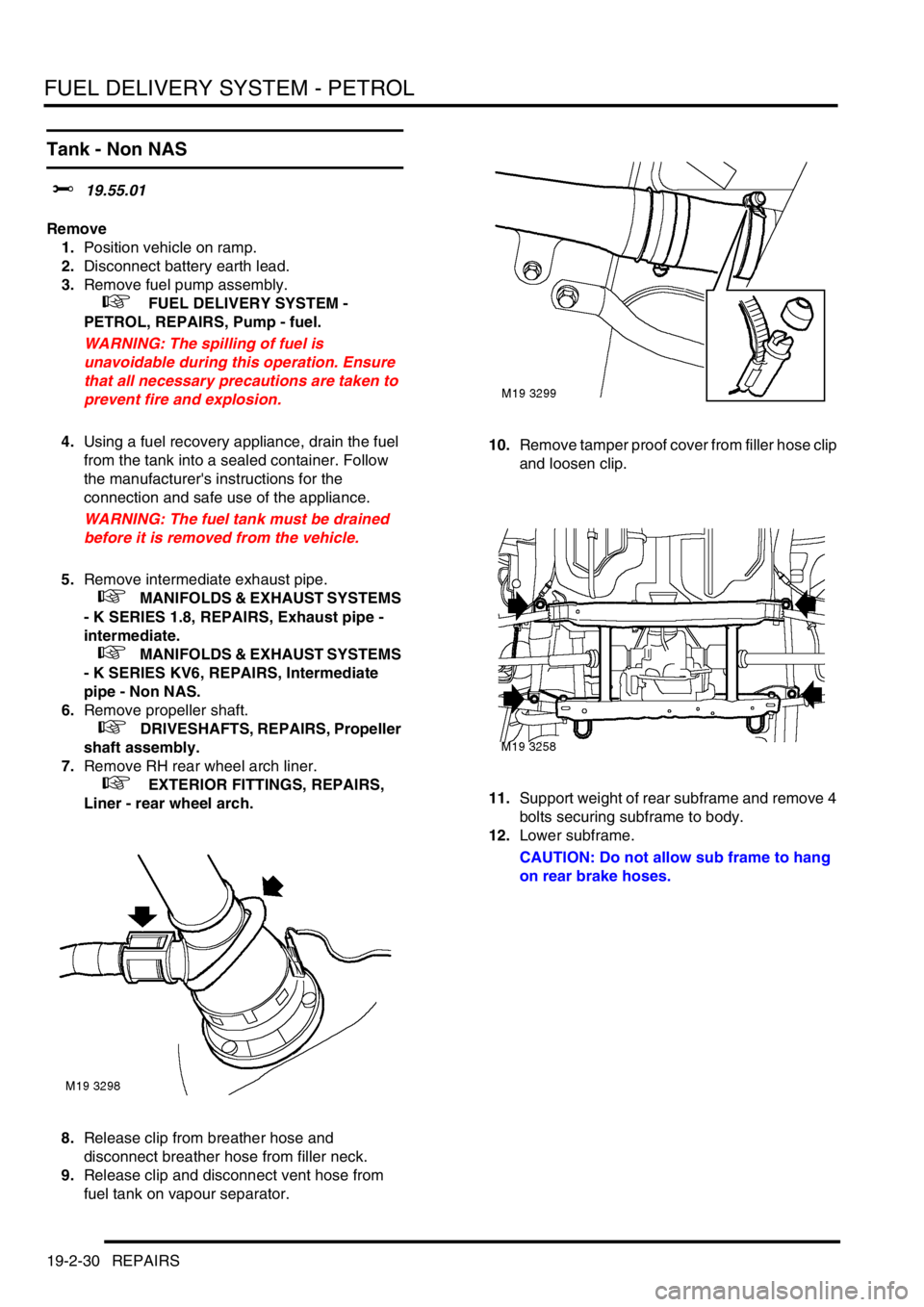

Catalytic converter - RH - KV6 - NAS

$% 17.50.01

Remove

1.Position vehicle on 4 post ramp.

2.Disconnect battery earth lead.

3.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

4.Release pre catalyst H02S harness from clips.

5.Release and disconnect HO2S multiplug.

6.Remove intermediate pipe and silencer.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Intermediate

pipe - NAS.

7.Remove 3 bolts and remove LH heat shield.

M19 3484

Page 336 of 1007

FUEL DELIVERY SYSTEM - PETROL

REPAIRS 19-2-15

Sensor - heated oxygen (H02S) - pre-

catalyst - RH - KV6 - Non NAS

$% 19.22.17

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove LH front road wheel.

3.Release RH HO2S multiplug from coolant rail

bracket and disconnect multiplug.

4.Remove HO2S from RH exhaust manifold.Refit

1.Clean HO2S and exhaust manifold mating

face.

2.Fit HO2S and tighten to 55 Nm (41 lbf.ft).

3.Connect RH HO2S multiplug, secure multiplug

in coolant rail bracket.

4.Fit LH front road wheel and tighten nuts to 115

Nm (85 lbf.ft).

5.Remove stands and lower vehicle.

M30 0996

Page 351 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-30 REPAIRS

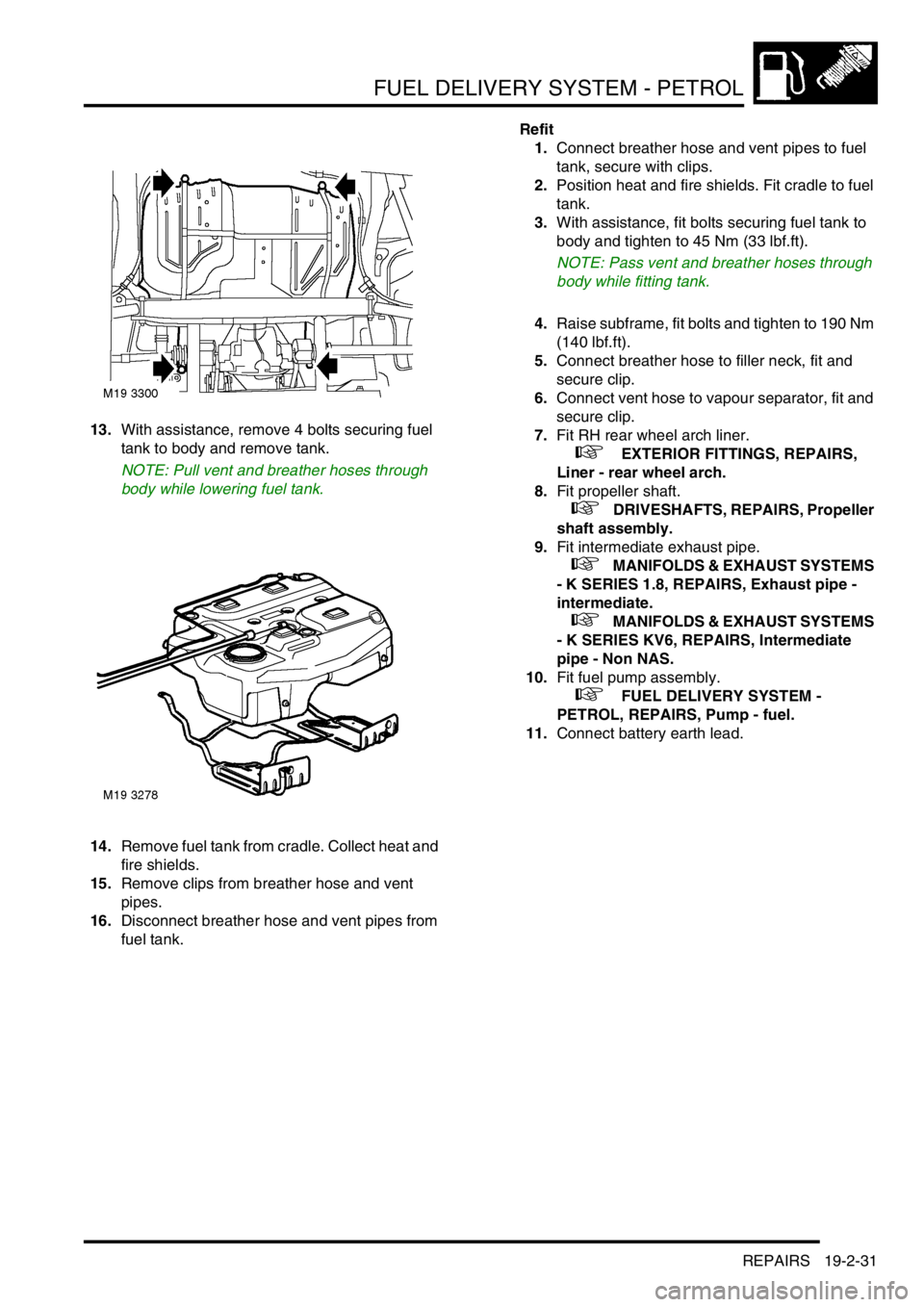

Tank - Non NAS

$% 19.55.01

Remove

1.Position vehicle on ramp.

2.Disconnect battery earth lead.

3.Remove fuel pump assembly.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Pump - fuel.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

4.Using a fuel recovery appliance, drain the fuel

from the tank into a sealed container. Follow

the manufacturer's instructions for the

connection and safe use of the appliance.

WARNING: The fuel tank must be drained

before it is removed from the vehicle.

5.Remove intermediate exhaust pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES 1.8, REPAIRS, Exhaust pipe -

intermediate.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Intermediate

pipe - Non NAS.

6.Remove propeller shaft.

+ DRIVESHAFTS, REPAIRS, Propeller

shaft assembly.

7.Remove RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

8.Release clip from breather hose and

disconnect breather hose from filler neck.

9.Release clip and disconnect vent hose from

fuel tank on vapour separator.10.Remove tamper proof cover from filler hose clip

and loosen clip.

11.Support weight of rear subframe and remove 4

bolts securing subframe to body.

12.Lower subframe.

CAUTION: Do not allow sub frame to hang

on rear brake hoses.

Page 352 of 1007

FUEL DELIVERY SYSTEM - PETROL

REPAIRS 19-2-31

13.With assistance, remove 4 bolts securing fuel

tank to body and remove tank.

NOTE: Pull vent and breather hoses through

body while lowering fuel tank.

14.Remove fuel tank from cradle. Collect heat and

fire shields.

15.Remove clips from breather hose and vent

pipes.

16.Disconnect breather hose and vent pipes from

fuel tank.Refit

1.Connect breather hose and vent pipes to fuel

tank, secure with clips.

2.Position heat and fire shields. Fit cradle to fuel

tank.

3.With assistance, fit bolts securing fuel tank to

body and tighten to 45 Nm (33 lbf.ft).

NOTE: Pass vent and breather hoses through

body while fitting tank.

4.Raise subframe, fit bolts and tighten to 190 Nm

(140 lbf.ft).

5.Connect breather hose to filler neck, fit and

secure clip.

6.Connect vent hose to vapour separator, fit and

secure clip.

7.Fit RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

8.Fit propeller shaft.

+ DRIVESHAFTS, REPAIRS, Propeller

shaft assembly.

9.Fit intermediate exhaust pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES 1.8, REPAIRS, Exhaust pipe -

intermediate.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Intermediate

pipe - Non NAS.

10.Fit fuel pump assembly.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Pump - fuel.

11.Connect battery earth lead.

Page 353 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-32 REPAIRS

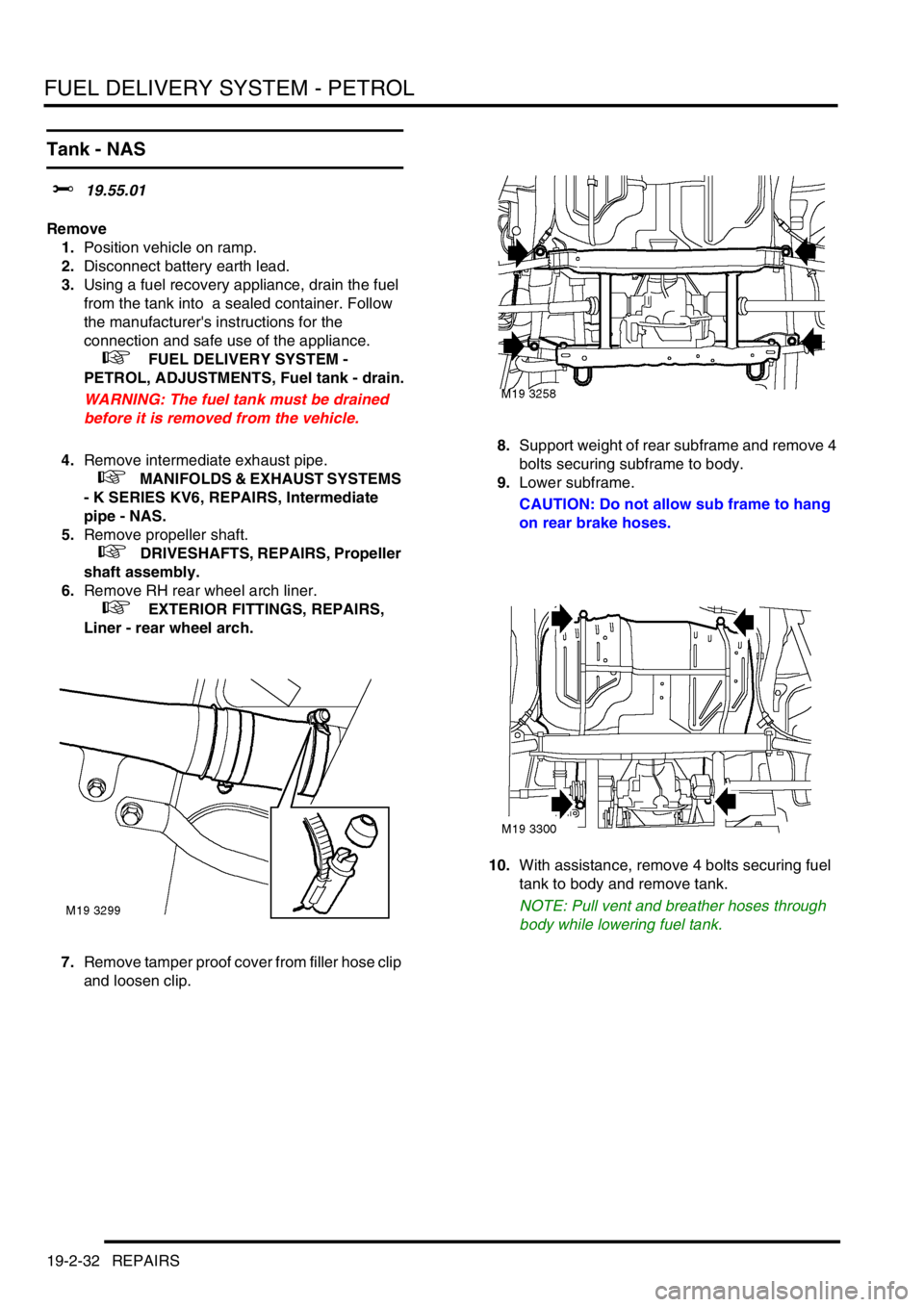

Tank - NAS

$% 19.55.01

Remove

1.Position vehicle on ramp.

2.Disconnect battery earth lead.

3.Using a fuel recovery appliance, drain the fuel

from the tank into a sealed container. Follow

the manufacturer's instructions for the

connection and safe use of the appliance.

+ FUEL DELIVERY SYSTEM -

PETROL, ADJUSTMENTS, Fuel tank - drain.

WARNING: The fuel tank must be drained

before it is removed from the vehicle.

4.Remove intermediate exhaust pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Intermediate

pipe - NAS.

5.Remove propeller shaft.

+ DRIVESHAFTS, REPAIRS, Propeller

shaft assembly.

6.Remove RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

7.Remove tamper proof cover from filler hose clip

and loosen clip.8.Support weight of rear subframe and remove 4

bolts securing subframe to body.

9.Lower subframe.

CAUTION: Do not allow sub frame to hang

on rear brake hoses.

10.With assistance, remove 4 bolts securing fuel

tank to body and remove tank.

NOTE: Pull vent and breather hoses through

body while lowering fuel tank.