wheel LAND ROVER FREELANDER 2001 Manual PDF

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 354 of 1007

FUEL DELIVERY SYSTEM - PETROL

REPAIRS 19-2-33

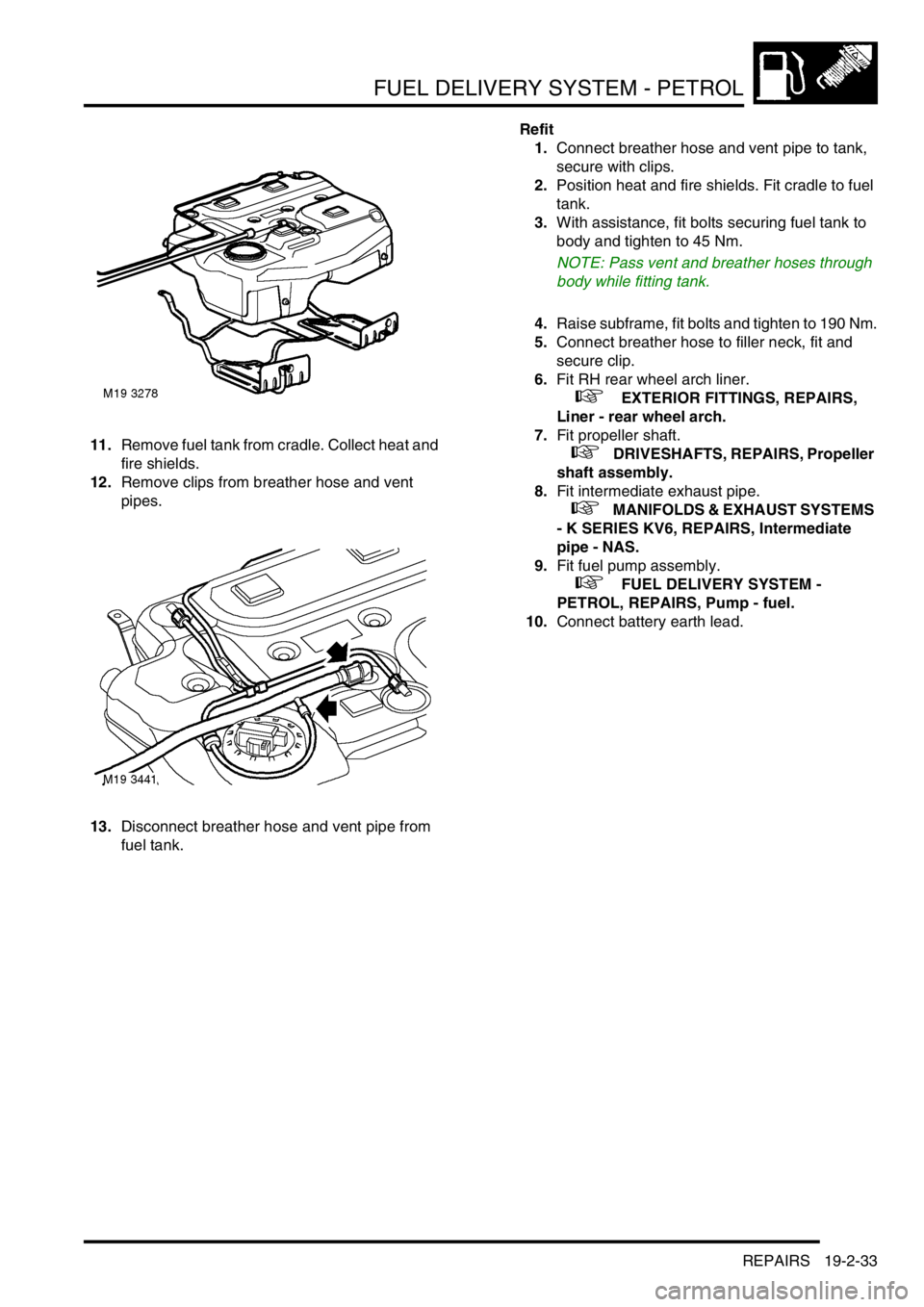

11.Remove fuel tank from cradle. Collect heat and

fire shields.

12.Remove clips from breather hose and vent

pipes.

13.Disconnect breather hose and vent pipe from

fuel tank.Refit

1.Connect breather hose and vent pipe to tank,

secure with clips.

2.Position heat and fire shields. Fit cradle to fuel

tank.

3.With assistance, fit bolts securing fuel tank to

body and tighten to 45 Nm.

NOTE: Pass vent and breather hoses through

body while fitting tank.

4.Raise subframe, fit bolts and tighten to 190 Nm.

5.Connect breather hose to filler neck, fit and

secure clip.

6.Fit RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

7.Fit propeller shaft.

+ DRIVESHAFTS, REPAIRS, Propeller

shaft assembly.

8.Fit intermediate exhaust pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Intermediate

pipe - NAS.

9.Fit fuel pump assembly.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Pump - fuel.

10.Connect battery earth lead.

Page 355 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-34 REPAIRS

Filler neck

$% 19.55.07

Remove

1.Disconnect battery earth lead.

2.Ensure fuel tank is less than half full. If not,

drain fuel tank to less than half full.

+ FUEL DELIVERY SYSTEM -

PETROL, ADJUSTMENTS, Fuel tank - drain.

3.Remove RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

4.Remove fuel filler cap.

CAUTION: Before disconnecting any part of

the fuel system, it is imperative that all dust,

dirt and debris is removed from around

components to prevent ingress of foreign

matter into fuel system.

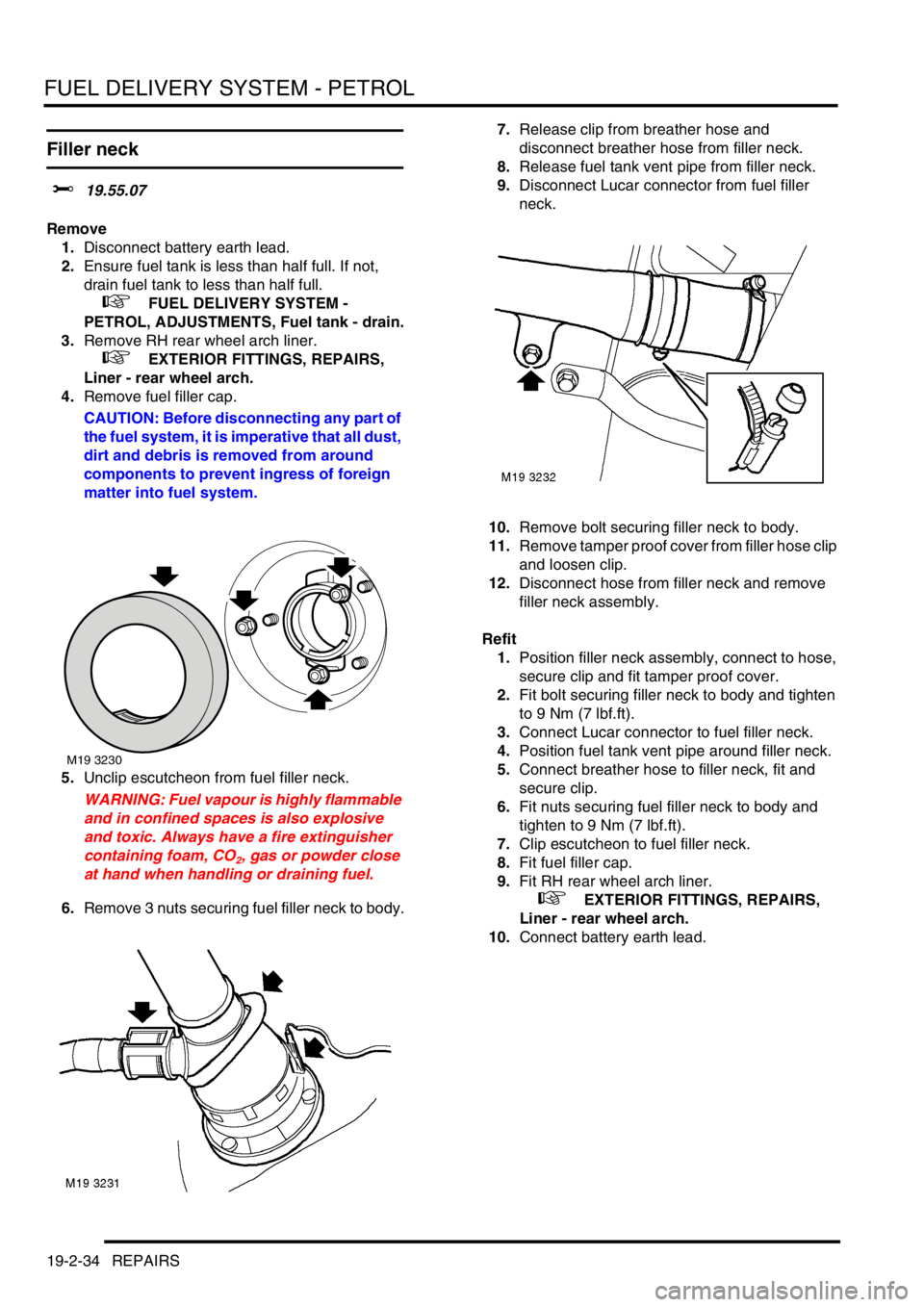

5.Unclip escutcheon from fuel filler neck.

WARNING: Fuel vapour is highly flammable

and in confined spaces is also explosive

and toxic. Always have a fire extinguisher

containing foam, CO

2, gas or powder close

at hand when handling or draining fuel.

6.Remove 3 nuts securing fuel filler neck to body.7.Release clip from breather hose and

disconnect breather hose from filler neck.

8.Release fuel tank vent pipe from filler neck.

9.Disconnect Lucar connector from fuel filler

neck.

10.Remove bolt securing filler neck to body.

11.Remove tamper proof cover from filler hose clip

and loosen clip.

12.Disconnect hose from filler neck and remove

filler neck assembly.

Refit

1.Position filler neck assembly, connect to hose,

secure clip and fit tamper proof cover.

2.Fit bolt securing filler neck to body and tighten

to 9 Nm (7 lbf.ft).

3.Connect Lucar connector to fuel filler neck.

4.Position fuel tank vent pipe around filler neck.

5.Connect breather hose to filler neck, fit and

secure clip.

6.Fit nuts securing fuel filler neck to body and

tighten to 9 Nm (7 lbf.ft).

7.Clip escutcheon to fuel filler neck.

8.Fit fuel filler cap.

9.Fit RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

10.Connect battery earth lead.

M19 3230

Page 363 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-42 REPAIRS

Switch - engagement (on/off) - from

04MY

$% 19.75.30

Remove

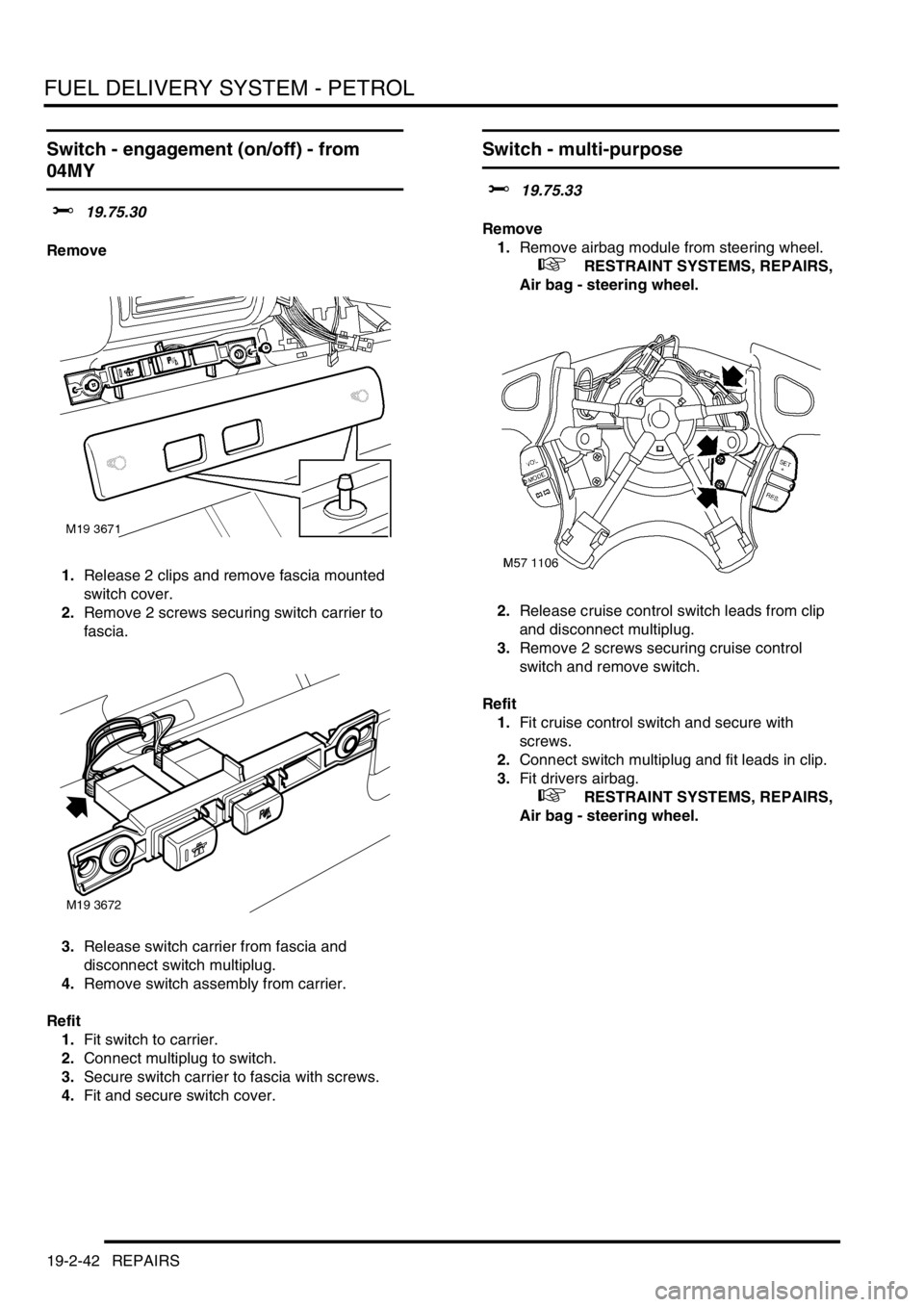

1.Release 2 clips and remove fascia mounted

switch cover.

2.Remove 2 screws securing switch carrier to

fascia.

3.Release switch carrier from fascia and

disconnect switch multiplug.

4.Remove switch assembly from carrier.

Refit

1.Fit switch to carrier.

2.Connect multiplug to switch.

3.Secure switch carrier to fascia with screws.

4.Fit and secure switch cover.

Switch - multi-purpose

$% 19.75.33

Remove

1.Remove airbag module from steering wheel.

+ RESTRAINT SYSTEMS, REPAIRS,

Air bag - steering wheel.

2.Release cruise control switch leads from clip

and disconnect multiplug.

3.Remove 2 screws securing cruise control

switch and remove switch.

Refit

1.Fit cruise control switch and secure with

screws.

2.Connect switch multiplug and fit leads in clip.

3.Fit drivers airbag.

+ RESTRAINT SYSTEMS, REPAIRS,

Air bag - steering wheel.

M19 3672

Page 406 of 1007

INTERMEDIATE REDUCTION DRIVE

REPAIRS 41-3

REPAIRS

Intermediate reduction drive (IRD) unit -

Td4

$% 41.25.01.99

Remove

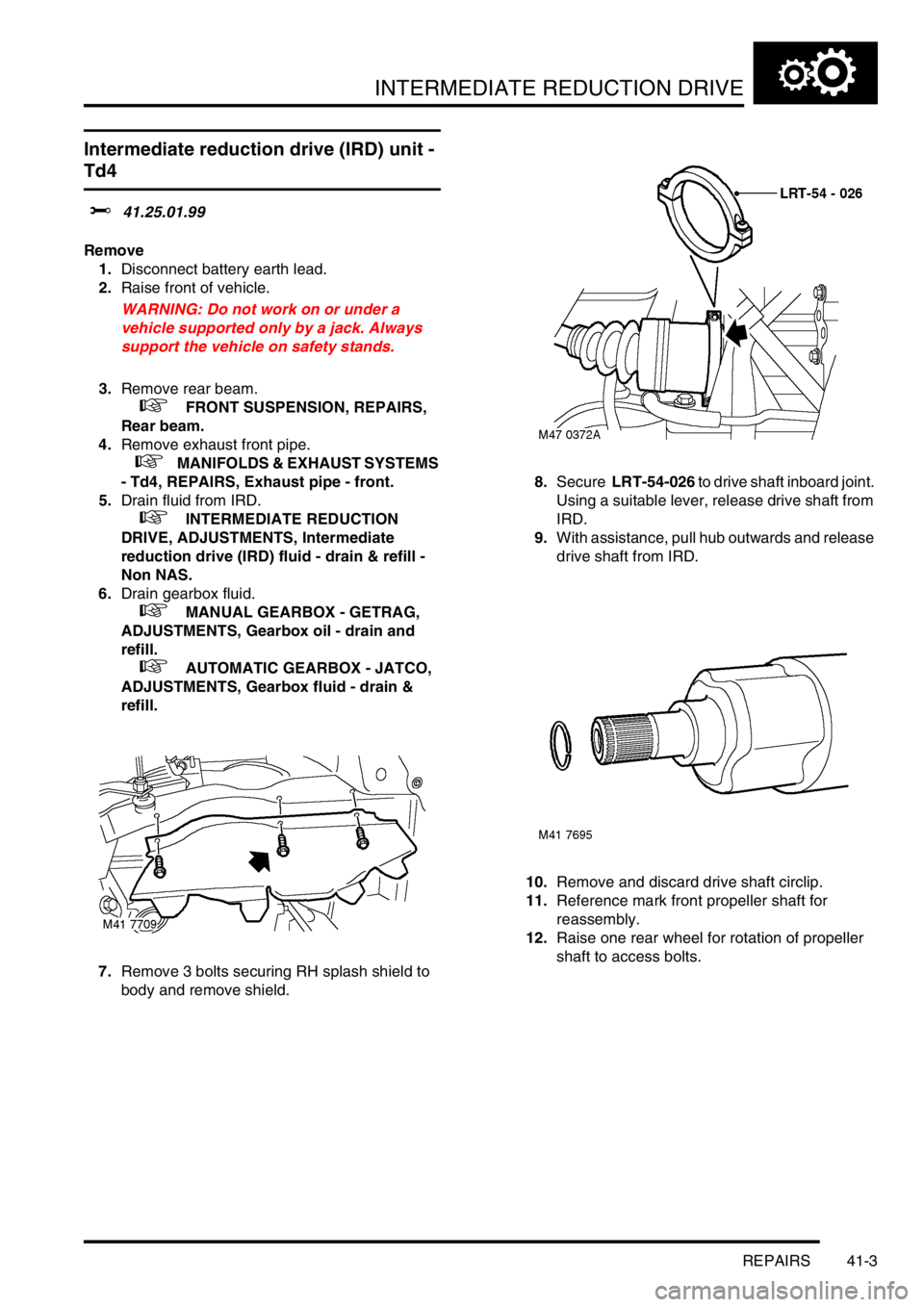

1.Disconnect battery earth lead.

2.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

3.Remove rear beam.

+ FRONT SUSPENSION, REPAIRS,

Rear beam.

4.Remove exhaust front pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- Td4, REPAIRS, Exhaust pipe - front.

5.Drain fluid from IRD.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

6.Drain gearbox fluid.

+ MANUAL GEARBOX - GETRAG,

ADJUSTMENTS, Gearbox oil - drain and

refill.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Gearbox fluid - drain &

refill.

7.Remove 3 bolts securing RH splash shield to

body and remove shield.8.Secure LRT-54-026 to drive shaft inboard joint.

Using a suitable lever, release drive shaft from

IRD.

9.With assistance, pull hub outwards and release

drive shaft from IRD.

10.Remove and discard drive shaft circlip.

11.Reference mark front propeller shaft for

reassembly.

12.Raise one rear wheel for rotation of propeller

shaft to access bolts.

Page 411 of 1007

INTERMEDIATE REDUCTION DRIVE

41-8 REPAIRS

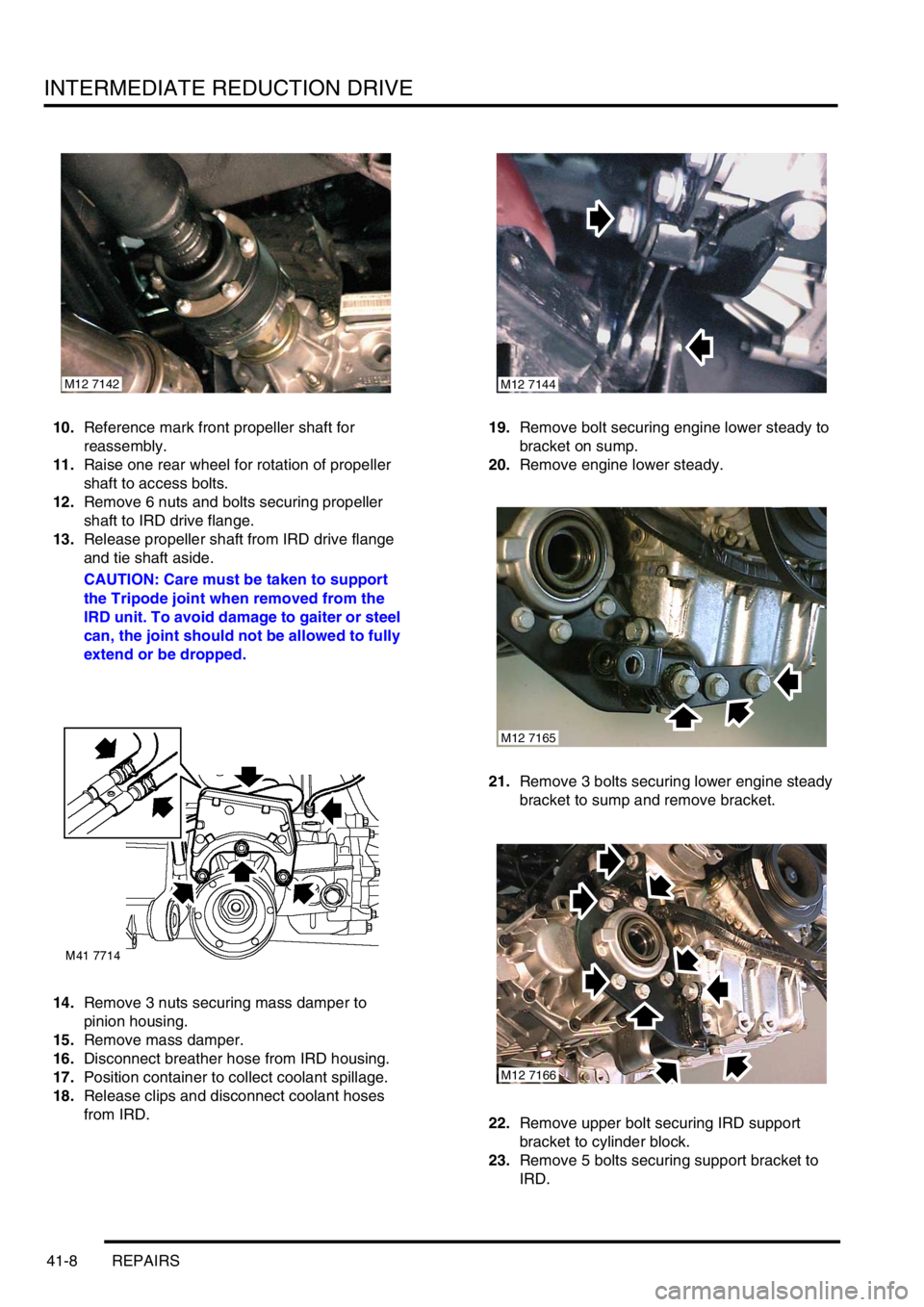

10.Reference mark front propeller shaft for

reassembly.

11.Raise one rear wheel for rotation of propeller

shaft to access bolts.

12.Remove 6 nuts and bolts securing propeller

shaft to IRD drive flange.

13.Release propeller shaft from IRD drive flange

and tie shaft aside.

CAUTION: Care must be taken to support

the Tripode joint when removed from the

IRD unit. To avoid damage to gaiter or steel

can, the joint should not be allowed to fully

extend or be dropped.

14.Remove 3 nuts securing mass damper to

pinion housing.

15.Remove mass damper.

16.Disconnect breather hose from IRD housing.

17.Position container to collect coolant spillage.

18.Release clips and disconnect coolant hoses

from IRD.19.Remove bolt securing engine lower steady to

bracket on sump.

20.Remove engine lower steady.

21.Remove 3 bolts securing lower engine steady

bracket to sump and remove bracket.

22.Remove upper bolt securing IRD support

bracket to cylinder block.

23.Remove 5 bolts securing support bracket to

IRD.

M12 7142M12 7144

M12 7165

M12 7166

Page 414 of 1007

INTERMEDIATE REDUCTION DRIVE

REPAIRS 41-11

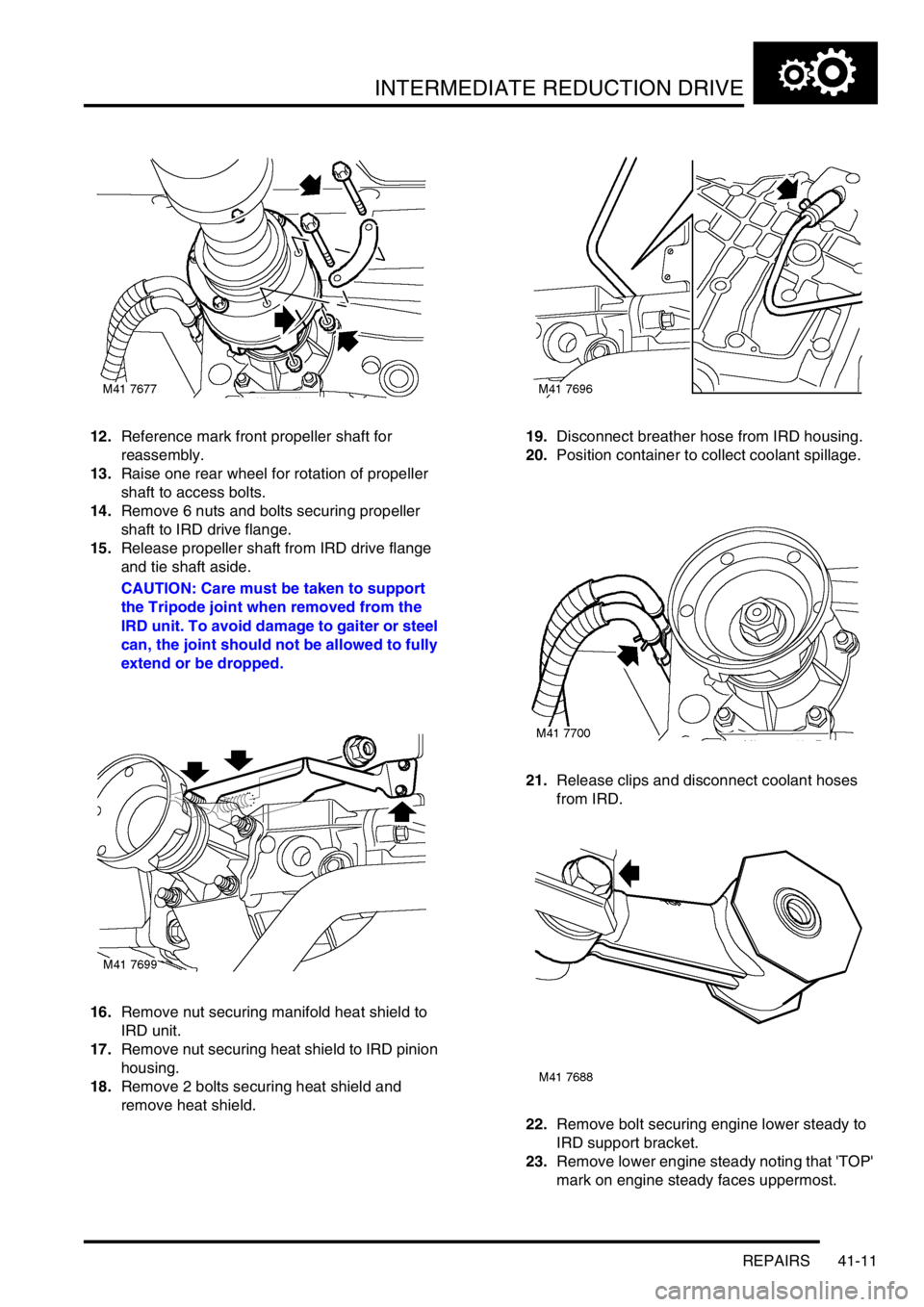

12.Reference mark front propeller shaft for

reassembly.

13.Raise one rear wheel for rotation of propeller

shaft to access bolts.

14.Remove 6 nuts and bolts securing propeller

shaft to IRD drive flange.

15.Release propeller shaft from IRD drive flange

and tie shaft aside.

CAUTION: Care must be taken to support

the Tripode joint when removed from the

IRD unit. To avoid damage to gaiter or steel

can, the joint should not be allowed to fully

extend or be dropped.

16.Remove nut securing manifold heat shield to

IRD unit.

17.Remove nut securing heat shield to IRD pinion

housing.

18.Remove 2 bolts securing heat shield and

remove heat shield.19.Disconnect breather hose from IRD housing.

20.Position container to collect coolant spillage.

21.Release clips and disconnect coolant hoses

from IRD.

22.Remove bolt securing engine lower steady to

IRD support bracket.

23.Remove lower engine steady noting that 'TOP'

mark on engine steady faces uppermost.

Page 428 of 1007

INTERMEDIATE REDUCTION DRIVE

REPAIRS 41-25

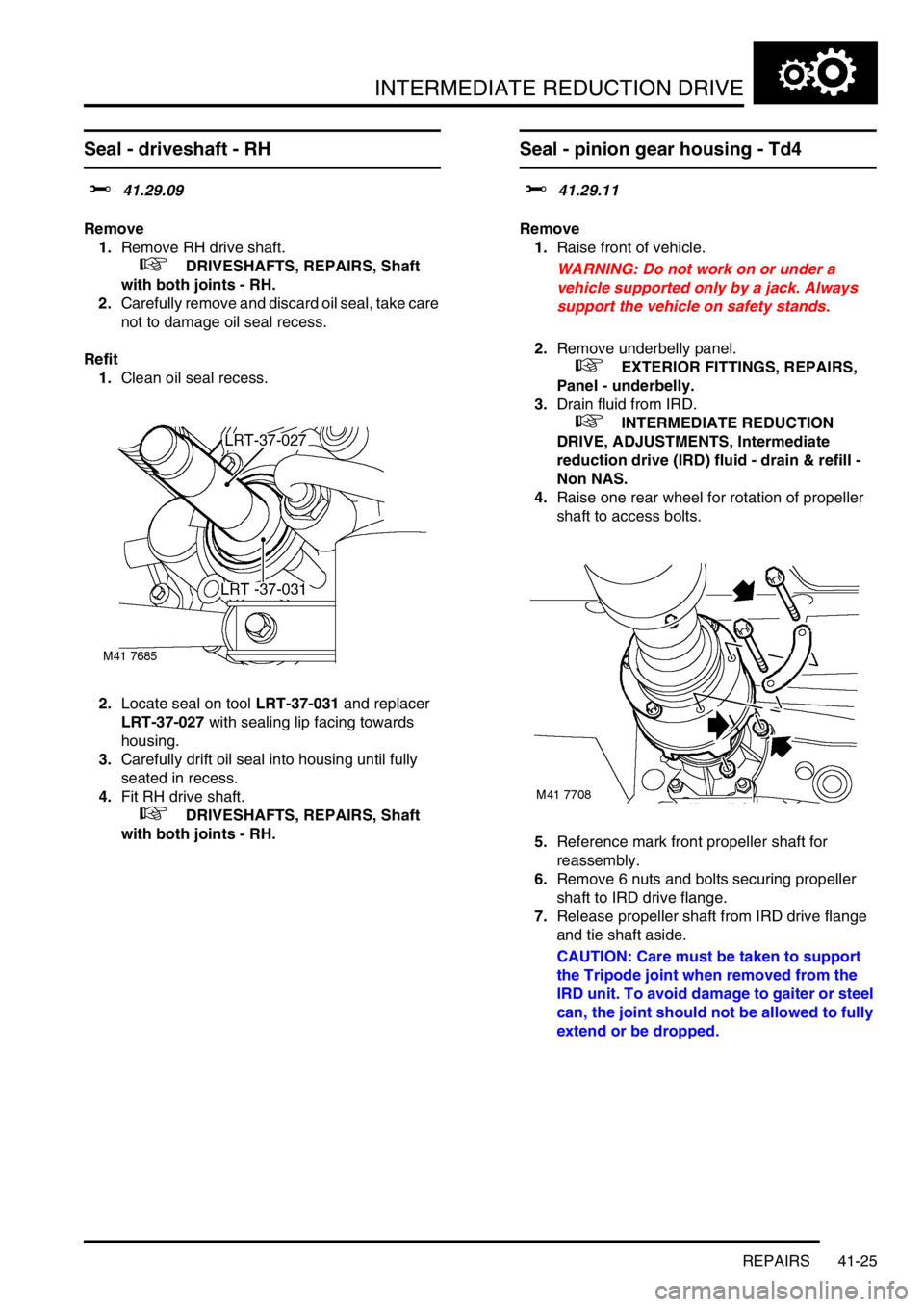

Seal - driveshaft - RH

$% 41.29.09

Remove

1.Remove RH drive shaft.

+ DRIVESHAFTS, REPAIRS, Shaft

with both joints - RH.

2.Carefully remove and discard oil seal, take care

not to damage oil seal recess.

Refit

1.Clean oil seal recess.

2.Locate seal on tool LRT-37-031 and replacer

LRT-37-027 with sealing lip facing towards

housing.

3.Carefully drift oil seal into housing until fully

seated in recess.

4.Fit RH drive shaft.

+ DRIVESHAFTS, REPAIRS, Shaft

with both joints - RH.

Seal - pinion gear housing - Td4

$% 41.29.11

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Drain fluid from IRD.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

4.Raise one rear wheel for rotation of propeller

shaft to access bolts.

5.Reference mark front propeller shaft for

reassembly.

6.Remove 6 nuts and bolts securing propeller

shaft to IRD drive flange.

7.Release propeller shaft from IRD drive flange

and tie shaft aside.

CAUTION: Care must be taken to support

the Tripode joint when removed from the

IRD unit. To avoid damage to gaiter or steel

can, the joint should not be allowed to fully

extend or be dropped.

Page 430 of 1007

INTERMEDIATE REDUCTION DRIVE

REPAIRS 41-27

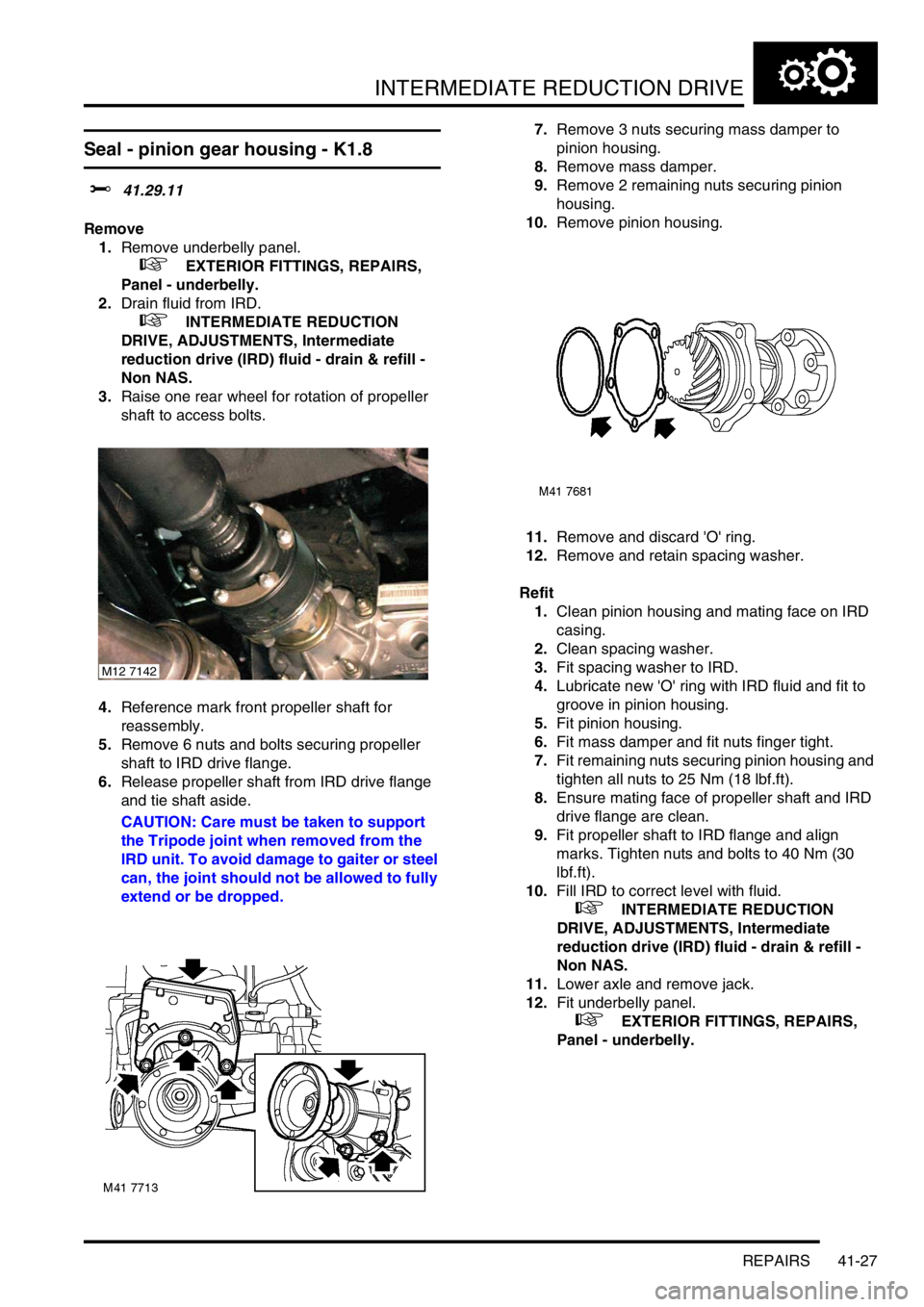

Seal - pinion gear housing - K1.8

$% 41.29.11

Remove

1.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

2.Drain fluid from IRD.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

3.Raise one rear wheel for rotation of propeller

shaft to access bolts.

4.Reference mark front propeller shaft for

reassembly.

5.Remove 6 nuts and bolts securing propeller

shaft to IRD drive flange.

6.Release propeller shaft from IRD drive flange

and tie shaft aside.

CAUTION: Care must be taken to support

the Tripode joint when removed from the

IRD unit. To avoid damage to gaiter or steel

can, the joint should not be allowed to fully

extend or be dropped.7.Remove 3 nuts securing mass damper to

pinion housing.

8.Remove mass damper.

9.Remove 2 remaining nuts securing pinion

housing.

10.Remove pinion housing.

11.Remove and discard 'O' ring.

12.Remove and retain spacing washer.

Refit

1.Clean pinion housing and mating face on IRD

casing.

2.Clean spacing washer.

3.Fit spacing washer to IRD.

4.Lubricate new 'O' ring with IRD fluid and fit to

groove in pinion housing.

5.Fit pinion housing.

6.Fit mass damper and fit nuts finger tight.

7.Fit remaining nuts securing pinion housing and

tighten all nuts to 25 Nm (18 lbf.ft).

8.Ensure mating face of propeller shaft and IRD

drive flange are clean.

9.Fit propeller shaft to IRD flange and align

marks. Tighten nuts and bolts to 40 Nm (30

lbf.ft).

10.Fill IRD to correct level with fluid.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

11.Lower axle and remove jack.

12.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

M12 7142

Page 431 of 1007

INTERMEDIATE REDUCTION DRIVE

41-28 REPAIRS

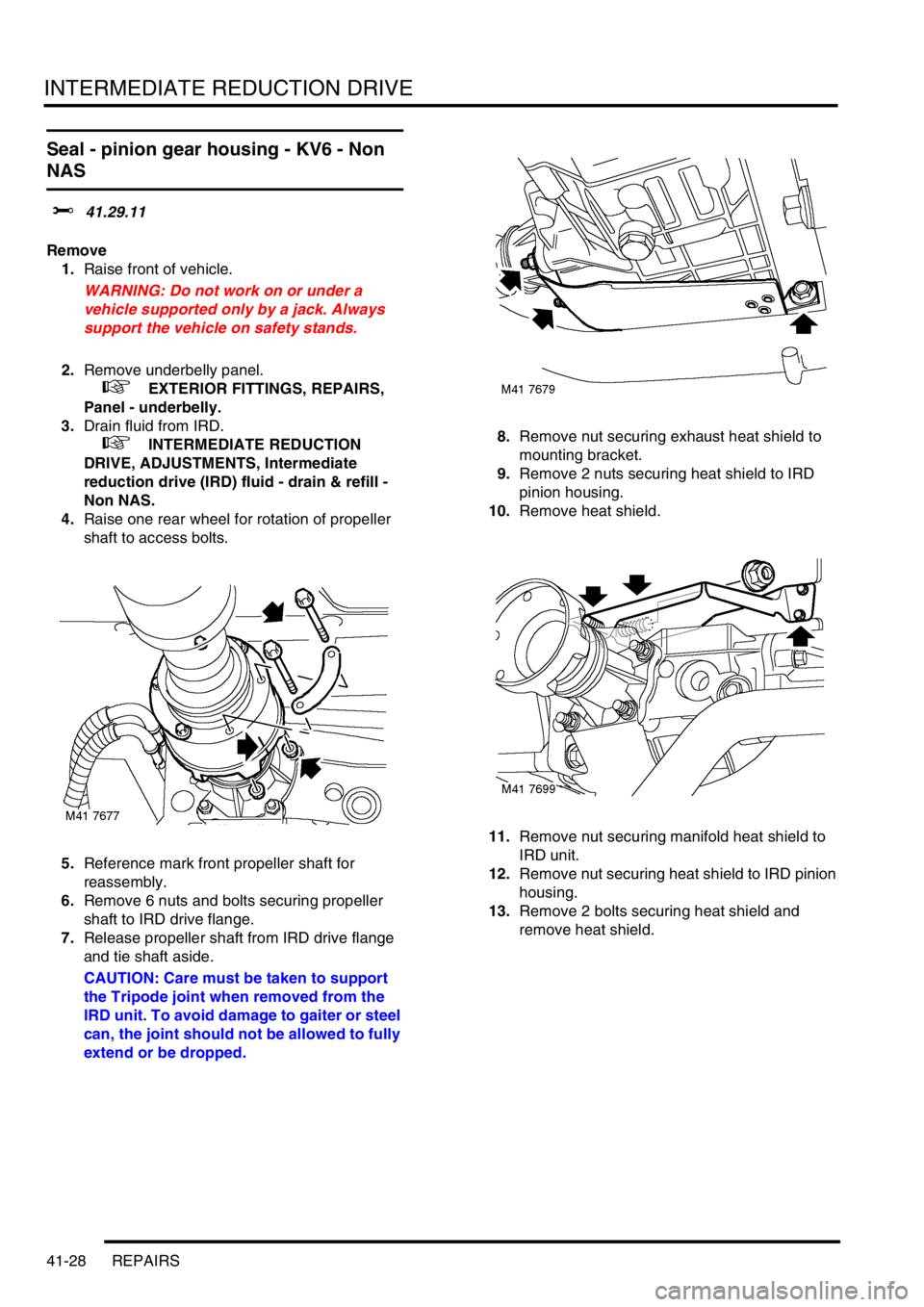

Seal - pinion gear housing - KV6 - Non

NAS

$% 41.29.11

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Drain fluid from IRD.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

4.Raise one rear wheel for rotation of propeller

shaft to access bolts.

5.Reference mark front propeller shaft for

reassembly.

6.Remove 6 nuts and bolts securing propeller

shaft to IRD drive flange.

7.Release propeller shaft from IRD drive flange

and tie shaft aside.

CAUTION: Care must be taken to support

the Tripode joint when removed from the

IRD unit. To avoid damage to gaiter or steel

can, the joint should not be allowed to fully

extend or be dropped.8.Remove nut securing exhaust heat shield to

mounting bracket.

9.Remove 2 nuts securing heat shield to IRD

pinion housing.

10.Remove heat shield.

11.Remove nut securing manifold heat shield to

IRD unit.

12.Remove nut securing heat shield to IRD pinion

housing.

13.Remove 2 bolts securing heat shield and

remove heat shield.

Page 433 of 1007

INTERMEDIATE REDUCTION DRIVE

41-30 REPAIRS

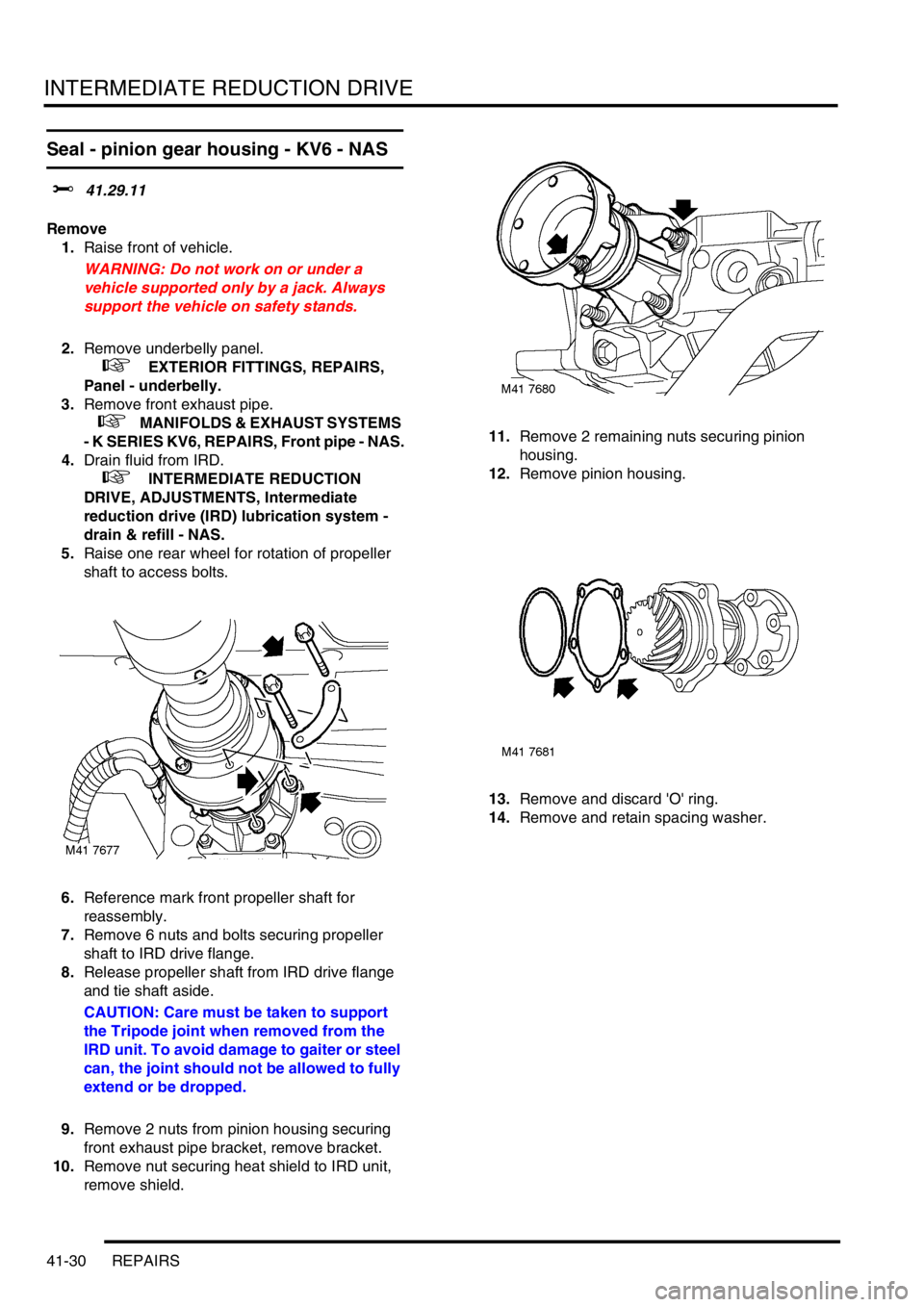

Seal - pinion gear housing - KV6 - NAS

$% 41.29.11

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Remove front exhaust pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - NAS.

4.Drain fluid from IRD.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) lubrication system -

drain & refill - NAS.

5.Raise one rear wheel for rotation of propeller

shaft to access bolts.

6.Reference mark front propeller shaft for

reassembly.

7.Remove 6 nuts and bolts securing propeller

shaft to IRD drive flange.

8.Release propeller shaft from IRD drive flange

and tie shaft aside.

CAUTION: Care must be taken to support

the Tripode joint when removed from the

IRD unit. To avoid damage to gaiter or steel

can, the joint should not be allowed to fully

extend or be dropped.

9.Remove 2 nuts from pinion housing securing

front exhaust pipe bracket, remove bracket.

10.Remove nut securing heat shield to IRD unit,

remove shield.11.Remove 2 remaining nuts securing pinion

housing.

12.Remove pinion housing.

13.Remove and discard 'O' ring.

14.Remove and retain spacing washer.