sensor LAND ROVER FREELANDER 2001 Manual PDF

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 395 of 1007

MANIFOLDS & EXHAUST SYSTEMS - K SERIES KV6

30-3-22 REPAIRS

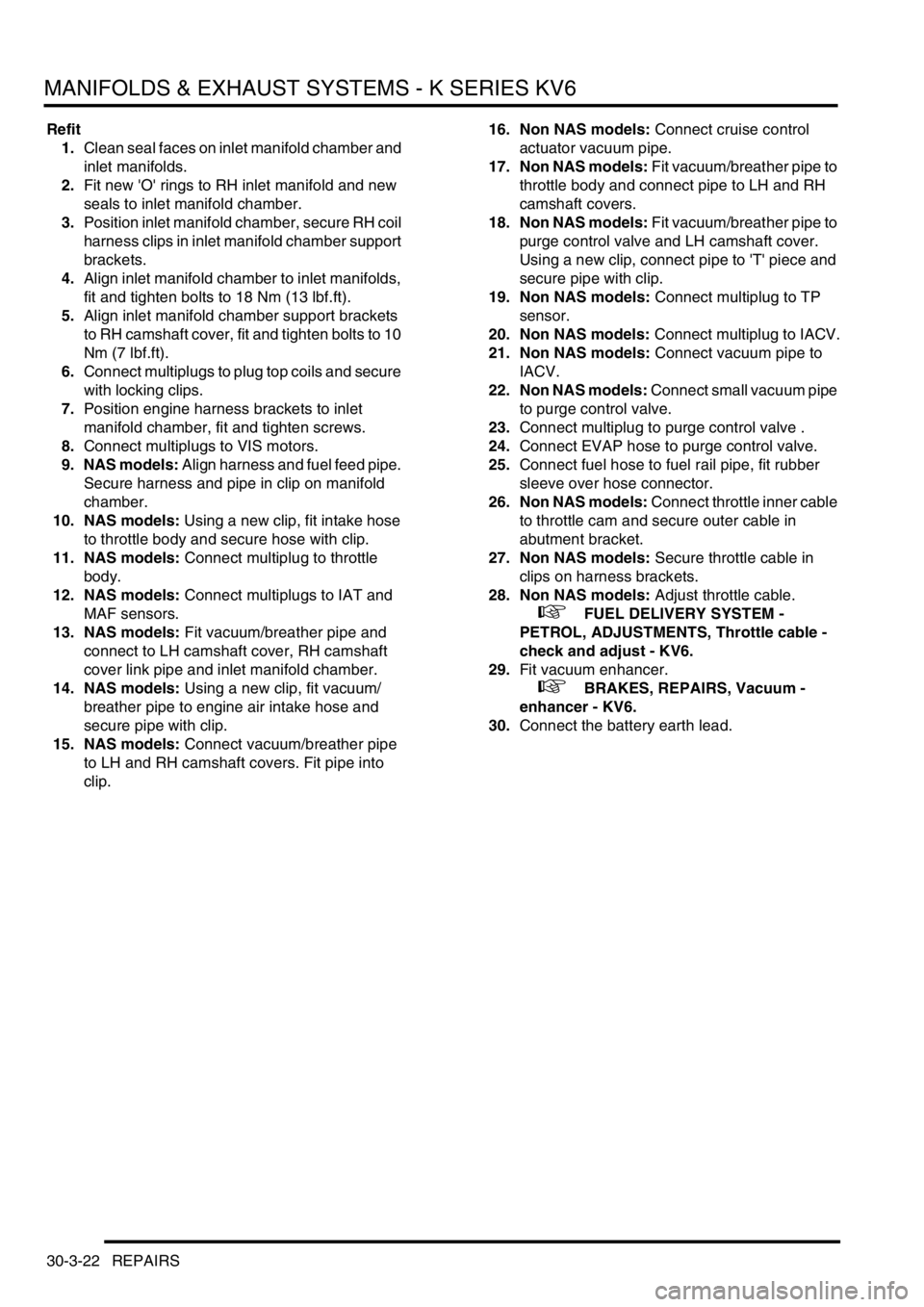

Refit

1.Clean seal faces on inlet manifold chamber and

inlet manifolds.

2.Fit new 'O' rings to RH inlet manifold and new

seals to inlet manifold chamber.

3.Position inlet manifold chamber, secure RH coil

harness clips in inlet manifold chamber support

brackets.

4.Align inlet manifold chamber to inlet manifolds,

fit and tighten bolts to 18 Nm (13 lbf.ft).

5.Align inlet manifold chamber support brackets

to RH camshaft cover, fit and tighten bolts to 10

Nm (7 lbf.ft).

6.Connect multiplugs to plug top coils and secure

with locking clips.

7.Position engine harness brackets to inlet

manifold chamber, fit and tighten screws.

8.Connect multiplugs to VIS motors.

9. NAS models: Align harness and fuel feed pipe.

Secure harness and pipe in clip on manifold

chamber.

10. NAS models: Using a new clip, fit intake hose

to throttle body and secure hose with clip.

11. NAS models: Connect multiplug to throttle

body.

12. NAS models: Connect multiplugs to IAT and

MAF sensors.

13. NAS models: Fit vacuum/breather pipe and

connect to LH camshaft cover, RH camshaft

cover link pipe and inlet manifold chamber.

14. NAS models: Using a new clip, fit vacuum/

breather pipe to engine air intake hose and

secure pipe with clip.

15. NAS models: Connect vacuum/breather pipe

to LH and RH camshaft covers. Fit pipe into

clip.16. Non NAS models: Connect cruise control

actuator vacuum pipe.

17. Non NAS models: Fit vacuum/breather pipe to

throttle body and connect pipe to LH and RH

camshaft covers.

18. Non NAS models: Fit vacuum/breather pipe to

purge control valve and LH camshaft cover.

Using a new clip, connect pipe to 'T' piece and

secure pipe with clip.

19. Non NAS models: Connect multiplug to TP

sensor.

20. Non NAS models: Connect multiplug to IACV.

21. Non NAS models: Connect vacuum pipe to

IACV.

22. Non NAS models: Connect small vacuum pipe

to purge control valve.

23.Connect multiplug to purge control valve .

24.Connect EVAP hose to purge control valve.

25.Connect fuel hose to fuel rail pipe, fit rubber

sleeve over hose connector.

26. Non NAS models: Connect throttle inner cable

to throttle cam and secure outer cable in

abutment bracket.

27. Non NAS models: Secure throttle cable in

clips on harness brackets.

28. Non NAS models: Adjust throttle cable.

+ FUEL DELIVERY SYSTEM -

PETROL, ADJUSTMENTS, Throttle cable -

check and adjust - KV6.

29.Fit vacuum enhancer.

+ BRAKES, REPAIRS, Vacuum -

enhancer - KV6.

30.Connect the battery earth lead.

Page 398 of 1007

MANIFOLDS & EXHAUST SYSTEMS - K SERIES KV6

OVERHAUL 30-3-25

OVERHAUL

Seals - manifold chamber - up to 03MY

$% 30.15.37.01

Remove

1.Disconnect multiplug from purge control valve.

2.Disconnect small vacuum hose from purge

control valve.

3.Depress locking collar and release vacuum

hose from IACV housing .

4.Disconnect multiplug from IACV.

5.Disconnect multiplug from TP sensor.

6.Depress locking collars and release vacuum/

breather hose from purge control valve and LH

camshaft cover. Release clip securing hose to

'T' piece and remove hose.

7.Depress locking collars and release vacuum/

breather hoses from throttle body, LH and RH

camshaft cover and remove hose.8.Disconnect multiplugs from VIS motors.

9.Remove 2 screws securing engine harness

brackets to inlet manifold chamber and position

harness aside.

10.Remove 2 bolts securing inlet manifold

chamber rear support brackets to RH camshaft

cover.

Page 399 of 1007

MANIFOLDS & EXHAUST SYSTEMS - K SERIES KV6

30-3-26 OVERHAUL

11.Release 2 clips securing RH plug top coil

harness to inlet manifold camber rear support

brackets.

12.Remove 4 bolts securing inlet manifold

chamber to LH inlet manifold.

13.Release and raise inlet manifold chamber from

inlet manifolds.

14.Remove inlet manifold chamber.15.Remove and discard seals from inlet manifold

chamber and 'O' rings from RH inlet manifold.

Refit

1.Clean seal faces on inlet manifold chamber and

inlet manifolds.

2.Fit new 'O' rings to RH inlet manifold and new

seals to manifold chamber.

3.Position inlet manifold chamber, secure RH coil

harness clips in inlet manifold chamber support

brackets.

4.Align inlet manifold chamber to inlet manifolds,

fit and tighten bolts to 18 Nm (13 lbf.ft).

5.Align inlet manifold chamber support brackets

to RH camshaft cover, fit and tighten bolts to 10

Nm (7.5 lbf.ft).

6.Position engine harness brackets to inlet

manifold chamber, fit and tighten screws.

7.Connect multiplugs to VIS motors.

8.Connect vacuum/breather hoses to LH and RH

camshaft covers and to throttle body.

9.Connect vacuum hose to IACV housing.

10.Connect multiplugs to TP and IACV sensors.

11.Connect vacuum/breather hoses to LH

camshaft cover, 'T' piece and purge control

valve.

12.Connect small vacuum hose to purge control

valve.

13.Connect multiplug to purge control valve .

Page 400 of 1007

MANIFOLDS & EXHAUST SYSTEMS - K SERIES KV6

OVERHAUL 30-3-27

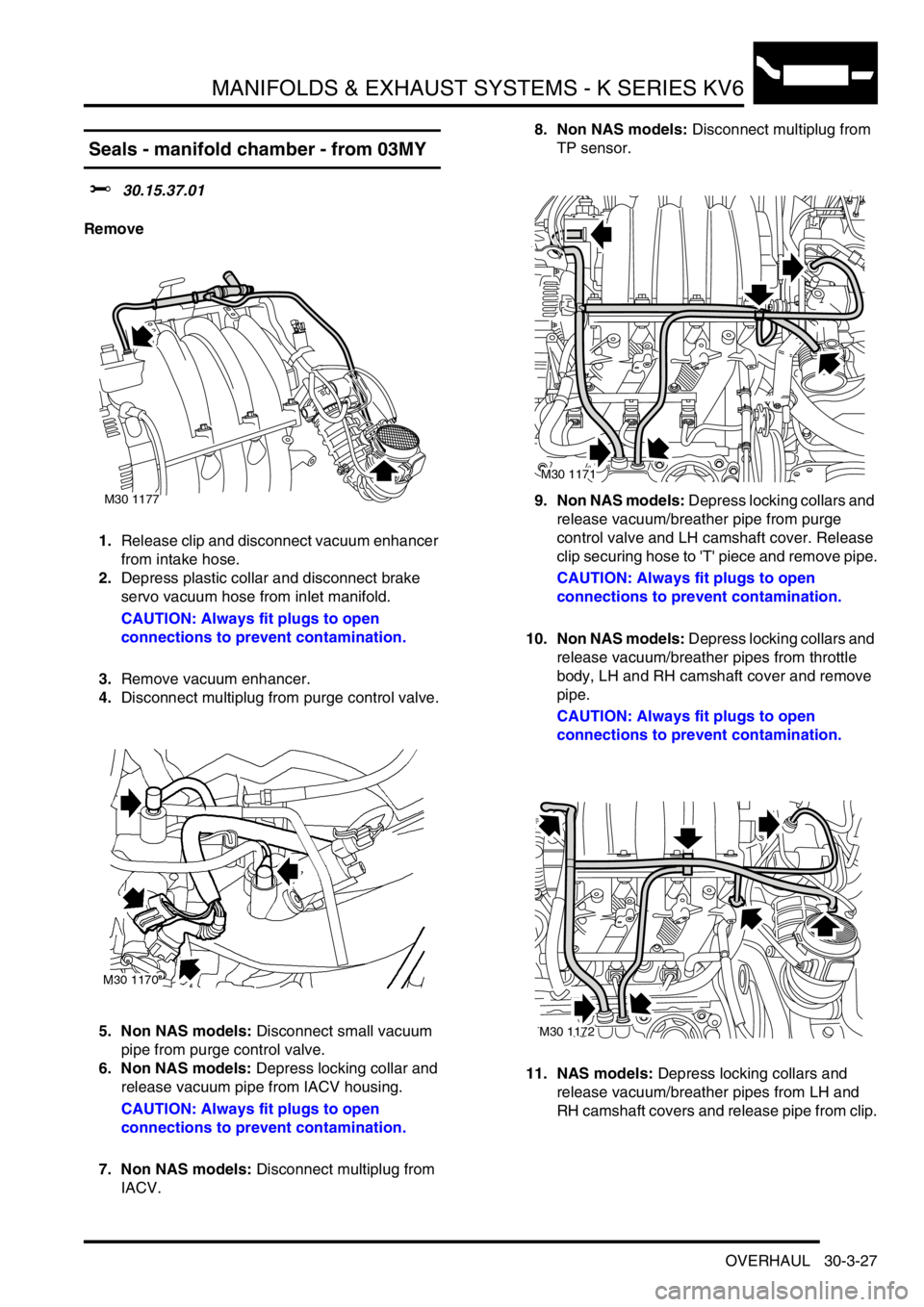

Seals - manifold chamber - from 03MY

$% 30.15.37.01

Remove

1.Release clip and disconnect vacuum enhancer

from intake hose.

2.Depress plastic collar and disconnect brake

servo vacuum hose from inlet manifold.

CAUTION: Always fit plugs to open

connections to prevent contamination.

3.Remove vacuum enhancer.

4.Disconnect multiplug from purge control valve.

5. Non NAS models: Disconnect small vacuum

pipe from purge control valve.

6. Non NAS models: Depress locking collar and

release vacuum pipe from IACV housing.

CAUTION: Always fit plugs to open

connections to prevent contamination.

7. Non NAS models: Disconnect multiplug from

IACV.8. Non NAS models: Disconnect multiplug from

TP sensor.

9. Non NAS models: Depress locking collars and

release vacuum/breather pipe from purge

control valve and LH camshaft cover. Release

clip securing hose to 'T' piece and remove pipe.

CAUTION: Always fit plugs to open

connections to prevent contamination.

10. Non NAS models: Depress locking collars and

release vacuum/breather pipes from throttle

body, LH and RH camshaft cover and remove

pipe.

CAUTION: Always fit plugs to open

connections to prevent contamination.

11. NAS models: Depress locking collars and

release vacuum/breather pipes from LH and

RH camshaft covers and release pipe from clip.

M30 1177

M30 1171

M30 1172

Page 401 of 1007

MANIFOLDS & EXHAUST SYSTEMS - K SERIES KV6

30-3-28 OVERHAUL

12. NAS models: Remove clip securing vacuum/

breather pipe to engine air intake hose and

disconnect vacuum/breather pipe from air

intake hose. Discard clip.

CAUTION: Always fit plugs to open

connections to prevent contamination.

13. NAS models: Depress locking collars and

release vacuum/breather pipe from LH

camshaft cover, RH camshaft cover link pipe

and inlet manifold chamber. Remove pipe.

CAUTION: Always fit plugs to open

connections to prevent contamination.

14. NAS models: Disconnect multiplug from IAT

and MAF sensors.

15. NAS models: Disconnect multiplug from

throttle body.

16. NAS models: Remove clip securing intake

hose to throttle body, remove intake hose and

MAF sensor assembly. Discard clip.

17. NAS models: Release harness and fuel feed

pipe from clip on inlet manifold chamber.

18.Disconnect multiplugs from VIS motors.19.Remove 2 screws securing engine harness

brackets to inlet manifold chamber and position

harness aside.

20.Release 3 locking clips and disconnect 3

multiplugs from RH plug top coils.

21.Release 2 clips securing RH plug top coil

harness to inlet manifold chamber support

brackets.

M30 1173

M30 1176

Page 403 of 1007

MANIFOLDS & EXHAUST SYSTEMS - K SERIES KV6

30-3-30 OVERHAUL

Refit

1.Clean seal faces on inlet manifold chamber and

inlet manifolds.

2.Fit new 'O' rings to RH inlet manifold and new

seals to inlet manifold chamber.

3.Fit inlet manifold chamber to inlet manifolds

and tighten bolts to 18 Nm (13 lbf.ft).

4.Align inlet manifold chamber support brackets

to RH camshaft cover, fit and tighten bolts to 10

Nm (7 lbf.ft).

5.Position engine harness brackets to inlet

manifold chamber, fit and tighten screws.

6.Secure RH plug top coil harness to manifold

chamber support brackets.

7.Connect multiplugs to plug top coils and secure

with locking clips.

8.Connect multiplugs to VIS motors.

9. NAS models: Align harness and fuel feed pipe.

Secure harness and pipe in clip on manifold

chamber.

10. NAS models: Using a new clip, fit intake hose

to throttle body and secure hose with clip.

11. NAS models: Connect multiplug to throttle

body.

12. NAS models: Connect multiplugs to IAT and

MAF sensors.13. NAS models: Fit vacuum/breather pipe and

connect to LH camshaft cover, RH camshaft

cover link pipe and inlet manifold chamber.

14. NAS models: Using a new clip, fit vacuum/

breather pipe to engine air intake hose and

secure pipe with clip.

15. NAS models: Connect vacuum/breather pipe

to LH and RH camshaft covers. Fit pipe into

clip.

16. Non NAS models: Fit vacuum/breather pipe to

throttle body and connect pipe to LH and RH

camshaft covers.

17. Non NAS models: Fit vacuum/breather pipe to

purge control valve and LH camshaft cover.

Using a new clip, connect pipe to 'T' piece and

secure pipe with clip.

18. Non NAS models: Connect multiplug to TP

sensor.

19. Non NAS models: Connect multiplug to IACV.

20. Non NAS models: Connect vacuum pipe to

IACV.

21. Non NAS models: Connect small vacuum pipe

to purge control valve..

22.Connect multiplug to purge control valve .

23.Fit vacuum enhancer and connect to inlet

manifold chamber.

24.Using a new clip, connect vacuum enhancer to

intake hose and secure hose with clip.

Page 449 of 1007

AUTOMATIC GEARBOX - JATCO

44-14 REPAIRS

18.Remove 2 bolts securing torque converter

access plate.

19.Remove access plate.

20.Mark drive plate to torque converter, for refit

purposes.

21.Remove 4 bolts securing drive plate to

converter.

22.Remove bolt securing IRD cooling hose

retainer. Remove retainer.23.Remove bolts securing LRT-44-026 lifting

bracket to gearbox and remove bracket.

24.Remove 3 bolts securing starter motor to

gearbox noting that the LH bolt also secures

the mounting bracket for the CKP sensor

multiplug.

25.Remove starter motor.

M44 1661

M44 1649

Page 450 of 1007

AUTOMATIC GEARBOX - JATCO

REPAIRS 44-15

26.Disconnect 2 fluid cooler hose unions and

discard 'O' rings.

CAUTION: Always fit plugs to open

connections to prevent contamination.

27.Release 2 clips and disconnect coolant hoses

from fluid cooler.

28.Remove bolts securing fluid cooler.

29.Remove fluid cooler.30.Remove bolt securing CKP sensor to gearbox,

release sensor and position aside.

31.Remove nut and bolt, adjacent to CKP sensor,

securing gearbox to engine.

32.Fit suitable lifting brackets to gearbox and

secure with nuts and bolts.

33.Connect lifting equipment to brackets.

34.Remove 2 bolts securing gearbox to engine.

M44 1639

M44 1665

M44 1651

Page 451 of 1007

AUTOMATIC GEARBOX - JATCO

44-16 REPAIRS

35.Remove 2 top bolts securing gearbox to

engine.

36.Release gearbox from 2 dowels.

37.Remove gearbox assembly.

38.Fit converter retaining plate and secure with

bolts.Refit

1.Remove torque converter retaining plate.

2.Ensure converter is fully located in oil pump

drive by checking depth 'A' as illustrated. Depth

A = 4 mm.

3.Clean gearbox to engine mating faces, dowels

and dowel holes.

4.Fit gearbox assembly.

5.Fit bolts securing gearbox and tighten to 85 Nm

(63 lbf.ft).

6.Disconnect lifting equipment.

7.Clean CKP sensor and mating face.

8.Fit CKP sensor, fit bolt and tighten to 9 Nm (7

lbf.ft).

9.Position fluid cooler, tighten M12 bolts to 85 Nm

(63 lbf.ft) and M8 bolt to 25 Nm (18 lbf.ft).

10.Connect hoses to fluid cooler.

11.Clean fluid cooler unions.

12.Lubricate new 'O' rings with clean transmission

fluid and fit 'O' rings to fluid cooler hoses.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

13.Connect fluid cooler hoses to gearbox and

tighten unions to 18 Nm (13 lbf.ft).

14.Clean starter motor mating faces.

15.Position starter motor to gearbox, align CKP

sensor multiplug bracket, fit and tighten bolts to

45 Nm (33 lbf.ft).

16.Using gearbox bracket bolts, secure LRT-44-

026 lifting bracket to gearbox.

17.Position IRD cooling hose retainer, fit bolt and

tighten to 25 Nm (18 lbf.ft).

18.Align marks on drive plate to torque converter.

19.Fit bolts securing drive plate to torque converter

and tighten bolts to 45 Nm (33 lbf.ft).

20.Clean torque converter access plate.

M44 1689

A

M44 1668

Page 454 of 1007

AUTOMATIC GEARBOX - JATCO

REPAIRS 44-19

16.Remove 2 bolts securing gearbox to engine.

17.Release HO2S multiplug from support bracket

on LH camshaft cover, disconnect multiplug.

18.Remove 4 nuts securing LH exhaust manifold

to cylinder head.

19.Remove exhaust manifold, remove and discard

gasket.

20.Position container to collect fluid spillage.21.Disconnect 2 fluid cooler hose unions and

discard 'O' rings.

CAUTION: Always fit plugs to open

connections to prevent contamination.

22.Remove 3 bolts securing fluid cooler bracket.

23.Move fluid cooler aside.

24.Remove bolt securing CKP sensor to gearbox,

release sensor and position aside.

M44 1651M44 1639

M44 1665