sensor LAND ROVER FREELANDER 2001 Service Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 220 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-43

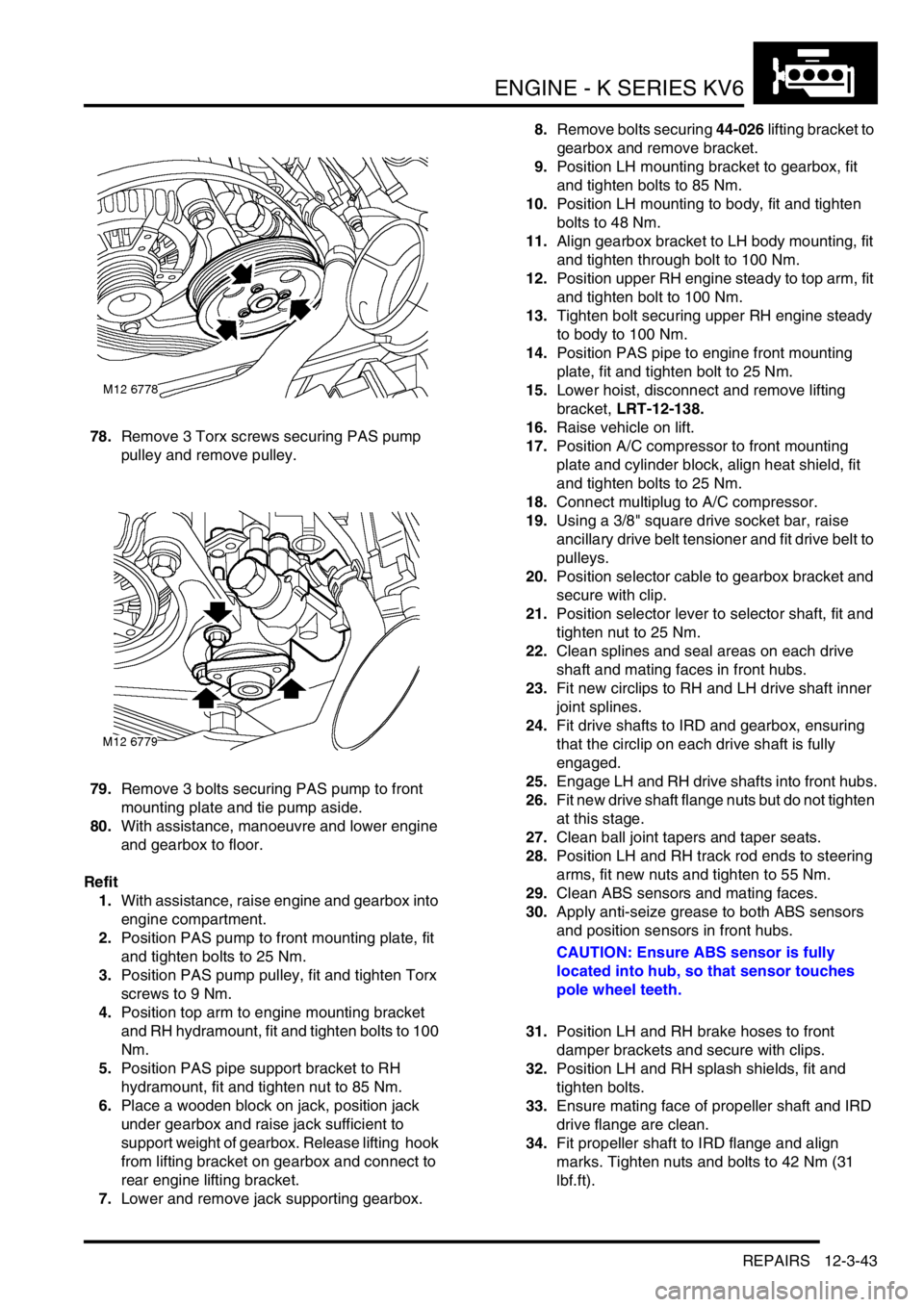

78.Remove 3 Torx screws securing PAS pump

pulley and remove pulley.

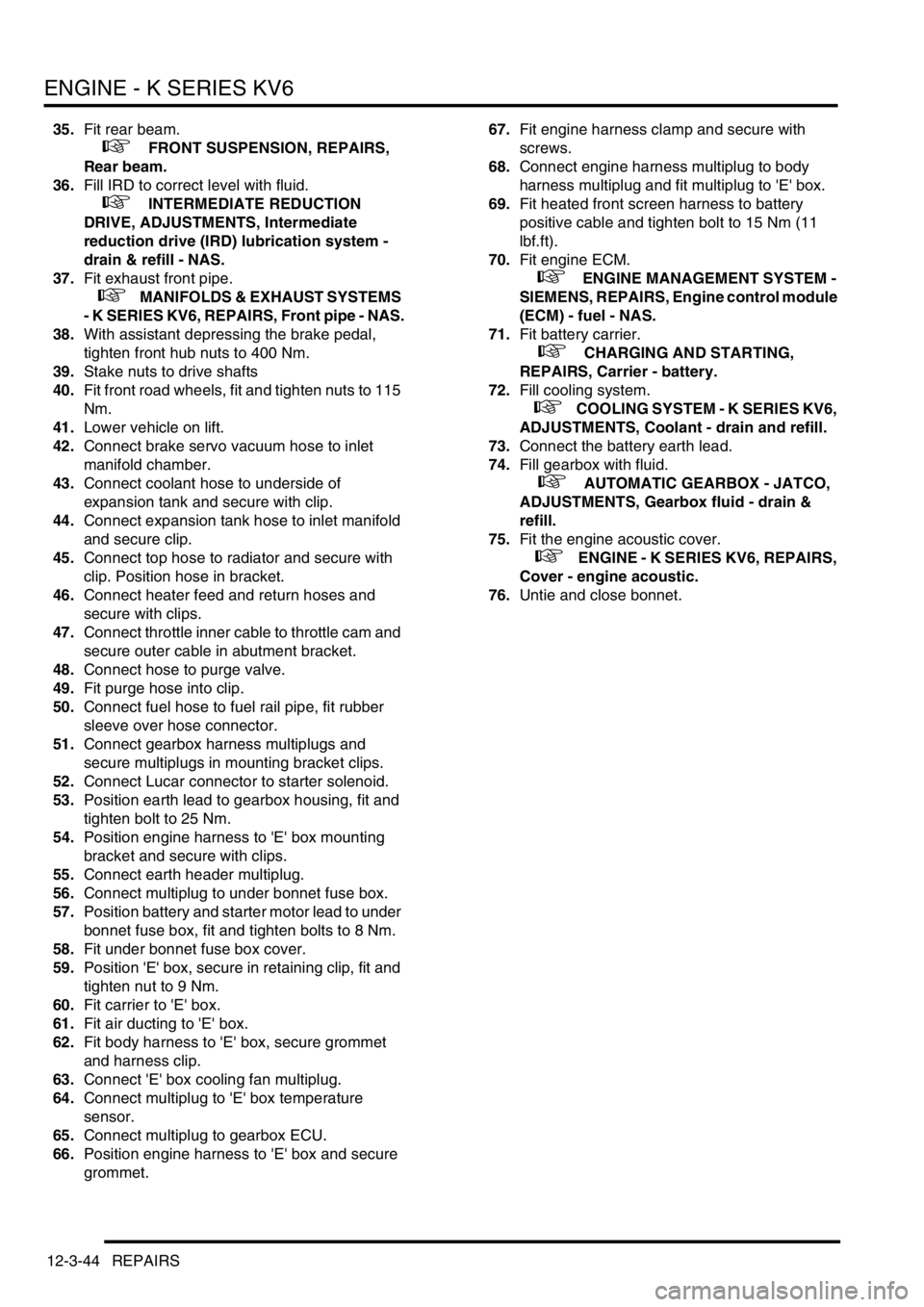

79.Remove 3 bolts securing PAS pump to front

mounting plate and tie pump aside.

80.With assistance, manoeuvre and lower engine

and gearbox to floor.

Refit

1.With assistance, raise engine and gearbox into

engine compartment.

2.Position PAS pump to front mounting plate, fit

and tighten bolts to 25 Nm.

3.Position PAS pump pulley, fit and tighten Torx

screws to 9 Nm.

4.Position top arm to engine mounting bracket

and RH hydramount, fit and tighten bolts to 100

Nm.

5.Position PAS pipe support bracket to RH

hydramount, fit and tighten nut to 85 Nm.

6.Place a wooden block on jack, position jack

under gearbox and raise jack sufficient to

support weight of gearbox. Release lifting hook

from lifting bracket on gearbox and connect to

rear engine lifting bracket.

7.Lower and remove jack supporting gearbox.8.Remove bolts securing 44-026 lifting bracket to

gearbox and remove bracket.

9.Position LH mounting bracket to gearbox, fit

and tighten bolts to 85 Nm.

10.Position LH mounting to body, fit and tighten

bolts to 48 Nm.

11.Align gearbox bracket to LH body mounting, fit

and tighten through bolt to 100 Nm.

12.Position upper RH engine steady to top arm, fit

and tighten bolt to 100 Nm.

13.Tighten bolt securing upper RH engine steady

to body to 100 Nm.

14.Position PAS pipe to engine front mounting

plate, fit and tighten bolt to 25 Nm.

15.Lower hoist, disconnect and remove lifting

bracket, LRT-12-138.

16.Raise vehicle on lift.

17.Position A/C compressor to front mounting

plate and cylinder block, align heat shield, fit

and tighten bolts to 25 Nm.

18.Connect multiplug to A/C compressor.

19.Using a 3/8" square drive socket bar, raise

ancillary drive belt tensioner and fit drive belt to

pulleys.

20.Position selector cable to gearbox bracket and

secure with clip.

21.Position selector lever to selector shaft, fit and

tighten nut to 25 Nm.

22.Clean splines and seal areas on each drive

shaft and mating faces in front hubs.

23.Fit new circlips to RH and LH drive shaft inner

joint splines.

24.Fit drive shafts to IRD and gearbox, ensuring

that the circlip on each drive shaft is fully

engaged.

25.Engage LH and RH drive shafts into front hubs.

26.Fit new drive shaft flange nuts but do not tighten

at this stage.

27.Clean ball joint tapers and taper seats.

28.Position LH and RH track rod ends to steering

arms, fit new nuts and tighten to 55 Nm.

29.Clean ABS sensors and mating faces.

30.Apply anti-seize grease to both ABS sensors

and position sensors in front hubs.

CAUTION: Ensure ABS sensor is fully

located into hub, so that sensor touches

pole wheel teeth.

31.Position LH and RH brake hoses to front

damper brackets and secure with clips.

32.Position LH and RH splash shields, fit and

tighten bolts.

33.Ensure mating face of propeller shaft and IRD

drive flange are clean.

34.Fit propeller shaft to IRD flange and align

marks. Tighten nuts and bolts to 42 Nm (31

lbf.ft).

Page 221 of 1007

ENGINE - K SERIES KV6

12-3-44 REPAIRS

35.Fit rear beam.

+ FRONT SUSPENSION, REPAIRS,

Rear beam.

36.Fill IRD to correct level with fluid.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) lubrication system -

drain & refill - NAS.

37.Fit exhaust front pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - NAS.

38.With assistant depressing the brake pedal,

tighten front hub nuts to 400 Nm.

39.Stake nuts to drive shafts

40.Fit front road wheels, fit and tighten nuts to 115

Nm.

41.Lower vehicle on lift.

42.Connect brake servo vacuum hose to inlet

manifold chamber.

43.Connect coolant hose to underside of

expansion tank and secure with clip.

44.Connect expansion tank hose to inlet manifold

and secure clip.

45.Connect top hose to radiator and secure with

clip. Position hose in bracket.

46.Connect heater feed and return hoses and

secure with clips.

47.Connect throttle inner cable to throttle cam and

secure outer cable in abutment bracket.

48.Connect hose to purge valve.

49.Fit purge hose into clip.

50.Connect fuel hose to fuel rail pipe, fit rubber

sleeve over hose connector.

51.Connect gearbox harness multiplugs and

secure multiplugs in mounting bracket clips.

52.Connect Lucar connector to starter solenoid.

53.Position earth lead to gearbox housing, fit and

tighten bolt to 25 Nm.

54.Position engine harness to 'E' box mounting

bracket and secure with clips.

55.Connect earth header multiplug.

56.Connect multiplug to under bonnet fuse box.

57.Position battery and starter motor lead to under

bonnet fuse box, fit and tighten bolts to 8 Nm.

58.Fit under bonnet fuse box cover.

59.Position 'E' box, secure in retaining clip, fit and

tighten nut to 9 Nm.

60.Fit carrier to 'E' box.

61.Fit air ducting to 'E' box.

62.Fit body harness to 'E' box, secure grommet

and harness clip.

63.Connect 'E' box cooling fan multiplug.

64.Connect multiplug to 'E' box temperature

sensor.

65.Connect multiplug to gearbox ECU.

66.Position engine harness to 'E' box and secure

grommet.67.Fit engine harness clamp and secure with

screws.

68.Connect engine harness multiplug to body

harness multiplug and fit multiplug to 'E' box.

69.Fit heated front screen harness to battery

positive cable and tighten bolt to 15 Nm (11

lbf.ft).

70.Fit engine ECM.

+ ENGINE MANAGEMENT SYSTEM -

SIEMENS, REPAIRS, Engine control module

(ECM) - fuel - NAS.

71.Fit battery carrier.

+ CHARGING AND STARTING,

REPAIRS, Carrier - battery.

72.Fill cooling system.

+ COOLING SYSTEM - K SERIES KV6,

ADJUSTMENTS, Coolant - drain and refill.

73.Connect the battery earth lead.

74.Fill gearbox with fluid.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Gearbox fluid - drain &

refill.

75.Fit the engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

76.Untie and close bonnet.

Page 313 of 1007

ENGINE MANAGEMENT SYSTEM - SIEMENS

18-3-8 REPAIRS

Sensor - intake air temperature (IAT) -

NAS

$% 18.30.09

Remove

1.Disconnect multiplug from IAT sensor.

2.Release clip and remove IAT sensor. Discard

seal.

Refit

1.Clean IAT sensor and mating face.

2.Fit new seal to sensor.

3.Fit IAT sensor and connect multiplug.

Sensor - engine coolant temperature

(ECT)

$% 18.30.10

Remove

1.Disconnect battery earth lead.

2.Remove thermostat.

+ COOLING SYSTEM - K SERIES KV6,

REPAIRS, Thermostat.

3.Disconnect multiplug from coolant temperature

sensor.

4.Remove coolant temperature sensor and

discard sealing washer.

5.Remove coolant temperature sensor from

cylinder block.

6.Remove steel shim and sealing washer from

temperature sensor, discard sealing washer.

Refit

1.Clean coolant temperature sensor and mating

face on cylinder block.

2.Fit new sealing washer, then steel shim to

coolant temperature sensor.

3.Position coolant temperature sensor and

tighten to 17 Nm (12.5 lbf.ft).

4.Fit thermostat.

+ COOLING SYSTEM - K SERIES KV6,

REPAIRS, Thermostat.

5.Connect battery earth lead.

Page 314 of 1007

ENGINE MANAGEMENT SYSTEM - SIEMENS

REPAIRS 18-3-9

Sensor - crankshaft position (CKP)

$% 18.30.12

Remove

1.Disconnect battery earth lead.

2.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

3.Disconnect CKP sensor multiplug from engine

harness.

4.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

5.Remove bolt securing CKP sensor to gearbox

housing and remove sensor.Refit

1.Clean CKP sensor and mating face.

2.Position CKP sensor, fit and tighten bolt to 9

Nm (6.5 lbf.ft).

3.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

4.Connect CKP sensor multiplug to engine

harness.

5.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

6.Connect battery earth lead.

Page 315 of 1007

ENGINE MANAGEMENT SYSTEM - SIEMENS

18-3-10 REPAIRS

Sensor - throttle position (TP)

$% 18.30.17

Remove

1.Disconnect battery earth lead.

2.Remove acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

3.Disconnect multiplug from TP sensor.

4.Remove and discard 2 Torx screws and wave

washers securing TP sensor to inlet manifold.

5.Remove TP sensor specification plate.6.Pull TP sensor from throttle spindle.

CAUTION: Do not twist or apply leverage to

throttle position sensor.

Refit

1.Clean mating faces of throttle housing and TP

sensor.

2.Fit TP sensor to throttle spindle. Ensure that

during fitting the machined flat on the throttle

spindle is aligned with the mating portion of the

TP sensor

CAUTION: The throttle position sensor can

be easily damaged during fitting. When

pressing the sensor onto the throttle

spindle, use fingers only, and only apply

pressure to the area shown shaded in the

illustration.

3.Rotate TP sensor in an anti-clockwise direction

to align fixing holes.

CAUTION: Do not rotate throttle position

sensor in a clockwise direction and ensure

that it is not rotated beyond its internal

stops.

4.Fit TP sensor specification plate.

M18 0695

Page 316 of 1007

ENGINE MANAGEMENT SYSTEM - SIEMENS

REPAIRS 18-3-11

5.Fit new Torx screws and wave washers, tighten

Torx screws to 1.5 Nm (1.1 lbf.ft).

6.Connect multiplug to TP sensor.

7.Operate throttle cable cam 2 or 3 times and

ensure that full travel to the throttle open and

the throttle closed positions is available.

8.Fit acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

9.Connect battery earth lead.

NOTE: A ‘throttle initialisation’ procedure

MUST be carried out using TestBook/T4

whenever the TP sensor is removed or

renewed.

Sensor - thermostat monitoring (TM) -

KV6 - NAS

$% 18.30.21

Remove

1.Disconnect battery earth lead.

2.Remove coolant expansion tank cap to release

pressure and refit cap.

WARNING: Since injury such as scalding

could be caused by escaping steam or

coolant, do not remove the filler cap from

the coolant expansion tank while the

system is hot.

3.Position absorbent cloth under TM sensor to

collect spillage.

4.Disconnect multiplug from TM sensor.

5.Release and remove sensor. Discard seal.

Refit

1.Clean sensor and mating face.

2.Using a new seal, fit and secure sensor.

3.Connect multiplug to sensor.

4.Remove absorbent cloth.

5.Check for leaks and fill expansion tank to 'MAX'

mark.

6.Connect battery earth lead.

M18 0764

Page 317 of 1007

ENGINE MANAGEMENT SYSTEM - SIEMENS

18-3-12 REPAIRS

Sensor - camshaft position (CMP)

$% 18.30.24

Remove

1.Disconnect battery earth lead.

2.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

3.Release CMP multiplug from bracket and

disconnect multiplug.

4.Remove bolt securing CMP sensor multiplug

bracket and release CMP sensor lead from

behind bracket.

5.Remove bolt securing CMP sensor to camshaft

cover.

6.Remove CMP sensor and discard seal.Refit

1.Clean CMP sensor and mating face.

2.Lubricate new seal with clean engine oil and fit

to CMP sensor.

3.Position CMP sensor, fit and tighten bolt to 8

Nm (6 lbf.ft).

4.Feed CMP sensor lead behind multiplug

bracket, align bracket, fit bolt and tighten to 8

Nm (6 lbf.ft).

5.Connect CMP sensor multiplug and secure to

bracket.

6.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

7.Connect battery earth lead.

Page 318 of 1007

ENGINE MANAGEMENT SYSTEM - SIEMENS

REPAIRS 18-3-13

Sensor - knock (KS)

$% 18.30.28

Remove

1.Disconnect battery earth lead.

2.Remove LH inlet manifold.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Gasket - inlet

manifold - LH.

3.Disconnect KS multiplug.

4.Note the routing of each KS harness.

5.Remove 2 bolts securing KS to cylinder block

and remove sensors.

Refit

1.Clean KS and mating faces on cylinder block.

2.Position KS, ensure that harnesses are

correctly routed, fit and tighten bolts to 25 Nm

(18 lbf.ft).

3.Connect KS multiplug.

4.Fit LH inlet manifold.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Gasket - inlet

manifold - LH.

5.Connect battery earth lead.

Switch - throttle pedal - Non NAS

$% 18.30.36

Remove

1.Remove 2 nuts securing throttle pedal

assembly to bulkhead.

2.Release clip securing throttle inner cable to

throttle pedal and disconnect inner cable from

pedal.

3.Disconnect multiplug from throttle pedal switch.

4.Remove throttle pedal assembly from vehicle.

Page 319 of 1007

ENGINE MANAGEMENT SYSTEM - SIEMENS

18-3-14 REPAIRS

5.Release throttle pedal switch from bracket on

throttle pedal assembly.

6.Release clips securing switch bracket to pedal

assembly and remove bracket.

Refit

1.Fit switch bracket to throttle pedal assembly

and secure with clips

2.Position switch and push fully into bracket on

pedal assembly.

3.To correctly position throttle pedal switch, move

throttle pedal to the closed position and ensure

that switch is in contact with tang on throttle

pedal.

4.Connect multiplug to throttle pedal switch.

5.Connect throttle inner cable to throttle pedal

and secure with clip.

6.Position throttle pedal assembly to bulkhead, fit

and tighten nuts to 25 Nm (18 lbf.ft).

Sensor - combined - manifold absolute

pressure/Intake air temperature (MAP/

IAT)

$% 19.22.26

Remove

1.Disconnect battery earth lead.

2.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

3.Disconnect multiplug from MAP/IAT sensor.

4.Remove 2 screws securing MAP/IAT sensor to

inlet manifold chamber, remove sensor.

Refit

1.Clean MAP/IAT sensor and mating face on inlet

manifold chamber.

2.Position MAP/IAT sensor, fit and tighten

screws.

3.Connect multiplug to MAP/IAT sensor.

4.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

5.Connect battery earth lead.

M19 3182

M19 3197

Page 320 of 1007

ENGINE MANAGEMENT SYSTEM - SIEMENS

REPAIRS 18-3-15

Sensor - throttle position (TP) - NAS - up

to 03MY

$% 19.22.49

Remove

1.Disconnect battery earth lead.

2.Remove 2 nuts and release throttle pedal from

studs.

3.Release TP sensor multiplug from bracket and

disconnect from main harness.

4.Remove nut and release lever from sensor.

5.Remove 2 nuts and bolts and remove sensor.Refit

1.Fit TP sensor and tighten nuts and bolts to 10

Nm (7 lbf.ft).

2.With throttle pedal held closed, fit lever to

sensor and tighten nut to 10 Nm (7 lbf.ft).

3.Position throttle pedal, connect multiplug and

secure to pedal bracket.

4.Fit pedal to studs and tighten nuts to 25 Nm (18

lbf.ft).

5.Connect battery earth lead.

6.Use TestBook/T4 to confirm correct operation.