LAND ROVER FRELANDER 2 2006 Repair Manual

Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 111 of 3229

Publ is hed: 28-Apr-2011

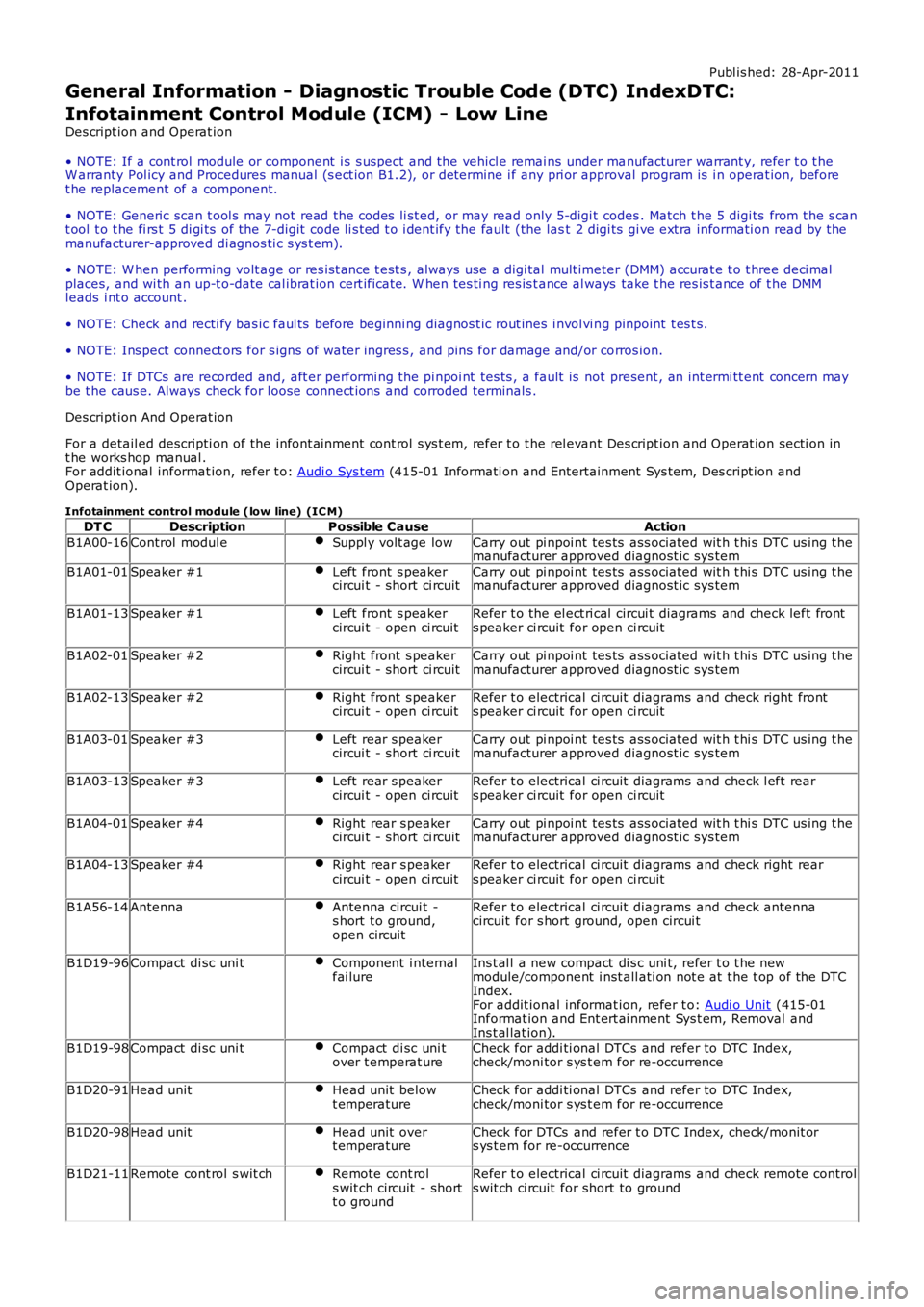

General Information - Diagnostic Trouble Code (DTC) IndexDTC:

Infotainment Control Module (ICM) - Low Line

Des cript ion and Operat ion

• NOTE: If a cont rol module or component i s s uspect and the vehicl e remai ns under manufacturer warrant y, refer t o t heW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval program is i n operat ion, beforet he replacement of a component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only 5-digi t codes . Match t he 5 digi ts from t he s cant ool t o t he fi rs t 5 di gi ts of the 7-digit code li s ted t o i dent ify the fault (the last 2 digi ts gi ve ext ra informati on read by themanufacturer-approved di agnos ti c s ys t em).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces, and wi th an up-t o-date cal ibrat ion cert ificate. W hen tes ti ng res is t ance al ways take t he res is t ance of t he DMMleads i nt o account .

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

Des cript ion And Operat ion

For a detail ed descripti on of the infont ai nment cont rol s ys t em, refer t o t he rel evant Des cript ion and Operat ion secti on int he works hop manual .For addit ional informat ion, refer t o: Audi o Sys tem (415-01 Informati on and Entertainment Sys tem, Des cript ion andOperat ion).

Infotainment control module (low line) (IC M)

DT CDescriptionPossible CauseAction

B1A00-16Control modul eSuppl y volt age lowCarry out pi npoi nt tes ts ass ociated wit h t hi s DTC us ing t hemanufacturer approved diagnost ic sys tem

B1A01-01Speaker #1Left front s peakercircui t - short ci rcuitCarry out pi npoi nt tes ts ass ociated wit h t hi s DTC us ing t hemanufacturer approved diagnost ic sys tem

B1A01-13Speaker #1Left front s peakercircui t - open ci rcuitRefer t o the el ect ri cal circui t diagrams and check left fronts peaker ci rcuit for open ci rcuit

B1A02-01Speaker #2Right front s peakercircui t - short ci rcuitCarry out pi npoi nt tes ts ass ociated wit h t hi s DTC us ing t hemanufacturer approved diagnost ic sys tem

B1A02-13Speaker #2Right front s peakercircui t - open ci rcuitRefer t o electrical ci rcuit diagrams and check right fronts peaker ci rcuit for open ci rcuit

B1A03-01Speaker #3Left rear s peakercircui t - short ci rcuitCarry out pi npoi nt tes ts ass ociated wit h t hi s DTC us ing t hemanufacturer approved diagnost ic sys tem

B1A03-13Speaker #3Left rear s peakercircui t - open ci rcuitRefer t o electrical ci rcuit diagrams and check l eft rears peaker ci rcuit for open ci rcuit

B1A04-01Speaker #4Right rear s peakercircui t - short ci rcuitCarry out pi npoi nt tes ts ass ociated wit h t hi s DTC us ing t hemanufacturer approved diagnost ic sys tem

B1A04-13Speaker #4Right rear s peakercircui t - open ci rcuitRefer t o electrical ci rcuit diagrams and check right rears peaker ci rcuit for open ci rcuit

B1A56-14AntennaAntenna circui t -s hort t o ground,open circuit

Refer t o electrical ci rcuit diagrams and check antennacircuit for s hort ground, open circui t

B1D19-96Compact di sc uni tComponent i nternalfai lureIns t al l a new compact di s c uni t, refer t o t he newmodule/component i nst all ati on not e at t he t op of the DTCIndex.For addit ional informat ion, refer t o: Audi o Unit (415-01Informat ion and Ent ert ai nment Sys t em, Removal andIns t al lat ion).

B1D19-98Compact di sc uni tCompact di sc uni tover t emperat ureCheck for addi ti onal DTCs and refer to DTC Index,check/moni tor s ys t em for re-occurrence

B1D20-91Head unitHead unit belowt emperatureCheck for addi ti onal DTCs and refer to DTC Index,check/moni tor s ys t em for re-occurrence

B1D20-98Head unitHead unit overt emperatureCheck for DTCs and refer t o DTC Index, check/monit ors ys t em for re-occurrence

B1D21-11Remote cont rol s wit chRemote cont rols wit ch circuit - shortt o ground

Refer t o electrical ci rcuit diagrams and check remote controls wit ch ci rcuit for short to ground

Page 112 of 3229

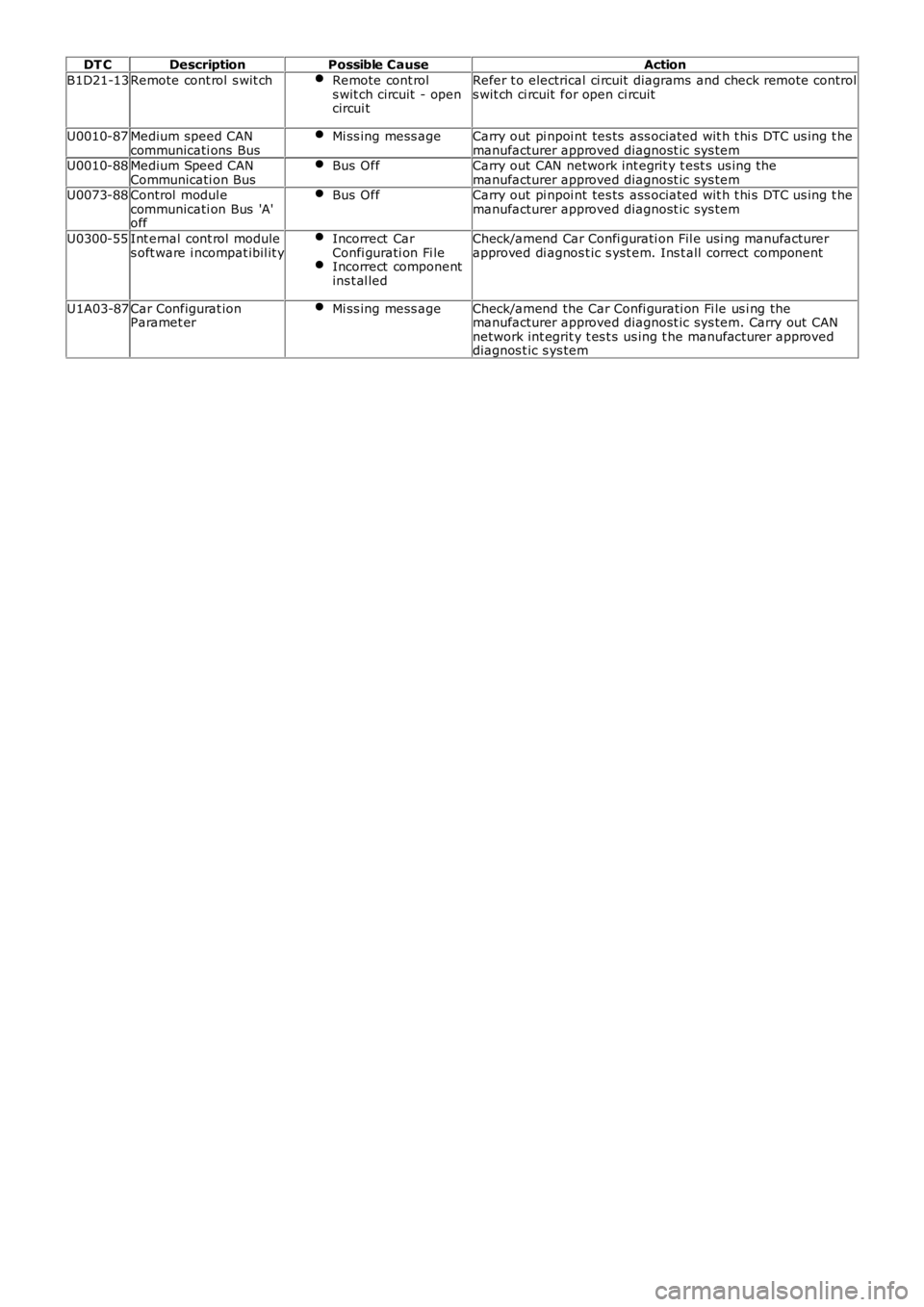

DT CDescriptionPossible CauseAction

B1D21-13Remote cont rol s wit chRemote cont rols wit ch circuit - opencircui t

Refer t o electrical ci rcuit diagrams and check remote controls wit ch ci rcuit for open ci rcuit

U0010-87Medium speed CANcommunicati ons BusMi ss ing mess ageCarry out pi npoi nt tes ts ass ociated wit h t hi s DTC us ing t hemanufacturer approved diagnost ic sys temU0010-88Medium Speed CANCommunicati on BusBus OffCarry out CAN network int egrit y t est s us ing t hemanufacturer approved diagnost ic sys temU0073-88Control modul ecommunicati on Bus 'A'off

Bus OffCarry out pi npoi nt tes ts ass ociated wit h t hi s DTC us ing t hemanufacturer approved diagnost ic sys tem

U0300-55Int ernal cont rol modules oft ware i ncompat ibil it yIncorrect CarConfi gurati on Fi leIncorrect componentins t al led

Check/amend Car Confi gurati on Fil e usi ng manufacturerapproved di agnos t ic s yst em. Ins t all correct component

U1A03-87Car Configurat ionParamet erMi ss ing mess ageCheck/amend the Car Confi gurati on Fi le us i ng themanufacturer approved diagnost ic sys tem. Carry out CANnetwork int egrit y t es t s us ing t he manufacturer approveddiagnos t ic s ys tem

Page 113 of 3229

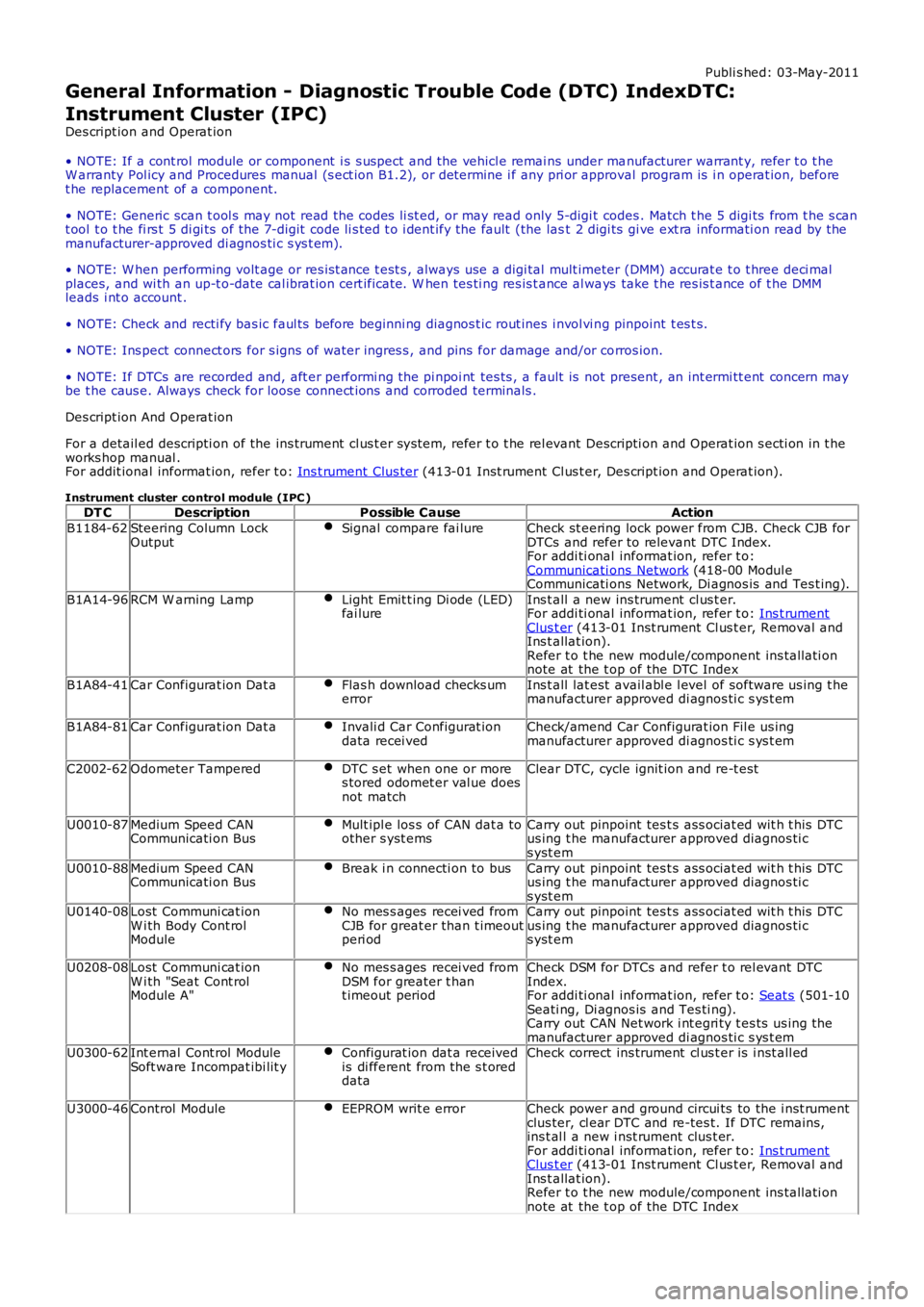

Publi s hed: 03-May-2011

General Information - Diagnostic Trouble Code (DTC) IndexDTC:

Instrument Cluster (IPC)

Des cript ion and Operat ion

• NOTE: If a cont rol module or component i s s uspect and the vehicl e remai ns under manufacturer warrant y, refer t o t heW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval program is i n operat ion, beforet he replacement of a component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only 5-digi t codes . Match t he 5 digi ts from t he s cant ool t o t he fi rs t 5 di gi ts of the 7-digit code li s ted t o i dent ify the fault (the last 2 digi ts gi ve ext ra informati on read by themanufacturer-approved di agnos ti c s ys t em).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces, and wi th an up-t o-date cal ibrat ion cert ificate. W hen tes ti ng res is t ance al ways take t he res is t ance of t he DMMleads i nt o account .

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

Des cript ion And Operat ion

For a detail ed descripti on of the ins trument cl us t er sys tem, refer t o t he rel evant Descripti on and Operat ion s ecti on in t heworks hop manual .For addit ional informat ion, refer t o: Ins t rument Clus ter (413-01 Inst rument Cl us t er, Des cript ion and Operat ion).

Instrument cluster control module (IPC )DT CDescriptionPossible CauseAction

B1184-62Steering Column LockOutputSignal compare fai lureCheck st eering lock power from CJB. Check CJB forDTCs and refer to relevant DTC Index.For addi ti onal informat ion, refer t o:Communicati ons Network (418-00 Modul eCommunicati ons Network, Di agnos is and Tes t ing).

B1A14-96RCM W arning LampLight Emit t ing Di ode (LED)fai lureIns t all a new ins trument cl us t er.For addi ti onal informat ion, refer t o: Ins t rumentClus t er (413-01 Inst rument Cl us t er, Removal andIns t allat ion).Refer t o t he new module/component ins tall ati onnote at the t op of the DTC Index

B1A84-41Car Configurat ion Dat aFlas h download checks umerrorIns t all lat est avail abl e l evel of software us ing t hemanufacturer approved di agnos ti c s ys t em

B1A84-81Car Configurat ion Dat aInvali d Car Configurat iondata recei vedCheck/amend Car Configurat ion Fil e us ingmanufacturer approved di agnos ti c s ys t em

C2002-62Odometer TamperedDTC s et when one or mores tored odomet er val ue doesnot match

Clear DTC, cycle ignit ion and re-t est

U0010-87Medium Speed CANCommunicati on BusMult ipl e los s of CAN dat a toother s yst emsCarry out pinpoint tes t s ass ociat ed wit h t his DTCus ing t he manufacturer approved diagnos ti cs yst em

U0010-88Medium Speed CANCommunicati on BusBreak i n connecti on to busCarry out pinpoint tes t s ass ociat ed wit h t his DTCus ing t he manufacturer approved diagnos ti cs yst emU0140-08Lost Communi cat ionW i th Body Cont rolModule

No mes s ages recei ved fromCJB for great er than t imeoutperi od

Carry out pinpoint tes t s ass ociat ed wit h t his DTCus ing t he manufacturer approved diagnos ti cs yst em

U0208-08Lost Communi cat ionW i th "Seat Cont rolModule A"

No mes s ages recei ved fromDSM for greater t hant imeout period

Check DSM for DTCs and refer t o rel evant DTCIndex.For addi ti onal informat ion, refer t o: Seat s (501-10Seati ng, Di agnos is and Tes ti ng).Carry out CAN Net work i nt egri ty t es ts us ing themanufacturer approved di agnos ti c s ys t emU0300-62Int ernal Cont rol ModuleSoft ware Incompat ibi lit yConfigurat ion dat a receivedis di fferent from the s t oreddata

Check correct ins trument cl us t er is i nst all ed

U3000-46Control ModuleEEPROM writ e errorCheck power and ground circui ts to the i nst rumentclus ter, cl ear DTC and re-tes t. If DTC remains ,ins t al l a new i nst rument clus t er.For addi ti onal informat ion, refer t o: Ins t rumentClus t er (413-01 Inst rument Cl us t er, Removal andIns t allat ion).Refer t o t he new module/component ins tall ati onnote at the t op of the DTC Index

Page 114 of 3229

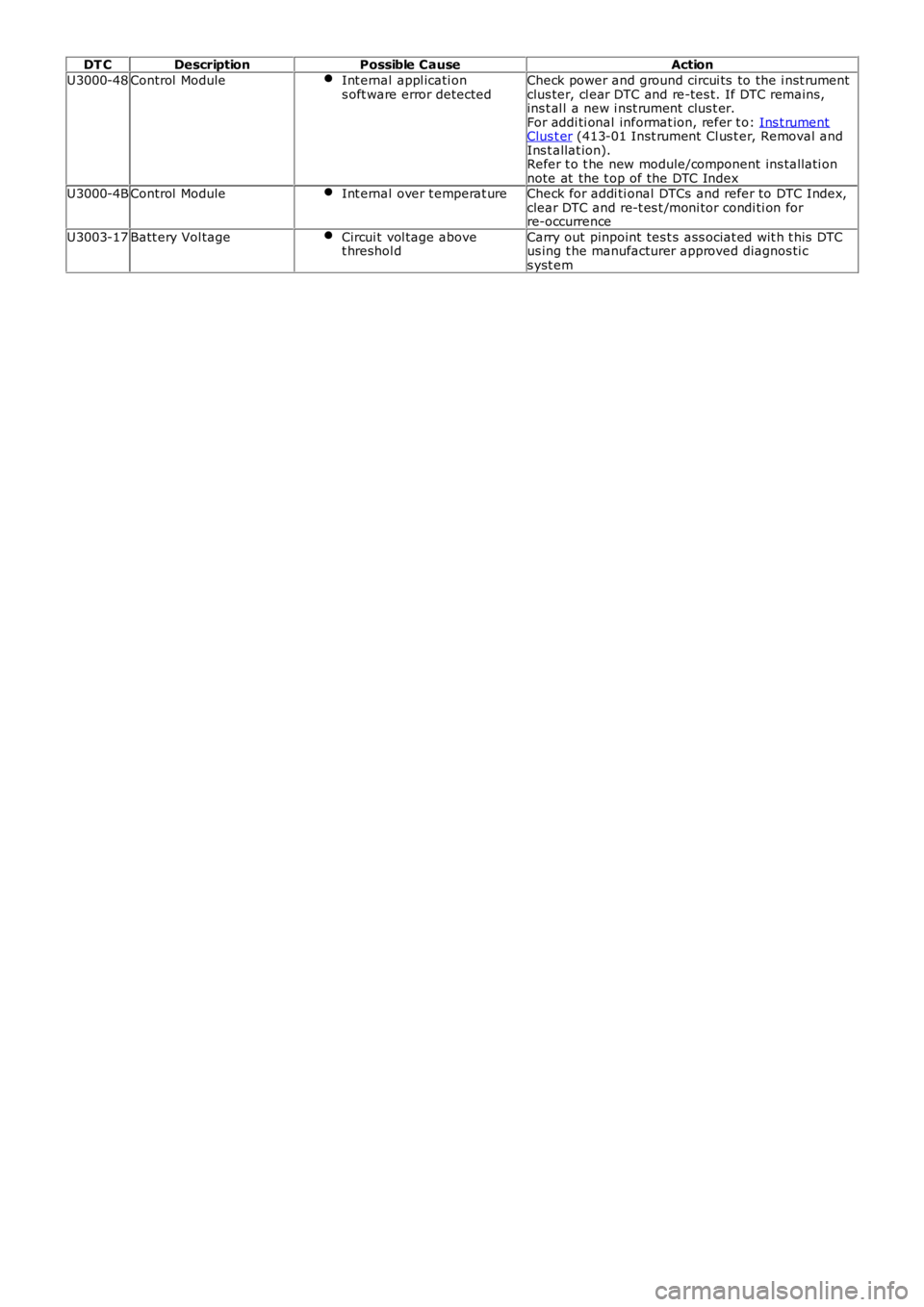

DT CDescriptionPossible CauseAction

U3000-48Control ModuleInt ernal appl icati ons oft ware error detectedCheck power and ground circui ts to the i nst rumentclus ter, cl ear DTC and re-tes t. If DTC remains ,ins t al l a new i nst rument clus t er.For addi ti onal informat ion, refer t o: Ins t rumentClus t er (413-01 Inst rument Cl us t er, Removal andIns t allat ion).Refer t o t he new module/component ins tall ati onnote at the t op of the DTC IndexU3000-4BControl ModuleInt ernal over t emperat ureCheck for addi ti onal DTCs and refer to DTC Index,clear DTC and re-t es t /moni tor condi ti on forre-occurrence

U3003-17Batt ery Vol tageCircui t vol tage abovet hreshol dCarry out pinpoint tes t s ass ociat ed wit h t his DTCus ing t he manufacturer approved diagnos ti cs yst em

Page 115 of 3229

Publ is hed: 28-Apr-2011

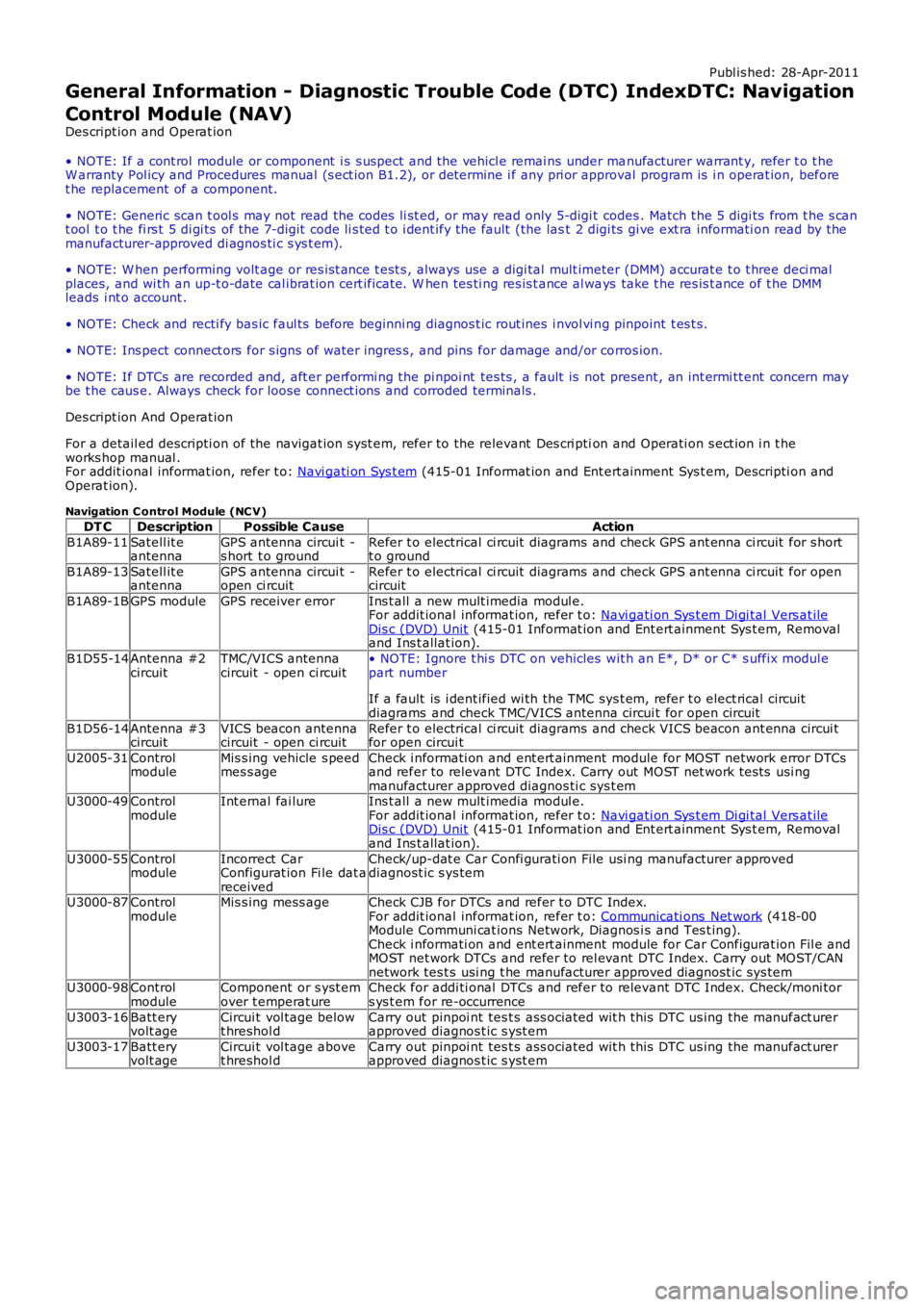

General Information - Diagnostic Trouble Code (DTC) IndexDTC: Navigation

Control Module (NAV)

Des cript ion and Operat ion

• NOTE: If a cont rol module or component i s s uspect and the vehicl e remai ns under manufacturer warrant y, refer t o t heW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval program is i n operat ion, beforet he replacement of a component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only 5-digi t codes . Match t he 5 digi ts from t he s cant ool t o t he fi rs t 5 di gi ts of the 7-digit code li s ted t o i dent ify the fault (the last 2 digi ts gi ve ext ra informati on read by themanufacturer-approved di agnos ti c s ys t em).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces, and wi th an up-t o-date cal ibrat ion cert ificate. W hen tes ti ng res is t ance al ways take t he res is t ance of t he DMMleads i nt o account .

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

Des cript ion And Operat ion

For a detail ed descripti on of the navigat ion s yst em, refer to the relevant Des cri ption and Operati on s ect ion i n t heworks hop manual .For addit ional informat ion, refer t o: Navi gati on Sys t em (415-01 Informat ion and Ent ert ainment Sys t em, Descripti on andOperat ion).

Navigation C ontrol Module (NC V)

DT CDescriptionPossible CauseAction

B1A89-11Satell it eantennaGPS antenna circui t -s hort t o groundRefer t o electrical ci rcuit diagrams and check GPS ant enna ci rcuit for s hortt o ground

B1A89-13Satell it eantennaGPS antenna circui t -open ci rcuitRefer t o electrical ci rcuit diagrams and check GPS ant enna ci rcuit for opencircuit

B1A89-1BGPS moduleGPS receiver errorIns t all a new mult imedia modul e.For addit ional informat ion, refer t o: Navi gati on Sys t em Di gi tal Vers at ileDis c (DVD) Unit (415-01 Informat ion and Ent ert ainment Sys t em, Removaland Ins t allat ion).

B1D55-14Antenna #2circuitTMC/VICS antennacircuit - open ci rcuit• NOTE: Ignore t hi s DTC on vehicles wit h an E*, D* or C* s uffix modul epart number

If a fault is i dent ified wi th the TMC sys t em, refer t o elect rical circuitdiagrams and check TMC/VICS antenna circui t for open circuit

B1D56-14Antenna #3circuitVICS beacon antennacircuit - open ci rcuitRefer t o electrical ci rcuit diagrams and check VICS beacon ant enna circui tfor open circui t

U2005-31ControlmoduleMis s ing vehicle s peedmes s ageCheck i nformati on and ent ert ainment module for MOST network error DTCsand refer to relevant DTC Index. Carry out MOST net work tes ts usi ngmanufacturer approved diagnos ti c sys t emU3000-49ControlmoduleInt ernal fai lureIns t all a new mult imedia modul e.For addit ional informat ion, refer t o: Navi gati on Sys t em Di gi tal Vers at ileDis c (DVD) Unit (415-01 Informat ion and Ent ert ainment Sys t em, Removaland Ins t allat ion).

U3000-55ControlmoduleIncorrect CarConfigurat ion Fi le dat areceived

Check/up-dat e Car Confi gurati on File usi ng manufacturer approveddiagnost ic s ys tem

U3000-87ControlmoduleMis s ing mess ageCheck CJB for DTCs and refer t o DTC Index.For addit ional informat ion, refer t o: Communicati ons Net work (418-00Module Communi cat ions Network, Diagnos i s and Tes t ing).Check i nformati on and ent ert ainment module for Car Configurat ion Fil e andMOST net work DTCs and refer to rel evant DTC Index. Carry out MOST/CANnetwork tes t s usi ng t he manufacturer approved diagnost ic sys temU3000-98ControlmoduleComponent or s yst emover t emperat ureCheck for addi ti onal DTCs and refer to relevant DTC Index. Check/moni tors ys t em for re-occurrence

U3003-16Batt eryvolt ageCircui t vol tage belowt hreshol dCarry out pinpoi nt tes t s ass ociated wit h t hi s DTC us ing the manufact urerapproved diagnos t ic s yst em

U3003-17Batt eryvolt ageCircui t vol tage abovet hreshol dCarry out pinpoi nt tes t s ass ociated wit h t hi s DTC us ing the manufact urerapproved diagnos t ic s yst em

Page 116 of 3229

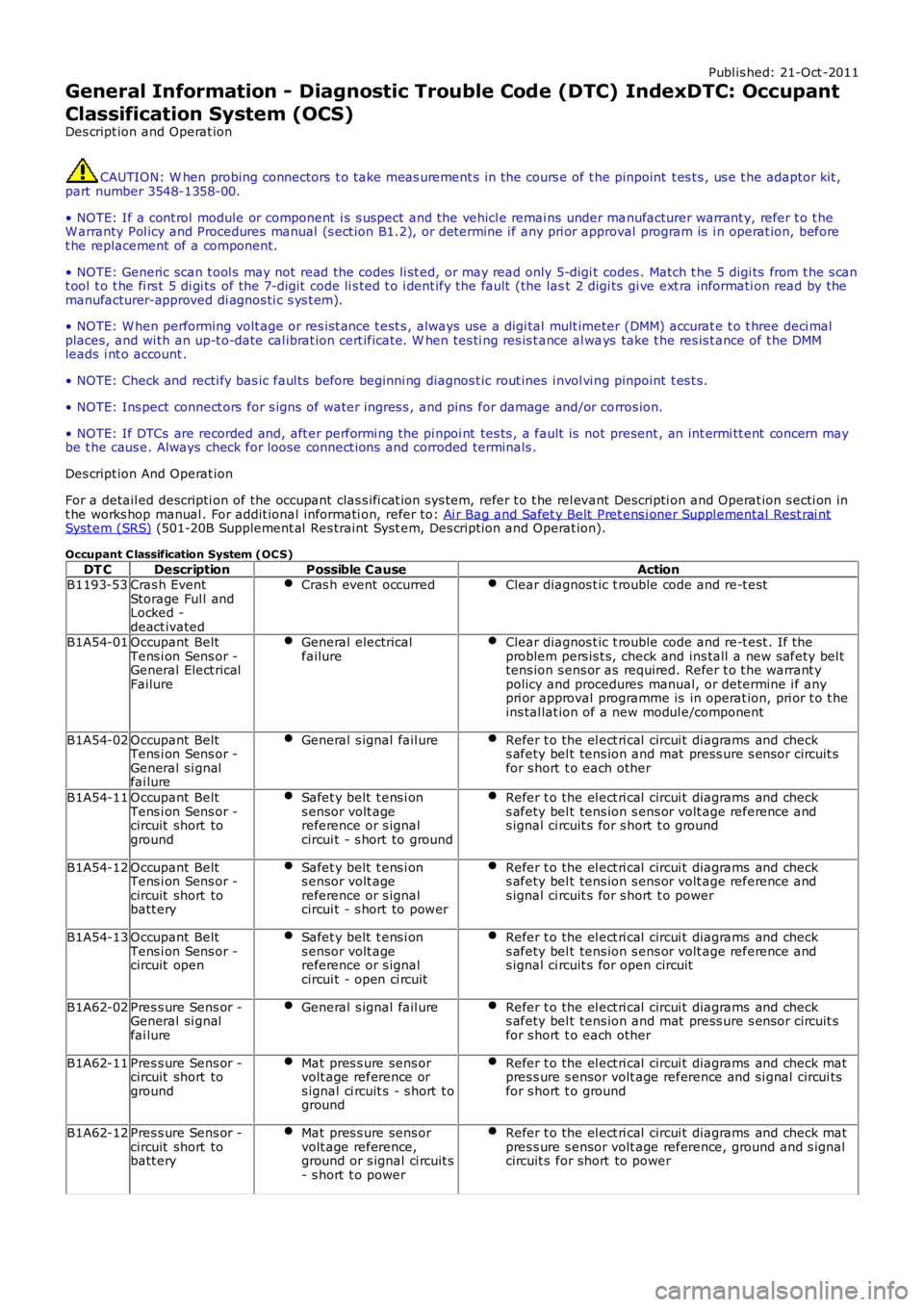

Publ is hed: 21-Oct -2011

General Information - Diagnostic Trouble Code (DTC) IndexDTC: Occupant

Classification System (OCS)

Des cript ion and Operat ion

CAUTION: W hen probing connectors t o take meas urement s in the cours e of t he pinpoint t es t s , us e t he adaptor kit ,part number 3548-1358-00.

• NOTE: If a cont rol module or component i s s uspect and the vehicl e remai ns under manufacturer warrant y, refer t o t heW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval program is i n operat ion, beforet he replacement of a component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only 5-digi t codes . Match t he 5 digi ts from t he s cant ool t o t he fi rs t 5 di gi ts of the 7-digit code li s ted t o i dent ify the fault (the last 2 digi ts gi ve ext ra informati on read by themanufacturer-approved di agnos ti c s ys t em).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces, and wi th an up-t o-date cal ibrat ion cert ificate. W hen tes ti ng res is t ance al ways take t he res is t ance of t he DMMleads i nt o account .

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

Des cript ion And Operat ion

For a detail ed descripti on of the occupant clas s ifi cat ion sys tem, refer t o t he rel evant Descripti on and Operat ion s ecti on int he works hop manual . For addit ional informati on, refer t o: Ai r Bag and Safet y Belt Pret ens i oner Suppl emental Rest rai ntSyst em (SRS) (501-20B Supplement al Res traint Syst em, Des cript ion and Operat ion).

Occupant C lassification System (OC S)

DT CDescriptionPossible CauseActionB1193-53Cras h EventStorage Ful l andLocked -deact ivated

Cras h event occurredClear diagnos t ic t rouble code and re-t est

B1A54-01Occupant BeltTens i on Sens or -General Elect ricalFailure

General electricalfailureClear diagnos t ic t rouble code and re-t est . If theproblem pers is t s, check and ins tall a new s afety bel ttens ion s ens or as required. Refer t o t he warrant ypolicy and procedures manual, or determine i f anypri or approval programme is in operat ion, pri or t o t heins tal lat ion of a new modul e/component

B1A54-02Occupant BeltTens i on Sens or -General si gnalfai lure

General s ignal fail ureRefer t o the el ect ri cal circui t diagrams and checks afety bel t tens ion and mat press ure s ens or circuit sfor s hort t o each other

B1A54-11Occupant BeltTens i on Sens or -circuit short toground

Safet y belt t ens i ons ensor volt agereference or s ignalcircui t - s hort to ground

Refer t o the el ect ri cal circui t diagrams and checks afety bel t tens ion s ens or volt age reference ands ignal ci rcuit s for s hort t o ground

B1A54-12Occupant BeltTens i on Sens or -circuit short tobatt ery

Safet y belt t ens i ons ensor volt agereference or s ignalcircui t - s hort to power

Refer t o the el ect ri cal circui t diagrams and checks afety bel t tens ion s ens or volt age reference ands ignal ci rcuit s for s hort t o power

B1A54-13Occupant BeltTens i on Sens or -circuit open

Safet y belt t ens i ons ensor volt agereference or s ignalcircui t - open ci rcuit

Refer t o the el ect ri cal circui t diagrams and checks afety bel t tens ion s ens or volt age reference ands ignal ci rcuit s for open circuit

B1A62-02Pres s ure Sens or -General si gnalfai lure

General s ignal fail ureRefer t o the el ect ri cal circui t diagrams and checks afety bel t tens ion and mat press ure s ens or circuit sfor s hort t o each other

B1A62-11Pres s ure Sens or -circuit short toground

Mat pres s ure sens orvolt age reference ors ignal ci rcuit s - s hort t oground

Refer t o the el ect ri cal circui t diagrams and check matpres s ure s ensor volt age reference and si gnal circui tsfor s hort t o ground

B1A62-12Pres s ure Sens or -circuit short tobatt ery

Mat pres s ure sens orvolt age reference,ground or s ignal ci rcuit s- s hort t o power

Refer t o the el ect ri cal circui t diagrams and check matpres s ure s ensor volt age reference, ground and s ignalcircuit s for short to power

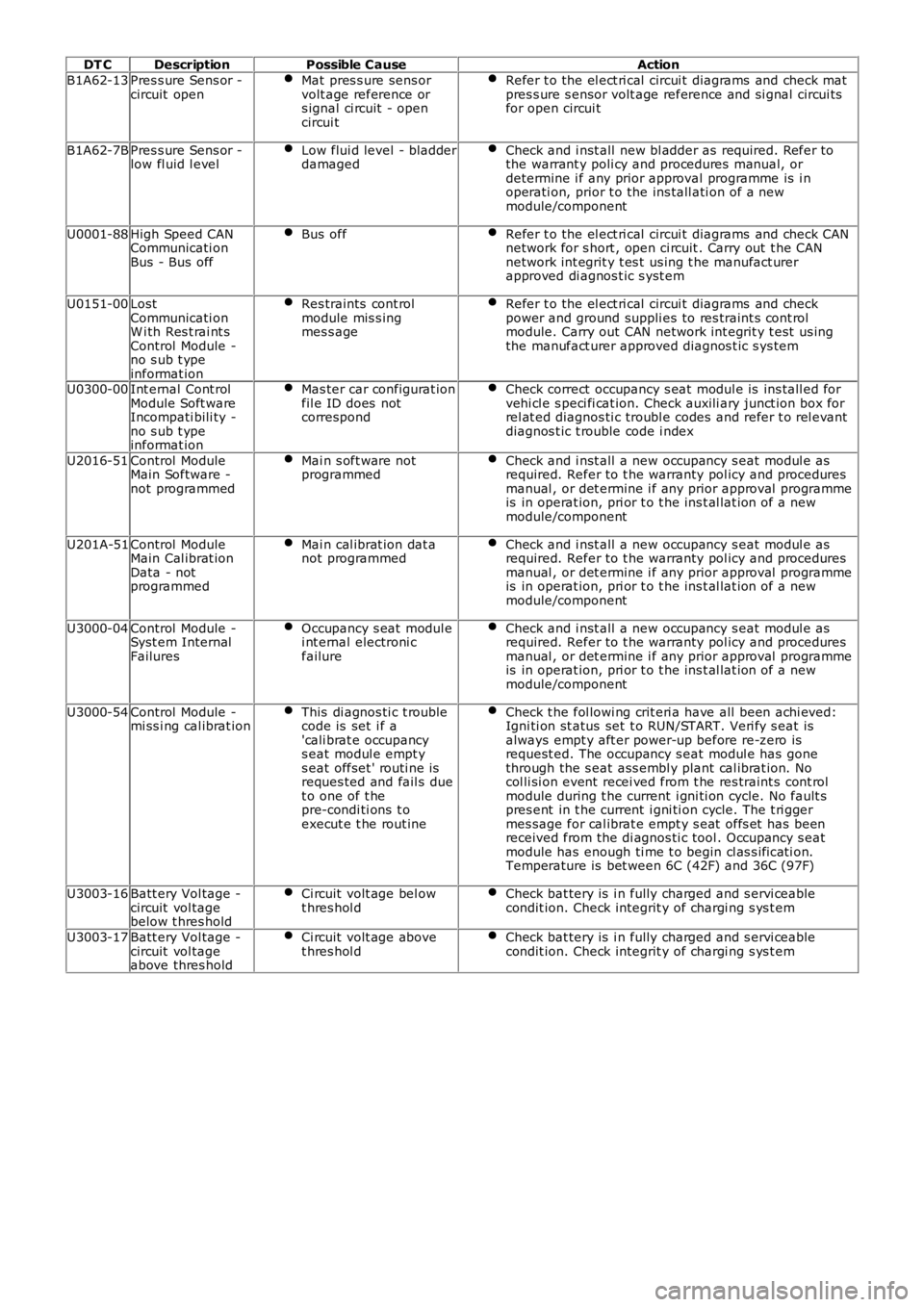

Page 117 of 3229

DT CDescriptionPossible CauseAction

B1A62-13Pres s ure Sens or -circuit openMat pres s ure sens orvolt age reference ors ignal ci rcuit - opencircui t

Refer t o the el ect ri cal circui t diagrams and check matpres s ure s ensor volt age reference and si gnal circui tsfor open circui t

B1A62-7BPres s ure Sens or -low fl uid l evelLow flui d level - bladderdamagedCheck and i nst all new bl adder as required. Refer tothe warrant y poli cy and procedures manual, ordetermine i f any prior approval programme is i noperati on, prior t o the ins tall ati on of a newmodule/component

U0001-88High Speed CANCommunicati onBus - Bus off

Bus offRefer t o the el ect ri cal circui t diagrams and check CANnetwork for s hort , open ci rcuit . Carry out t he CANnetwork int egrit y t es t us ing t he manufact urerapproved di agnos t ic s yst em

U0151-00LostCommunicati onW i th Res t rai nt sControl Module -no s ub t ypeinformat ion

Res traints cont rolmodule mis s ingmes s age

Refer t o the el ect ri cal circui t diagrams and checkpower and ground suppli es to res traint s cont rolmodule. Carry out CAN network int egrit y t est us ingthe manufact urer approved diagnos t ic s ys tem

U0300-00Int ernal Cont rolModule Soft wareIncompati bili ty -no s ub t ypeinformat ion

Mas ter car configurat ionfil e ID does notcorrespond

Check correct occupancy s eat modul e is ins tall ed forvehi cl e s peci fi cat ion. Check auxili ary junct ion box forrel at ed diagnos ti c troubl e codes and refer t o rel evantdiagnos t ic t rouble code i ndex

U2016-51Control ModuleMain Software -not programmed

Mai n s oft ware notprogrammedCheck and i nst all a new occupancy s eat modul e asrequired. Refer to t he warranty pol icy and proceduresmanual , or det ermine i f any prior approval programmeis in operat ion, pri or t o t he ins t al lat ion of a newmodule/component

U201A-51Control ModuleMain Cal ibrat ionData - notprogrammed

Mai n cal ibrat ion dat anot programmedCheck and i nst all a new occupancy s eat modul e asrequired. Refer to t he warranty pol icy and proceduresmanual , or det ermine i f any prior approval programmeis in operat ion, pri or t o t he ins t al lat ion of a newmodule/component

U3000-04Control Module -Syst em InternalFailures

Occupancy s eat modul ei nt ernal electroni cfailure

Check and i nst all a new occupancy s eat modul e asrequired. Refer to t he warranty pol icy and proceduresmanual , or det ermine i f any prior approval programmeis in operat ion, pri or t o t he ins t al lat ion of a newmodule/component

U3000-54Control Module -mi ss i ng cal ibrat ionThis di agnos ti c t roublecode is set i f a'cali brat e occupancys eat modul e empt ys eat offset ' routi ne isreques ted and fail s duet o one of t hepre-condi ti ons t oexecut e t he rout ine

Check t he fol lowi ng crit eri a have all been achi eved:Igni ti on st atus set t o RUN/START. Veri fy s eat isalways empt y aft er power-up before re-zero isrequest ed. The occupancy s eat modul e has gonethrough the s eat ass embl y plant cal ibrat ion. Nocol li si on event recei ved from t he res traint s cont rolmodule during t he current i gni ti on cycle. No fault spres ent in t he current i gni ti on cycle. The t ri ggermes sage for cal ibrat e empt y s eat offs et has beenreceived from the di agnos ti c tool . Occupancy s eatmodule has enough ti me t o begin cl as s ificati on.Temperature is bet ween 6C (42F) and 36C (97F)

U3003-16Batt ery Vol tage -circuit vol tagebelow t hres hold

Ci rcuit volt age bel owt hres hol dCheck bat tery is i n fully charged and s ervi ceablecondit ion. Check integrit y of chargi ng s ys t em

U3003-17Batt ery Vol tage -circuit vol tageabove thres hold

Ci rcuit volt age abovet hres hol dCheck bat tery is i n fully charged and s ervi ceablecondit ion. Check integrit y of chargi ng s ys t em

Page 118 of 3229

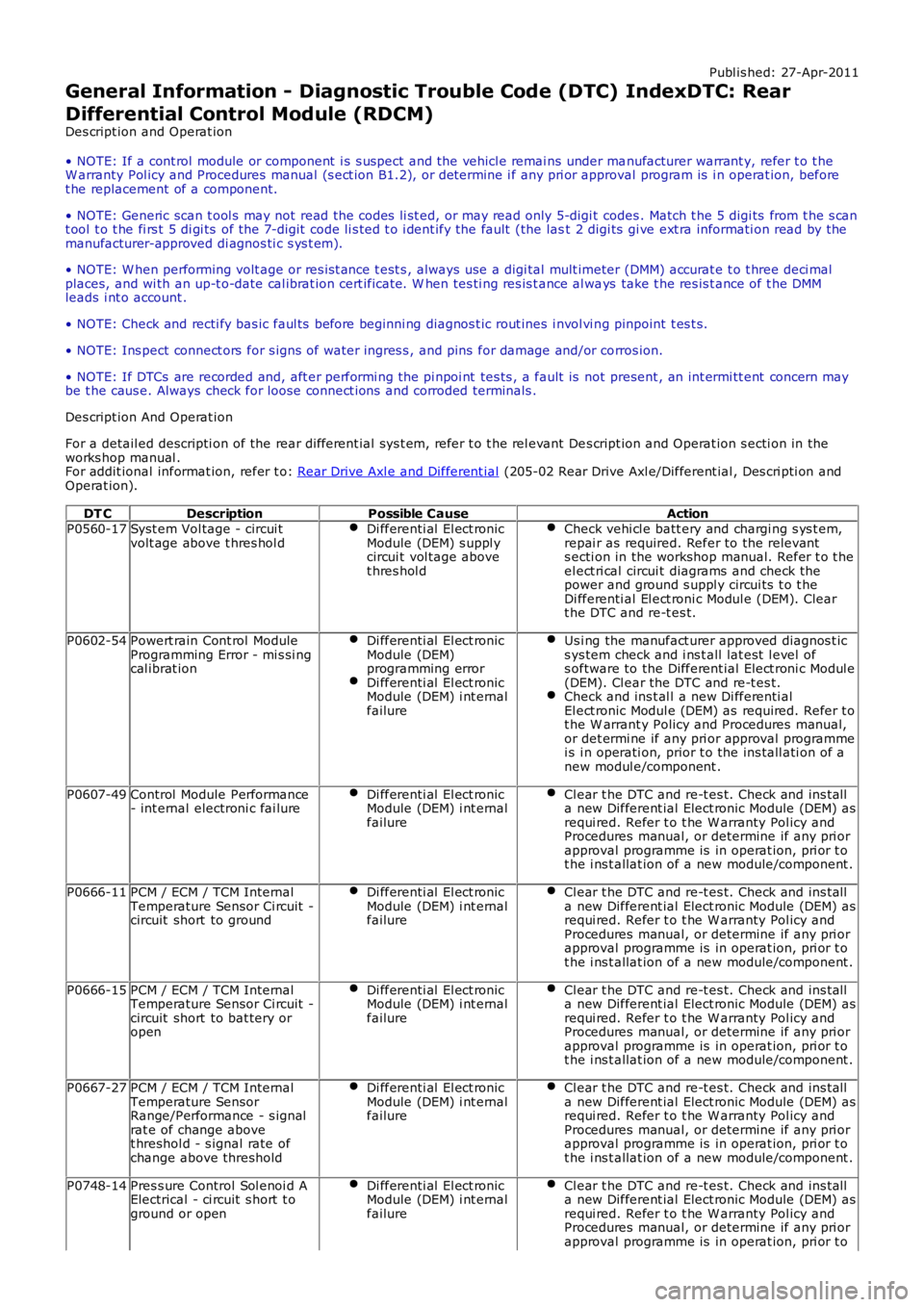

Publ is hed: 27-Apr-2011

General Information - Diagnostic Trouble Code (DTC) IndexDTC: Rear

Differential Control Module (RDCM)

Des cript ion and Operat ion

• NOTE: If a cont rol module or component i s s uspect and the vehicl e remai ns under manufacturer warrant y, refer t o t heW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval program is i n operat ion, beforet he replacement of a component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only 5-digi t codes . Match t he 5 digi ts from t he s cant ool t o t he fi rs t 5 di gi ts of the 7-digit code li s ted t o i dent ify the fault (the last 2 digi ts gi ve ext ra informati on read by themanufacturer-approved di agnos ti c s ys t em).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces, and wi th an up-t o-date cal ibrat ion cert ificate. W hen tes ti ng res is t ance al ways take t he res is t ance of t he DMMleads i nt o account .

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

Des cript ion And Operat ion

For a detail ed descripti on of the rear different ial sys t em, refer t o t he rel evant Des cript ion and Operat ion s ecti on in theworks hop manual .For addit ional informat ion, refer t o: Rear Drive Axl e and Different ial (205-02 Rear Drive Axl e/Different ial , Des cri pti on andOperat ion).

DT CDescriptionPossible CauseActionP0560-17Syst em Vol tage - circui tvolt age above t hres hol dDi fferenti al El ect ronicModule (DEM) s uppl ycircui t vol tage abovet hres hol d

Check vehi cl e batt ery and chargi ng s ys t em,repai r as required. Refer to the relevants ecti on in the workshop manual. Refer t o t heel ect ri cal circui t diagrams and check thepower and ground s uppl y circui ts t o t heDi fferenti al El ect roni c Modul e (DEM). Cleart he DTC and re-t es t.

P0602-54Powert rain Cont rol ModuleProgramming Error - mi s si ngcal ibrat ion

Di fferenti al El ect ronicModule (DEM)programming errorDi fferenti al El ect ronicModule (DEM) i nt ernalfailure

Us i ng the manufact urer approved diagnos t ics ys tem check and i ns t all lat est l evel ofs oftware to the Different ial Elect roni c Modul e(DEM). Cl ear the DTC and re-t es t.Check and ins t al l a new Di fferenti alEl ect ronic Modul e (DEM) as required. Refer t ot he W arrant y Policy and Procedures manual,or det ermi ne if any pri or approval programmei s i n operati on, prior t o the ins tall ati on of anew modul e/component .

P0607-49Control Module Performance- int ernal electroni c fai lureDi fferenti al El ect ronicModule (DEM) i nt ernalfailure

Cl ear t he DTC and re-t es t. Check and ins talla new Different ial Elect ronic Module (DEM) asrequi red. Refer t o t he W arranty Pol icy andProcedures manual, or determine if any pri orapproval programme is in operat ion, pri or t ot he i ns t allat ion of a new module/component .

P0666-11PCM / ECM / TCM InternalTemperature Sensor Ci rcuit -circuit short to ground

Di fferenti al El ect ronicModule (DEM) i nt ernalfailure

Cl ear t he DTC and re-t es t. Check and ins talla new Different ial Elect ronic Module (DEM) asrequi red. Refer t o t he W arranty Pol icy andProcedures manual, or determine if any pri orapproval programme is in operat ion, pri or t ot he i ns t allat ion of a new module/component .

P0666-15PCM / ECM / TCM InternalTemperature Sensor Ci rcuit -circuit short to bat tery oropen

Di fferenti al El ect ronicModule (DEM) i nt ernalfailure

Cl ear t he DTC and re-t es t. Check and ins talla new Different ial Elect ronic Module (DEM) asrequi red. Refer t o t he W arranty Pol icy andProcedures manual, or determine if any pri orapproval programme is in operat ion, pri or t ot he i ns t allat ion of a new module/component .

P0667-27PCM / ECM / TCM InternalTemperature SensorRange/Performance - s ignalrat e of change abovet hreshol d - s ignal rate ofchange above threshold

Di fferenti al El ect ronicModule (DEM) i nt ernalfailure

Cl ear t he DTC and re-t es t. Check and ins talla new Different ial Elect ronic Module (DEM) asrequi red. Refer t o t he W arranty Pol icy andProcedures manual, or determine if any pri orapproval programme is in operat ion, pri or t ot he i ns t allat ion of a new module/component .

P0748-14Pres s ure Control Sol enoi d AElectrical - ci rcuit s hort t oground or open

Di fferenti al El ect ronicModule (DEM) i nt ernalfailure

Cl ear t he DTC and re-t es t. Check and ins talla new Different ial Elect ronic Module (DEM) asrequi red. Refer t o t he W arranty Pol icy andProcedures manual, or determine if any pri orapproval programme is in operat ion, pri or t o

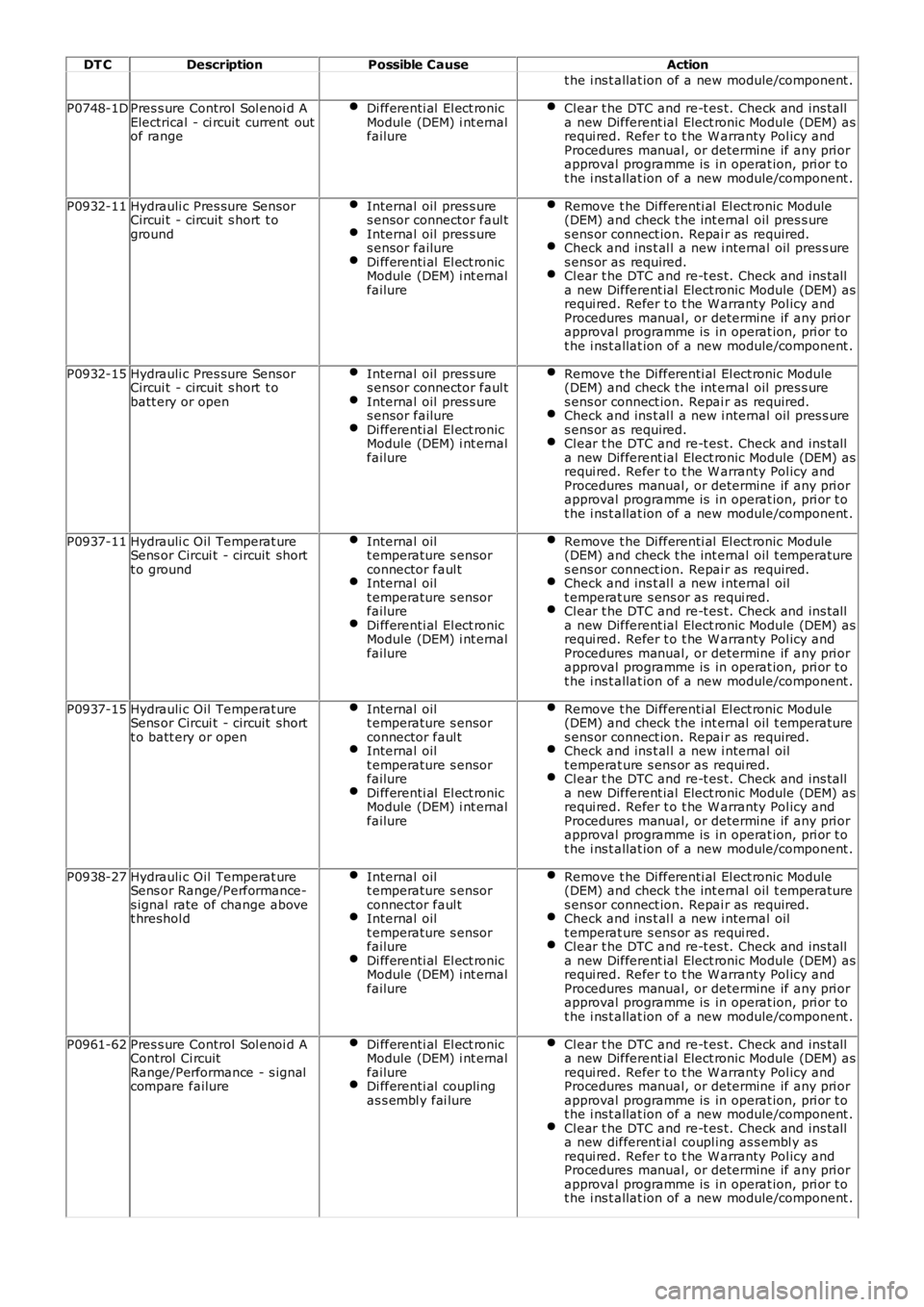

Page 119 of 3229

DT CDescriptionPossible CauseAction

t he i ns t allat ion of a new module/component .

P0748-1DPres s ure Control Sol enoi d AElectrical - ci rcuit current outof range

Di fferenti al El ect ronicModule (DEM) i nt ernalfailure

Cl ear t he DTC and re-t es t. Check and ins talla new Different ial Elect ronic Module (DEM) asrequi red. Refer t o t he W arranty Pol icy andProcedures manual, or determine if any pri orapproval programme is in operat ion, pri or t ot he i ns t allat ion of a new module/component .

P0932-11Hydrauli c Pres sure SensorCircui t - circuit s hort t oground

Internal oil pres s ures ensor connector faul tInternal oil pres s ures ensor failureDi fferenti al El ect ronicModule (DEM) i nt ernalfailure

Remove t he Di fferenti al El ect ronic Module(DEM) and check t he int ernal oil pres s ures ens or connect ion. Repai r as required.Check and ins t al l a new i nternal oil pres s ures ens or as required.Cl ear t he DTC and re-t es t. Check and ins talla new Different ial Elect ronic Module (DEM) asrequi red. Refer t o t he W arranty Pol icy andProcedures manual, or determine if any pri orapproval programme is in operat ion, pri or t ot he i ns t allat ion of a new module/component .

P0932-15Hydrauli c Pres sure SensorCircui t - circuit s hort t obatt ery or open

Internal oil pres s ures ensor connector faul tInternal oil pres s ures ensor failureDi fferenti al El ect ronicModule (DEM) i nt ernalfailure

Remove t he Di fferenti al El ect ronic Module(DEM) and check t he int ernal oil pres s ures ens or connect ion. Repai r as required.Check and ins t al l a new i nternal oil pres s ures ens or as required.Cl ear t he DTC and re-t es t. Check and ins talla new Different ial Elect ronic Module (DEM) asrequi red. Refer t o t he W arranty Pol icy andProcedures manual, or determine if any pri orapproval programme is in operat ion, pri or t ot he i ns t allat ion of a new module/component .

P0937-11Hydrauli c Oil Temperat ureSens or Circui t - circuit shortt o ground

Internal oilt emperature s ensorconnector faul tInternal oilt emperature s ensorfailureDi fferenti al El ect ronicModule (DEM) i nt ernalfailure

Remove t he Di fferenti al El ect ronic Module(DEM) and check t he int ernal oil t emperatures ens or connect ion. Repai r as required.Check and ins t al l a new i nternal oilt emperat ure s ens or as requi red.Cl ear t he DTC and re-t es t. Check and ins talla new Different ial Elect ronic Module (DEM) asrequi red. Refer t o t he W arranty Pol icy andProcedures manual, or determine if any pri orapproval programme is in operat ion, pri or t ot he i ns t allat ion of a new module/component .

P0937-15Hydrauli c Oil Temperat ureSens or Circui t - circuit shortt o batt ery or open

Internal oilt emperature s ensorconnector faul tInternal oilt emperature s ensorfailureDi fferenti al El ect ronicModule (DEM) i nt ernalfailure

Remove t he Di fferenti al El ect ronic Module(DEM) and check t he int ernal oil t emperatures ens or connect ion. Repai r as required.Check and ins t al l a new i nternal oilt emperat ure s ens or as requi red.Cl ear t he DTC and re-t es t. Check and ins talla new Different ial Elect ronic Module (DEM) asrequi red. Refer t o t he W arranty Pol icy andProcedures manual, or determine if any pri orapproval programme is in operat ion, pri or t ot he i ns t allat ion of a new module/component .

P0938-27Hydrauli c Oil Temperat ureSens or Range/Performance-s ignal rate of change abovet hreshol d

Internal oilt emperature s ensorconnector faul tInternal oilt emperature s ensorfailureDi fferenti al El ect ronicModule (DEM) i nt ernalfailure

Remove t he Di fferenti al El ect ronic Module(DEM) and check t he int ernal oil t emperatures ens or connect ion. Repai r as required.Check and ins t al l a new i nternal oilt emperat ure s ens or as requi red.Cl ear t he DTC and re-t es t. Check and ins talla new Different ial Elect ronic Module (DEM) asrequi red. Refer t o t he W arranty Pol icy andProcedures manual, or determine if any pri orapproval programme is in operat ion, pri or t ot he i ns t allat ion of a new module/component .

P0961-62Pres s ure Control Sol enoi d AControl Ci rcuitRange/Performance - s ignalcompare failure

Di fferenti al El ect ronicModule (DEM) i nt ernalfailureDi fferenti al couplingas s embl y fai lure

Cl ear t he DTC and re-t es t. Check and ins talla new Different ial Elect ronic Module (DEM) asrequi red. Refer t o t he W arranty Pol icy andProcedures manual, or determine if any pri orapproval programme is in operat ion, pri or t ot he i ns t allat ion of a new module/component .Cl ear t he DTC and re-t es t. Check and ins talla new different ial coupl ing as s embl y asrequi red. Refer t o t he W arranty Pol icy andProcedures manual, or determine if any pri orapproval programme is in operat ion, pri or t ot he i ns t allat ion of a new module/component .

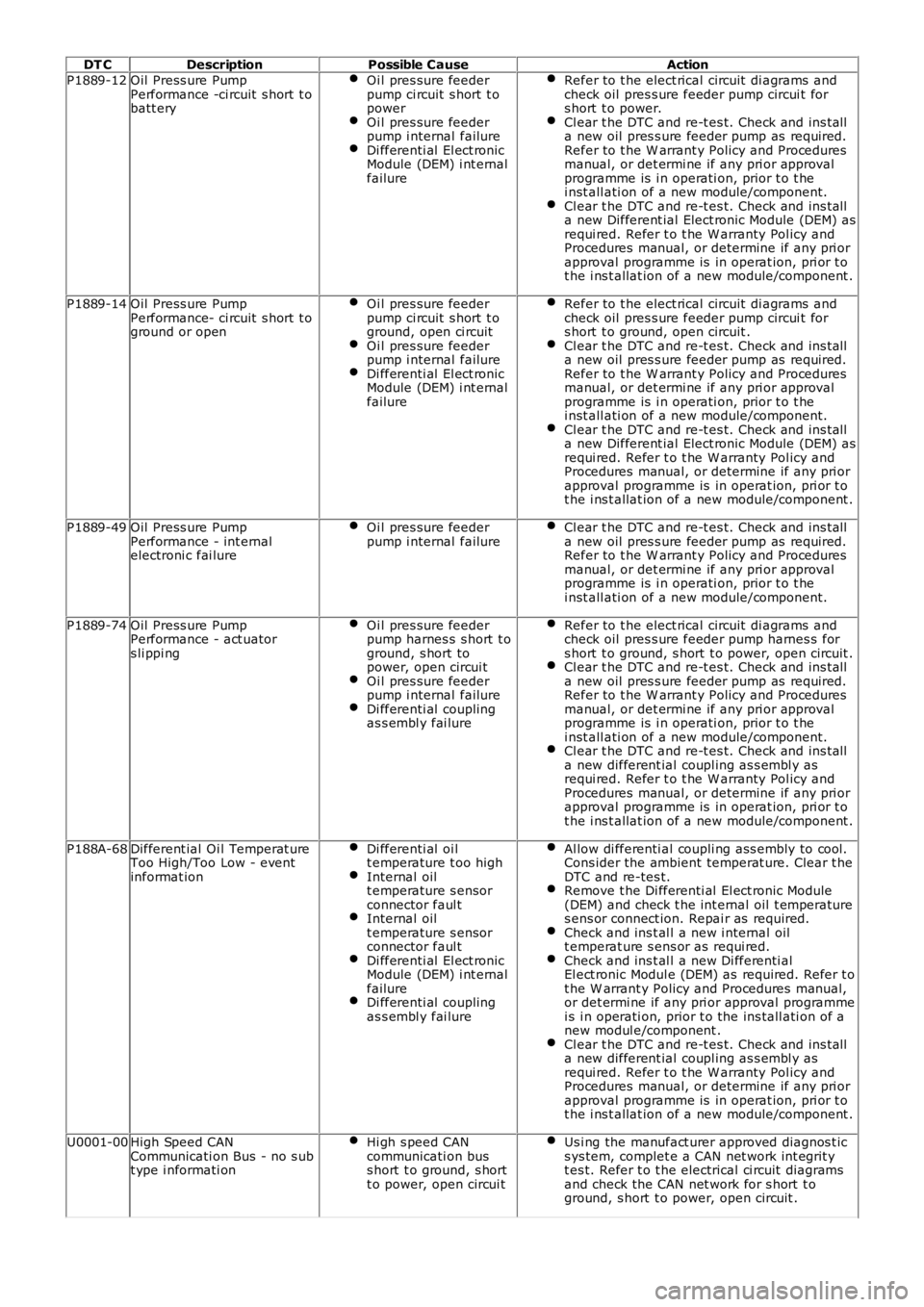

Page 120 of 3229

DT CDescriptionPossible CauseAction

P1889-12Oil Press ure PumpPerformance -ci rcuit s hort t obatt ery

Oi l pres sure feederpump ci rcuit s hort t opowerOi l pres sure feederpump i nternal failureDi fferenti al El ect ronicModule (DEM) i nt ernalfailure

Refer to t he elect rical circuit di agrams andcheck oil pres s ure feeder pump circui t fors hort t o power.Cl ear t he DTC and re-t es t. Check and ins talla new oil pres s ure feeder pump as required.Refer to t he W arrant y Policy and Proceduresmanual, or det ermi ne if any pri or approvalprogramme is i n operati on, prior t o t hei nst all ati on of a new module/component.Cl ear t he DTC and re-t es t. Check and ins talla new Different ial Elect ronic Module (DEM) asrequi red. Refer t o t he W arranty Pol icy andProcedures manual, or determine if any pri orapproval programme is in operat ion, pri or t ot he i ns t allat ion of a new module/component .

P1889-14Oil Press ure PumpPerformance- ci rcuit s hort t oground or open

Oi l pres sure feederpump ci rcuit s hort t oground, open ci rcuitOi l pres sure feederpump i nternal failureDi fferenti al El ect ronicModule (DEM) i nt ernalfailure

Refer to t he elect rical circuit di agrams andcheck oil pres s ure feeder pump circui t fors hort t o ground, open circuit .Cl ear t he DTC and re-t es t. Check and ins talla new oil pres s ure feeder pump as required.Refer to t he W arrant y Policy and Proceduresmanual, or det ermi ne if any pri or approvalprogramme is i n operati on, prior t o t hei nst all ati on of a new module/component.Cl ear t he DTC and re-t es t. Check and ins talla new Different ial Elect ronic Module (DEM) asrequi red. Refer t o t he W arranty Pol icy andProcedures manual, or determine if any pri orapproval programme is in operat ion, pri or t ot he i ns t allat ion of a new module/component .

P1889-49Oil Press ure PumpPerformance - int ernalelectroni c fai lure

Oi l pres sure feederpump i nternal failureCl ear t he DTC and re-t es t. Check and ins talla new oil pres s ure feeder pump as required.Refer to t he W arrant y Policy and Proceduresmanual, or det ermi ne if any pri or approvalprogramme is i n operati on, prior t o t hei nst all ati on of a new module/component.

P1889-74Oil Press ure PumpPerformance - act uators li ppi ng

Oi l pres sure feederpump harnes s s hort t oground, s hort topower, open circui tOi l pres sure feederpump i nternal failureDi fferenti al couplingas s embl y fai lure

Refer to t he elect rical circuit di agrams andcheck oil pres s ure feeder pump harnes s fors hort t o ground, s hort t o power, open circuit .Cl ear t he DTC and re-t es t. Check and ins talla new oil pres s ure feeder pump as required.Refer to t he W arrant y Policy and Proceduresmanual, or det ermi ne if any pri or approvalprogramme is i n operati on, prior t o t hei nst all ati on of a new module/component.Cl ear t he DTC and re-t es t. Check and ins talla new different ial coupl ing as s embl y asrequi red. Refer t o t he W arranty Pol icy andProcedures manual, or determine if any pri orapproval programme is in operat ion, pri or t ot he i ns t allat ion of a new module/component .

P188A-68Different ial Oi l Temperat ureToo High/Too Low - eventinformat ion

Di fferenti al oi lt emperature t oo highInternal oilt emperature s ensorconnector faul tInternal oilt emperature s ensorconnector faul tDi fferenti al El ect ronicModule (DEM) i nt ernalfailureDi fferenti al couplingas s embl y fai lure

Al low di fferenti al coupli ng ass embly to cool.Cons ider the ambient temperat ure. Clear t heDTC and re-tes t.Remove t he Di fferenti al El ect ronic Module(DEM) and check t he int ernal oil t emperatures ens or connect ion. Repai r as required.Check and ins t al l a new i nternal oilt emperat ure s ens or as requi red.Check and ins t al l a new Di fferenti alEl ect ronic Modul e (DEM) as required. Refer t ot he W arrant y Policy and Procedures manual,or det ermi ne if any pri or approval programmei s i n operati on, prior t o the ins tall ati on of anew modul e/component .Cl ear t he DTC and re-t es t. Check and ins talla new different ial coupl ing as s embl y asrequi red. Refer t o t he W arranty Pol icy andProcedures manual, or determine if any pri orapproval programme is in operat ion, pri or t ot he i ns t allat ion of a new module/component .

U0001-00High Speed CANCommunicati on Bus - no s ubt ype i nformati on

Hi gh s peed CANcommunicati on buss hort t o ground, s hortt o power, open circui t

Us i ng the manufact urer approved diagnos t ics ys tem, complet e a CAN net work int egrit yt es t. Refer t o t he electrical ci rcuit diagramsand check the CAN net work for s hort t oground, s hort t o power, open circuit .