LAND ROVER FRELANDER 2 2006 Repair Manual

Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 141 of 3229

Publi s hed: 05-May-2011

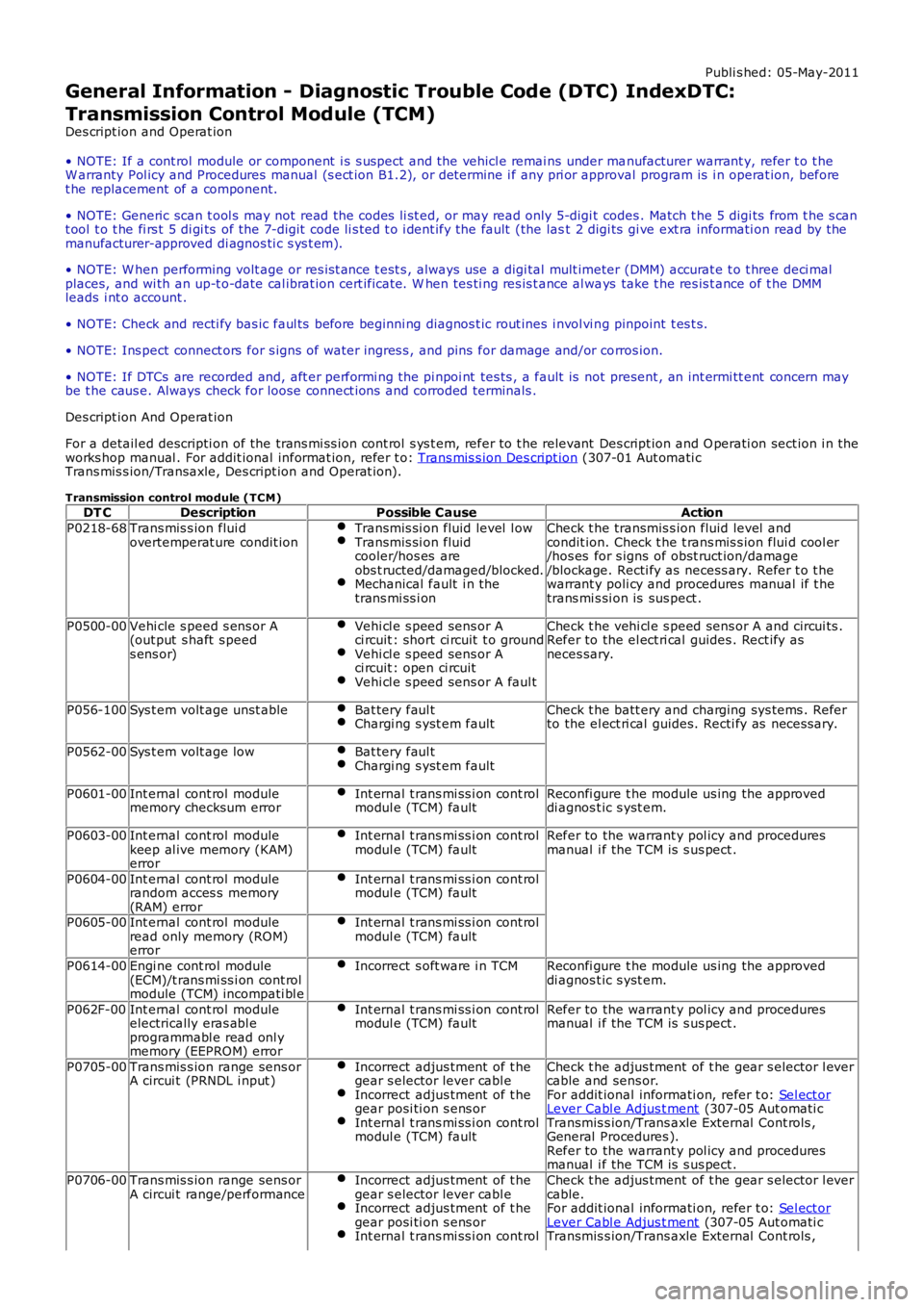

General Information - Diagnostic Trouble Code (DTC) IndexDTC:

Transmission Control Module (TCM)

Des cript ion and Operat ion

• NOTE: If a cont rol module or component i s s uspect and the vehicl e remai ns under ma nufacturer warrant y, refer t o t he

W arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or appr oval program is i n operat ion, before

t he replacement of a component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only 5-digi t c odes . Match t he 5 digi ts from t he s can

t ool t o t he fi rs t 5 di gi ts of the 7-digit code li s ted t o i dent ify the fault (the las t 2 digi ts gi ve ext ra informati on read by the

manufacturer-approved di agnos ti c s ys t em).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci mal

places, and wi th an up-t o-date cal ibrat ion cert ificate. W hen tes ti ng res is t ance al wa ys take t he res is t ance of t he DMM

leads i nt o account .

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi n g pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or co rros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is no t present , an int ermi tt ent concern may

be t he caus e. Always check for loose connect ions and corroded terminals .

Des cript ion And Operat ion

For a detail ed descripti on of the trans mi ss i on cont rol s ys t em, refer to t he relevant Des cript ion and O perati on sect ion i n the

works hop manual . For addit ional informat ion, refer t o: Trans mis s ion Des cript ion (307-01 Aut omati c

Trans mis s ion/Transaxle, Des cript ion and Operat ion).

Transmission control module (TCM) DT C Description Possible Cause Action

P0218-68 Trans mis s ion flui d

overtemperat ure condit ion Transmis si on fluid level l ow Transmis si on fluid

cooler/hos es are

obs t ructed/damaged/blocked. Mechanical fault i n the

trans mi ss i on Check t he transmis s ion fluid level and

condit ion. Check t he t rans mis s ion flui d cool er

/hos es for s igns of obst ruct ion/damage

/blockage. Recti fy as necess ary. Refer t o t he

warrant y poli cy and procedures manual if t he

trans mi s si on is sus pect .

P0500-00 Vehi cle s peed s ens or A

(out put s haft s peed

s ens or) Vehi cl e s peed sens or A

ci rcuit : short ci rcuit t o ground Vehi cl e s peed sens or A

ci rcuit : open ci rcuit Vehi cl e s peed sens or A faul t Check t he vehi cl e s peed sens or A and circui ts .

Refer to the el ect ri cal guides . Rect ify as

neces sary.

P056-100 Sys t em volt age unst able Bat tery faul t Chargi ng s yst em fault Check t he batt ery and charging sys tems . Refer

to the el ect ri cal guides. Recti fy as neces sary.

P0562-00 Sys t em volt age low Bat tery faul t Chargi ng s yst em fault

P0601-00

Int ernal cont rol module

memory checksum error Int ernal t rans mi ss i on cont rol

modul e (TCM) fault Reconfi gure t he module us ing the approved

di agnos t ic s yst em.

P0603-00 Int ernal cont rol module

keep al ive memory (KAM)

error Int ernal t rans mi ss i on cont rol

modul e (TCM) fault Refer to the warrant y pol icy and procedures

manual i f the TCM is s us pect .

P0604-00 Int ernal cont rol module

random acces s memory

(RAM) error Int ernal t rans mi ss i on cont rol

modul e (TCM) fault P0605-00

Int ernal cont rol module

read only memory (ROM)

error Int ernal t rans mi ss i on cont rol

modul e (TCM) fault P0614-00

Engi ne cont rol module

(ECM)/t rans mi ss i on cont rol

module (TCM) incompati bl e Incorrect s oft ware i n TCM Reconfi gure t he module us ing the approved

di agnos t ic s yst em.

P062F-00 Int ernal cont rol module

electrically eras abl e

programmabl e read onl y

memory (EEPROM) error Int ernal t rans mi ss i on cont rol

modul e (TCM) fault Refer to the warrant y pol icy and procedures

manual i f the TCM is s us pect .

P0705-00 Trans mis s ion range sens or

A circui t (PRNDL i nput ) Incorrect adjus tment of t he

gear s elector lever cabl e Incorrect adjus tment of t he

gear posi ti on s ens or Int ernal t rans mi ss i on cont rol

modul e (TCM) fault Check t he adjus tment of t he gear s elector l ever

cable and sens or.

For addit ional informati on, refer t o: Sel ect or Lever Cabl e Adjus t ment (307-05 Aut omati c

Transmis s ion/Trans axle External Cont rols ,

General Procedures ).

Refer to the warrant y pol icy and procedures

manual i f the TCM is s us pect .

P0706-00 Trans mis s ion range sens or

A circui t range/performance Incorrect adjus tment of t he

gear s elector lever cabl e Incorrect adjus tment of t he

gear posi ti on s ens or Int ernal t rans mi ss i on cont rol Check t he adjus tment of t he gear s elector l ever

cable.

For addit ional informati on, refer t o: Sel ect or Lever Cabl e Adjus t ment (307-05 Aut omati c

Transmis s ion/Trans axle External Cont rols ,

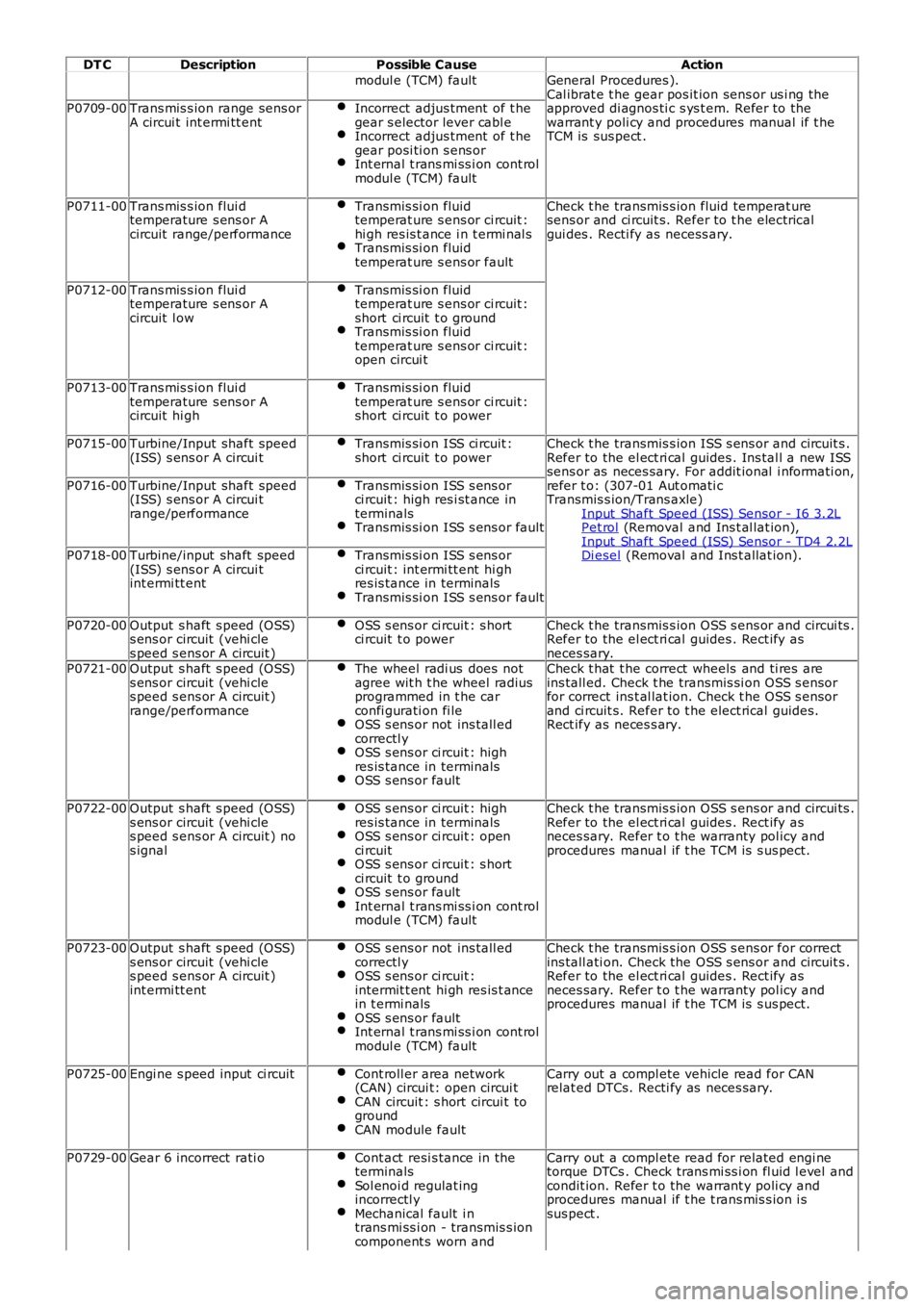

Page 142 of 3229

DT C

Description Possible Cause Action

modul e (TCM) fault General Procedures ).

Cal ibrat e t he gear pos it ion sens or us i ng the

approved di agnos ti c s ys t em. Refer to the

warrant y poli cy and procedures manual if t he

TCM is sus pect .

P0709-00

Trans mis s ion range sens or

A circui t int ermi tt ent Incorrect adjus tment of t he

gear s elector lever cabl e Incorrect adjus tment of t he

gear posi ti on s ens or Int ernal t rans mi ss i on cont rol

modul e (TCM) fault P0711-00

Trans mis s ion flui d

temperature s ens or A

circuit range/performance Transmis si on fluid

temperat ure s ens or ci rcuit :

hi gh res is t ance i n t ermi nal s Transmis si on fluid

temperat ure s ens or fault Check t he transmis s ion fluid temperat ure

sens or and ci rcuit s. Refer to t he elect rical

gui des . Recti fy as necess ary.

P0712-00 Trans mis s ion flui d

temperature s ens or A

circuit l ow Transmis si on fluid

temperat ure s ens or ci rcuit :

short ci rcuit t o ground Transmis si on fluid

temperat ure s ens or ci rcuit :

open circui t P0713-00

Trans mis s ion flui d

temperature s ens or A

circuit hi gh Transmis si on fluid

temperat ure s ens or ci rcuit :

short ci rcuit t o power P0715-00

Turbine/Input shaft speed

(ISS) s ens or A circui t Transmis si on ISS ci rcuit :

short ci rcuit t o power Check t he transmis s ion ISS s ens or and circuit s .

Refer to the el ect ri cal guides . Ins tal l a new ISS

sens or as neces sary. For addit ional i nformati on,

refer t o: (307-01 Aut omati c

Transmis s ion/Trans axle)

Input Shaft Speed (ISS) Sensor - I6 3.2L Pet rol (Removal and Ins t al lat ion),

Input Shaft Speed (ISS) Sensor - TD4 2.2L Di esel (Removal and Ins t allat ion).

P0716-00

Turbine/Input shaft speed

(ISS) s ens or A circui t

range/performance Transmis si on ISS s ens or

ci rcuit : high res i st ance in

terminals Transmis si on ISS s ens or fault

P0718-00

Turbine/input shaft speed

(ISS) s ens or A circui t

int ermi tt ent Transmis si on ISS s ens or

ci rcuit : int ermi tt ent hi gh

res is tance in terminals Transmis si on ISS s ens or fault

P0720-00

Output s haft s peed (OSS)

s ens or circuit (vehi cle

s peed s ens or A circuit ) OSS s ens or ci rcuit : s hort

ci rcuit t o power Check t he transmis s ion OSS s ens or and circui ts .

Refer to the el ect ri cal guides . Rect ify as

neces sary.

P0721-00 Output s haft s peed (OSS)

s ens or circuit (vehi cle

s peed s ens or A circuit )

range/performance The wheel radi us does not

agree wit h t he wheel radius

programmed in t he car

confi gurati on fi le OSS s ens or not ins tall ed

correctl y OSS s ens or ci rcuit : high

res is tance in terminals OSS s ens or fault Check t hat t he correct wheels and ti res are

ins tall ed. Check t he transmis si on OSS s ensor

for correct ins t al lat ion. Check t he OSS s ensor

and ci rcuit s. Refer to t he elect rical guides.

Rect ify as neces s ary.

P0722-00 Output s haft s peed (OSS)

s ens or circuit (vehi cle

s peed s ens or A circuit ) no

s ignal OSS s ens or ci rcuit : high

res is tance in terminals OSS s ens or ci rcuit : open

ci rcuit OSS s ens or ci rcuit : s hort

ci rcuit t o ground OSS s ens or fault

Int ernal t rans mi ss i on cont rol

modul e (TCM) fault Check t he transmis s ion OSS s ens or and circui ts .

Refer to the el ect ri cal guides . Rect ify as

neces sary. Refer t o t he warranty pol icy and

procedures manual if t he TCM is s us pect.

P0723-00 Output s haft s peed (OSS)

s ens or circuit (vehi cle

s peed s ens or A circuit )

int ermi tt ent OSS s ens or not ins tall ed

correctl y OSS s ens or ci rcuit :

intermit t ent hi gh res is t ance

in t ermi nals OSS s ens or fault

Int ernal t rans mi ss i on cont rol

modul e (TCM) fault Check t he transmis s ion OSS s ens or for correct

ins tall ati on. Check the OSS s ens or and circuit s .

Refer to the el ect ri cal guides . Rect ify as

neces sary. Refer t o t he warranty pol icy and

procedures manual if t he TCM is s us pect.

P0725-00 Engi ne s peed input ci rcuit Cont roll er area network

(CAN) circui t: open circui t CAN circuit : s hort circui t to

ground CAN module fault Carry out a compl ete vehicle read for CAN

relat ed DTCs. Recti fy as neces sary.

P0729-00 Gear 6 incorrect rati o Cont act resi s tance in the

terminals Sol enoi d regulat ing

incorrectl y Mechanical fault i n

trans mi ss i on - transmis s ion

component s worn and Carry out a compl ete read for related engi ne

torque DTCs . Check trans mi ss i on fl uid l evel and

condit ion. Refer t o the warrant y poli cy and

procedures manual if t he t rans mis s ion i s

sus pect .

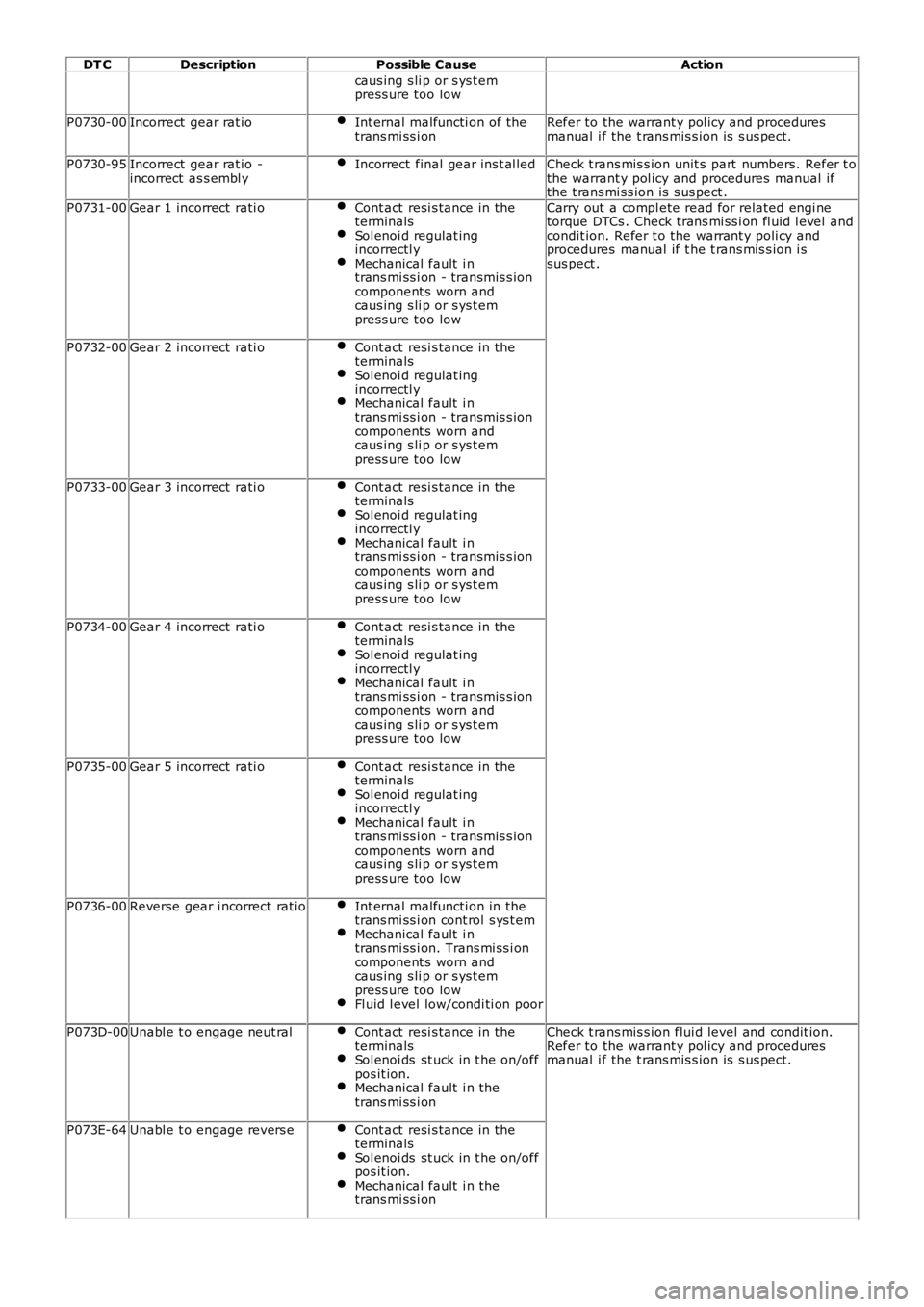

Page 143 of 3229

DT C

Description Possible Cause Action

caus ing s li p or s ys t em

press ure too low

P0730-00 Incorrect gear rat io Int ernal malfuncti on of the

trans mi ss i on Refer to the warrant y pol icy and procedures

manual i f the t rans mis s ion is s us pect.

P0730-95 Incorrect gear rat io -

incorrect as s embl y Incorrect final gear ins t al led Check t rans mis s ion unit s part numbers. Refer t o

the warrant y pol icy and procedures manual if

the t rans mi ss ion is s us pect .

P0731-00 Gear 1 incorrect rati o Cont act resi s tance in the

terminals Sol enoi d regulat ing

incorrectl y Mechanical fault i n

trans mi ss i on - transmis s ion

component s worn and

caus ing s li p or s ys t em

press ure too low Carry out a compl ete read for related engi ne

torque DTCs . Check trans mi ss i on fl uid l evel and

condit ion. Refer t o the warrant y poli cy and

procedures manual if t he t rans mis s ion i s

sus pect .

P0732-00 Gear 2 incorrect rati o Cont act resi s tance in the

terminals Sol enoi d regulat ing

incorrectl y Mechanical fault i n

trans mi ss i on - transmis s ion

component s worn and

caus ing s li p or s ys t em

press ure too low P0733-00

Gear 3 incorrect rati o Cont act resi s tance in the

terminals Sol enoi d regulat ing

incorrectl y Mechanical fault i n

trans mi ss i on - transmis s ion

component s worn and

caus ing s li p or s ys t em

press ure too low P0734-00

Gear 4 incorrect rati o Cont act resi s tance in the

terminals Sol enoi d regulat ing

incorrectl y Mechanical fault i n

trans mi ss i on - transmis s ion

component s worn and

caus ing s li p or s ys t em

press ure too low P0735-00

Gear 5 incorrect rati o Cont act resi s tance in the

terminals Sol enoi d regulat ing

incorrectl y Mechanical fault i n

trans mi ss i on - transmis s ion

component s worn and

caus ing s li p or s ys t em

press ure too low P0736-00

Reverse gear i ncorrect rat io Int ernal malfuncti on in the

trans mi ss i on cont rol s ys t em Mechanical fault i n

trans mi ss i on. Trans mi ss i on

component s worn and

caus ing s li p or s ys t em

press ure too low Fl uid l evel low/condi ti on poor

P073D-00

Unabl e t o engage neut ral Cont act resi s tance in the

terminals Sol enoi ds st uck in t he on/off

pos it ion. Mechanical fault i n the

trans mi ss i on Check t rans mis s ion flui d level and condit ion.

Refer to the warrant y pol icy and procedures

manual i f the t rans mis s ion is s us pect.

P073E-64 Unabl e t o engage revers e Cont act resi s tance in the

terminals Sol enoi ds st uck in t he on/off

pos it ion. Mechanical fault i n the

trans mi ss i on

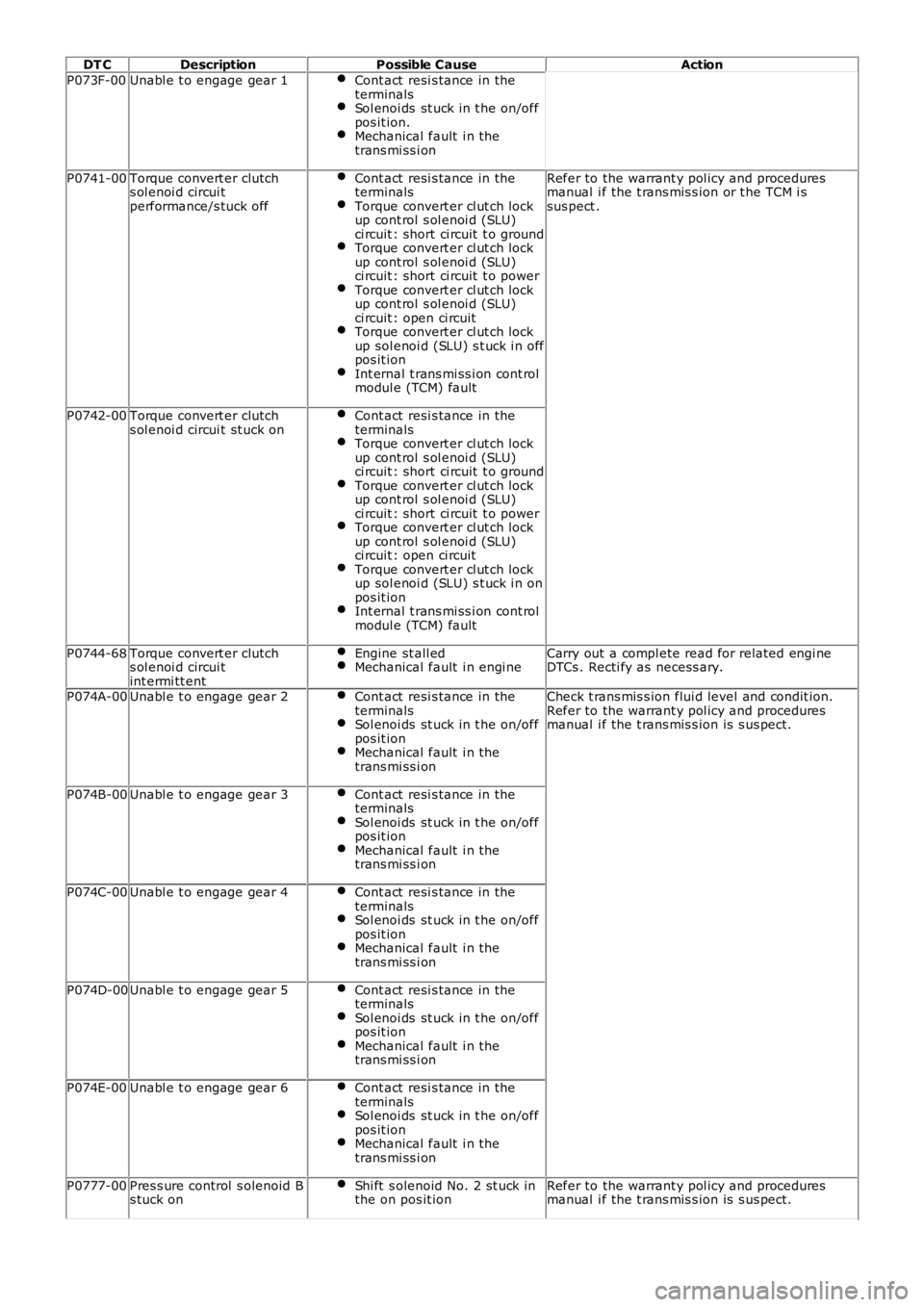

Page 144 of 3229

DT C

Description Possible Cause Action

P073F-00 Unabl e t o engage gear 1 Cont act resi s tance in the

terminals Sol enoi ds st uck in t he on/off

pos it ion. Mechanical fault i n the

trans mi ss i on P0741-00

Torque convert er clutch

s ol enoi d circui t

performance/s tuck off Cont act resi s tance in the

terminals Torque convert er cl ut ch lock

up cont rol s ol enoi d (SLU)

ci rcuit : short ci rcuit t o ground Torque convert er cl ut ch lock

up cont rol s ol enoi d (SLU)

ci rcuit : short ci rcuit t o power Torque convert er cl ut ch lock

up cont rol s ol enoi d (SLU)

ci rcuit : open ci rcuit Torque convert er cl ut ch lock

up sol enoi d (SLU) s t uck i n off

pos it ion Int ernal t rans mi ss i on cont rol

modul e (TCM) fault Refer to the warrant y pol icy and procedures

manual i f the t rans mis s ion or t he TCM i s

sus pect .

P0742-00 Torque convert er clutch

s ol enoi d circui t st uck on Cont act resi s tance in the

terminals Torque convert er cl ut ch lock

up cont rol s ol enoi d (SLU)

ci rcuit : short ci rcuit t o ground Torque convert er cl ut ch lock

up cont rol s ol enoi d (SLU)

ci rcuit : short ci rcuit t o power Torque convert er cl ut ch lock

up cont rol s ol enoi d (SLU)

ci rcuit : open ci rcuit Torque convert er cl ut ch lock

up sol enoi d (SLU) s t uck i n on

pos it ion Int ernal t rans mi ss i on cont rol

modul e (TCM) fault P0744-68

Torque convert er clutch

s ol enoi d circui t

int ermi tt ent Engine st all ed Mechanical fault i n engi ne Carry out a compl ete read for related engi ne

DTCs . Recti fy as necess ary.

P074A-00 Unabl e t o engage gear 2 Cont act resi s tance in the

terminals Sol enoi ds st uck in t he on/off

pos it ion Mechanical fault i n the

trans mi ss i on Check t rans mis s ion flui d level and condit ion.

Refer to the warrant y pol icy and procedures

manual i f the t rans mis s ion is s us pect.

P074B-00 Unabl e t o engage gear 3 Cont act resi s tance in the

terminals Sol enoi ds st uck in t he on/off

pos it ion Mechanical fault i n the

trans mi ss i on P074C-00

Unabl e t o engage gear 4 Cont act resi s tance in the

terminals Sol enoi ds st uck in t he on/off

pos it ion Mechanical fault i n the

trans mi ss i on P074D-00

Unabl e t o engage gear 5 Cont act resi s tance in the

terminals Sol enoi ds st uck in t he on/off

pos it ion Mechanical fault i n the

trans mi ss i on P074E-00

Unabl e t o engage gear 6 Cont act resi s tance in the

terminals Sol enoi ds st uck in t he on/off

pos it ion Mechanical fault i n the

trans mi ss i on P0777-00

Pres s ure control s olenoid B

s tuck on Shi ft s olenoid No. 2 st uck in

the on pos it ion Refer to the warrant y pol icy and procedures

manual i f the t rans mis s ion is s us pect.

Page 145 of 3229

DT C

Description Possible Cause Action

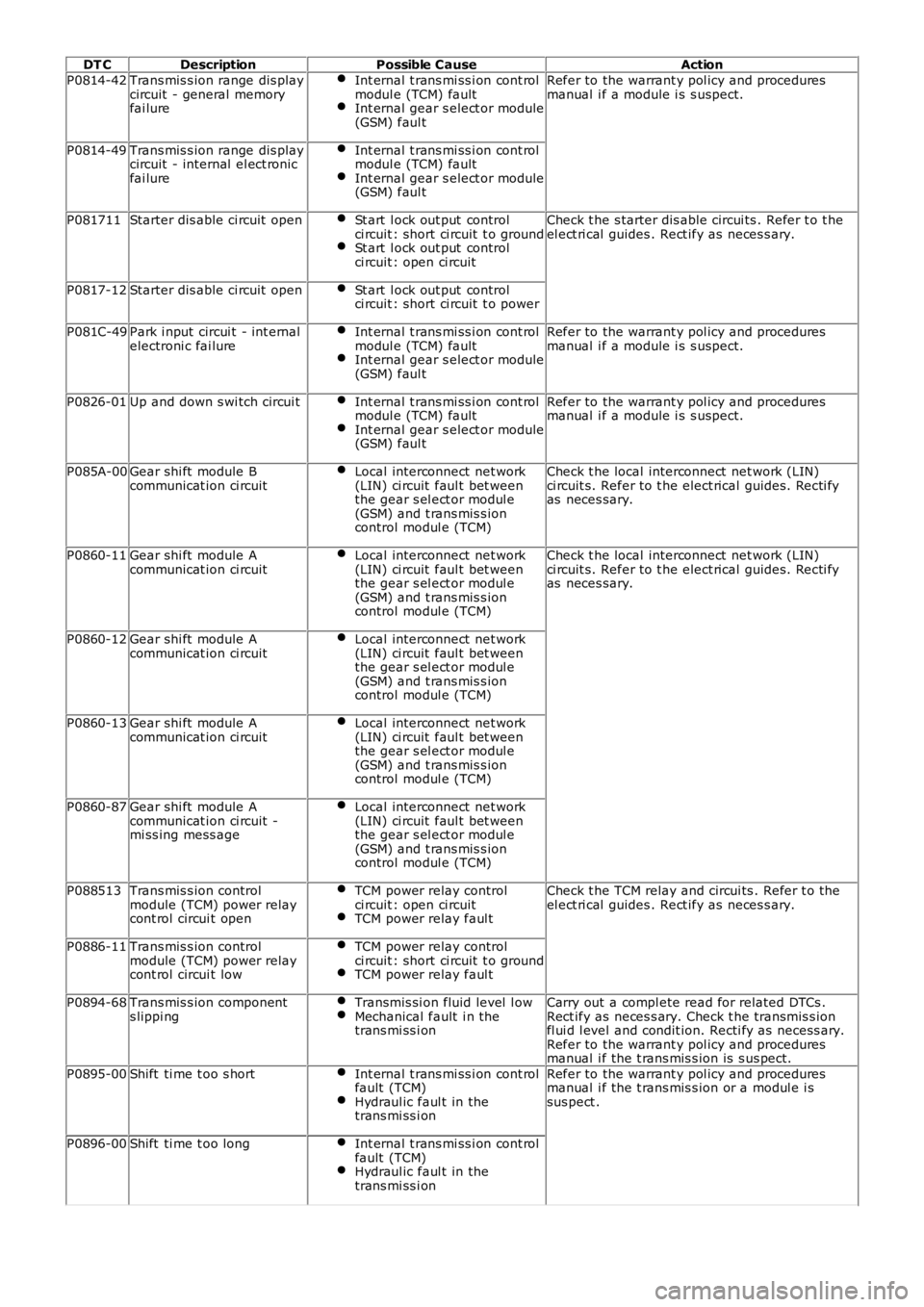

P0814-42 Trans mis s ion range dis play

circuit - general memory

fai lure Int ernal t rans mi ss i on cont rol

modul e (TCM) fault Int ernal gear s elect or module

(GSM) faul t Refer to the warrant y pol icy and procedures

manual i f a module i s s uspect.

P0814-49 Trans mis s ion range dis play

circuit - internal el ect ronic

fai lure Int ernal t rans mi ss i on cont rol

modul e (TCM) fault Int ernal gear s elect or module

(GSM) faul t P081711

Starter dis able ci rcuit open St art l ock out put control

ci rcuit : short ci rcuit t o ground St art l ock out put control

ci rcuit : open ci rcuit Check t he s tarter dis able circui ts . Refer t o t he

el ect ri cal guides . Rect ify as neces s ary.

P0817-12 Starter dis able ci rcuit open St art l ock out put control

ci rcuit : short ci rcuit t o power P081C-49

Park i nput circui t - int ernal

electroni c fai lure Int ernal t rans mi ss i on cont rol

modul e (TCM) fault Int ernal gear s elect or module

(GSM) faul t Refer to the warrant y pol icy and procedures

manual i f a module i s s uspect.

P0826-01 Up and down s wi tch circui t Int ernal t rans mi ss i on cont rol

modul e (TCM) fault Int ernal gear s elect or module

(GSM) faul t Refer to the warrant y pol icy and procedures

manual i f a module i s s uspect.

P085A-00 Gear shi ft module B

communicat ion ci rcuit Local interconnect net work

(LIN) ci rcuit faul t bet ween

the gear s el ect or modul e

(GSM) and t rans mis s ion

control modul e (TCM) Check t he local interconnect net work (LIN)

ci rcuit s. Refer to t he elect rical guides. Recti fy

as neces sary.

P0860-11 Gear shi ft module A

communicat ion ci rcuit Local interconnect net work

(LIN) ci rcuit faul t bet ween

the gear s el ect or modul e

(GSM) and t rans mis s ion

control modul e (TCM) Check t he local interconnect net work (LIN)

ci rcuit s. Refer to t he elect rical guides. Recti fy

as neces sary.

P0860-12 Gear shi ft module A

communicat ion ci rcuit Local interconnect net work

(LIN) ci rcuit faul t bet ween

the gear s el ect or modul e

(GSM) and t rans mis s ion

control modul e (TCM) P0860-13

Gear shi ft module A

communicat ion ci rcuit Local interconnect net work

(LIN) ci rcuit faul t bet ween

the gear s el ect or modul e

(GSM) and t rans mis s ion

control modul e (TCM) P0860-87

Gear shi ft module A

communicat ion ci rcuit -

mi ss ing mess age Local interconnect net work

(LIN) ci rcuit faul t bet ween

the gear s el ect or modul e

(GSM) and t rans mis s ion

control modul e (TCM) P088513

Trans mis s ion control

module (TCM) power relay

cont rol circui t open TCM power relay control

ci rcuit : open ci rcuit TCM power relay faul t Check t he TCM relay and circui ts . Refer t o the

el ect ri cal guides . Rect ify as neces s ary.

P0886-11 Trans mis s ion control

module (TCM) power relay

cont rol circui t low TCM power relay control

ci rcuit : short ci rcuit t o ground TCM power relay faul t

P0894-68

Trans mis s ion component

s lippi ng Transmis si on fluid level l ow Mechanical fault i n the

trans mi ss i on Carry out a compl ete read for related DTCs .

Rect ify as neces s ary. Check t he transmis s ion

fl ui d l evel and condit ion. Recti fy as necess ary.

Refer to the warrant y pol icy and procedures

manual i f the t rans mis s ion is s us pect.

P0895-00 Shift ti me t oo s hort Int ernal t rans mi ss i on cont rol

fault (TCM) Hydraul ic faul t in the

trans mi ss i on Refer to the warrant y pol icy and procedures

manual i f the t rans mis s ion or a modul e i s

sus pect .

P0896-00 Shift ti me t oo long Int ernal t rans mi ss i on cont rol

fault (TCM) Hydraul ic faul t in the

trans mi ss i on

Page 146 of 3229

DT C

Description Possible Cause Action

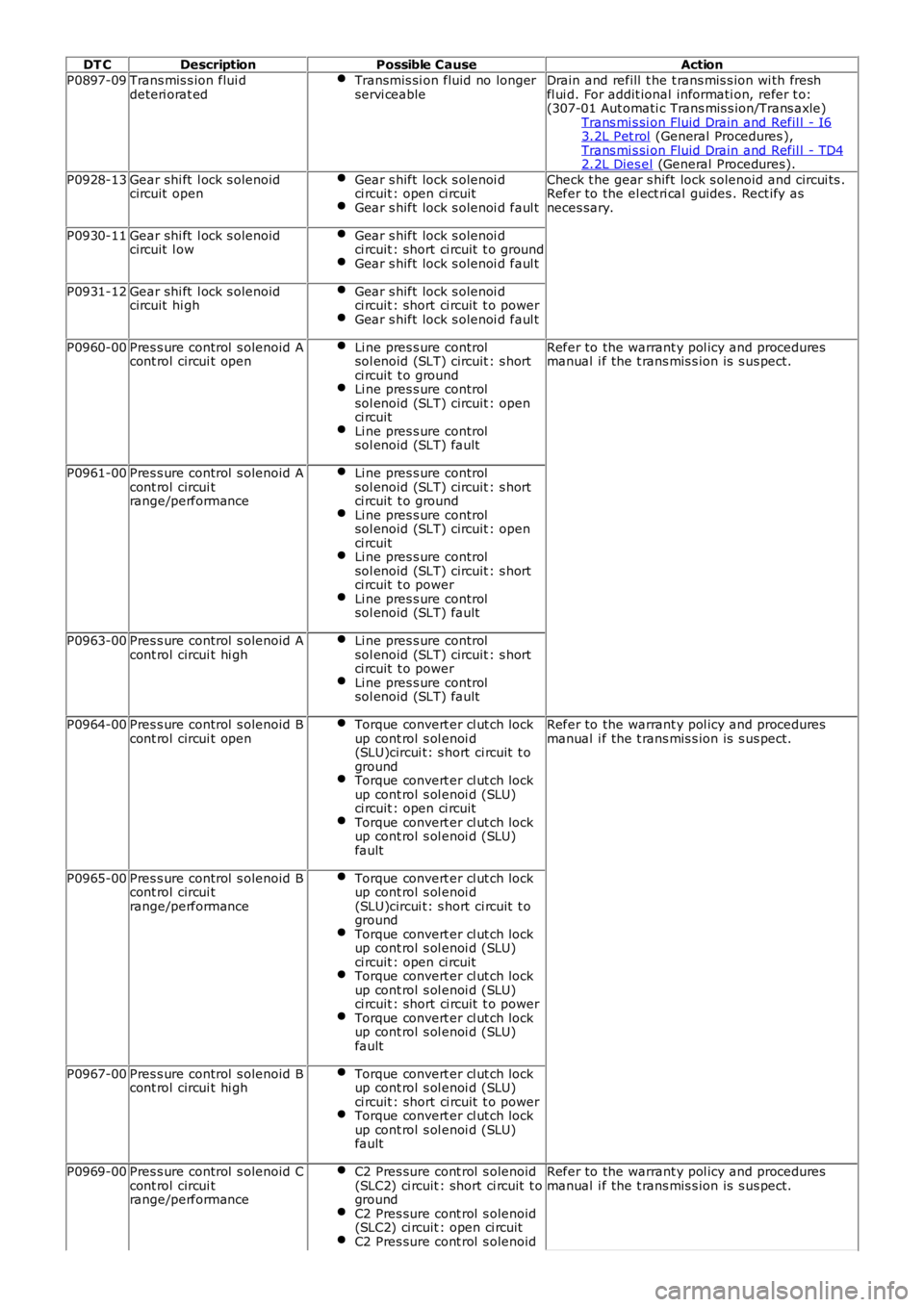

P0897-09 Trans mis s ion flui d

deteri orat ed Transmis si on fluid no longer

servi ceable Drain and refill t he t rans mis s ion wi th fresh

fl ui d. For addit ional informati on, refer t o:

(307-01 Aut omati c Trans mis s ion/Trans axle)

Trans mi s si on Fluid Drain and Refil l - I6 3.2L Pet rol (General Procedures ),

Trans mi s si on Fluid Drain and Refil l - TD4 2.2L Dies el (General Procedures).

P0928-13 Gear shi ft l ock s olenoid

circuit open Gear s hift lock s olenoi d

ci rcuit : open ci rcuit Gear s hift lock s olenoi d faul t Check t he gear s hift lock s olenoid and circui ts .

Refer to the el ect ri cal guides . Rect ify as

neces sary.

P0930-11 Gear shi ft l ock s olenoid

circuit l ow Gear s hift lock s olenoi d

ci rcuit : short ci rcuit t o ground Gear s hift lock s olenoi d faul t

P0931-12

Gear shi ft l ock s olenoid

circuit hi gh Gear s hift lock s olenoi d

ci rcuit : short ci rcuit t o power Gear s hift lock s olenoi d faul t

P0960-00

Pres s ure control s olenoid A

cont rol circui t open Li ne pres s ure control

sol enoid (SLT) circuit : s hort

ci rcuit t o ground Li ne pres s ure control

sol enoid (SLT) circuit : open

ci rcuit Li ne pres s ure control

sol enoid (SLT) fault Refer to the warrant y pol icy and procedures

manual i f the t rans mis s ion is s us pect.

P0961-00 Pres s ure control s olenoid A

cont rol circui t

range/performance Li ne pres s ure control

sol enoid (SLT) circuit : s hort

ci rcuit t o ground Li ne pres s ure control

sol enoid (SLT) circuit : open

ci rcuit Li ne pres s ure control

sol enoid (SLT) circuit : s hort

ci rcuit t o power Li ne pres s ure control

sol enoid (SLT) fault P0963-00

Pres s ure control s olenoid A

cont rol circui t hi gh Li ne pres s ure control

sol enoid (SLT) circuit : s hort

ci rcuit t o power Li ne pres s ure control

sol enoid (SLT) fault P0964-00

Pres s ure control s olenoid B

cont rol circui t open Torque convert er cl ut ch lock

up cont rol s ol enoi d

(SLU)circui t: s hort ci rcuit t o

ground Torque convert er cl ut ch lock

up cont rol s ol enoi d (SLU)

ci rcuit : open ci rcuit Torque convert er cl ut ch lock

up cont rol s ol enoi d (SLU)

fault Refer to the warrant y pol icy and procedures

manual i f the t rans mis s ion is s us pect.

P0965-00 Pres s ure control s olenoid B

cont rol circui t

range/performance Torque convert er cl ut ch lock

up cont rol s ol enoi d

(SLU)circui t: s hort ci rcuit t o

ground Torque convert er cl ut ch lock

up cont rol s ol enoi d (SLU)

ci rcuit : open ci rcuit Torque convert er cl ut ch lock

up cont rol s ol enoi d (SLU)

ci rcuit : short ci rcuit t o power Torque convert er cl ut ch lock

up cont rol s ol enoi d (SLU)

fault P0967-00

Pres s ure control s olenoid B

cont rol circui t hi gh Torque convert er cl ut ch lock

up cont rol s ol enoi d (SLU)

ci rcuit : short ci rcuit t o power Torque convert er cl ut ch lock

up cont rol s ol enoi d (SLU)

fault P0969-00

Pres s ure control s olenoid C

cont rol circui t

range/performance C2 Pres sure cont rol s olenoid

(SLC2) ci rcuit : short ci rcuit t o

ground C2 Pres sure cont rol s olenoid

(SLC2) ci rcuit : open ci rcuit C2 Pres sure cont rol s olenoid Refer to the warrant y pol icy and procedures

manual i f the t rans mis s ion is s us pect.

Page 147 of 3229

DT C

Description Possible Cause Action

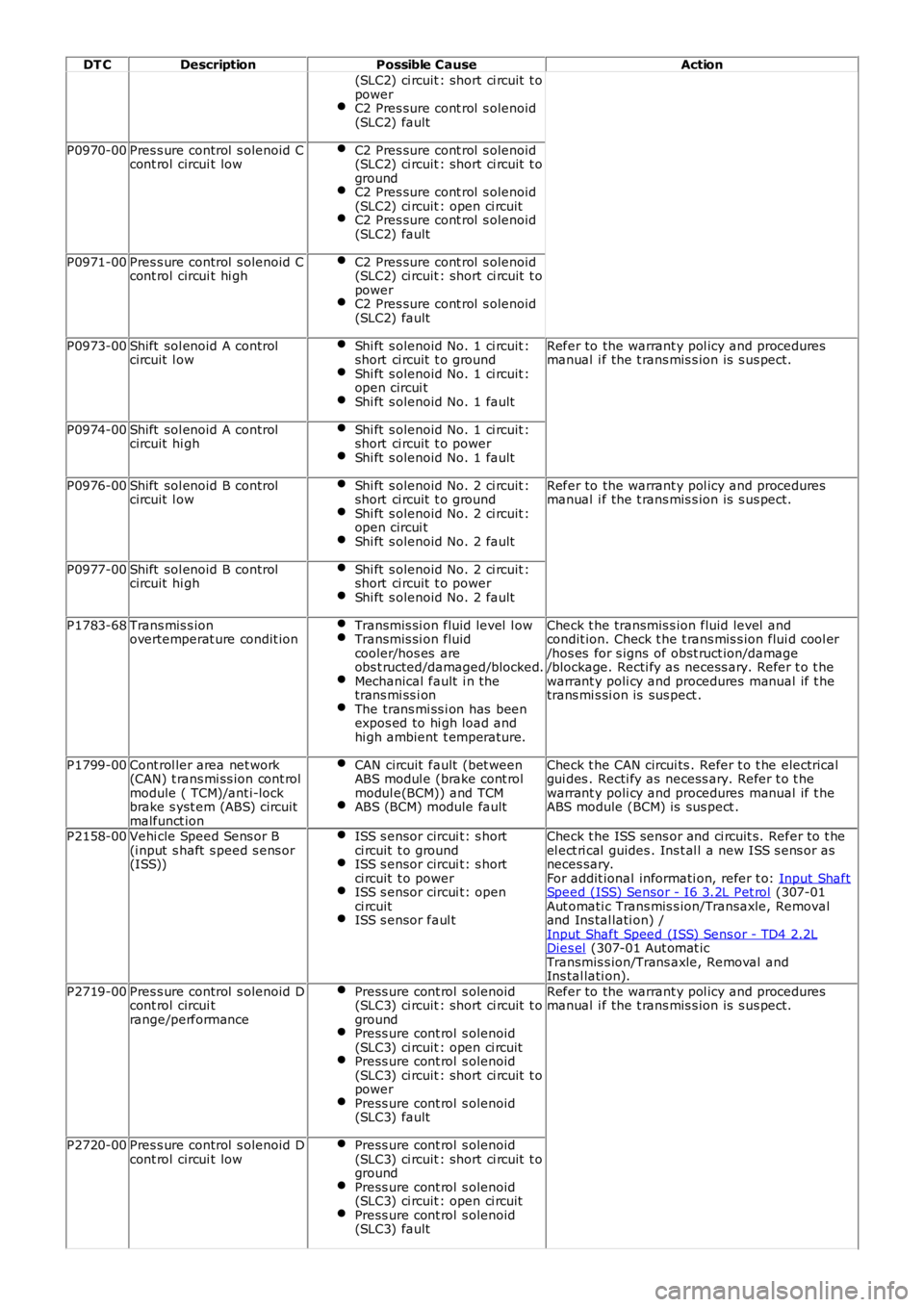

(SLC2) ci rcuit : short ci rcuit t o

power

C2 Pres sure cont rol s olenoid

(SLC2) fault P0970-00

Pres s ure control s olenoid C

cont rol circui t low C2 Pres sure cont rol s olenoid

(SLC2) ci rcuit : short ci rcuit t o

ground C2 Pres sure cont rol s olenoid

(SLC2) ci rcuit : open ci rcuit C2 Pres sure cont rol s olenoid

(SLC2) fault P0971-00

Pres s ure control s olenoid C

cont rol circui t hi gh C2 Pres sure cont rol s olenoid

(SLC2) ci rcuit : short ci rcuit t o

power C2 Pres sure cont rol s olenoid

(SLC2) fault P0973-00

Shift sol enoid A control

circuit l ow Shi ft s olenoid No. 1 ci rcuit :

short ci rcuit t o ground Shi ft s olenoid No. 1 ci rcuit :

open circui t Shi ft s olenoid No. 1 fault Refer to the warrant y pol icy and procedures

manual i f the t rans mis s ion is s us pect.

P0974-00 Shift sol enoid A control

circuit hi gh Shi ft s olenoid No. 1 ci rcuit :

short ci rcuit t o power Shi ft s olenoid No. 1 fault

P0976-00

Shift sol enoid B control

circuit l ow Shi ft s olenoid No. 2 ci rcuit :

short ci rcuit t o ground Shi ft s olenoid No. 2 ci rcuit :

open circui t Shi ft s olenoid No. 2 fault Refer to the warrant y pol icy and procedures

manual i f the t rans mis s ion is s us pect.

P0977-00 Shift sol enoid B control

circuit hi gh Shi ft s olenoid No. 2 ci rcuit :

short ci rcuit t o power Shi ft s olenoid No. 2 fault

P1783-68

Trans mis s ion

overtemperat ure condit ion Transmis si on fluid level l ow Transmis si on fluid

cooler/hos es are

obs t ructed/damaged/blocked. Mechanical fault i n the

trans mi ss i on The trans mi ss i on has been

expos ed to hi gh load and

hi gh ambient t emperature. Check t he transmis s ion fluid level and

condit ion. Check t he t rans mis s ion flui d cool er

/hos es for s igns of obst ruct ion/damage

/blockage. Recti fy as necess ary. Refer t o t he

warrant y poli cy and procedures manual if t he

trans mi s si on is sus pect .

P1799-00 Cont rol ler area net work

(CAN) t rans mi ss ion cont rol

module ( TCM)/ant i-lock

brake s yst em (ABS) circuit

malfunct ion CAN circuit fault (bet ween

ABS modul e (brake cont rol

modul e(BCM)) and TCM ABS (BCM) module fault Check t he CAN circui ts . Refer t o t he electrical

gui des . Recti fy as necess ary. Refer t o t he

warrant y poli cy and procedures manual if t he

ABS module (BCM) is sus pect .

P2158-00 Vehi cle Speed Sens or B

(i nput s haft s peed s ens or

(ISS)) ISS s ensor circui t: s hort

ci rcuit t o ground ISS s ensor circui t: s hort

ci rcuit t o power ISS s ensor circui t: open

ci rcuit ISS s ensor faul t Check t he ISS sens or and ci rcuit s. Refer to t he

el ect ri cal guides . Ins t al l a new ISS s ens or as

neces sary.

For addit ional informati on, refer t o: Input Shaft Speed (ISS) Sensor - I6 3.2L Pet rol (307-01

Aut omati c Trans mis s ion/Transaxle, Removal

and Ins tal lati on) /

Input Shaft Speed (ISS) Sens or - TD4 2.2L Dies el (307-01 Aut omat ic

Transmis s ion/Trans axle, Removal and

Ins tal lati on).

P2719-00 Pres s ure control s olenoid D

cont rol circui t

range/performance Press ure cont rol s olenoid

(SLC3) ci rcuit : short ci rcuit t o

ground Press ure cont rol s olenoid

(SLC3) ci rcuit : open ci rcuit Press ure cont rol s olenoid

(SLC3) ci rcuit : short ci rcuit t o

power Press ure cont rol s olenoid

(SLC3) fault Refer to the warrant y pol icy and procedures

manual i f the t rans mis s ion is s us pect.

P2720-00 Pres s ure control s olenoid D

cont rol circui t low Press ure cont rol s olenoid

(SLC3) ci rcuit : short ci rcuit t o

ground Press ure cont rol s olenoid

(SLC3) ci rcuit : open ci rcuit Press ure cont rol s olenoid

(SLC3) fault

Page 148 of 3229

DT C

Description Possible Cause Action

P2721-00 Pres s ure control s olenoid D

cont rol circui t hi gh Press ure cont rol s olenoid

(SLC3) ci rcuit : short ci rcuit t o

power Press ure cont rol s olenoid

(SLC3) fault P2728-00

Pres s ure control s olenoid E

cont rol circui t

range/performance Press ure cont rol s olenoid

(SLB1) ci rcuit : short ci rcuit t o

ground Press ure cont rol s olenoid

(SLB1) ci rcuit : open ci rcuit Press ure cont rol s olenoid

(SLB1) ci rcuit : short ci rcuit t o

power Press ure cont rol s olenoid

(SLB1) fault Refer to the warrant y pol icy and procedures

manual i f the t rans mis s ion is s us pect.

P2729-00 Pres s ure control s olenoid E

cont rol circui t low Press ure cont rol s olenoid

(SLB1) ci rcuit : short ci rcuit t o

ground Press ure cont rol s olenoid

(SLB1) ci rcuit : open ci rcuit Press ure cont rol s olenoid

(SLB1) fault P2730-00

Pres s ure control s olenoid E

cont rol circui t hi gh Press ure cont rol s olenoid

(SLB1) ci rcuit : short ci rcuit t o

power Press ure cont rol s olenoid

(SLB1) fault P2733-00

Pres s ure control s olenoid F

s tuck on SLC1 s olenoid has jammed Mechanical fault s in

trans mi ss i on Refer to the warrant y pol icy and procedures

manual i f the t rans mis s ion is s us pect.

P2737-00 Pres s ure control s olenoid F

cont rol circui t

range/performance Press ure cont rol s olenoid

(SLC1) ci rcuit : short ci rcuit t o

ground Press ure cont rol s olenoid

(SLC1) ci rcuit : open ci rcuit Press ure cont rol s olenoid

(SLC1) ci rcuit : short ci rcuit t o

power Press ure cont rol s olenoid

(SLC1) fault P2738-00

Pres s ure control s olenoid F

cont rol circui t low Press ure cont rol s olenoid

(SLC1) ci rcuit : short ci rcuit t o

ground Press ure cont rol s olenoid

(SLC1) ci rcuit : open ci rcuit Press ure cont rol s olenoid

(SLC1) fault P2739-00

Pres s ure control s olenoid F

cont rol circui t hi gh Press ure cont rol s olenoid

(SLC1) ci rcuit : short ci rcuit t o

power Press ure cont rol s olenoid

(SLC1) fault P2783-68

Torque convert er

temperature too hi gh Transmis si on fluid level l ow Transmis si on fluid

cooler/hos es are

obs t ructed/damaged/blocked. Mechanical fault i n the

trans mi ss i on The trans mi ss i on has been

expos ed to ext reme load and

hi gh ambient t emperature Check t he transmis s ion fluid level and

condit ion. Check t he t rans mis s ion flui d cool er

/hos es for s igns of obst ruct ion/damage

/blockage. Recti fy as necess ary. Refer t o t he

warrant y poli cy and procedures manual if t he

trans mi s si on is sus pect .

P2787-68 Clut ch temperat ure too

high Transmis si on fluid level l ow Transmis si on fluid

cooler/hos es are

obs t ructed/damaged/blocked. Mechanical fault i n the

trans mi ss i on The trans mi ss i on has been

expos ed to ext reme load and

hi gh ambient t emperature Check t he transmis s ion fluid level and

condit ion. Check t he t rans mis s ion flui d cool er

/hos es for s igns of obst ruct ion/damage

/blockage. Recti fy as necess ary. Refer t o t he

warrant y poli cy and procedures manual if t he

trans mi s si on is sus pect .

Page 149 of 3229

DT C

Description Possible Cause Action

P2800-00 Trans mis s ion range sens or

B circui t (PRNDL i nput ) Incorrect adjus tment of t he

gear s elector lever cabl e Int ernal t rans mi ss i on cont rol

modul e (TCM) fault Check t hat t he gear sel ect or lever cable is

correctl y adjus ted.

For addit ional informati on, refer t o: Sel ect or Lever Cabl e Adjus t ment (307-05 Aut omati c

Transmis s ion/Trans axle External Cont rols ,

General Procedures ).

Refer to the warrant y pol icy and procedures

manual i f the TCM is s us pect

P2801-00

Trans mis s ion range sens or

B circui t range/performance Incorrect adjus tment of t he

gear s elector lever cabl e Int ernal t rans mi ss i on cont rol

modul e (TCM) fault P2805-00

Trans mis s ion range sens or

A/B correl at ion Incorrect adjus tment of t he

gear s elector lever cabl e Int ernal t rans mi ss i on cont rol

modul e (TCM) fault U0001-00

High s peed cont rol ler area

network (CAN)

communicat ion bus CAN circuit : open circuit CAN circuit : s hort circui t to

each ot her CAN circuit : s hort circui t to

power CAN cont rol module fail ure Carry out a compl ete vehicle read for DTCs

indicati ng a CAN or module fault . Rect ify as

neces sary. Refer t o t he warranty pol icy and

procedures manual if a module i s s uspect.

U0100-00 Los t communicati on wi th

ECM "A" CAN circuit : open circuit CAN circuit : s hort circui t to

each ot her CAN circuit : s hort circui t to

power CAN cont rol module fail ure Carry out a compl ete vehicle read for DTCs

indicati ng a CAN or module fault . Rect ify as

neces sary. Refer t o t he warranty pol icy and

procedures manual if a module i s s uspect.

U0121-00 Cont rol ler area net work

(CAN) t rans mi ss ion cont rol

module ( TCM)/ant i-lock

brake s yst em (ABS) circuit

malfunct ion no

communicat ion CAN circuit : open circuit CAN circuit : s hort circui t to

each ot her CAN circuit : s hort circui t to

power CAN cont rol module fail ure Carry out a compl ete vehicle read for DTCs

indicati ng a CAN or module fault . Rect ify as

neces sary. Refer t o t he warranty pol icy and

procedures manual if a module i s s uspect.

U0300-00 Int ernal cont rol module

s oft ware i ncompat ibil it y Incorrect cont rol ler area

net work (CAN) configurat ion

ID

- incorrect

hardware/s oft ware level Check t hat t he modules are correct for the

vehicl e and that t he correct level of software is

ins tall ed. Reconfi gure t he CAN s yst em us i ng the

approved di agnos ti c s ys t em.

U0401-00 Invali d data recei ved from

engi ne cont rol module

(ECM) Incorrect s ignal from t he ECM Carry out a compl ete vehicle read for DTCs

indicati ng a cont rol ler area net work (CAN) or

ECM faul t. Recti fy as necess ary. Refer t o t he

warrant y poli cy and procedures manual if t he

ECM is sus pect .

U0415-00 Invali d data recei ved from

the ant i-lock brake s ys tem

(ABS) control modul e The engine cont rol module

(ECM) has t he wrong code for

the i mmobil izer The ABS modul e (brake

control modul e (BCM)) has

the wrong code for the

immobi lizer Transmis si on cont rol module

(TCM) faul t Reprogramme the modules as neces sary. Refer

to the warranty pol icy and procedures manual if

a module i s s uspect.

U2100-00 Ini ti al confi gurati on not

compl ete Cont roll er area network

(CAN) circui t fault Init ial cent ral confi gurati on

has never been sent Check for ot her controll er area network (CAN)

DTCs or apparent ly unrel at ed cust omer

compl ai nts . Carry out a complet e vehi cl e DTC

read. Check t he CAN circui ts . Refer t o t he

el ect ri cal guides . Rect ify as neces s ary. Clear

the DTCs and t es t for normal operat ion. Check

correct cent ral car confi gurati on s oftware i s

ins tall ed. Reprogramme t he module as

neces sary.

U2101-00 Cont rol module

configurat ion i ncompat ible Cent ral car confi gurati on

parameter mi ss i ng or

corrupted Check correct central car configurat ion s oft ware

is i nst all ed. Reprogramme t he module as

neces sary.

U2023-00 Engi ne t orque s ignal Cont roll er area network

(CAN) circui t (between

engine cont rol module (ECM)

and trans mi ss i on cont rol

modul e (TCM)): open ci rcuit CAN circuit (between ECM

and TCM): s hort circui t CAN module fault Carry out a compl ete read for related DTCs .

Rect ify as neces s ary. Check t he CAN circui ts .

Refer to the el ect ri cal guides . Rect ify as

neces sary.

U2105-11 Swit ch pack s i gnal "A" Shi ft l ock s olenoid ci rcuit

fault : s hort ci rcuit t o ground Gear s elector module (GSM)

fault Check t he GSM and circui ts . Refer t o t he

el ect ri cal guides . Rect ify as neces s ary. Refer to

the warrant y pol icy and procedures manual if

the GSM is s us pect .

Page 150 of 3229

DT C

Description Possible Cause Action

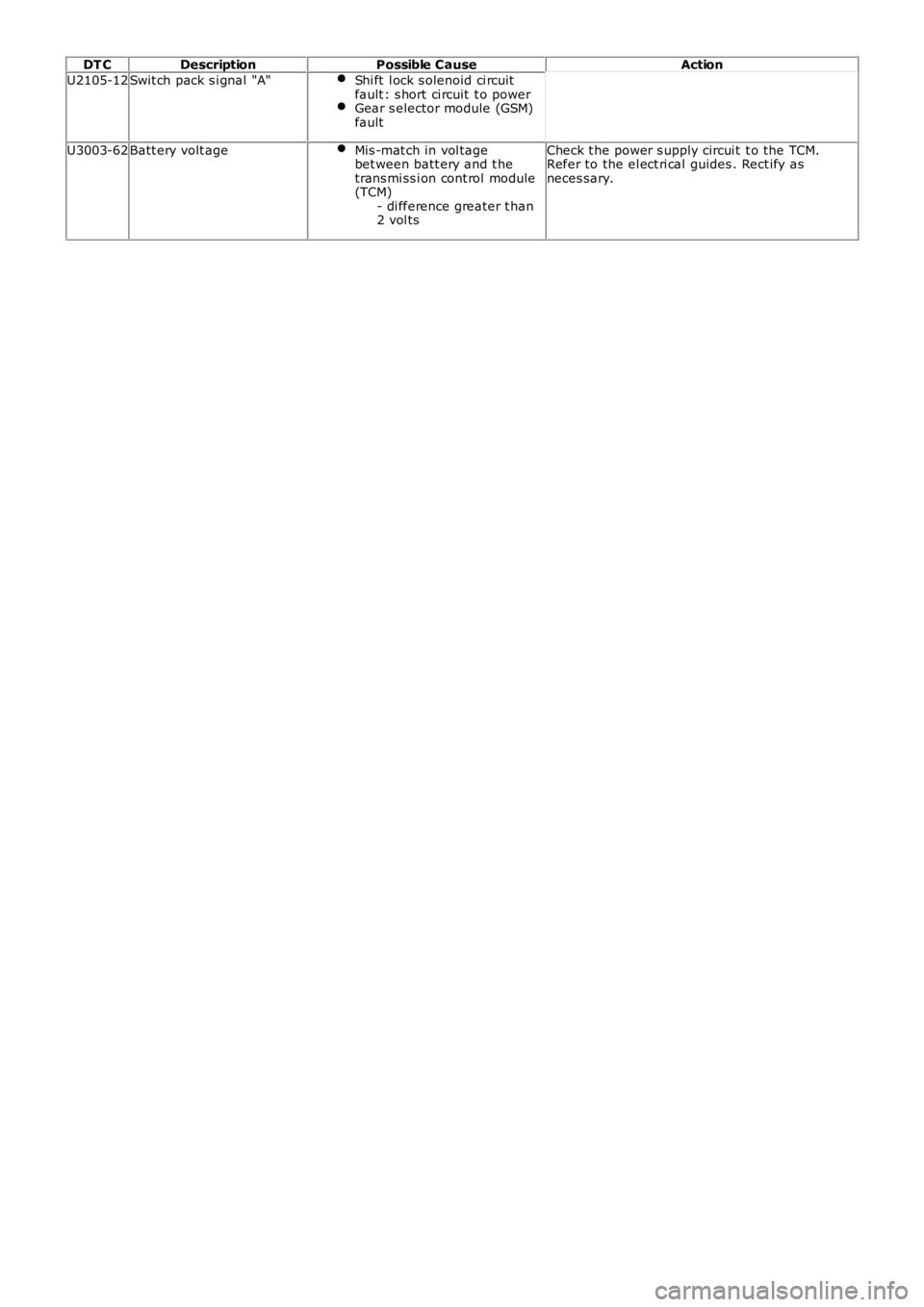

U2105-12 Swit ch pack s i gnal "A" Shi ft l ock s olenoid ci rcuit

fault : s hort ci rcuit t o power Gear s elector module (GSM)

fault U3003-62

Batt ery volt age Mis -mat ch in vol tage

bet ween batt ery and t he

trans mi ss i on cont rol module

(TCM)

- di fference greater t han

2 vol ts Check t he power s upply circui t t o the TCM.

Refer to the el ect ri cal guides . Rect ify as

neces sary.