engine LAND ROVER FRELANDER 2 2006 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 774 of 3229

For furt her det ail s on connecti ng rod bi g-end beari ng ins tal lati on, refer t o t he relevant Service Repair Procedures (SRP).

The pis t ons are manufactured from al uminum alloy and are i ns t alled wit h 2 compres s ion rings , and an oil cont rol ring wi tha s piral spring. A s teel ins ert i s i ns t alled in t he pis t on upper ring groove t o provi de reinforcement. The pis t on crown i s at oroidal des i gn that forms a pronounced bowl in t he center of the pi s ton head. Recesses are als o formed in t he pis t oncrown t o provi de cl earance for t he 4 valve heads. This des ign of combus ti on chamber promot es high l evel s of swirl andt urbulence required for complete combus t ion of t he air/fuel mi xture, and al so improves t he engine emi ss i ons .

The 3 pi st on rings mus t be ins t al led wi th the ring gaps s paced at 120° (wit h permis sible tolerance of 15° t o 20°) to eachother, around the pi st on. The 2 upper compres s ion rings are s tamped wi th 't op' t o aid ins tall ati on. The gap of t he doubl ebevel ed oil cont rol ring mus t als o be oppos it e t he s pi ral s pri ng joint .

The ful l ski rt pis t on is coated wit h a graphi te bas ed s ubst ance to reduce fri cti on wit h t he cyl inder bore. The graphi te bas edcoat ing i s es pecial ly i mport ant during t he engine runni ng in period and s t art-up. The pis ton al so incorporat es 2 oil coolingchannels t hat are formed on the unders i de of the pi st on head.

Two bus hed hol es are formed at oppos it e s ides of t he pis ton s kirt for i nst all at ion of a full y floati ng gudgeon pin. Thegudgeon pi n pass es t hrough the pi s ton bus hed hol es and connecti ng rod s mal l-end, and i s ret ained at each end wit h acircl ip. The pis ton, gudgeon pi n and connecti ng rod smal l-end are s uppli ed wit h oil from an oil s pray jet, l ocat ed bel oweach cyli nder bore.

Duri ng ins tal lat ion of t he pis tons , the s t amped direct ion arrow and 'DIST' on each pis ton crown mus t face t oward t he frontof the engine (acces s ory drive end).

For furt her det ail s on pis t on and pis ton ring ins tall ati on, refer t o the relevant Service Repai r Procedures (SRP) manual.

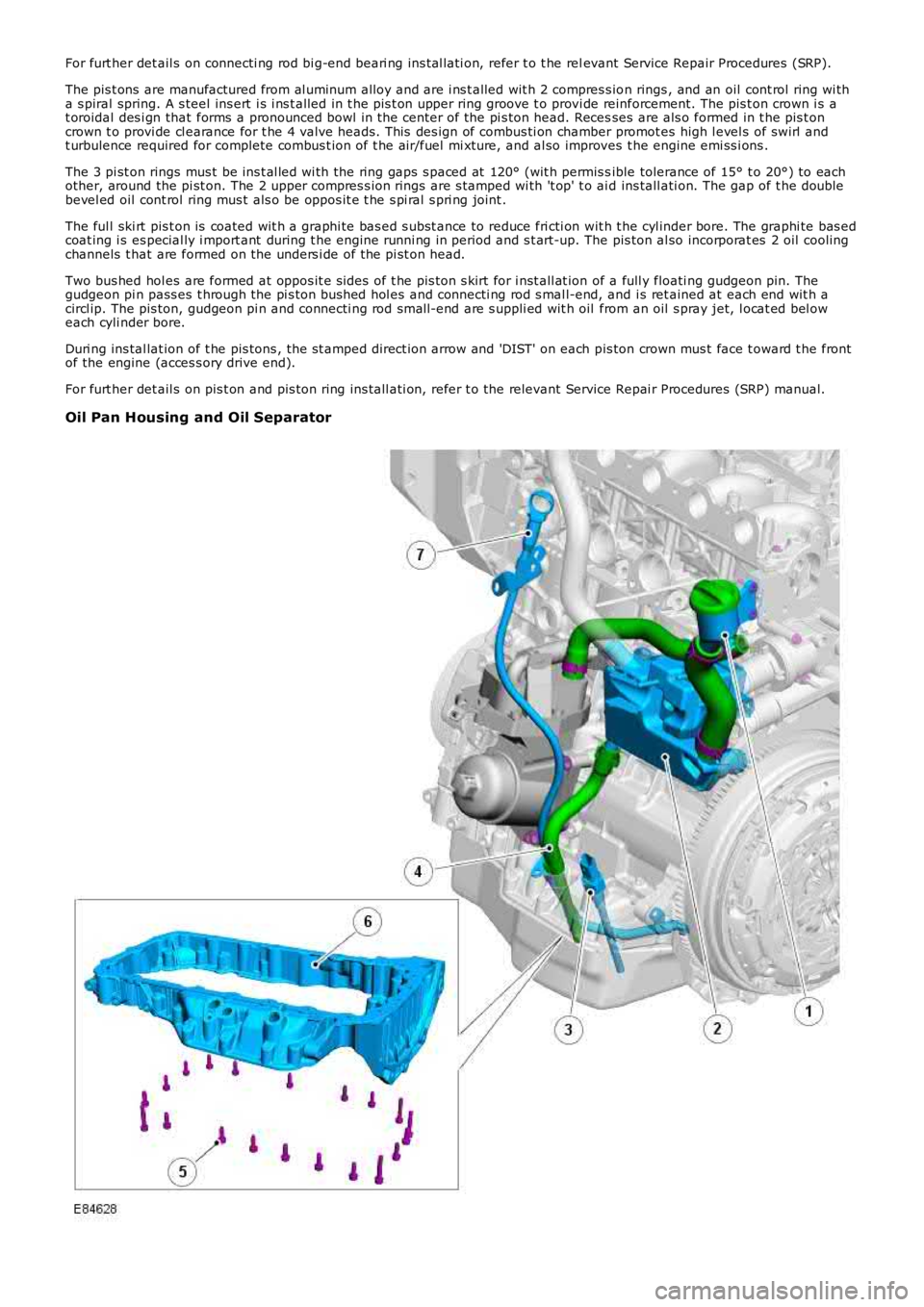

Oil Pan Housing and Oil Separator

Page 775 of 3229

ItemPart NumberDescription

1-Oil fill er tube

2-Oil s eparator3-Oil t emperature s ens or

4-Oil s eparator ret urn pi pe

5-Oil pan housi ng bolt s (20 off)6-Oil pan housi ng

7-Oil level gage

The alumi num oil pan hous ing i s s ecured wit h 20 bolt s t o t he bot t om of t he cyl inder bl ock, and forms an ext ens ionbetween t he cyl inder block and oil pan. The oi l pan hous ing i s requi red i n order t o increas e t he dis tance between t he oilpump and oil pan, due to the ins tall ati on of the counter-balance s haft ass embly.

The rear of t he oil pan hous i ng provides t he lower mounti ng poi nts for the trans mi s si on cas i ng. Dril lings formed in t he LHs ide of t he hous i ng provide t he locati on for t he oil l evel gage tube, oil t emperature s ens or, and t he ret urn hos e from t hecrankcas e venti lati on oil s eparator.

The crankcas e venti lati on oil s eparator i s als o connected to t he oil fil ler t ube, located at t he rear LH si de of the engine. Oi lfor repl enis hing t he s ys t em pas ses through t he oil s eparator and return hos e, and int o t he oil pan. An oil baffle pl ate i sins t al led i n t he oil pan housi ng to reduce oil aerat ion and s plas h.

Oil Pump

The rot or type oil pump is l ocat ed bet ween t he oil pan and oil pan housi ng, and at t ached wi th 5 bol ts to the front of t hecount er-bal ance s haft as s embly. The oil pump i s dri ven by the cranks haft via a s ingle row chain. For furt her informati on,refer to 'Lubricati on Sys t em' wit hin t his s ecti on.

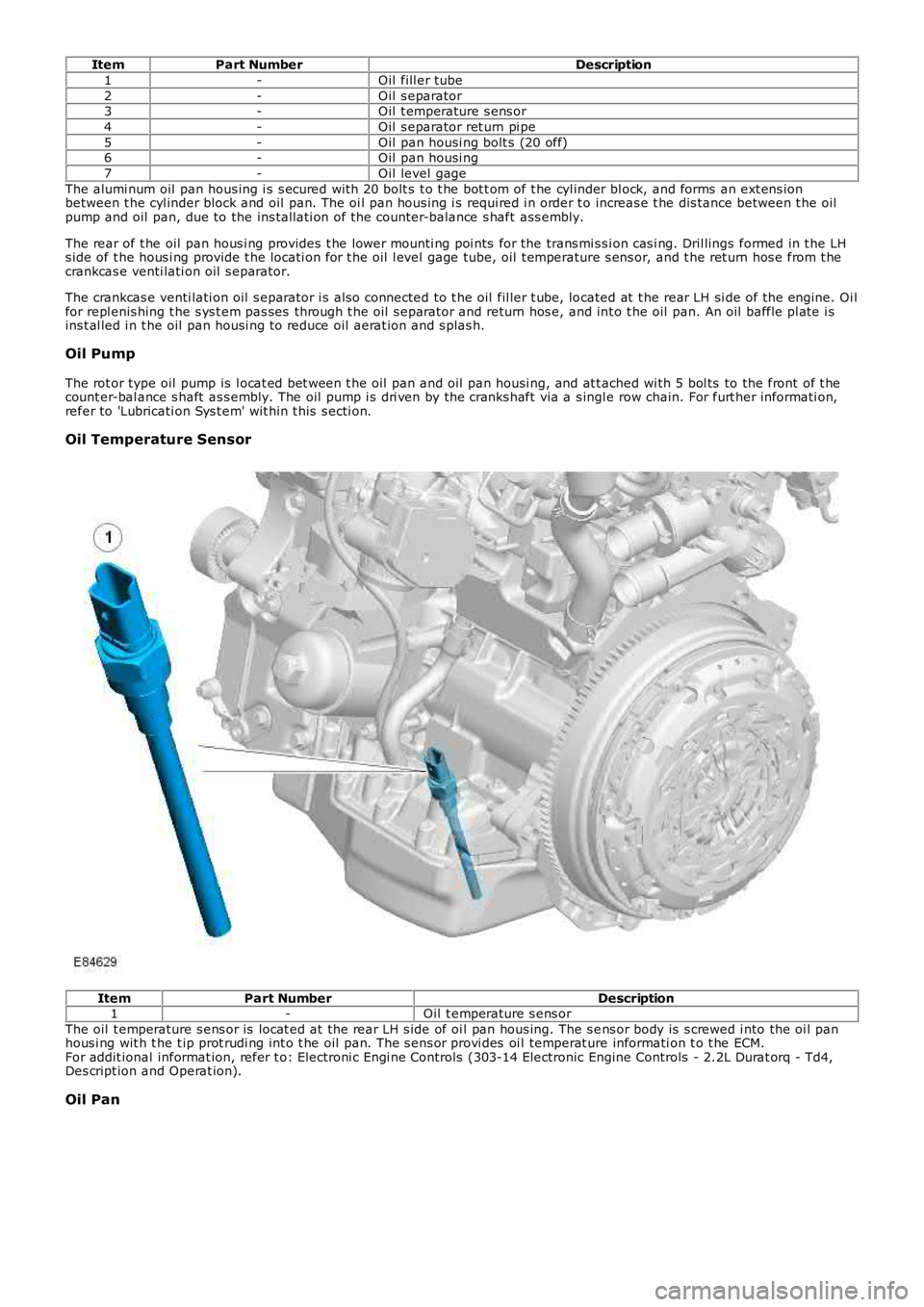

Oil Temperature Sensor

ItemPart NumberDescription1-Oil t emperature s ens or

The oil t emperature s ens or is locat ed at t he rear LH s ide of oi l pan hous ing. The s ens or body is s crewed i nto the oi l panhous i ng wit h t he t ip prot rudi ng int o t he oil pan. The s ens or provi des oi l temperat ure informati on t o t he ECM.For addit ional informat ion, refer t o: Electroni c Engi ne Controls (303-14 Electronic Engine Controls - 2.2L Durat orq - Td4,Des cript ion and Operat ion).

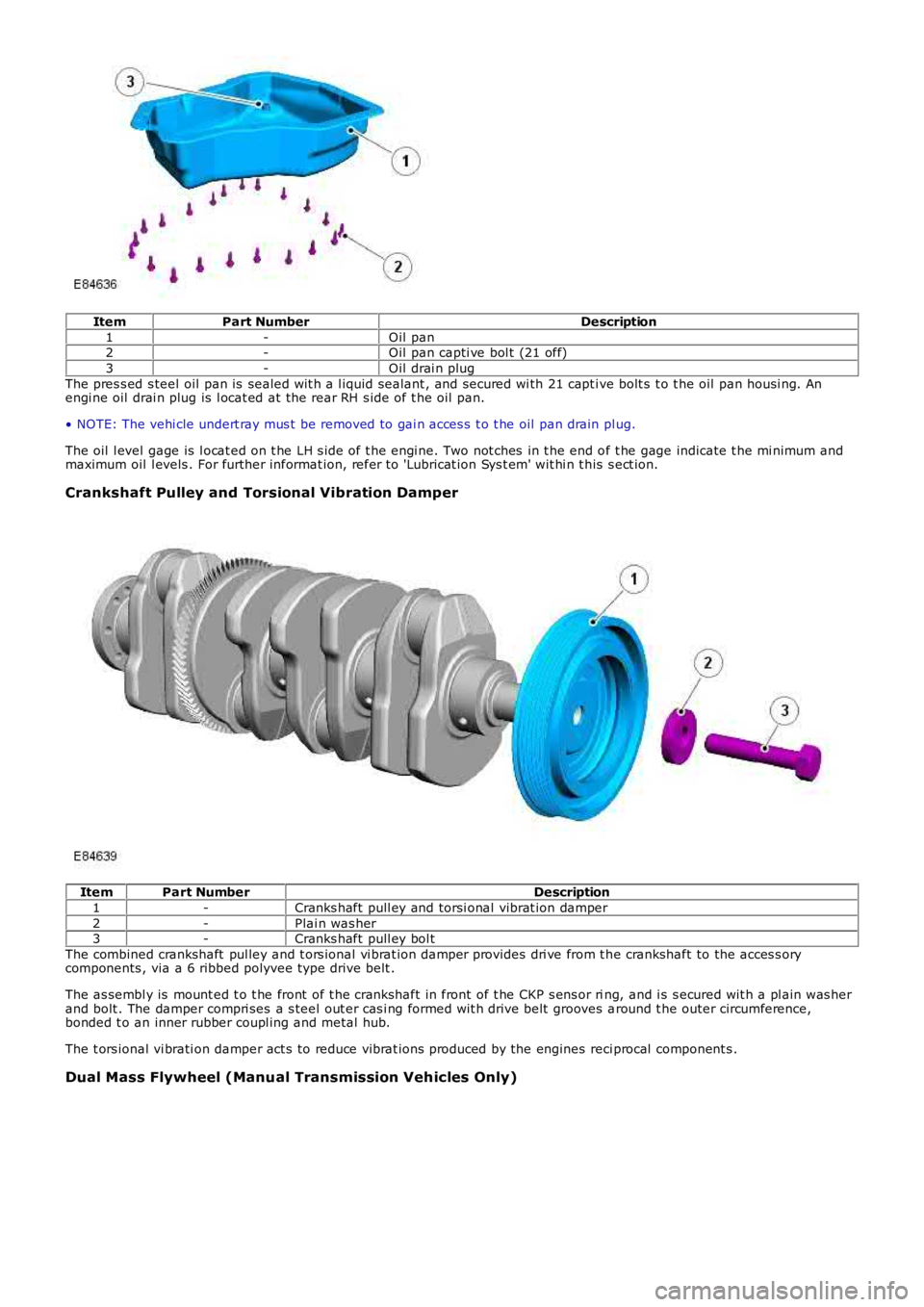

Oil Pan

Page 776 of 3229

ItemPart NumberDescription

1-Oil pan2-Oil pan capti ve bol t (21 off)

3-Oil drai n plug

The pres s ed s teel oil pan is sealed wit h a l iquid sealant , and secured wi th 21 capt ive bolt s t o t he oil pan housi ng. Anengi ne oil drai n plug is l ocat ed at the rear RH s ide of t he oil pan.

• NOTE: The vehi cle undert ray mus t be removed to gai n acces s t o t he oil pan drain plug.

The oil l evel gage is l ocat ed on t he LH s ide of t he engi ne. Two not ches in t he end of t he gage indicate t he mi nimum andmaximum oil l evels . For further informat ion, refer t o 'Lubricat ion Sys t em' wit hi n t his s ect ion.

Crankshaft Pulley and Torsional Vibration Damper

ItemPart NumberDescription

1-Cranks haft pull ey and torsi onal vibrat ion damper

2-Plai n was her3-Cranks haft pull ey bol t

The combined crankshaft pul ley and t ors ional vi brat ion damper provides dri ve from t he crankshaft to the acces s orycomponents , via a 6 ribbed polyvee type drive belt .

The as sembl y is mount ed t o t he front of t he crankshaft in front of t he CKP s ens or ring, and i s s ecured wit h a pl ain was herand bolt . The damper compri ses a s teel out er cas i ng formed wit h drive belt grooves around t he outer circumference,bonded t o an inner rubber coupl ing and metal hub.

The t ors ional vi brati on damper act s to reduce vibrat ions produced by the engines reci procal component s .

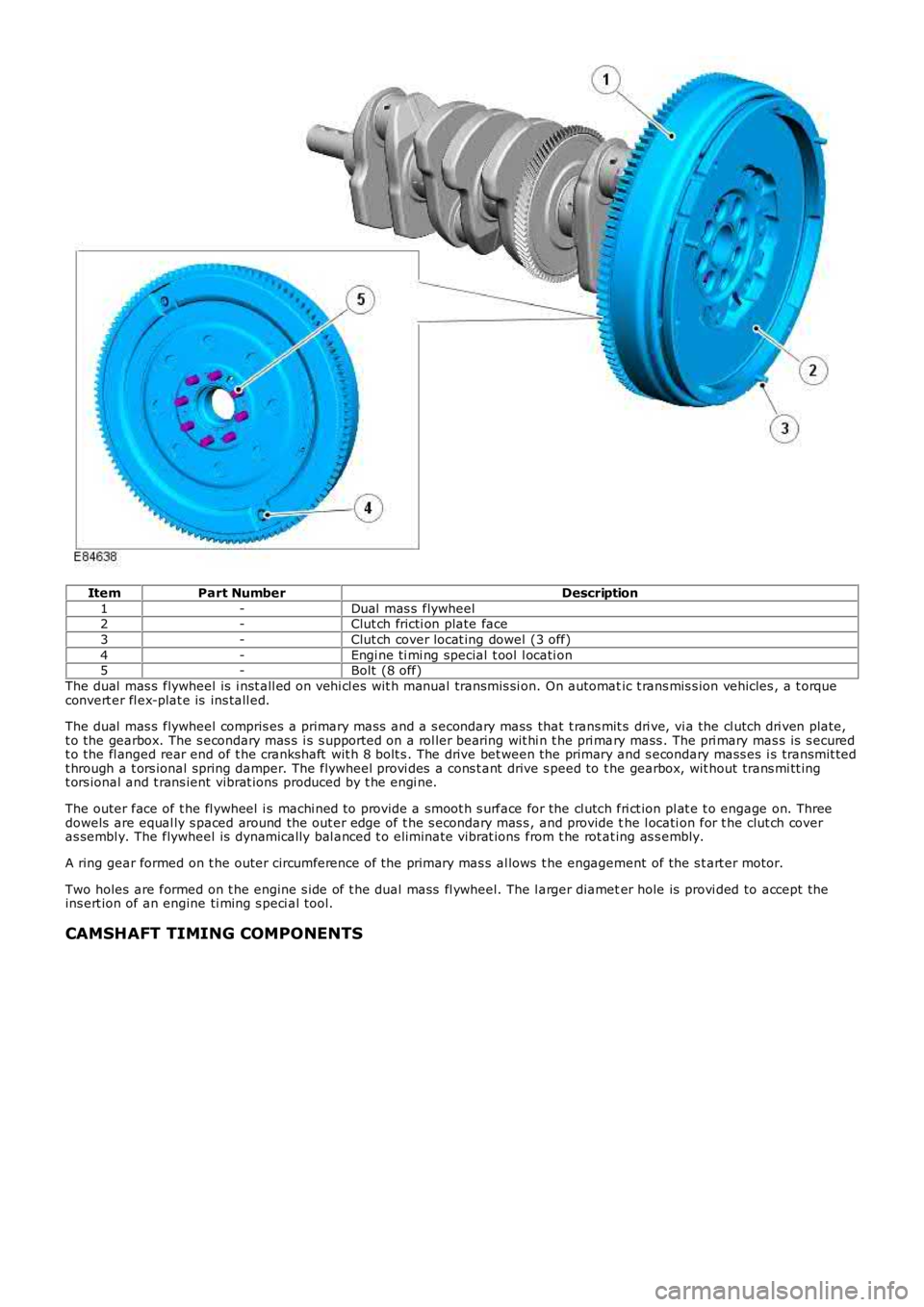

Dual Mass Flywheel (Manual Transmission Vehicles Only)

Page 777 of 3229

ItemPart NumberDescription

1-Dual mas s flywheel2-Clut ch fricti on plate face

3-Clut ch cover locat ing dowel (3 off)

4-Engi ne ti mi ng special t ool l ocati on5-Bolt (8 off)

The dual mas s flywheel is i nst all ed on vehi cl es wit h manual transmis si on. On automatic t rans mis s ion vehicles , a t orqueconvert er fl ex-plat e is ins tall ed.

The dual mas s flywheel compris es a primary mas s and a s econdary mass that t rans mit s dri ve, vi a the cl utch dri ven plate,t o the gearbox. The s econdary mas s i s s upported on a rol ler bearing wit hi n t he pri mary mass . The pri mary mas s is s ecuredt o the fl anged rear end of t he crankshaft wit h 8 bolt s . The drive bet ween the primary and s econdary mass es i s transmit tedt hrough a t ors ional spring damper. The flywheel provi des a cons t ant drive s peed to the gearbox, wit hout trans mi tt ingt ors ional and t rans ient vibrat ions produced by t he engi ne.

The outer face of t he fl ywheel i s machi ned to provide a smoot h s urface for the cl utch fri ct ion pl at e t o engage on. Threedowels are equal ly s paced around the out er edge of t he s econdary mas s , and provide the l ocati on for t he clut ch coveras sembl y. The flywheel is dynamically bal anced t o eli mi nat e vibrat ions from t he rot at ing as s embly.

A ring gear formed on t he outer circumference of the primary mas s al lows t he engagement of the s t art er motor.

Two holes are formed on t he engine s ide of t he dual mass fl ywheel. The l arger diameter hole is provi ded to accept theins ert ion of an engine ti ming s peci al tool.

CAMSHAFT TIMING COMPONENTS

Page 784 of 3229

The cyl inder head and st ructural cams haft cover are manufactured to form mat ing parts . The part s are mil led i n a si ngl eoperati on and accurat ely pos it ioned wi th 2 alignment s leeves. The 2 components mus t al ways be ins tall ed t oget her, andnot renewed as s eparate component s . The cyl inder head and cams haft cover are s eal ed to each ot her during manufact urewit h a gas ket and s ili cone bas ed s eal ant, and are s ecured wit h 27 bolt s . An oil s eal i nst all ed at the front of t he cyl inderhead provides s eal ing of t he exhaus t camshaft hous ing. The open port s at the rear of the cyli nder head are sealed wit ht he vacuum pump and hi gh-pres s ure fuel pump s eal ing rings .

Two ali gnment sl eeves correct ly l ocat e t he cyl inder head and gas ket to t he cylinder block. The cyli nder head is secured t ot he cyl inder bl ock wit h 10 deep-s eat ed bolt s .

• NOTE: The cyl inder head bol ts are not acces si ble wit h the st ruct ural cams haft cover i nst all ed.

• NOTE: The cyl inder head is not t o be reworked.

The cyl inder head is manufact ured from al uminum alloy, havi ng valve s eats and guides made of s i nt ered st eel. Thecyl inder head is precis ely machi ned and mil led t o i ncorporate t he 4 combus ti on chambers, cams haft l ower beari nghous i ngs , oil drill ings and cool ant gal leri es, and t he air i ntake, val ve ti ming and fuel sys t em component bores andhous i ngs .

The desi gn of the cyli nder head maximizes air flow and s wi rl i n the combus ti on chambers. The 2 int ake val ve seat s aremachined wit h rais ed profil es that act to promote swi rl of t he int ake ai r fl ow. Combined wit h t he acti on of the i ntakemanifold heli cal port , t he s wirl effect of the 2 int ake port profi les al lows t he air and i nject ed fuel t o complet el y mi x, andreach t he outer edge of the combus ti on chamber.

The s truct ural camshaft cover is manufact ured from alumi num all oy, and i s machined on t he upper s urface wit h t hecamshaft upper bearing hous ings . The cover is al so formed wi th 4 int ake ai r fi ll ing t racts , fuel i nject or bores and ori fi cesfor t he cyl inder head cover PCV components . The i nt ake air t racts join the i ntake air mani fold to the cyli nder head int akefi ll ing port s .

The cyl inder head al s o provides t he mounti ng locati ons for the foll owing:

Front engi ne mounti ngFront and rear engine l ifti ng eyesInt ake and exhaus t manifol dsEGR valve and coolerFuel fil ter s upport bracketThermal cont rol moduleVacuum pump and high-press ure fuel pump.

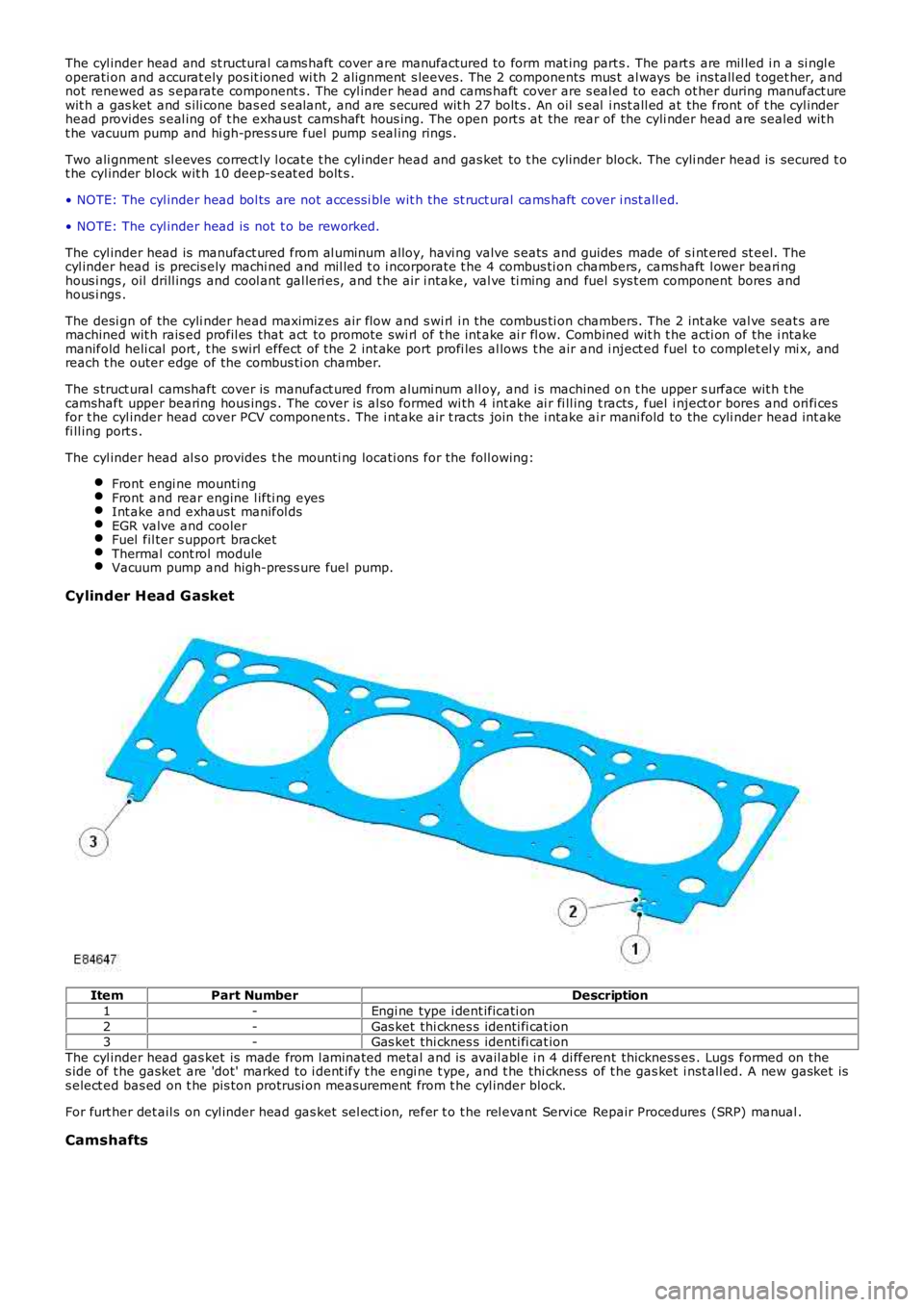

Cylinder Head G asket

ItemPart NumberDescription

1-Engi ne type i dent ificati on

2-Gas ket thi cknes s identi fi cat ion3-Gas ket thi cknes s identi fi cat ion

The cyl inder head gas ket is made from l aminated metal and is avail abl e i n 4 di fferent thickness es . Lugs formed on thes ide of t he gasket are 'dot' marked to i dent ify t he engi ne t ype, and t he thi ckness of t he gas ket i nst all ed. A new gasket iss elect ed bas ed on t he pis ton protrusi on meas urement from t he cyl inder block.

For furt her det ail s on cyl inder head gas ket sel ect ion, refer t o t he rel evant Servi ce Repair Procedures (SRP) manual .

Camshafts

Page 785 of 3229

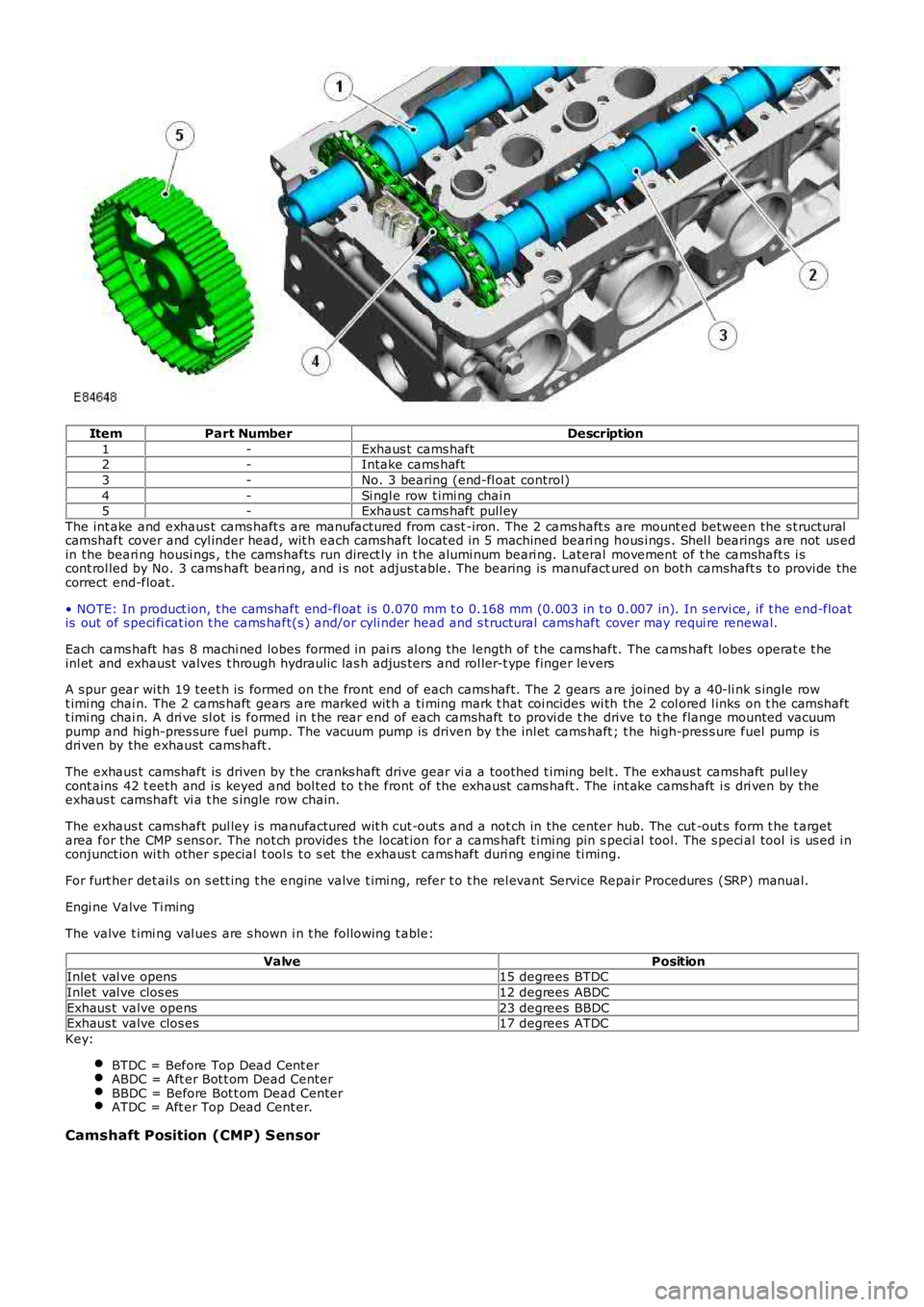

ItemPart NumberDescription

1-Exhaus t cams haft2-Intake cams haft

3-No. 3 bearing (end-fl oat control)

4-Si ngl e row t imi ng chai n5-Exhaus t cams haft pull ey

The int ake and exhaus t cams haft s are manufactured from cast -iron. The 2 cams haft s are mount ed between the s t ructuralcamshaft cover and cyl inder head, wit h each camshaft locat ed i n 5 machined beari ng hous i ngs . Shel l bearings are not us edin the beari ng housi ngs , t he camshafts run direct ly in t he alumi num beari ng. Lateral movement of t he camshaft s i scont rol led by No. 3 cams haft beari ng, and i s not adjust able. The bearing is manufactured on both camshaft s t o provi de thecorrect end-float.

• NOTE: In product ion, t he camshaft end-fl oat i s 0.070 mm t o 0.168 mm (0.003 in t o 0.007 in). In s ervi ce, if t he end-floatis out of s peci fi cat ion t he cams haft(s ) and/or cyli nder head and s t ructural cams haft cover may requi re renewal.

Each cams haft has 8 machi ned lobes formed in pai rs al ong the length of t he cams haft. The cams haft lobes operat e t heinl et and exhaust valves t hrough hydraulic las h adjus ters and rol ler-t ype finger levers

A s pur gear wi th 19 teet h is formed on t he front end of each cams haft. The 2 gears are joined by a 40-li nk s ingle rowt imi ng chai n. The 2 cams haft gears are marked wit h a ti ming mark t hat coi ncides wi th the 2 col ored l inks on t he camshaftt imi ng chai n. A dri ve sl ot is formed in t he rear end of each camshaft to provi de t he drive to t he flange mounted vacuumpump and high-pres sure fuel pump. The vacuum pump is driven by t he inl et cams haft ; the hi gh-pres s ure fuel pump isdri ven by the exhaust cams haft .

The exhaus t camshaft is driven by t he cranks haft drive gear vi a a toothed t iming belt . The exhaus t camshaft pul leycont ains 42 t eeth and is keyed and bol ted to t he front of the exhaust cams haft . The int ake cams haft i s dri ven by theexhaus t camshaft vi a t he s ingle row chain.

The exhaus t camshaft pul ley i s manufactured wit h cut-out s and a not ch in the center hub. The cut -out s form t he t argetarea for the CMP s ens or. The not ch provides the locat ion for a cams haft t imi ng pin speci al tool. The s peci al tool is us ed i nconjunct ion wi th other s pecial t ool s t o s et the exhaus t cams haft duri ng engi ne ti ming.

For furt her det ail s on s ett ing t he engine valve t imi ng, refer t o t he rel evant Service Repair Procedures (SRP) manual.

Engi ne Valve Ti ming

The valve t imi ng val ues are s hown i n t he fol lowing t able:

ValvePositionInlet val ve opens15 degrees BTDC

Inlet val ve clos es12 degrees ABDC

Exhaus t valve opens23 degrees BBDCExhaus t valve clos es17 degrees ATDC

Key:

BTDC = Before Top Dead Cent erABDC = Aft er Bot t om Dead CenterBBDC = Before Bot t om Dead CenterATDC = Aft er Top Dead Cent er.

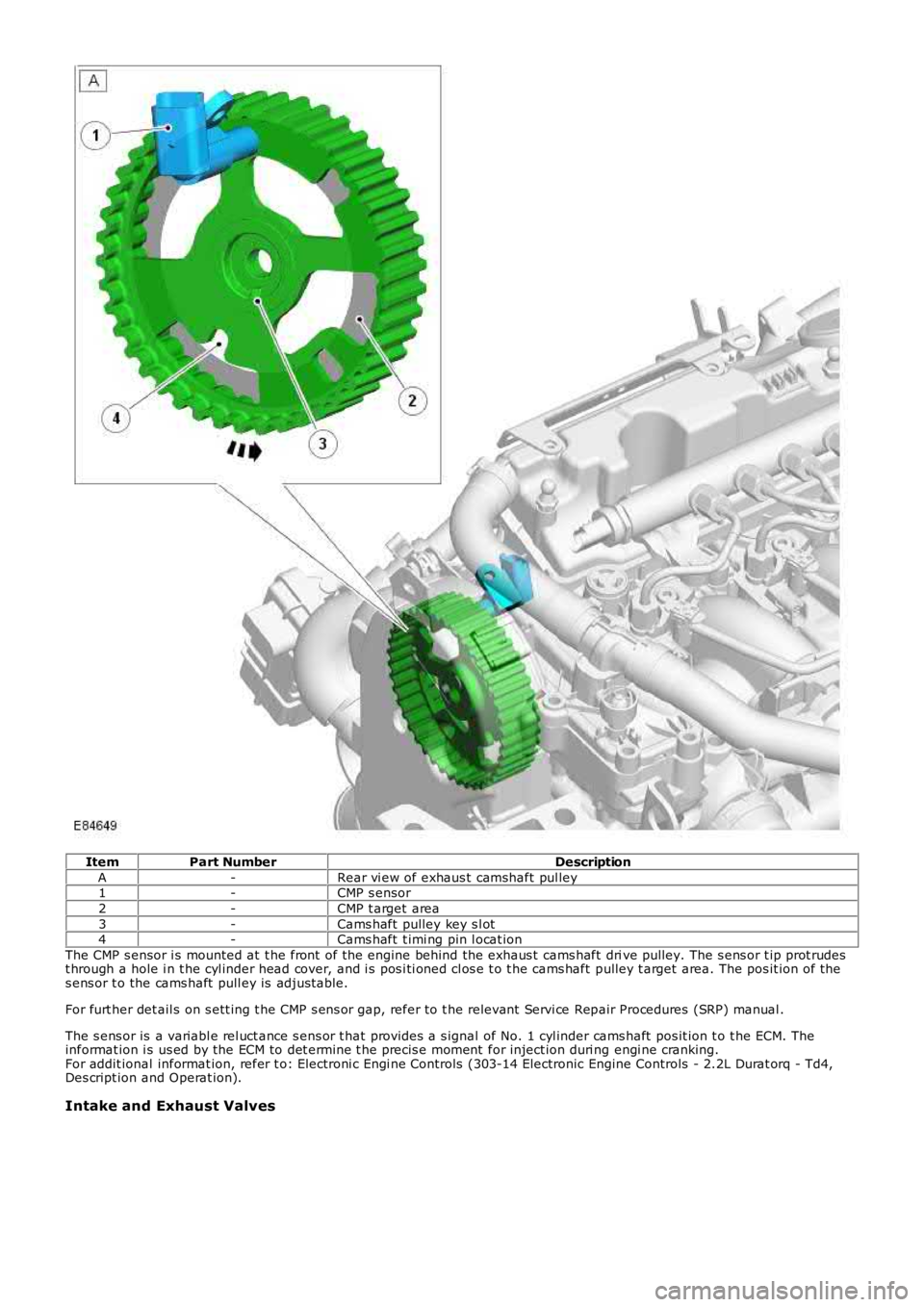

Camshaft Position (CMP) Sensor

Page 786 of 3229

ItemPart NumberDescription

A-Rear vi ew of exhaus t camshaft pul ley1-CMP s ensor

2-CMP t arget area

3-Cams haft pulley key s l ot4-Cams haft t imi ng pin l ocat ion

The CMP s ensor i s mounted at t he front of the engine behind the exhaus t cams haft drive pulley. The s ens or t ip prot rudest hrough a hole i n t he cyl inder head cover, and i s pos i ti oned cl os e t o t he cams haft pulley t arget area. The pos it ion of t hes ens or t o the cams haft pull ey is adjust able.

For furt her det ail s on s ett ing t he CMP s ens or gap, refer to t he relevant Servi ce Repair Procedures (SRP) manual .

The s ens or is a variabl e rel uct ance s ens or t hat provides a s ignal of No. 1 cyl inder cams haft pos it ion t o t he ECM. Theinformat ion i s us ed by the ECM to det ermine t he precis e moment for inject ion duri ng engi ne cranking.For addit ional informat ion, refer t o: Electroni c Engi ne Controls (303-14 Electronic Engine Controls - 2.2L Durat orq - Td4,Des cript ion and Operat ion).

Intake and Exhaust Valves

Page 789 of 3229

6-Hydraul ic l ash adjust er

7-Pl unger s pri ng

8-High-pres s ure chamber9-Bal l val ve

10-Pl unger

11-Res ervoir chamber12-Oil pass age

13-Hydraul ic l ash adjust er body

14-Pl unger capMovement of t he cams haft lobe pres s es down on t he fi nger rocker rol ler, and cons equentl y, t he hydrauli c las h adjus ter andvalve mechani sm are forced down together. The res pecti ve valve is forced down against valve s pri ng pres sure, and thehydraulic pl unger i s als o forced int o an oil chamber in t he cyl inder head. This t ype of val ve act uati on mini mizes fri ct ionbetween t he valve operat ing component s, and al so eliminates t he requi rement for manual adjust ment .

The body of the hydrauli c las h adjus t er contai ns a plunger, and 2 chambers for oil feed and press uri zed oil. Thepres s urized oi l i s s uppl ied t o t he las h adjus t er vi a t he cyl inder head oi l gal lery, and t hrough a hole in t he s ide of t he las hadjus ter body. The oi l pas s es int o a feed chamber wi thin the l ash adjus ter, and t hen t hrough to a s eparate press urechamber via a one-way ball valve.

Oil flow from t he pres s ure chamber is det ermi ned by the clearance bet ween the l ash adjust er outer body and the centerplunger. Oi l es capes up the s i de of the pl unger each ti me t he las h adjus t er i s operated. The downward press ure on t heplunger forces a corres ponding amount of oil i n the las h adjus ter body to be dis placed.

As t he camshaft lobe rot ates furt her, downward press ure on the cams haft and finger rocker i s removed. The las h adjus t erplunger is forced up by t he oil pres s ure contai ned in t he pres s ure chamber. The press ure i s not s uffi cient to affect valveoperati on, but i s s uffi cient to el iminate the clearance between the finger rocker and t op of the val ve st em.

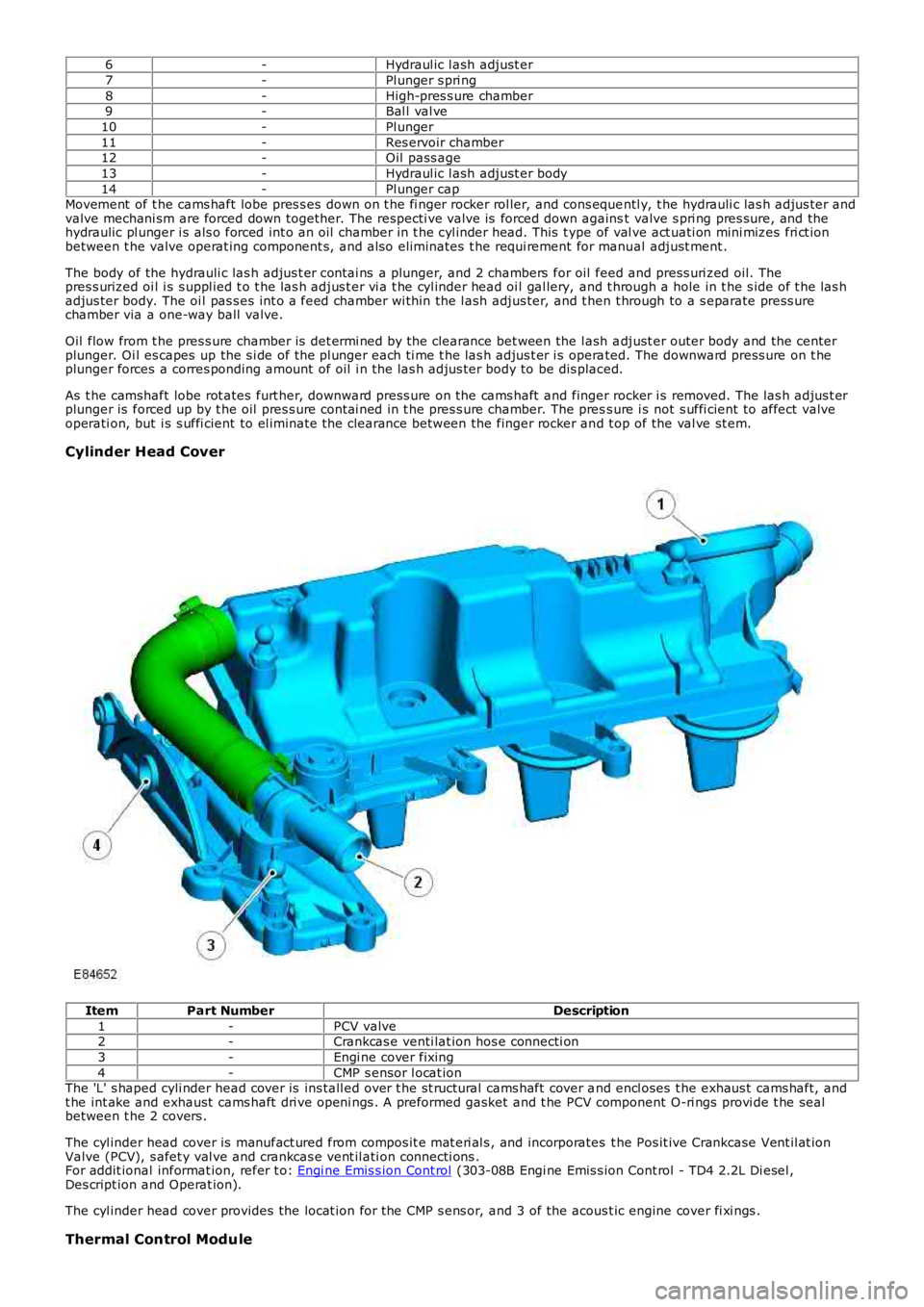

Cylinder Head Cover

ItemPart NumberDescription

1-PCV valve2-Crankcas e venti lat ion hos e connecti on

3-Engi ne cover fixing

4-CMP s ensor l ocat ionThe 'L' s haped cyli nder head cover is ins tall ed over t he s t ructural cams haft cover and encl oses t he exhaus t cams haft, andt he int ake and exhaust cams haft dri ve openi ngs . A preformed gasket and t he PCV component O-ri ngs provi de t he sealbetween t he 2 covers .

The cyl inder head cover is manufact ured from compos it e mat eri al s , and incorporates the Pos it ive Crankcase Vent il at ionValve (PCV), s afet y val ve and crankcas e vent il ati on connecti ons .For addit ional informat ion, refer t o: Engi ne Emis s ion Cont rol (303-08B Engi ne Emis s ion Cont rol - TD4 2.2L Di esel ,Des cript ion and Operat ion).

The cyl inder head cover provides the locat ion for the CMP s ens or, and 3 of the acoust ic engine cover fi xi ngs .

Thermal Control Module

Page 790 of 3229

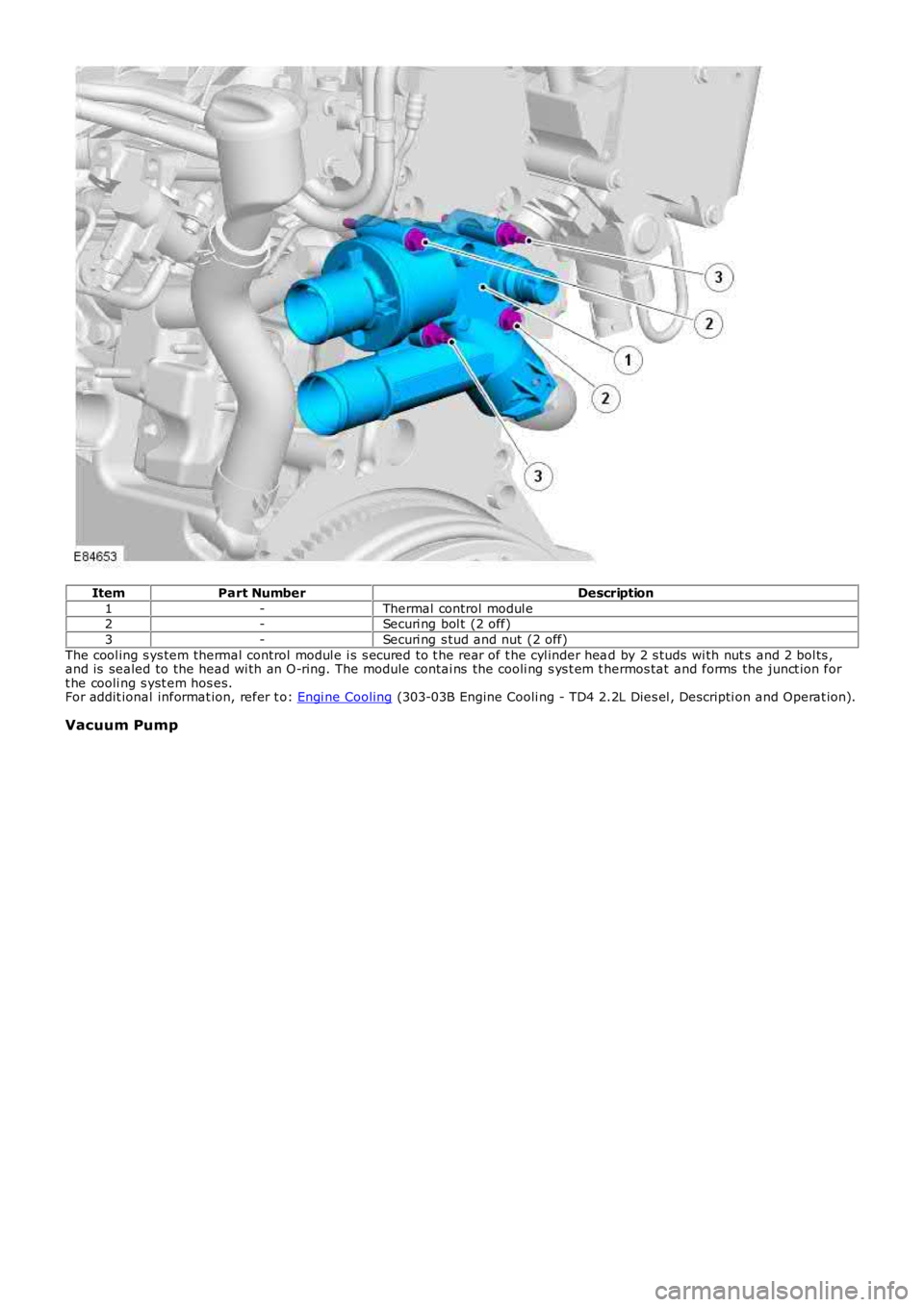

ItemPart NumberDescription

1-Thermal control modul e2-Securi ng bol t (2 off)

3-Securi ng s tud and nut (2 off)

The cool ing s ys tem thermal control modul e i s s ecured to t he rear of t he cyl inder head by 2 s tuds wi th nut s and 2 bol ts ,and is sealed to the head wi th an O-ring. The module contai ns the cooli ng s ys t em t hermos tat and forms the junct ion fort he cooli ng s yst em hos es.For addit ional informat ion, refer t o: Engi ne Cooling (303-03B Engine Cooli ng - TD4 2.2L Dies el , Descripti on and Operat ion).

Vacuum Pump

Page 795 of 3229

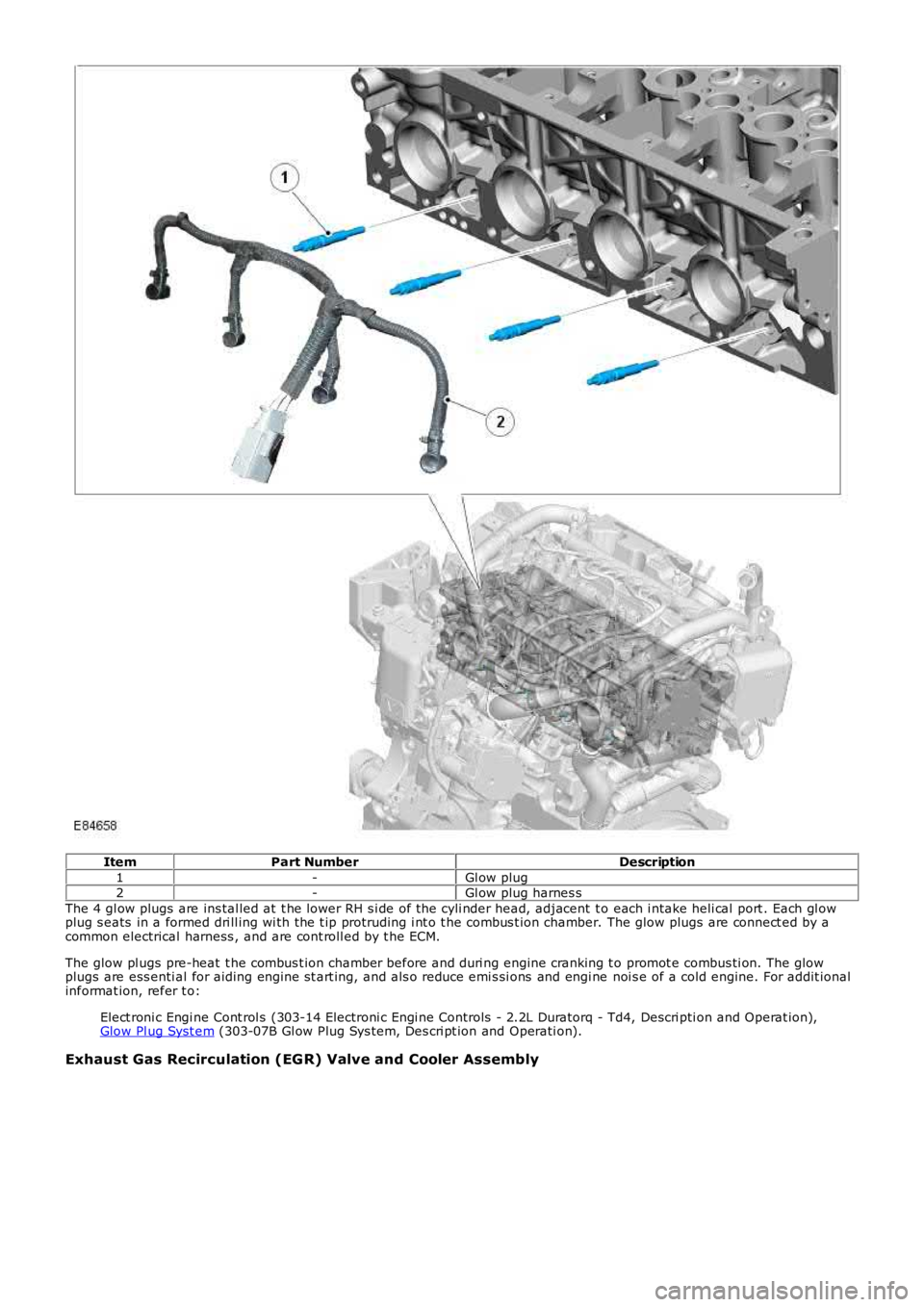

ItemPart NumberDescription

1-Gl ow plug2-Gl ow plug harnes s

The 4 gl ow plugs are ins tal led at t he lower RH s i de of the cyli nder head, adjacent to each i ntake heli cal port . Each gl owplug s eats in a formed dri ll ing wi th the t ip protruding i nt o t he combus t ion chamber. The glow plugs are connect ed by acommon electrical harness , and are cont roll ed by t he ECM.

The glow pl ugs pre-heat t he combus t ion chamber before and duri ng engine cranking t o promot e combus ti on. The glowplugs are ess enti al for aiding engine st art ing, and als o reduce emi s si ons and engi ne noi s e of a cold engine. For addit ionalinformat ion, refer t o:

Elect roni c Engi ne Cont rol s (303-14 Electroni c Engi ne Controls - 2.2L Duratorq - Td4, Descri pti on and Operat ion),Glow Pl ug Syst em (303-07B Gl ow Plug Sys tem, Des cri pt ion and Operati on).

Exhaust Gas Recirculation (EG R) Valve and Cooler Assembly