oil filter LAND ROVER FRELANDER 2 2006 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 697 of 3229

Publi s hed: 11-May-2011

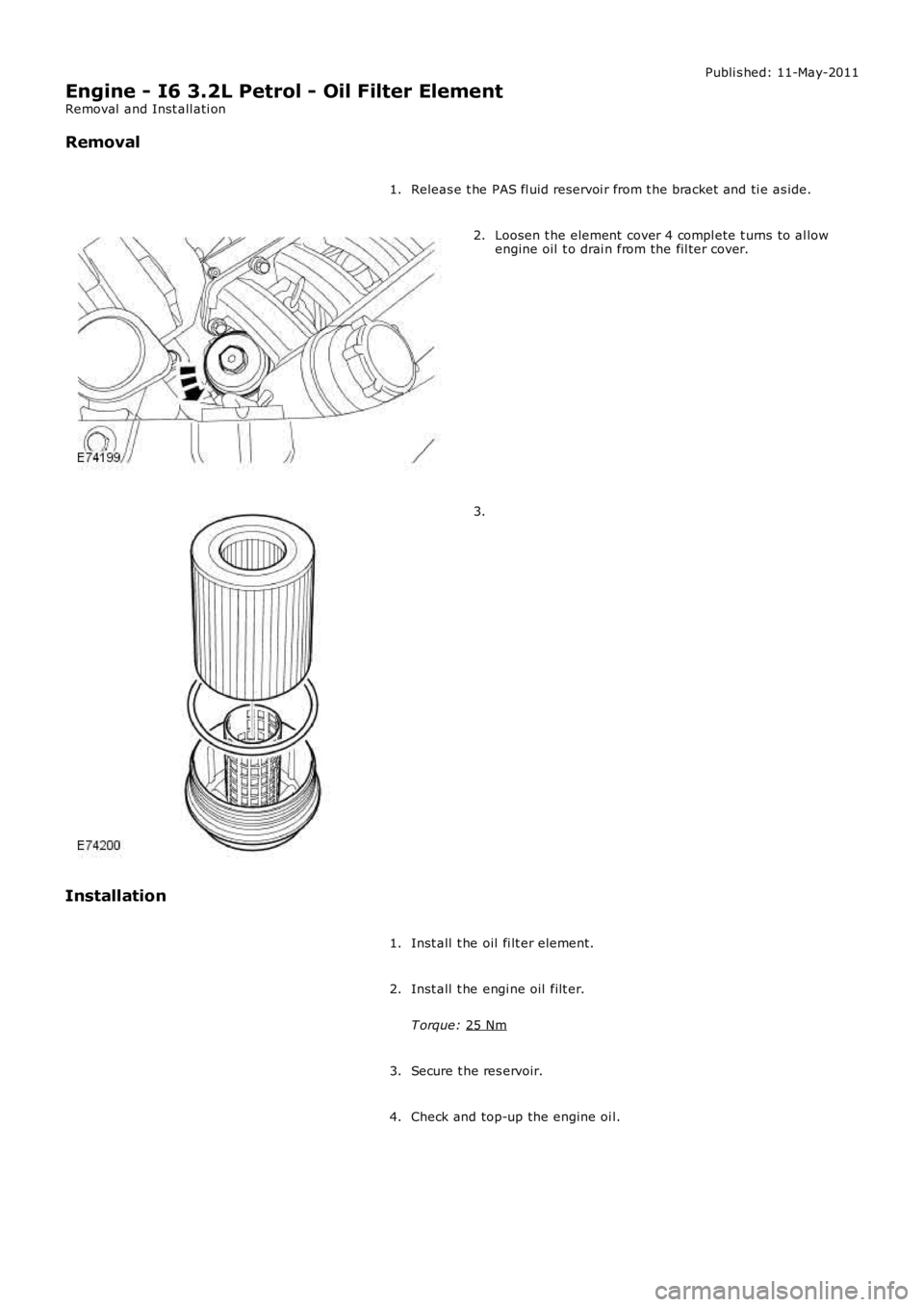

Engine - I6 3.2L Petrol - Oil Filter Element

Removal and Inst all ati on

Removal

Releas e t he PAS fl uid reservoi r from t he bracket and ti e as ide.

1. Loosen t he element cover 4 compl ete t urns t o al low

engine oil t o drai n from the fil ter cover.

2. 3.

Installation Inst all t he oil fi lt er element.

1.

Inst all t he engi ne oil filt er.

T orque: 25 Nm 2.

Secure t he res ervoir.

3.

Check and top-up the engine oi l.

4.

Page 766 of 3229

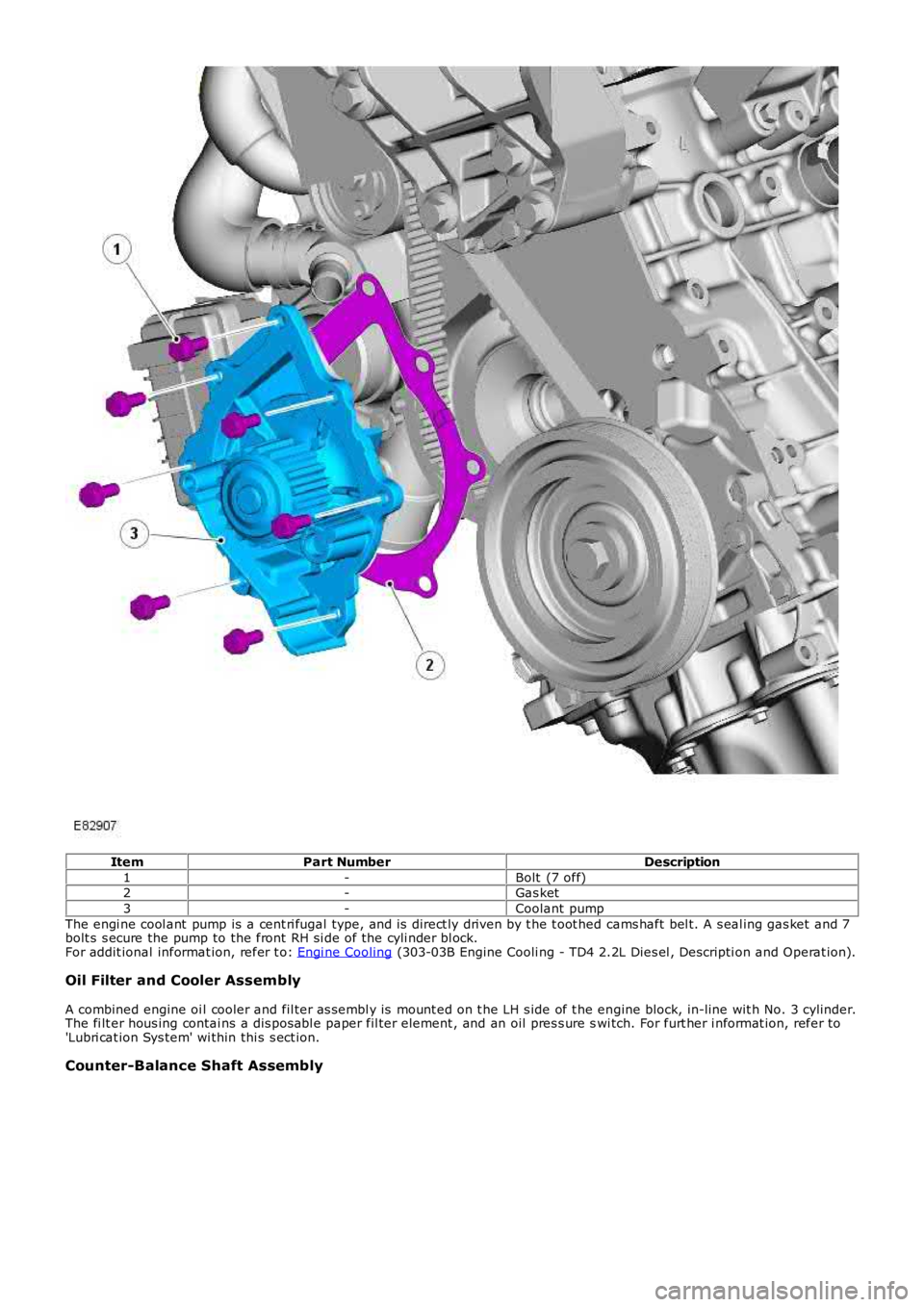

ItemPart NumberDescription

1-Bolt (7 off)2-Gas ket

3-Coolant pump

The engi ne cool ant pump is a cent ri fugal type, and is direct ly driven by t he t oot hed cams haft bel t. A s eal ing gas ket and 7bolt s s ecure the pump to the front RH si de of the cyli nder bl ock.For addit ional informat ion, refer t o: Engi ne Cooling (303-03B Engine Cooli ng - TD4 2.2L Dies el , Descripti on and Operat ion).

Oil Filter and Cooler Assembly

A combined engine oi l cooler and fil ter as sembl y is mount ed on t he LH s ide of t he engine block, in-line wit h No. 3 cylinder.The fi lt er hous ing contai ns a dis pos abl e paper fil ter element , and an oil pres s ure swi tch. For furt her i nformat ion, refer to'Lubri cat ion Sys tem' wi thin thi s s ect ion.

Counter-Balance Shaft Assembly

Page 800 of 3229

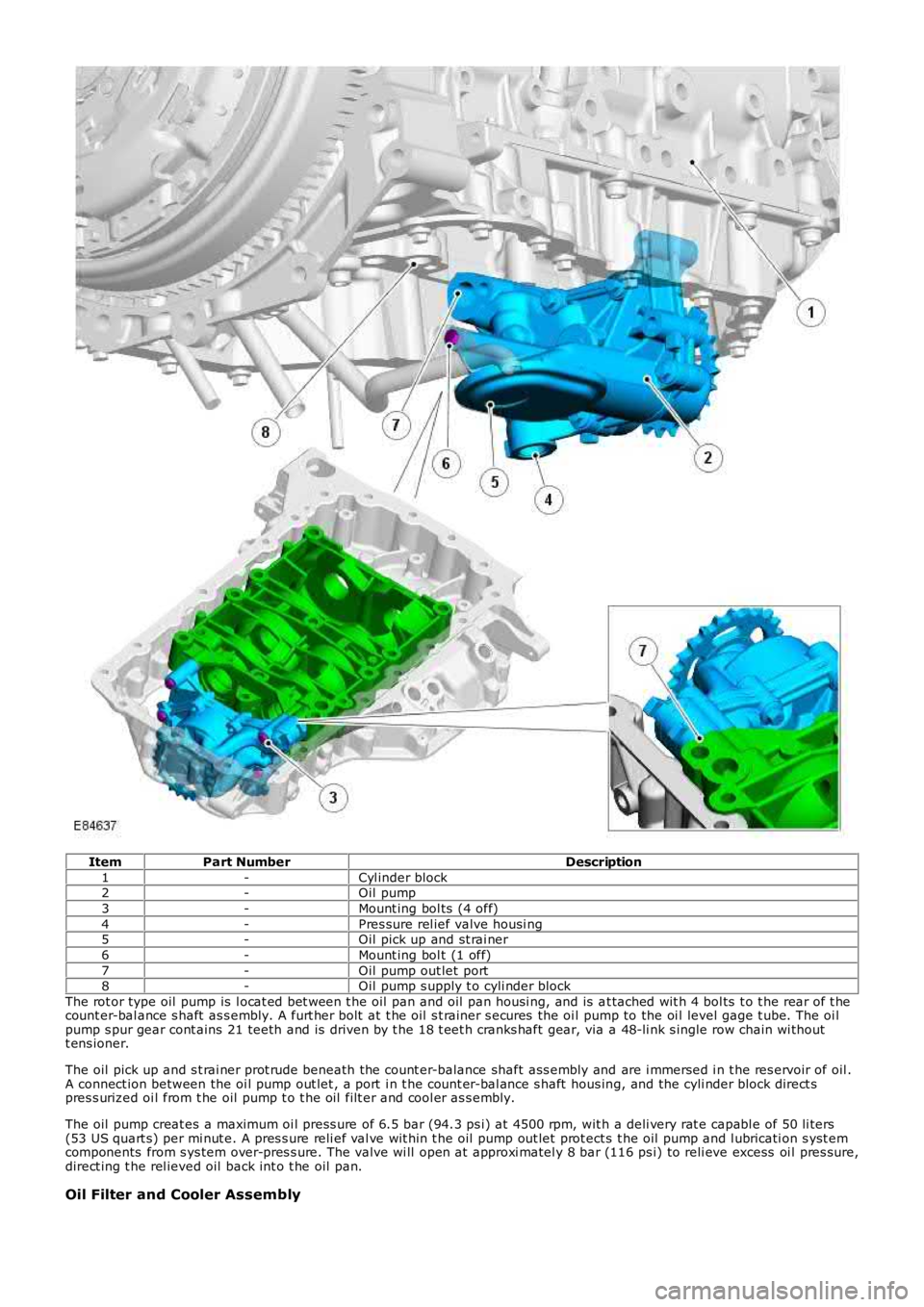

ItemPart NumberDescription

1-Cyl inder block2-Oil pump

3-Mount ing bol ts (4 off)

4-Pres sure rel ief valve housi ng5-Oil pick up and st rai ner

6-Mount ing bol t (1 off)

7-Oil pump out let port8-Oil pump s upply t o cyli nder block

The rot or type oil pump is l ocat ed bet ween t he oil pan and oil pan housi ng, and is at tached wit h 4 bol ts t o t he rear of t hecount er-bal ance s haft as s embly. A furt her bolt at t he oil s t rainer s ecures the oi l pump to the oi l level gage t ube. The oi lpump s pur gear cont ains 21 teeth and is driven by t he 18 t eet h cranks haft gear, via a 48-li nk s ingle row chain wi thoutt ens ioner.

The oil pick up and s t rai ner prot rude beneath the count er-balance shaft ass embly and are i mmersed i n t he res ervoir of oil .A connect ion between the oi l pump out let , a port i n t he count er-bal ance s haft hous ing, and the cyli nder block direct spres s urized oi l from t he oil pump t o t he oil filt er and cool er as s embly.

The oil pump creat es a maximum oi l press ure of 6.5 bar (94.3 ps i) at 4500 rpm, wit h a deli very rat e capabl e of 50 li ters(53 US quart s) per mi nut e. A pres s ure reli ef val ve wit hin t he oil pump out let prot ect s t he oil pump and l ubricati on s yst emcomponents from s ys tem over-pres s ure. The valve wi ll open at approxi matel y 8 bar (116 ps i) to reli eve excess oi l pres sure,direct ing t he rel ieved oil back int o t he oil pan.

Oil Filter and Cooler Assembly

Page 874 of 3229

Publi s hed: 11-May-2011

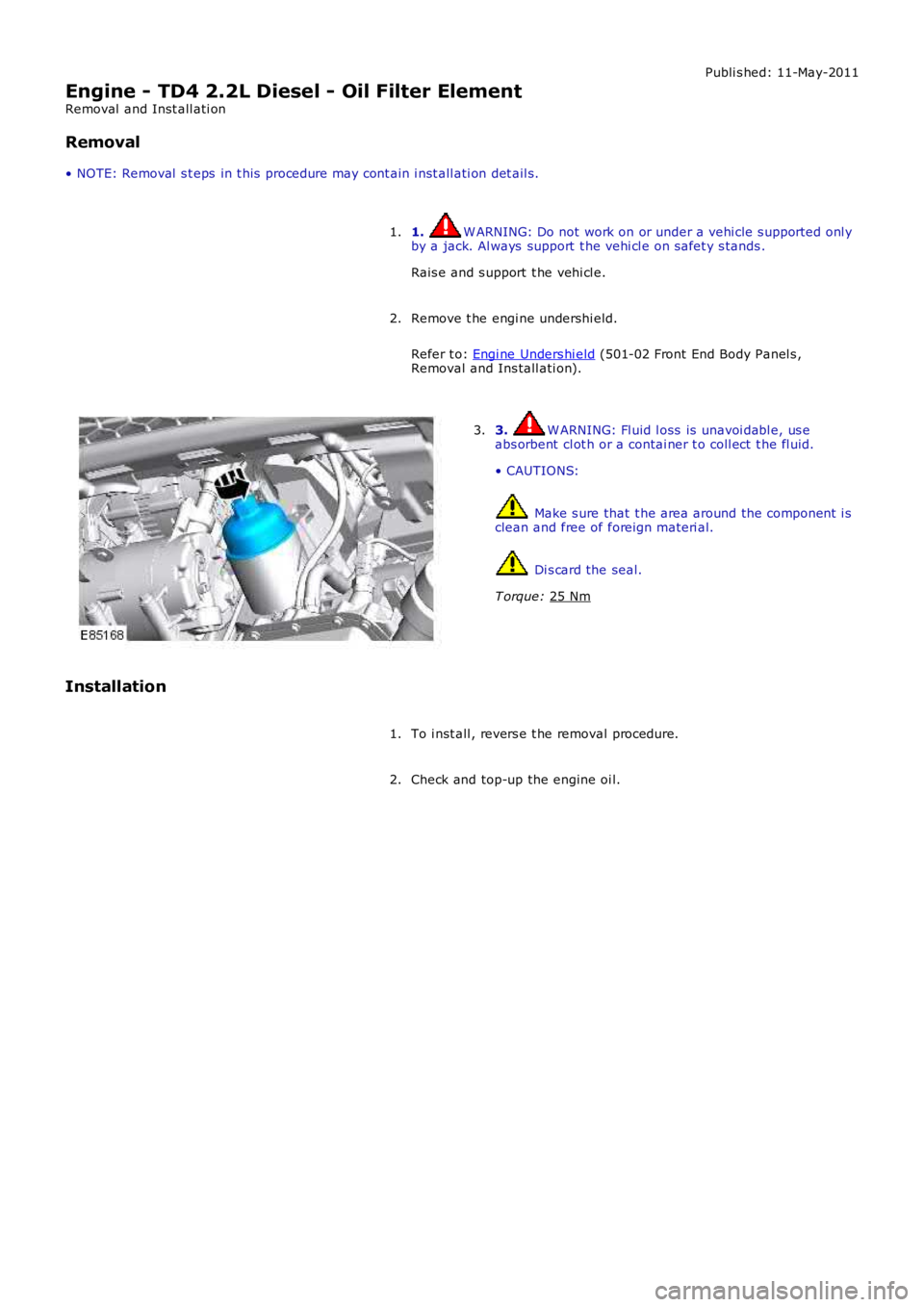

Engine - TD4 2.2L Diesel - Oil Filter Element

Removal and Inst all ati on

Removal

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

1. W ARNING: Do not work on or under a vehi cle s upported onl y

by a jack. Al ways support t he vehi cl e on s afet y s tands .

Rais e and s upport t he vehi cl e.

1.

Remove t he engi ne undershi eld.

Refer t o: Engi ne Unders hi eld (501-02 Front End Body Panel s ,

Removal and Ins tall ati on).

2. 3. W ARNING: Fl uid l oss is unavoi dabl e, us e

abs orbent cl ot h or a contai ner t o coll ect t he fl uid.

• CAUTIONS: Make s ure that t he area around the component i s

clean and free of foreign materi al. Di s card the seal.

T orque: 25 Nm 3.

Installation To i nst all , revers e t he removal procedure.

1.

Check and top-up the engine oi l.

2.

Page 1233 of 3229

All vehicles

To i nst all , revers e t he removal procedure.1.

Vehicles with diesel particulate filter (DPF)

Renew t he engi ne oil and filt er.

Refer t o: Engi ne Oil Draining and Fi lli ng (303-01B Engi ne - TD4 2.2LDi es el, General Procedures ).

2.

All vehicles

If a new component has been ins t al led, configure usi ng Land Roverapproved diagnos t ic equipment .3.

Page 1268 of 3229

All vehicles

To i nst all , revers e t he removal procedure.

1.

Vehicles with diesel particulate filter (DPF) Renew t he engi ne oil and filt er.

Refer t o: Engi ne Oil Draining and Fi lli ng (303-01B Engi ne - TD4 2.2L

Di es el, General Procedures ).

2.

All vehicles If a new component has been ins t al led, configure usi ng Land Rover

approved diagnos t ic equipment .

3.

Page 1319 of 3229

Publi s hed: 11-May-2011

Automatic Transmission/Transaxle - Transmission Fluid Pan, Gasket and

Filter

Removal and Inst all ati on

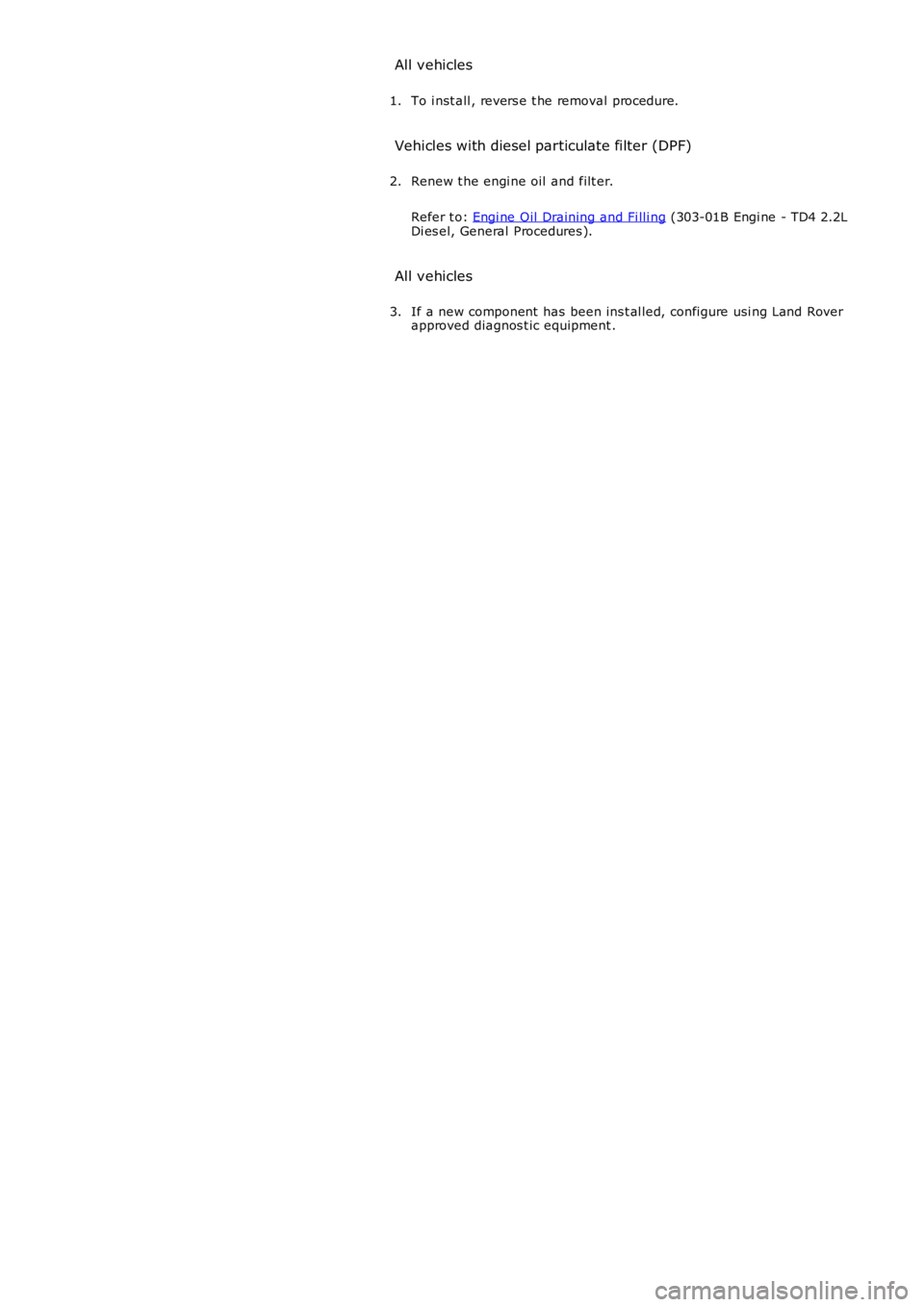

Removal

Remove t he cover and dis connect the bat tery ground cabl e.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -General Informat ion, Specificati ons).

1.

2. W ARNING: Make sure t o s upport the vehicle wit h axles tands .

Rais e and s upport t he vehi cl e.

2.

Drai n t he t ransmis s ion fluid.

Refer t o: Transmis s ion Flui d Drai n and Refi ll - I6 3.2L Pet rol (307-01Automat ic Transmis si on/Trans axl e, General Procedures ).

3.

Remove t he front subframe as s embly.

Refer t o: Front Subframe (502-00 Uni -Body, Subframe and Mount ingSyst em, Removal and Ins tall ati on).

4.

5. CAUTION: Be prepared to col lect escaping oil .5.

Remove t he gas ket.6.

Installation

For seal ant s peci fi cat ion, refer to t he s peci fi cat ions s ect ion.

Refer t o: Specificati ons (307-01 Aut omati c Trans mis s ion/Trans axle,Speci fi cat ions ).

1.

Page 1534 of 3229

t he DPF temperat ure.

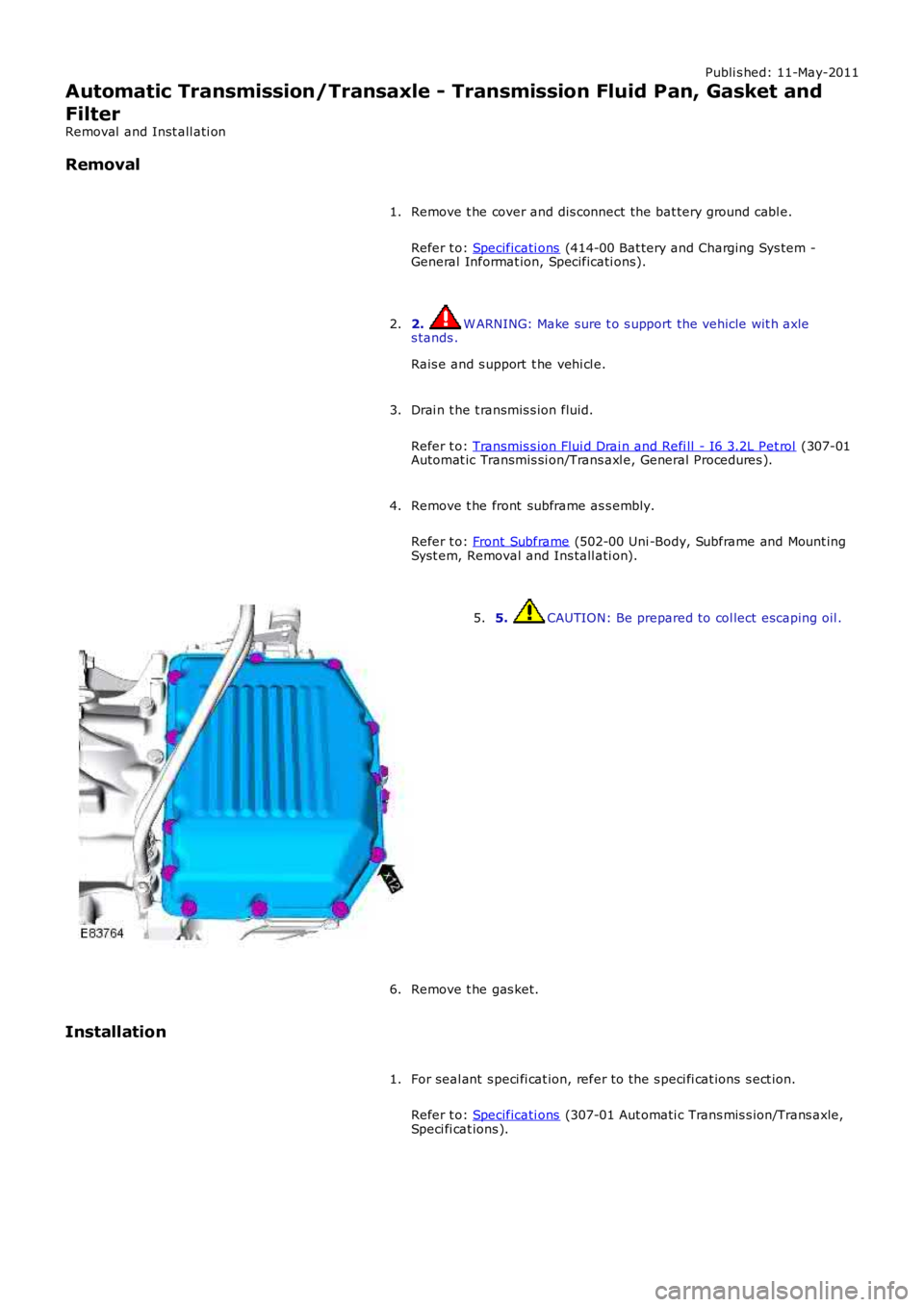

Instrument Cluster Indications

For drivers who make regular s hort journeys at low s peeds , i t may not be poss i bl e t o efficient ly regenerat e t he DPF. In t hiscas e, t he DPF s oft ware wi ll detect a bl ockage of the DPF from s ignals from t he different ial pres sure s ens or and wi ll alertt he driver as fol lows .

ItemPart NumberDescription

1-'DPF FULL' mess age2-'DPF FULL VISIT DEALER' mess age

The dri ver wi ll be al erted to this condit ion by a mes sage 'DPF FULL' accompanied by a handbook symbol . As det ail ed in theOwners Handbook, t he dri ver s hould drive t he vehi cl e unti l the engine is at i ts normal operat ing temperat ure and thendri ve for a furt her 20 minut es at speeds of not les s than 30 mph (48 km/h). Success ful regenerat ion of t he DPF i s indicatedt o the driver by t he 'DPF FULL' mes s age no longer bei ng dis played. If t he DPF s oft ware det ect s t hat t he DPF i s s ti llblocked, t he mes sage will change to 'DPF FULL VISIT DEALER', the driver should take t he vehi cl e t o an authorized deal er tohave the DPF force regenerat ed.

Diesel Particulate Filter Side Effects

The fol lowing secti on detai ls s ome s i de effect s caus ed by t he act ive regenerati on proces s .

Engine Oil Dilution

Engi ne oil dil uti on can occur due to smal l amount s of fuel entering t he engine crankcas e duri ng t he pos t -i njecti on phas es .This has made i t neces s ary t o i nt roduce a calculat ion bas ed on dri vi ng s tyle to reduce oil s ervice i nt ervals if neces s ary.The dri ver i s alerted t o t he oil s ervice by a mes sage i n t he ins trument cl ust er.

The DPF s oft ware moni tors t he drivi ng s tyle and the frequency of t he acti ve regenerati on and durati on. Us i ng thi sinformat ion a cal culat ion can be made on the engi ne oil dil ut ion. W hen t he DPF s oft ware cal cul at es t he engi ne oil dil uti onhas reached a predetermined t hres hold (fuel being 7% of engi ne oil volume) a s ervi ce mes sage i s dis played in theins t rument clus ter.

Dependi ng on dri vi ng s tyle, s ome vehicles may require an oil s ervi ce before t he des ignated i nterval. If an s ervice mess ageis di s pl ayed, t he vehi cl e wi ll be requi red have a full s ervice and t he s ervice i nt erval count er will be res et .

Fuel consumption

Duri ng the act ive regenerat ion proces s of the DPF, t here wi ll be an i ncrease in fuel cons umpt ion. However, becaus e acti veregenerat ion occurs infrequent ly and for li mit ed peri ods of t ime, the overall effect on fuel cons umpt ion i s approxi mat el y2%. The addit ional fuel us ed during t he act ive regenerat ion proces s i s accounted for in t he i ns t ant aneous and average fuelcons umpt ion dis plays i n t he ins trument cl ust er.

Page 2724 of 3229

Contents

4

L

Climate control

AIR VENTS ................................................... 101

MANUAL CLIMATE CONTROL ...................... 102

AUTOMATIC CLIMATE CONTROL ................. 103

HEATED WINDOWS AND MIRRORS ............ 104

AUXILIARY HEATER ..................................... 104

ELECTRIC SUNROOF .................................... 105

Convenience features

SUN VISORS ................................................ 107

CLOCK .......................................................... 107

CIGAR LIGHTER ........................................... 109

ASHTRAY ..................................................... 109

AUXILIARY POWER SOCKETS ..................... 110

CUP HOLDERS ............................................. 111

STORAGE COMPARTMENTS ........................ 112

Starting the engine

GENERAL INFORMATION ............................. 113

STARTING A PETROL ENGINE ..................... 114

STARTING A DIESEL ENGINE ....................... 115

DIESEL PARTICULATE FILTER (DPF) ........... 116

Transmission

MANUAL TRANSMISSION ............................ 118

AUTOMATIC TRANSMISSION ...................... 118

TECHNICAL SPECIFICATIONS ...................... 122

Brakes

PRINCIPLE OF OPERATION .......................... 123

HINTS ON DRIVING WITH ABS .................... 123

PARKING BRAKE .......................................... 124

Parking aid

PRINCIPLE OF OPERATION .......................... 126

USING THE PARKING AID ............................ 127

Driving hints

GENERAL DRIVING POINTS ......................... 128

REDUCED ENGINE PERFORMANCE ............. 128

RUNNING-IN ................................................ 128

ECONOMICAL DRIVING ................................ 129

Cruise control

PRINCIPLE OF OPERATION .......................... 130

USING CRUISE CONTROL ............................ 130

Terrain response

PRINCIPLE OF OPERATION .......................... 132

USING TERRAIN RESPONSE ........................ 132

Hill descent control (HDC)

PRINCIPLE OF OPERATION .......................... 136

USING HDC ................................................... 137

Traction control

USING TRACTION CONTROL ........................ 139

Stability control

PRINCIPLE OF OPERATION .......................... 140

USING STABILITY CONTROL ........................ 141

Fuel and refuelling

SAFETY PRECAUTIONS................................. 142

FUEL QUALITY .............................................. 142

RUNNING OUT OF FUEL................................ 144

FUEL CUT-OFF............................................... 144

FUEL FILLER FLAP ........................................ 144

REFUELLING ................................................. 145

TECHNICAL SPECIFICATIONS ....................... 146

Load carrying

GENERAL INFORMATION.............................. 147

LUGGAGE ANCHOR POINTS ......................... 148

LUGGAGE COVERS ....................................... 149

Towing

TOWING A TRAILER...................................... 150

LEVELLING.................................................... 151

ESSENTIAL TOWING CHECKS ...................... 151

RECOMMENDED TOWING WEIGHTS ............ 152

TOW BAR ...................................................... 153

Vehicle care

CLEANING THE ALLOY WHEELS................... 154

CLEANING THE EXTERIOR ............................ 154

CLEANING THE INTERIOR ............................ 155

REPAIRING MINOR PAINT DAMAGE ............ 156

Maintenance

GENERAL INFORMATION.............................. 157

OPENING AND CLOSING THE BONNET......... 160

ENGINE COMPARTMENT OVERVIEW ........... 161

ENGINE OIL CHECK....................................... 162

Page 2741 of 3229

21

Quick start

R

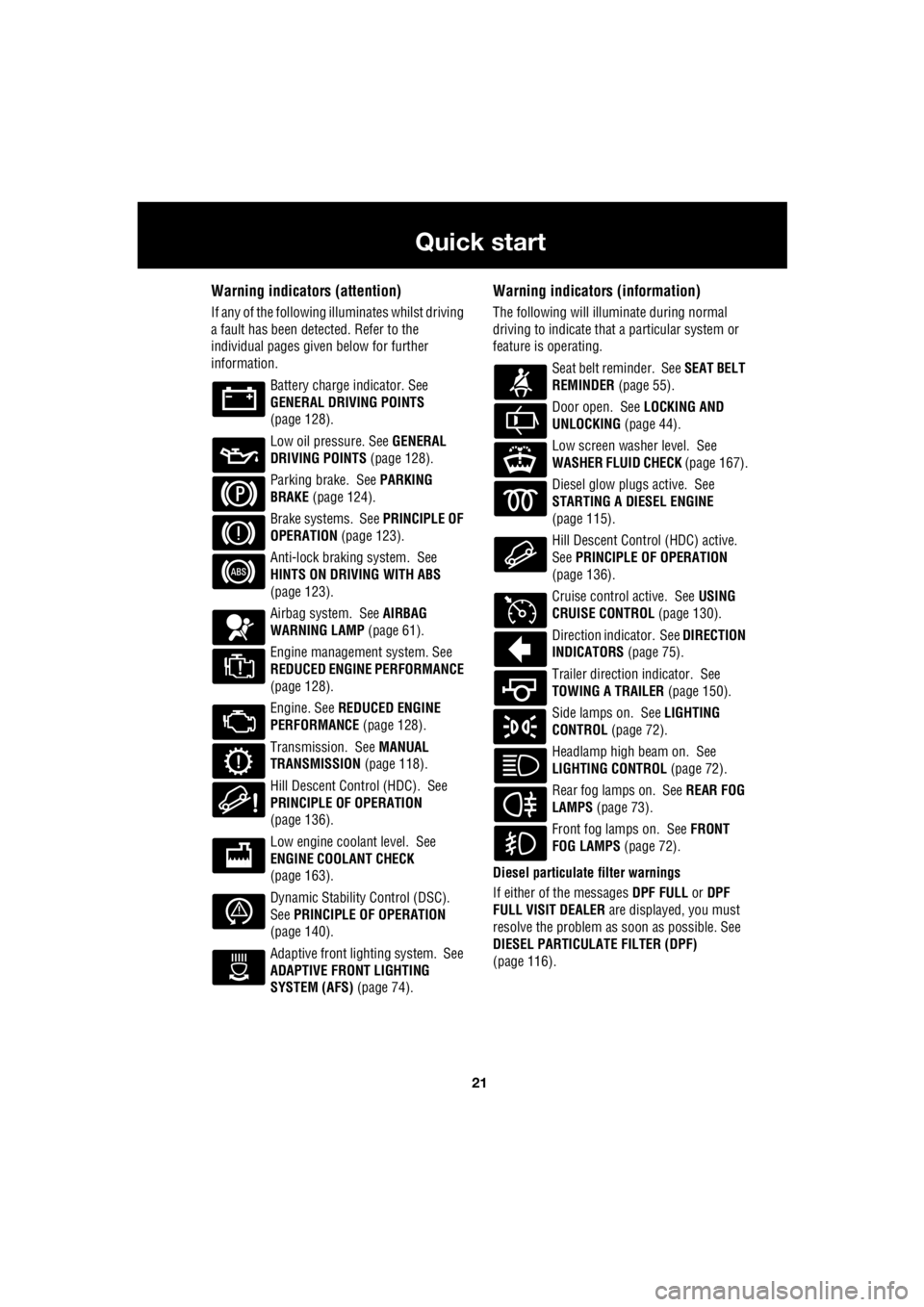

Warning indicators (attention)

If any of the following illuminates whilst driving

a fault has been detected. Refer to the

individual pages give n below for further

information.

Battery charge indicator. See

GENERAL DRIVING POINTS

(page 128).

Low oil pressure. See GENERAL

DRIVING POINTS (page 128).

Parking brake. See PARKING

BRAKE (page 124).

Brake systems. See PRINCIPLE OF

OPERATION (page 123).

Anti-lock braking system. See

HINTS ON DRIVING WITH ABS

(page 123).

Airbag system. See AIRBAG

WARNING LAMP (page 61).

Engine management system. See

REDUCED ENGINE PERFORMANCE

(page 128).

Engine. See REDUCED ENGINE

PERFORMANCE (page 128).

Transmission. See MANUAL

TRANSMISSION (page 118).

Hill Descent Control (HDC). See

PRINCIPLE OF OPERATION

(page 136).

Low engine coolant level. See

ENGINE COOLANT CHECK

(page 163).

Dynamic Stability Control (DSC).

See PRINCIPLE OF OPERATION

(page 140).

Adaptive front lighting system. See

ADAPTIVE FRONT LIGHTING

SYSTEM (AFS) (page 74).

Warning indicators (information)

The following will illuminate during normal

driving to indicate that a particular system or

feature is operating.

Seat belt reminder. See SEAT BELT

REMINDER (page 55).

Door open. See LOCKING AND

UNLOCKING (page 44).

Low screen washer level. See

WASHER FLUID CHECK (page 167).

Diesel glow plugs active. See

STARTING A DIESEL ENGINE

(page 115).

Hill Descent Control (HDC) active.

See PRINCIPLE OF OPERATION

(page 136).

Cruise control active. See USING

CRUISE CONTROL (page 130).

Direction indicator. See DIRECTION

INDICATORS (page 75).

Trailer direction indicator. See

TOWING A TRAILER (page 150).

Side lamps on. See LIGHTING

CONTROL (page 72).

Headlamp high beam on. See

LIGHTING CONTROL (page 72).

Rear fog lamps on. See REAR FOG

LAMPS (page 73).

Front fog lamps on. See FRONT

FOG LAMPS (page 72).

Diesel particulate filter warnings

If either of the messages DPF FULL or DPF

FULL VISIT DEALER are displayed, you must

resolve the problem as soon as possible. See

DIESEL PARTICULATE FILTER (DPF)

(page 116).