remote control LAND ROVER FRELANDER 2 2006 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 1217 of 3229

To s top the engine t he s t op/s tart but ton must be pres sed. Forcibly removing t he remote hands et from t he s tart controlmodule will not s top the engine. On models wit h automat ic t rans mi ss i on, once the engi ne has st opped the remotehands et wil l not be releas ed by t he s tart cont rol module unt il the trans mi s si on s el ect or lever is i n t he Park (P) pos i ti on.

Throttle Control

The ECM controls t he posi ti oni ng of the throt t le di sc i n t he electric t hrot tl e us ing i nformat ion from t he APP s ens or and t heTP s ensor. Dat a from t he A/C pres sure s ens or, TCM, ECT s ens or, MAF s ensor and t he MAP/IAT s ensor i s als o us ed todetermine t he correct t hrot tl e cont rol .

The t wo Hall effect sens ors i n t he TP s ens or are des ignat ed 1 and 2. Both sens ors out put an i ncreasi ng vol tage as thet hrott le di s c angl e increas es. Smal l air fl ows t hrough the throt tl e requi re comprehens ive regul at ion, t herefore the vol tageri s e in one of the s ensors increas es more quickl y t han the ot her s ens or whi ch gives accurat e cont rol of t he thrott le andensure t he thrott le di sc is i n t he correct posi ti on.

The ECM moni tors the si gnal s from bot h s ens ors to ens ure they are wit hin the minimum and maximum t hres hol ds and thatt he si gnal s corres pond t o the same thrott le di sc pos it ion. If there is a difference in the si gnal s the ECM us es a defaultt hrott le si gnal calculated from t he electric t hrot tl e load, engi ne s peed and ai r pres s ure and t emperature s ignals . Thes ens or whose out put s ignal i s clos est t o t he calcul ated t hrot tl e dis c angle will be us ed as t he correct output . A faul t codewil l be recorded for the ot her s ens or and t his can be read us ing a Land Rover approved di agnos ti c s ys t em. The ECM t henmonit ors t he remaining s ens or out put s i gnal and compares it agains t t he cal cul ated value. If a difference i n thecomparis on occurs t he ECM wi ll dis count t he output from bot h s ens ors and dis abl e t he electric t hrot tl e cont rol and revert toa l imp home mode. The throt t le di sc has s prings for opening and clos ing and t he ECM can meas ure the l oad appl ied byt hes e s pri ngs for a l oad s ignal . If a fault occurs whi ch prevent s t he damper mot or from being operat ed, the s prings ret urnt he throt t le di sc to a pos i ti on which all ows a t hrot tl e openi ng large enough t o all ow t he vehi cle t o driven, but wi th reduceddri ve abi li ty.

Throt tl e Adapt ions

The ECM has a learning adapti on which al lows t he ECM t o calculate the preci s e cont rol required for t he elect ric throt t ledamper motor. The adapti on process is performed when the ignit ion i s on and t he engine is not runni ng. The t hrot tl e dis cis moved by the damper mot or to t he fully cl osed pos it ion and t he ECM records t he val ues out put by the TP sens orpotenti ometers.

If the permanent batt ery supply t o t he ECM has been removed, t hen previous adapt ions wi ll have been los t. If adapt ionsare st ored, t hen the ECM compares the s t ored adapti on val ues wit h t he current t hrottle angl e and us es an average of thes tored and current values t o create the new adapt ion value.

If the el ect ri c throt t le unit has been repl aced, t he power s upply mus t be removed from t he ECM t o eras e al l previousl ys tored adapt ion values .

Fuel Pressure Regulation

Fuel pres s ure regulati on is cont roll ed by t he ECM t o res pond t o fuel pres s ure demand and provi des s t epl ess cont rol of the

pump output us ing t he FPDM t o control t he pump operat ion. The ECM can vary t he fuel pres s ure to bet ween 55.1 l bf/in2

(3.8 bar) and 72.5 lbf/i n2 (5 bar). The hi gh pres s ure i s only us ed in ext reme condit ions s uch as heavy engine loads andengi ne s tarts .

The ECM us es t he si gnal s from the fuel rail pres s ure/temperat ure s ens or t o det ermi ne informat ion regardi ng t he pres sureand t emperature of the fuel and provi de precis e i njecti on periods , improvi ng engi ne s tarti ng under all condit ions. Theadvant age of controll ing t he fuel pump output pres s ure are t hat pump power consumpt ion is reduced, loweri ng the load ont he power s upply s yst em and reduci ng fuel cons umpt ion, improved s ervi ce life of t he pump and reduced fuel pump nois e.

• NOTE: W hen t he i gni ti on is swi tched off t he FPDM reduces t he fuel li ne pres s ure regul at ion to 29 lbf/in2 (2 bar) to hel preduce inject or leakage.

Knock Control

Knock occurs i n a cyli nder when t he fuel and air s elf i gni tes at t he wrong ti ming. This can occur eit her before or after t hes park i s produced. The fuel mi xt ure can ignit e in different areas of t he combus t ion chamber and res ul ts in a fas tcombus t ion proces s creati ng s everal s eparat e fuel combus t ions which t oget her combi ne to produce a mechani cal knockings ound. The s ounds produce a certain type of vibrat ion through t he engine cylinder block and thes e are detected by t heknock s ensors . The two knock s ens ors det ect knocks on cyl inders 1, 2 and 3 and 4, 5 and 6 respecti vel y.

The vibrat ions act upon the peizo crys t als wi thi n t he sens ors whi ch res ult s in a volt age bei ng produced whi ch is sens ed byt he ECM. The ECM, us ing the CMP sens ors and t he CKP s ensor, can det ermi ne which cylinder(s ) are knocking. The ECM isable t o fil ter t he s ignal t o det ect vibrat ions creat ed duri ng normal engi ne operati on and dis card t hem from the knockdetecti on. The i gni ti on t imi ng is gradual ly advanced unti l the knocki ng is det ect ed once agai n.

Once the ECM has determined knocking is occurri ng usi ng other input s s uch as cat al yti c convert er temperat ure for exampl ein addi ti on to the s i gnal s from t he knock s ens ors , it first retards the ignit ion t imi ng and s ubs equent ly ri chens t he air/fuel i frequired.

Variable Camshaft Timing (VCT) Control

The inl et cams haft i s cont rol led by t he ECM us ing the VCT s olenoid. The exhaus t camshaft is fixed and i ts ti ming cannotbe changed.

Both cams haft s are dri ven i ndirect ly from the cranks haft via a chai n. The chain is driven from a s haft in the gear hous i ngas sembl y.For addit ional informat ion, refer t o: Engi ne - 3.2L (303-01, Descripti on and Operat ion).The VCT all ows t he ECM t o adus t t he inl et cams haft pos it ion i n rel ati on to the cranks haft , al tering t he t imi ng of theopeni ng and clos ing of t he inlet and exhaus t valves rel ati ve to the cranks haft posi ti on. Thi s allows the ECM to provideincreas ed engi ne performance, i mproved i dl e quali ty and reduced emi ss i ons .

Page 1741 of 3229

Publi s hed: 11-May-2011

Auxiliary Climate Control - Fuel Fired Booster Heater

Des cript ion and Operat ion

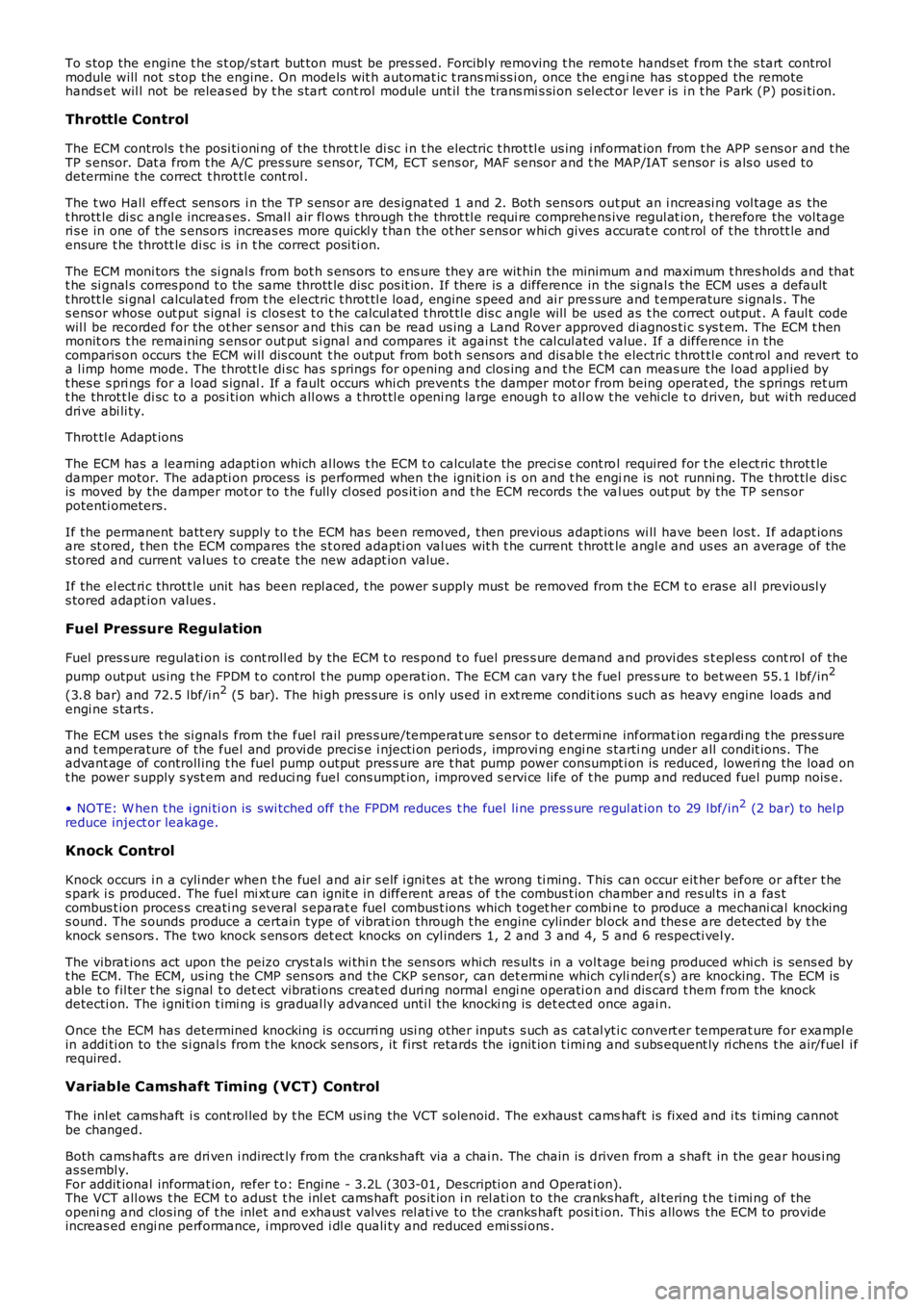

COMPONENT LOCATION - VEHICLES WITHOUT FFBH REMOTE CONTROL

ItemPart NumberDescription1-Automat ic Temperat ure Cont rol (ATC) modul e

2-Fuel Fi red Boos ter Heater (FFBH)

3-Auxili ary coolant pump4-Ambi ent ai r temperat ure s ens or

5-Auxili ary fuel pump

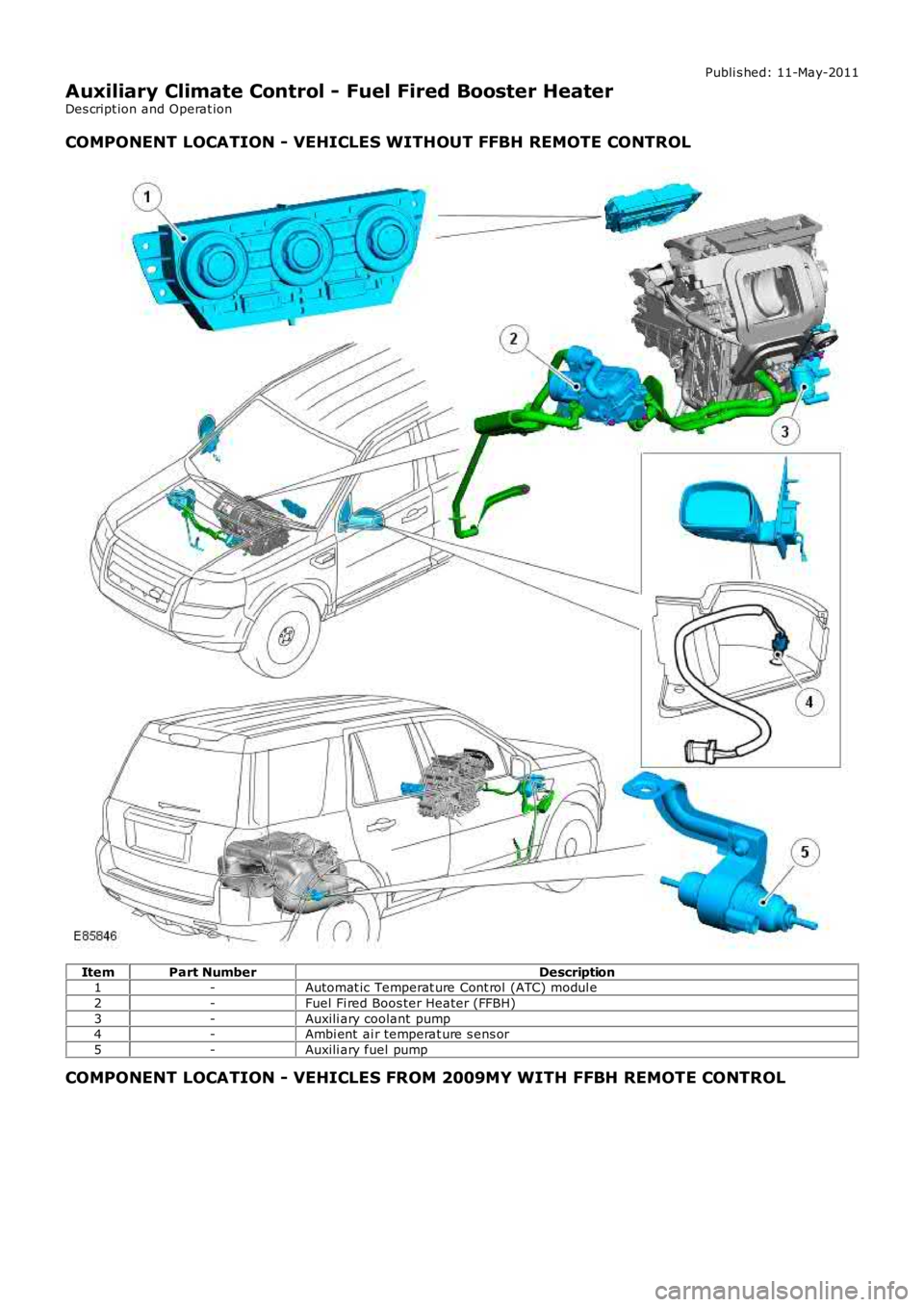

COMPONENT LOCATION - VEHICLES FROM 2009MY WITH FFBH REMOTE CONTROL

Page 1742 of 3229

ItemPart NumberDescription

1-Automat ic Temperat ure Cont rol (ATC) modul e2-Fuel Fi red Boos ter Heater (FFBH)

3-Auxili ary coolant pump

4-Ambi ent ai r temperat ure s ens or5-Auxili ary fuel pump

6-FFBH Recei ver

7-FFBH antenna mat chi ng unit

OVERVIEW

The Fuel fired Boos t er Heat er (FFBH) is rated at 5 kW and compensat es for t he rel ativel y low coolant t emperaturesinherent i n the di esel engine. The uni t is locat ed behind t he Right Hand (RH) front fender s plas h s hield and heat s enginecool ant downs tream of t he heat er core.

Operat ion of t he FFBH is controlled by the Aut omati c Temperature Control (ATC) module via the medi um s peed ControllerArea Net work (CAN) bus . Operati on of the FFBH i s influenced by:

Ambient air t emperat ureEngi ne cool ant temperat ure.

The FFBH wil l operate i f the ambient air t emperature is lower than 5 °C (41 °F) and s top if ambient t emperature reaches 8°C (46 °F). Operat ion of t he FFBH may als o be inhibit ed if t he fuel l evel drops below a predet ermi ned level .

Remote Operation - Vehicles from 2009MY

On vehicles from 2009MY the FFBH has remote operati on. The remote sys tem includes t he addi ti on of a FFBH receiver,

Page 1743 of 3229

FFBH antenna mat chi ng uni t and a remote hands et for operati on of the s ys tem. The FFBH unit remains as previ ous l y fi tt edbut has upgraded s oftware. The Engine Cont rol Modul e (ECM) als o has a s oft ware cal ibrat ion upgrade. The ins trumentclus ter mes s age cent er di spl ays FFBH mes s ages when required.

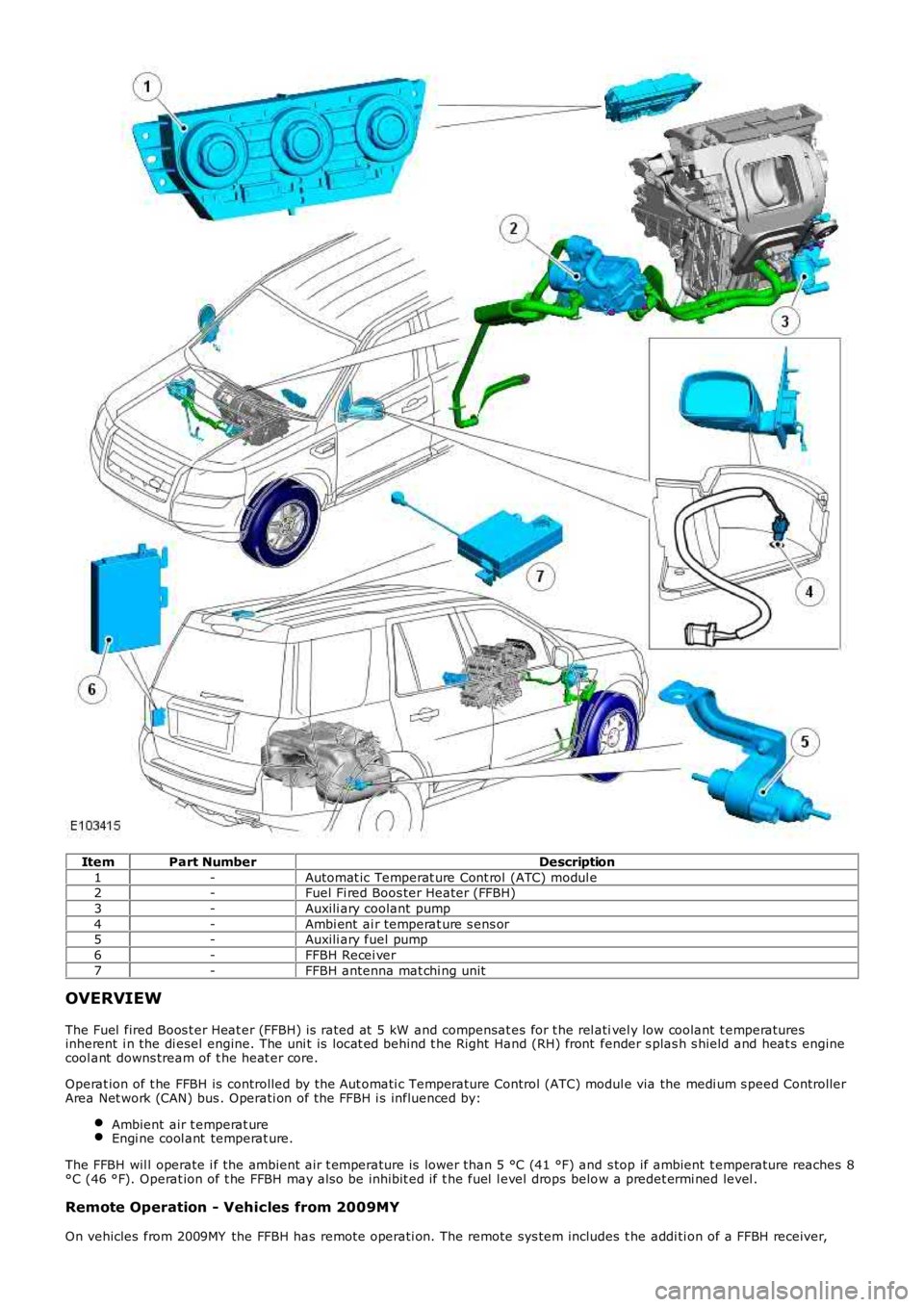

AUTOMATIC TEMPERATURE CONTROL MODULE

The ATC module is mount ed in the center cons ole and is i ntegral wi th the control panel. The module works i n conjunct ionwit h t he ECM t o control al l aspects of heati ng, venti lat ion, and Air Condit ioning (A/C).For addit ional informat ion, refer t o: Cont rol Component s (412-01 Cli mat e Cont rol , Descripti on and Operat ion).

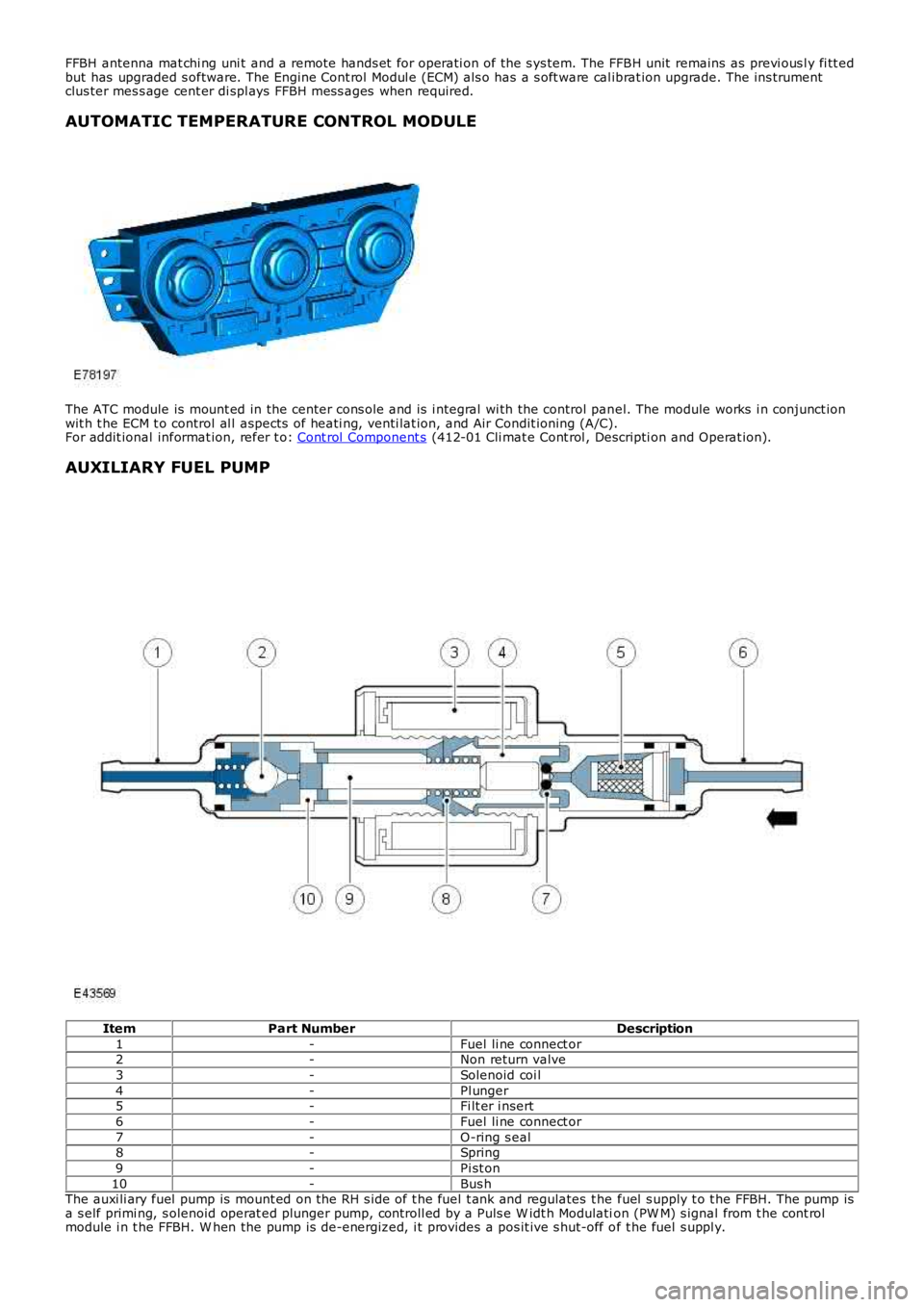

AUXILIARY FUEL PUMP

ItemPart NumberDescription

1-Fuel li ne connect or2-Non return valve

3-Solenoid coi l

4-Pl unger5-Fi lt er i nsert

6-Fuel li ne connect or

7-O-ring s eal8-Spring

9-Pi st on

10-Bus hThe auxi li ary fuel pump is mount ed on the RH s ide of t he fuel t ank and regulates t he fuel s upply t o t he FFBH. The pump isa s elf primi ng, s olenoid operat ed plunger pump, controll ed by a Puls e W idt h Modulation (PW M) s ignal from t he cont rolmodule i n t he FFBH. W hen the pump is de-energized, i t provides a pos it ive s hut-off of t he fuel s uppl y.

Page 1747 of 3229

The ambient air t emperat ure s ensor i s a Negati ve Temperature Co-effi ci ent (NTC) thermis t or, and is mount ed in the LeftHand (LH) door mi rror. The s ens or is connect ed t o the Engi ne Cont rol Module (ECM) which t rans mit s an ambi ent ai rt emperature val ue over t he high speed CAN bus . This value i s rel ayed to the ATC modul e by t he Cent ral Junct ion Box (CJB)over t he medium s peed CAN bus.For addit ional informat ion, refer t o: Cont rol Component s (412-01 Cli mat e Cont rol , Descripti on and Operat ion).

REMOTE CONTROL COMPONENTS - VEHICLES FROM 2009MY WITH FFBH REMOTE

CONTROL

The addi ti on of remot e control retai ns the FFBH component s fit ted t o pre 2009MY vehicl es wit h t he addi ti on of thefol lowing components :

FFBH wit h upgraded s oft ware and cali brat ionFFBH remot e handsetFFBH remot e receiverRecei ver power, communicati on and antenna harnes sesAntenna mat chi ng unit harnes s to connect recei ver co-axial cable t o exis t ing DAB antenna in s ide window.

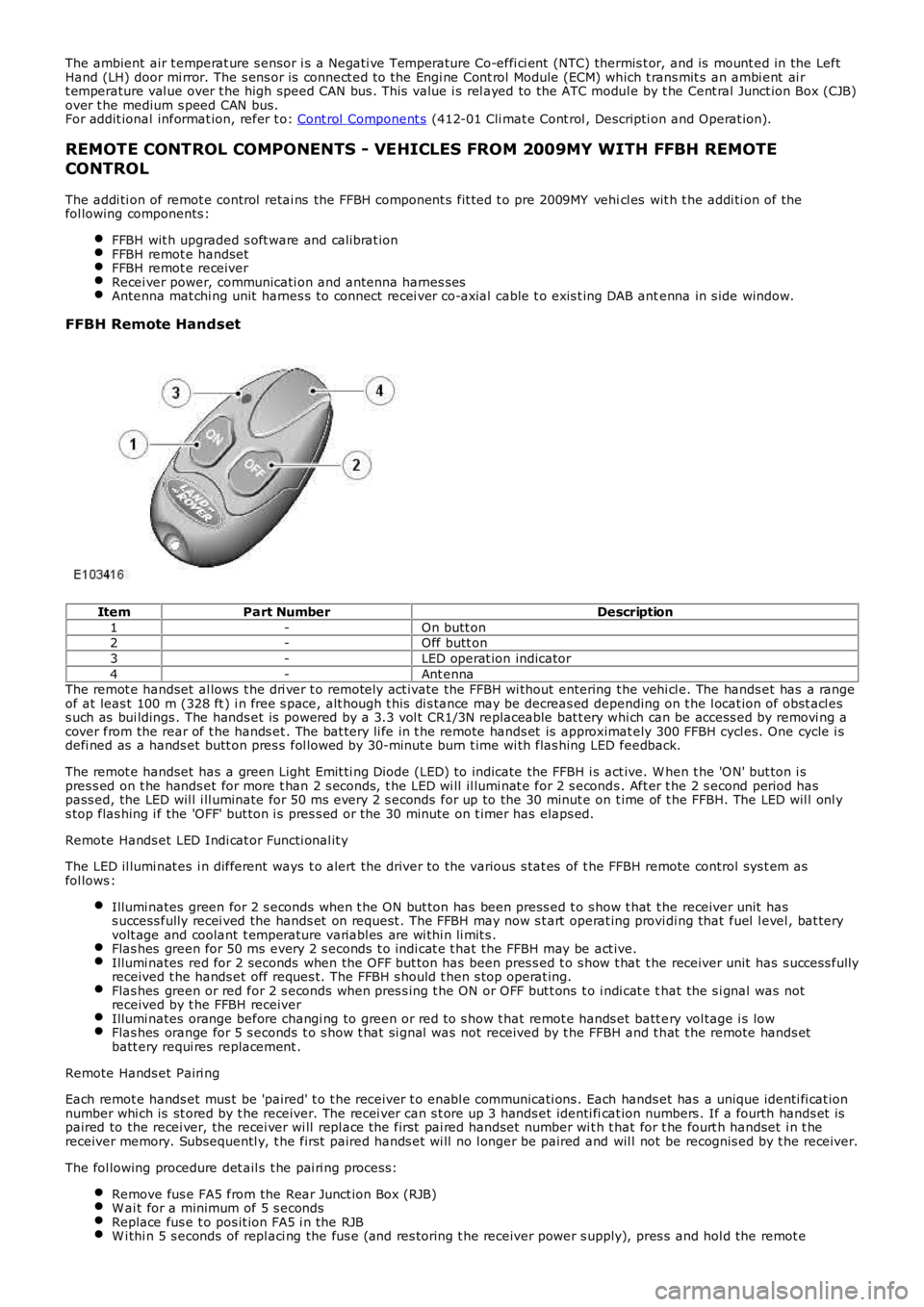

FFBH Remote Handset

ItemPart NumberDescription

1-On butt on2-Off butt on

3-LED operat ion indicator

4-Ant ennaThe remot e handset al lows t he dri ver t o remotely act ivate the FFBH wi thout entering t he vehi cl e. The hands et has a rangeof at leas t 100 m (328 ft ) i n free s pace, alt hough t his di s tance may be decreas ed depending on t he l ocat ion of obst acl ess uch as bui ldings . The hands et is powered by a 3.3 vol t CR1/3N replaceable bat t ery whi ch can be access ed by removi ng acover from the rear of t he hands et . The bat tery li fe in t he remote hands et is approximat ely 300 FFBH cycl es. One cycle i sdefi ned as a hands et butt on pres s fol lowed by 30-minut e burn t ime wi th flas hing LED feedback.

The remot e handset has a green Light Emit ti ng Diode (LED) to indicate the FFBH i s act ive. W hen t he 'O N' but ton i spres s ed on t he hands et for more t han 2 s econds, t he LED wi ll il lumi nat e for 2 s econds . Aft er t he 2 s econd period haspass ed, the LED wil l i ll uminate for 50 ms every 2 s econds for up to the 30 minut e on t ime of t he FFBH. The LED wil l onl ys top flas hing i f the 'OFF' but ton i s pres s ed or the 30 minute on t imer has elaps ed.

Remote Hands et LED Indi cat or Functi onal it y

The LED il lumi nat es i n different ways t o alert the driver to the various s tat es of the FFBH remote control sys t em asfol lows :

Illumi nates green for 2 s econds when t he ON but ton has been press ed t o s how t hat t he receiver unit hass uccess fully recei ved the hands et on request . The FFBH may now s t art operat ing providi ng that fuel l evel , bat teryvolt age and coolant t emperature variabl es are wi thi n li mit s .Flas hes green for 50 ms every 2 s econds t o i ndi cat e t hat the FFBH may be act ive.Illumi nates red for 2 seconds when the OFF but ton has been pres s ed t o s how t hat t he receiver unit has s uccess fullyreceived t he hands et off reques t. The FFBH s hould t hen s top operat ing.Flas hes green or red for 2 s econds when pres s ing t he ON or OFF but t ons t o i ndi cat e that the s i gnal was notreceived by t he FFBH receiverIllumi nates orange before changi ng to green or red to s how t hat remot e hands et batt ery vol tage i s lowFlas hes orange for 5 s econds t o s how t hat si gnal was not received by t he FFBH and t hat t he remote hands etbatt ery requi res replacement .

Remote Hands et Pairi ng

Each remot e hands et mus t be 'paired' t o t he receiver t o enabl e communicati ons . Each hands et has a unique identi fi cat ionnumber whi ch is st ored by t he receiver. The recei ver can s t ore up 3 hands et identi ficat ion numbers . If a fourth hands et ispaired to the recei ver, the recei ver wi ll repl ace the first pai red handset number wit h t hat for t he fourt h handset i n t hereceiver memory. Subsequentl y, t he first paired hands et wi ll no l onger be paired and wil l not be recognis ed by t he receiver.

The fol lowing procedure det ail s t he pai ri ng process :

Remove fus e FA5 from the Rear Junct ion Box (RJB)W ai t for a minimum of 5 s econdsReplace fus e t o pos it ion FA5 i n the RJBW i thi n 5 s econds of repl aci ng the fus e (and res toring t he receiver power s upply), pres s and hol d the remot e

Page 1749 of 3229

Audio Broadcast (DAB) s yst em.

Sit uat ed above the DAB antenna unit , behi nd the headli ni ng, is an ant enna matching unit . A flying lead from this uni tconnects di rectl y t o a s t ud on the gl ass ant enna. The recei ver unit connect s to the matching unit vi a a co-axial cabl e.

The glas s mounted ant enna recei ves RF transmit ted s i gnals from t he remot e handset and t rans mi ts t hem, via t hemat chi ng uni t and co-axial cable, t o t he FFBH receiver.

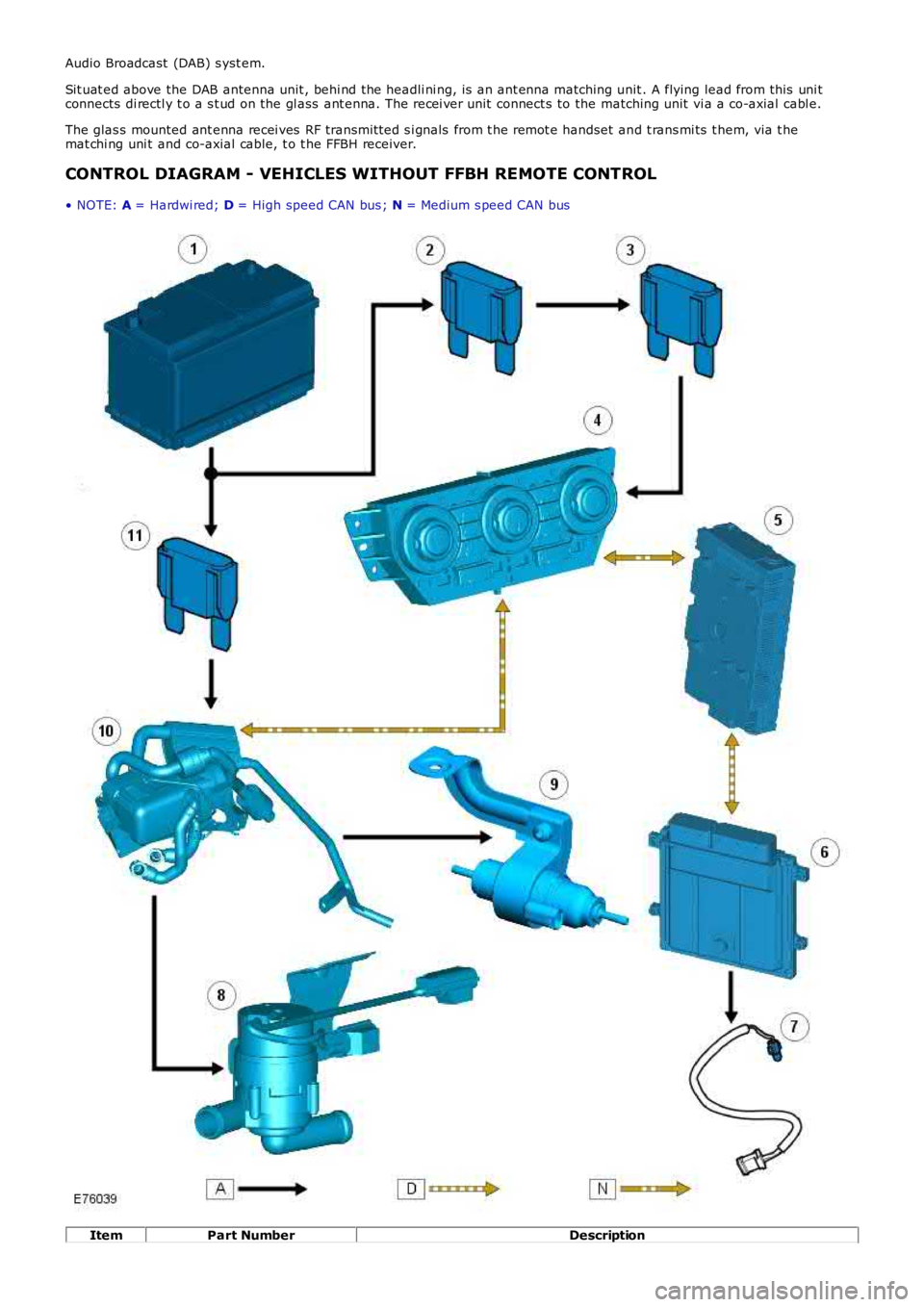

CONTROL DIAGRAM - VEHICLES WITHOUT FFBH REMOTE CONTROL

• NOTE: A = Hardwi red; D = High speed CAN bus ; N = Medium s peed CAN bus

ItemPart NumberDescription

Page 1750 of 3229

1-Batt ery

2-Fuse 17, BJB

3-Fuse 27, CJB4-ATC module

5-CJB

6-Engi ne Control Module (ECM)7-Ambient air t emperat ure s ensor

8-Auxi li ary coolant pump

9-Auxi li ary fuel pump10-Fuel fired boos t er heat er

11-Fuse 32, BJB

CONTROL DIAGRAM - VEHICLES FROM 2009MY WITH FFBH REMOTE CONTROL

• NOTE: A = Hardwi red; D = High speed CAN bus ; F = RF Trans mis s ion; N = Medium s peed CAN bus; T = Co-axi al; AA =W ebas to 'W ' bus

Page 1754 of 3229

s tart fail ure or flameout, and decreas ed by one if a subs equent s tart is succes s ful . If t he event t imer i ncreas es t ot hree (over any number of drive cycl es), the cont rol module ent ers t he error lockout mode.Heat exchanger casing overheat: To prot ect t he s ys t em from exces s ive t emperatures , t he cont rol module ent erst he error l ockout mode if t he heat exchanger coolant temperat ure exceeds 125 °C (257 °F).Battery voltage out of limits: Error lockout wi ll occur if bat tery vol tage fall s bel ow 10.25 or ris es above 15.5 volt s .

The error lockout mode can be cleared usi ng the Land Rover approved di agnos ti c s ys t em, or by dis connect ing the bat terypower supply for a mi nimum of 10 s econds.

Remote Operation - Vehicles from 2009MY with FFBH Remote Control

The 868.3 MHz Radi o Frequency (RF) si gnal s t ransmit ted by the remote hands et are recei ved by the DAB/FFBH ant ennalocated i n t he LH rear s i de window. The s ignal s received by t he antenna are detected by t he FFBH receiver. A 'handshake's ignal is s ent back from the recei ver t o t he hands et t o confirm a val id on or off reques t and act ivate the handset LEDaccordi ngl y. The recei ver proces s es the s i gnal it recei ved and trans mi ts the appropriate si gnal s via a dedi cat ed bus t o theFFBH cont rol module.

• NOTE: The ‘handshake’ si gnal only confi rms hands et-receiver communi cat ions were s uccess ful , and not that t he FFBH hast urned on.

W hen t he FFBH is act ivated by the remote hands et, t he FFBH cont rol module will al low t he FFBH t o operate for 30 minutesor unt il an off request is received from t he remot e hands et or CJB. During t he 30 minut e period, the FFBH may operat e i neit her full l oad combus ti on, part load combus t ion or a controll ed idle phas e of operat ion, depending on t he t emperature oft he coolant i n t he heat exchanger.

Pre-burn Thresholds

The FFBH unit wi ll only acti vat e remotely if t he fol lowing thres hold condit ions are met:

Pre-burn batt ery vol tage check: ≥11.5V (volt age at FFBH terminals )Pre-burn coolant temperat ure check: ≤15°C (int ernal FFBH measurement )Pre-burn fuel l evel check: ≥7.5 lit ers (value s t ored i n FFBH at ignit ion off)

The fuel level val ue s tored wit hin t he FFBH unit i s only updated when t he engine i s running. W hen s t art ing t he FFBH viaremot e control wit h the engi ne off, the fuel l evel value us ed in the FFBH calculat ions wi ll be t hat s t ored at t he las t key offevent . It i s t herefore poss ibl e for t he FFBH t o fai l to operat e remotel y if t he engine was s t opped wi th a low fuel level; i ft he fuel tank i s s ubs equent ly refuell ed, the FFBH s t ored fuel l evel wil l st il l read l ow i f the engine has not been s tarteds ince refuel li ng.

If the FFBH does not act ivate due to low bat tery vol tage or l ow fuel l evel, t he FFBH cont rol module transmit s a mes s age ispass ed on t he medi um and high speed CAN bus es, vi a t he CJB to the i nst rument clus ter mes s age cent er which wil l dis playone of the foll owing mes s ages at i gnit ion on:

AUXILIARY HEATER UNAVAILABLE LOW FUELAUXILIARY HEATER UNAVAILABLE LOW BATTERY .

If bot h l ow fuel and low batt ery volt age mes sages are val id, t he ins trument cl ust er mes sage center wi ll alt ernate bet weent he two mes sages .

Remote Control ‘Park Heat’ to ATC ‘Supplementary Heat’ Transitions

• NOTE: The FFBH can s ti ll be acti vat ed by t he ATC module as previ ous l y descri bed

If the FFBH has been operated remot el y (‘park heat’) and the vehicl e is st art ed whilst the FFBH i s s ti ll act ive, it willt ransi ti on int o t he ATC-control led ‘s upplement ary heat’ mode if t he ATC request s i t.

Shoul d t he ATC t hen send a mess age t o t he FFBH to turn off, the FFBH will remain active if 30 minut es has not yetelaps ed from t he ori ginal remot e cont rol ‘park heat ’ request . Once t he remai nder of 30 mi nut es has elaps ed, t he FFBH wil lt urn off.

Swit chi ng Point Temperatures

W hen remotel y s tarted t he FFBH us es a different s et of s wit chi ng poi nt temperat ures t o t he normal ‘supplement al heat’mode. Thi s is because the remot e s tart feature can s tart the FFBH wi th the engine off – t hus different t hres hol ds arerequired t o opti mis e t he heati ng of the engine coolant.

Swit chi ng Point Temperatures

Page 1791 of 3229

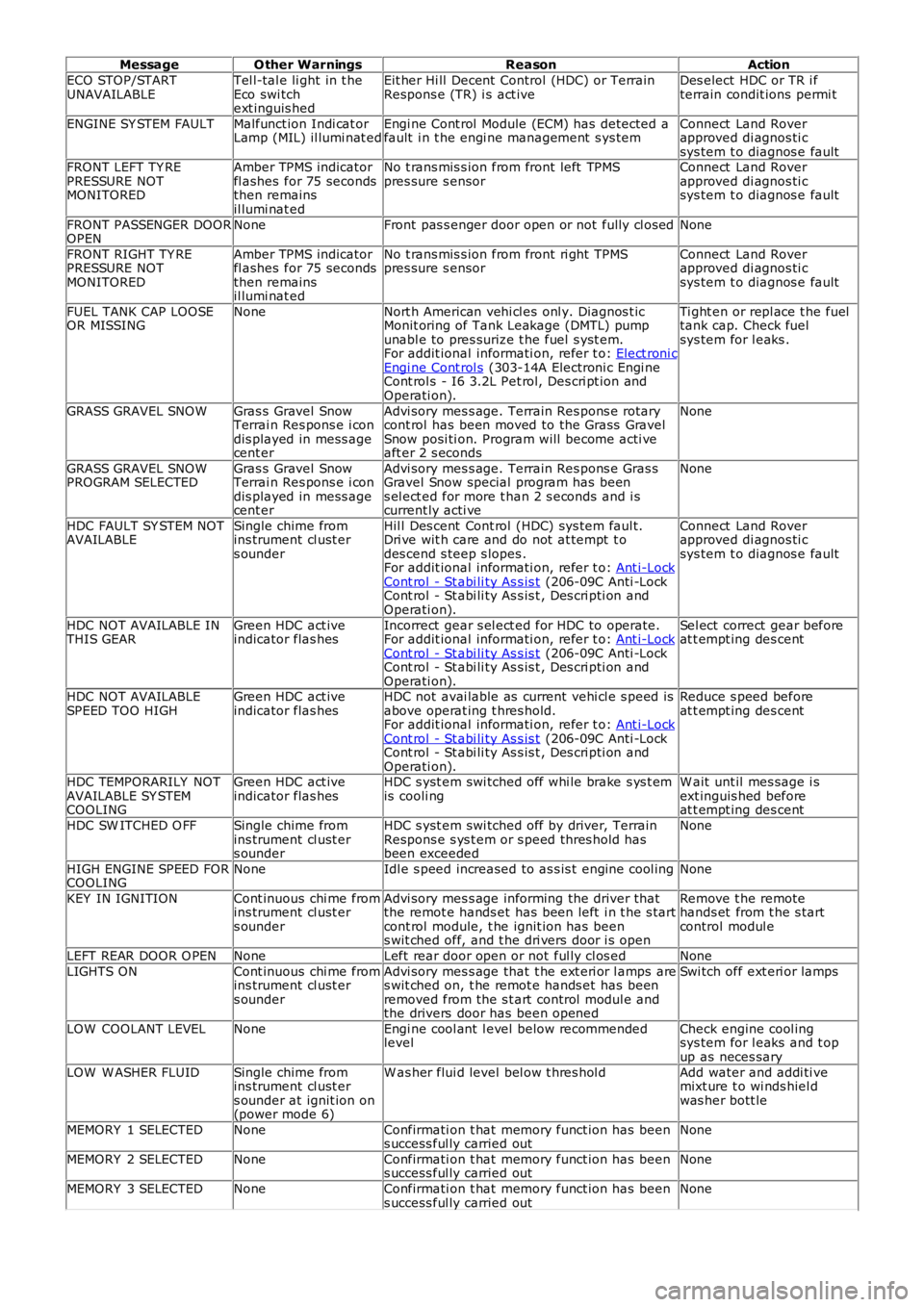

MessageO ther WarningsReasonAction

ECO STOP/STARTUNAVAILABLETel l-tal e li ght in t heEco swi tchext inguis hed

Eit her Hi ll Decent Control (HDC) or TerrainRespons e (TR) i s act iveDes elect HDC or TR i fterrain condit ions permi t

ENGINE SY STEM FAULTMalfunct ion Indi cat orLamp (MIL) il lumi nat edEngi ne Cont rol Module (ECM) has detected afault i n t he engi ne management s ys temConnect Land Roverapproved di agnos ti csys tem t o diagnos e faultFRONT LEFT TY REPRESSURE NOTMONITORED

Amber TPMS indicatorfl ashes for 75 secondsthen remainsil lumi nat ed

No t rans mis s ion from front left TPMSpres sure s ensorConnect Land Roverapproved di agnos ti csys tem t o diagnos e fault

FRONT PASSENGER DOOROPENNoneFront pas s enger door open or not fully cl osedNone

FRONT RIGHT TY REPRESSURE NOTMONITORED

Amber TPMS indicatorfl ashes for 75 secondsthen remainsil lumi nat ed

No t rans mis s ion from front ri ght TPMSpres sure s ensorConnect Land Roverapproved di agnos ti csys tem t o diagnos e fault

FUEL TANK CAP LOOSEOR MISSINGNoneNort h American vehi cl es onl y. Diagnos t icMonit oring of Tank Leakage (DMTL) pumpunabl e to pres surize t he fuel s yst em.For addit ional informati on, refer t o: Elect roni cEngi ne Cont rol s (303-14A Electroni c Engi neCont rol s - I6 3.2L Pet rol, Des cri pt ion andOperati on).

Ti ght en or repl ace t he fueltank cap. Check fuelsys tem for l eaks .

GRASS GRAVEL SNOWGras s Gravel SnowTerrai n Res pons e i condis played in mess agecent er

Advi sory mes s age. Terrain Res pons e rotarycont rol has been moved to the Grass GravelSnow posi ti on. Program will become acti veaft er 2 s econds

None

GRASS GRAVEL SNOWPROGRAM SELECTEDGras s Gravel SnowTerrai n Res pons e i condis played in mess agecent er

Advi sory mes s age. Terrain Res pons e Gras sGravel Snow special program has beens el ect ed for more t han 2 s econds and i scurrent ly acti ve

None

HDC FAULT SY STEM NOTAVAILABLESingle chime fromins trument cl ust ers ounder

Hil l Des cent Cont rol (HDC) sys tem faul t.Dri ve wit h care and do not at tempt t odes cend s teep s lopes .For addit ional informati on, refer t o: Ant i-LockCont rol - St abi li ty As s is t (206-09C Anti -LockCont rol - St abi li ty As s is t , Des cri pti on andOperati on).

Connect Land Roverapproved di agnos ti csys tem t o diagnos e fault

HDC NOT AVAILABLE INTHIS GEARGreen HDC act iveindicator flas hesIncorrect gear s el ect ed for HDC to operate.For addit ional informati on, refer t o: Ant i-LockCont rol - St abi li ty As s is t (206-09C Anti -LockCont rol - St abi li ty As s is t , Des cri pti on andOperati on).

Sel ect correct gear beforeat t empt ing des cent

HDC NOT AVAILABLESPEED TOO HIGHGreen HDC act iveindicator flas hesHDC not avai lable as current vehi cl e s peed isabove operat ing t hres hold.For addit ional informati on, refer t o: Ant i-LockCont rol - St abi li ty As s is t (206-09C Anti -LockCont rol - St abi li ty As s is t , Des cri pti on andOperati on).

Reduce s peed beforeat t empt ing des cent

HDC TEMPORARILY NOTAVAILABLE SY STEMCOOLING

Green HDC act iveindicator flas hesHDC s yst em swi tched off whi le brake s ys t emis cooli ngW ait unt il mes sage i sext inguis hed beforeat t empt ing des cent

HDC SW ITCHED O FFSingle chime fromins trument cl ust ers ounder

HDC s yst em swi tched off by driver, TerrainRespons e s ys t em or s peed thres hold hasbeen exceeded

None

HIGH ENGINE SPEED FORCOOLINGNoneIdl e s peed increased to as s is t engine cool ingNone

KEY IN IGNITIONCont inuous chi me fromins trument cl ust ers ounder

Advi sory mes s age informing the driver thatthe remot e hands et has been left i n t he s tartcont rol module, t he ignit ion has beens wit ched off, and t he dri vers door i s open

Remove t he remotehands et from t he s tartcontrol modul e

LEFT REAR DOOR O PENNoneLeft rear door open or not ful ly cl os edNone

LIGHTS ONCont inuous chi me fromins trument cl ust ers ounder

Advi sory mes s age that t he ext eri or l amps ares wit ched on, t he remot e hands et has beenremoved from the s t art control modul e andthe drivers door has been opened

Swi tch off ext eri or lamps

LOW COOLANT LEVELNoneEngi ne cool ant l evel below recommendedlevelCheck engine cool ingsys tem for l eaks and t opup as neces sary

LOW W ASHER FLUIDSingle chime fromins trument cl ust ers ounder at ignit ion on(power mode 6)

W as her flui d level bel ow t hres hol dAdd water and addi ti vemixt ure t o wi nds hiel dwas her bott le

MEMORY 1 SELECTEDNoneConfirmati on t hat memory funct ion has beens uccess ful ly carried outNone

MEMORY 2 SELECTEDNoneConfirmati on t hat memory funct ion has beens uccess ful ly carried outNone

MEMORY 3 SELECTEDNoneConfirmati on t hat memory funct ion has beens uccess ful ly carried outNone

Page 1811 of 3229

Publi s hed: 11-May-2011

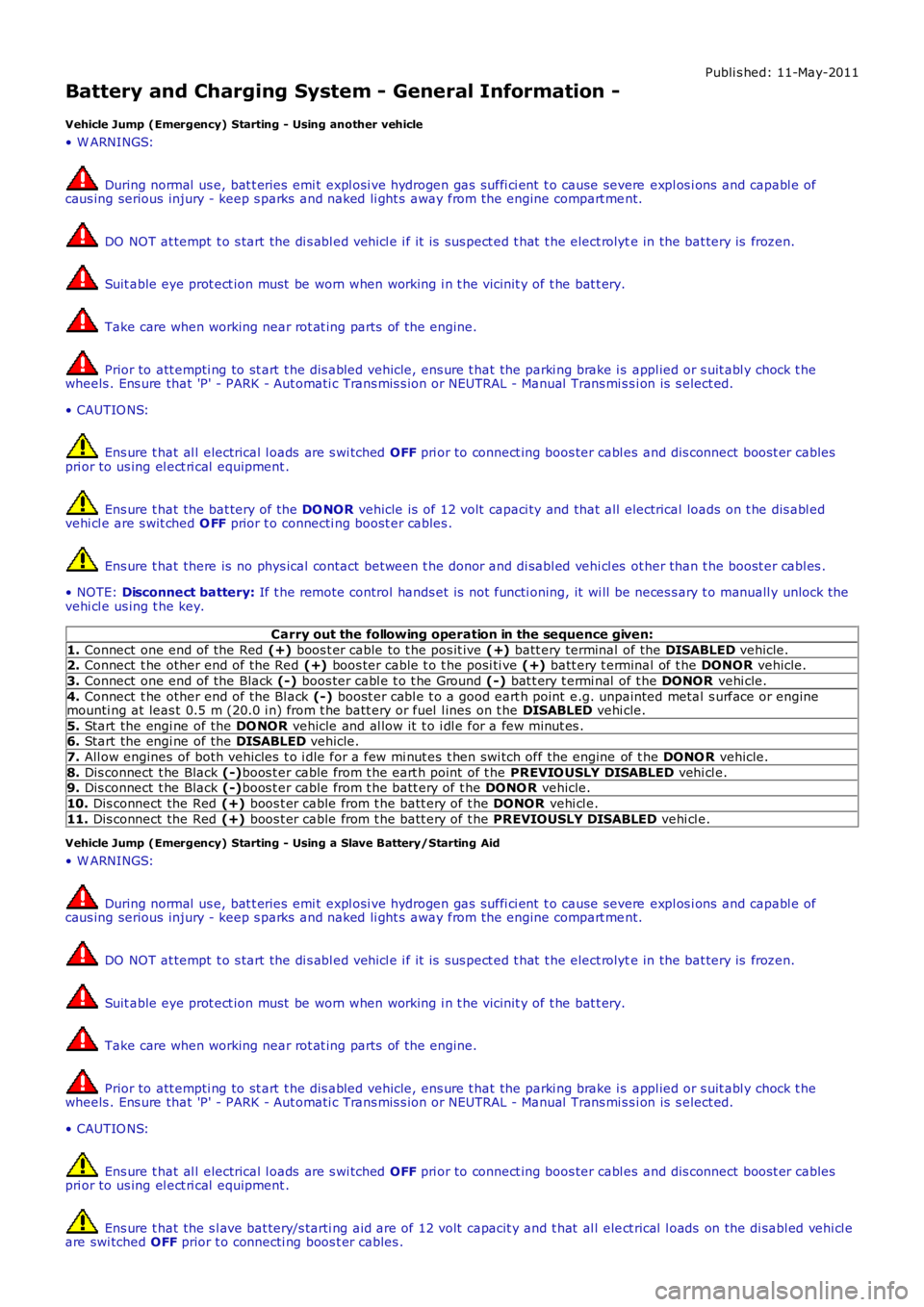

Battery and Charging System - General Information -

Vehicle Jump (Emergency) Starting - Using another vehicle

• W ARNINGS:

During normal us e, bat t eries emi t expl osi ve hydrogen gas suffi ci ent t o cause severe expl os i ons and capabl e ofcaus ing serious injury - keep s parks and naked li ght s away from the engine compart ment.

DO NOT at tempt t o s tart the di s abl ed vehi cl e i f it is sus pect ed t hat t he elect rolyte in the bat tery is frozen.

Suit able eye prot ect ion must be worn when working i n t he vicinit y of t he bat t ery.

Take care when working near rot at ing parts of t he engine.

Prior to att empti ng to st art t he dis abled vehicle, ens ure t hat the parki ng brake i s appl ied or s uit abl y chock t hewheels . Ens ure that 'P' - PARK - Aut omati c Trans mis s ion or NEUTRAL - Manual Trans mi ss i on is s elect ed.

• CAUTIO NS:

Ens ure t hat al l electrical l oads are s wi tched OFF pri or to connect ing boos ter cabl es and dis connect boos t er cablespri or to us ing el ect ri cal equipment .

Ens ure t hat the bat tery of the DO NOR vehicle is of 12 volt capaci ty and that all electrical loads on t he dis abl edvehi cl e are s wit ched O FF prior t o connecti ng boost er cables .

Ens ure t hat there is no phys ical contact between t he donor and di sabl ed vehi cl es other than t he boost er cabl es .

• NOTE: Disconnect battery: If t he remote control hands et is not functi oning, it wi ll be neces s ary t o manuall y unlock thevehi cl e us ing t he key.

Carry out the following operation in the sequence given:

1. Connect one end of the Red (+) boos t er cable to t he pos it ive (+) batt ery terminal of the DISABLED vehicle.2. Connect t he other end of the Red (+) boos ter cable t o t he posi ti ve (+) batt ery t erminal of t he DONOR vehicle.

3. Connect one end of the Black (-) boos ter cabl e t o t he Ground (-) bat t ery t ermi nal of t he DONOR vehi cle.

4. Connect t he other end of the Bl ack (-) boost er cabl e t o a good eart h point e.g. unpainted metal s urface or enginemounti ng at leas t 0.5 m (20.0 i n) from t he batt ery or fuel l ines on t he DISABLED vehi cle.

5. Start the engi ne of the DO NOR vehicle and al low it t o i dl e for a few minut es .6. Start the engi ne of the DISABLED vehicle.

7. All ow engines of both vehicles t o i dle for a few mi nut es t hen swi tch off the engine of t he DONO R vehicle.

8. Dis connect t he Black (-)boos t er cable from t he eart h point of t he PREVIO USLY DISABLED vehi cl e.9. Dis connect t he Black (-)boos t er cable from t he batt ery of t he DONO R vehicle.

10. Dis connect the Red (+) boos t er cable from t he batt ery of t he DONOR vehi cl e.

11. Dis connect the Red (+) boos t er cable from t he batt ery of t he PREVIOUSLY DISABLED vehi cl e.

Vehicle Jump (Emergency) Starting - Using a Slave Battery/Starting Aid

• W ARNINGS:

During normal us e, bat t eries emi t expl osi ve hydrogen gas suffi ci ent t o cause severe expl os i ons and capabl e ofcaus ing serious injury - keep s parks and naked li ght s away from the engine compart ment.

DO NOT at tempt t o s tart the di s abl ed vehi cl e i f it is sus pect ed t hat t he elect rolyte in the bat tery is frozen.

Suit able eye prot ect ion must be worn when working i n t he vicinit y of t he bat t ery.

Take care when working near rot at ing parts of t he engine.

Prior to att empti ng to st art t he dis abled vehicle, ens ure t hat the parki ng brake i s appl ied or s uit abl y chock t hewheels . Ens ure that 'P' - PARK - Aut omati c Trans mis s ion or NEUTRAL - Manual Trans mi ss i on is s elect ed.

• CAUTIO NS:

Ens ure t hat al l electrical l oads are s wi tched OFF pri or to connect ing boos ter cabl es and dis connect boos t er cablespri or to us ing el ect ri cal equipment .

Ens ure t hat the s l ave bat tery/s tarti ng aid are of 12 volt capacit y and t hat al l elect rical l oads on the di sabl ed vehi cl eare swi tched OFF prior t o connecti ng boos t er cables .