tow LAND ROVER FRELANDER 2 2006 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 1400 of 3229

s ynchronizi ng hub towards the revers e gear i dler gear.

The coupl ing s leeve and s ynchronizi ng hub lock t he revers e gear idler gear at the revers e s haft.

The t orque of the engine is t rans ferred via the cl ut ch t o the input shaft. The 1s t gear on t he i nput s haft t rans fers power t ot he 1st gear idl er gear. The power is then t rans ferred t o t he revers e gear idl er gear and then t o t he reverse gear coupl ings leeve. From t here power is trans ferred to t he i nt ermedi ate s haft 1s t - 2nd and 5t h - 6th and to the final dri ve which i nt urn t rans fers power t o t he ring gear. The ring gear is connect ed to the drive s hafts t hrough the di fferenti al.

Differential

The different ial dis t ribut es dri ve from t he t ransmis s ion equally bet ween t he LH and RH front half s haft s and als o provi desdri ve torque to the rear di fferenti al vi a t he power t rans fer unit .

The different ial is locat ed at t he rear of the trans mi ss i on hous ing. Both s ides of the di fferenti al are connected to t he LHand RH drive s haft s, s upplying t orque t o t he front wheel s The different ial is als o connected t o t he Power Transfer Unit viaa s pli ned shaft to the RH s ide of t he trans mi s si on, s upplying t orque t o t he rear driveline.

Reverse Switch

The revers e s wi tch i s located i n t he front of the t rans mis s ion cas ing, above t he 1s t gear det ect ion s wi tch. The swi tch i sus ed by the Ant i-lock Brake Sys tem (ABS) module for Hil l Descent Cont rol (HDC) and als o for revers ing l amp operati on.

1st Gear Position Switch

The 1s t gear s wit ch is locat ed on t he front of the t rans mi ss ion cas ing, below t he reverse swit ch. The s wit ch is us ed by t heABS module for HDC.

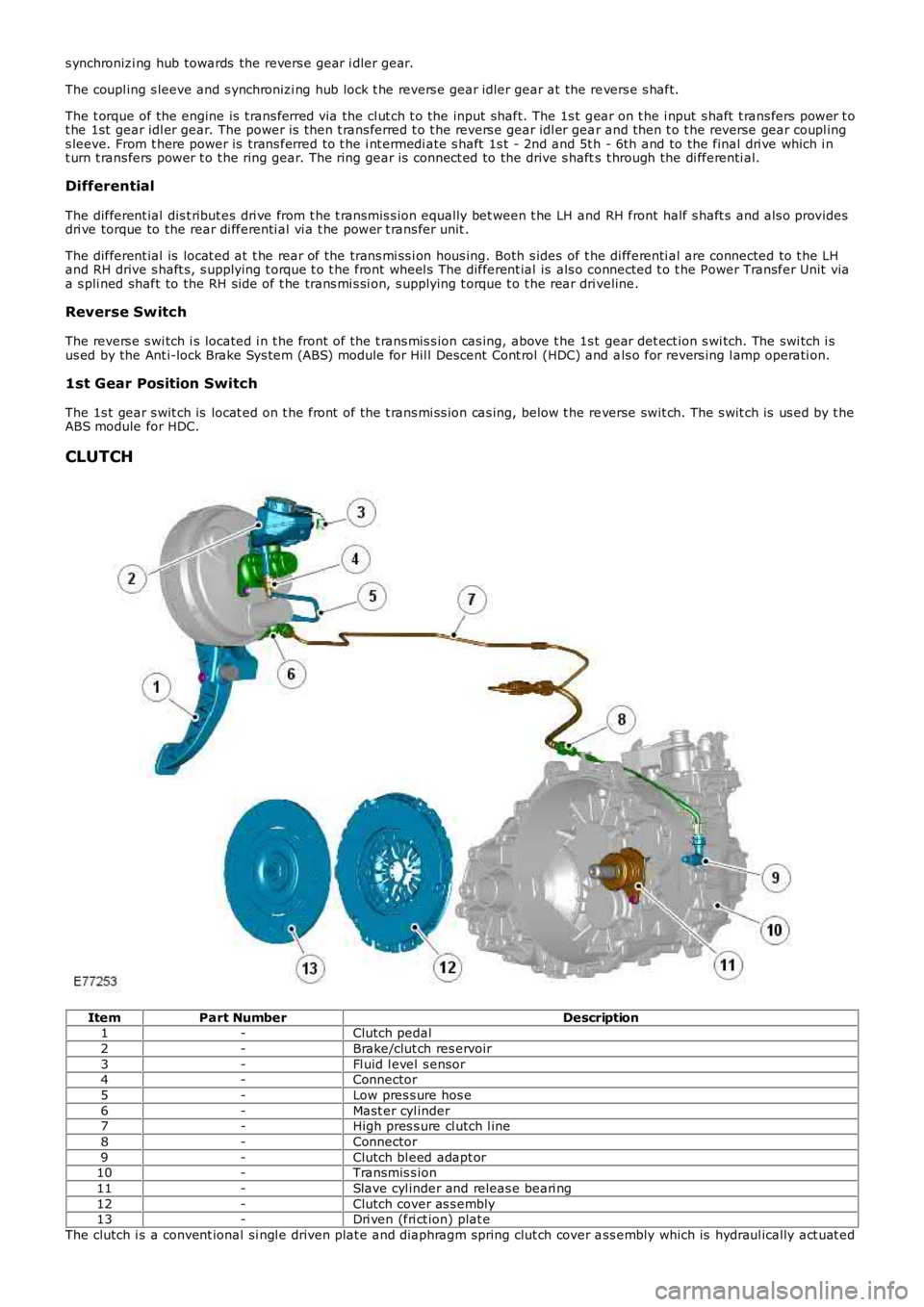

CLUTCH

ItemPart NumberDescription1-Clutch pedal

2-Brake/clut ch res ervoir

3-Fl uid l evel s ensor4-Connector

5-Low pres s ure hos e

6-Mast er cyl inder7-High pres s ure cl utch l ine

8-Connector

9-Clutch bl eed adapt or10-Transmis s ion

11-Slave cyl inder and releas e beari ng

12-Clutch cover as s embly13-Dri ven (fri ct ion) plat e

The clutch i s a convent ional si ngl e driven plat e and diaphragm spring clut ch cover ass embly which is hydraul ically act uat ed

Page 1408 of 3229

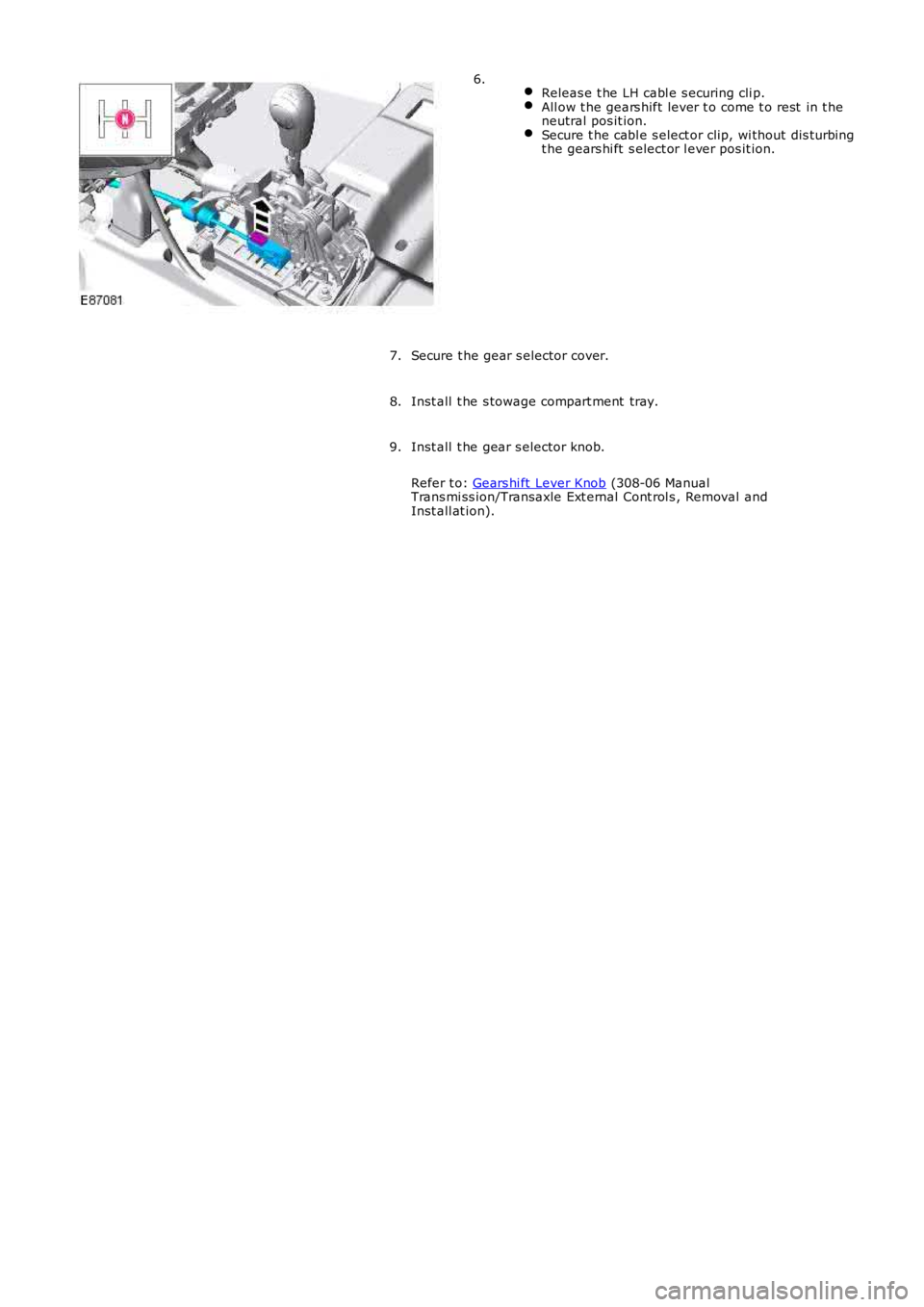

Releas e t he LH cabl e s ecuring cli p.All ow t he gears hift lever t o come t o rest in t heneutral pos it ion.Secure t he cabl e s elect or clip, wi thout dis turbingt he gears hi ft s elect or l ever pos it ion.

6.

Secure t he gear s elector cover.7.

Inst all t he s towage compart ment tray.8.

Inst all t he gear s elector knob.

Refer t o: Gears hi ft Lever Knob (308-06 ManualTrans mi ss ion/Transaxle Ext ernal Cont rol s , Removal andInst all at ion).

9.

Page 1444 of 3229

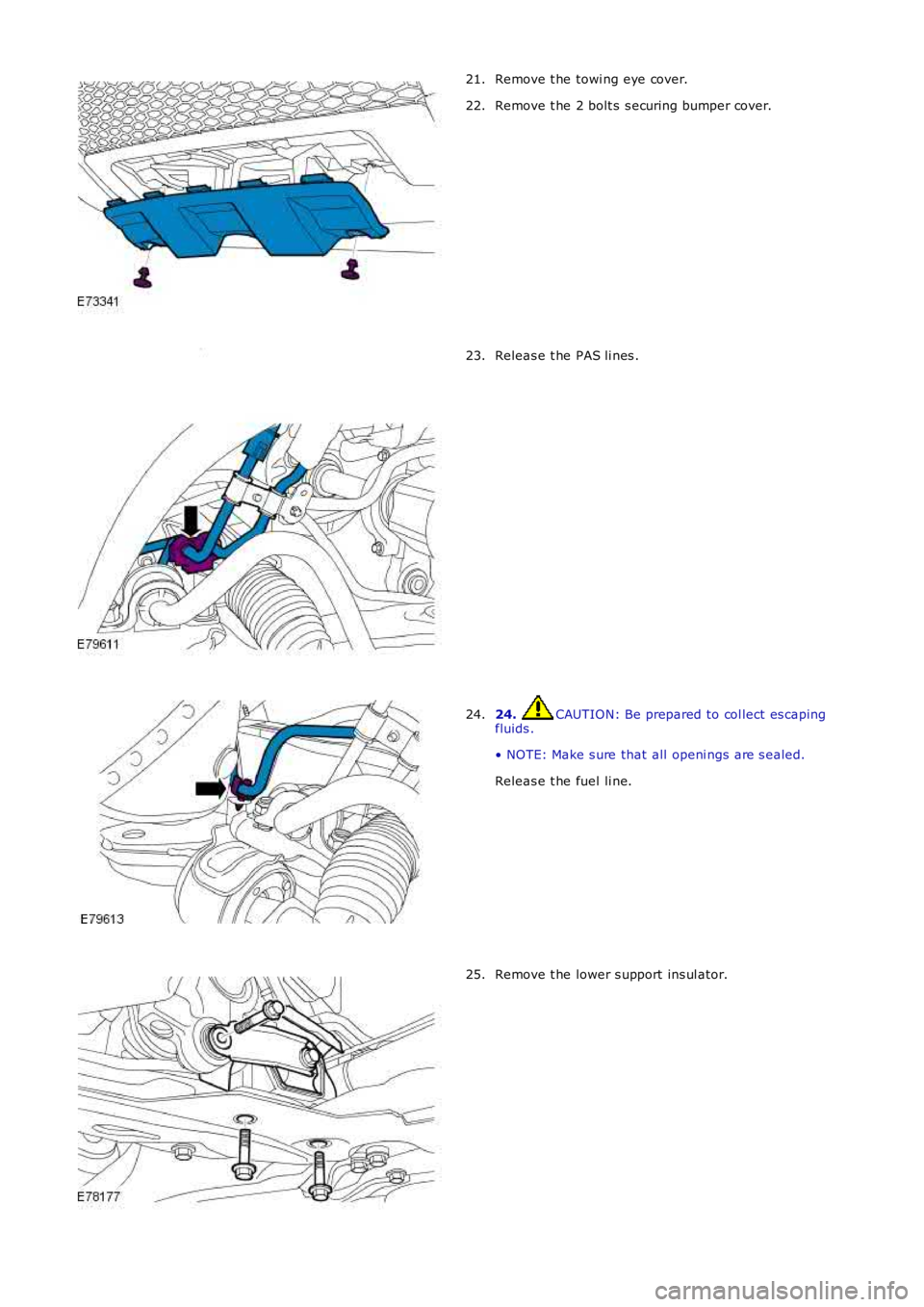

Remove t he towi ng eye cover.21.

Remove t he 2 bolt s s ecuring bumper cover.22.

Releas e t he PAS li nes .23.

24. CAUTION: Be prepared to col lect es capingfluids .

• NOTE: Make s ure that all openi ngs are s ealed.

Releas e t he fuel li ne.

24.

Remove t he lower s upport ins ul ator.25.

Page 1455 of 3229

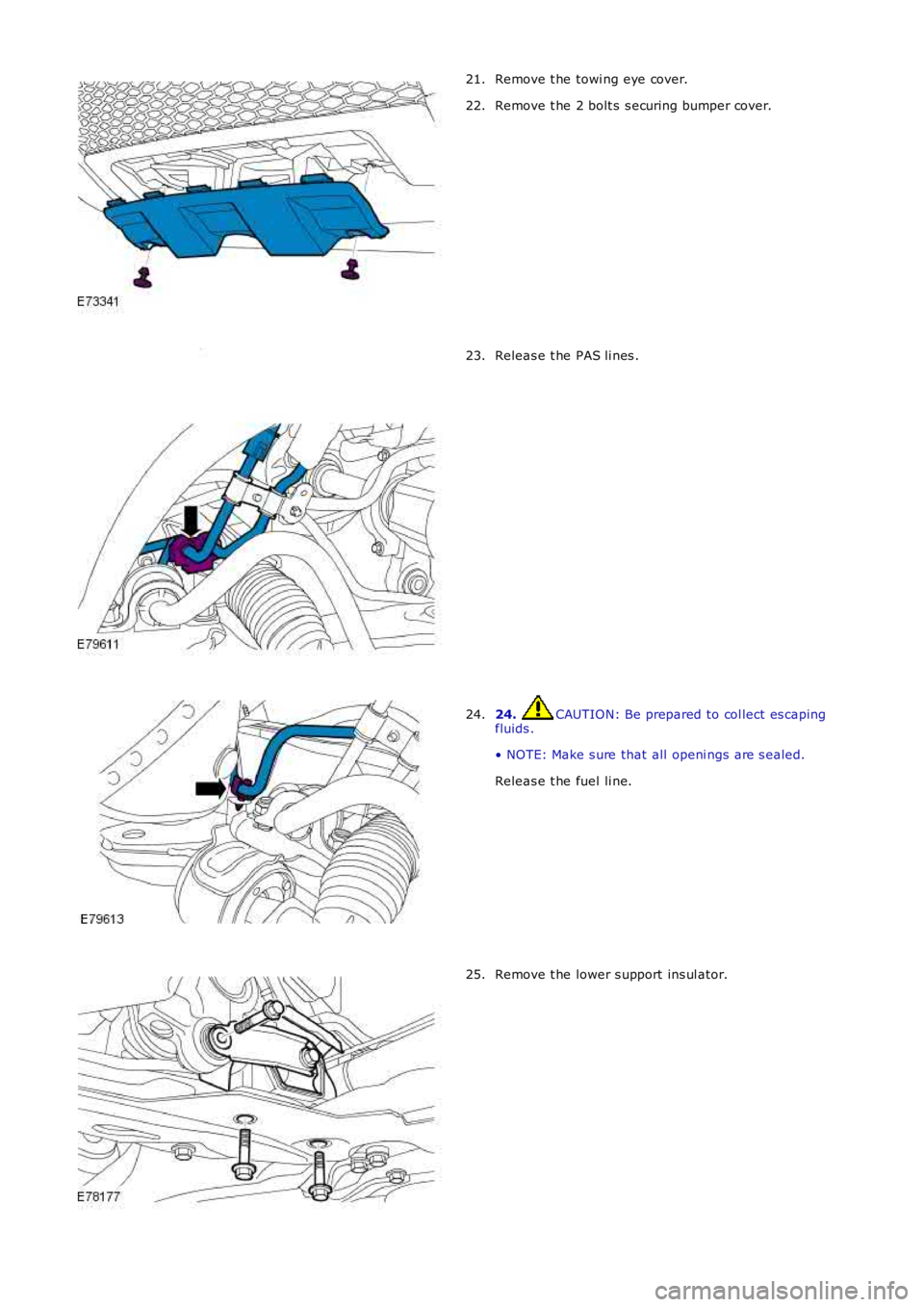

Remove t he towi ng eye cover.

21.

Remove t he 2 bolt s s ecuring bumper cover.

22. Releas e t he PAS li nes .

23. 24. CAUTION: Be prepared to col lect es caping

fluids .

• NOTE: Make s ure that all openi ngs are s ealed.

Releas e t he fuel li ne.

24. Remove t he lower s upport ins ul ator.

25.

Page 1744 of 3229

The s olenoi d coil of the auxil iary fuel pump i s ins tal led around a hous ing which cont ains a pl unger and pis t on. The pi st onlocates i n a bus h, and a s pri ng is i nst all ed on t he pis ton bet ween the bus h and t he plunger. A fil ter i nsert and a fuel l ineconnector are ins tal led i n the inlet end of t he hous ing. A non return valve and a fuel line connect or are i nst all ed in the fueloutl et end of t he housi ng.

W hi le t he s olenoid coil i s de-energized, the spring holds t he pis t on and plunger i n t he clos ed pos i ti on at the i nlet end oft he hous ing. An O-ri ng s eal on the pl unger provides a fuel ti ght s eal bet ween t he plunger and t he filt er ins ert , prevent ingany fl ow t hrough t he pump. W hen the sol enoi d coi l is energi zed, t he pis ton and pl unger move t owards t he outl et end oft he hous ing, unti l the pl unger cont act s t he bush; fuel i s t hen drawn i n t hrough the i nlet connecti on and fi lt er. The i ni ti almovement of t he pis t on als o clos es t rans verse dril li ngs in t he bus h and is olat es the pumpi ng chamber at t he out let end oft he hous ing. Subsequent movement of t he pis ton then forces fuel from t he pumping chamber through t he non return val veand int o t he li ne to the fuel fi red boost er heat er. W hen the s olenoid de-energizes , the s pri ng moves the pi s ton andplunger back t owards t he cl osed pos it ion. As t he pis t on and plunger move towards t he clos ed posi ti on, fuel fl ows pas t t heplunger and through t he annul ar gaps and t rans vers e holes i n t he bus h t o replenis h the pumping chamber.

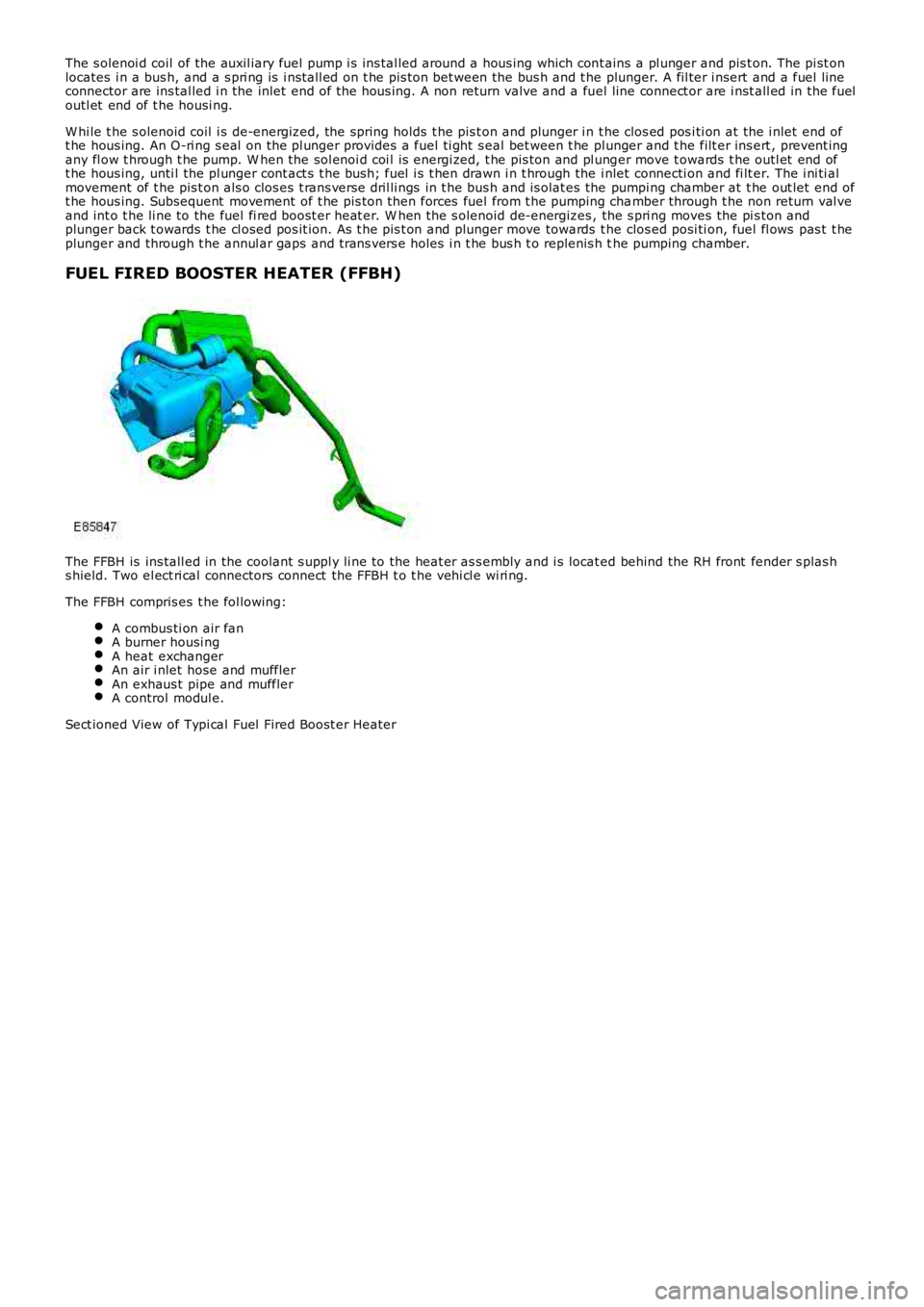

FUEL FIRED BOOSTER HEATER (FFBH)

The FFBH is ins tall ed in the coolant s uppl y li ne to the heat er as s embly and i s located behind the RH front fender s plas hs hield. Two el ect ri cal connectors connect the FFBH t o t he vehi cl e wi ri ng.

The FFBH compris es t he fol lowing:

A combus ti on air fanA burner housi ngA heat exchangerAn air i nlet hose and mufflerAn exhaus t pipe and mufflerA control modul e.

Sect ioned View of Typi cal Fuel Fired Boost er Heater

Page 2118 of 3229

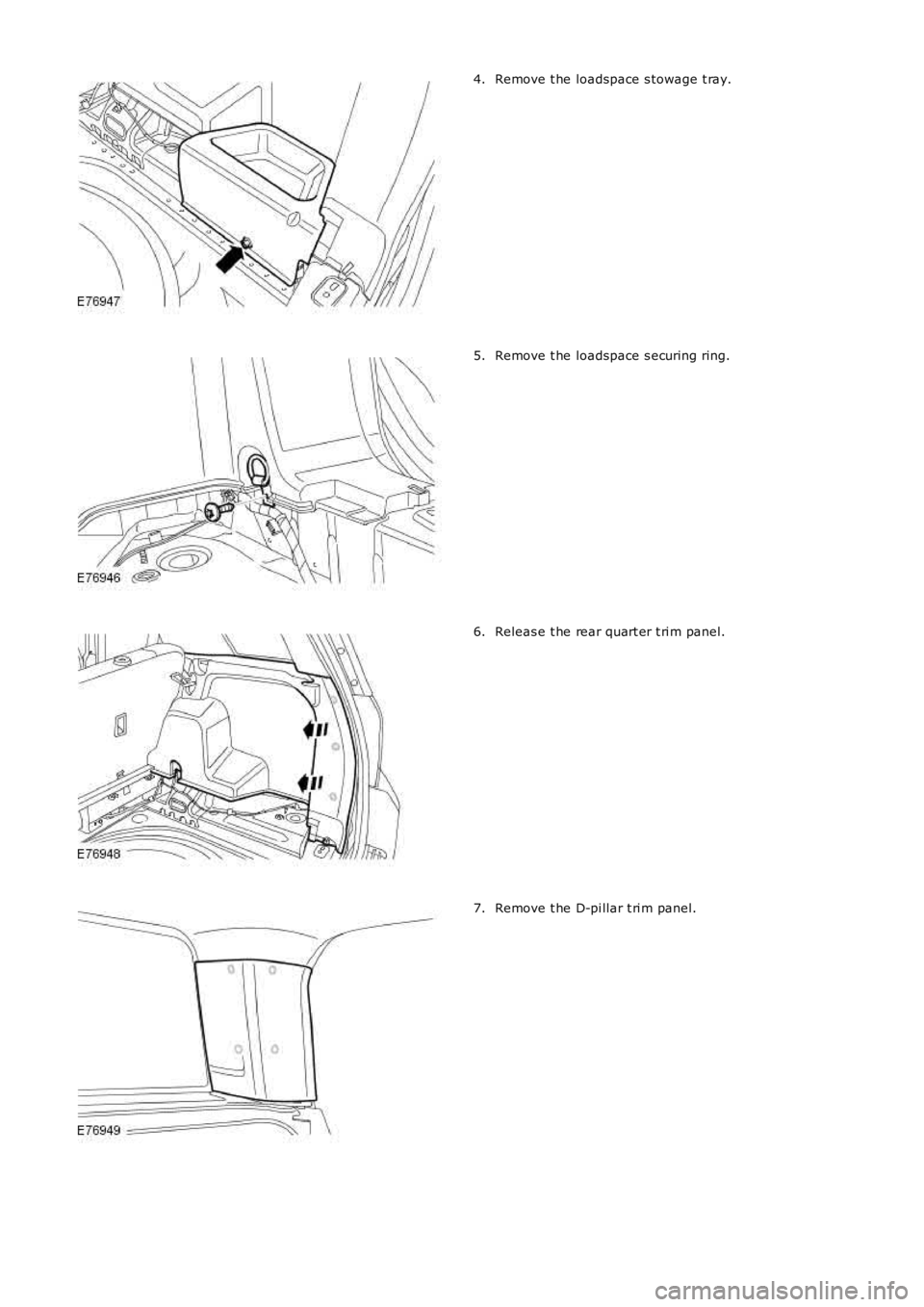

Remove t he loadspace s towage t ray.4.

Remove t he loadspace s ecuring ring.5.

Releas e t he rear quart er t ri m panel.6.

Remove t he D-pi llar t ri m panel.7.

Page 2119 of 3229

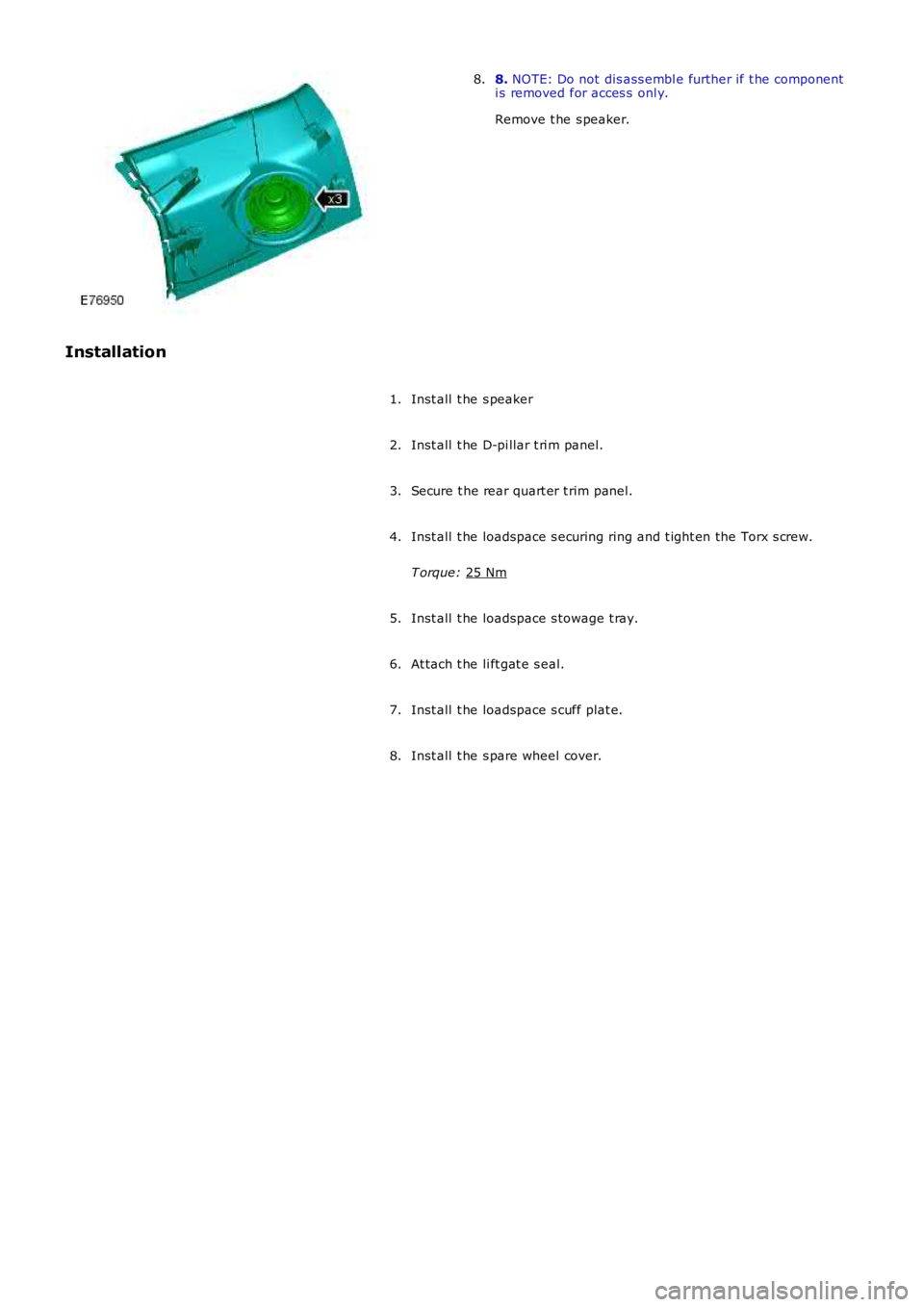

8.

NOTE: Do not dis ass embl e further if t he component

i s removed for acces s onl y.

Remove t he s peaker.

8.

Installation Inst all t he s peaker

1.

Inst all t he D-pi llar t ri m panel.

2.

Secure t he rear quart er t rim panel.

3.

Inst all t he loadspace s ecuring ring and t ight en the Torx s crew.

T orque: 25 Nm 4.

Inst all t he loadspace s towage t ray.

5.

At tach t he li ft gat e s eal.

6.

Inst all t he loadspace s cuff plat e.

7.

Inst all t he s pare wheel cover.

8.

Page 2155 of 3229

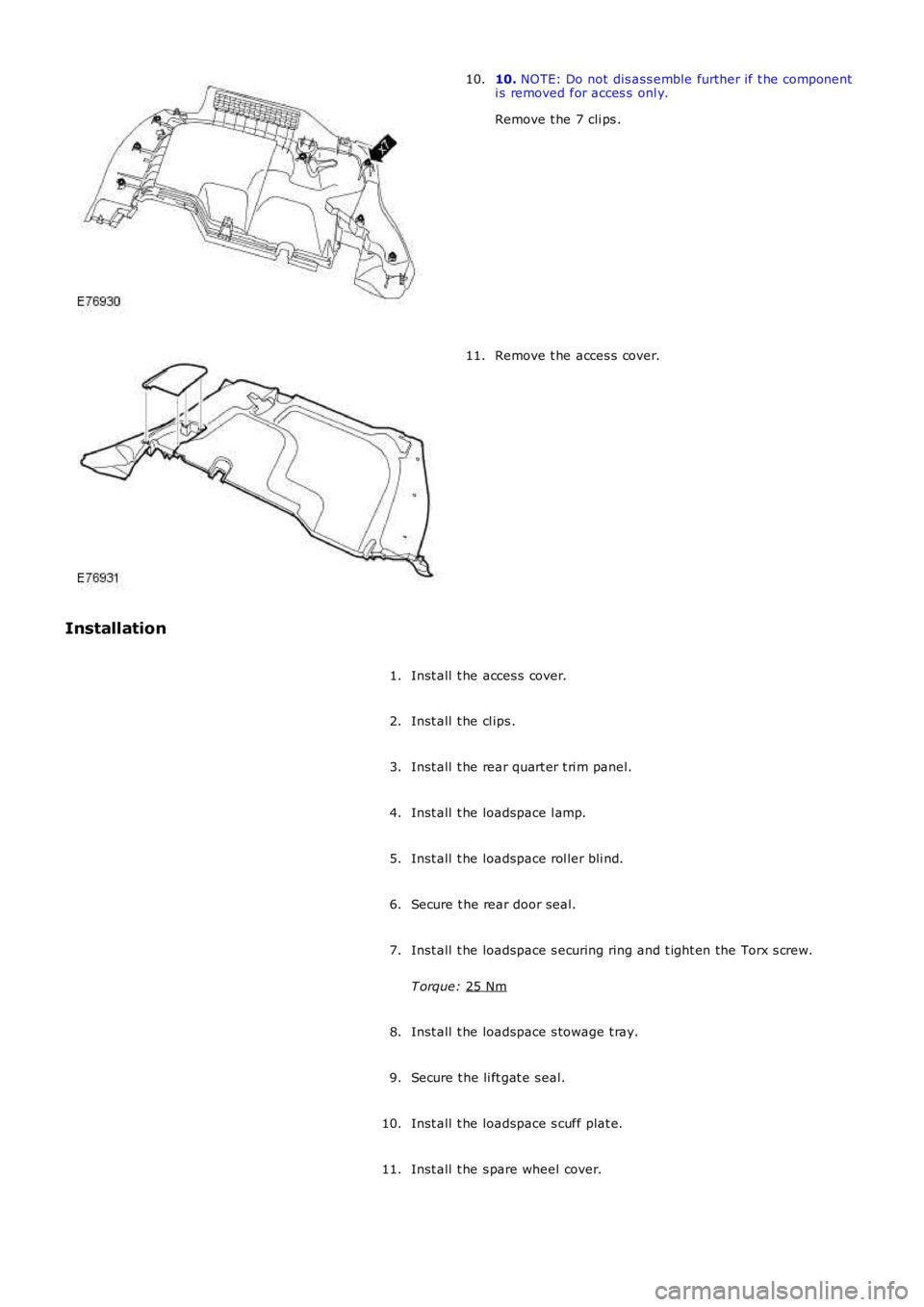

10.

NOTE: Do not dis ass emble further if t he component

i s removed for acces s onl y.

Remove t he 7 cli ps .

10. Remove t he acces s cover.

11.

Installation Inst all t he acces s cover.

1.

Inst all t he cl ips .

2.

Inst all t he rear quart er t ri m panel.

3.

Inst all t he loadspace l amp.

4.

Inst all t he loadspace rol ler bli nd.

5.

Secure t he rear door seal.

6.

Inst all t he loadspace s ecuring ring and t ight en the Torx s crew.

T orque: 25 Nm 7.

Inst all t he loadspace s towage t ray.

8.

Secure t he li ft gat e s eal.

9.

Inst all t he loadspace s cuff plat e.

10.

Inst all t he s pare wheel cover.

11.

Page 2180 of 3229

3

-Seat heati ng module

Dependi ng on vehi cl e s peci fi cat ion, seat heati ng is avail abl e for bot h t he manual ly operat ed and t he power operat ed

s eat s . A heati ng element is incorporated wit hi n each s eat cus hi on and s quab. A seat heati ng modul e and elect rical wiring

is locat ed beneat h each front seat .

The s eat heat ing modules are connected on the LIN bus t o t he ATC, and are als o hardw ired to the AJB for the power

s uppl y. A ground t ermi nal from each s eat heat ing modul e completes the circui t.

For addit ional informat ion, refer t o: Cont rol Component s (412-01 Cli mat e Cont rol , Descripti on and Operat ion).

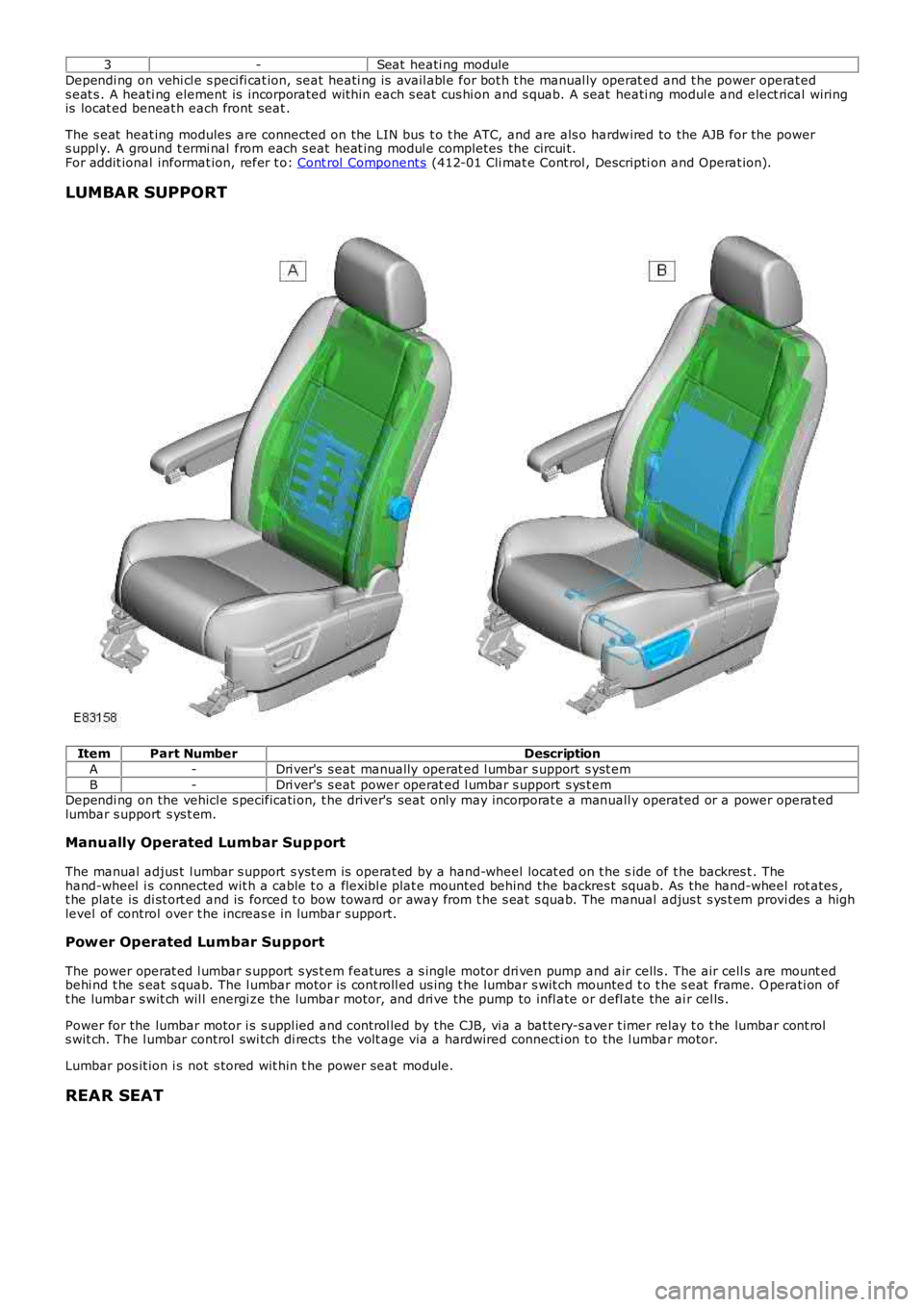

LUMBAR SUPPORT Item

Part Number Description

A -Dri ver's s eat manually operat ed l umbar s upport s yst em

B -Dri ver's s eat power operat ed l umbar s upport s ys t em

Dependi ng on the vehicl e s pecificati on, t he driver's seat only may incorporat e a man uall y operated or a power operat ed

lumbar s upport s ys t em.

Manually Operated Lumbar Sup port

The manual adjus t l umbar s upport s yst em is operat ed by a hand-wheel locat ed on t he s ide of t he backres t . The

hand-wheel i s connected wit h a cable t o a flexibl e plat e mounted behind the backres t squab. As the hand-wheel rot ates ,

t he plate is di st ort ed and is forced t o bow toward or away from t he s eat s quab. The manual adjus t s ys t em provi des a high

level of control over t he increas e in lumbar s upport.

Power Operated Lumbar Support

The power operat ed l umbar s upport s ys t em features a s ingle motor dri ven pump and air cells . The air cell s are mount ed

behi nd t he s eat s quab. The l umbar motor is cont roll ed us ing t he lumbar s wit ch mounte d t o t he s eat frame. O perati on of

t he lumbar s wit ch wil l energi ze the lumbar motor, and dri ve the pump to infl ate or d efl ate the ai r cel ls .

Power for the lumbar motor i s s uppl ied and control led by the CJB, vi a a bat tery-s ave r t imer relay t o t he lumbar cont rol

s wit ch. The l umbar control swi tch di rects the volt age via a hardwired connecti on to the l umbar motor.

Lumbar pos it ion i s not s tored wit hin t he power seat module.

REAR SEAT

Page 2298 of 3229

Publi s hed: 11-May-2011

Instrument Panel and Console - Floor Console

Removal and Inst all ati on

Removal

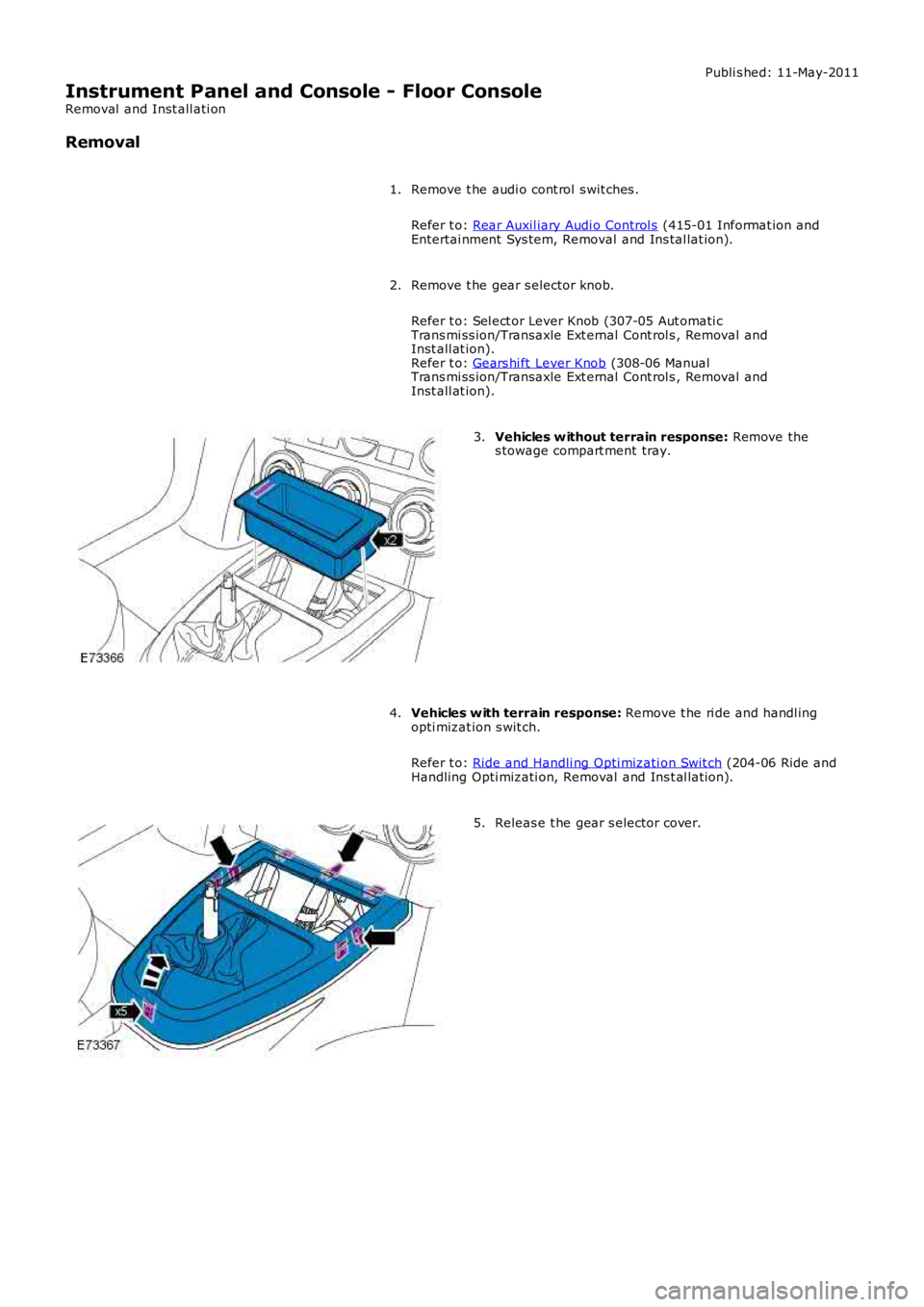

Remove t he audi o cont rol s wit ches .

Refer t o: Rear Auxil iary Audi o Control s (415-01 Informat ion andEntertai nment Sys tem, Removal and Ins tal lat ion).

1.

Remove t he gear s elector knob.

Refer t o: Sel ect or Lever Knob (307-05 Aut omati cTrans mi ss ion/Transaxle Ext ernal Cont rol s , Removal andInst all at ion).Refer t o: Gears hi ft Lever Knob (308-06 ManualTrans mi ss ion/Transaxle Ext ernal Cont rol s , Removal andInst all at ion).

2.

Vehicles w ithout terrain response: Remove thes towage compart ment tray.3.

Vehicles w ith terrain response: Remove t he ri de and handl ingopti mizat ion s wit ch.

Refer t o: Ride and Handli ng Opti mizati on Swit ch (204-06 Ride andHandling Opti mizati on, Removal and Ins t al lat ion).

4.

Releas e t he gear s elector cover.5.