tow LAND ROVER FRELANDER 2 2006 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 648 of 3229

Interpretation of the Results

• NOTE: Due t o t he poss ibi li ty of l oos e carbon t hat has become t rapped between t he valve face and seat effect ing thepres s ure readi ngs , when carryi ng out a compres s ion t est and cyli nders are found to have low press ures , ins t al l the s parkplugs , road t est t he vehicle and re-t est the s us pect cyl inders . If the correct pressures are rest ored, no further acti on isrequired.

The indicat ed compress i on pres sures are cons idered wi thi n s pecificati on if t he l owest readi ng cyl inder is wi thi n 75% of t hehighest reading.

If the cyli nder pres s ures are found t o be l ow, carry out a l eakdown t est to det ermi ne the locat ion of t he faul t (i f anyleakback can be heard through t he engine breat her sys tem s uspect the pi st on rings , if any leakback can be heard throught he inlet s ys tem sus pect t he i nl et val ve or seat , if any leakback can be heard through the exhaus t mani fold sus pect t heexhaus t val ve or s eat . If t he meas urements for t wo cyl inders next t o each ot her are bot h t oo low then i t is very likely thatt he cyl inder head gas ket bet ween them is burnt t hrough. Thi s can als o be recognized by t races of engi ne oil in the coolantand/or cool ant i n t he engi ne oil ).

Oil Consump tion Test

The amount of oi l an engi ne uses will vary wit h t he way t he vehi cl e is driven i n addit ion t o normal engine-t o-enginevariat ion. This i s es pecial ly t rue during t he fi rs t 16,100 km (10,000 mil es) when a new engine i s bei ng broken i n or unt ilcert ai n i nt ernal components become condit ioned. Vehicles us ed i n heavy-dut y operati on may us e more oil . The fol lowingare exampl es of heavy-duty operat ion:

Trai ler towi ng appl icati onsSevere loading appli cat ionsSust ained high speed operat ion

Engi nes need oi l to lubri cat e t he fol lowing internal component s :

Cylinder block cyl inder wallsPis t ons and pi st on ringsInt ake and exhaus t val ve s temsInt ake and exhaus t val ve guidesAll i nt ernal engi ne component s

W hen t he pis t ons move downward, a t hi n film of oil i s left on the cyli nder wal ls . As t he vehi cl e is operated, s ome oil i sals o drawn int o t he combus t ion chambers pas t the i ntake and exhaus t valve s tem s eal s and burned.

The fol lowing are examples of condi ti ons that can affect oil consumpt ion rates :

Engi ne s izeOperat or driving habit sAmbient t emperaturesQuali ty and vi scos it y of oi lEngi ne is bei ng run in an overfil led condit ion (check t he oil level at least five minutes after a hot s hutdown wi th thevehi cl e parked on a level surface. The oi l level s hould not be above the top of t he cros s-hatched area and t he l et t er"F" i n FULL).

Operat ion under varyi ng condi ti ons can frequent ly be mi sl eadi ng. A vehi cl e t hat has been run for s everal t housand miles ons hort t rips or i n below-freezi ng ambient temperat ures may have cons umed a "normal" amount of oil . However, whenchecking t he engine oil l evel , it may meas ure up to the full mark on t he oil l evel indicator due t o dil uti on (condens ati onand fuel ) in t he engine crankcas e. The vehi cl e t hen might be driven at high s peeds on the hi ghway where t he condens at ionand fuel boil off. The next t ime t he engi ne oil is checked it may appear that a l it er of oi l was us ed i n about 160 km (100mi les ). Oi l cons umpti on rat e is about one l it er per 2,400 km (1,500 mil es).

Make s ure t he s elected engine oi l meets manufact urer s pecificati on and t he recommended API performance cat egory "SG"and SAE vis cos i ty grade as s hown in t he vehicle O wner's Gui de. It is al s o important t hat t he engine oi l i s changed at t heint ervals s peci fi ed for t he t ypi cal operati ng condi ti ons .

The fol lowing di agnos t ic procedure i s us ed to det ermi ne t he s ource of excess i ve oi l cons umpti on.

• NOTE: Oi l us e i s normal ly great er during the first 16,100 km (10,000 mi les ) of servi ce. As mil eage i ncreas es , oil us edecreas es . High s peed dri vi ng, towing, high ambi ent temperat ure and ot her factors may res ult in great er oil use.

1. Defi ne exces si ve cons umpti on, s uch as t he number of miles driven per li ter of oil used. Al so det ermine cust omersdriving habit s , such as s us tai ned hi gh s peed operat ion, t owing, ext ended i dle and other cons iderat ions.1.

2. Verify t hat the engine has no ext ernal oi l leaks as descri bed under Engine Oi l Leaks i n thi s s ect ion.2.

3. Carry out an oil cons umpti on t es t :

Run t he engi ne to normal operati ng t emperature. Swi tch engine OFF and al low oi l to drain back for at l eas tfi ve mi nut es .W i th vehi cl e parked on l evel s urface, check t he engi ne oil l evel.If required, add engine oil t o s et level exactl y t o t he FULL mark.Record t he vehi cl e mi leage.Ins t ruct the cus tomer t o return for a l evel check after driving t he vehi cle as us ual for 1,610 km (1000 mi les ).Check t he oil l evel under t he s ame condit ions and at the same locat ion as the i nit ial check.

3.

• NOTE: If the oi l cons umpti on rat e is unaccept abl e go t o St ep 4.

4. Check t he Posi ti ve Crankcas e Vent ilat ion (PCV) sys t em. Make sure t he s ys t em i s not pl ugged.4.

5. Check for pl ugged oi l drain-back holes i n t he cyl inder head and cyli nder bl ock.5.

6. Carry out a cyl inder compress ion tes t. Refer t o t he Compres s ion Tes t procedure in thi s s ect ion. Thi s can help6.

Page 664 of 3229

T orque:

10 Nm Connect t he purge l ine.

14.

Inst all t he lower int ake manifol d bolt s .

T orque: 10 Nm 15.

Inst all t he air cleaner out let pipe.

16.

Inst all t he engi ne undershi eld.

Refer t o: Engi ne Unders hi eld (501-02 Front End Body Panel s ,

Removal and Ins tall ati on).

17.

Inst all t he front unders hiel d.

18.

Inst all t he front towing eye cover.

19.

Inst all t he air cleaner as s embly.

Refer t o: Air Cleaner (303-12B Intake Ai r Dis tribut ion and Fil tering -

TD4 2.2L Dies el, Removal and Inst all ati on).

20.

Inst all t he engi ne cover.

Refer t o: Engi ne Cover - I6 3.2L Pet rol (501-05 Int eri or Trim and

Ornament ati on, Removal and Ins tal lat ion).

21.

Connect t he batt ery ground cable.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -

General Informat ion, Specificati ons).

22.

Check and top-up the coolant.

23.

Page 771 of 3229

Lateral movement of the cranks haft is res trict ed by 4 half-round thrus t was hers , located on bot h s ides of No. 2 mai nbearing. Lubricati on grooves are formed on t he thrus t was hers and mus t face toward the main beari ng. The cranks haftend-float mus t be bet ween 0.07 mm (0.003 in) and 0.32 mm (0.013 i n).

Each main beari ng housi ng and half cap cont ains an upper and lower bearing half s hell manufactured from al uminum/ti n.The upper half s hell s are formed wit h a dril li ng and annular groove t o t rans fer press uri zed oi l from t he main bearing,t hrough cranks haft drill ings t o t he connecti ng rod bi g-end bearings .

The main bearing half caps and t he upper and l ower beari ng half s hel ls are formed with a l ug. The l ug allows correctali gnment of t he bearing and cap, and prevent s radi al movement of t he bearing.

To mai nt ain the correct cranks haft mai n bearing cl earance, the main beari ng half s hells are avail abl e in varying t hicknes s .The upper mai n beari ng hal f s hel l is only avail abl e i n 1 s ize; t he lower mai n bearing hal f shell i s avai lable in 5 si zes . Bot ht he upper and lower mai n bearing hal f shel ls are col or coded for i dent ificati on. To det ermi ne t he correct s ize of bearing hal fs hel l, clas s ificat ion markings on t he cranks haft front face and on t he cyl inder bl ock front face are us ed in conjunct ion wi tha beari ng s ize chart .

For furt her det ail s on main bearing half s hell i ns t allat ion, refer to the relevant Servi ce Repai r Procedures (SRP).

A drive gear is formed as a 's hri nk-fit ' on No. 3 cranks haft web, located bet ween No. 2 mai n bearing journal and No. 2connecti ng rod bi g-end journal . The dri ve gear i s s ingle hel ical cut and provides t he dri ve to the counter-balance s haftgears . An 18 t eet h s pur gear i s located on the front of the cranks haft , behi nd the front cranks haft s eal ing pl at e. The s purgear provi des the drive t o t he oil pump as s embly via a s ingle row chain, and i s locked to the cranks haft wit h a woodruffkey.

A t oothed gear mount ed t o t he front of t he cranks haft provides t he dri ve for t he cams haft t iming belt . The dri ve gearcont ains 21 t eeth and is keyed to the cranks haft wit h a woodruff key.

Crankshaft Oil Seals

Page 773 of 3229

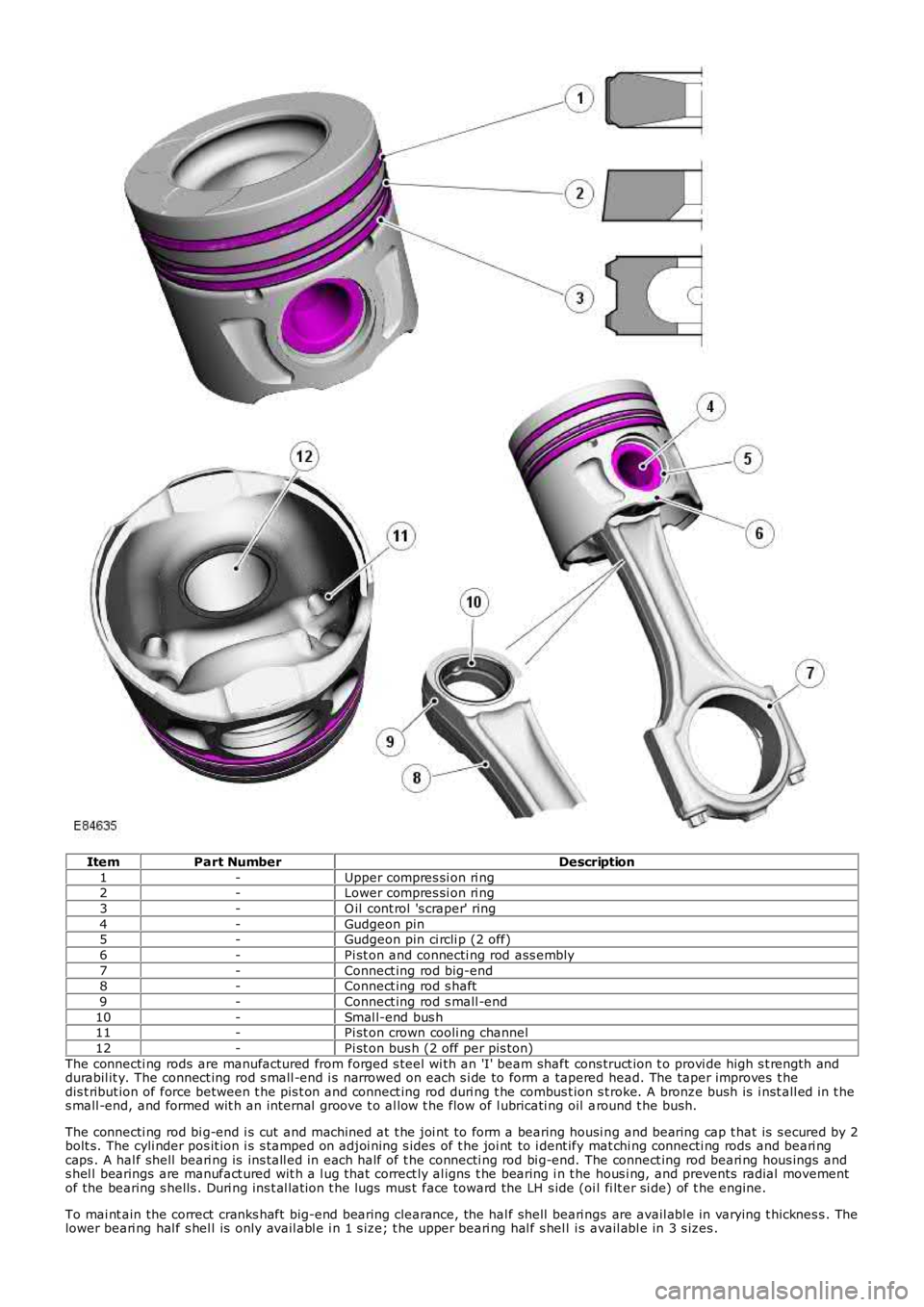

ItemPart NumberDescription

1-Upper compres si on ri ng2-Lower compres si on ri ng

3-O il cont rol 's craper' ring

4-Gudgeon pin5-Gudgeon pin ci rcli p (2 off)

6-Pi st on and connecti ng rod ass embly

7-Connect ing rod big-end8-Connect ing rod s haft

9-Connect ing rod s mall -end

10-Smal l-end bus h11-Pi st on crown cooli ng channel

12-Pi st on bus h (2 off per pis ton)

The connecti ng rods are manufactured from forged s teel wi th an 'I' beam shaft cons truct ion t o provi de high s t rength anddurabil it y. The connect ing rod s mall -end i s narrowed on each s i de to form a tapered head. The taper improves t hedis t ribut ion of force between t he pis t on and connect ing rod duri ng t he combus t ion s troke. A bronze bush is i nst all ed in t hes mall -end, and formed wit h an internal groove t o al low t he flow of l ubricati ng oil around t he bush.

The connecti ng rod bi g-end i s cut and machined at t he joi nt to form a bearing housi ng and bearing cap t hat is s ecured by 2bolt s. The cyli nder pos it ion i s s tamped on adjoi ning s ides of t he joi nt to i dent ify mat chi ng connecti ng rods and beari ngcaps . A hal f shell beari ng is ins tall ed in each half of t he connecti ng rod bi g-end. The connect ing rod beari ng hous ings ands hel l bearings are manufact ured wit h a l ug that correct ly al igns t he bearing i n t he hous i ng, and prevents radial movementof the bearing s hells . Duri ng ins t al lat ion t he lugs mus t face toward the LH s ide (oil fi lt er si de) of t he engine.

To mai nt ain the correct cranks haft big-end bearing clearance, the hal f shell beari ngs are avail abl e in varying t hicknes s . Thelower beari ng hal f s hel l is only avail abl e i n 1 s ize; t he upper beari ng hal f s hel l is avail abl e in 3 s izes .

Page 986 of 3229

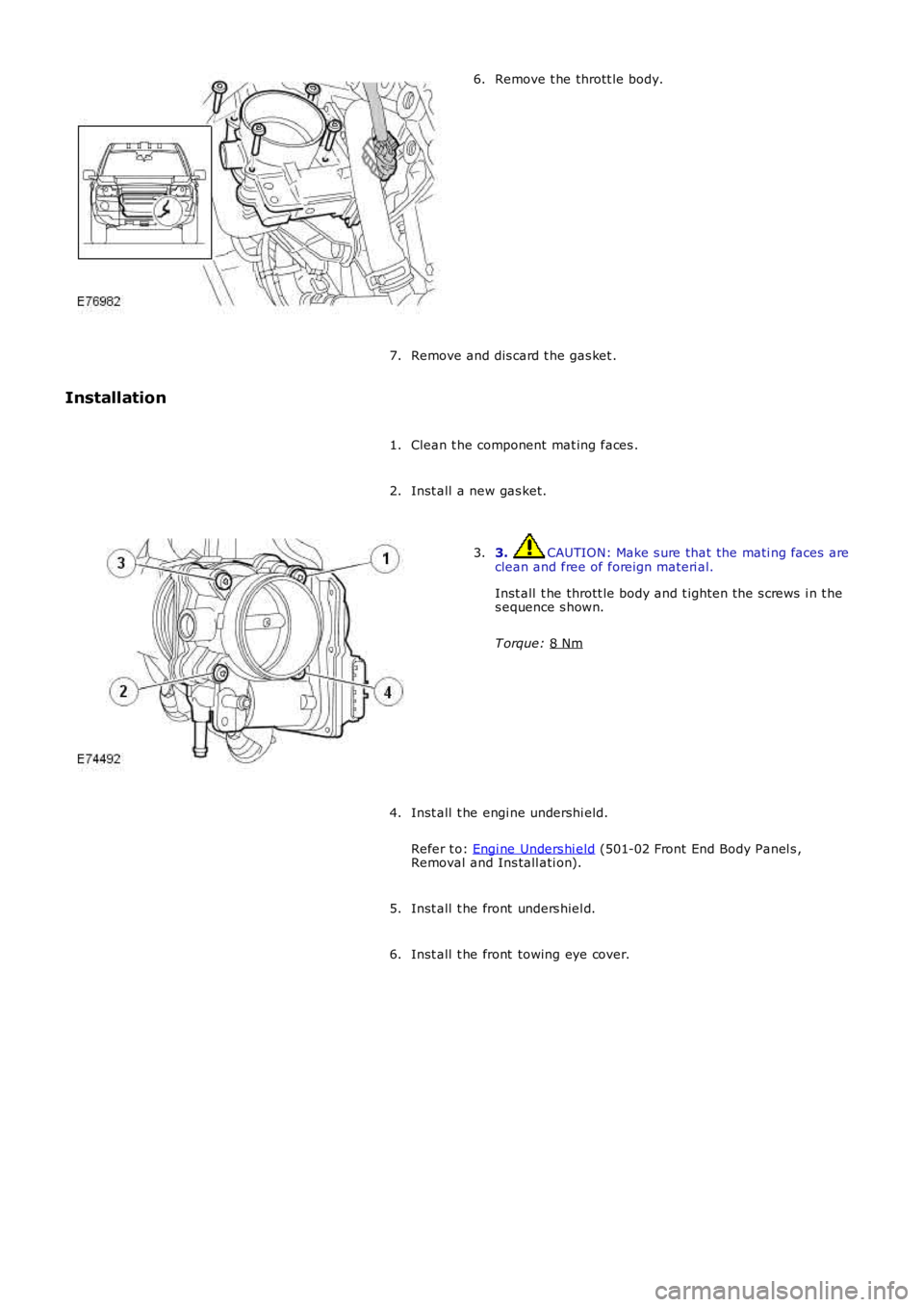

Remove t he thrott le body.

6.

Remove and dis card t he gas ket .

7.

Installation

Clean t he component mat ing faces .

1.

Inst all a new gas ket.

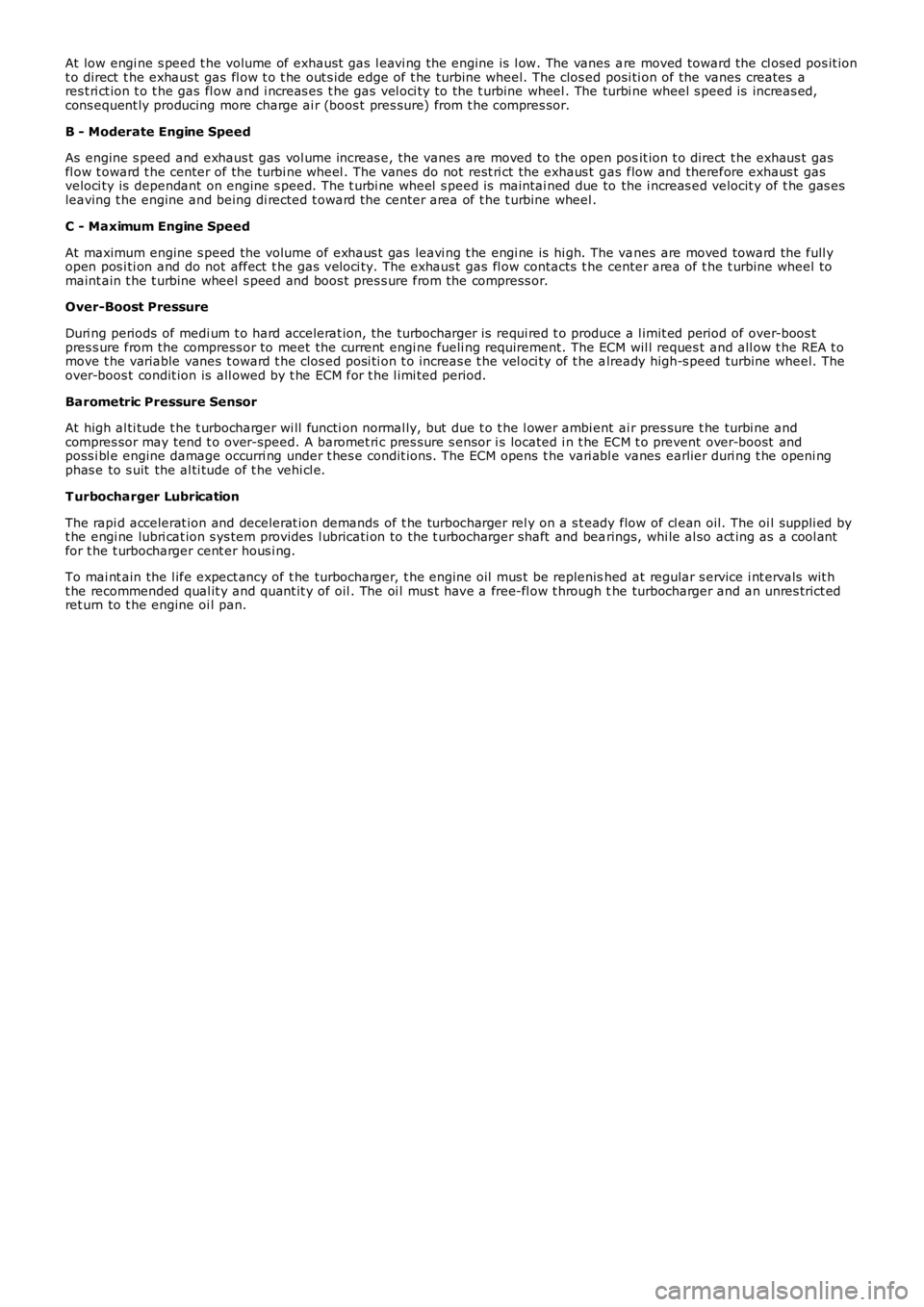

2. 3. CAUTION: Make s ure that the mati ng faces are

clean and free of foreign materi al.

Inst all t he thrott le body and t ighten the s crews i n t he

s equence s hown.

T orque: 8 Nm 3.

Inst all t he engi ne undershi eld.

Refer t o: Engi ne Unders hi eld (501-02 Front End Body Panel s ,

Removal and Ins tall ati on).

4.

Inst all t he front unders hiel d.

5.

Inst all t he front towing eye cover.

6.

Page 1027 of 3229

At low engi ne s peed t he volume of exhaust gas l eavi ng the engine is l ow. The vanes are moved toward the cl osed pos it iont o direct t he exhaus t gas fl ow t o t he out s ide edge of t he turbine wheel. The clos ed posi ti on of the vanes creates ares t ri ct ion t o t he gas fl ow and i ncreas es t he gas vel oci ty to the t urbine wheel . The turbi ne wheel s peed is increas ed,cons equent ly producing more charge ai r (boos t pres sure) from t he compres sor.

B - Moderate Engine Speed

As engine s peed and exhaus t gas vol ume increas e, the vanes are moved to the open posit ion t o direct t he exhaus t gasfl ow t oward t he center of the turbi ne wheel . The vanes do not rest ri ct the exhaus t gas flow and therefore exhaus t gasveloci ty is dependant on engine s peed. The t urbi ne wheel s peed is maintai ned due to the i ncreas ed velocit y of t he gas esleaving t he engine and being di rected t oward the center area of t he t urbine wheel .

C - Maximum Engine Speed

At maximum engine s peed the volume of exhaus t gas leavi ng t he engi ne is hi gh. The vanes are moved toward the full yopen pos i ti on and do not affect t he gas vel oci ty. The exhaus t gas fl ow contacts t he center area of t he t urbine wheel tomaint ain t he t urbine wheel s peed and boos t pres s ure from the compress or.

Over-Boost Pressure

Duri ng periods of medi um t o hard accelerat ion, the turbocharger is requi red t o produce a l imit ed period of over-boos tpres s ure from the compress or to meet the current engi ne fueli ng requirement. The ECM wil l reques t and all ow t he REA t omove t he variable vanes t oward t he clos ed posi ti on t o increas e t he vel oci ty of t he already high-s peed turbine wheel. Theover-boos t condit ion is all owed by t he ECM for t he l imi ted period.

Barometric Pressure Sensor

At high al ti tude t he t urbocharger wi ll functi on normal ly, but due t o t he l ower ambi ent ai r pres sure t he turbi ne andcompres sor may tend t o over-speed. A baromet ri c pres sure s ensor i s located i n t he ECM t o prevent over-boost andposs i bl e engine damage occurri ng under t hes e condit ions. The ECM opens t he vari abl e vanes earlier duri ng t he openi ngphas e to s uit the al ti tude of t he vehi cl e.

T urbocharger Lubrication

The rapi d accelerat ion and decelerat ion demands of t he turbocharger rel y on a s t eady flow of cl ean oil. The oi l suppli ed byt he engi ne lubri cat ion s ys tem provides l ubricati on to the t urbocharger shaft and bearings, whi le al so act ing as a cool antfor t he t urbocharger cent er hous i ng.

To mai nt ain the l ife expect ancy of t he turbocharger, t he engine oil mus t be replenished at regular s ervice i nt ervals wit ht he recommended qual it y and quant it y of oil . The oi l mus t have a free-fl ow t hrough the turbocharger and an unres trict edret urn to t he engine oi l pan.

Page 1108 of 3229

however remain i ll uminated.

A ‘st all recovery’ event is the onl y s tat e when t he Stop/St art s yst em wil l permit t he engine t o be s t art ed when thet ransmis s ion i s in gear; hence t he requirement for t he cl utch pedal to be full y depres sed. If the s t all recovery fai ls and t heengi ne does not res tart, t he dri ver wi ll be reques ted vi a t he Mess age Center t o ‘s elect neutral ’ to at t empt anot her rest art .

If the engine does not res t art aft er thi s request t he ‘st all recovery’ mode wil l ti me-out and deact ivate. At t his point t he‘Eco’ i con in t he i ns t rument panel wi ll exti ngui sh and the light s usual ly as s ociat ed wi th an engi ne st all wi ll il lumi nat e. As ares ult t he dri ver will be requi red to perform a convent ional engi ne res tart.

Alt hough st all recovery i s a feat ure of t he St op/Start sys t em i t is pos si ble for it t o acti vat e i ndependent ly from t heStop/St art parameters . For exampl e:

If the St op/Start s ys t em has been deact ivated by the driver st all recovery wi ll s ti ll funct ion.Stal l recovery wil l act ivate at ambi ent temperat ures as l ow as (minus ) - 2°C, whereas the St op/Syst em operat ingt emperature threshold is above 4°C.Different t o t he operat ion of t he Stop/St art s yst em, s tal l recovery wil l st il l functi on when the vehicle is t owing;refer to the ‘Trail er Towi ng’ s ect ion.

• NOTE: As t he neces s ary cri teria will not have been sat is fi ed when t he vehi cl e i s at the beginning of a journey s t allrecovery wi ll not functi on. For exampl e, if t he vehi cl e s tal ls when l eavi ng the garage or driveway a convent ional engineres t art wi ll be required.

Trailer Towing

The Stop/St art s ys tem wil l aut omati cal ly di sabl e when t rail er light s are det ect ed by t he CJB via s ignals from t he t rail ermodule, t hi s informat ion i s t hen trans mi tt ed t o t he ECM. It i s not pos s ibl e for t he s ys t em t o det ect when a trai ler powerplug i s ins ert ed i n the vehicl e’s t owi ng s ocket s o it us es operat ion of t he trail er l ights as it s indi cat or.

The t rail er towing sys tem inhi bi ts St op/St art as i t is pos s ible that trail er power requirements could interfere wit h t heoperati on of the bat tery monit ori ng s ys t em. In parti cul ar, a t rai ler batt ery could revers e t he feed current t o t he vehicleduri ng an engi ne cranking event , t hi s coul d pos si bly:

Confus e t he bat t ery monit ori ng s ys t em i nto det ect ing an unreal is t ically smal l current at engi ne cranking.Rupture the fus e as sociat ed wit h t he t rail er modul e.

Climate Control System

• NOTE: The ‘ECON’ butt on has been renamed ‘A/C’ to prevent confus ion wi th the St op/St art s yst em ‘Eco’ s wit ch.

A number of changes have been made to the l ogi c and operati on of climat e control system, wit hi n a St op/St art cycle to:

maint ain occupant comfortprevent winds hi eld mis ti ngcons erve bat tery power.

This has been achi eved by the ATC (automat ic t emperat ure control) module monit oring and varyi ng, as necess ary variousclimate control funct ions wi thi n a St op/Start cycle.

In s ome circums t ances t he ATC has t he capabil it y to inhibit an engi ne s hut down or init iat e an engine rest art wit hi n aStop/St art cycle. Thi s i s achi eved by t he ATC module communi cat ing wit h t he CJB on the medi um s peed CAN. The variousoverri de functi ons the ATC has in a St op/St art cycl e are di s cus s ed bel ow:

Coolant temperat ure

The ATC module wil l i nhibit an engine shut down or i nit iat e an engine res t art wi thi n a St op/Start cycle if t he coolantt emperature fal ls below the calculat ed t hreshol d to s upport t he cabin t emperat ure s et by t he vehi cl e occupant s .

W i nds hiel d demis t ing

The variant of cli mate control fi tt ed t o the vehicl e influences t he s oft ware changes that have been made. For exampl e, thebase cl imat e-control s ys tem does not have a humi dit y s ens or, as us ed on a highline sys tem t o ini ti at e a winds hi elddemis t . Therefore, a calculat ion for demis ti ng the winds hi eld i s made us ing t he s ignals from t he rai n s ens or and ambientt emperature s ens or. Us i ng the probabi lit y t hat windshi eld mis ti ng wil l occur if i t is raining and t he ambi ent t emperat ure i scool , the ATC wil l presume a wi nds hiel d demis t is required and s tart the engine when i n a St op/St art cycl e.

Evaporat or temperat ure the main cause of windshi eld mis ti ng is al s o monit ored and t he high-line cl imat e cont rol s yst emwil l periodicall y cool t he evaporat or as neces s ary t o reduce mi s ti ng during a Stop/St art cycl e. The sys tem operates thewinds hield demis t s hut ter and i f the evaporator i s wet t he shut ter wi ll remai n clos ed for a few seconds after an engineres t art unti l the vapor is di ss ipat ed.

If the driver sel ect s eit her ‘programmed defros t ’ or t he ‘wi ndshi el d heater’ i t is as s umed t hat a qui ck demis t of thewinds hield is requi red. Therefore, t he ATC vi a the CJB will ei ther: i nhibit an engine shut down or i nit iat e an engine res t art .

Heater fan speed

Duri ng an engine s hutdown t he ATC monit ors cabin temperat ure and maint ai ns the fan speed at a l evel that wi ll cons erve,for as l ong as poss ibl e t he heat i n t he core of t he cabi n heat er. If the driver s elect s a hi gher fan s peed and the heatcannot be mai ntained i n t he heat er core, the engine will rest art .

Heated rear window and heated s eats

If the heated rear window or heated s eats are acti ve or act ivated during an engine shut down event t he power out put oft he relevant s ys t em wi ll be i nt errupted unt il the engi ne is rest art ed. The tell -t ale light i n t he relevant s wit ch wil lil lumi nat e t o i ndi cat e t he s ys t em i s act ive even t hough the s ys tem is recei vi ng no power. This feature is us ed t o conservebatt ery power.

Page 1295 of 3229

Reverse Lock-Out

If the s elector l ever is moved from N to R and t he vehi cl e i s travel li ng forwards , revers e s electi on is prevent ed if t hevehi cl e s peed is 11 km/h (6.8 mph) or more. W hen revers e lock-out is act ivated, t he cl utch (C3) is released wit houtenergizing sol enoid (SLC3), preventi ng t he transmis si on from sel ect ing reverse gear.

TRANSMISSION FAULT STATUS

If the TCM det ect s a fault wi th the t rans mi ss ion sys tem, it wi ll enter a defaul t (l imp home) mode to prevent furt herdamage to the trans mi ss i on and allow the vehicl e to be dri ven. If pos s ibl e revers e gear wil l be avai lable and al s o 3rd gearonly.

W hen a fault i s detected a high s peed CAN mes s age is s ent from the TCM and is recei ved by the i nst rument clus ter. Theins t rument clus ter il lumi nat es t he MIL (i f required) and di spl ays an appl icabl e mes sage in t he mes s age cent er.For addit ional informat ion, refer t o: Informat ion and Mes s age Cent er (413-08 Informat ion and Mes s age Cent er, Des cript ionand Operat ion).

Some t rans mis s ion fault s may not il lumi nat e t he MIL or dis play a fault mes s age, but t he driver may not ice a reduct ion i ns hift quali ty.

ENGINE SPEED AND TORQUE MONITORING

The ECM const antl y s uppl ies t he TCM wi th informati on on engine s peed and torque through mes s ages on the CAN bus. TheTCM us es t hi s informat ion t o calculat e the correct and appropriat e t imi ng of shi ft changes .

If the mes s ages are not received by t he ECM, the TCM wil l impl ement a back-up st rat egy to prot ect t he transmis s ion fromdamage and all ow t he vehi cl e t o be dri ven.

In the event of an engi ne s peed or t orque s i gnal fai lure, t he t rans mis s ion wi ll adopt the el ect ri cal li mp home mode wit ht he trans mi s si on operati ng in a fixed gear.

TOWING FOR RECOVERY

W ARNING: Ens ure that t he remot e hands et remains docked whi ls t the vehicl e is bei ng towed. Removing t he remot ehands et wil l engage t he s teering l ock, which wi ll prevent the vehicle from s t eering correct ly.

If the engine cannot be run whi ls t the vehicl e is bei ng towed, t here wi ll be no power ass i st ance for the st eeri ng or brakes .This wi ll res ult in great er effort being requi red t o s t eer or s low the vehicle, and great ly i ncreas ed s t oppi ng dis tances.

CAUTION: The vehicle s hould only be towed wit h four wheels on the ground. Towing wi th two wheel s on t he groundwil l res ult i n s erious damage t o t he t ransmis s ion.

The vehi cl e s houl d only be towed for a maximum of 80 km (50 miles ), at a maximum s peed of 80 km/h (50 mph). Towi ngfor a greater dis t ance, or at a higher speed may res ul t in serious damage t o t he trans mi s si on.

• NOTE: The recommended recovery met hod is by trailer or recovery vehicle.

Secure t he towi ng att achment from the recovery vehicl e to the front t owing eye.

Ins ert the remote hands et in t he s tart cont rol module and swi tch on the i gni ti on by pres s ing t he s tart/s top but ton once.

• NOTE: Leavi ng the ignit ion s wit ched on for extended peri ods will cause the bat tery t o drain.

Apply t he foot brake, and move t he s el ect or lever to the neutral 'N' pos i ti on. W it h t he foot brake s ti ll appl ied, rel eas e t hepark brake. If elect rical power t o the sel ect or is not avai lable, t he emergency releas e l ever on t he s elect or lever can beus ed to releas e t he int erlock s olenoid.

The vehi cl e can be t owed a maximum of 80 km (50 mil es ) at a maxi mum speed of 80 km/h (50 mph).

Park t he vehicle on firm, l evel ground. Appl y the park brake and move t he s elector lever t o the park 'P' posi ti on.

Swit ch off t he ignit ion and remove t he remot e handset .

CAUTION: The vehicle cannot be towed i n a revers e direct ion.

Page 1337 of 3229

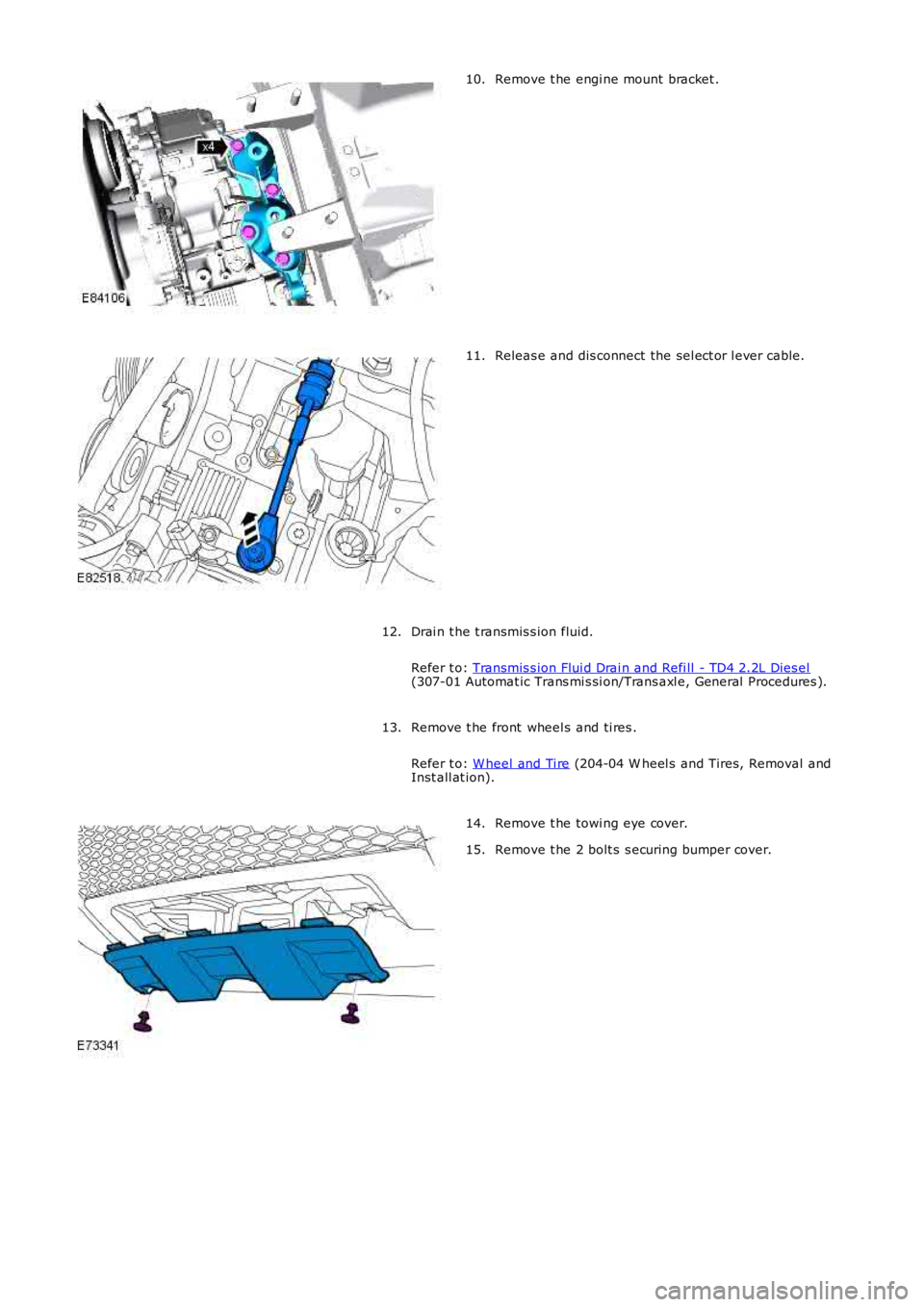

Remove t he engi ne mount bracket .

10. Releas e and dis connect the sel ect or l ever cable.

11.

Drai n t he t ransmis s ion fluid.

Refer t o: Transmis s ion Flui d Drai n and Refi ll - TD4 2.2L Dies el (307-01 Automat ic Trans mi s si on/Trans axl e, General Procedures ).

12.

Remove t he front wheel s and ti res .

Refer t o: W heel and Ti re (204-04 W heel s and Tires, Removal and

Inst all at ion).

13. Remove t he towi ng eye cover.

14.

Remove t he 2 bolt s s ecuring bumper cover.

15.

Page 1353 of 3229

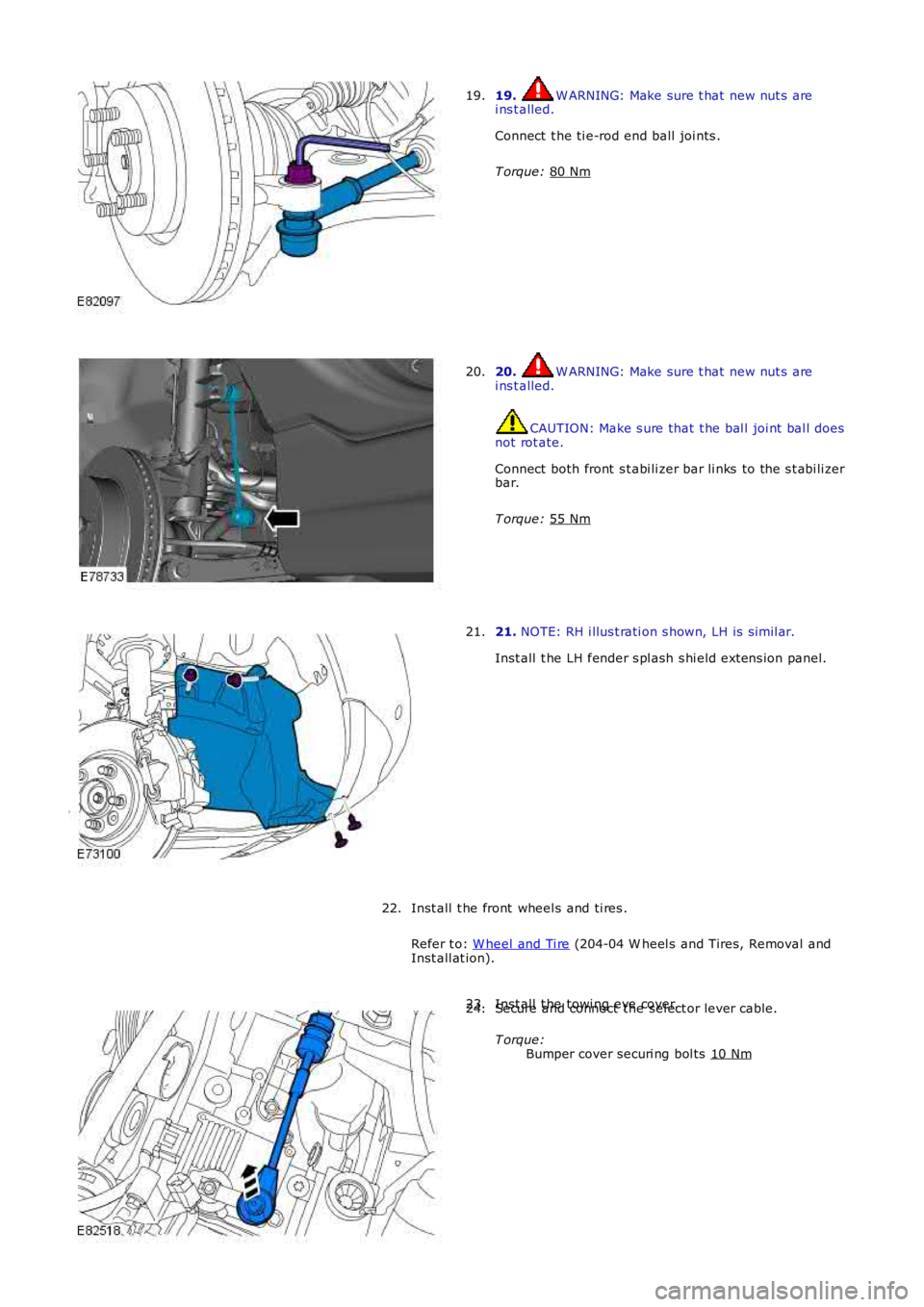

19. W ARNING: Make sure t hat new nut s are

i ns t alled.

Connect t he ti e-rod end ball joi nts .

T orque: 80 Nm 19.

20. W ARNING: Make sure t hat new nut s are

i ns t alled. CAUTION: Make s ure that t he bal l joi nt bal l does

not rot ate.

Connect both front s t abi li zer bar li nks to the s t abi li zer

bar.

T orque: 55 Nm 20.

21.

NOTE: RH i llus t rati on s hown, LH is s imil ar.

Inst all t he LH fender s pl ash s hi eld ext ens ion panel.

21.

Inst all t he front wheel s and ti res .

Refer t o: W heel and Ti re (204-04 W heel s and Tires, Removal and

Inst all at ion).

22. Inst all t he towi ng eye cover.

T orque: Bumper cover securi ng bol ts 10 Nm 23.

Secure and connect the sel ect or lever cable.

24.