engine LAND ROVER FRELANDER 2 2006 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 996 of 3229

Dies el, Des cript ion and Operat ion).

Fuel i njecti on pres sure is generat ed i ndependent ly of engine s peed and fuel inject ion events . The HP fuel s ys tem iscont rol lable t o t he opti mum level for smoot h operat ion, and is capabl e of devel opi ng an i nject ion press ure up t o 1,600 bar(23,206 psi ). The fuel i njecti on ti ming and vol ume are cal cul at ed by t he ECM t hat als o energizes t he appropriat e piezo-act uated i njector.

The fuel s yst em features a pre-inject ion (pilot ) phas e t o reduce combus ti on noi s e and mechani cal load. On vehiclesins t al led wi th a Di es el Part iculate Fi lt er (DPF), t he fuel s ys tem als o provides a pos t -i nject ion phas e t hat is requi red forregenerat ing t he DPF.For addit ional informat ion, refer t o: Exhaus t Sys t em (309-00B Exhaus t Syst em - TD4 2.2L Di es el, Des cri pt ion andOperat ion).

This t ype of fuel sys t em all ows t he TD4 engi ne t o achi eve excellent l evels of performance and engine res pons e, whilebeing able to meet current and fut ure exhaus t emi s si on legis l at ion.

Fuel charging is achieved wit h a LP and HP fuel s ys t em. The LP fuel s yst em compris es:

Saddl e t ype fuel tankTank mount ed fuel deli very module and integral t rans fer pumpFuel s upply and return li nesFil ter and water s eparator as s embly.For addit ional informat ion, refer t o: Fuel Tank and Lines (310-01B Fuel Tank and Lines - TD4 2.2L Dies el ,Des cript ion and Operat ion).

The HP fuel s ys tem compris es :

HP fuel pump wit h int egral mounted l ift pump and Volume Cont rol Valve (VCV)Common fuel rail wi th integral PCV and press ure s ens or4 pi ezo-injectorsHP connect ing pipesFuel l eak-off pipes .

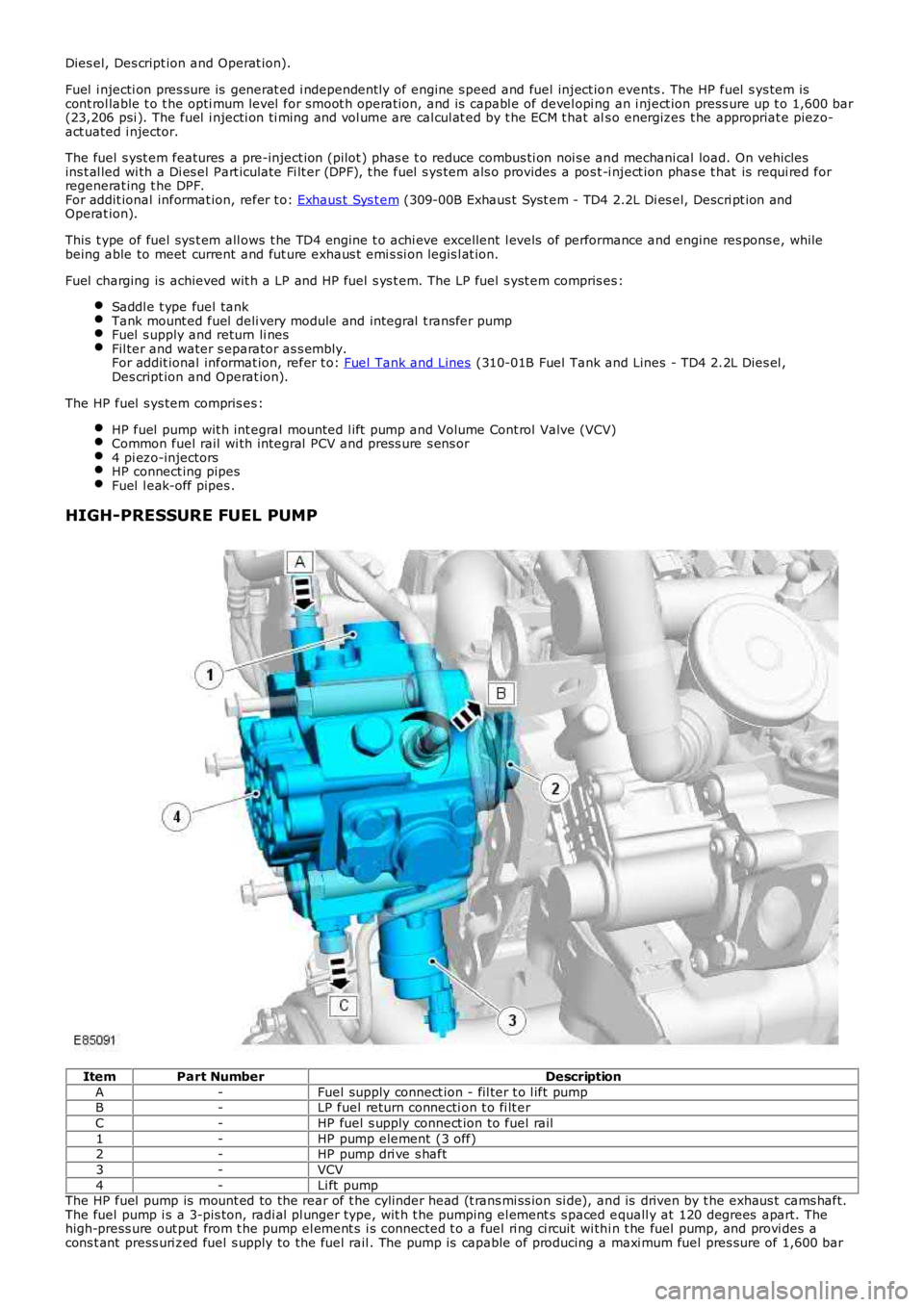

HIGH-PRESSURE FUEL PUMP

ItemPart NumberDescription

A-Fuel supply connect ion - fil ter t o l ift pumpB-LP fuel return connecti on t o fi lt er

C-HP fuel s upply connect ion to fuel rail

1-HP pump element (3 off)2-HP pump dri ve s haft

3-VCV

4-Li ft pumpThe HP fuel pump is mount ed to the rear of t he cylinder head (t rans mi ss ion si de), and is driven by t he exhaus t cams haft.The fuel pump i s a 3-pis ton, radi al pl unger type, wit h t he pumping el ement s s paced equall y at 120 degrees apart. Thehigh-press ure out put from t he pump el ement s i s connected t o a fuel ri ng ci rcuit wi thi n t he fuel pump, and provi des acons t ant press uri zed fuel s upply to the fuel rail . The pump is capable of producing a maxi mum fuel pres sure of 1,600 bar

Page 997 of 3229

(23,206 psi ).

The fuel s yst em HP pump compri ses t he fol lowi ng components :

3 HP pumpi ng element sInt egral li ft pumpVolume Cont rol Valve (VCV).

The HP pump and integral l ift pump mus t not be s eparat ed. The HP pump i s not ti med to t he engi ne.

A controlled amount of fuel i s all owed to leak-off t hrough t he HP pump, and ret urned t hrough a l eak-off pipe t o t he fuelfi lt er. The l eak-off fuel provides cooling and lubri cat ion for the HP pump int ernal components .

Lift Pump

A fuel l ift pump i s mounted t o t he rear of t he fuel pump, and forms an int egral ass embly wit h t he HP pump. The fuel li ftpump i s a gear type pump and connect ed to the fuel fi lt er s upply l ine. The li ft pump creat es a vacuum (negati ve pres s ure)in the s upply l ine t o t he fuel t ank, and draws the fuel from t he tank. The fuel passes t hrough the fuel fi lt er and i s t hendelivered at lift pump pres s ure to the HP pump inl et port.

The li ft pump normal operati ng, negati ve pres sure values are shown for the foll owing engine condi ti ons:

Engine ConditionLift Pump Negative PressureCranking-133 ± 7 mbar (-10 ± 0.5 cmHg)

Full load-267 ± 133 mbar (-20 ± 10 cmHg)

Volume Control Valve (VCV)

The VCV i s mounted on the HP pump, and l ocat ed in the feed port between t he HP pump elements and the fuel l ift pump.The VCV i s a vari abl e pos it ion s olenoid-operat ed valve t hat i s cont rol led by t he ECM wit h a 12V Puls e W idt h Modulat ed(PW M) s ignal. The VCV controls t he quant it y of fuel deli vered by the lift pump t o t he HP pump el ements .

W hen t he HP fuel pump rot ates , pres sure is created when t he VCV i s open and the fuel rail mount ed PCV is cl osed. TheVCV and PCV are vari abl e posi ti on valves, and us ed by t he ECM t o cont rol fuel deli very and fuel s ys tem pres sure.

Duri ng the fuel heat ing period when t he s uppl y fuel t emperature is les s than 40°C (104°F), t he ECM will fully open theVCV. Fuel volume and press ure is t hen cont rol led di rectl y by the PCV under t he cont rol of the ECM.

The VCV i s normal ly open when t he s ol enoi d i s not energi zed by the ECM. The resi s tance val ue of the VCV s ol enoi d coil is2.8 ohms at 20°C (68°F).For addit ional informat ion, refer t o: Electroni c Engi ne Controls - 2.2L Dies el (303-14 El ect ronic Engine Cont rols - 2.2LDies el, Des cript ion and Operat ion).

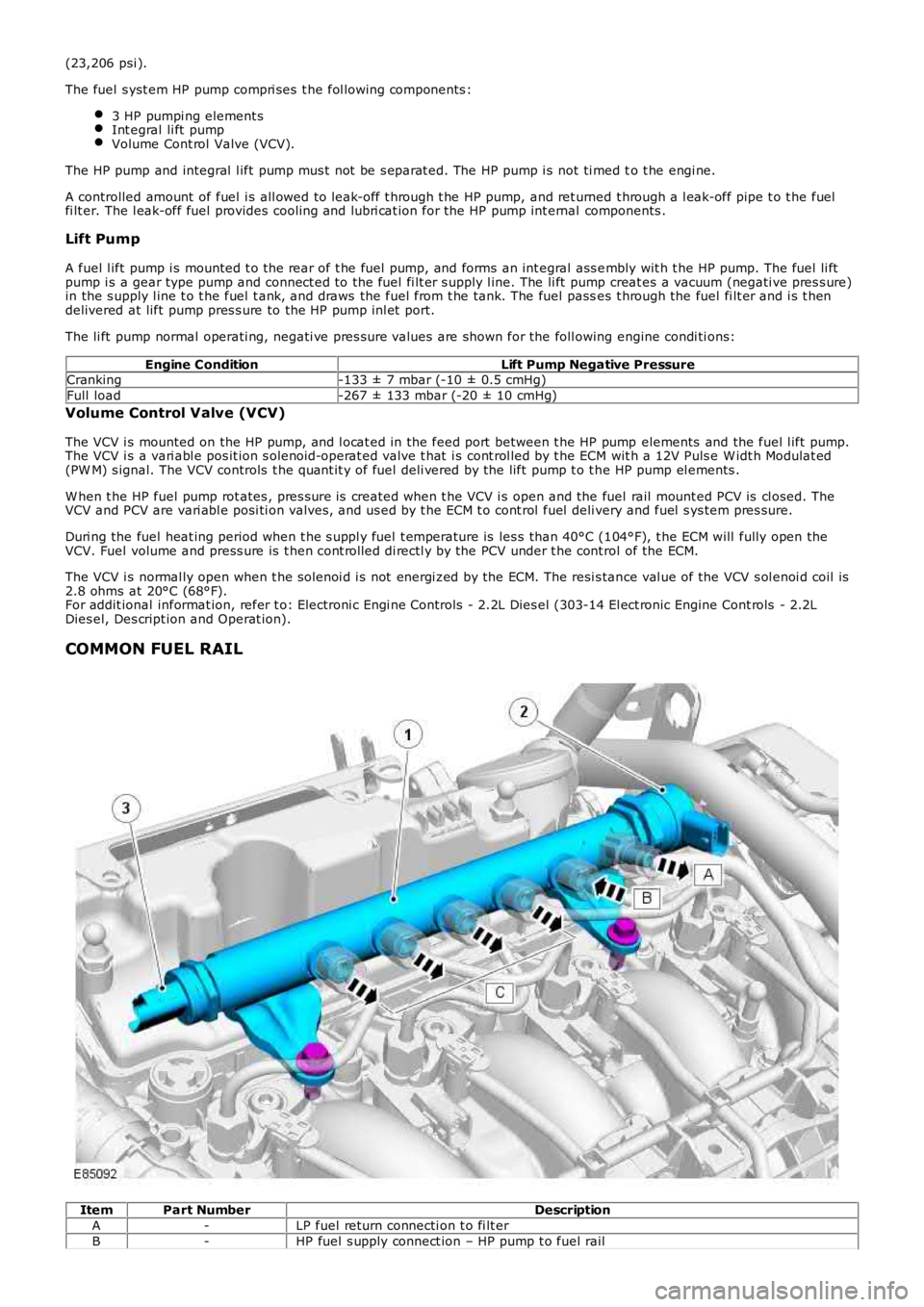

COMMON FUEL RAIL

ItemPart NumberDescription

A-LP fuel return connecti on t o fi lt er

B-HP fuel s upply connect ion – HP pump t o fuel rail

Page 998 of 3229

C-HP pipe connecti on – fuel rail t o inject or (4 off)

1-Fuel rail

2-PCV3-Fuel rail press ure sens or

The fuel rai l is manufact ured from forged st eel and secured t o t he cyl inder head with 2 fixings . The fuel rai l st orespres s urized fuel from t he HP pump, and prevent s pres s ure fluct uat ions i n the HP s ys tem. A fuel rail pres s ure s ens or and aPW M PCV are ins tall ed int o t he bore at each end of the fuel rail . The pres s ure s ensor i s ins tal led at t he acces sory dri veend of the fuel rail ; the PCV ins tal led at t he transmis s ion end of t he fuel rai l.

High-pres sure fuel pipes connect t he fuel rai l t o t he HP pump and fuel inject ors . A l eak-off pipe connect s the fuel rail t ot he fuel fi lt er return circui t.

The common fuel rail, fuel press ure s ens or and PCV form an int egral as s embly, and mus t not be separat ed. If a faultoccurs that requires component renewal, t hen t he compl ete fuel rail as s embl y mus t be renewed.

Fuel Rail Pressure Sensor

The fuel rai l pres sure s ens or is mount ed i n t he end of the fuel rail (access ory drive end) and connected to t he ECM vi a t heengi ne harnes s. The press ure sens or is provi ded wit h a 5V power s upply, ground and signal connect ions . The fuel railpres s ure s ensor i s a pi ezo-res is ti ve type s ens or contai ni ng an actuati ng diaphragm. Deflect ion of t he diaphragm provides aproport ional si gnal (output) volt age t o t he ECM, dependant on t he fuel pres s ure wit hin t he fuel rai l.

Pressure Sensor ParametersPressure Sensor Output VoltageFuel Rail Pressure

0.5V230 bar (3,336 ps i)

4.5V1,600 bar (23,206 ps i)The ECM compares t he s ens or s ignal vol tage t o s tored memory val ues, i n order t o cal cul ate the actual fuel pres s urepres ent in t he fuel rail. The ECM then us es t he fuel rai l press ure informat ion t o cont rol t he operati ng posi ti on of the VCVand PCV.For addit ional informat ion, refer t o: Electroni c Engi ne Controls - 2.2L Dies el (303-14 El ect ronic Engine Cont rols - 2.2LDies el, Des cript ion and Operat ion).

Pressure Control Valve (PCV)

The PCV i s mounted i n t he end of the fuel rail (trans mi s si on end) and connect ed t o the ECM via t he engine harnes s . ThePCV i s a s olenoid-operat ed valve cont rol led by a 12V PW M si gnal . The ECM operat es the PCV to adjus t t he fuel pres s urewit hin the fuel rail . Rel ieved fuel is direct ed through t he fuel rail leak-off pipe t o t he fuel fi lt er ret urn circui t. The l eak-offfuel als o provi des cooli ng and lubricat ion for t he PCV.For addit ional informat ion, refer t o: Electroni c Engi ne Controls - 2.2L Dies el (303-14 El ect ronic Engine Cont rols - 2.2LDies el, Des cript ion and Operat ion).

The PCV i s normall y open when t he s ol enoi d is not energi zed by the ECM. The resi s tance val ue of the PCV sol enoi d coi l is3.6 ohms at 20°C (68°F).

The PCV i s als o us ed by t he ECM t o provide di rect cont rol of the fuel sys tem, in t he fol lowi ng si tuat ions :

Duri ng s udden t rans ient phas es i n engine s peed (s uddenl y li ft ing off the accel erat or pedal, for example) where VCVact ion is not s ufficient to affect t he s uppl y of fuel to the fuel rail .To cont rol fuel press ure in t he event that the VCV fai ls .Duri ng the fuel heat ing period, when supply fuel temperat ure is l ess than 40°C (104°F). The VCV i s ful ly opened byt he ECM and t he HP pump compres s es a maximum quanti ty of fuel t o rais e t he fuel t emperature. The PCV is t henmodulat ed by the ECM to provide l eak-off fuel from the fuel rail t o t he fuel fi lt er ret urn circui t. The fuel i s t henrecircul ated t hrough t he fuel fi lt er and back t o t he HP pump.W hen t he fuel s uppl y t emperature is greater t han 70°C (158°F). The PCV is modul ated by t he ECM t o releas e fuelrai l pres sure, s ubs equentl y decreasi ng the fuel temperat ure to protect the fuel sys tem component s. Leak-off fuelfrom the fuel rail is direct ed to the fuel fil ter return ci rcuit and back t o the fuel tank.Duri ng engi ne s hut down t o progres s ively coll aps e fuel rail pres s ure.

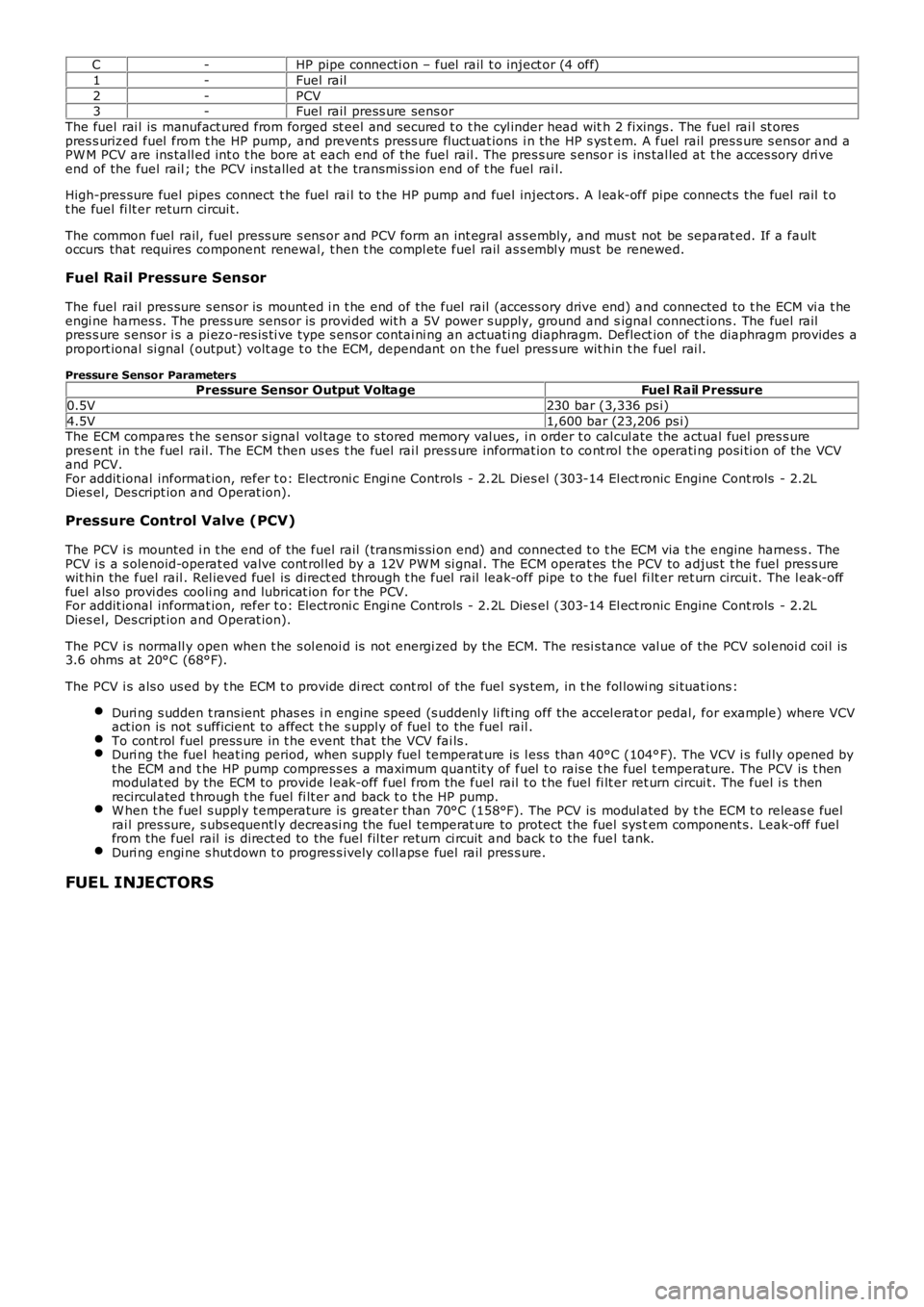

FUEL INJECTORS

Page 999 of 3229

ItemPart NumberDescription

1-HP fuel s uppl y connecti on from fuel rail2-LP fuel leak-off connect ion to fil ter

3-Electrical connect ion t o ECM

4-Inject or 10-digit codeThe 4 fuel i njectors are of t he piezo-el ect ri c act uat ed t ype, each manufactured wit h 7 s pray hol es in the i njector nozzl e.The inject ors are located centrall y wit hin the cyli nder head combus t ion chambers t o s pray at omized fuel direct ly ont o t het oroidal dome of the pi s tons .

Technical Details

O perating ParameterValue

Suppl y volt age 110V to 150V230 bar (3,336 ps i) t o 1,600 bar (23,206 psi )Res is tance180 Kohms at 20°C (68°F)

Mi ni mum chargi ng t ime100 µS

Mi ni mum dis charge ti me100 µSSpray nozzle di amet er143 µm

Maximum capable del ivery11 cm3/s econd

Duri ng manufacture each injector i s tes t ed to measure t he act ual i njected quanti ty of fuel, compared t o a referencequant it y for s i mulat ed condit ions . The tes ts are us ed t o categori ze the i njectors, the difference i n t he inject ion analys isres ult s i s transl ated t o a 10-digit al pha-numerical code t hat is s t amped on t he inject or cas ing.

The 10-digi t codes are s tored in t he ECM memory al ong wit h t he corres pondi ng cyl inder numbers for each inject or, and anengi ne performance s oft ware map. The ECM recogni zes each inject or 10-digit code and adapts t he operat ion of eachinject or to provi de s imi lar i nject ion press ures and quant it y of del ivered fuel for the current operati ng condit ion, inaccordance wit h t he programmed s oft ware map.

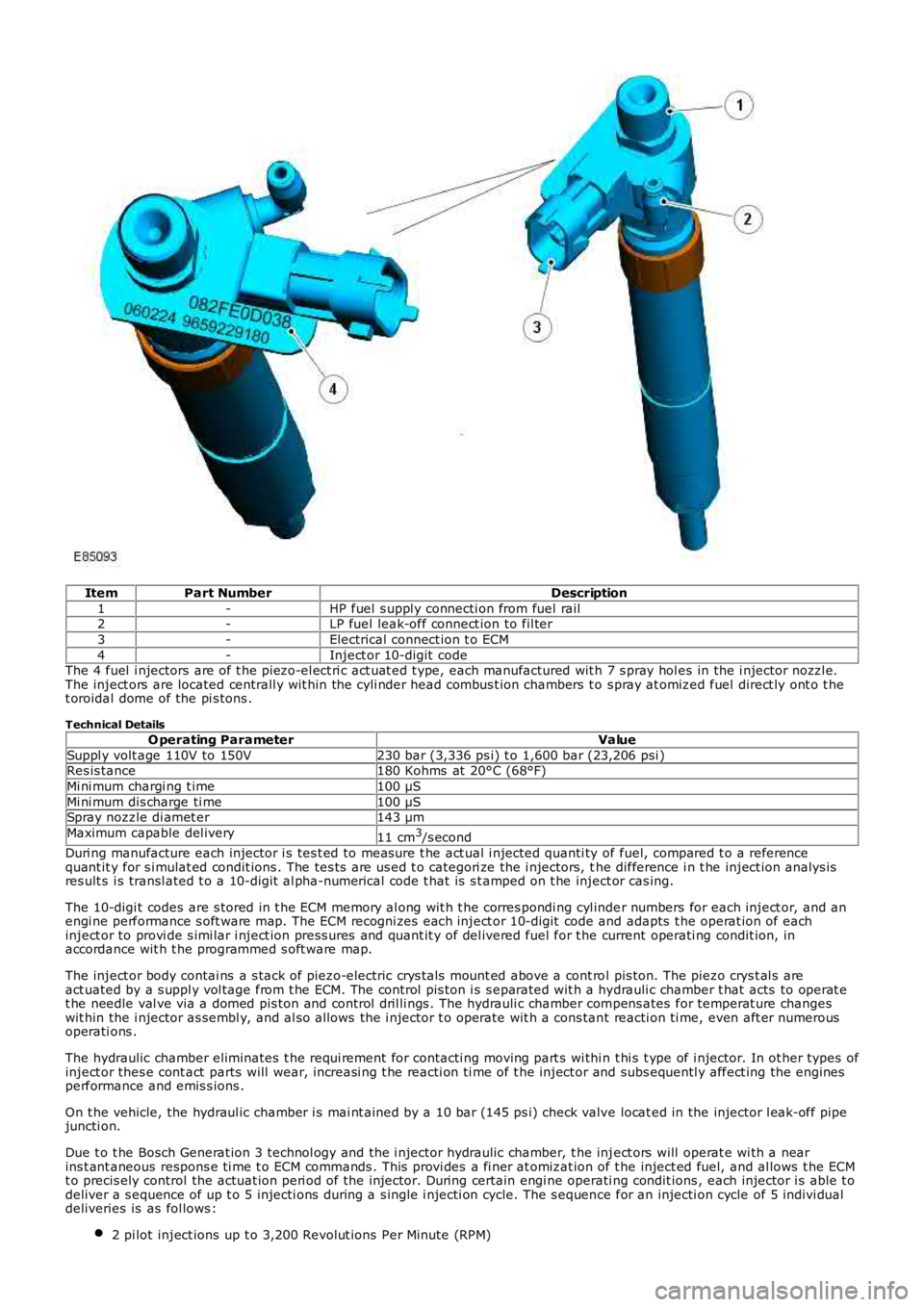

The inject or body contai ns a s tack of piezo-electric crys t als mount ed above a cont rol pis ton. The piezo crys t al s areact uated by a s uppl y vol tage from t he ECM. The control pis ton i s s eparated wit h a hydrauli c chamber t hat acts to operat et he needle val ve via a domed pis ton and control dril li ngs . The hydrauli c chamber compens ates for temperat ure changeswit hin the i njector as sembl y, and al so allows the i njector t o operate wit h a cons tant reacti on ti me, even aft er numerousoperati ons .

The hydraulic chamber eliminates t he requi rement for contacti ng moving part s wi thi n t hi s t ype of i njector. In ot her types ofinject or thes e cont act parts will wear, increasi ng t he reacti on ti me of t he inject or and subs equentl y affect ing the enginesperformance and emis s ions .

On t he vehicle, the hydraul ic chamber i s mai nt ained by a 10 bar (145 ps i) check valve locat ed in the injector l eak-off pipejuncti on.

Due t o t he Bosch Generat ion 3 technol ogy and the i njector hydraulic chamber, t he inject ors will operat e wi th a nearins t ant aneous respons e ti me t o ECM commands . This provi des a fi ner at omizat ion of t he inject ed fuel, and al lows t he ECMt o precis ely control the actuat ion peri od of the injector. During certain engi ne operati ng condit ions , each injector i s able t odeliver a s equence of up t o 5 injecti ons during a s ingle i njecti on cycle. The s equence for an injecti on cycle of 5 indivi dualdeliveries is as fol lows :

2 pi lot inject ions up t o 3,200 Revolut ions Per Minute (RPM)

Page 1000 of 3229

1 control i njecti on up t o 4,500 RPM1 mai n i nject ion above 4,500 RPM2 pos t-inject ions duri ng DPF regenerati on phase (no l oad val ues ).

The pil ot injecti on phas e is deli vered ahead of t he mai n charge of fuel t o produce a s teady flame front , and create aprogres s ive pres s ure ri se in t he cylinder. The pi lot inject ion phas e reduces the l ag between t he i nject ion of fuel andcombus t ion occurri ng, al lowing the remaining charge of fuel t o be injected whi le combus ti on is taking pl ace. This i njecti onpri nci pl e creat es an increas e in power, and als o reduces combus t ion Noi se, Vibrati on and Hars hnes s (NVH) and exhaus temis s ions .

On vehicles i nst all ed wit h an exhaus t s ys tem DPF, t he high-press ure fueli ng s yst em provi des a post -injecti on phase of fuelint o t he combus t ion chambers . During the regenerat ion st age of the DPF, t he ECM all ows fuel t o be i nject ed aft er thecombus t ion s t roke and int o t he commencement of t he exhaus t st roke. The post -i njecti on phas e caus es fuel to burn i n theexhaus t s ys t em, creati ng high exhaus t gas t emperatures required to regenerate the DPF.

For addit ional informat ion, refer t o: Electroni c Engi ne Controls - 2.2L Dies el (303-14 El ect ronic Engine Cont rols - 2.2LDies el, Des cript ion and Operat ion) / Exhaus t Sys tem (309-00B Exhaust Sys tem - TD4 2.2L Dies el , Descripti on andOperat ion).

Injector Service Information

CAUTION: This t ype of inject or contai ns a hydraulic chamber. It is important that t he inject or is handled correct ly t oprevent the hydrauli c chamber from emptying. The i nject or is t o be capped and maint ained in an upri ght pos it ion, andmus t not be laid on t he si de or s haken.

Do not att empt t o remove carbon depos it s from t he dies el inject or nozzle.

The inject or is s upplied as a complete ass embly. The ori ginal inject or mus t not be separated.

• NOTE: The TD4 engine cyli nders are numbered from t he rear of t he engi ne (t rans mi ssi on end). Therefore, No. 1 cyli nderand No. 1 i nject or are l ocat ed at the rear of the engine.

A new copper washer mus t be ins t al led and t he old washer dis carded, whenever an inject or i s removed from t he cyl inderhead. The i njector cent eri ng ri ng may be re-us ed.

If an inject or i s removed, the injector mus t be i nst all ed to the original cyl inder, and does not require re-programming i ntot he ECM.

If an inject or i s renewed, the new inject or 10-digit code and corres pondi ng cyl inder number mus t be programmed i nto theECM, usi ng t he Land Rover approved di agnos ti c s yst em.

If the ECM is renewed, all 4 injector 10-di git codes and corres ponding cyli nder numbers must be programmed into the newECM, usi ng t he Land Rover approved di agnos ti c s yst em.

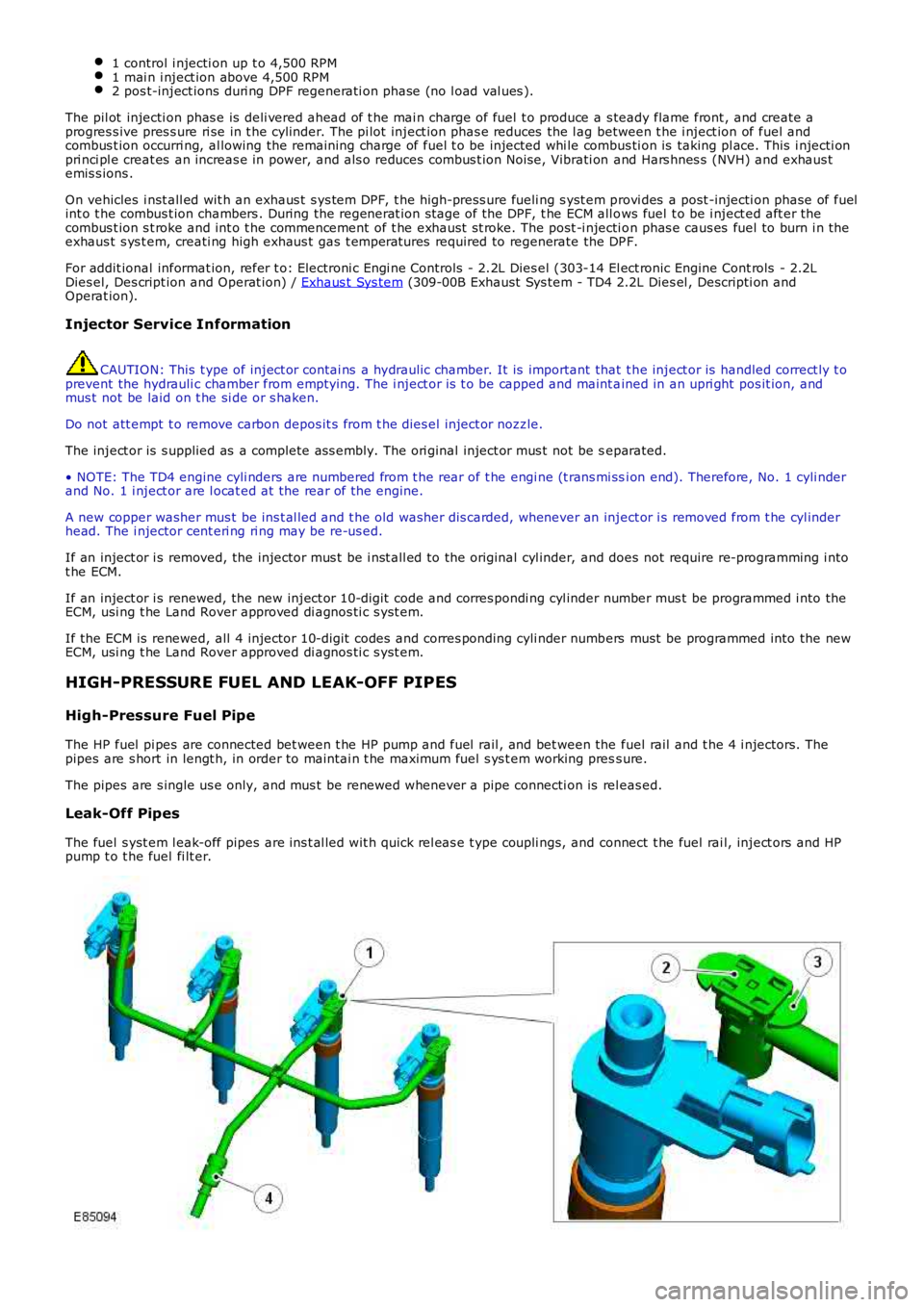

HIGH-PRESSURE FUEL AND LEAK-OFF PIPES

High-Pressure Fuel Pipe

The HP fuel pi pes are connected bet ween t he HP pump and fuel rail , and bet ween the fuel rail and t he 4 i njectors. Thepipes are s hort in lengt h, in order to maintai n t he maximum fuel s ys t em working press ure.

The pipes are s ingle us e only, and mus t be renewed whenever a pipe connecti on is releas ed.

Leak-Off Pipes

The fuel s yst em l eak-off pipes are ins t al led wit h quick rel eas e t ype coupli ngs, and connect t he fuel rai l, inject ors and HPpump t o t he fuel fi lt er.

Page 1002 of 3229

Publi s hed: 11-May-2011

Fuel Charging and Controls - TD4 2.2L Diesel - Fuel Charging and Controls

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the fuel chargi ng and cont rol s, refer t o the relevant Descri pti on and Operat ion s ect ion in t heworks hop manual .REFER to: Fuel Chargi ng and Controls (303-04B Fuel Chargi ng and Cont rol s - TD4 2.2L Dies el , Descripti on and Operat ion) /Turbocharger (303-04C Fuel Chargi ng and Cont rol s - Turbocharger - TD4 2.2L Di es el, Des cri pt ion and Operati on).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.2.

Visual Inspection

MechanicalElectrical

Fuel l evelFuel l eaksDamaged fuel l inesDamaged push connect fit t ingsFuel contami nati on/grade/quali tyThrot tl e body

Fus esLoos e or corroded electrical connect orsHarnes s esSens or(s)Engine Cont rol Modul e (ECM)

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Chart, al ternat ively, check forDi agnos ti c Trouble Codes (DTCs) and refer t o t he DTC Index.4.

Symptom Chart

SymptomPossible CauseAction

Engine cranks butdoes not st artFuel l evelContami nat ed fuelFuel s ys temleaking/bl ockedAir i ntake s yst emElectronic enginecont rol s

Check fuel level and for cont aminat ion. Check fuel and air i ntakes yst em integrit y. Check for DTCs and refer to the relevant DTC Index

Di fficul t t o s tartFuel l evelContami nat ed fuelFuel s ys temleaking/bl ockedAir i ntake s yst emElectronic enginecont rol s

Check fuel level and for cont aminat ion. Check fuel and air i ntakes yst em integrit y. Check for DTCs and refer to the relevant DTC Index

Rough idl eLow/contami nat ed fuelFuel s ys temleaking/bl ockedElectronic enginecont rol s

Check fuel level/condit ion. Check i ntegri ty of fuel and engine cont rols yst ems . Check for DTCs and refer t o relevant DTC Index.

Lack of power underaccel erati onContami nat ed fuelAir i ntake s yst emBlockedexhaus t/catalyt icconvert erTurbocharger faultFuel s ys temElectronic enginecont rol sLow enginecompres si ons

Check for fuel cont ami nat ion. Check for DTCs and refer t o relevantDTC Index. Check int egrit y of air i nt ake, exhaus t , turbocharger, andengine control s ys tems

Engine s t ops /st all sLow/contami nat ed fuelFuel s ys temAir i ntake s yst emElectronic enginecont rol s

Check for fuel cont ami nat ion. Check for DTCs and refer t o t he rel evantDTC Index. Check int egrit y of fuel, ai r int ake, and engi ne s yst ems

Page 1005 of 3229

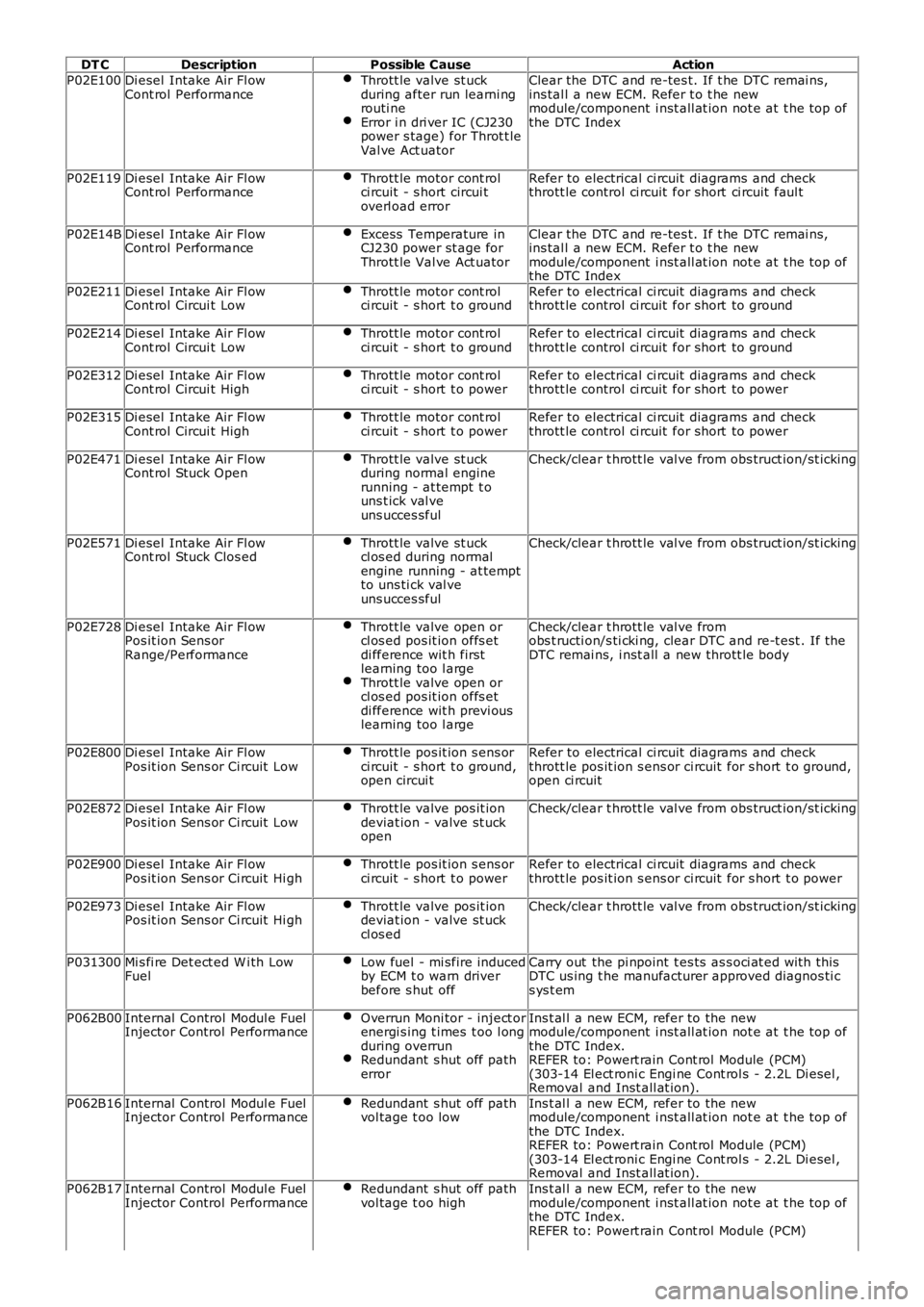

DT CDescriptionPossible CauseAction

P02E100Di esel Intake Air Fl owCont rol PerformanceThrott le valve st uckduring after run learni ngrouti neError i n dri ver IC (CJ230power s tage) for Throt t leVal ve Act uator

Clear the DTC and re-tes t. If t he DTC remai ns,ins tal l a new ECM. Refer t o t he newmodule/component i nst all at ion not e at t he top ofthe DTC Index

P02E119Di esel Intake Air Fl owCont rol PerformanceThrott le motor cont rolci rcuit - s hort circui toverl oad error

Refer to electrical ci rcuit diagrams and checkthrott le control ci rcuit for short ci rcuit faul t

P02E14BDi esel Intake Air Fl owCont rol PerformanceExcess Temperature inCJ230 power st age forThrott le Val ve Act uator

Clear the DTC and re-tes t. If t he DTC remai ns,ins tal l a new ECM. Refer t o t he newmodule/component i nst all at ion not e at t he top ofthe DTC Index

P02E211Di esel Intake Air Fl owCont rol Circui t LowThrott le motor cont rolci rcuit - s hort t o groundRefer to electrical ci rcuit diagrams and checkthrott le control ci rcuit for short to ground

P02E214Di esel Intake Air Fl owCont rol Circui t LowThrott le motor cont rolci rcuit - s hort t o groundRefer to electrical ci rcuit diagrams and checkthrott le control ci rcuit for short to ground

P02E312Di esel Intake Air Fl owCont rol Circui t HighThrott le motor cont rolci rcuit - s hort t o powerRefer to electrical ci rcuit diagrams and checkthrott le control ci rcuit for short to power

P02E315Di esel Intake Air Fl owCont rol Circui t HighThrott le motor cont rolci rcuit - s hort t o powerRefer to electrical ci rcuit diagrams and checkthrott le control ci rcuit for short to power

P02E471Di esel Intake Air Fl owCont rol Stuck OpenThrott le valve st uckduring normal enginerunning - at tempt t ouns t ick val veuns ucces sful

Check/clear t hrott le val ve from obs truct ion/st icking

P02E571Di esel Intake Air Fl owCont rol Stuck Clos edThrott le valve st uckcl os ed during normalengine running - at temptto uns ti ck val veuns ucces sful

Check/clear t hrott le val ve from obs truct ion/st icking

P02E728Di esel Intake Air Fl owPos it ion Sens orRange/Performance

Thrott le valve open orcl os ed pos it ion offs etdi fference wit h firstlearning too l argeThrott le valve open orcl os ed pos it ion offs etdi fference wit h previ ouslearning too l arge

Check/clear t hrott le val ve fromobs t ructi on/s ti cki ng, clear DTC and re-t est . If theDTC remai ns, i nst all a new thrott le body

P02E800Di esel Intake Air Fl owPos it ion Sens or Ci rcuit LowThrott le pos it ion s ens orci rcuit - s hort t o ground,open circui t

Refer to electrical ci rcuit diagrams and checkthrott le pos it ion s ens or ci rcuit for s hort t o ground,open ci rcuit

P02E872Di esel Intake Air Fl owPos it ion Sens or Ci rcuit LowThrott le valve pos it iondeviat ion - valve st uckopen

Check/clear t hrott le val ve from obs truct ion/st icking

P02E900Di esel Intake Air Fl owPos it ion Sens or Ci rcuit Hi ghThrott le pos it ion s ens orci rcuit - s hort t o powerRefer to electrical ci rcuit diagrams and checkthrott le pos it ion s ens or ci rcuit for s hort t o power

P02E973Di esel Intake Air Fl owPos it ion Sens or Ci rcuit Hi ghThrott le valve pos it iondeviat ion - valve st uckcl os ed

Check/clear t hrott le val ve from obs truct ion/st icking

P031300Mi s fi re Det ect ed W i th LowFuelLow fuel - mi sfire inducedby ECM t o warn driverbefore s hut off

Carry out the pi npoint t es ts as s oci at ed wi th thisDTC us ing t he manufacturer approved diagnos ti cs ys t em

P062B00Internal Control Modul e FuelInjector Control PerformanceOverrun Moni tor - inject orenergi s ing t imes t oo l ongduring overrunRedundant s hut off patherror

Ins t al l a new ECM, refer to the newmodule/component i nst all at ion not e at t he top ofthe DTC Index.REFER to: Powert rain Cont rol Module (PCM)(303-14 El ect roni c Engi ne Cont rol s - 2.2L Di esel ,Removal and Inst all at ion).

P062B16Internal Control Modul e FuelInjector Control PerformanceRedundant s hut off pathvol tage t oo lowIns t al l a new ECM, refer to the newmodule/component i nst all at ion not e at t he top ofthe DTC Index.REFER to: Powert rain Cont rol Module (PCM)(303-14 El ect roni c Engi ne Cont rol s - 2.2L Di esel ,Removal and Inst all at ion).

P062B17Internal Control Modul e FuelInjector Control PerformanceRedundant s hut off pathvol tage t oo highIns t al l a new ECM, refer to the newmodule/component i nst all at ion not e at t he top ofthe DTC Index.REFER to: Powert rain Cont rol Module (PCM)

Page 1007 of 3229

Publi s hed: 11-May-2011

Fuel Charging and Controls - TD4 2.2L Diesel - Fuel Injector

Removal and Inst all ati on

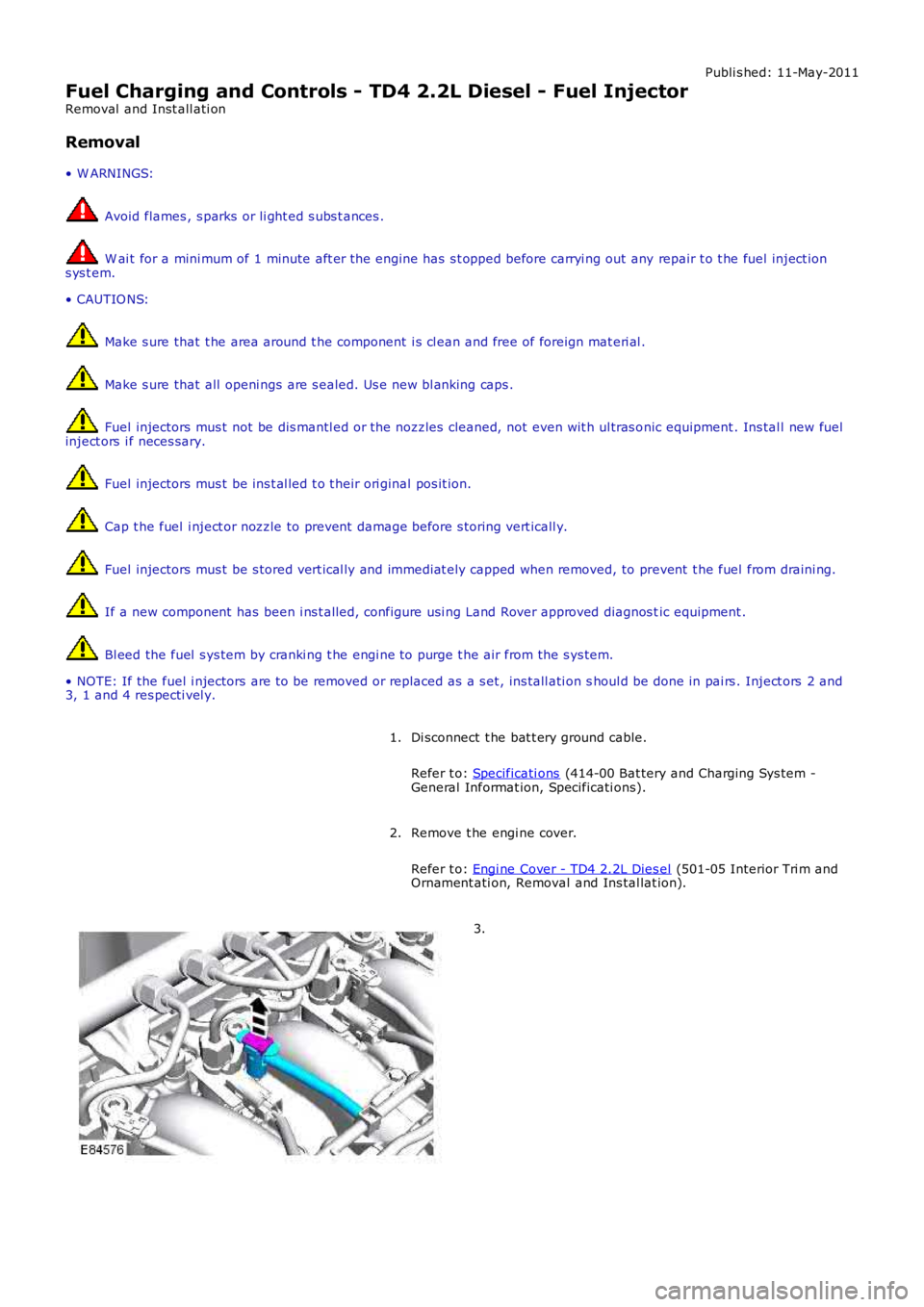

Removal

• W ARNINGS:

Avoid flames , s parks or li ght ed s ubs t ances .

W ai t for a mini mum of 1 minute aft er the engine has s t opped before carryi ng out any repair t o t he fuel inject ions ys t em.

• CAUTIO NS:

Make s ure that t he area around t he component i s cl ean and free of foreign mat eri al .

Make s ure that all openi ngs are s ealed. Us e new bl anking caps .

Fuel injectors mus t not be dis mantl ed or the nozzles cleaned, not even wit h ul tras onic equipment . Ins tal l new fuelinject ors i f neces sary.

Fuel injectors mus t be ins t al led t o t heir ori ginal pos it ion.

Cap t he fuel i nject or nozzle to prevent damage before s toring vert icall y.

Fuel injectors mus t be s tored vert ical ly and immedi at ely capped when removed, to prevent t he fuel from draini ng.

If a new component has been i ns t alled, configure usi ng Land Rover approved diagnos tic equipment .

Bl eed the fuel s ys tem by cranki ng t he engi ne to purge t he air from the s ys tem.

• NOTE: If the fuel i njectors are to be removed or replaced as a s et , ins tall ati on shoul d be done in pai rs . Inject ors 2 and3, 1 and 4 res pecti vel y.

Di sconnect t he bat t ery ground cable.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -General Informat ion, Specificati ons).

1.

Remove t he engi ne cover.

Refer t o: Engi ne Cover - TD4 2.2L Dies el (501-05 Interior Tri m andOrnament ati on, Removal and Ins tal lat ion).

2.

3.

Page 1011 of 3229

Publi s hed: 11-May-2011

Fuel Charging and Controls - TD4 2.2L Diesel - Fuel Rail

Removal and Inst all ati on

Removal

• W ARNINGS:

Avoid flames , s parks or li ght ed s ubs t ances .

W ai t for a mini mum of 1 minute aft er the engine has s t opped before carryi ng out any repair t o t he fuel inject ions ys t em.

• CAUTIO NS:

Make s ure that t he area around t he component i s cl ean and free of foreign mat eri al .

Make s ure that all openi ngs are s ealed. Us e new bl anking caps .

Bl eed the fuel s ys tem by cranki ng t he engi ne to purge t he air from the s ys tem.

• NOTE: The fuel pres s ure and t emperat ure s ens ors are an int egral part of the fuel rail and mus t not be changeds eparately.

Di sconnect t he bat t ery ground cable.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -General Informat ion, Specificati ons).

1.

Remove t he engi ne cover.

Refer t o: Engi ne Cover - TD4 2.2L Dies el (501-05 Interior Tri m andOrnament ati on, Removal and Ins tal lat ion).

2.

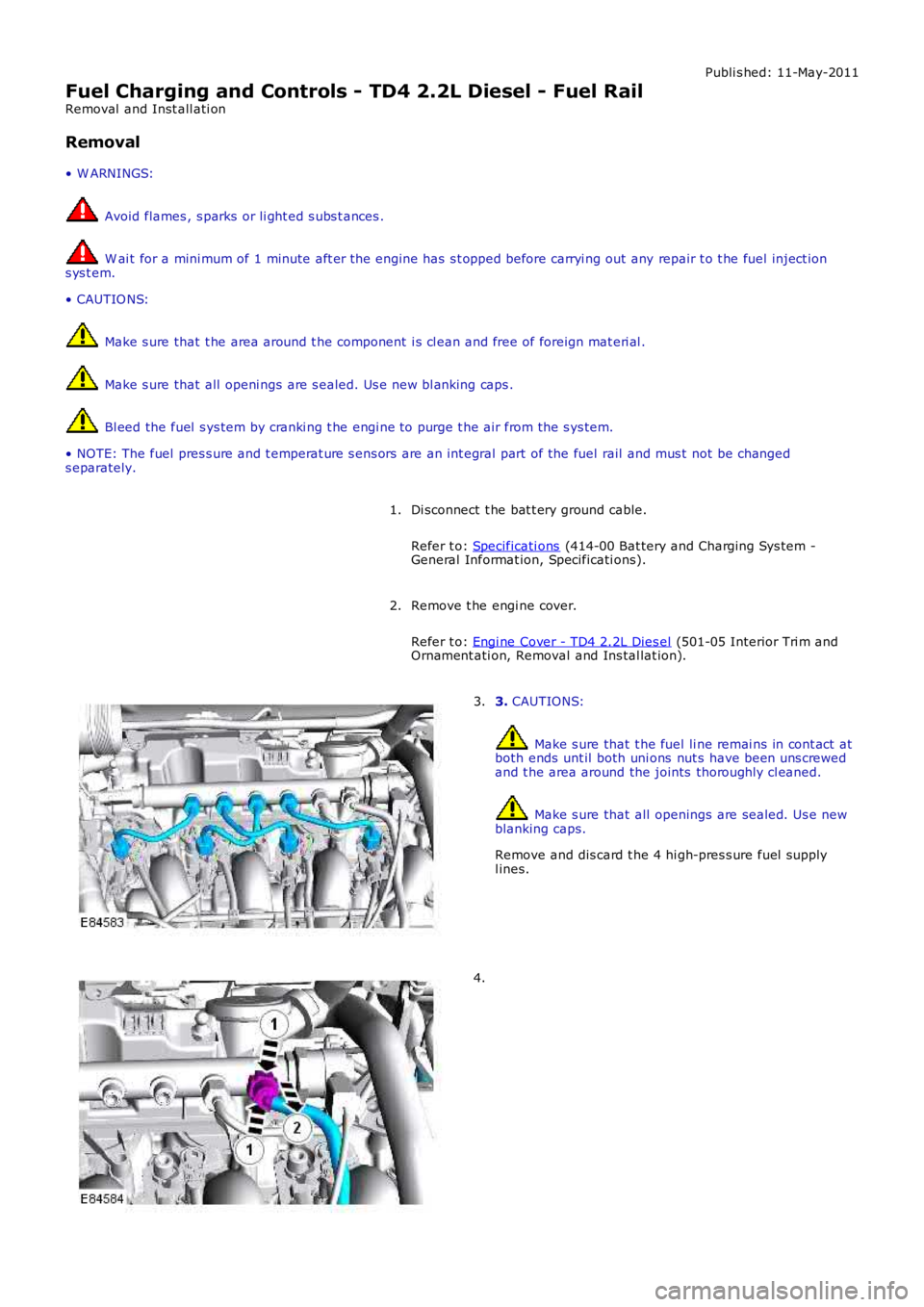

3. CAUTIONS:

Make s ure that t he fuel li ne remai ns in cont act atboth ends unt il both uni ons nut s have been uns crewedand t he area around the joints thoroughly cl eaned.

Make s ure that all openings are sealed. Us e newblanking caps.

Remove and dis card t he 4 hi gh-pres s ure fuel s upplyl ines.

3.

4.

Page 1016 of 3229

Publi s hed: 11-May-2011

Fuel Charging and Controls - TD4 2.2L Diesel - Fuel Pump

Removal and Inst all ati on

Removal

• W ARNINGS:

Avoid flames , s parks or li ght ed s ubs t ances .

W ai t for a mini mum of 1 minute aft er the engine has s t opped before carryi ng out any repair t o t he fuel inject ions ys t em.

• CAUTIO NS:

Make s ure that t he area around t he component i s cl ean and free of foreign mat eri al .

Make s ure that all openi ngs are s ealed. Us e new bl anking caps .

Bl eed the fuel s ys tem by cranki ng t he engi ne to purge t he air from the s ys tem.

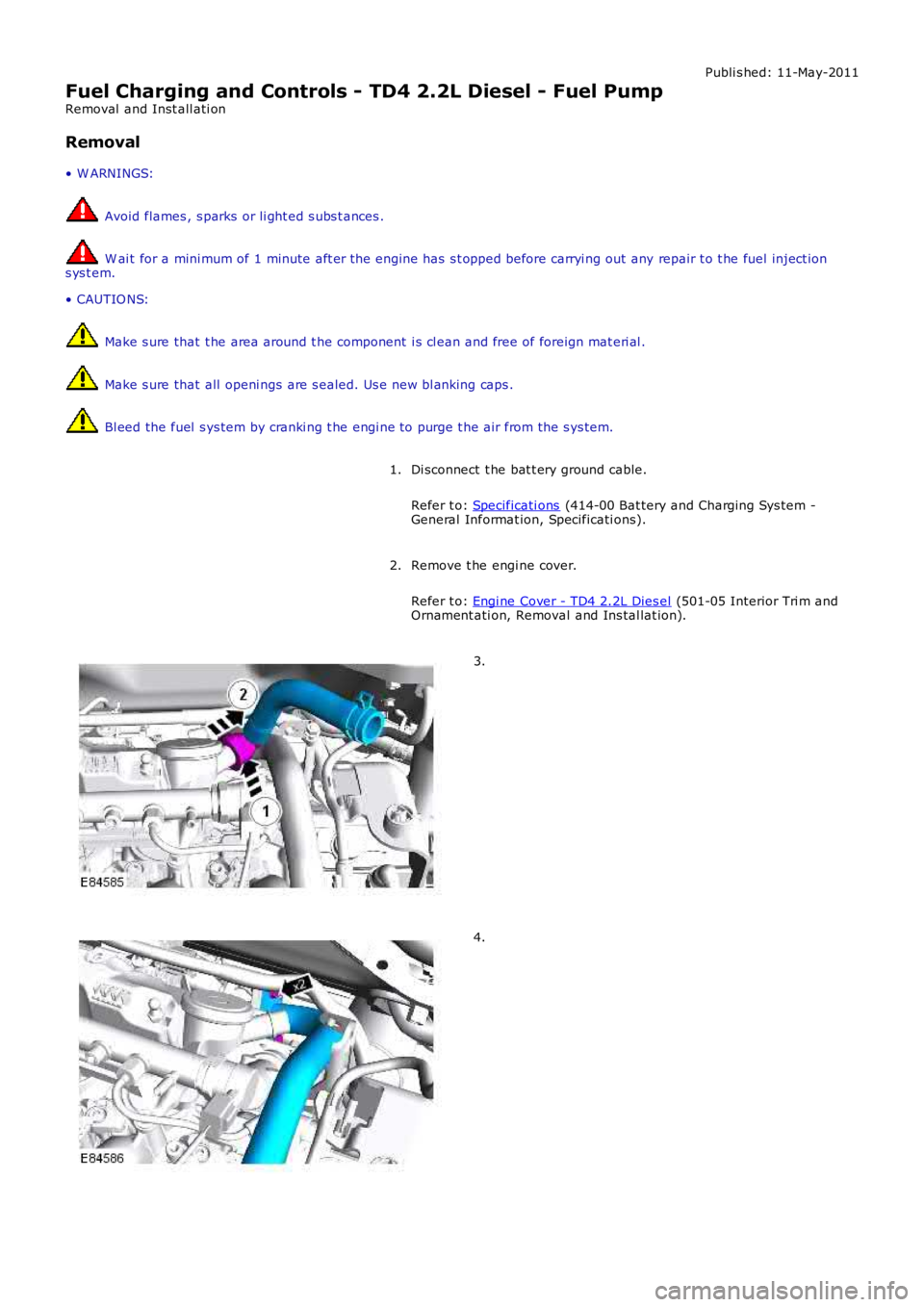

Di sconnect t he bat t ery ground cable.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -General Informat ion, Specificati ons).

1.

Remove t he engi ne cover.

Refer t o: Engi ne Cover - TD4 2.2L Dies el (501-05 Interior Tri m andOrnament ati on, Removal and Ins tal lat ion).

2.

3.

4.