engine LAND ROVER FRELANDER 2 2006 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 1108 of 3229

however remain i ll uminated.

A ‘st all recovery’ event is the onl y s tat e when t he Stop/St art s yst em wil l permit t he engine t o be s t art ed when thet ransmis s ion i s in gear; hence t he requirement for t he cl utch pedal to be full y depres sed. If the s t all recovery fai ls and t heengi ne does not res tart, t he dri ver wi ll be reques ted vi a t he Mess age Center t o ‘s elect neutral ’ to at t empt anot her rest art .

If the engine does not res t art aft er thi s request t he ‘st all recovery’ mode wil l ti me-out and deact ivate. At t his point t he‘Eco’ i con in t he i ns t rument panel wi ll exti ngui sh and the light s usual ly as s ociat ed wi th an engi ne st all wi ll il lumi nat e. As ares ult t he dri ver will be requi red to perform a convent ional engi ne res tart.

Alt hough st all recovery i s a feat ure of t he St op/Start sys t em i t is pos si ble for it t o acti vat e i ndependent ly from t heStop/St art parameters . For exampl e:

If the St op/Start s ys t em has been deact ivated by the driver st all recovery wi ll s ti ll funct ion.Stal l recovery wil l act ivate at ambi ent temperat ures as l ow as (minus ) - 2°C, whereas the St op/Syst em operat ingt emperature threshold is above 4°C.Different t o t he operat ion of t he Stop/St art s yst em, s tal l recovery wil l st il l functi on when the vehicle is t owing;refer to the ‘Trail er Towi ng’ s ect ion.

• NOTE: As t he neces s ary cri teria will not have been sat is fi ed when t he vehi cl e i s at the beginning of a journey s t allrecovery wi ll not functi on. For exampl e, if t he vehi cl e s tal ls when l eavi ng the garage or driveway a convent ional engineres t art wi ll be required.

Trailer Towing

The Stop/St art s ys tem wil l aut omati cal ly di sabl e when t rail er light s are det ect ed by t he CJB via s ignals from t he t rail ermodule, t hi s informat ion i s t hen trans mi tt ed t o t he ECM. It i s not pos s ibl e for t he s ys t em t o det ect when a trai ler powerplug i s ins ert ed i n the vehicl e’s t owi ng s ocket s o it us es operat ion of t he trail er l ights as it s indi cat or.

The t rail er towing sys tem inhi bi ts St op/St art as i t is pos s ible that trail er power requirements could interfere wit h t heoperati on of the bat tery monit ori ng s ys t em. In parti cul ar, a t rai ler batt ery could revers e t he feed current t o t he vehicleduri ng an engi ne cranking event , t hi s coul d pos si bly:

Confus e t he bat t ery monit ori ng s ys t em i nto det ect ing an unreal is t ically smal l current at engi ne cranking.Rupture the fus e as sociat ed wit h t he t rail er modul e.

Climate Control System

• NOTE: The ‘ECON’ butt on has been renamed ‘A/C’ to prevent confus ion wi th the St op/St art s yst em ‘Eco’ s wit ch.

A number of changes have been made to the l ogi c and operati on of climat e control system, wit hi n a St op/St art cycle to:

maint ain occupant comfortprevent winds hi eld mis ti ngcons erve bat tery power.

This has been achi eved by the ATC (automat ic t emperat ure control) module monit oring and varyi ng, as necess ary variousclimate control funct ions wi thi n a St op/Start cycle.

In s ome circums t ances t he ATC has t he capabil it y to inhibit an engi ne s hut down or init iat e an engine rest art wit hi n aStop/St art cycle. Thi s i s achi eved by t he ATC module communi cat ing wit h t he CJB on the medi um s peed CAN. The variousoverri de functi ons the ATC has in a St op/St art cycl e are di s cus s ed bel ow:

Coolant temperat ure

The ATC module wil l i nhibit an engine shut down or i nit iat e an engine res t art wi thi n a St op/Start cycle if t he coolantt emperature fal ls below the calculat ed t hreshol d to s upport t he cabin t emperat ure s et by t he vehi cl e occupant s .

W i nds hiel d demis t ing

The variant of cli mate control fi tt ed t o the vehicl e influences t he s oft ware changes that have been made. For exampl e, thebase cl imat e-control s ys tem does not have a humi dit y s ens or, as us ed on a highline sys tem t o ini ti at e a winds hi elddemis t . Therefore, a calculat ion for demis ti ng the winds hi eld i s made us ing t he s ignals from t he rai n s ens or and ambientt emperature s ens or. Us i ng the probabi lit y t hat windshi eld mis ti ng wil l occur if i t is raining and t he ambi ent t emperat ure i scool , the ATC wil l presume a wi nds hiel d demis t is required and s tart the engine when i n a St op/St art cycl e.

Evaporat or temperat ure the main cause of windshi eld mis ti ng is al s o monit ored and t he high-line cl imat e cont rol s yst emwil l periodicall y cool t he evaporat or as neces s ary t o reduce mi s ti ng during a Stop/St art cycl e. The sys tem operates thewinds hield demis t s hut ter and i f the evaporator i s wet t he shut ter wi ll remai n clos ed for a few seconds after an engineres t art unti l the vapor is di ss ipat ed.

If the driver sel ect s eit her ‘programmed defros t ’ or t he ‘wi ndshi el d heater’ i t is as s umed t hat a qui ck demis t of thewinds hield is requi red. Therefore, t he ATC vi a the CJB will ei ther: i nhibit an engine shut down or i nit iat e an engine res t art .

Heater fan speed

Duri ng an engine s hutdown t he ATC monit ors cabin temperat ure and maint ai ns the fan speed at a l evel that wi ll cons erve,for as l ong as poss ibl e t he heat i n t he core of t he cabi n heat er. If the driver s elect s a hi gher fan s peed and the heatcannot be mai ntained i n t he heat er core, the engine will rest art .

Heated rear window and heated s eats

If the heated rear window or heated s eats are acti ve or act ivated during an engine shut down event t he power out put oft he relevant s ys t em wi ll be i nt errupted unt il the engi ne is rest art ed. The tell -t ale light i n t he relevant s wit ch wil lil lumi nat e t o i ndi cat e t he s ys t em i s act ive even t hough the s ys tem is recei vi ng no power. This feature is us ed t o conservebatt ery power.

Page 1109 of 3229

Fuel fired heat er

The FFBH (fuel fired boost er heat er) and St op/Start s ys t em wi ll not operate si mult aneous ly, due to low ambientt emperatures bei ng a fact or in t he funct ion of both sys tems .

Hood Latch Ajar-Switch

W ARNING: To avoi d injury when performing repai r work on t he vehicle al ways di s abl e the Stop/St art s ys tem bypres s ing t he ‘ECO’ butt on, ens ure that ‘ECO STOP/START OFF’ is di s pl ayed in t he mes sage Cent er and the ECO tel l-taleli ght in t he s wit ch is ext inguis hed.

The hood lat ch ajar-s wit ch hardwired to the CJB, has two functi ons :

Acts as a s top i nhi bit or, all owing t he engi ne t o remai n running if t he hood latch i s rel eased.Deact ivates the St op/Start s ys t em i f an engi ne s top i s t aki ng place, t his res ul ts in an engine st all ed condit ion. Theengi ne can be res t art ed usi ng t he ignit ion but ton. Stal l recovery wil l not funct ion i n t hi s condi ti on; refer t o t he StallRecovery secti on.

Aft er the hood i s clos ed reacti vat ion of t he Stop/Start sys tem is achieved by manuall y s tarti ng the engine.

System Fault

The Stop/St art s ys tem is aut omati cal ly acti vat ed each ti me an ignit ion cycl e occurs; t he dri ver will be i nformed t he sys t emis operat ing by the t ell -t ale l ight in the Eco s wi tch i lluminati ng. If the tell -t ale light does not il luminat e t hi s wi ll indicat et hat t here i s eit her a s ys t em faul t or the sys tem is not avail abl e. Onl y when t he dri ver at tempt s t o act ivat e t he sys t em bypres s ing t he ‘Eco’ but ton will t hey be informed of a fault by ‘ECO STOP/START FAULT’ being di spl ayed i n t he mes sageCenter.

Owi ng to the St op/Start s ys t em’s complexit y due t o many ot her vehicle modul es and communicat ion net works i nvol ved i nit s funct ion. It i s recommended t hat al l ot her sys tem faul ts be init ial ly diagnos ed and eliminated when inves t igati ngStop/St art fault s as t hes e could affect the operat ion of t he St op/Start sys tem.

Syst em DTC (di agnos ti c troubl e code)can be diagnos ed us ing Land Rover approved di agnos ti c equi pment.

STOP INHIBITORS, START INITIATORS AND START INHIBITORS

A number of s el ect able feat ures or vehicle si tuat ions can infl uence t he operat ion of t he Stop/St art s yst em’s operati on.Thes e can, depending on the parti cular circumst ances :

prevent the engine s hutt ing down (s t op inhibi tor),ini ti at e an aut onomous res tart (s tart ini ti at or),prevent an engi ne res t art (st art i nhi bit or).

Stop Inhibitors

Under normal ci rcums tances the St op/St art s ys t em wi ll automat icall y s hut down t he engi ne if:

t he vehi cl e is st ati onary,t he trans mi s si on is in neutral,t he cl utch pedal i s ful ly releas ed.

The fol lowing condit ions wi ll inhibi t the engine from s hutt ing down:

Dri ver effected st op inhi bi tor

The fol lowing driver effect ed condi ti ons will i nhi bit t he engi ne from shut ti ng down:

Dri ver s wi tches off t he Stop/St art s ys temTrans mis s ion not i n neut ral((no te that the d rive r re sting their ha nd o n the g ea r le ve r ca n move the tra ns mis sion o ut o f the ne utra l w ind o w w itho ut e nga g ing a ge a r))

Clut ch pedal not full y rel easedAccelerator pedal depres s edHood is openDri ver’s door is openDri ver’s safet y belt i s dis engagedHDC (hil l decent cont rol) i s acti veTR (terrain res pons e) mode i s act iveCli mate cont rol s ys t em us ed above cal ibrat ed thresholdW i nds hiel d demis t i s operati ngTrai ler electrical connect ion det ect ed

Vehicle s ys tem effect ed s top i nhi bit or

The fol lowing vehicl e s ys t em condi ti ons wil l inhibit t he engine from s hut ti ng down:

Dri ver s wi tches off t he Stop/St art s ys temBrake s ervo vacuum below thres holdBatt ery cold cranki ng capabil it y below t hres holdBatt ery s t ate of charge i s lowCatal yt ic converter out si de eit her pre or post cali brati on rangeDPF (di esel part iculat e filt er) i s regenerat ingEngi ne cool ant temperat ure bel ow t hreshol dEngi ne oil t emperature below thres hold

Page 1110 of 3229

Envi ronmental effected s t op inhibi tor

The fol lowing environmental condit ions wi ll i nhi bit t he engi ne from s hutt ing down:

External t emperature above 35°CExternal t emperature below 4°C

Start Initiators

W hen t he engine has s hutdown wi thi n a St op/Start cycle the followi ng condi ti ons will i nit iate an early res tart wit hin t hes ame St op/Start cycle:

Dri ver effected st art i nit iator

The fol lowing driver effect ed condi ti ons will i nit iate an earl y engi ne res t art:

Dri ver s wi tches off t he Stop/St art s ys temVehicle s peed above cali brat ed threshold 3 Km/hour (2 mi le/hour)- A res tart will only occur if t he transmis s ion i s in neut ral and the driver’s pres ence is det ect ed for example, thedri ver’s s afet y belt remains s ecured and t he driver’s door remains latchedBrake s ervo vacuum below thres hold (dri ver operat ing brake pedal)HDC (hil l decent cont rol) i s acti vat edTR (terrain res pons e) mode i s act ivat edA hi gher heater fan speed i s s elect edW i nds hiel d demis t i s act ivat ed

Vehicle s ys tem effect ed s tart init iat or

The fol lowing vehicl e s ys t em condi ti ons wil l init iat e an earl y engine res t art :

Batt ery cranking capabili ty is near it s l ower t hres hol dBatt ery s t ate of charge i s near it s lower t hreshol dW i nds hiel d demis t acti vat esThe int eri or cabin t emperat ure decreas es bel ow or increas es above the occupant’s s et thres holds

Envi ronmental effected s t art ini ti ator

The fol lowing environmental condit ions wi ll i ni ti ate an early engi ne res tart:

External t emperature ri s es above 35°CExternal t emperature reduces bel ow 4°C

Start Inhibitors

W hen t he engine has s hutdown wi thi n a St op/Start cycle the followi ng condi ti ons will prevent an automat ic res tart :

Dri ver effected st art i nhi bit or

The fol lowing driver effect ed condi ti ons will i nhi bit an aut omati c engi ne res tart:

Hood has been openedThe accelerator pedal i s depress edGear sel ect or moved out of neutral; mes s age Cent er wil l di spl ay: ‘Sel ect Neut ral To Res tart ’Dri ver’s safet y belt i s dis engaged; t hi s i s an automat ic s t art inhi bi tor t herefore the engi ne can be res tarted bydepres si ng the cl utch pedalDri ver’s door is unl atched; t his is an aut omati c st art i nhibit or therefore t he engine can be rest art ed by depres si ngt he cl utch pedal

Vehicle s ys tem effect ed s tart inhibit or

The fol lowing vehicl e s ys t em condi ti ons wil l inhibit an aut omati c engi ne res t art :

Engi ne has s hut down for l onger t han 5 mi nut es : a conventi onal res t art wi ll be requi redThere i s a s ys tem fault

Page 1111 of 3229

Publi s hed: 11-May-2011

Engine Ignition -

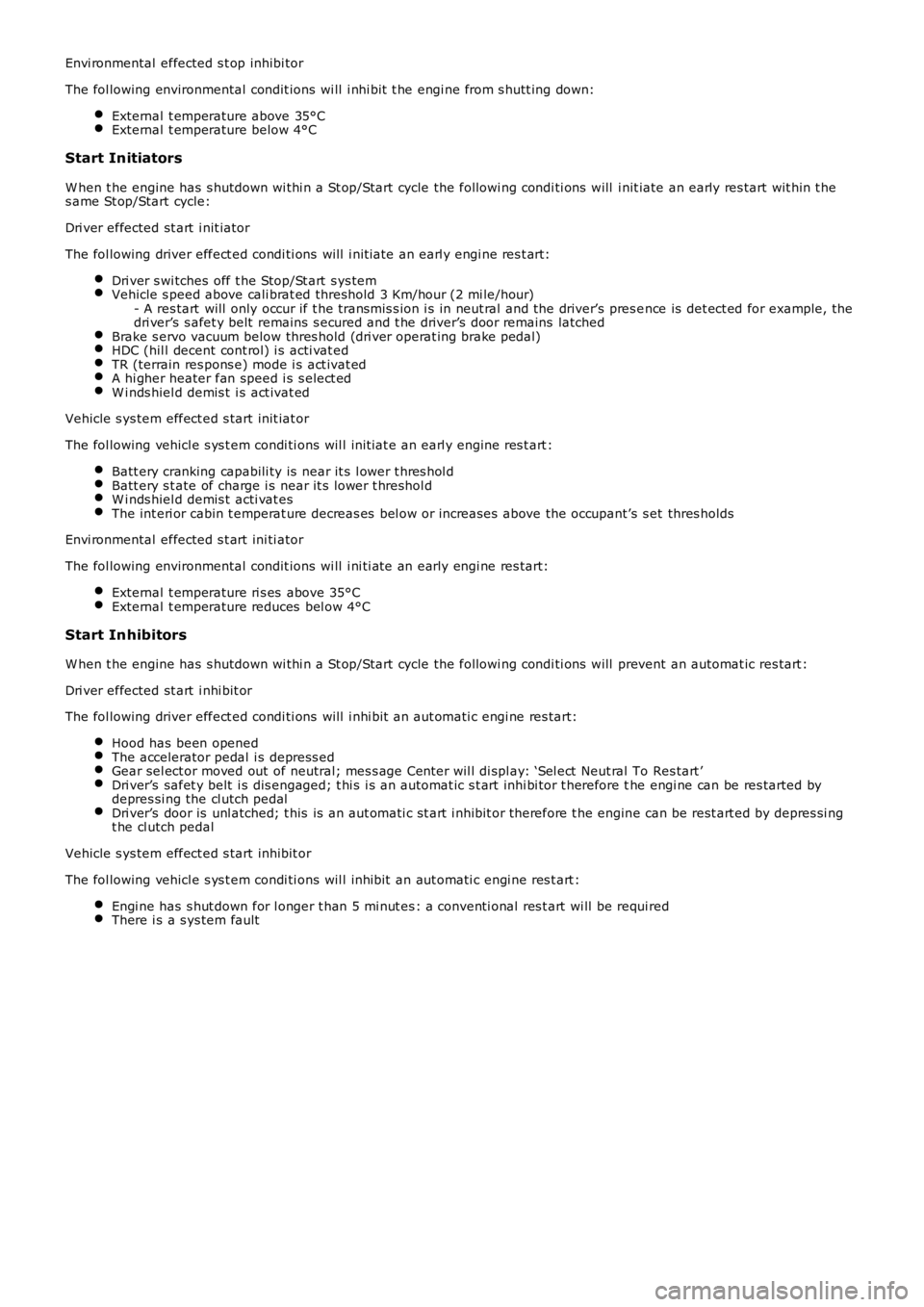

General SpecificationItemSpecification

Spark plugs

Vehicles built up to VIN 7H038589MakeNGK

TypeLPR6D

Gap0.6mm (non-adjust able)Vehicles built after VIN 7H038589

MakeNGK

TypeILRF6BGap0.75mm ± 0.05mm

Ignition coils:

MakeDensoTypeCoil-on-pl ugs

Torque SpecificationsDescriptionNmlb-ft

Igni ti on coi l ret aining bolt s107

Spark pl ugs2821

Page 1112 of 3229

Publi s hed: 11-May-2011

Engine Ignition - Engine Ignition

Des cript ion and Operat ion

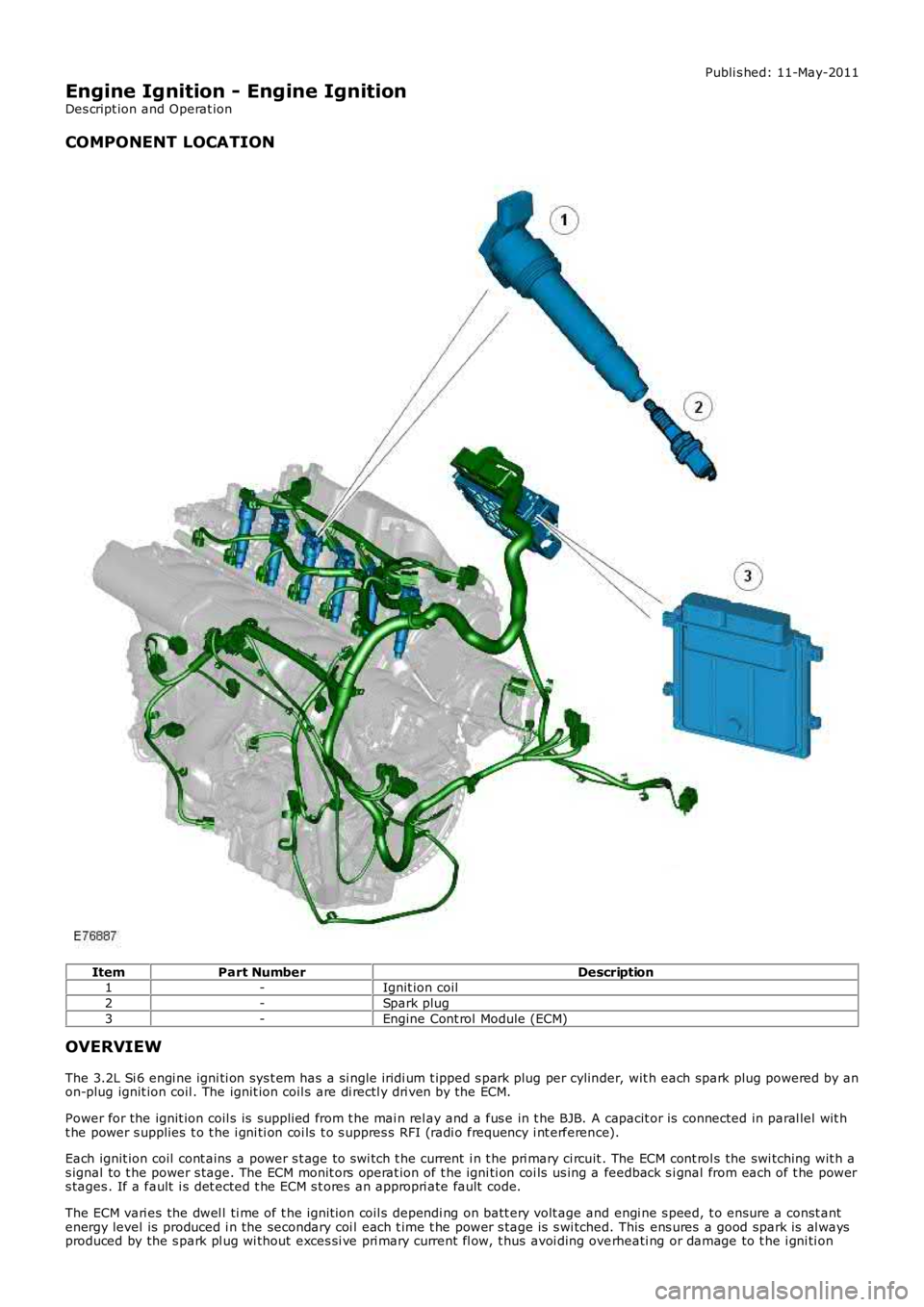

COMPONENT LOCATION

ItemPart NumberDescription1-Ignit ion coil

2-Spark plug

3-Engine Cont rol Module (ECM)

OVERVIEW

The 3.2L Si 6 engi ne igni ti on sys t em has a s i ngl e iridi um t ipped s park plug per cylinder, wit h each spark plug powered by anon-plug ignit ion coil . The ignit ion coil s are di rectl y dri ven by the ECM.

Power for the ignit ion coil s is suppli ed from t he mai n rel ay and a fus e in t he BJB. A capacit or is connected in paral lel wit ht he power s upplies t o t he i gni ti on coi ls t o s uppres s RFI (radi o frequency i nt erference).

Each ignit ion coil cont ains a power s t age to swi tch t he current i n t he pri mary ci rcuit . The ECM cont rol s the swi tching wit h as ignal to t he power s tage. The ECM monit ors operat ion of t he igni ti on coi ls us ing a feedback s i gnal from each of t he powers tages . If a fault i s det ected t he ECM s t ores an appropri ate fault code.

The ECM vari es the dwel l ti me of t he ignit ion coil s dependi ng on batt ery volt age and engi ne s peed, t o ensure a const antenergy level is produced i n the secondary coi l each t ime t he power s t age is s wi tched. This ens ures a good spark is al waysproduced by the s park pl ug wi thout exces si ve pri mary current fl ow, t hus avoi ding overheati ng or damage to t he i gni ti on

Page 1115 of 3229

Publi s hed: 11-May-2011

Engine Ignition - Engine Ignition

Diagnosi s and Tes ti ng

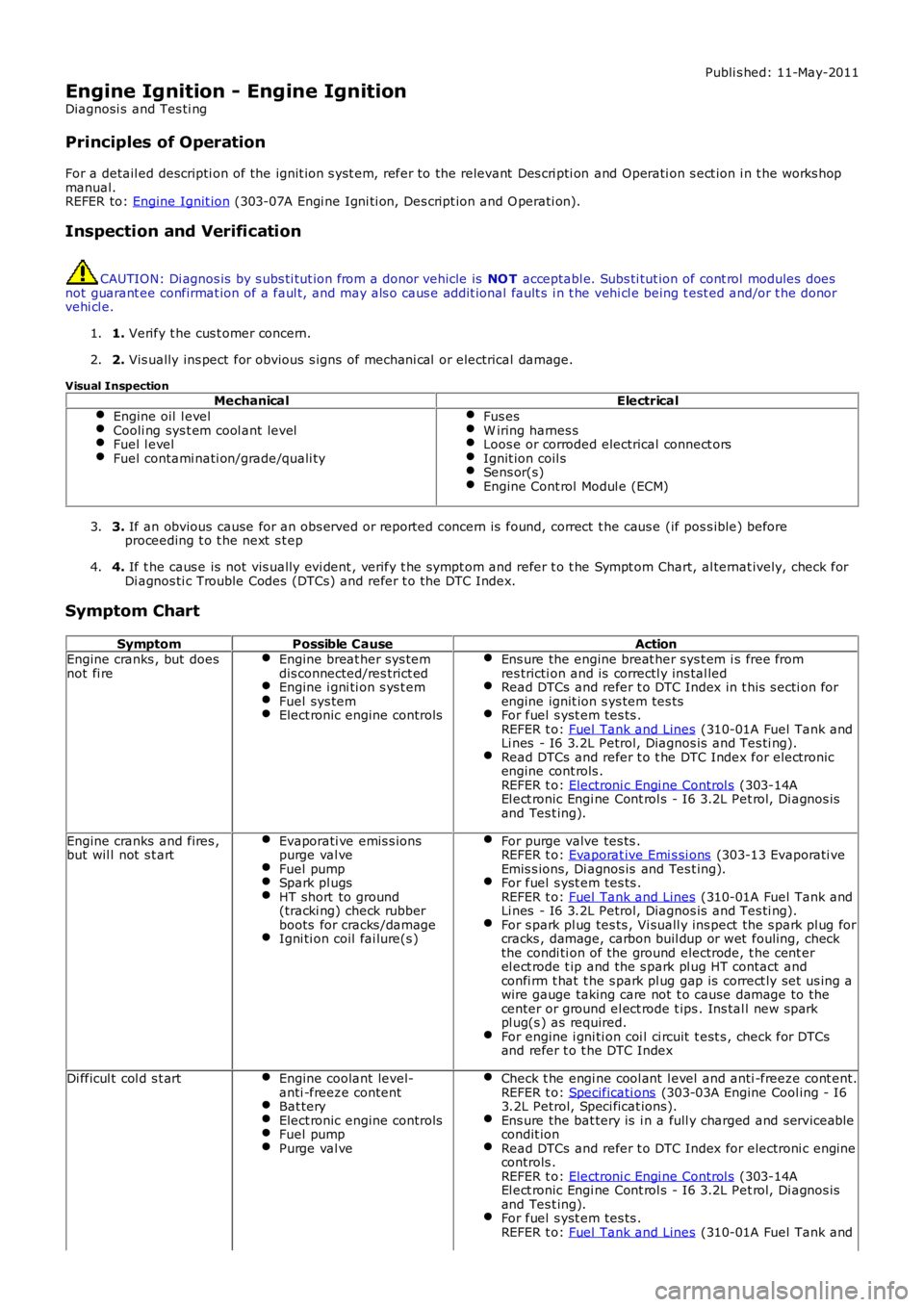

Principles of Operation

For a detail ed descripti on of the ignit ion s yst em, refer to the relevant Des cri pti on and Operati on s ect ion i n t he works hopmanual.REFER to: Engine Ignit ion (303-07A Engi ne Igni ti on, Des cript ion and O perati on).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.2.

Visual InspectionMechanicalElectrical

Engine oil l evelCooli ng sys t em cool ant levelFuel l evelFuel contami nati on/grade/quali ty

Fus esW iring harnes sLoos e or corroded electrical connect orsIgnit ion coil sSens or(s)Engine Cont rol Modul e (ECM)

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Chart, al ternat ively, check forDi agnos ti c Trouble Codes (DTCs) and refer t o t he DTC Index.4.

Symptom Chart

SymptomPossible CauseActionEngine cranks , but doesnot fi reEngine breat her sys temdis connected/res trict edEngine i gni ti on s ys t emFuel sys temElect ronic engine controls

Ens ure the engine breat her sys t em i s free fromres tricti on and is correctl y ins tal ledRead DTCs and refer t o DTC Index in t his s ecti on forengine ignit ion s ys tem tes tsFor fuel s yst em tes ts .REFER t o: Fuel Tank and Lines (310-01A Fuel Tank andLi nes - I6 3.2L Petrol, Diagnos is and Tes ti ng).Read DTCs and refer t o t he DTC Index for elect roni cengine cont rols .REFER t o: Electroni c Engi ne Control s (303-14AEl ect ronic Engi ne Cont rol s - I6 3.2L Pet rol, Di agnos isand Tes t ing).

Engine cranks and fires ,but wil l not s t artEvaporati ve emis s ionspurge val veFuel pumpSpark pl ugsHT short to ground(tracki ng) check rubberboots for cracks /damageIgni ti on coil fai lure(s )

For purge valve tes ts .REFER t o: Evaporat ive Emi s si ons (303-13 Evaporati veEmis s ions, Di agnos is and Tes t ing).For fuel s yst em tes ts .REFER t o: Fuel Tank and Lines (310-01A Fuel Tank andLi nes - I6 3.2L Petrol, Diagnos is and Tes ti ng).For s park pl ug tes ts , Vi suall y ins pect t he s park pl ug forcracks , damage, carbon buil dup or wet fouling, checkthe condi ti on of the ground electrode, t he cent erel ect rode t ip and the s park pl ug HT contact andconfi rm t hat t he s park pl ug gap is correct ly set us ing awire gauge taking care not t o cause damage to thecenter or ground el ect rode t ips . Ins tal l new s parkpl ug(s ) as required.For engine i gni ti on coi l ci rcuit t est s , check for DTCsand refer t o t he DTC Index

Di fficul t col d s t artEngine coolant level-anti -freeze contentBat teryElect ronic engine controlsFuel pumpPurge val ve

Check t he engi ne cool ant l evel and anti -freeze cont ent.REFER t o: Specificati ons (303-03A Engine Cool ing - I63.2L Petrol, Speci ficat ions).Ens ure the bat tery is i n a full y charged and s erviceabl econdit ionRead DTCs and refer t o DTC Index for electroni c enginecontrols .REFER t o: Electroni c Engi ne Control s (303-14AEl ect ronic Engi ne Cont rol s - I6 3.2L Pet rol, Di agnos isand Tes t ing).For fuel s yst em tes ts .REFER t o: Fuel Tank and Lines (310-01A Fuel Tank and

Page 1116 of 3229

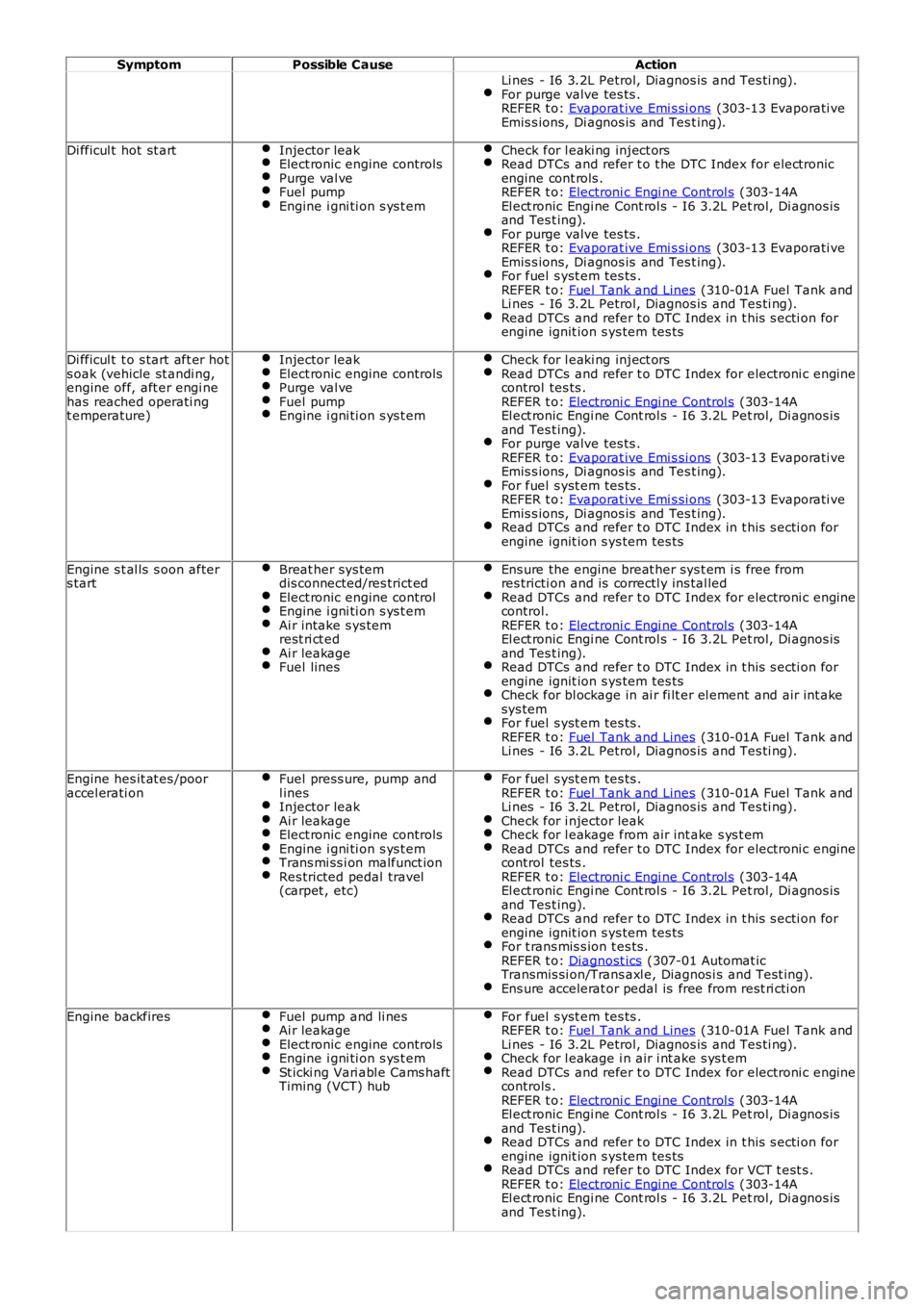

SymptomPossible CauseAction

Li nes - I6 3.2L Petrol, Diagnos is and Tes ti ng).For purge valve tes ts .REFER t o: Evaporat ive Emi s si ons (303-13 Evaporati veEmis s ions, Di agnos is and Tes t ing).

Di fficul t hot st artInjector leakElect ronic engine controlsPurge val veFuel pumpEngine i gni ti on s ys t em

Check for l eaki ng inject orsRead DTCs and refer t o t he DTC Index for elect roni cengine cont rols .REFER t o: Electroni c Engi ne Control s (303-14AEl ect ronic Engi ne Cont rol s - I6 3.2L Pet rol, Di agnos isand Tes t ing).For purge valve tes ts .REFER t o: Evaporat ive Emi s si ons (303-13 Evaporati veEmis s ions, Di agnos is and Tes t ing).For fuel s yst em tes ts .REFER t o: Fuel Tank and Lines (310-01A Fuel Tank andLi nes - I6 3.2L Petrol, Diagnos is and Tes ti ng).Read DTCs and refer t o DTC Index in t his s ecti on forengine ignit ion s ys tem tes ts

Di fficul t t o s tart aft er hots oak (vehicle st andi ng,engine off, aft er engi nehas reached operati ngt emperature)

Injector leakElect ronic engine controlsPurge val veFuel pumpEngine i gni ti on s ys t em

Check for l eaki ng inject orsRead DTCs and refer t o DTC Index for electroni c enginecontrol tes ts .REFER t o: Electroni c Engi ne Control s (303-14AEl ect ronic Engi ne Cont rol s - I6 3.2L Pet rol, Di agnos isand Tes t ing).For purge valve tes ts .REFER t o: Evaporat ive Emi s si ons (303-13 Evaporati veEmis s ions, Di agnos is and Tes t ing).For fuel s yst em tes ts .REFER t o: Evaporat ive Emi s si ons (303-13 Evaporati veEmis s ions, Di agnos is and Tes t ing).Read DTCs and refer t o DTC Index in t his s ecti on forengine ignit ion s ys tem tes ts

Engine s t al ls s oon afters tartBreat her sys temdis connected/res trict edElect ronic engine controlEngine i gni ti on s ys t emAi r intake s ys temrest ri ct edAi r leakageFuel lines

Ens ure the engine breat her sys t em i s free fromres tricti on and is correctl y ins tal ledRead DTCs and refer t o DTC Index for electroni c enginecontrol.REFER t o: Electroni c Engi ne Control s (303-14AEl ect ronic Engi ne Cont rol s - I6 3.2L Pet rol, Di agnos isand Tes t ing).Read DTCs and refer t o DTC Index in t his s ecti on forengine ignit ion s ys tem tes tsCheck for bl ockage in ai r fi lt er el ement and air int akesys temFor fuel s yst em tes ts .REFER t o: Fuel Tank and Lines (310-01A Fuel Tank andLi nes - I6 3.2L Petrol, Diagnos is and Tes ti ng).

Engine hes it at es /pooraccel erati onFuel press ure, pump andl inesInjector leakAi r leakageElect ronic engine controlsEngine i gni ti on s ys t emTrans mi ss i on malfunct ionRes tricted pedal travel(carpet , etc)

For fuel s yst em tes ts .REFER t o: Fuel Tank and Lines (310-01A Fuel Tank andLi nes - I6 3.2L Petrol, Diagnos is and Tes ti ng).Check for i njector leakCheck for l eakage from air int ake s ys t emRead DTCs and refer t o DTC Index for electroni c enginecontrol tes ts .REFER t o: Electroni c Engi ne Control s (303-14AEl ect ronic Engi ne Cont rol s - I6 3.2L Pet rol, Di agnos isand Tes t ing).Read DTCs and refer t o DTC Index in t his s ecti on forengine ignit ion s ys tem tes tsFor t rans mis s ion t es ts .REFER t o: Diagnost ics (307-01 Automat icTransmis si on/Trans axl e, Diagnos i s and Test ing).Ens ure accelerat or pedal is free from rest ri cti on

Engine backfiresFuel pump and li nesAi r leakageElect ronic engine controlsEngine i gni ti on s ys t emSt icki ng Vari abl e Cams haftTiming (VCT) hub

For fuel s yst em tes ts .REFER t o: Fuel Tank and Lines (310-01A Fuel Tank andLi nes - I6 3.2L Petrol, Diagnos is and Tes ti ng).Check for l eakage i n air i nt ake s ys t emRead DTCs and refer t o DTC Index for electroni c enginecontrols .REFER t o: Electroni c Engi ne Control s (303-14AEl ect ronic Engi ne Cont rol s - I6 3.2L Pet rol, Di agnos isand Tes t ing).Read DTCs and refer t o DTC Index in t his s ecti on forengine ignit ion s ys tem tes tsRead DTCs and refer t o DTC Index for VCT t est s .REFER t o: Electroni c Engi ne Control s (303-14AEl ect ronic Engi ne Cont rol s - I6 3.2L Pet rol, Di agnos isand Tes t ing).

Page 1117 of 3229

SymptomPossible CauseAction

Engine s urgesFuel pump and li nesElect ronic engine controlsEngine i gni ti on s ys t em

For fuel s yst em tes ts .REFER t o: Fuel Tank and Lines (310-01A Fuel Tank andLi nes - I6 3.2L Petrol, Diagnos is and Tes ti ng).Read DTCs and refer t o DTC Index for electroni c enginecontrols .REFER t o: Electroni c Engi ne Control s (303-14AEl ect ronic Engi ne Cont rol s - I6 3.2L Pet rol, Di agnos isand Tes t ing).Read DTCs and refer t o DTC Index in t his s ecti on forengine ignit ion s ys tem tes ts

Engine detonat es /knocksElect ronic engine controlsFuel pump and li nesAi r leakageSt icki ng VCT hub

Read DTCs and refer t o DTC Index for electroni c enginecontrolsFor fuel s yst em tes ts .REFER t o: Fuel Tank and Lines (310-01A Fuel Tank andLi nes - I6 3.2L Petrol, Diagnos is and Tes ti ng).Check for l eakage from air int ake s ys t emRead DTCs and refer t o DTC Index for VCT t est s .REFER t o: Electroni c Engi ne Control s (303-14AEl ect ronic Engi ne Cont rol s - I6 3.2L Pet rol, Di agnos isand Tes t ing).

No t hrot tl e res ponseElect ronic engine controlsRead DTCs and refer t o DTC Index for electroni c enginecontrol tes ts

Poor throt t le respons eBreat her sys temdis connected/res trict edElect ronic engine controlTrans mi ss i on malfunct ionTract ion control eventAi r leakage

Ens ure the engine breat her sys t em i s free fromres tricti on and is correctl y ins tal ledRead DTCs and refer t o DTC Index for electroni c enginecontrol tes ts .REFER t o: Electroni c Engi ne Control s (303-14AEl ect ronic Engi ne Cont rol s - I6 3.2L Pet rol, Di agnos isand Tes t ing).For t rans mis s ion t es ts .REFER t o: Diagnost ics (307-01 Automat icTransmis si on/Trans axl e, Diagnos i s and Test ing).Check for l eakage from air int ake s ys t em

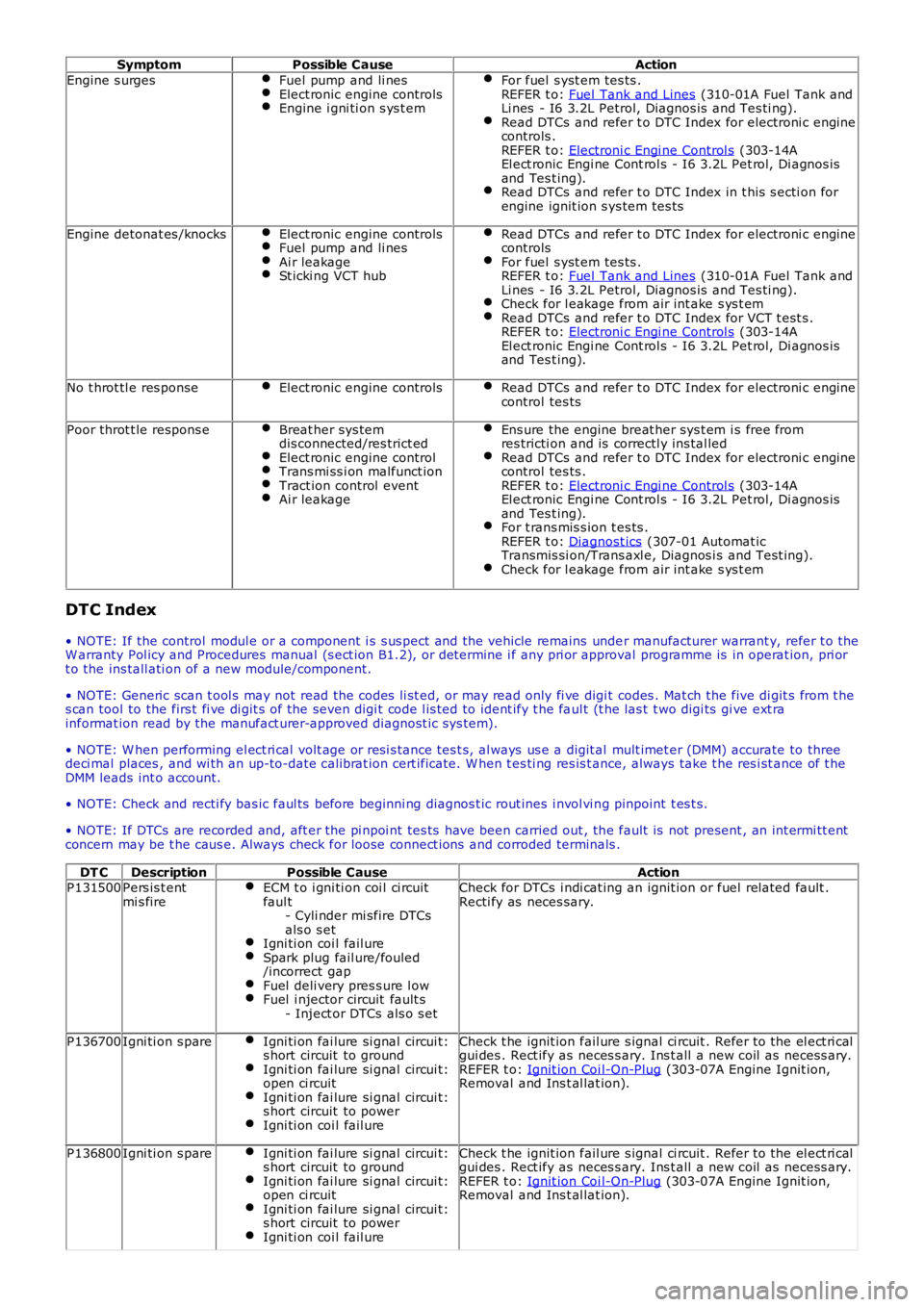

DTC Index

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains under manufacturer warrant y, refer t o theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve ext rainformat ion read by the manufact urer-approved diagnost ic s ys tem).

• NOTE: W hen performing el ect ri cal volt age or resi s tance tes t s, al ways us e a digit al mult imet er (DMM) accurate to threedeci mal places , and wi th an up-to-date cali brat ion cert ificate. W hen t es ti ng res is t ance, always take t he res i st ance of t heDMM leads int o account.

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: If DTCs are recorded and, aft er the pi npoi nt tes ts have been carried out , the fault is not present , an int ermi tt entconcern may be t he caus e. Always check for loose connect ions and corroded terminals .

DT CDescriptionPossible CauseActionP131500Pers is t entmi s fireECM t o i gni ti on coi l ci rcuitfaul t- Cyli nder mi sfire DTCsals o s etIgni ti on coi l fail ureSpark plug fail ure/fouled/incorrect gapFuel deli very pres s ure l owFuel i njector circuit fault s- Inject or DTCs als o s et

Check for DTCs i ndi cat ing an ignit ion or fuel related fault .Recti fy as neces sary.

P136700Igni ti on s pareIgni ti on fai lure si gnal circui t:s hort circuit to groundIgni ti on fai lure si gnal circui t:open ci rcuitIgni ti on fai lure si gnal circui t:s hort circuit to powerIgni ti on coi l fail ure

Check t he ignit ion fail ure s ignal ci rcuit . Refer t o the el ect ri calgui des . Rect ify as neces s ary. Ins t all a new coil as necess ary.REFER t o: Ignit ion Coi l-On-Plug (303-07A Engine Ignit ion,Removal and Ins t al lat ion).

P136800Igni ti on s pareIgni ti on fai lure si gnal circui t:s hort circuit to groundIgni ti on fai lure si gnal circui t:open ci rcuitIgni ti on fai lure si gnal circui t:s hort circuit to powerIgni ti on coi l fail ure

Check t he ignit ion fail ure s ignal ci rcuit . Refer t o the el ect ri calgui des . Rect ify as neces s ary. Ins t all a new coil as necess ary.REFER t o: Ignit ion Coi l-On-Plug (303-07A Engine Ignit ion,Removal and Ins t al lat ion).

Page 1118 of 3229

Publi s hed: 11-May-2011

Engine Ignition - Ignition Coil-On-Plug

Removal and Inst all ati on

Removal

1. CAUTION: After s wit chi ng of the i gnit ion, wait for 2 minut es

before dis connecti ng the bat tery. Fail ure to wai t for 2 minutes will

damage t he navi gat ion computer.

Di sconnect t he bat t ery ground cable.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -

General Informat ion, Specificati ons).

1.

Remove t he engi ne cover.

Refer t o: Engi ne Cover - I6 3.2L Pet rol (501-05 Int eri or Trim and

Ornament ati on, Removal and Ins tal lat ion).

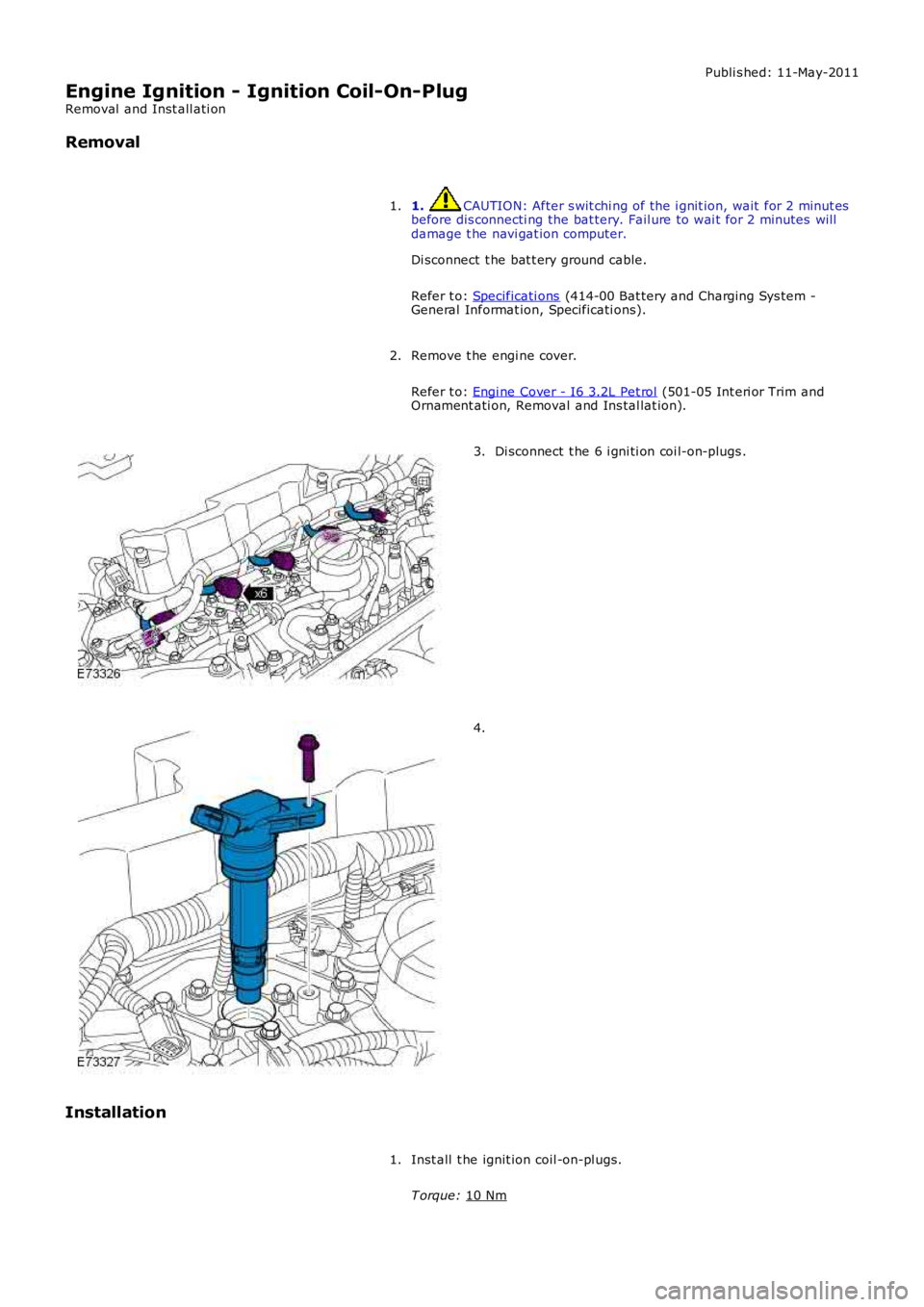

2. Di sconnect t he 6 i gni ti on coi l-on-plugs .

3. 4.

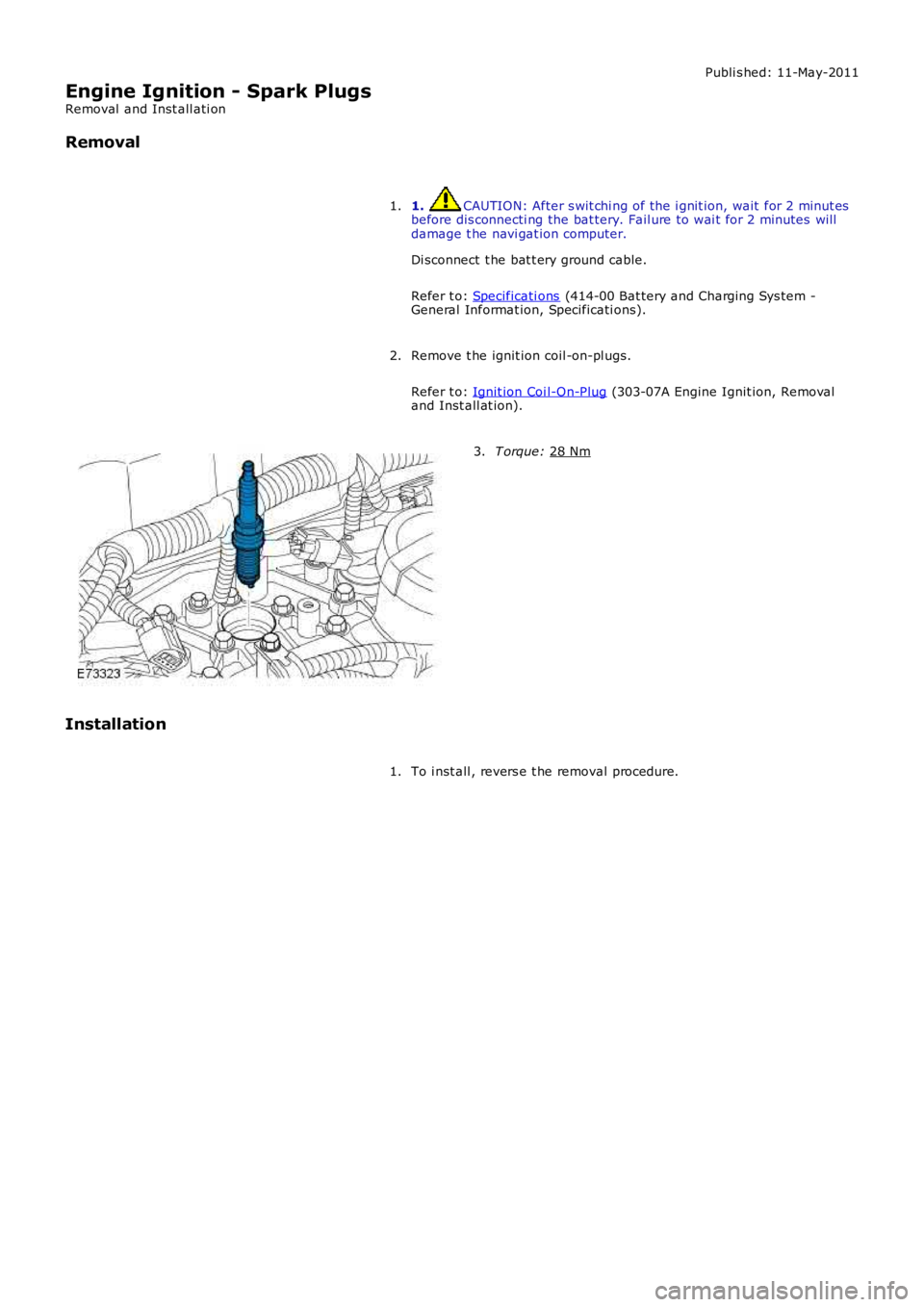

Installation Inst all t he ignit ion coil -on-pl ugs.

T orque: 10 Nm 1.

Page 1120 of 3229

Publi s hed: 11-May-2011

Engine Ignition - Spark Plugs

Removal and Inst all ati on

Removal

1. CAUTION: After s wit chi ng of the i gnit ion, wait for 2 minut es

before dis connecti ng the bat tery. Fail ure to wai t for 2 minutes will

damage t he navi gat ion computer.

Di sconnect t he bat t ery ground cable.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -

General Informat ion, Specificati ons).

1.

Remove t he ignit ion coil -on-pl ugs.

Refer t o: Ignit ion Coi l-On-Plug (303-07A Engine Ignit ion, Removal

and Inst all at ion).

2. T orque:

28 Nm 3.

Installation To i nst all , revers e t he removal procedure.

1.