engine LAND ROVER FRELANDER 2 2006 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 1021 of 3229

Publi s hed: 11-May-2011

Fuel Charging and Controls - TD4 2.2L Diesel - Throttle Body

Removal and Inst all ati on

Removal

Remove t he cover and dis connect the bat tery ground cabl e.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -General Informat ion, Specificati ons).

1.

Remove t he engi ne cover.

Refer t o: Engi ne Cover - TD4 2.2L Dies el (501-05 Interior Tri m andOrnament ati on, Removal and Ins tal lat ion).

2.

Remove t he manifol d abs ol ute pres sure (MAP) s ens or.

Refer t o: Mani fol d Absol ute Press ure (MAP) Sens or (303-14BElectronic Engine Controls - TD4 2.2L Di es el, Removal andInst all at ion).

3.

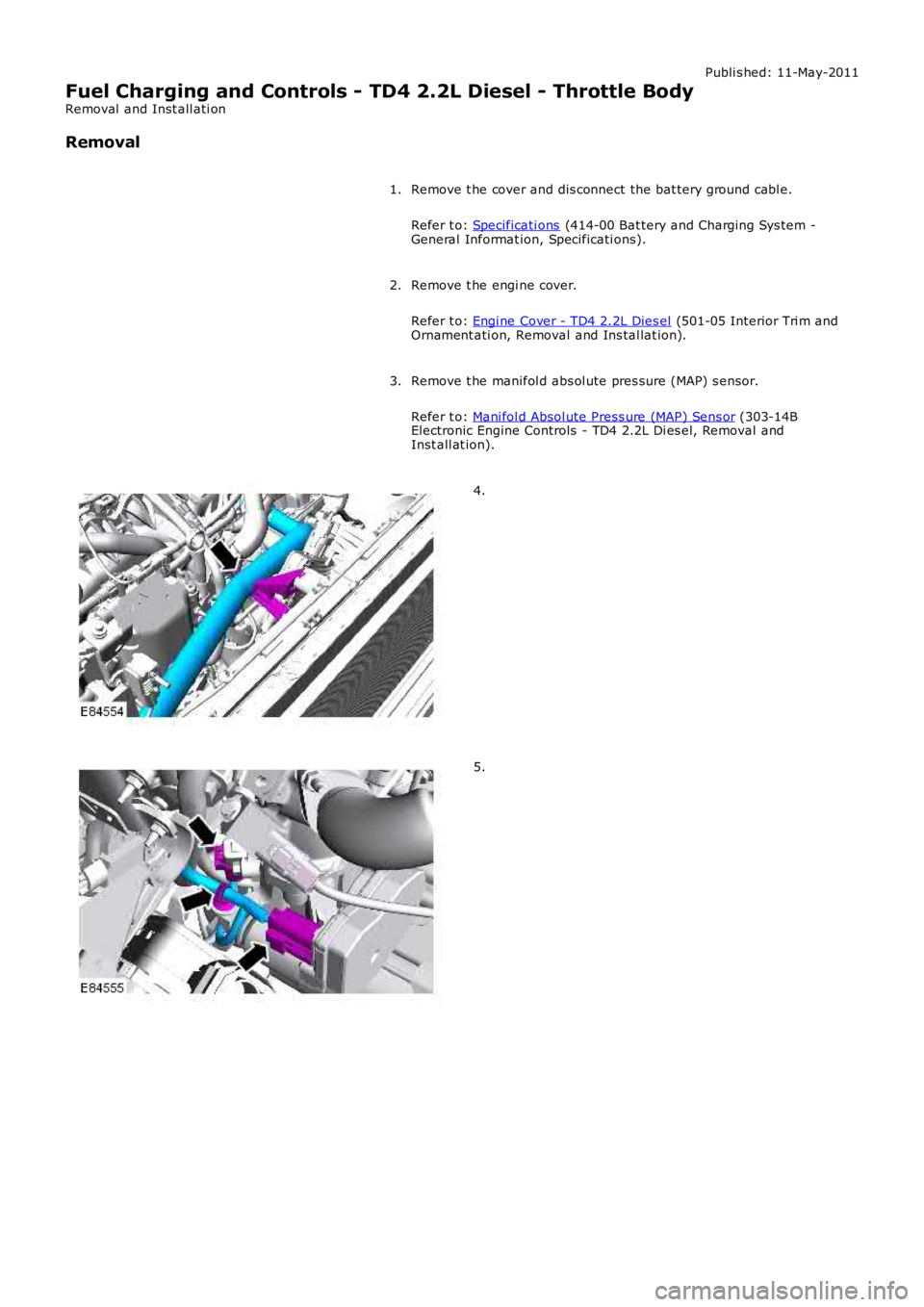

4.

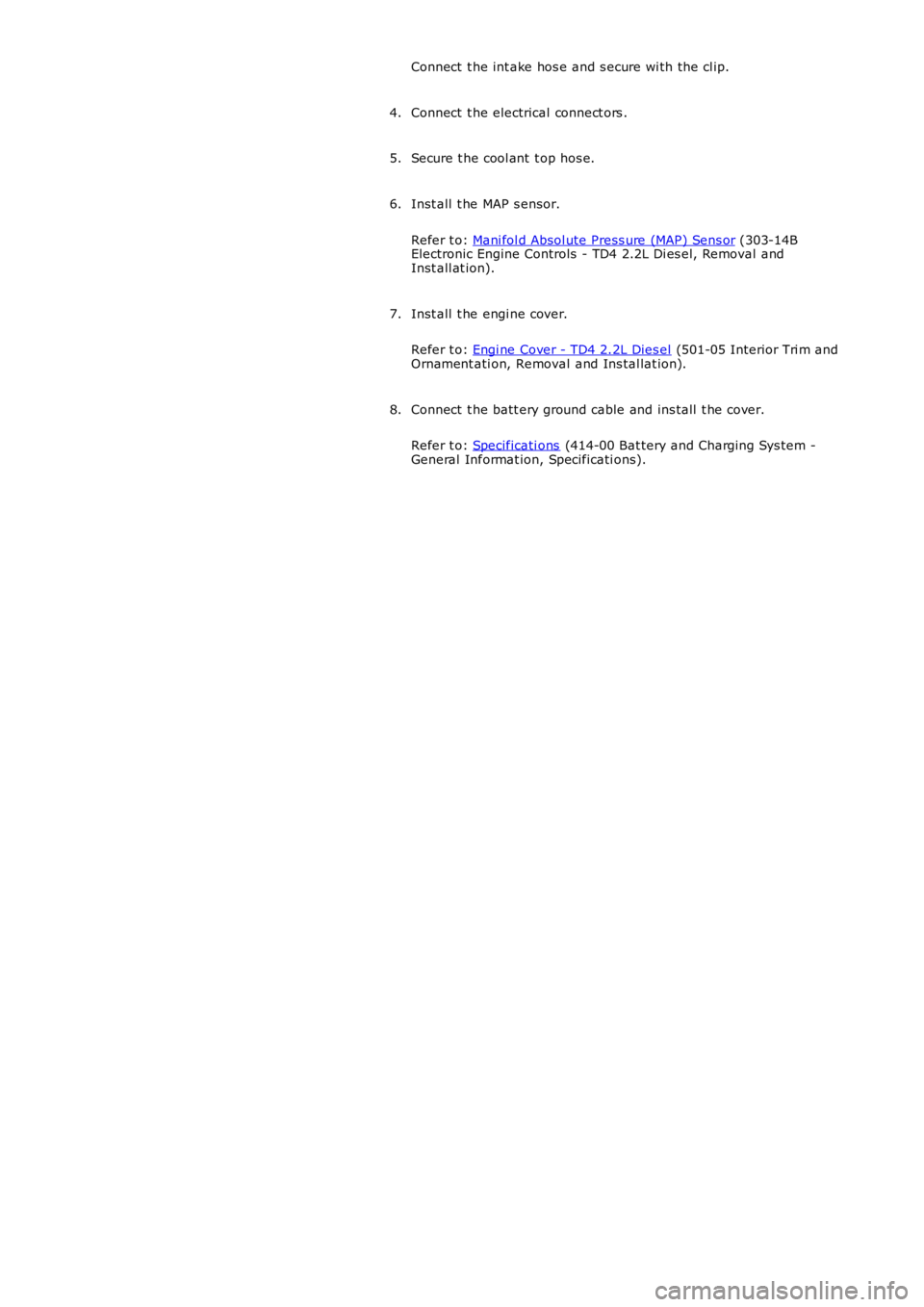

5.

Page 1023 of 3229

Connect t he int ake hos e and s ecure wi th the cl ip.

Connect t he electrical connect ors .4.

Secure t he cool ant t op hos e.5.

Inst all t he MAP s ensor.

Refer t o: Mani fol d Absol ute Press ure (MAP) Sens or (303-14BElectronic Engine Controls - TD4 2.2L Di es el, Removal andInst all at ion).

6.

Inst all t he engi ne cover.

Refer t o: Engi ne Cover - TD4 2.2L Dies el (501-05 Interior Tri m andOrnament ati on, Removal and Ins tal lat ion).

7.

Connect t he batt ery ground cable and ins tall t he cover.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -General Informat ion, Specificati ons).

8.

Page 1024 of 3229

Publi s hed: 11-May-2011

Fuel Charging and Controls - Turbocharger - TD4 2.2L Diesel -

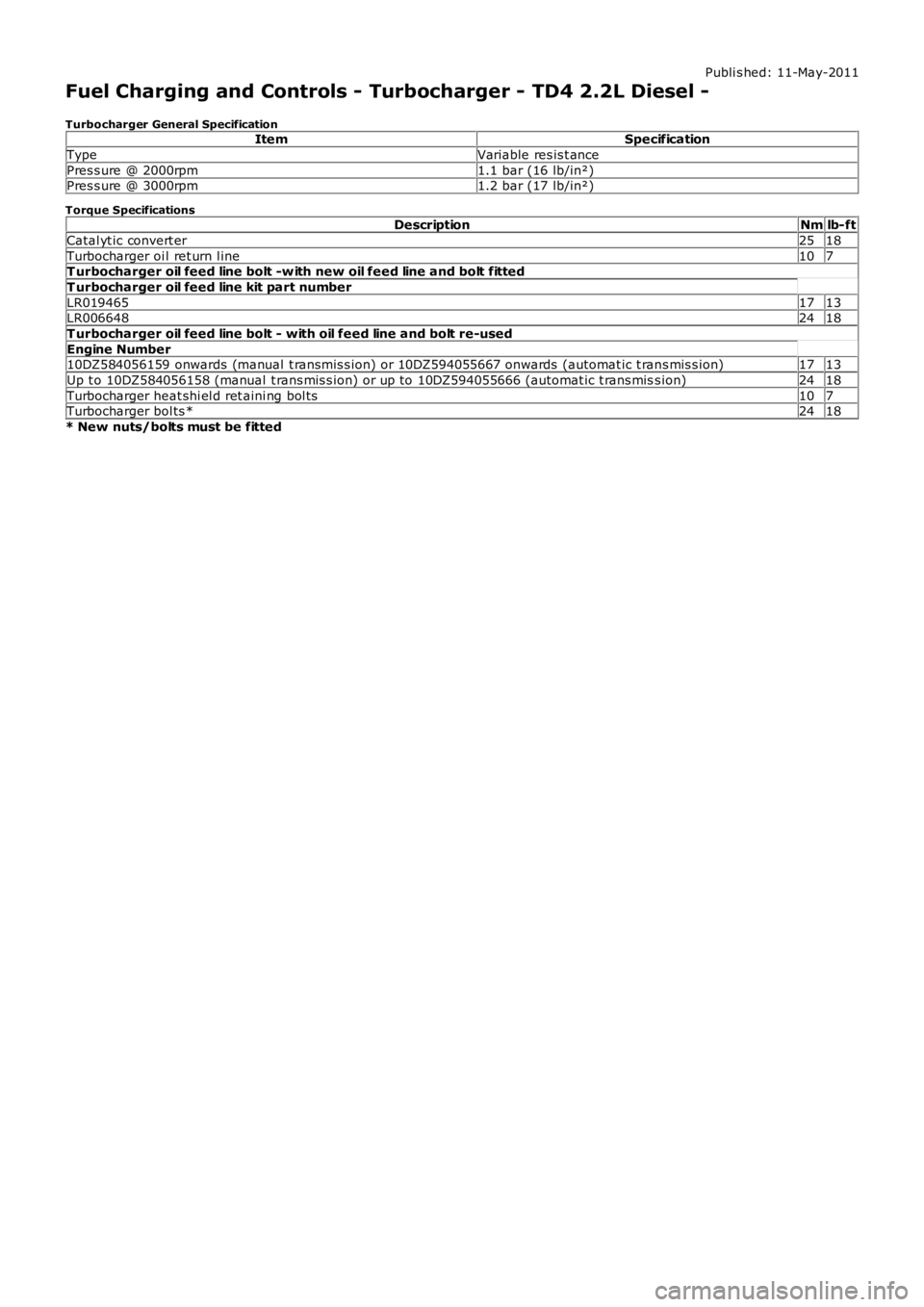

Turbocharger General SpecificationItemSpecification

TypeVariable res is t ance

Pres s ure @ 2000rpm1.1 bar (16 lb/in²)Pres s ure @ 3000rpm1.2 bar (17 lb/in²)

Torque SpecificationsDescriptionNmlb-ft

Catal yt ic convert er2518

Turbocharger oi l ret urn l ine107T urbocharger oil feed line bolt -w ith new oil feed line and bolt fitted

T urbocharger oil feed line kit part number

LR0194651713LR0066482418

T urbocharger oil feed line bolt - with oil feed line and bolt re-used

Engine Number10DZ584056159 onwards (manual t ransmis s ion) or 10DZ594055667 onwards (automat ic t rans mis s ion)1713

Up t o 10DZ584056158 (manual t rans mis s ion) or up to 10DZ594055666 (automat ic t rans miss ion)2418

Turbocharger heat shi el d ret aini ng bol ts107Turbocharger bol ts *2418

* New nuts/bolts must be fitted

Page 1025 of 3229

Publi s hed: 11-May-2011

Fuel Charging and Controls - Turbocharger - TD4 2.2L Diesel - Turbocharger

Des cript ion and Operat ion

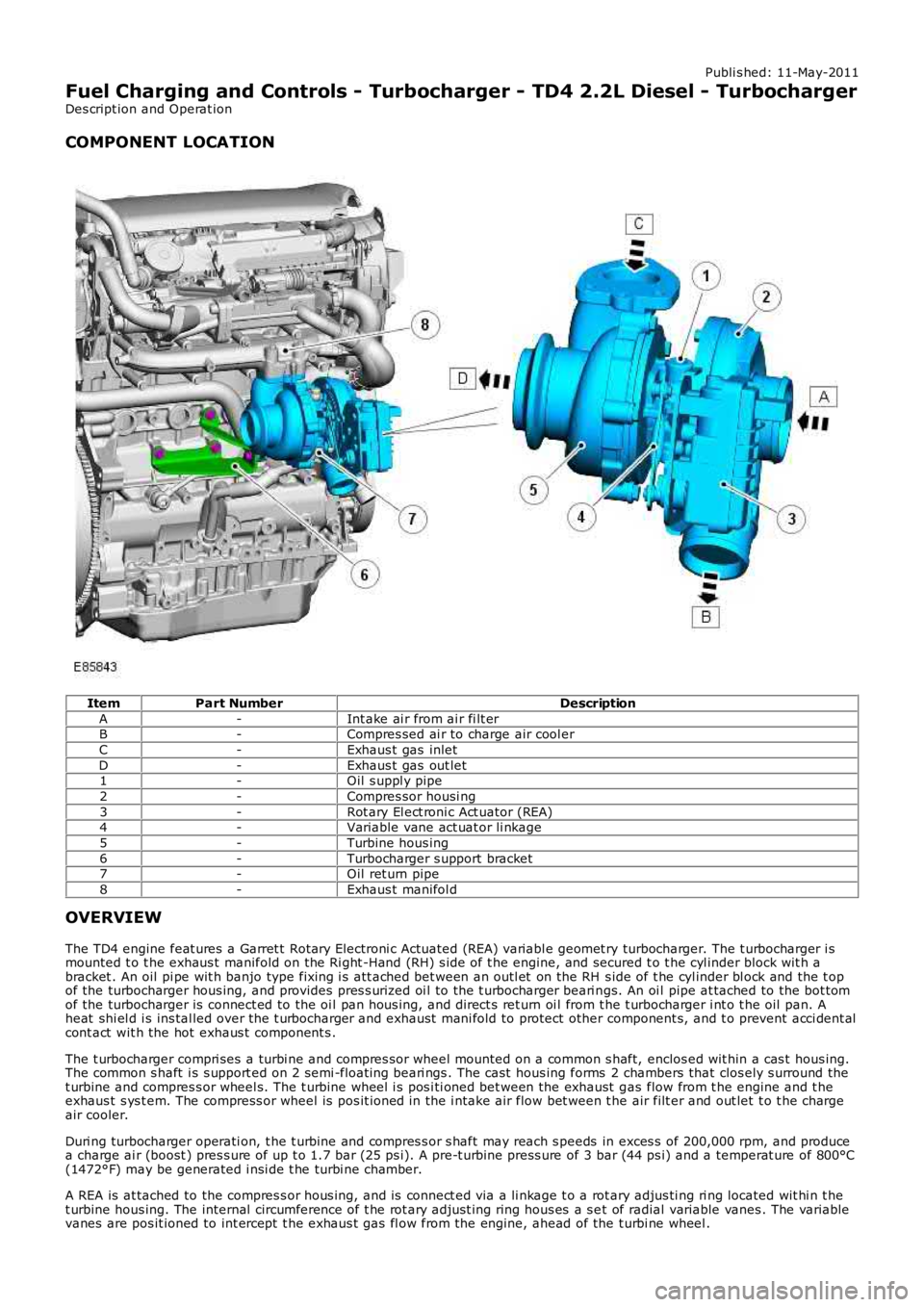

COMPONENT LOCATION

ItemPart NumberDescription

A-Int ake ai r from ai r fi lt erB-Compres sed ai r to charge air cool er

C-Exhaus t gas inlet

D-Exhaus t gas out let1-Oil s uppl y pipe

2-Compres sor housi ng

3-Rot ary El ect roni c Act uator (REA)4-Variable vane act uat or li nkage

5-Turbine hous ing

6-Turbocharger s upport bracket7-Oil ret urn pipe

8-Exhaus t manifol d

OVERVIEW

The TD4 engine feat ures a Garret t Rotary Electroni c Actuated (REA) variabl e geomet ry turbocharger. The t urbocharger i smounted t o t he exhaus t manifold on the Ri ght -Hand (RH) s ide of t he engine, and secured t o t he cyl inder block wit h abracket . An oil pi pe wit h banjo type fixing i s att ached bet ween an outl et on the RH s ide of t he cyl inder bl ock and the t opof the turbocharger hous ing, and provides pres s uri zed oi l to the t urbocharger beari ngs. An oi l pipe at tached to the bot tomof the turbocharger is connect ed to the oi l pan hous ing, and direct s ret urn oi l from t he t urbocharger i nt o t he oil pan. Aheat shi el d i s ins tal led over the t urbocharger and exhaust mani fold to protect other component s, and t o prevent acci dent alcont act wit h the hot exhaus t component s .

The t urbocharger compri ses a turbi ne and compres sor wheel mounted on a common s haft, enclos ed wit hin a cas t hous ing.The common s haft i s s upport ed on 2 semi -float ing beari ngs . The cast hous ing forms 2 chambers that clos ely s urround thet urbine and compres s or wheel s. The t urbine wheel i s pos i ti oned bet ween the exhaust gas flow from t he engine and t heexhaus t s ys t em. The compress or wheel is pos it ioned in the i ntake air flow bet ween t he air filt er and out let t o t he chargeair cooler.

Duri ng turbocharger operati on, t he t urbine and compres s or s haft may reach s peeds in exces s of 200,000 rpm, and producea charge ai r (boost ) pres s ure of up t o 1.7 bar (25 ps i). A pre-t urbine press ure of 3 bar (44 ps i) and a temperat ure of 800°C(1472°F) may be generated i nsi de t he turbi ne chamber.

A REA is at tached to the compres s or hous ing, and is connect ed via a li nkage t o a rotary adjus ti ng ri ng located wit hi n t het urbine hous ing. The internal circumference of t he rot ary adjus t ing ring hous es a s et of radial variable vanes . The variablevanes are pos it ioned to int ercept t he exhaus t gas fl ow from the engine, ahead of the t urbi ne wheel .

Page 1026 of 3229

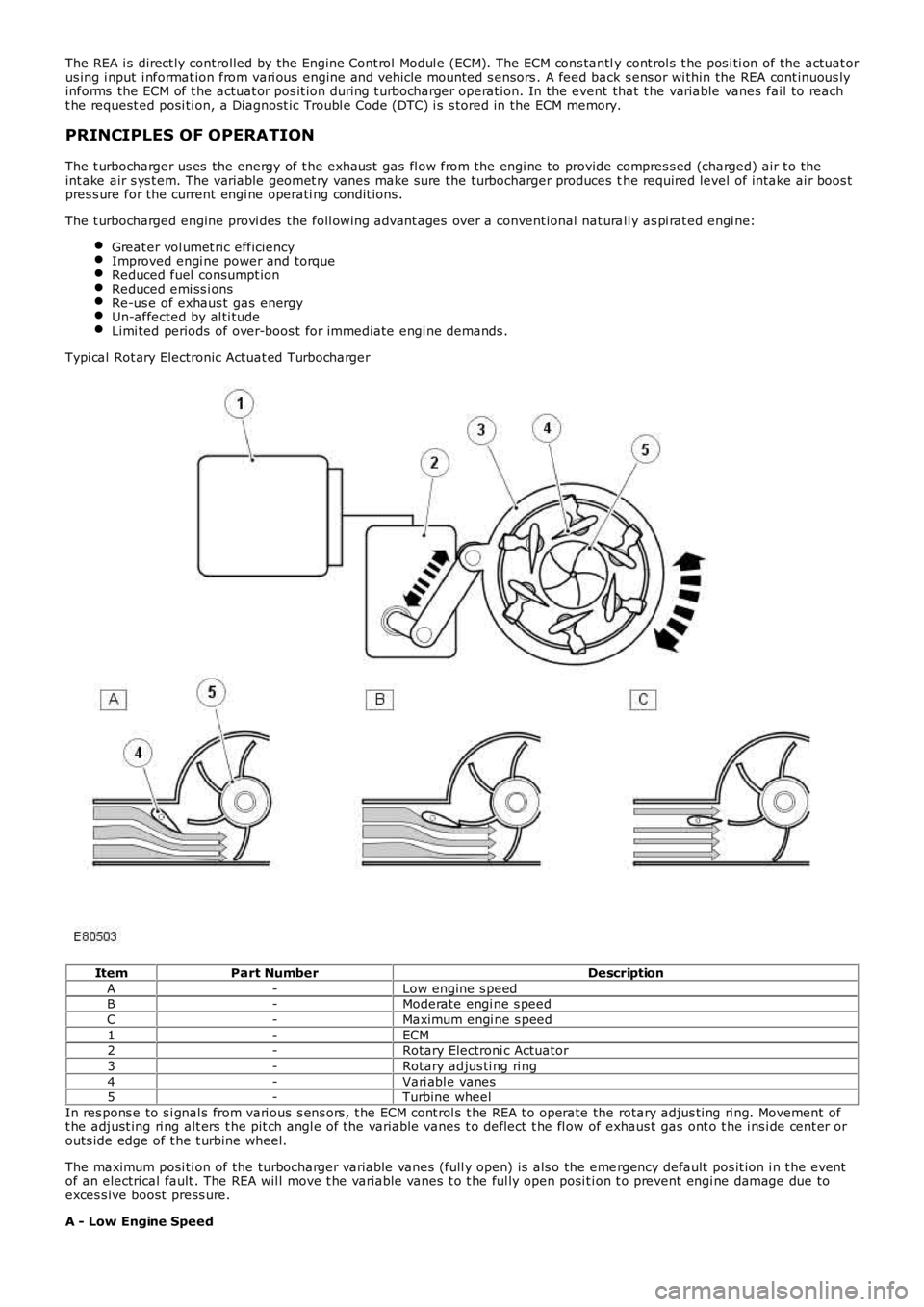

The REA i s direct ly controlled by the Engine Cont rol Modul e (ECM). The ECM cons tantly cont rol s t he pos i ti on of the actuat orus ing i nput i nformat ion from vari ous engine and vehicle mounted s ensors . A feed back s ens or wi thin the REA cont inuous lyinforms the ECM of t he actuat or pos it ion during t urbocharger operat ion. In the event that t he variable vanes fail to reacht he request ed posi ti on, a Diagnost ic Troubl e Code (DTC) i s s tored in the ECM memory.

PRINCIPLES OF OPERATION

The t urbocharger us es the energy of t he exhaus t gas fl ow from the engi ne to provide compres s ed (charged) air t o theint ake air s ys t em. The variable geomet ry vanes make s ure the turbocharger produces the required level of intake ai r boos tpres s ure for the current engi ne operati ng condit ions .

The t urbocharged engine provi des the foll owing advant ages over a convent ional nat urall y as pi rat ed engi ne:

Great er vol umet ric efficiencyImproved engi ne power and torqueReduced fuel consumpt ionReduced emi ss i onsRe-us e of exhaus t gas energyUn-affected by al ti tudeLimi ted periods of over-boos t for immediate engi ne demands .

Typi cal Rot ary Electronic Actuat ed Turbocharger

ItemPart NumberDescription

A-Low engine s peedB-Moderate engi ne s peed

C-Maximum engi ne s peed

1-ECM2-Rotary Electroni c Actuator

3-Rotary adjus ti ng ri ng

4-Vari abl e vanes5-Turbine wheel

In res pons e to s i gnal s from vari ous s ens ors , t he ECM cont rol s t he REA t o operate the rotary adjus ti ng ri ng. Movement oft he adjust ing ri ng alt ers t he pit ch angl e of the variable vanes t o deflect t he fl ow of exhaus t gas ont o t he i ns i de cent er orouts ide edge of t he t urbine wheel.

The maximum posi ti on of the turbocharger variable vanes (full y open) is als o the emergency default pos it ion i n t he eventof an electrical fault . The REA wil l move t he variable vanes t o t he ful ly open posi ti on t o prevent engi ne damage due toexces s ive boost press ure.

A - Low Engine Speed

Page 1027 of 3229

At low engi ne s peed t he volume of exhaust gas l eavi ng the engine is l ow. The vanes are moved toward the cl osed pos it iont o direct t he exhaus t gas fl ow t o t he out s ide edge of t he turbine wheel. The clos ed posi ti on of the vanes creates ares t ri ct ion t o t he gas fl ow and i ncreas es t he gas vel oci ty to the t urbine wheel . The turbi ne wheel s peed is increas ed,cons equent ly producing more charge ai r (boos t pres sure) from t he compres sor.

B - Moderate Engine Speed

As engine s peed and exhaus t gas vol ume increas e, the vanes are moved to the open posit ion t o direct t he exhaus t gasfl ow t oward t he center of the turbi ne wheel . The vanes do not rest ri ct the exhaus t gas flow and therefore exhaus t gasveloci ty is dependant on engine s peed. The t urbi ne wheel s peed is maintai ned due to the i ncreas ed velocit y of t he gas esleaving t he engine and being di rected t oward the center area of t he t urbine wheel .

C - Maximum Engine Speed

At maximum engine s peed the volume of exhaus t gas leavi ng t he engi ne is hi gh. The vanes are moved toward the full yopen pos i ti on and do not affect t he gas vel oci ty. The exhaus t gas fl ow contacts t he center area of t he t urbine wheel tomaint ain t he t urbine wheel s peed and boos t pres s ure from the compress or.

Over-Boost Pressure

Duri ng periods of medi um t o hard accelerat ion, the turbocharger is requi red t o produce a l imit ed period of over-boos tpres s ure from the compress or to meet the current engi ne fueli ng requirement. The ECM wil l reques t and all ow t he REA t omove t he variable vanes t oward t he clos ed posi ti on t o increas e t he vel oci ty of t he already high-s peed turbine wheel. Theover-boos t condit ion is all owed by t he ECM for t he l imi ted period.

Barometric Pressure Sensor

At high al ti tude t he t urbocharger wi ll functi on normal ly, but due t o t he l ower ambi ent ai r pres sure t he turbi ne andcompres sor may tend t o over-speed. A baromet ri c pres sure s ensor i s located i n t he ECM t o prevent over-boost andposs i bl e engine damage occurri ng under t hes e condit ions. The ECM opens t he vari abl e vanes earlier duri ng t he openi ngphas e to s uit the al ti tude of t he vehi cl e.

T urbocharger Lubrication

The rapi d accelerat ion and decelerat ion demands of t he turbocharger rel y on a s t eady flow of cl ean oil. The oi l suppli ed byt he engi ne lubri cat ion s ys tem provides l ubricati on to the t urbocharger shaft and bearings, whi le al so act ing as a cool antfor t he t urbocharger cent er hous i ng.

To mai nt ain the l ife expect ancy of t he turbocharger, t he engine oil mus t be replenished at regular s ervice i nt ervals wit ht he recommended qual it y and quant it y of oil . The oi l mus t have a free-fl ow t hrough the turbocharger and an unres trict edret urn to t he engine oi l pan.

Page 1035 of 3229

T orque:

10 Nm Inst all t he turbocharger outl et pi pe.

T orque: 25 Nm 5.

Inst all t he cat alyti c convert er.

Refer t o: Cat alyt ic Converter - Vehicles W it hout : Di es el Part iculate Fil ter (DPF) (309-00B Exhaus t Syst em - TD4 2.2L Di es el, Removal

and Inst all at ion).

6.

Inst all t he EGR cool er.

Refer t o: Exhaus t Gas Reci rculati on (EGR) Cooler (303-08B Engi ne

Emi ss i on Cont rol - TD4 2.2L Dies el, Removal and Ins tall ati on).

7.

Check and top-up the engine oi l.

8.

Page 1038 of 3229

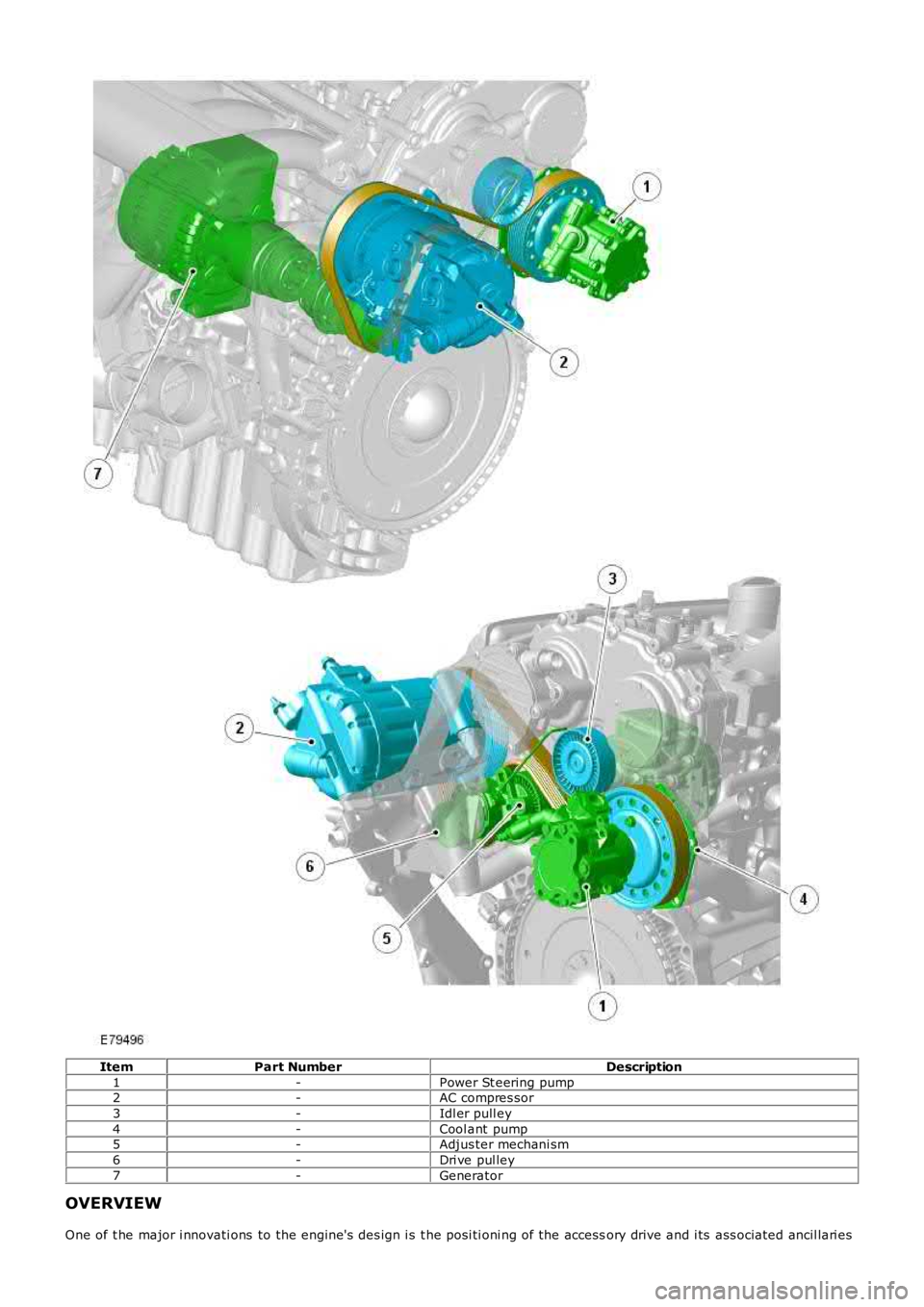

ItemPart NumberDescription

1-Power St eering pump2-AC compres sor

3-Idl er pull ey

4-Cool ant pump5-Adjus ter mechani sm

6-Dri ve pul ley

7-Generator

OVERVIEW

One of t he major i nnovati ons to the engine's des ign i s t he posi ti oni ng of the accessory drive and i ts ass ociated ancil lari es

Page 1039 of 3229

at the rear of the engine. The acces sory dri ve s ys t em overhangs the trans mi ss i on, allowing t he front of the engine to befree of prot rus ions . Thi s unique desi gn cont ri butes t o providi ng a compact and robust engine.

The polyvee access ory dri ve-bel t obtains i ts drive from a s haft , powered by t he crankshaft. The acces s ory drive-belt powerst he:

AC compres s or,engi ne cool ant pump, andpower st eering pump

The engi ne cool ant pump and the power-s t eering pump share a common coupl ing.

Belt t ens i on is maintai ned by an automat ic t ens i on s ys t em whi ch provi des a cons t ant tens ion wi thout bel t s li p.

The generator is direct ly at tached by a coupl ing t o t he rear of t he cranks haft driven s haft. Thi s direct dri ve arrangementimproves the generat or's durabi li ty by prevent ing s ide-loadings, caus ed by the tens ion of a drive belt , act ing on thegenerator's rot or bearing.

In addi ti on t o helping make the engine compact and robust , the novel arrangement of the access ory drive s ys tem als o aidsin reduci ng engi ne weight .

Page 1040 of 3229

Publi s hed: 11-May-2011

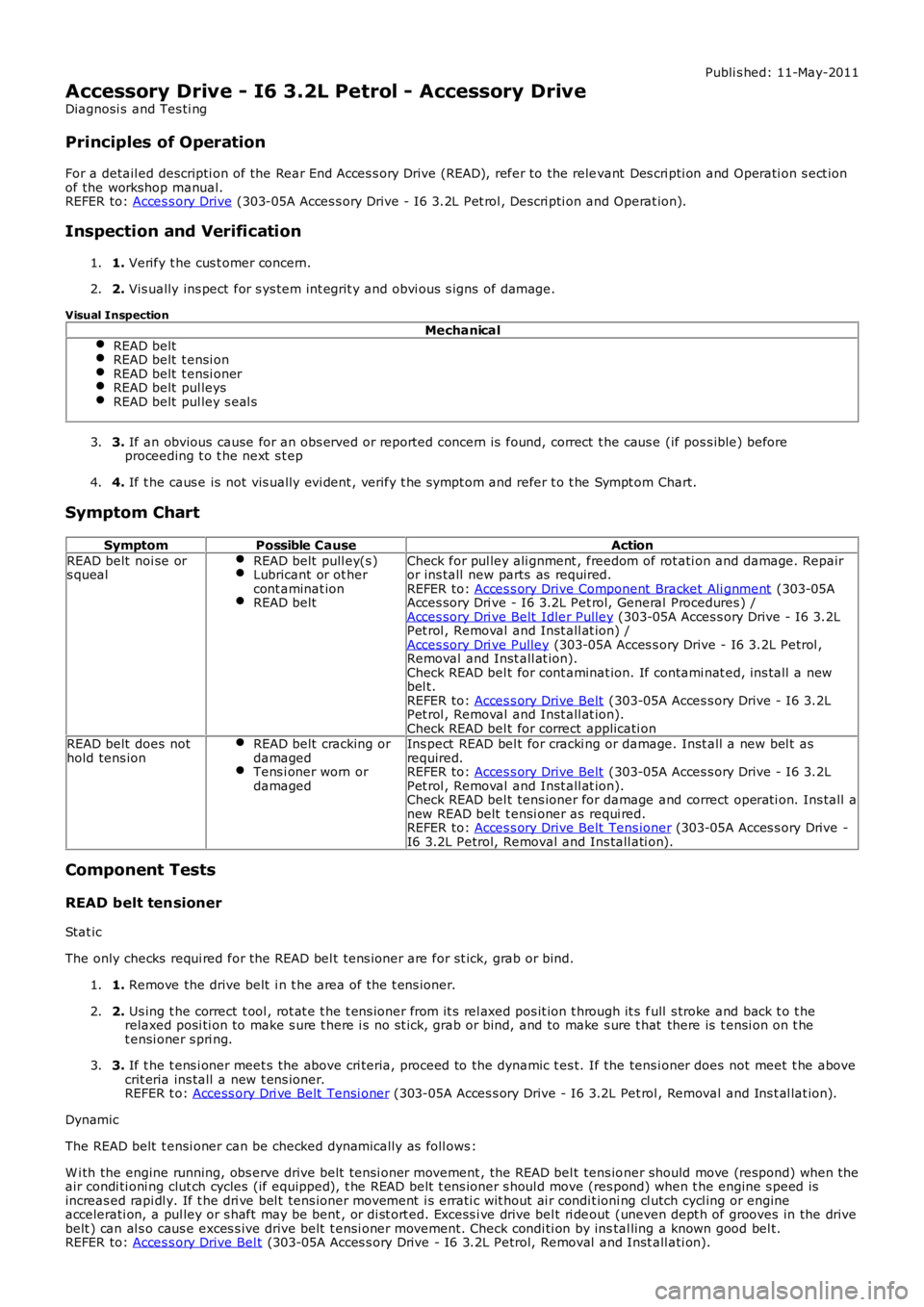

Accessory Drive - I6 3.2L Petrol - Accessory Drive

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the Rear End Acces s ory Drive (READ), refer to the relevant Des cri pti on and Operati on s ect ionof the workshop manual.REFER to: Acces s ory Drive (303-05A Acces s ory Drive - I6 3.2L Pet rol , Descri pti on and Operat ion).

Inspection and Verification

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for s ys tem int egrit y and obvi ous s igns of damage.2.

Visual Inspection

Mechanical

READ beltREAD belt t ensi onREAD belt t ensi onerREAD belt pul leysREAD belt pul ley s eal s

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Chart.4.

Symptom Chart

SymptomPossible CauseAction

READ belt noi se ors quealREAD belt pull ey(s )Lubricant or ot hercont aminat ionREAD belt

Check for pul ley ali gnment , freedom of rot ati on and damage. Repairor ins tall new parts as required.REFER to: Acces s ory Drive Component Bracket Ali gnment (303-05AAcces sory Dri ve - I6 3.2L Pet rol, General Procedures ) /Acces sory Dri ve Belt Idler Pulley (303-05A Acces s ory Drive - I6 3.2LPet rol , Removal and Inst all at ion) /Acces sory Dri ve Pulley (303-05A Acces s ory Drive - I6 3.2L Petrol ,Removal and Inst all at ion).Check READ bel t for cont aminat ion. If contami nat ed, ins tall a newbel t.REFER to: Acces s ory Drive Belt (303-05A Acces s ory Drive - I6 3.2LPet rol , Removal and Inst all at ion).Check READ bel t for correct applicati onREAD belt does nothold tens ionREAD belt cracking ordamagedTens i oner worn ordamaged

Ins pect READ bel t for cracki ng or damage. Inst all a new bel t asrequired.REFER to: Acces s ory Drive Belt (303-05A Acces s ory Drive - I6 3.2LPet rol , Removal and Inst all at ion).Check READ bel t tens ioner for damage and correct operati on. Ins tall anew READ belt t ensi oner as requi red.REFER to: Acces s ory Drive Belt Tens ioner (303-05A Acces s ory Drive -I6 3.2L Petrol, Removal and Ins tall ati on).

Component Tests

READ belt tensioner

Stat ic

The only checks requi red for the READ bel t tens ioner are for st ick, grab or bind.

1. Remove the drive belt i n t he area of t he t ens ioner.1.

2. Us ing t he correct t ool , rot at e t he t ens ioner from it s rel axed pos it ion t hrough it s full s troke and back t o t herelaxed posi ti on to make s ure t here i s no s t ick, grab or bind, and to make s ure t hat there is t ensi on on t het ensi oner s pri ng.

2.

3. If t he t ens i oner meet s the above cri teria, proceed to the dynamic t es t. If the tens ioner does not meet t he abovecrit eria ins tall a new t ens ioner.REFER t o: Access ory Dri ve Belt Tensi oner (303-05A Acces s ory Drive - I6 3.2L Pet rol , Removal and Ins t al lat ion).

3.

Dynamic

The READ belt t ensi oner can be checked dynamically as foll ows :

W i th the engine running, obs erve drive belt t ensi oner movement , the READ bel t tens ioner should move (respond) when theair condi ti oni ng clut ch cycles (if equipped), t he READ belt t ens ioner s houl d move (res pond) when t he engine s peed isincreas ed rapi dl y. If t he dri ve bel t tens ioner movement i s errati c wit hout ai r condit ioni ng cl utch cycl ing or engineaccelerati on, a pul ley or s haft may be bent , or di st ort ed. Excess i ve drive bel t ri deout (uneven dept h of grooves in the drivebelt ) can al s o caus e exces s ive drive belt t ensi oner movement. Check condi ti on by instal ling a known good bel t.REFER to: Acces s ory Drive Bel t (303-05A Acces s ory Drive - I6 3.2L Petrol, Removal and Inst all ati on).