engine LAND ROVER FRELANDER 2 2006 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 1234 of 3229

Publi s hed: 11-May-2011

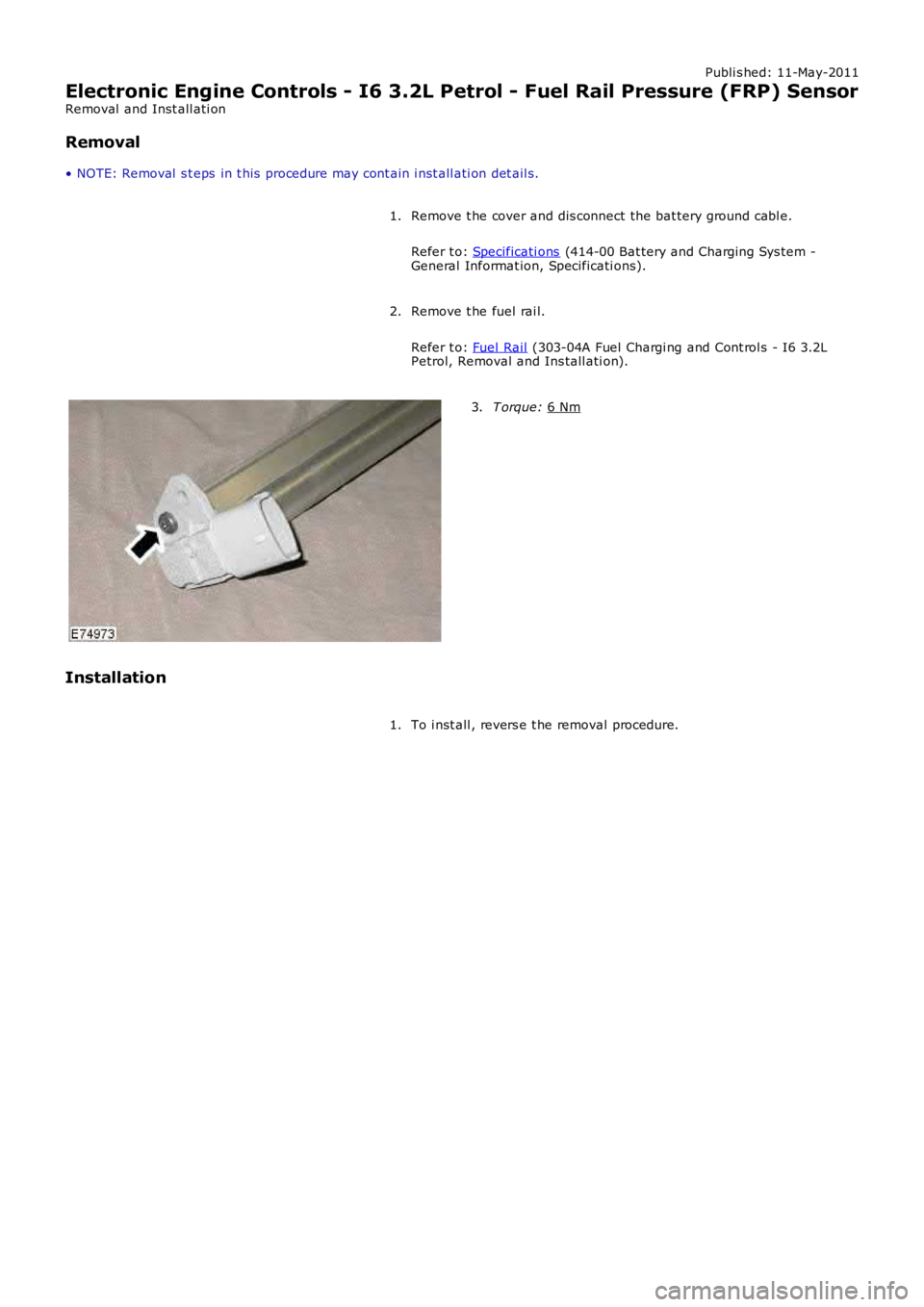

Electronic Engine Controls - I6 3.2L Petrol - Fuel Rail Pressure (FRP) Sensor

Removal and Inst all ati on

Removal

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

Remove t he cover and dis connect the bat tery ground cabl e.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -

General Informat ion, Specificati ons).

1.

Remove t he fuel rai l.

Refer t o: Fuel Rail (303-04A Fuel Chargi ng and Cont rol s - I6 3.2L

Petrol, Removal and Ins tall ati on).

2. T orque:

6 Nm 3.

Installation To i nst all , revers e t he removal procedure.

1.

Page 1235 of 3229

Publi s hed: 11-May-2011

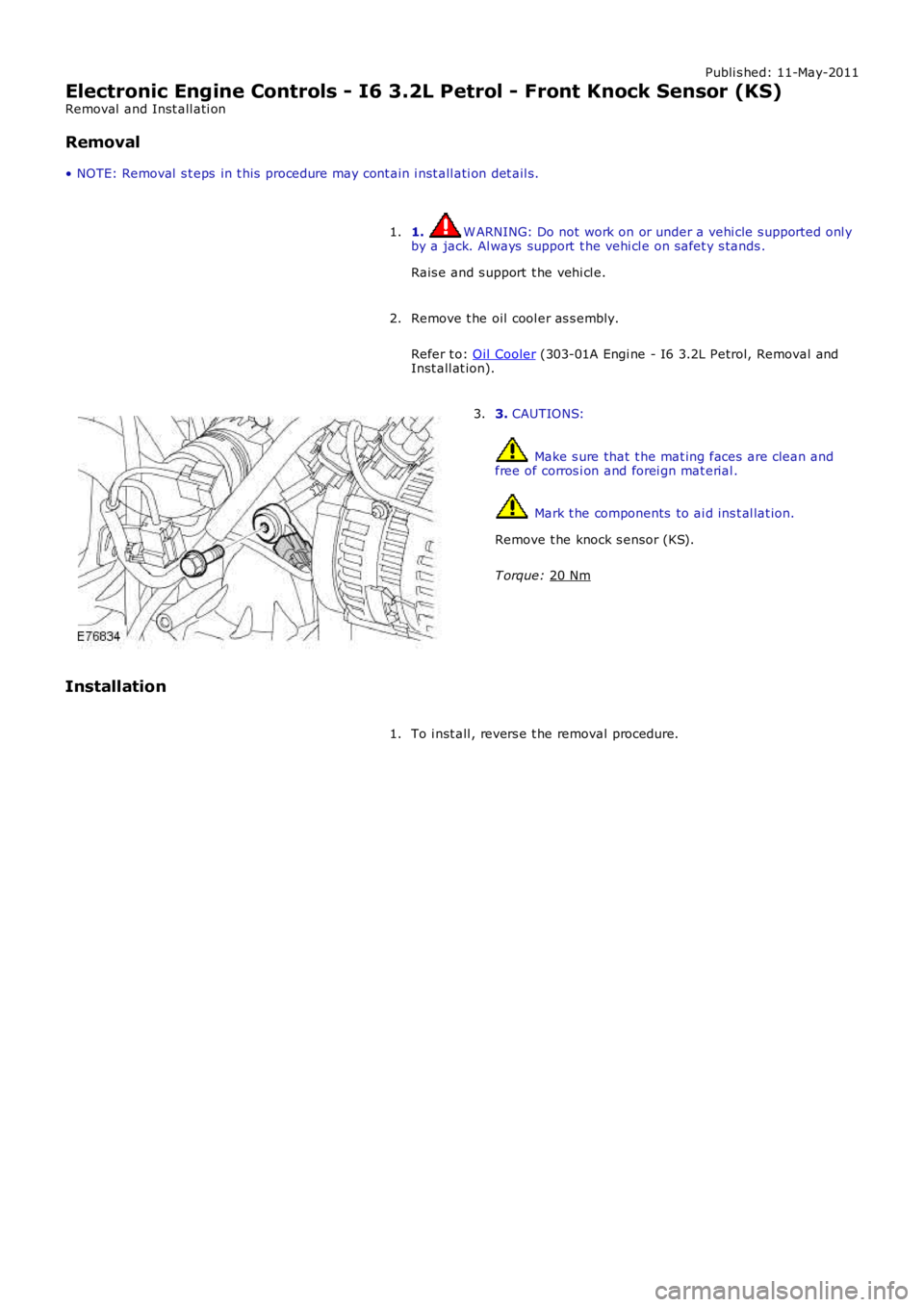

Electronic Engine Controls - I6 3.2L Petrol - Front Knock Sensor (KS)

Removal and Inst all ati on

Removal

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

1. W ARNING: Do not work on or under a vehi cle s upported onl y

by a jack. Al ways support t he vehi cl e on s afet y s tands .

Rais e and s upport t he vehi cl e.

1.

Remove t he oil cool er as s embly.

Refer t o: Oil Cooler (303-01A Engi ne - I6 3.2L Petrol, Removal and

Inst all at ion).

2. 3.

CAUTIONS: Make s ure that t he mat ing faces are clean and

free of corros i on and forei gn mat erial . Mark t he components to ai d ins t al lat ion.

Remove t he knock s ensor (KS).

T orque: 20 Nm 3.

Installation To i nst all , revers e t he removal procedure.

1.

Page 1236 of 3229

Publi s hed: 11-May-2011

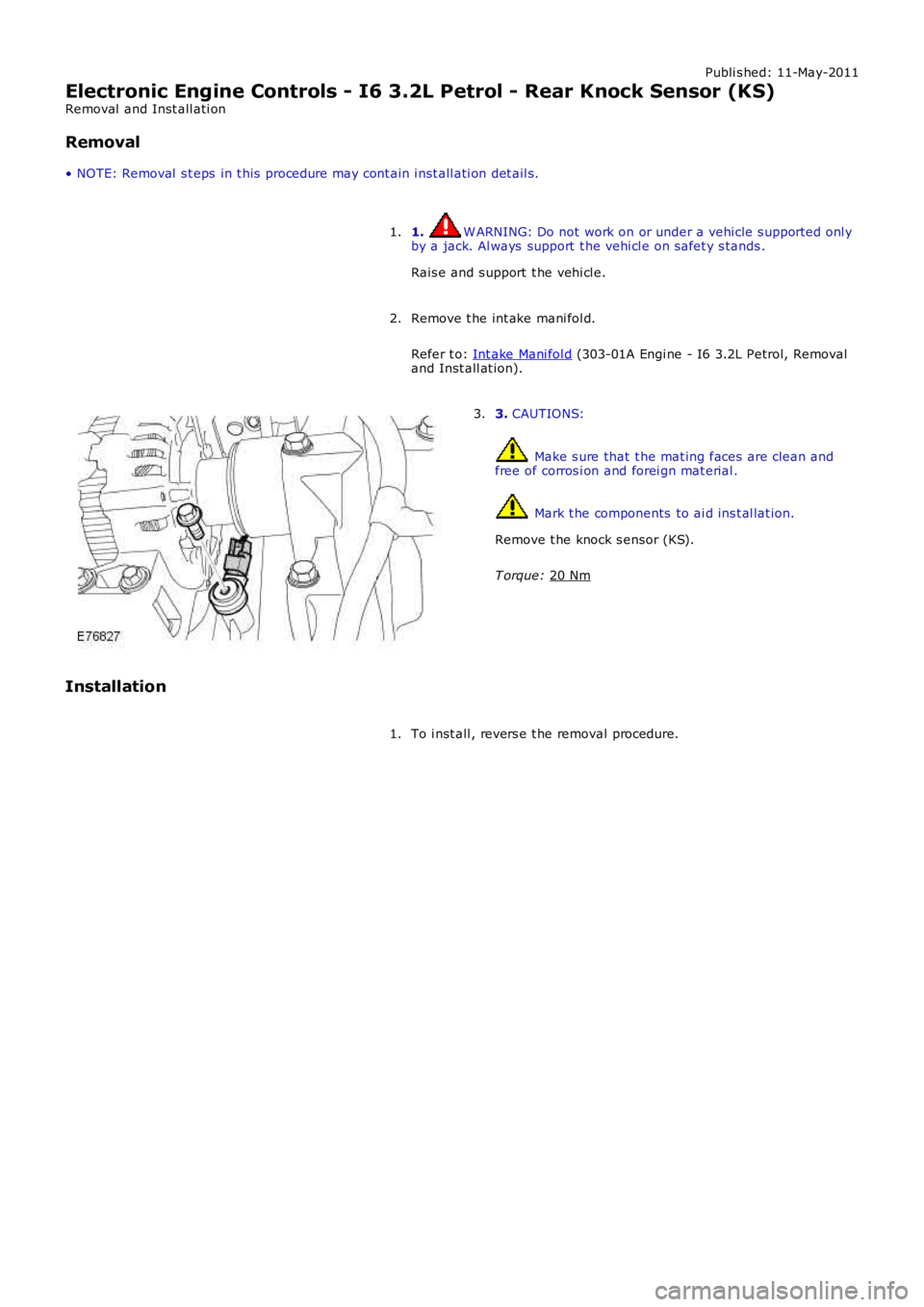

Electronic Engine Controls - I6 3.2L Petrol - Rear Knock Sensor (KS)

Removal and Inst all ati on

Removal

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

1. W ARNING: Do not work on or under a vehi cle s upported onl y

by a jack. Al ways support t he vehi cl e on s afet y s tands .

Rais e and s upport t he vehi cl e.

1.

Remove t he int ake mani fol d.

Refer t o: Int ake Mani fol d (303-01A Engi ne - I6 3.2L Petrol, Removal

and Inst all at ion).

2. 3.

CAUTIONS: Make s ure that t he mat ing faces are clean and

free of corros i on and forei gn mat erial . Mark t he components to ai d ins t al lat ion.

Remove t he knock s ensor (KS).

T orque: 20 Nm 3.

Installation To i nst all , revers e t he removal procedure.

1.

Page 1237 of 3229

Publi s hed: 11-May-2011

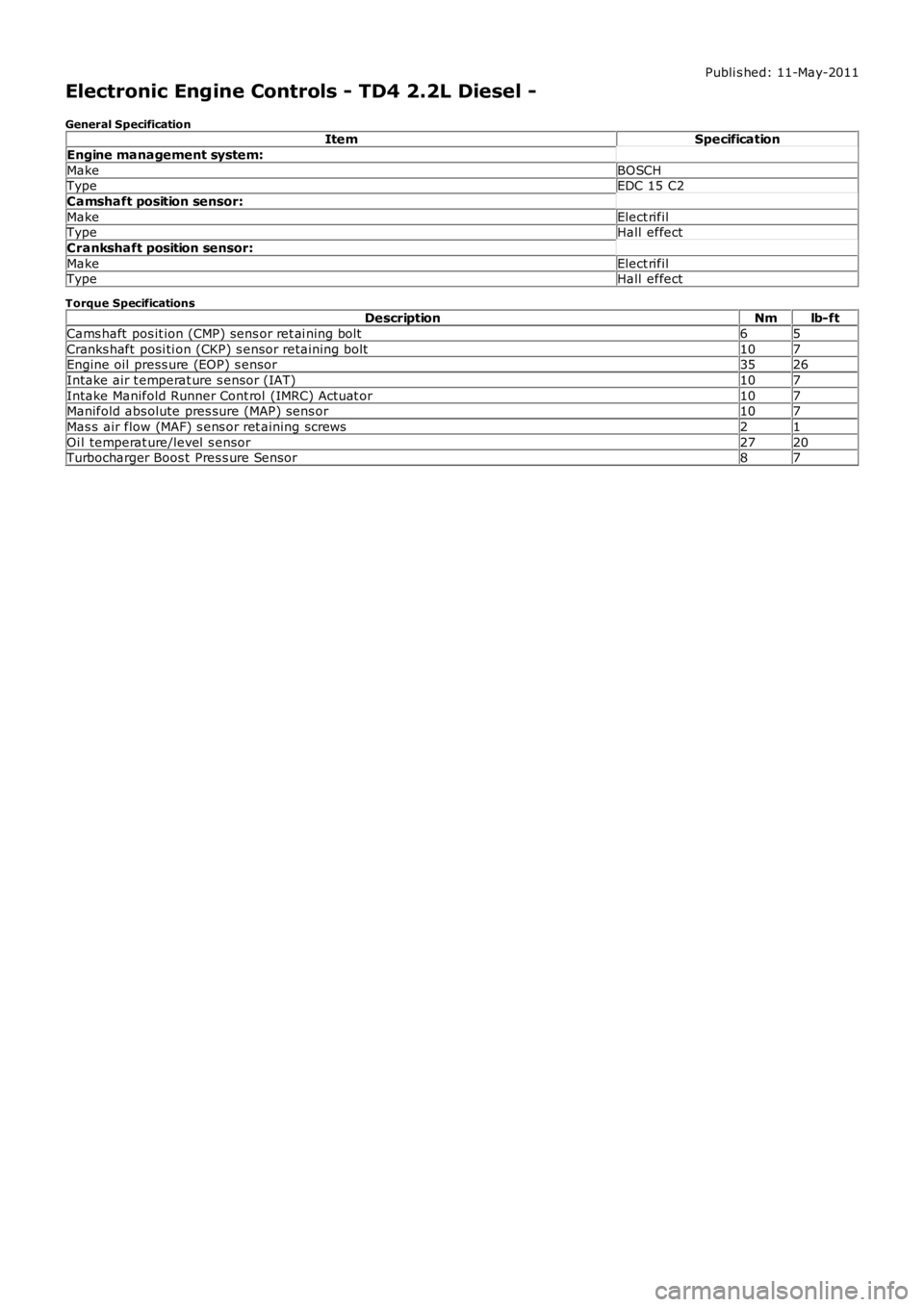

Electronic Engine Controls - TD4 2.2L Diesel -

General SpecificationItemSpecification

Engine management system:

MakeBOSCHTypeEDC 15 C2

Camshaft position sensor:

MakeElect rifilTypeHall effect

Crankshaft position sensor:

MakeElect rifilTypeHall effect

Torque SpecificationsDescriptionNmlb-ft

Cams haft pos it ion (CMP) sens or ret ai ning bolt65

Cranks haft posi ti on (CKP) s ensor retaini ng bolt107Engine oil press ure (EOP) s ensor3526

Intake air t emperat ure s ensor (IAT)107

Intake Manifold Runner Cont rol (IMRC) Actuat or107Manifold abs olute pres sure (MAP) sens or107

Mas s air flow (MAF) s ens or ret aining screws21

Oi l temperat ure/level s ensor2720Turbocharger Boos t Pres s ure Sensor87

Page 1238 of 3229

Publi s hed: 11-May-2011

Electronic Engine Controls - TD4 2.2L Diesel - Electronic Engine Controls

Des cript ion and Operat ion

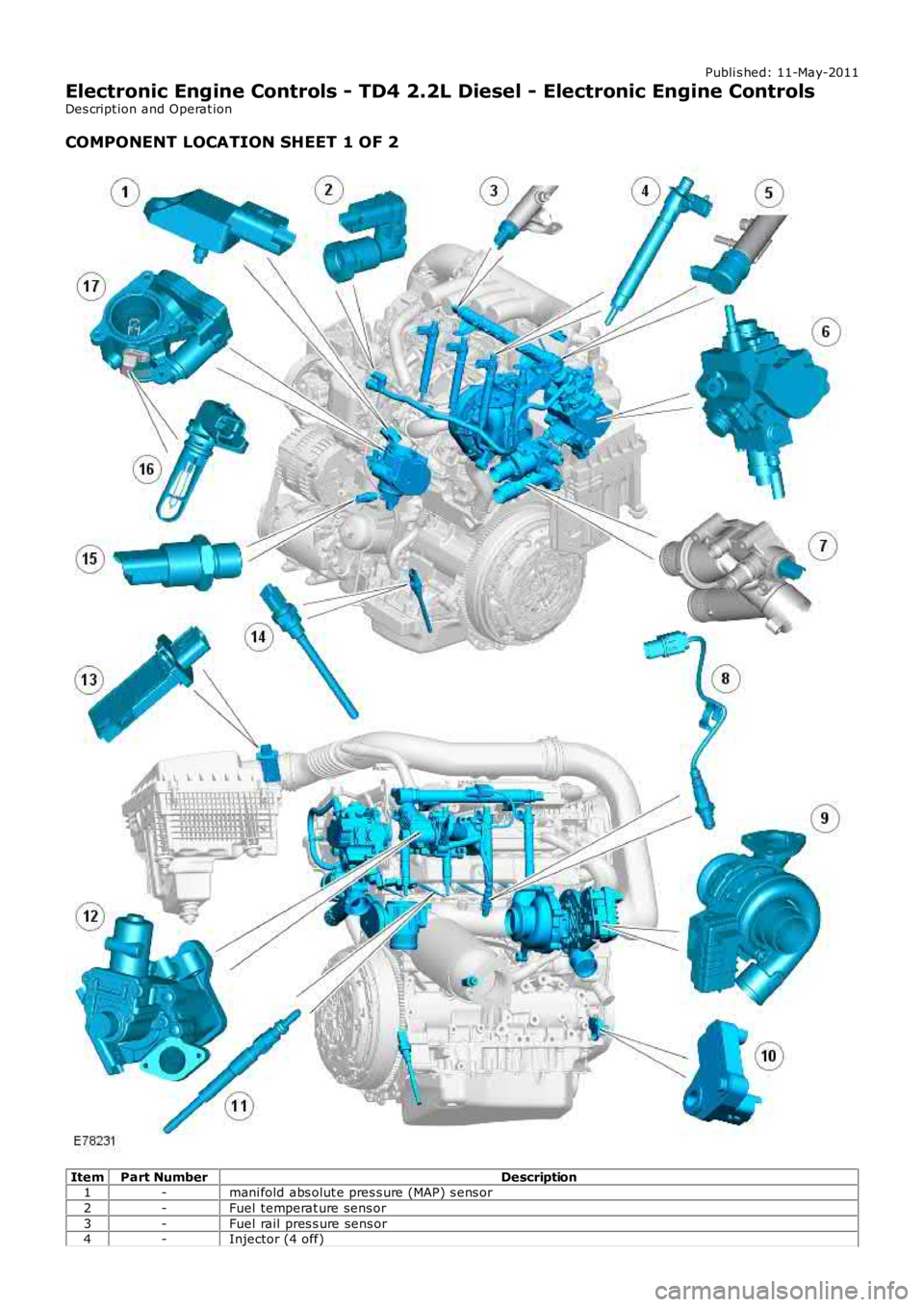

COMPONENT LOCATION SHEET 1 OF 2

ItemPart NumberDescription1-mani fold abs olut e pres s ure (MAP) s ens or

2-Fuel temperat ure sens or

3-Fuel rail pres s ure sens or4-Injector (4 off)

Page 1239 of 3229

5-Pres s ure cont rol val ve

6-Fuel pump (i ncorporati ng vol ume control valve)

7-engine coolant temperature (ECT) s ens or8-heated oxygen s ens or (HO 2S)

9-Variable nozzle t urbocharger (VNT) cont roll er

10-cranks haft posi ti on (CKP) s ensor11-Gl ow plugs (4 off)

12-exhaus t gas reci rculati on (EGR) valve

13-mas s ai r fl ow (MAF)/i ntake air t emperat ure (IAT) s ens or14-Oi l level and t emperat ure s ens or (Dies el Parti cul ate Fi lt er (DPF) vehi cl es onl y)

15-engine oi l press ure (EOP) s ensor

16-IAT s ensor17-El ect ri c throt t le

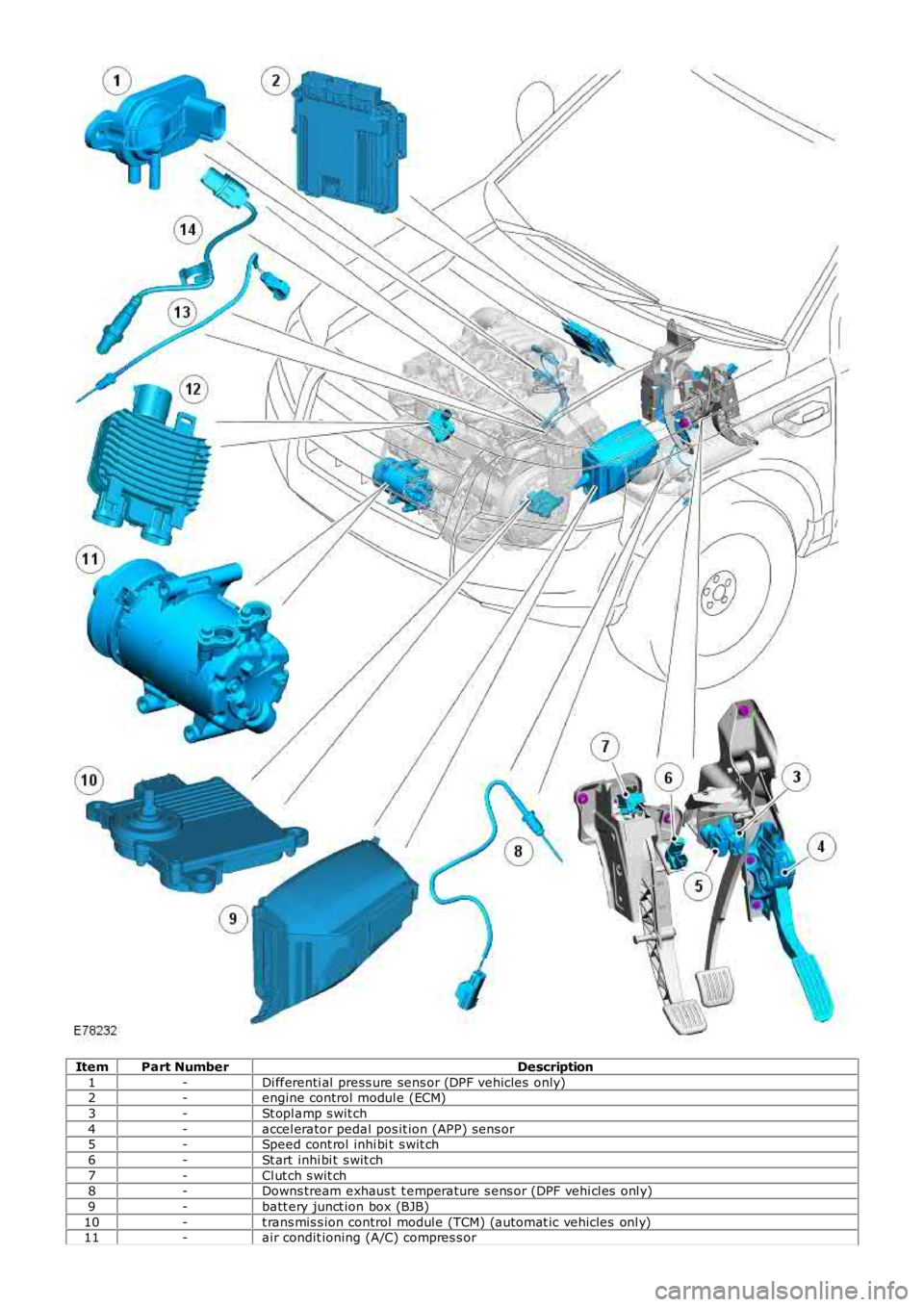

COMPONENT LOCATION SHEET 2 OF 2

• NOTE: left-hand (LH) drive vehi cle s hown, ri ght -hand (RH) dri ve si mil ar

Page 1240 of 3229

ItemPart NumberDescription

1-Di fferenti al press ure sens or (DPF vehicles only)2-engine control modul e (ECM)

3-St opl amp s wit ch

4-accel erator pedal pos it ion (APP) sens or5-Speed cont rol inhi bi t s wit ch

6-St art inhi bi t s wit ch

7-Cl ut ch s wit ch8-Downs tream exhaus t t emperature s ens or (DPF vehi cl es onl y)

9-batt ery junct ion box (BJB)

10-t rans mis s ion control modul e (TCM) (automat ic vehicles onl y)11-air condit ioning (A/C) compres s or

Page 1241 of 3229

12-Cooli ng fan control modul e

13-Ups tream t emperat ure s ensor (DPF vehi cl es only)

14-Heated oxygen s ens or

OVERVIEW

The TD4 dies el engi ne has an Electroni c Dies el Cont rol (EDC) engine management s yst em. The s ys t em i s cont rol led by anECM whi ch is able to monit or, adapt and preci sel y cont rol t he fuel inject ion. The ECM us es mult iple s ens or inputs andprecis ion control of act uat ors t o achieve opti mum performance during all driving condit ions.

The ECM controls fuel deli very t o all 4 cyli nders via a common rai l inject ion s yst em. The common rail s ys t em us es a fuelrai l to accumulate highly press uri zed fuel and feed t he 4, electroni cal ly controlled injectors . The fuel rail i s located i n clos eproximit y to the i njectors, whi ch ass is t s in maint aining full s yst em press ure at each i njector at all t imes .

The ECM us es t he drive by wire pri nci pl e for accelerat ion control. Accelerator pedal demand i s communicat ed t o t he ECM by2 pot ent iomet ers l ocat ed in a thrott le pos it ion sens or. The ECM us es t he 2 s ignals to det ermi ne the pos it ion, rat e ofmovement and di recti on of movement of t he pedal . The ECM t hen uses t his dat a, al ong wit h ot her engine i nformati on fromother s ens ors, t o achieve the opt imum engine respons e.

The ECM proces ses informati on from t he followi ng input s ources :

camshaft pos i ti on (CMP)CKPManifol d air t emperat ure and press ureEngi ne cool ant temperat ureOil t emperat ureInt ake air flow and t emperat ureFuel t emperat ure

The ECM out put s cont rol li ng si gnal s t o t he foll owing s ens ors and actuators :

Fuel i njectors (4 off)Cooling fan control modul eElectric t hrot tl e valveElectroni c vane cont roll ed t urbochargerPort deact ivat ionFuel pres s ure cont rol val veFuel volume cont rol val veEGRGlow plugs (4 off).

CONTROL DIAGRAM SHEET 1 OF 2

• NOTE: A = Hardwi red

Page 1246 of 3229

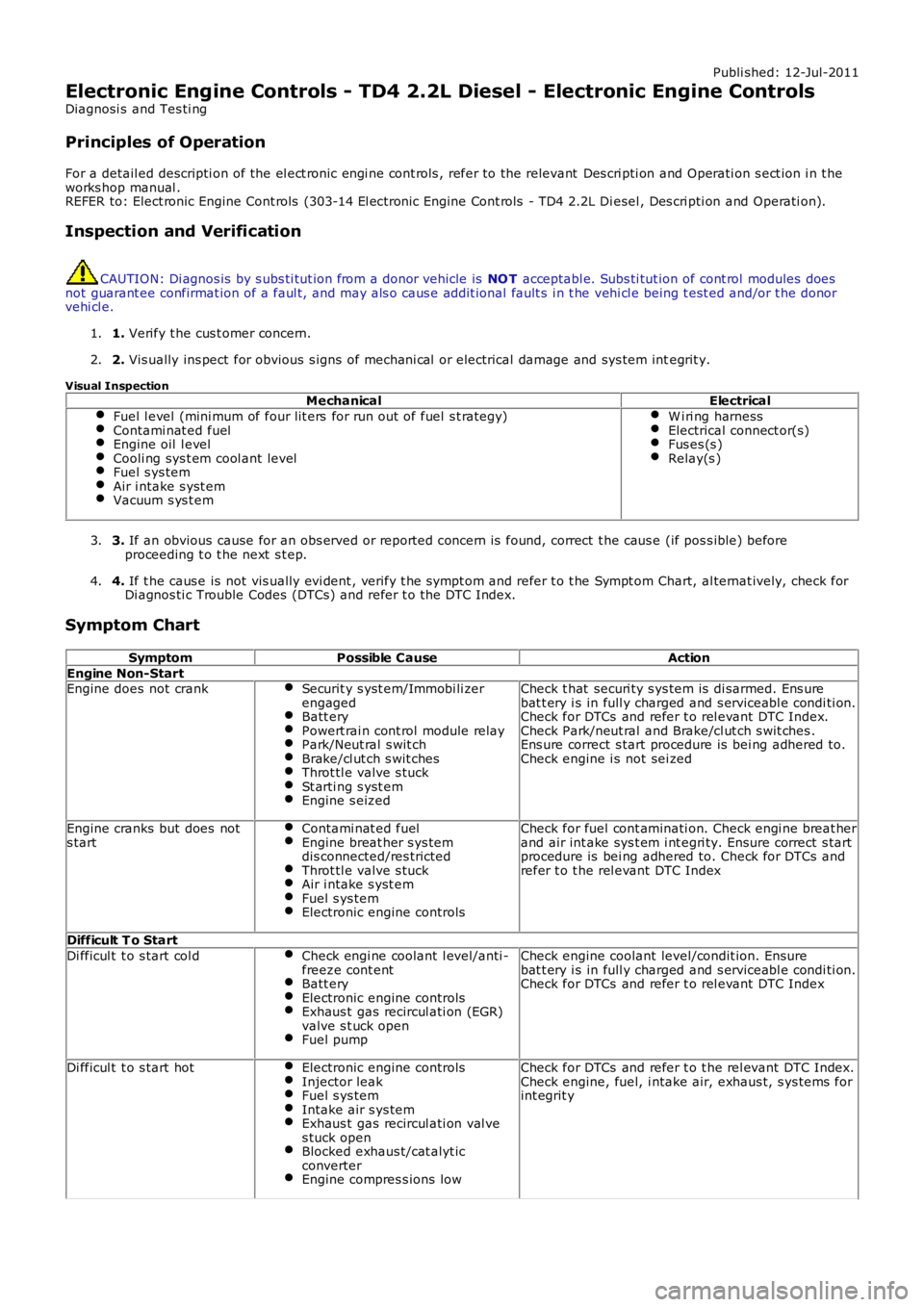

Publi shed: 12-Jul-2011

Electronic Engine Controls - TD4 2.2L Diesel - Electronic Engine Controls

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the el ect ronic engi ne cont rols , refer to the relevant Des cri pti on and Operati on s ect ion i n t heworks hop manual .REFER to: Elect ronic Engine Cont rols (303-14 El ect ronic Engine Cont rols - TD4 2.2L Di esel , Des cri pti on and Operati on).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage and sys tem integrit y.2.

Visual InspectionMechanicalElectrical

Fuel l evel (mini mum of four lit ers for run out of fuel s t rategy)Contami nat ed fuelEngine oil l evelCooli ng sys t em cool ant levelFuel s ys temAir i ntake s yst emVacuum s ys t em

W i ri ng harnessElectrical connect or(s)Fus es (s )Relay(s )

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep.3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Chart, al ternat ively, check forDi agnos ti c Trouble Codes (DTCs) and refer t o t he DTC Index.4.

Symptom Chart

SymptomPossible CauseAction

Engine Non-StartEngine does not crankSecurit y s yst em/Immobi li zerengagedBatt eryPowert rai n cont rol module relayPark/Neut ral s wit chBrake/cl ut ch s wit chesThrot tl e valve s tuckSt arti ng s yst emEngine s eized

Check t hat securi ty s ys tem is di sarmed. Ens urebat t ery i s in full y charged and s erviceabl e condi ti on.Check for DTCs and refer t o rel evant DTC Index.Check Park/neut ral and Brake/cl ut ch s wit ches .Ens ure correct s tart procedure is bei ng adhered to.Check engine i s not sei zed

Engine cranks but does nots tartContami nat ed fuelEngine breat her s ys temdis connected/res trictedThrot tl e valve s tuckAir i ntake s yst emFuel s ys temElectronic engine controls

Check for fuel cont aminati on. Check engi ne breat herand air int ake sys t em i nt egri ty. Ensure correct s tartprocedure is bei ng adhered to. Check for DTCs andrefer t o t he rel evant DTC Index

Difficult T o Start

Di fficul t t o s tart col dCheck engi ne coolant l evel/anti -freeze cont entBatt eryElectronic engine controlsExhaus t gas recircul ati on (EGR)valve s t uck openFuel pump

Check engine coolant level/condit ion. Ensurebat t ery i s in full y charged and s erviceabl e condi ti on.Check for DTCs and refer t o rel evant DTC Index

Di fficul t t o s tart hotElectronic engine controlsInjector leakFuel s ys temIntake air s ys temExhaus t gas recircul ati on val ves tuck openBlocked exhaus t/cat alyt icconverterEngine compres s ions low

Check for DTCs and refer t o t he rel evant DTC Index.Check engine, fuel, i ntake air, exhaus t, s ys tems forint egrit y

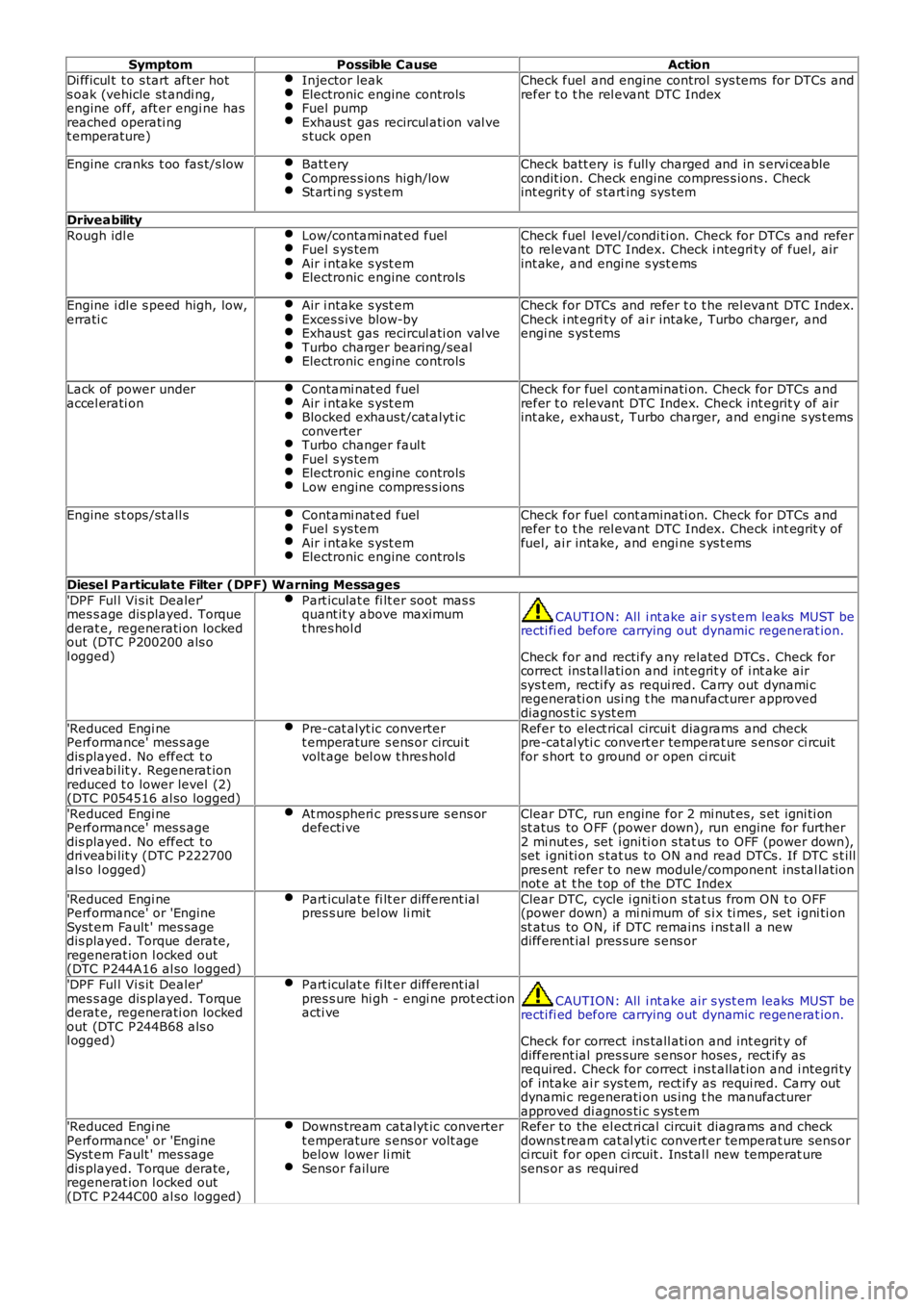

Page 1247 of 3229

SymptomPossible CauseAction

Di fficul t t o s tart aft er hots oak (vehicle st andi ng,engine off, aft er engi ne hasreached operati ngt emperature)

Injector leakElectronic engine controlsFuel pumpExhaus t gas recircul ati on val ves tuck open

Check fuel and engine control sys tems for DTCs andrefer t o t he rel evant DTC Index

Engine cranks t oo fas t/s lowBatt eryCompres s ions high/lowSt arti ng s yst em

Check batt ery is fully charged and in s ervi ceablecondit ion. Check engine compres s ions . Checkint egrit y of s tart ing sys tem

Driveability

Rough idl eLow/contami nat ed fuelFuel s ys temAir i ntake s yst emElectronic engine controls

Check fuel l evel /condi ti on. Check for DTCs and referto relevant DTC Index. Check i ntegri ty of fuel, airint ake, and engi ne s yst ems

Engine i dl e s peed high, low,errati cAir i ntake s yst emExces s ive blow-byExhaus t gas recircul ati on val veTurbo charger bearing/sealElectronic engine controls

Check for DTCs and refer t o t he rel evant DTC Index.Check i nt egri ty of ai r intake, Turbo charger, andengi ne s ys t ems

Lack of power underaccel erati onContami nat ed fuelAir i ntake s yst emBlocked exhaus t/cat alyt icconverterTurbo changer faul tFuel s ys temElectronic engine controlsLow engine compres s ions

Check for fuel cont aminati on. Check for DTCs andrefer t o relevant DTC Index. Check int egrit y of airint ake, exhaus t, Turbo charger, and engi ne s ys t ems

Engine s t ops /st all sContami nat ed fuelFuel s ys temAir i ntake s yst emElectronic engine controls

Check for fuel cont aminati on. Check for DTCs andrefer t o t he rel evant DTC Index. Check int egrit y offuel, ai r intake, and engi ne s ys t ems

Diesel Particulate Filter (DPF) Warning Messages

'DPF Ful l Vi s it Dealer'mes s age dis played. Torquederat e, regenerati on lockedout (DTC P200200 als ol ogged)

Part iculat e fi lt er soot mas squant it y above maximumt hres hol dCAUTION: All i nt ake air s yst em leaks MUST berecti fi ed before carrying out dynamic regenerat ion.

Check for and recti fy any related DTCs . Check forcorrect ins tal lati on and int egrit y of i nt ake airsys t em, recti fy as requi red. Carry out dynami cregenerati on usi ng t he manufacturer approveddiagnos t ic s yst em

'Reduced Engi nePerformance' mes s agedis played. No effect t odri veabi lit y. Regenerat ionreduced t o lower level (2)(DTC P054516 al so logged)

Pre-cat alyt ic convertert emperature s ens or circui tvolt age bel ow t hres hol d

Refer to elect rical circui t diagrams and checkpre-cat al yti c convert er temperat ure s ens or ci rcuitfor s hort t o ground or open ci rcuit

'Reduced Engi nePerformance' mes s agedis played. No effect t odri veabi lit y (DTC P222700als o l ogged)

At mospheri c pres s ure s ens ordefecti veClear DTC, run engine for 2 mi nut es, s et igni ti onst atus to O FF (power down), run engine for further2 mi nut es , set i gni ti on s tat us to OFF (power down),set i gni ti on s tat us to ON and read DTCs. If DTC s t illpres ent refer t o new module/component ins tal lati onnot e at t he t op of the DTC Index

'Reduced Engi nePerformance' or 'EngineSyst em Fault ' mes sagedis played. Torque derate,regenerat ion l ocked out(DTC P244A16 al so logged)

Part iculat e fi lt er different ialpres s ure bel ow li mitClear DTC, cycle i gni ti on s tat us from ON t o OFF(power down) a mi ni mum of s i x ti mes , set i gni ti onst atus to O N, if DTC remains i ns t all a newdifferent ial pres sure s ens or

'DPF Ful l Vi s it Dealer'mes s age dis played. Torquederat e, regenerati on lockedout (DTC P244B68 als ol ogged)

Part iculat e fi lt er different ialpres s ure hi gh - engi ne prot ect ionacti veCAUTION: All i nt ake air s yst em leaks MUST berecti fi ed before carrying out dynamic regenerat ion.

Check for correct ins tall ati on and int egrit y ofdifferent ial pres sure s ens or hoses , rect ify asrequired. Check for correct i ns t allat ion and i ntegri tyof intake ai r sys tem, rect ify as requi red. Carry outdynami c regenerati on us ing t he manufacturerapproved di agnos ti c s ys t em'Reduced Engi nePerformance' or 'EngineSyst em Fault ' mes sagedis played. Torque derate,regenerat ion l ocked out(DTC P244C00 al so logged)

Downs tream catalyt ic convertert emperature s ens or volt agebelow lower li mitSensor failure

Refer to the el ect ri cal circui t diagrams and checkdowns t ream cat al yti c convert er temperat ure sens orci rcuit for open ci rcuit . Ins tal l new temperat uresens or as required