engine LAND ROVER FRELANDER 2 2006 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 1624 of 3229

A CANCEL s wit ch.

The s ys t em al so uses t he fol lowi ng:

The ECMThe s toplamp s wit ch.The APP s ens orA clut ch s wit ch

The ECM controls t he s et speed by modi fying engine speed/t orque and reques ti ng gearchanges from the t rans mis s ion(aut omati c variant s only).

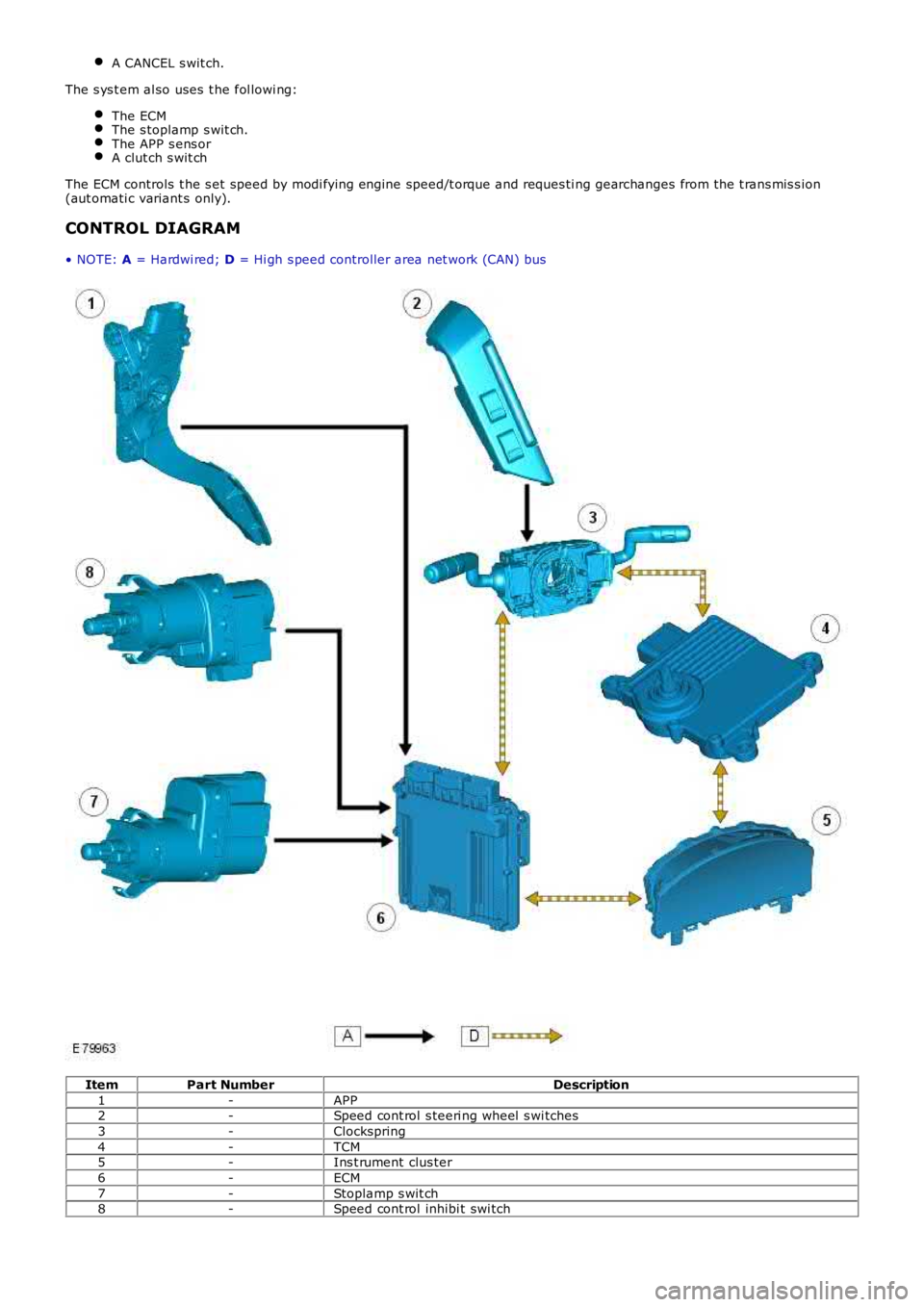

CONTROL DIAGRAM

• NOTE: A = Hardwi red; D = Hi gh s peed controller area net work (CAN) bus

ItemPart NumberDescription

1-APP2-Speed cont rol s teeri ng wheel s wi tches

3-Clockspring

4-TCM5-Ins t rument clus ter

6-ECM

7-Stoplamp s wit ch8-Speed cont rol inhibi t swi tch

Page 1635 of 3229

Publi s hed: 11-May-2011

Climate Control - Heating and Ventilation

Des cript ion and Operat ion

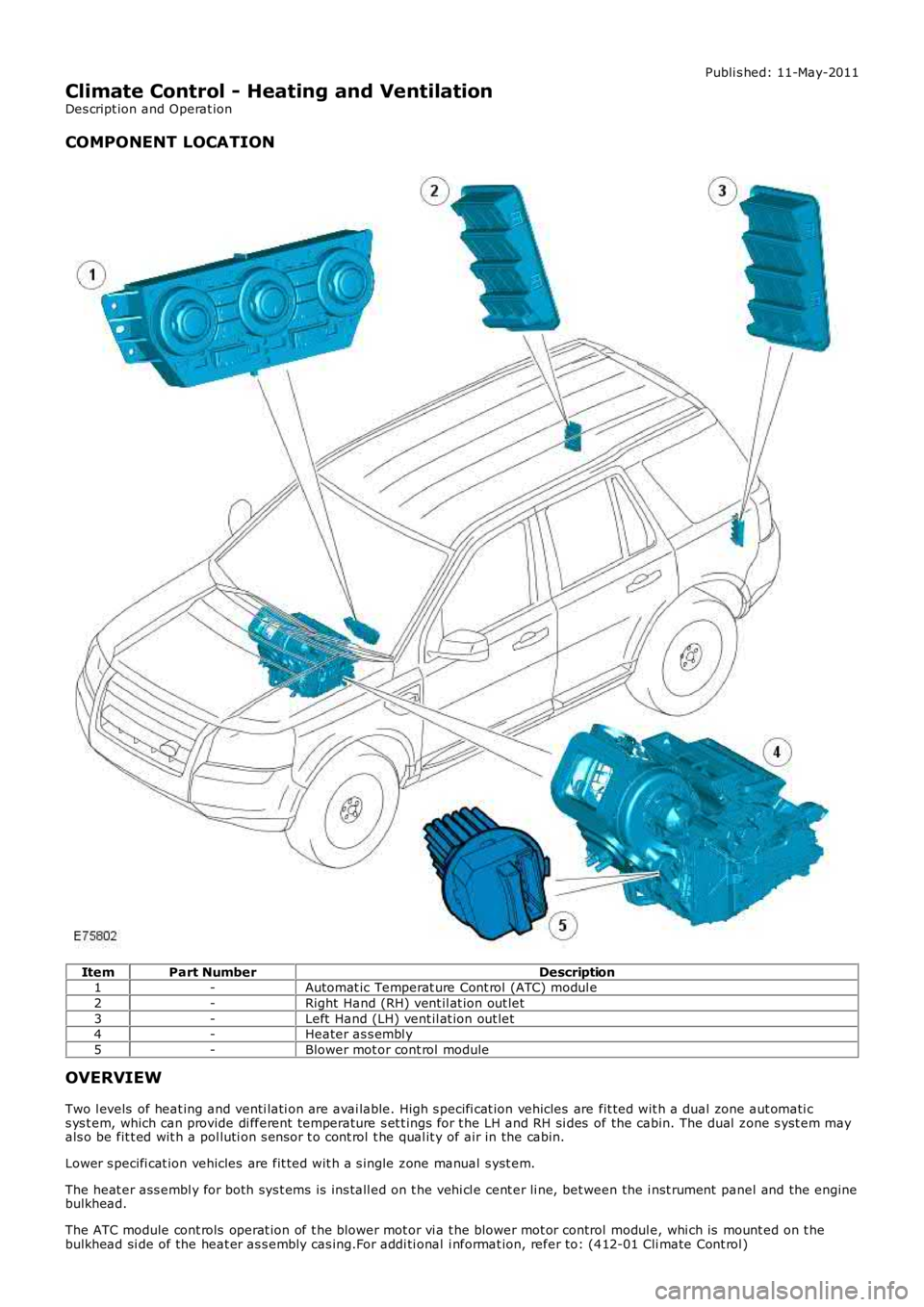

COMPONENT LOCATION

ItemPart NumberDescription1-Automat ic Temperat ure Cont rol (ATC) modul e

2-Right Hand (RH) vent il at ion out let

3-Left Hand (LH) vent il at ion out let4-Heater as s embl y

5-Blower mot or cont rol module

OVERVIEW

Two l evels of heat ing and venti lati on are avai lable. High s pecifi cat ion vehicles are fit ted wit h a dual zone aut omati cs ys t em, which can provide di fferent temperature s et t ings for t he LH and RH si des of the cabin. The dual zone s yst em mayals o be fit t ed wit h a pol luti on s ens or t o cont rol t he qual it y of air in the cabin.

Lower s pecifi cat ion vehicles are fit ted wit h a s ingle zone manual s yst em.

The heat er ass embl y for both sys t ems is ins tall ed on t he vehi cl e cent er li ne, bet ween the i nst rument panel and the enginebulkhead.

The ATC module cont rols operat ion of t he blower mot or vi a t he blower mot or control modul e, whi ch is mount ed on t hebulkhead si de of the heat er as s embly cas ing.For addi ti onal i nformat ion, refer to: (412-01 Cli mate Cont rol )

Page 1637 of 3229

Blower mot orHeater coreCabin ai r fil ter.For addit ional informat ion, refer t o: Air Di st ri buti on and Fi lt eri ng (412-01 Climat e Cont rol, Des cript ion andOperat ion).A/C evaporat or.For addit ional informat ion, refer t o: Air Condit ioning (412-01 Cli mat e Cont rol , Descripti on and Operat ion).Air i ntake flap and s tepper motor.For addit ional informat ion, refer t o: Cont rol Component s (412-01 Cli mat e Cont rol , Descripti on and Operat ion).Air di st ri but ion fl aps and s t epper mot ors .For addit ional informat ion, refer t o: Cont rol Component s (412-01 Cli mat e Cont rol , Descripti on and Operat ion).Temperature blend flaps and s t epper mot ors .For addit ional informat ion, refer t o: Cont rol Component s (412-01 Cli mat e Cont rol , Descripti on and Operat ion).Electric boos ter heater (if fi tt ed).For addit ional informat ion, refer t o: Electric Boos ter Heater (412-02 Auxi li ary Cl imat e Control, Des cript ion andOperat ion).

Blower Motor

The blower mot or compris es an open hub, centrifugal fan powered by an elect ric motor. Operati on of the bl ower motor iscont rol led by t he ATC module in conjuncti on wit h t he blower mot or control modul e. The ATC module provi des a Puls e W i dthModulated (PW M) si gnal t o t he blower motor control modul e based on the requi red bl ower speed. The bl ower motor cont rolmodule i nterprets the PW M s ignal as a blower mot or speed and controls t he volt age to t he blower mot or accordingl y.For addit ional informat ion, refer t o: Cont rol Component s (412-01 Cli mat e Cont rol , Descripti on and Operat ion).

Heater Core

The heat er core provi des t he heat s ource to warm the ai r bei ng s uppl ied i nto t he cabin. The heat er core is an alumi num, 2pass , fin and t ube heat exchanger ins t al led acros s t he widt h of t he heat er ass embly. Two al uminum tubes att ached t o t heheat er core extend t hrough t he engi ne bulkhead and connect t o t he engine cool ing s ystem. W hen the engine is runni ng,engi ne cool ant is const antl y ci rculat ed through the heater core by the coolant pump. For addit ional informati on, refer t o:

Engi ne Cool ing (303-03A Engine Cooli ng - I6 3.2L Petrol, Des cript ion and Operat ion),Engi ne Cool ing (303-03B Engine Cooli ng - TD4 2.2L Di esel , Descri pti on and Operat ion).

VENTILATION OUTLETS

The vent il ati on out let s all ow t he free flow of ai r through t he cabi n. The out let s are ins tall ed in the LH and RH rear quart erpanel s, behind the t ail lamps .

Each vent ilat ion out let compri ses a gril le covered by a s oft rubber fl ap, and i s effect ively a non-ret urn val ve. The flapsopen and cl ose aut omat ical ly depending on t he different ial between cabin and out si de air pres s ures .

PRINCIPLES OF OPERATION

Operat ion of t he heat ing and venti lat ion s ys tem is controlled by the ATC modul e.For addit ional informat ion, refer t o: Cont rol Component s (412-01 Cli mat e Cont rol , Descripti on and Operat ion).

Page 1639 of 3229

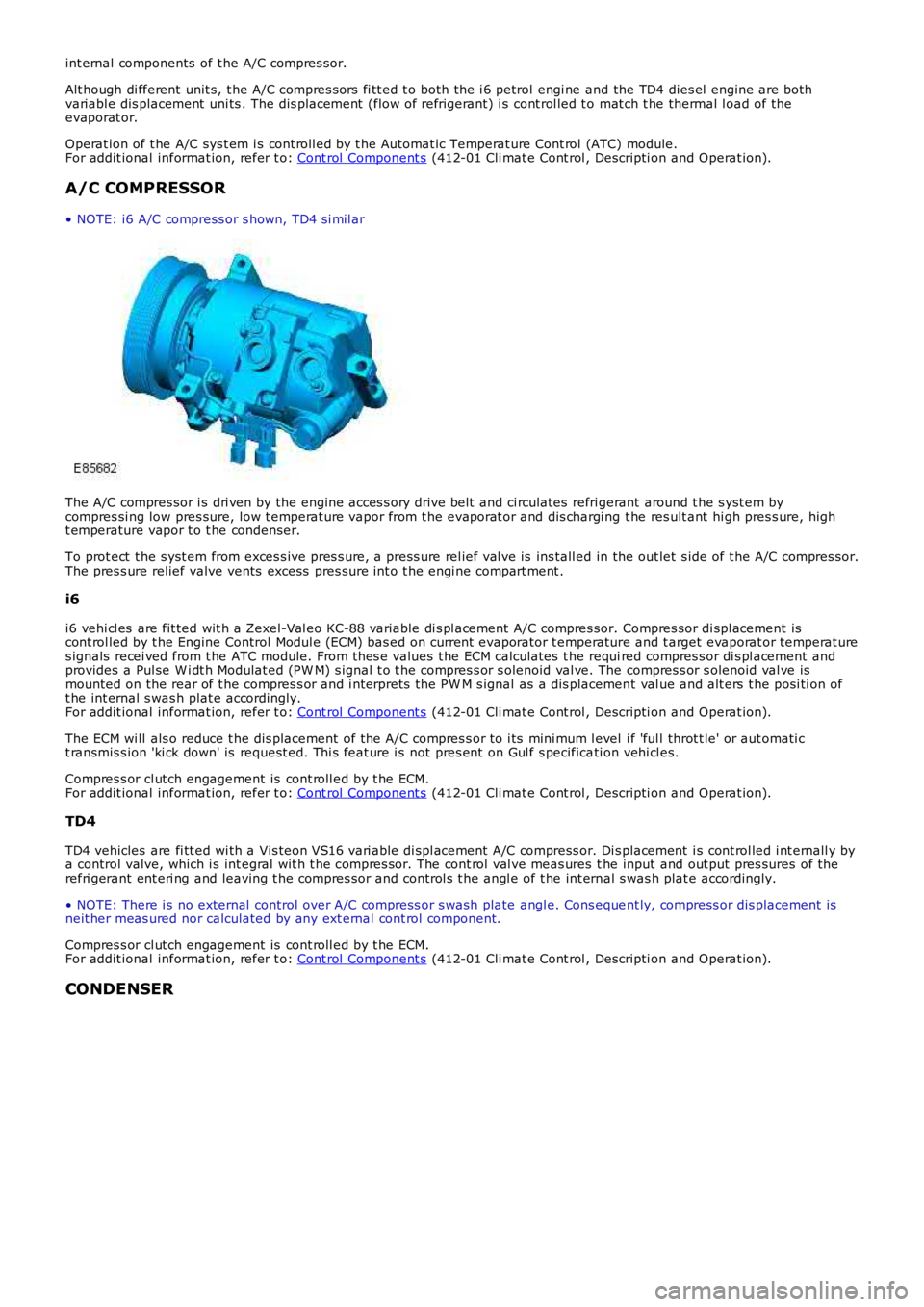

int ernal components of t he A/C compres sor.

Alt hough di fferent unit s, t he A/C compres sors fi tt ed t o both the i 6 petrol engi ne and the TD4 dies el engine are bothvariabl e dis placement uni ts . The dis placement (flow of refrigerant) i s cont rol led t o mat ch t he thermal l oad of theevaporat or.

Operat ion of t he A/C sys t em i s cont roll ed by t he Automat ic Temperat ure Cont rol (ATC) module.For addit ional informat ion, refer t o: Cont rol Component s (412-01 Cli mat e Cont rol , Descripti on and Operat ion).

A/C COMPRESSOR

• NOTE: i6 A/C compress or s hown, TD4 s i mil ar

The A/C compres sor i s dri ven by the engine acces s ory drive belt and ci rculates refrigerant around t he s yst em bycompres si ng low pres sure, low t emperat ure vapor from t he evaporat or and dis chargi ng t he res ult ant hi gh pres s ure, hight emperature vapor t o t he condenser.

To prot ect t he s yst em from exces s ive pres s ure, a press ure rel ief val ve is ins tall ed in the out let s ide of t he A/C compres sor.The pres s ure relief valve vents excess pres sure int o t he engi ne compart ment .

i6

i6 vehi cl es are fit ted wit h a Zexel-Val eo KC-88 variable di s pl acement A/C compres sor. Compres sor di spl acement iscont rol led by t he Engine Control Modul e (ECM) bas ed on current evaporator t emperature and t arget evaporat or temperat ures ignals recei ved from t he ATC module. From thes e values t he ECM calculates t he required compres s or di s pl acement andprovides a Pul se W i dt h Modulat ed (PW M) s ignal t o t he compres s or s olenoid val ve. The compres s or s olenoid val ve ismounted on the rear of t he compres s or and i nterprets the PW M s ignal as a dis placement val ue and alt ers t he posi ti on oft he int ernal s was h plat e accordingly.For addit ional informat ion, refer t o: Cont rol Component s (412-01 Cli mat e Cont rol , Descripti on and Operat ion).

The ECM wi ll als o reduce t he dis placement of the A/C compres s or to i ts mini mum l evel i f 'ful l throt t le' or aut omati ct ransmis s ion 'ki ck down' is request ed. Thi s feat ure i s not pres ent on Gul f s pecificati on vehi cl es.

Compres s or cl ut ch engagement is cont roll ed by t he ECM.For addit ional informat ion, refer t o: Cont rol Component s (412-01 Cli mat e Cont rol , Descripti on and Operat ion).

TD4

TD4 vehicles are fi tt ed wi th a Vis teon VS16 vari able di spl acement A/C compress or. Dis placement i s cont rol led i nt ernall y bya control valve, which i s int egral wit h t he compres sor. The cont rol val ve meas ures the input and out put pres sures of therefri gerant ent eri ng and leaving t he compres sor and control s t he angl e of t he int ernal s was h plat e accordingly.

• NOTE: There i s no external control over A/C compress or s wash plate angl e. Cons equent ly, compress or dis placement isneit her meas ured nor calculated by any ext ernal cont rol component.

Compres s or cl ut ch engagement is cont roll ed by t he ECM.For addit ional informat ion, refer t o: Cont rol Component s (412-01 Cli mat e Cont rol , Descripti on and Operat ion).

CONDENSER

Page 1644 of 3229

Publishe d: 11-May-2011

Climate Control - Control ComponentsDescripti on a nd O pe ration

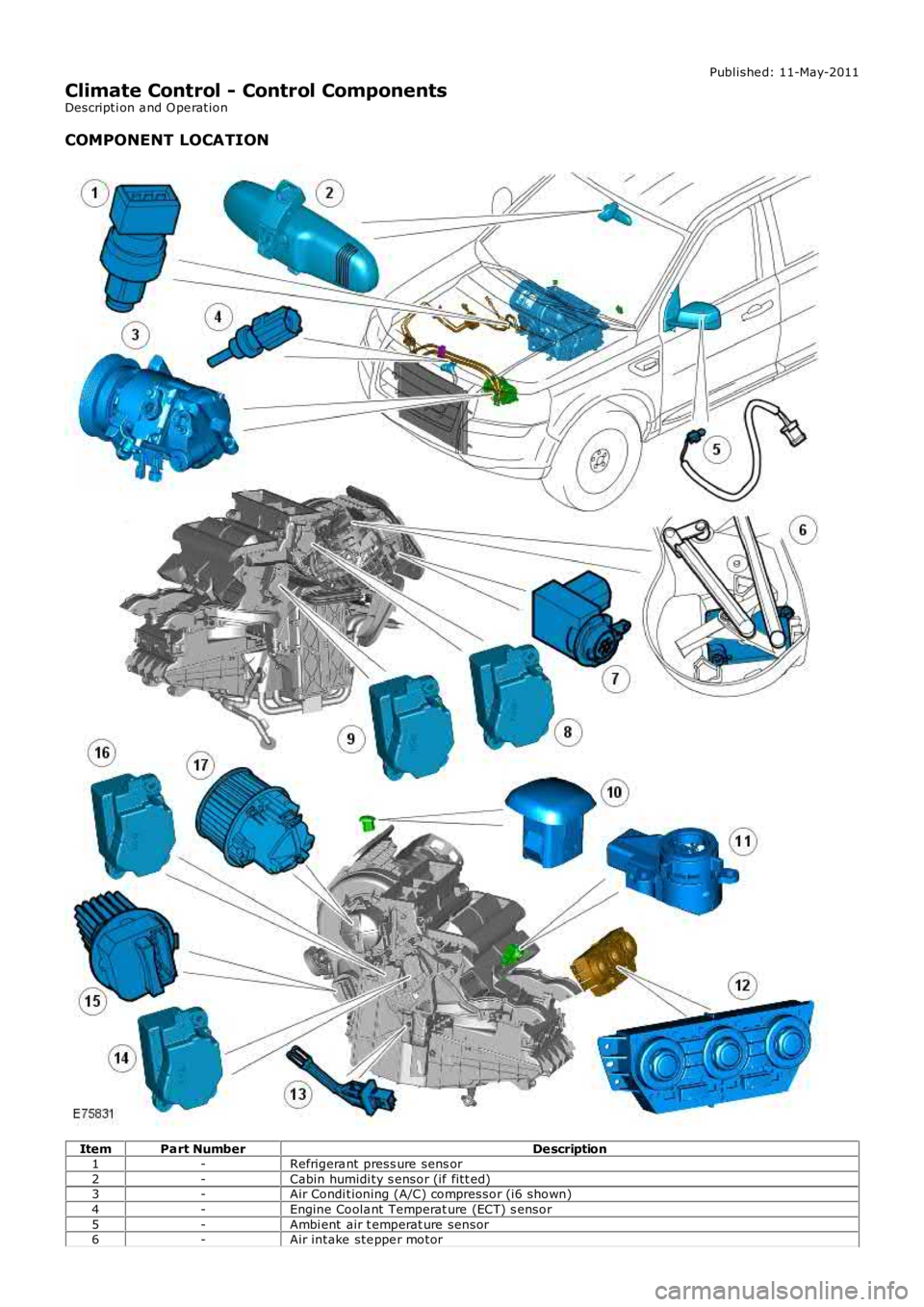

COMPONENT LOCATION

ItemPart NumberDe scription1-Refrigera nt press ure sens or2-Cabin humidi ty s ensor (if fitt ed)3-Air Condi tioning (A/C) compressor (i6 shown)4-Engine Coola nt Temperat ure (ECT) s ensor5-Ambi ent air t emperat ure sensor6-Air intake ste ppe r motor

Page 1645 of 3229

7-P ollution sensor (if fi tted)8-W indshie ld distri buti on (defrost) ste pper motor9-Right Hand (RH) tempera ture ble nd s tepper mot or10-Sunload s ens or11-Cabin temperature se nsor12-Automati c Te mpe rature Cont rol (ATC) modul e13-Evaporator te mpe rature s ens or14-Left Hand (LH) te mpe rature blend st eppe r motor15-Blowe r motor control module16-Face/feet dis tribution ste ppe r motor17-Blowe r motor

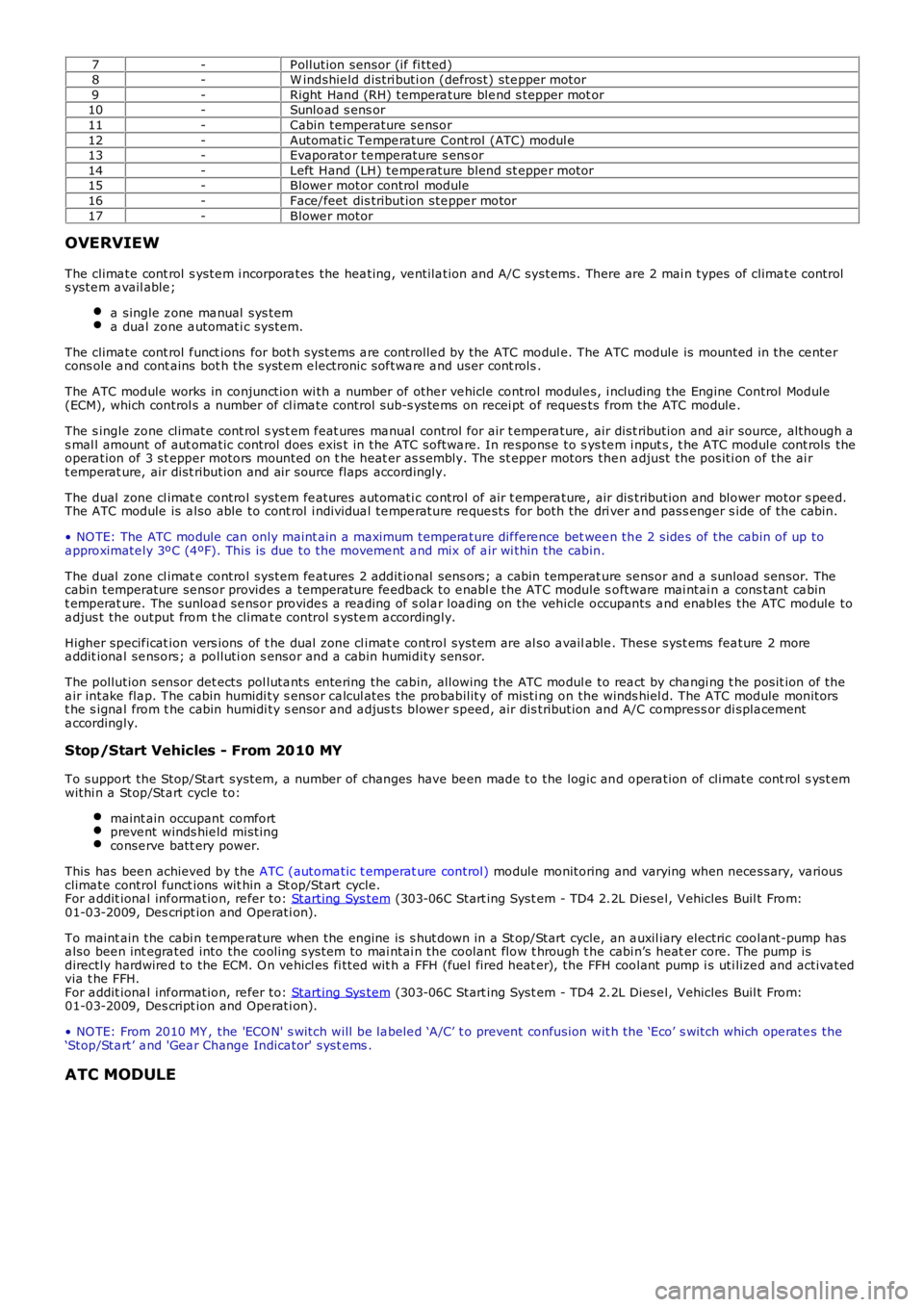

OVERVIEW

The clima te cont rol s yste m i ncorpora tes the hea ting, ve ntila tion and A/C systems. There are 2 mai n types of clima te controls yste m a vail able ;

a single z one ma nual sys tema dua l zone a utomati c system.

The clima te cont rol f unct ions for bot h systems a re controlle d by the ATC modul e. The ATC module is mounted in the ce nte rcons ole a nd cont ains bot h the syste m e lectronic sof twa re a nd user cont rols .

The ATC module works in conjunction wi th a number of othe r ve hicle control module s, i ncluding the Engine Control Module(ECM), which control s a number of cl ima te control sub-s yste ms on recei pt of reques ts f rom the ATC module .

The s ingle zone climate cont rol s yst em f eat ures ma nual control for air t empera ture , air dist ribution and air source, although as mal l amount of aut oma tic control does exis t in the ATC softwa re. In re sponse to s yste m i nput s, t he ATC module cont rols theopera tion of 3 st epper motors mounted on t he heat er as sembly. The st eppe r motors then a djust the positi on of the ai rt emperat ure, air dist ribution and air source flaps accordingly.

The dual zone cl imat e control system fe atures a utomati c control of air t empera ture , air dis tribution and blower motor s pee d.The ATC module is a lso able to cont rol i ndividua l te mpe rature re que sts for both the dri ver a nd pass enger s ide of the cabin.

• NO TE: The ATC module can only maint ain a maximum tempera ture dif fere nce bet wee n the 2 side s of the cabin of up toa pproximate ly 3ºC (4ºF). This is due to the moveme nt a nd mix of a ir wi thin the cabin.

The dual zone cl imat e control system fe atures 2 additional sens ors; a cabin temperature se nsor and a sunload sensor. Thecabin temperature se nsor provides a temperature fe edback to e nabl e the ATC module s oftware mai ntai n a cons tant ca bint emperat ure. The sunloa d se nsor provide s a rea ding of s ola r loa ding on the vehicle occupants a nd enables the ATC module toa djus t the output from t he clima te control s yste m a ccordingly.

Higher specif icat ion vers ions of t he dual zone cl imat e control system are al so a vailable . These syst ems fea ture 2 morea ddit iona l se nsors; a polluti on s ensor and a cabin humidity sensor.

The pollution sensor det ects pol luta nts ente ring the cabin, allowing the ATC modul e to rea ct by cha ngi ng t he posit ion of thea ir intake fla p. The cabin humidi ty s ensor ca lcul ates the probability of misti ng on the winds hiel d. The ATC module monitorst he s igna l from t he cabin humidi ty s ensor and a djus ts blowe r speed, air dis tribution and A/C compress or di spla cementa ccordingly.

Stop/Start Vehicles - From 2010 MY

To support the Stop/Start system, a number of changes have be en made to the logic and opera tion of climate cont rol s yst emwithi n a Stop/Sta rt cycle to:

maint ain occupant comfortpreve nt winds hie ld mistingconse rve batt ery power.

This has bee n achieved by the ATC (automa tic t emperat ure control) module monitoring and varying when nece ssary, va riousclima te control funct ions wit hin a St op/Start cycle.For a ddit iona l inf ormation, re fer to: Starting Sys tem (303-06C Start ing Syst em - TD4 2.2L Diese l, Vehicles Buil t From:01-03-2009, Des cript ion and Ope rati on).

To maint ain the cabi n te mpe rature when the engine is s hut down in a St op/Start cycle, an a uxil iary electric coolant-pump hasa lso bee n int egra ted into the cooling system to mai ntai n the coolant flow t hrough t he cabi n’s heat er core. The pump isdirectly hardwire d to the ECM. O n ve hicl es fi tted wit h a FFH (fue l fired heat er), the FFH coolant pump i s uti lize d and activa tedvia t he FFH.For a ddit iona l inf ormation, re fer to: Starting Sys tem (303-06C Start ing Syst em - TD4 2.2L Diese l, Vehicles Buil t From:01-03-2009, Des cript ion and Ope rati on).

• NO TE: From 2010 MY , the 'ECO N' s witch will be la bele d ‘A/C’ t o prevent confusion wit h the ‘Eco’ s witch which ope rate s the‘Stop/Sta rt’ a nd 'Gea r Change Indica tor' syst ems .

ATC MODULE

Page 1654 of 3229

a utomati c control.

Air distri buti on can be re turned t o automatic control by pres sing the 'AUTO' swi tch loca ted in the ce nte r of the blower motorrotary controller. Thi s wi ll ill uminate the 'AUTO' LED and allow t he ATC module to control a ir di stribution in line wit h it s'comfort' algorithm

Air distri buti on is control led by 2 air dist ribution doors. The ATC module control s the position of the air dis tribution doors byprovi ding LIN bus me ssa ges to t he door ste pper motors . Ha ll ef fect sensors located wit hin the stepper mot ors inform t he ATCmodule t hat moveme nt of the st epper motors is taking place.

ECON - Single Zone Manual System

P ress ing the 'ECO N' moment ary swit ch on the control pa nel will swi tch off t he A/C s yste m. W he n s elected, the ATC modulewill t rans mit a mess age ove r the high speed CAN bus to the ECM re que sting the A/C compressor is dis able d. The ECMdisables the compres sor by de-e nergizing the A/C compress or control re lay loca ted in the BJB. The tell-tale LED in the swit chwill i lluminat e to ale rt the ve hicl e occupants tha t the system is in 'ECO N' mode .

W he n 'ECON' mode i s se lect ed, tempera ture control is s till a vai lable but no cooling of i ntake ai r wi ll ta ke place . The minimumoutput a ir te mpe rature f rom the sys tem will be ambient air tempera ture plus any heat pick up in the ai r int ake pat h.

A/C can be s witched back on by pres sing the 'ECON' swi tch a se cond time. This will als o extinguish the 'ECON' LED.

Stop/Sta rt Ve hicl es - From 2010 MY

From 2010 MY , t he 'ECON' switch wi ll be labeled ‘A/C’ to pre vent confus ion with the ‘Eco’ switch which operates the‘Stop/Sta rt’ a nd 'Gea r Change Indica tor' syst ems .For a ddit iona l inf ormation, re fer to: Starting Sys tem (303-06C Start ing Syst em - TD4 2.2L Diese l, Vehicles Buil t From:01-03-2009, Des cript ion and Ope rati on).

ECON - Dual Zone Automatic System

P ress ing the 'ECO N/O FF' momentary swi tch in the control pa nel will swi tch off t he A/C s yste m. W he n s elected, the ATCmodule will t rans mit a mess age ove r the high speed CAN bus to the ECM re que sting the A/C compress or is dis able d. The ECMdisables the compres sor by de-e nergizing the A/C compress or control re lay loca ted in the BJB. The 'ECO N' t ell-tale LED in t hes witch will il lumi nate to alert the ve hicle occupa nts that the sys tem is i n 'ECON' mode.

W he n 'ECON' mode i s se lect ed, tempera ture control is s till a vai lable but no cooling of i ntake ai r wi ll ta ke place . The minimumoutput a ir te mpe rature f rom the sys tem will be ambient air tempera ture plus any heat pick up in the ai r int ake pat h.

A second pre ss of the 'ECON/OFF' switch wil l ext inguish the 'ECO N' LED and illuminate the 'OFF' LED. W hen in 'OFF' mode t heATC module sets the blower mot or s pee d to 0. Air distri buti on i nto the cabi n wi ll remai n as pre viously sele cted. Al l LED's ont he control pane l wil l be ext inguishe d, a lthough night ti me illumina tion will remain acti ve.

• NO TE: W he n in 'OFF' mode , the he ated se at, heat ed windshie ld a nd heat ed rear window functions wi ll st ill be availa ble.

A thi rd press of t he 'ECO N/O FF' s wit ch re turns the s yste m to norma l (A/C) operation and extinguishes t he 'OFF' LED. Thes yste m can be re turned to a utomati c operat ion at a ny t ime by press ing the 'AUTO' swit ch mounted in t he cent ral (blowermotor) rotary control ler.

Stop/Sta rt Ve hicl es - From 2010 MY

From 2010 MY , t he 'ECON' switch wi ll be labeled ‘A/C’ to pre vent confus ion with the ‘Eco’ switch which operates the‘Stop/Sta rt’ a nd 'Gea r Change Indica tor' syst ems .For a ddit iona l inf ormation, re fer to: Starting Sys tem (303-06C Start ing Syst em - TD4 2.2L Diese l, Vehicles Buil t From:01-03-2009, Des cript ion and Ope rati on).

Programmed Defrost

The programmed def rost function is only ava ilable on ve hicl es fi tted wit h a dua l zone heati ng, vent ilat ion a nd A/C syst em.The f unction is s elected by press ing the 'PRO G' moment ary swit ch on the control pa nel. W hen s ele cted, the ATC moduleprovi des maximum winds hie ld de fros ting/de mist ing by confi guri ng t he s yste m a s follows:

'AUTO ' mode offIntake air set to fres h airAir di stribution se t to windshieldBlowe r motor spe ed s et t o maximumHeate d winds hiel d onRear window hea ter on.

W he n progra mmed defrost is sel ecte d, t he s et t emperat ure will remain unchanged. Programme d de fros t ca n be cancell ed bya ny of the following met hods:

P ress ing any air distribut ion moment ary swit chP ress ing the 'AUTO' s witch locate d in the center of t he blowe r motor rot ary cont rolle rP ress ing the 'PRO G' momenta ry s witch a second time .

• NO TE: Blower motor speed can be adjuste d wi thout te rmi nating programmed defrost.

Windshield Heater

The windshie ld heate r comprises 2 heate r el eme nts , LH and RH, bonded be twee n the glass laminat ions . The s yste m iss witched on by press ing the momentary swi tch l ocat ed on t he control panel . W hen selected, the ATC module t rans mits aheat ing request on t he high spe ed CAN bus to t he CJB. On rece ipt of the messa ge, the CJB ene rgiz es t he windshie ld heate rrelay loca ted in t he BJB by provi ding a ground path for t he relay coi l. The energized rela y provides a ba ttery fe ed t o bothheat er el eme nts . Aft er a period of 4 minutes the ATC module re moves t he request for windshie ld heati ng. The CJB the npowe rs down the windshield hea ter by re moving the ground pat h for the rel ay coil.

The ATC module will only reques t wi ndshield he ater ope rati on if the engine is runni ng. An e ngi ne s tatus si gnal is provi ded tot he ATC module by t he ECM over the high speed CAN bus.

Page 1655 of 3229

Rear Window Heater

The rear window hea ter comprise s a single heat er e leme nt bonded to the inner surf ace of t he glass . The syste m is swi tche don by pre ssing the mome nta ry s witch locate d on the control panel. W he n se lected, the ATC module tra nsmits a he atingreque st on the high spee d CAN bus to the CJB. On recei pt of the me ssa ge, the CJB energiz es t he rear window hea ter relayl ocat ed i n the Auxilia ry Junct ion Box (AJB) by providing a ground pa th for the re lay coil. The energiz ed relay provide s a bat teryf eed to t he heat er e leme nt. Afte r a period of 12 minute s the ATC module re moves the heat ing request . The CJB then powe rsdown the rea r wi ndow he ate r by removing the ground pa th f or t he relay coil .

The ATC module will only reques t re ar window heate r opera tion if the e ngine is running. An engine stat us s ignal is provide d tot he ATC module by t he ECM over the high speed CAN bus.

Exterior Mirror Heaters

O peration of the ext erior mirror heat ers is fully a utomat ic a nd re qui res no input from the driver. The exterior mirror hea tersa re a ctive when the ambient air tempera ture is below 5°C (41°F) and e ngine coolant te mpe rature i s be low 65° C (149° F).Ambi ent air a nd engine coola nt t empera ture val ues are provided by the ECM on the high speed CAN bus. O n re ceipt of the set emperat ure values, the CJB det ermines if e xterior mirror he ating is require d.

The CJB requests exterior mirror hea ting by transmit ting a high spe ed CAN bus mes sage to bot h the drivers and pa sse ngerdoor module s. The door modules provide fee d and ground paths to the respecti ve e xterior mirror he ating el eme nts . W hena mbi ent and engine cool ant tempera ture ris es a bove the va lues sta ted earl ier, the CJB transmi ts a high speed CAN busmess age to the door module s ca nce lling the hea ting reques t.

Seat Heaters

O peration of the sea t he aters is controll ed by the ATC module on re ceipt of a heati ng reque st f rom either of the se at heat ermomenta ry s witches loca ted on the cont rol pane l. The s witches are mounte d in the LH and RH rota ry controllers. A singlepress of a se at heat er switch wi ll implement low level heati ng a nd illumina te a tell-tale LED. A second pre ss of the switch willi mple me nt high l eve l hea ting and ill uminate 2 te ll-t ale LED's. A third press of t he s witch will turn t he s eat hea ter off.

Seat hea ting request s are transmitte d from the ATC module to the seat hea ter control modules on the LIN bus . Two se atheat er control modul es a re f itted, one under each front seat . The se at heat er control modules provide an e lect rical supply tot he s eat hea ter e lement s and a tempera ture sensor loca ted in t he s eat cus hion.

The s eat hea ter cont rol module provides a 5 V reference fee d to the sea t he ate r te mpe rature s ensor. The s eat hea tert emperat ure sensor is an NTC thermistor. By monitoring the ret urne d voltage, t he control module can calculate thet emperat ure of t he s eat. If t he t empera ture rise s above the target tempera ture , the control module wi ll dis abl e operat ion oft he heat er e leme nts .

Page 1687 of 3229

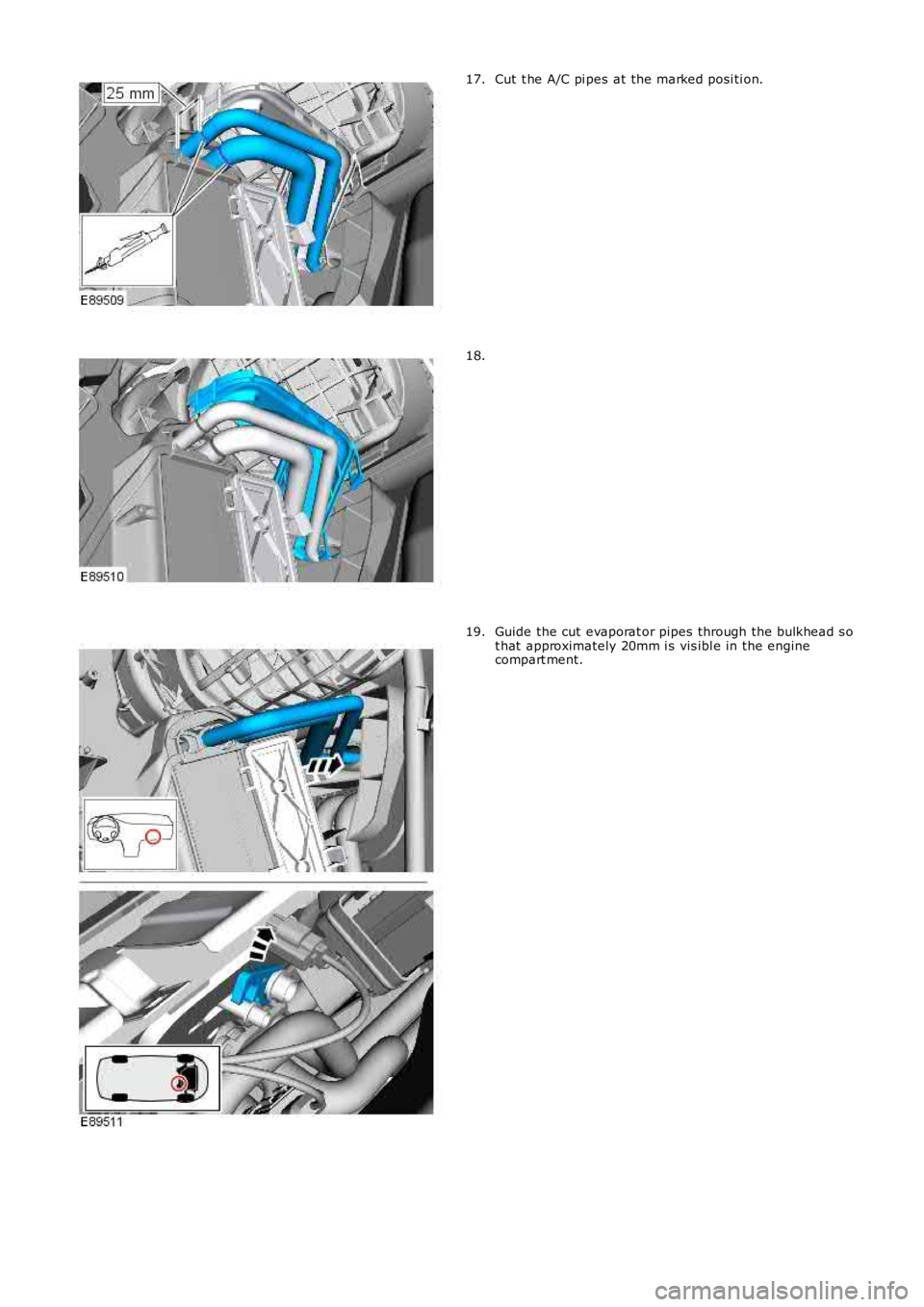

Cut t he A/C pi pes at the marked posi ti on.17.

18.

Guide the cut evaporat or pipes through the bulkhead s ot hat approximately 20mm i s vis ibl e in the enginecompart ment.

19.

Page 1690 of 3229

blanking caps.

Remove t he TXV as sembl y from t he s ervice replacement evaporator

pipes .

Guide the s ervi ce replacement evaporator pi pes t hrough t he

bulkhead s o that approximat ely 20mm is vi s ible in t he engine

compart ment.

7.

Inst all t he TXV capt ive clampi ng plat e.

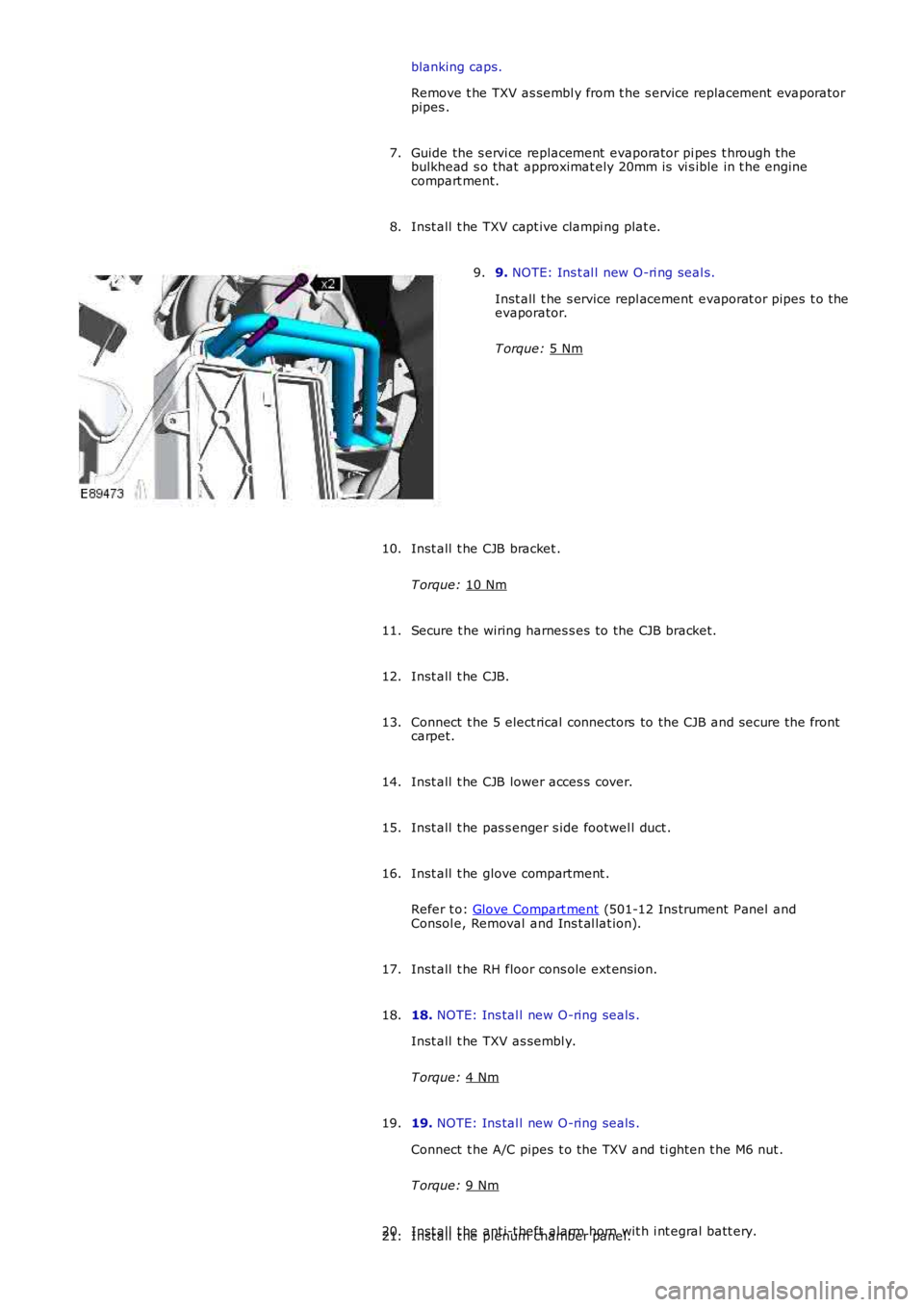

8. 9.

NOTE: Ins t al l new O-ri ng seal s.

Inst all t he s ervice repl acement evaporat or pipes t o the

evaporator.

T orque: 5 Nm 9.

Inst all t he CJB bracket .

T orque: 10 Nm 10.

Secure t he wiring harnes s es to the CJB bracket.

11.

Inst all t he CJB.

12.

Connect t he 5 elect rical connectors to the CJB and s ecure t he front

carpet.

13.

Inst all t he CJB lower acces s cover.

14.

Inst all t he pas s enger s ide footwel l duct .

15.

Inst all t he glove compartment .

Refer t o: Glove Compart ment (501-12 Ins trument Panel and

Consol e, Removal and Ins t al lat ion).

16.

Inst all t he RH floor cons ole ext ens ion.

17.

18. NOTE: Ins tal l new O-ring seals .

Inst all t he TXV as sembl y.

T orque: 4 Nm 18.

19. NOTE: Ins tal l new O-ring seals .

Connect t he A/C pipes t o the TXV and ti ght en t he M6 nut .

T orque: 9 Nm 19.

Inst all t he ant i-t heft alarm horn wit h i nt egral batt ery.

20.

Inst all t he plenum chamber panel.

21.