engine LAND ROVER FRELANDER 2 2006 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 1401 of 3229

from the clut ch pedal .

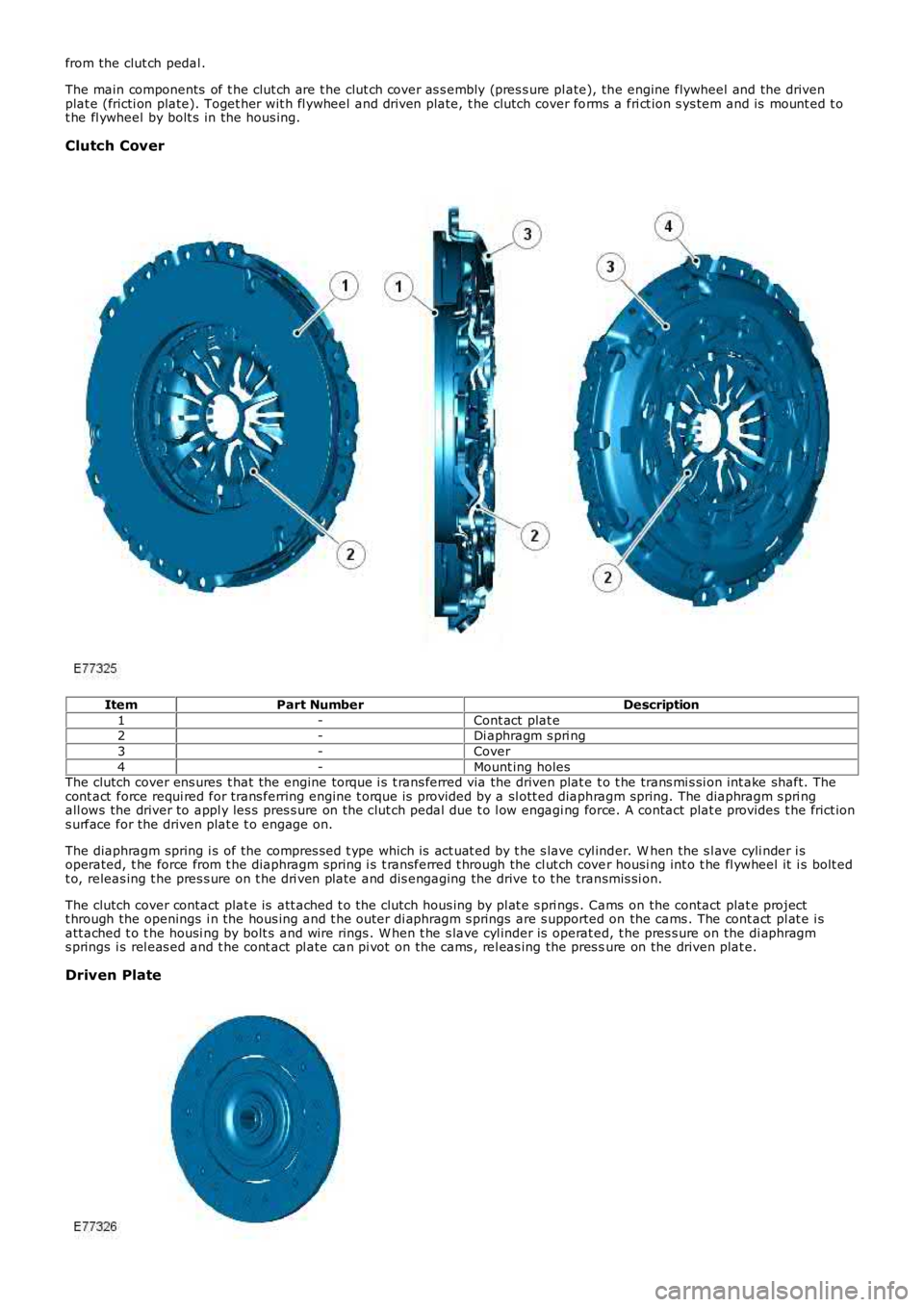

The main components of t he clut ch are t he clut ch cover as s embly (pres s ure pl ate), the engine flywheel and the drivenplat e (fricti on plate). Toget her wit h fl ywheel and dri ven plate, t he clutch cover forms a fri ct ion s ys tem and is mount ed t ot he fl ywheel by bolt s in the hous ing.

Clutch Cover

ItemPart NumberDescription

1-Cont act plat e2-Di aphragm s pri ng

3-Cover

4-Mount ing holesThe clutch cover ens ures t hat the engine torque i s t rans ferred via the driven plat e t o t he trans mi s si on int ake shaft. Thecont act force requi red for trans ferring engine t orque i s provided by a sl ott ed diaphragm spring. The diaphragm s pri ngall ows the driver to appl y les s pres s ure on the cl ut ch pedal due t o l ow engagi ng force. A contact plat e provides t he frict ions urface for the driven plat e t o engage on.

The diaphragm spring i s of the compres s ed t ype which is act uat ed by t he s lave cyl inder. W hen the s l ave cyli nder i soperated, t he force from t he diaphragm spring i s t ransferred t hrough the cl ut ch cover housi ng int o t he fl ywheel it i s bolt edt o, releas ing t he pres s ure on t he dri ven plate and dis engaging the drive t o t he transmis si on.

The clutch cover contact plat e is att ached t o t he clutch hous ing by pl at e s pri ngs . Cams on the contact plat e projectt hrough the openings i n the hous ing and t he outer di aphragm s prings are s upported on the cams . The cont act pl at e i satt ached t o t he housi ng by bolt s and wire rings . W hen t he s lave cyl inder is operat ed, t he pres s ure on the di aphragms prings i s rel eas ed and t he cont act pl ate can pi vot on the cams , rel eas ing the pres sure on the driven plat e.

Driven Plate

Page 1402 of 3229

The dri ven pl ate is t he cent ral connecti on element i n the cl utch. In combi nat ion wi th the cl ut ch cover as sembl y, its eparates and l inks engi ne and powert rain by connect ing the engine cranks haft t o t he trans mi s si on input s haft.

The dri ven pl ate is a ri gi d t ype fricti on plat e. The flywheel is of t he dual mas s t ype and abs orbs torque fluct uat ionsgenerated by t he combust ion proces s es to reduce noi s e and wear in t he t rans mis s ion.

Dual Mass Flywheel

The dual mas s flywheel compris es t wo main components ; t he pri mary s i de which i s att ached t o t he engi ne crankshaft andt he secondary s ide t o whi ch the clut ch cover as sembl y is at t ached.

The pri mary si de has the st art er ri ng gear at tached to it s outer circumference. The ring gear is us ed by t he s tarter mot or torot ate the engine during engine crank at s t art up. The primary s ide is s ecured t o t he cranks haft wi th eight bol ts . A dowelin the cranks haft flange ens ures that t he fl ywheel is correctl y located.

The s econdary s ide has the s moot h frict ion s urface on which t he dri ven pl ate fri cti on material engages . Dowel s and fixingholes all ow for the correct al ignment and att achment of the cl utch cover as s embl y.

The pri mary and secondary s ides are connect ed wi th l ong coi l springs . The two si des can rotat e agains t each ot her, li mi tedby t he coi l springs , whi ch absorb t orque loading on cl ut ch engagement and t ors ional vi brati ons from t he engine.

Page 1404 of 3229

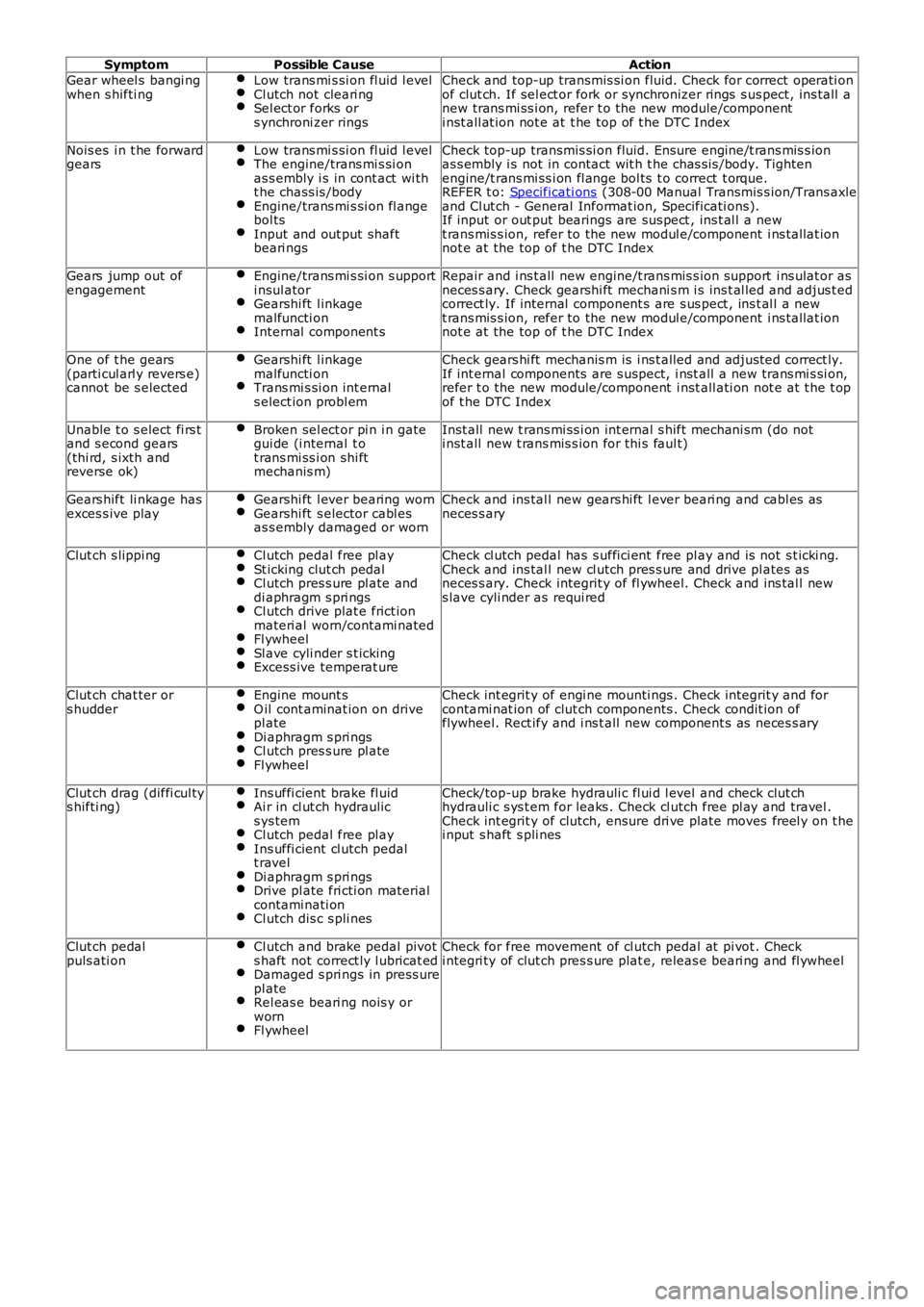

SymptomPossible CauseAction

Gear wheel s bangi ngwhen s hifti ngLow trans mi s si on fl uid l evelCl utch not cleari ngSel ect or forks ors ynchroni zer rings

Check and top-up transmis si on fluid. Check for correct operati onof clut ch. If sel ect or fork or synchronizer rings s us pect , ins tall anew trans mi ss i on, refer t o the new module/componenti nst all at ion not e at t he top of t he DTC Index

Nois es i n t he forwardgearsLow trans mi s si on fl uid l evelThe engine/trans mi s si onas s embly i s in cont act wi tht he chass is /bodyEngine/trans mi s si on fl angebol tsInput and out put shaftbeari ngs

Check top-up transmis si on fluid. Ensure engine/t rans mis s ionas s embly i s not in contact wit h t he chas s is /body. Tightenengine/t rans mi ss i on fl ange bol ts t o correct t orque.REFER t o: Specificati ons (308-00 Manual Transmis s ion/Trans axleand Cl ut ch - General Informat ion, Specificati ons).If input or out put bearings are sus pect , ins t al l a newt rans mis s ion, refer to the new modul e/component i ns t allat ionnot e at the top of t he DTC Index

Gears jump out ofengagementEngine/trans mi s si on s upporti nsul atorGearshi ft l inkagemalfuncti onInternal component s

Repair and i ns t all new engine/t rans mis s ion support i ns ulat or asneces s ary. Check gearshi ft mechani s m i s ins t al led and adjus t edcorrect ly. If internal component s are s us pect , ins t al l a newt rans mis s ion, refer to the new modul e/component i ns t allat ionnot e at the top of t he DTC Index

One of t he gears(parti cul arl y revers e)cannot be s elected

Gearshi ft l inkagemalfuncti onTrans mi s si on int ernals elect ion probl em

Check gears hi ft mechanis m is i ns t alled and adjust ed correct ly.If int ernal components are s uspect, i nst all a new trans mi s si on,refer t o the new module/component i nst all ati on not e at t he t opof t he DTC Index

Unable t o s elect fi rs tand s econd gears(thi rd, s ixth andreverse ok)

Broken sel ect or pi n i n gategui de (i nternal t ot rans mi ss i on shi ftmechanis m)

Inst all new t rans mi ss i on int ernal s hift mechani sm (do noti nst all new t rans mis s ion for thi s faul t)

Gears hift li nkage hasexces s ive playGearshi ft l ever bearing wornGearshi ft s elector cabl esas s embly damaged or worn

Check and ins tal l new gears hi ft l ever beari ng and cabl es asneces s ary

Clut ch s lippi ngCl utch pedal free pl aySt icking clut ch pedalCl utch pres s ure pl ate anddi aphragm s pri ngsCl utch drive plat e frict ionmateri al worn/contami natedFl ywheelSl ave cyli nder s t ickingExcess ive temperat ure

Check cl utch pedal has s uffici ent free pl ay and is not s t icki ng.Check and ins tal l new cl utch pres s ure and drive pl ates asneces s ary. Check integrit y of fl ywheel. Check and ins tal l news lave cyli nder as requi red

Clut ch chat ter ors hudderEngine mount sO il cont aminat ion on drivepl ateDi aphragm s pri ngsCl utch pres s ure pl ateFl ywheel

Check int egrit y of engi ne mounti ngs . Check integrit y and forcontami nat ion of clut ch components . Check condit ion offlywheel. Rect ify and i ns t all new component s as neces s ary

Clut ch drag (diffi cul tys hifti ng)Ins uffi cient brake fl uidAi r in cl ut ch hydraulics ys temCl utch pedal free pl ayIns uffi cient cl utch pedalt ravelDi aphragm s pri ngsDrive pl ate fri cti on materialcontami nati onCl utch dis c s pli nes

Check/top-up brake hydrauli c fl ui d l evel and check clut chhydrauli c s ys t em for leaks . Check cl utch free pl ay and travel .Check int egrit y of clutch, ensure dri ve plate moves freel y on t hei nput s haft s pli nes

Clut ch pedalpuls ati onCl utch and brake pedal pivots haft not correct ly l ubricat edDamaged s pri ngs in press urepl ateRel eas e beari ng nois y orwornFl ywheel

Check for free movement of cl utch pedal at pi vot . Checki ntegri ty of clut ch pres s ure plat e, releas e beari ng and fl ywheel

Page 1416 of 3229

which i s hydraulicall y act uated from t he cl utch pedal.

Pres s ing t he clutch pedal pres surizes t he hydraul ic fluid in the mas t er cyli nder. The fl uid pres s ure is t rans ferred via a pipefrom the mas t er cyli nder t o t he s lave cyl inder in the t rans mis s ion. The fluid press ure operates t he s lave cylinder which i nt urn pus hes the fingers of t he clut ch cover, rel easi ng the driven pl at e and di sengagi ng t he dri ve from t he engi ne crankshaftt o the trans mi s si on.

A hydrauli c clutch bl eed adapt or i s l ocated on the front of t he transmis s ion. The adapt or provi des the connect ion betweent he pres sure pipe from t he mas ter cyl inder to the s l ave cyli nder. The adapt or contains a bleed s crew to purge t he cl utchhydraulic sys tem of air aft er s ervice repl acement of one of the hydrauli c components. The adaptor als o i ncl udes a peakt orque li mit er. This prevent s ins t ant clut ch engagement if t he dri ver accident all y rel eas es t he clutch l ever t o preventdamage to the driveli ne components .

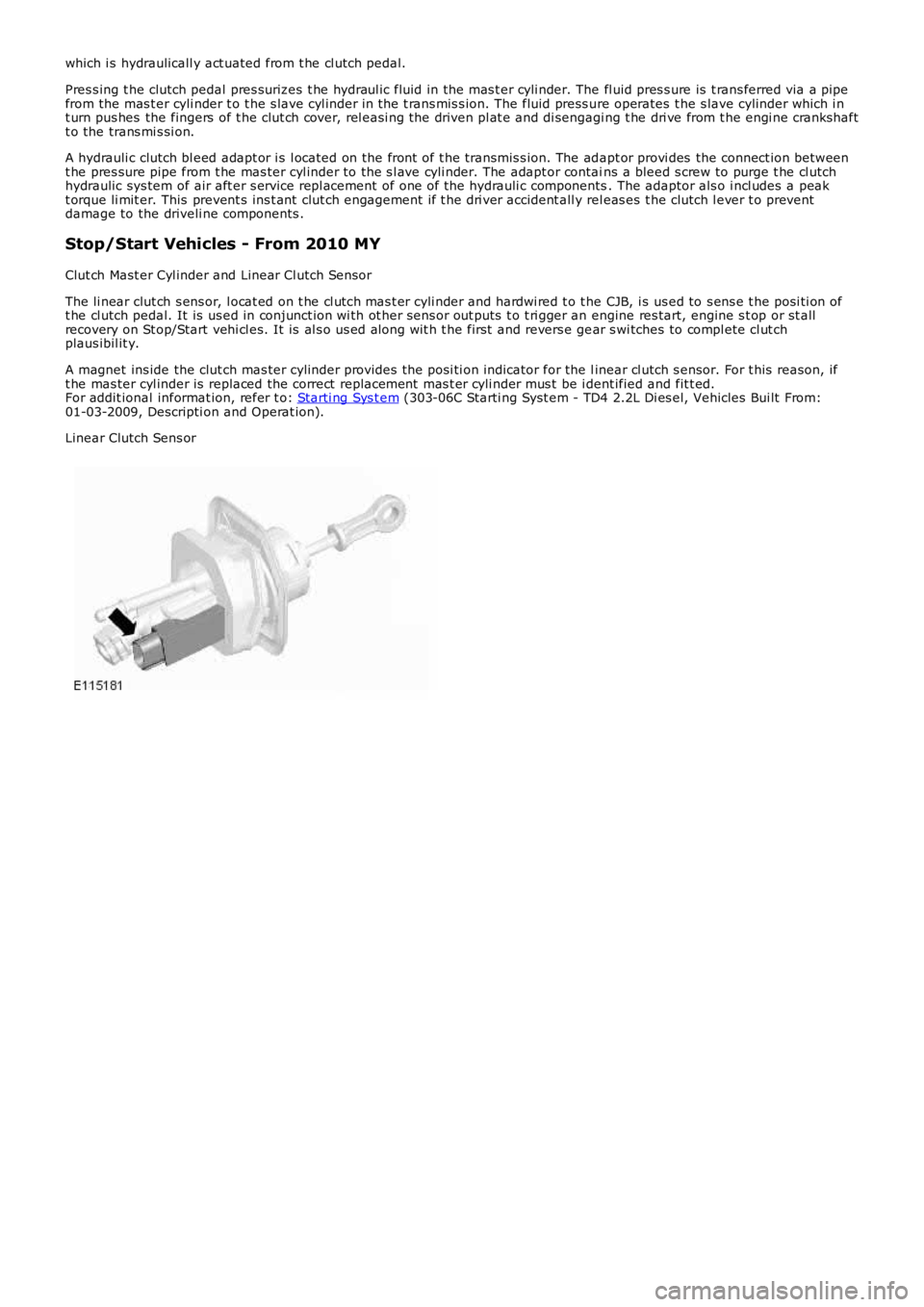

Stop/Start Vehicles - From 2010 MY

Clut ch Mast er Cyl inder and Linear Cl utch Sensor

The li near clut ch s ens or, l ocat ed on t he cl utch mas t er cyli nder and hardwi red t o t he CJB, i s us ed to s ens e t he posi ti on oft he cl utch pedal. It is us ed in conjunct ion wi th ot her sens or out puts t o t ri gger an engine res tart, engine s t op or st allrecovery on St op/Start vehi cl es. It is al s o us ed along wit h t he first and revers e gear s wi tches to compl ete cl ut chplaus ibil it y.

A magnet ins ide the clut ch mas ter cylinder provides t he posi ti on indicator for the linear cl utch s ensor. For t his reason, ift he mas ter cyl inder is replaced the correct replacement mas t er cyli nder mus t be i dent ified and fit t ed.For addit ional informat ion, refer t o: Starti ng Sys t em (303-06C Starti ng Syst em - TD4 2.2L Di es el, Vehicles Bui lt From:01-03-2009, Descripti on and Operat ion).

Linear Clutch Sens or

Page 1484 of 3229

Publi s hed: 11-May-2011

Four-Wheel Drive Systems - Four-Wheel Drive Systems

Des cript ion and Operat ion

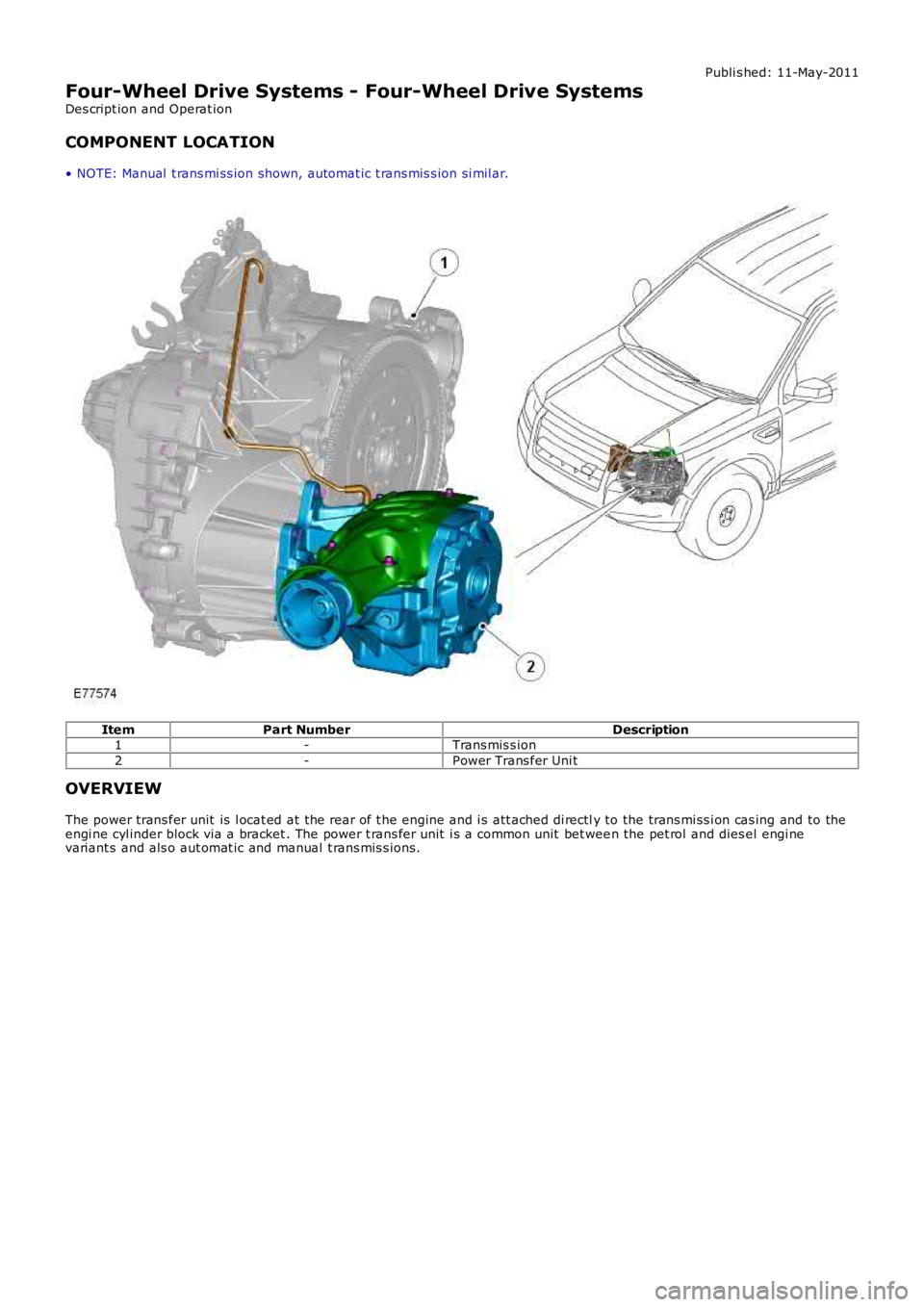

COMPONENT LOCATION

• NOTE: Manual t rans mi ss ion shown, automat ic t rans mis s ion si mil ar.

ItemPart NumberDescription1-Trans mis s ion

2-Power Trans fer Uni t

OVERVIEW

The power trans fer unit is l ocat ed at the rear of t he engine and i s att ached di rectly to the trans mi ss i on cas ing and to theengi ne cyl inder block via a bracket . The power t rans fer unit i s a common unit bet ween the pet rol and dies el engi nevariant s and als o aut omat ic and manual t rans mis s ions .

Page 1488 of 3229

Publi s hed: 25-Nov-2011

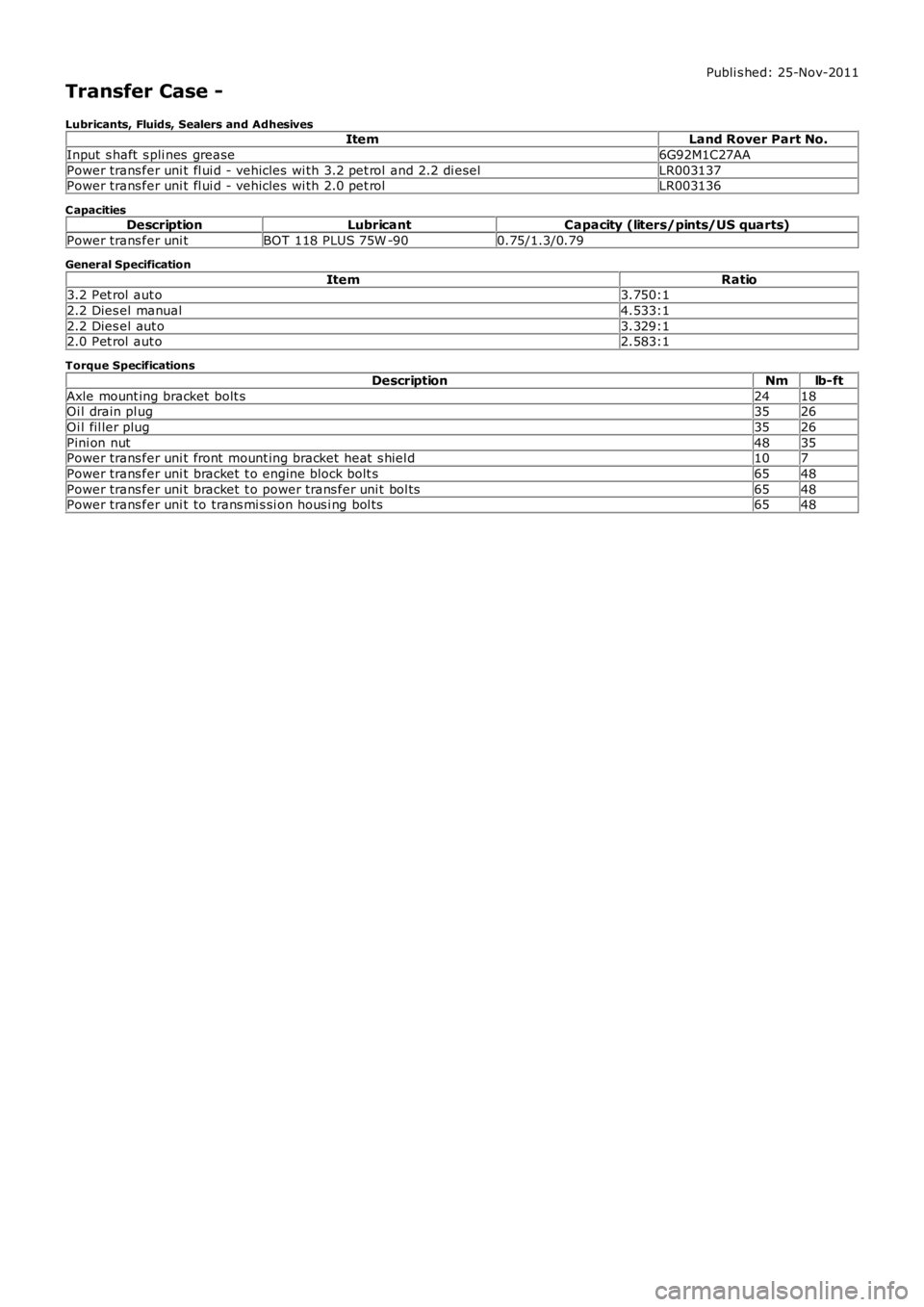

Transfer Case -

Lubricants, Fluids, Sealers and AdhesivesItemLand Rover Part No.

Input s haft s pli nes grease6G92M1C27AA

Power trans fer uni t fl ui d - vehicles wi th 3.2 pet rol and 2.2 di eselLR003137Power trans fer uni t fl ui d - vehicles wi th 2.0 pet rolLR003136

C apacitiesDescriptionLubricantCapacity (liters/pints/US quarts)

Power trans fer uni tBOT 118 PLUS 75W -900.75/1.3/0.79

General Specification

ItemRatio3.2 Pet rol aut o3.750:1

2.2 Dies el manual4.533:1

2.2 Dies el aut o3.329:12.0 Pet rol aut o2.583:1

Torque Specifications

DescriptionNmlb-ft

Axle mount ing bracket bolt s2418Oi l drain pl ug3526

Oi l fil ler plug3526

Pini on nut4835Power trans fer uni t front mount ing bracket heat s hiel d107

Power trans fer uni t bracket t o engine block bolt s6548

Power trans fer uni t bracket t o power trans fer uni t bol ts6548Power trans fer uni t to trans mi s si on hous i ng bol ts6548

Page 1494 of 3229

Publi s hed: 11-May-2011

Transfer Case - Power Transfer UnitTD4 2.2L Diesel, Vehicles With: M66

6-Speed Manual Transmission AWD

Removal and Inst all ati on

Removal

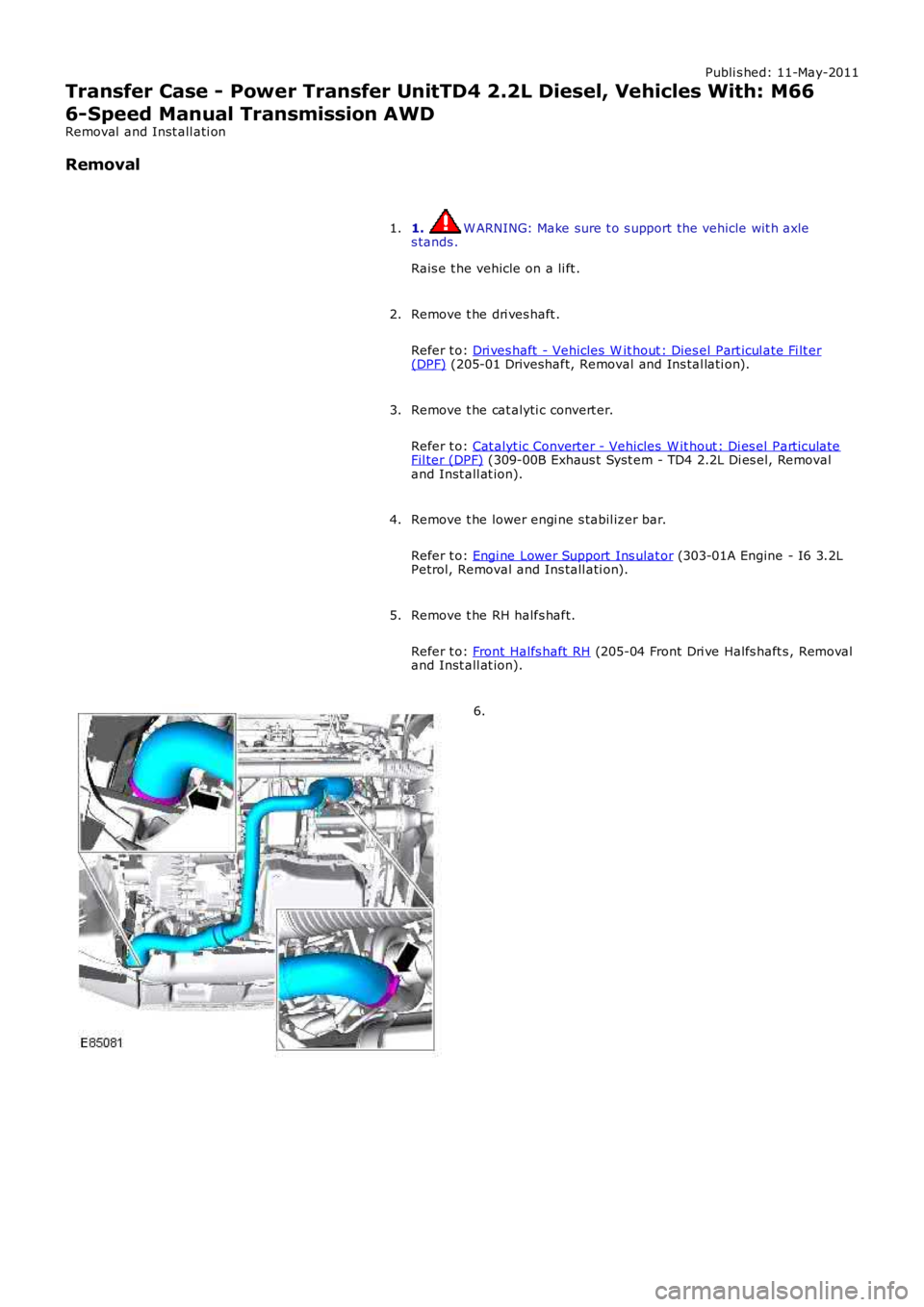

1. W ARNING: Make sure t o s upport the vehicle wit h axles tands .

Rais e t he vehicle on a li ft .

1.

Remove t he dri ves haft .

Refer t o: Dri ves haft - Vehicles W it hout : Dies el Part icul ate Fi lt er(DPF) (205-01 Driveshaft, Removal and Ins tal lati on).

2.

Remove t he cat alyti c convert er.

Refer t o: Cat alyt ic Converter - Vehicles W it hout : Di es el Part iculateFil ter (DPF) (309-00B Exhaus t Syst em - TD4 2.2L Di es el, Removaland Inst all at ion).

3.

Remove t he lower engi ne s tabil izer bar.

Refer t o: Engi ne Lower Support Ins ulat or (303-01A Engine - I6 3.2LPetrol, Removal and Ins tall ati on).

4.

Remove t he RH halfs haft.

Refer t o: Front Halfs haft RH (205-04 Front Dri ve Halfs haft s , Removaland Inst all at ion).

5.

6.

Page 1497 of 3229

Publi s hed: 11-May-2011

Transfer Case - Power Transfer UnitTD4 2.2L Diesel, Vehicles With: M66

6-Speed Manual Transmission AWD

Removal and Inst all ati on

Removal

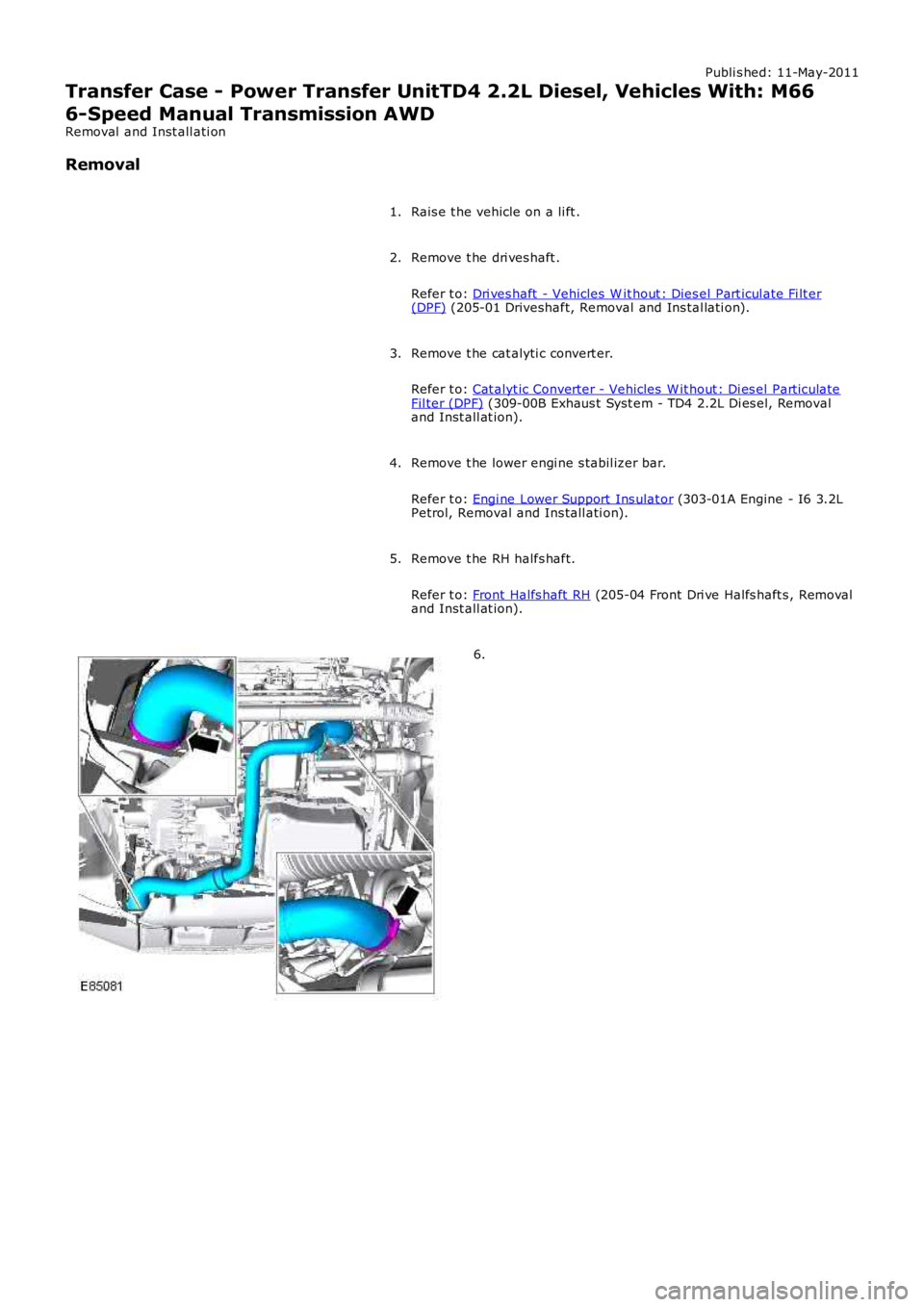

Rais e t he vehicle on a li ft .

1.

Remove t he dri ves haft .

Refer t o: Dri ves haft - Vehicles W it hout : Dies el Part icul ate Fi lt er (DPF) (205-01 Driveshaft, Removal and Ins tal lati on).

2.

Remove t he cat alyti c convert er.

Refer t o: Cat alyt ic Converter - Vehicles W it hout : Di es el Part iculate Fil ter (DPF) (309-00B Exhaus t Syst em - TD4 2.2L Di es el, Removal

and Inst all at ion).

3.

Remove t he lower engi ne s tabil izer bar.

Refer t o: Engi ne Lower Support Ins ulat or (303-01A Engine - I6 3.2L

Petrol, Removal and Ins tall ati on).

4.

Remove t he RH halfs haft.

Refer t o: Front Halfs haft RH (205-04 Front Dri ve Halfs haft s , Removal

and Inst all at ion).

5. 6.

Page 1515 of 3229

5-Gasket

6-Tailpi pe fi nis her (opti onal )

7-Mount ing rubber (6 off)8-Rear muffler

9-Cent re muffler

10-Flange11-Bracket

12-Catalyt ic converter (2 off)

13-Flange14-Catalyt ic converter (2 off)

15-Exhaus t manifol d gas ket s

OVERVIEW

The 3.2L SI6 exhaus t s yst em i s fabricated from s tai nl ess st eel and is s upplied as two separat e as sembl ies ; a front s ect ionincorporat ing t wo catal yt ic convert ers and a rear sect ion i ncorporat ing centre and rear s i lencers.

EXHAUST MANIFOLDS

The exhaus t manifold compri s es two separat e manifold as s embli es . One mani fol d is us ed for cyli nders 1 t o 3 and thes econd mani fold is us ed for cyli nders 4 t o 6. The manifolds are s eal ed to the cyli nder head wi th a gas ket and s ecured wit h14 bolt s .

Each manifol d compri ses t hree fabri cat ed branches whi ch merge i nto an int egral cat alyti c convert er. A threaded bos s isposi ti oned where t he t hree branches merge and provi des for t he fi tment of a pre-catalys t HO2S. The cat alyti c convert eroutl et s have offs et flanges which mat e wi th corres pondi ng fl anges on t he front s ect ion exhaus t s ys tem.

A bracket on each out let flange all ows for t he att achment of an exhaus t mani fold heat s hield.

FRONT SECTION

The front sect ion has t wo flanged pi pes which mat e wi th the offs et fl anges of t he exhaus t manifol ds. The flanges ares eal ed wit h gas ket s and s ecured wit h bolt s . The fl anges are connected vi a curved pipes t o decouplers which provide afl exi ble joint i n the sys tem. The out let from each decoupl er compris es a curved pipe wit h a t hreaded bos s whi ch providesfor t he fit ment of a pos t -catal ys t HO2S.

Each pi pe is connect ed i nt o a smal ler catalyt ic converter whi ch in t urn is connected to a doubl e fl ange which mat es wit ht he rear s ect ion of t he exhaus t s ys t em.

Two mount ing rubbers are l ocat ed at the rear of the flexible coupli ng and are at t ached t o a bracket mounted on the fronts ubframe.

REAR SECTION

The rear s ect ion has a doubl e fl ange which mat es wit h t he doubl e fl ange of the front s ect ion. The doubl e flanges of eachs ect ion are s eal ed wi th a gas ket and s ecured wit h s tuds , washers and nuts . Two s hort pipes from the double fl angeconnect int o the cent re muffl er.

The cent re muffler is a fabricated unit wit h a capaci ty of 7.6 li ters. The muffl er compris es a pair of perforat ed baffle t ubescont ained wi thin the muffler body. The t wo baffle tubes merge into one s ingle t ube which provi des the out let from t hemuffler. A rubber mounti ng is at t ached t o t he rear of the muffler and att aches t o a hanger bracket l ocat ed on theunders ide of t he vehi cl e fl oorpan.

A s i ngl e pipe from t he rear of the centre muffl er is rout ed along t he unders ide of the vehi cl e body to the rear muffler. Thepipe ent ers t he rear muffl er t hrough a connect ion i n t he forward face of the muffl er.

The rear muffl er i s a fabri cat ed uni t wit h a capacit y of 29.3 l it ers . The rear muffler i s pos i ti oned t rans vers ely at t he rear oft he vehi cl e, forward of the rear bumper. The muffler compri ses baffl e plat es and perforated baffle tubes . Each end of t hemuffler body has an outl et which direct exhaus t gas ses to exit at t he rear of t he vehi cl e. The muffler is support ed by as ingle rubber mount ing on t he Left Hand (LH) s ide and by t wo rubber mounti ngs on the Right Hand (RH) s ide.

CATALYTIC CONVERTERS

The cat alyt ic converters are fit t ed in t he front s ect ion of t he exhaus t s ys t em, aft er the HO2S.

The HO2S moni tors the exhaust gas s es leavi ng t he engi ne. The engine management s ys t em us es t hi s informat ion t oprovide accuratel y met ered quant it ies of fuel t o t he combus t ion chambers t o ens ure the mos t efficient us e of fuel and t omi ni mi se the exhaus t emi s si ons .

In the cat alyti c convert ers , t he exhaus t gas es are pas s ed t hrough honeycombed ceramic el ement s coated wi th a s peci als urface t reat ment cal led 'was hcoat '. The was hcoat i ncreas es t he s urface area of the cerami c element s by a fact or ofapproximat el y 7000. O n top of t he was hcoat i s a coat ing cont ai ning plat inum, whi ch is t he act ive cons ti tuent forconvert ing harmful emi ss i ons into inert by-product s. The pl at inum adds oxygen t o the carbon monoxi de and thehydrocarbons i n t he exhaus t gases , to convert t hem i nto carbon di oxi de and water respecti vel y.

Page 1516 of 3229

Publi s hed: 11-May-2011

Exhaust System - I6 3.2L Petrol - Exhaust System

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the exhaust s ys tem, refer t o t he relevant Descripti on and Operat ion s ect ion in t he works hopmanual. REFER to:

Exhaus t Sys t em (309-00A Exhaus t Sys t em - I6 3.2L Pet rol , Descri pti on and Operat ion),Exhaus t Sys t em (309-00B Exhaus t Sys t em - TD4 2.2L Dies el, Des cript ion and Operat ion).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for s ys tem int egrit y and obvi ous s igns of mechanical damage.2.

Visual InspectionMechanical

LeaksMet al fati guePipes , mufflers and cat alyt ic convertersJointsMounti ngsClearance around component s

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep.3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Chart.4.

Symptom Chart

SymptomPossible CauseAction

Exces s ivelynois y/l eaki ng exhaus tExhaus tsys t em/component sInspect exhaus t sys t em, refer t o Vi sual Ins pect ion aboveRecti fy l eaks or Inst all new component s as neces s ary. Refert o Removal and Ins tall ati on ins truct ions i n t his s ect ion

Loss of powerRes t ri ct ed exhaus tsys t emFuel s yst emIgnit ion sys temElect roni c engi necont rol

Inst all new exhaus t component s as neces s ary. Refer t oRemoval and Ins tal lati on ins t ructi ons i n t his s ecti onFor fuel s ys t em t est s .REFER t o: Fuel Tank and Li nes (310-01A Fuel Tank and Li nes -I6 3.2L Pet rol , Diagnos is and Tes t ing).For ignit ion s ys tem tes t s.REFER t o: Engine Ignit ion (303-07A Engine Igni ti on, Diagnos isand Tes ti ng).For electroni c engi ne cont rol t est s .REFER t o: El ect ronic Engine Cont rol s (303-14A El ect ronicEngine Controls - I6 3.2L Petrol , Diagnosi s and Test ing) /Elect ronic Engine Cont rols - 2.2L Durat orq-TDCi (DW ) Di esel(303-14 Electronic Engine Controls - 3.2L, Di agnos is andTes ti ng).