check engine LAND ROVER FRELANDER 2 2006 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 672 of 3229

Publi s hed: 11-May-2011

Engine - I6 3.2L Petrol - Camshafts

Removal and Inst all ati on

Removal

1. W ARNING: Make sure t o s upport the vehicle wit h axles tands .

Rais e and s upport t he vehi cl e.

1.

Remove t he cover and dis connect the bat tery ground cabl e.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -General Informat ion, Specificati ons).

2.

Remove t he camshaft bearing housi ng.

Refer t o: Val ve Cover (303-01A Engine - I6 3.2L Pet rol , Removal andInst all at ion).

3.

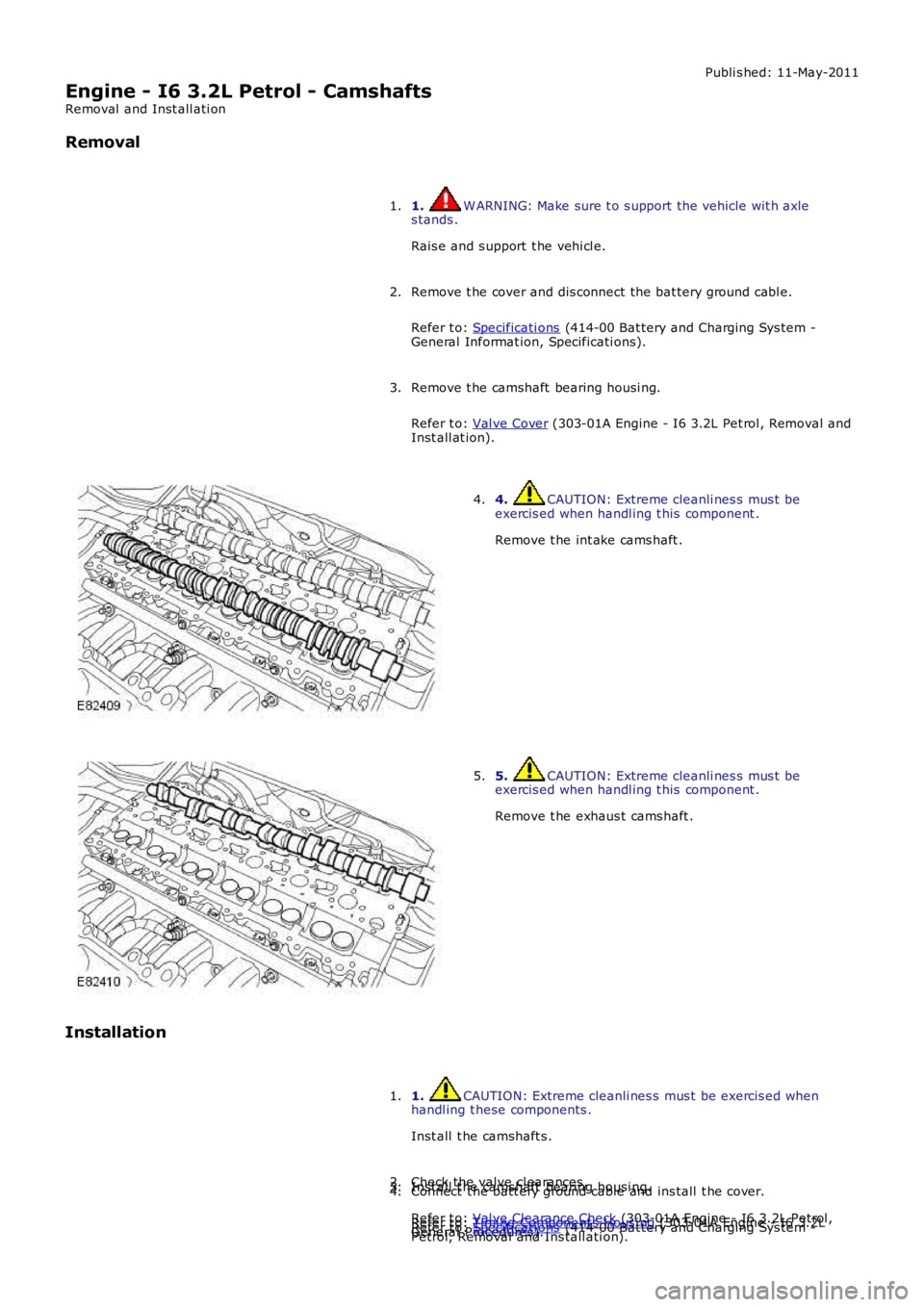

4. CAUTION: Extreme cleanli nes s mus t beexercis ed when handl ing t his component .

Remove t he int ake cams haft .

4.

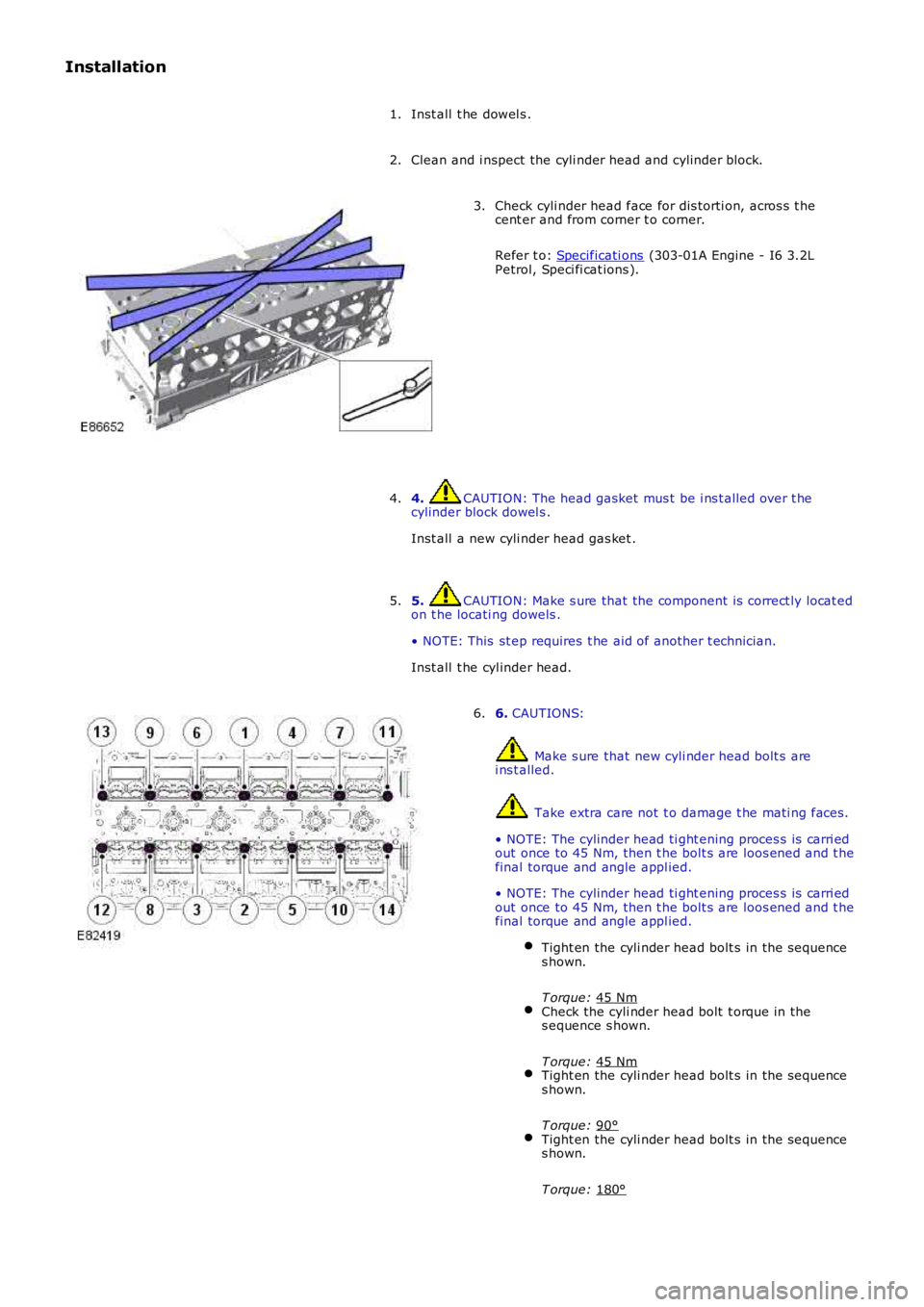

5. CAUTION: Extreme cleanli nes s mus t beexercis ed when handl ing t his component .

Remove t he exhaus t cams haft .

5.

Installation

1. CAUTION: Extreme cleanli nes s mus t be exercis ed whenhandl ing t hese components .

Inst all t he camshaft s .

1.

Check the valve cl earances .

Refer t o: Val ve Clearance Check (303-01A Engine - I6 3.2L Petrol ,General Procedures).

2.Inst all t he camshaft bearing housi ng.

Refer t o: Timi ng Component s Hous i ng (303-01A Engine - I6 3.2LPetrol, Removal and Ins tall ati on).

3.Connect t he batt ery ground cable and ins tall t he cover.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -

4.

Page 684 of 3229

Installation

Inst all t he dowel s .

1.

Clean and i nspect the cyli nder head and cylinder block.

2. Check cyli nder head face for dis torti on, acros s t he

cent er and from corner t o corner.

Refer t o: Specificati ons (303-01A Engine - I6 3.2L

Petrol, Speci fi cat ions ).

3.

4. CAUTION: The head gasket mus t be i ns t alled over t he

cylinder block dowel s .

Inst all a new cyli nder head gas ket .

4.

5. CAUTION: Make s ure that the component is correct ly locat ed

on t he locati ng dowels .

• NOTE: This st ep requires t he aid of another t echnician.

Inst all t he cyl inder head.

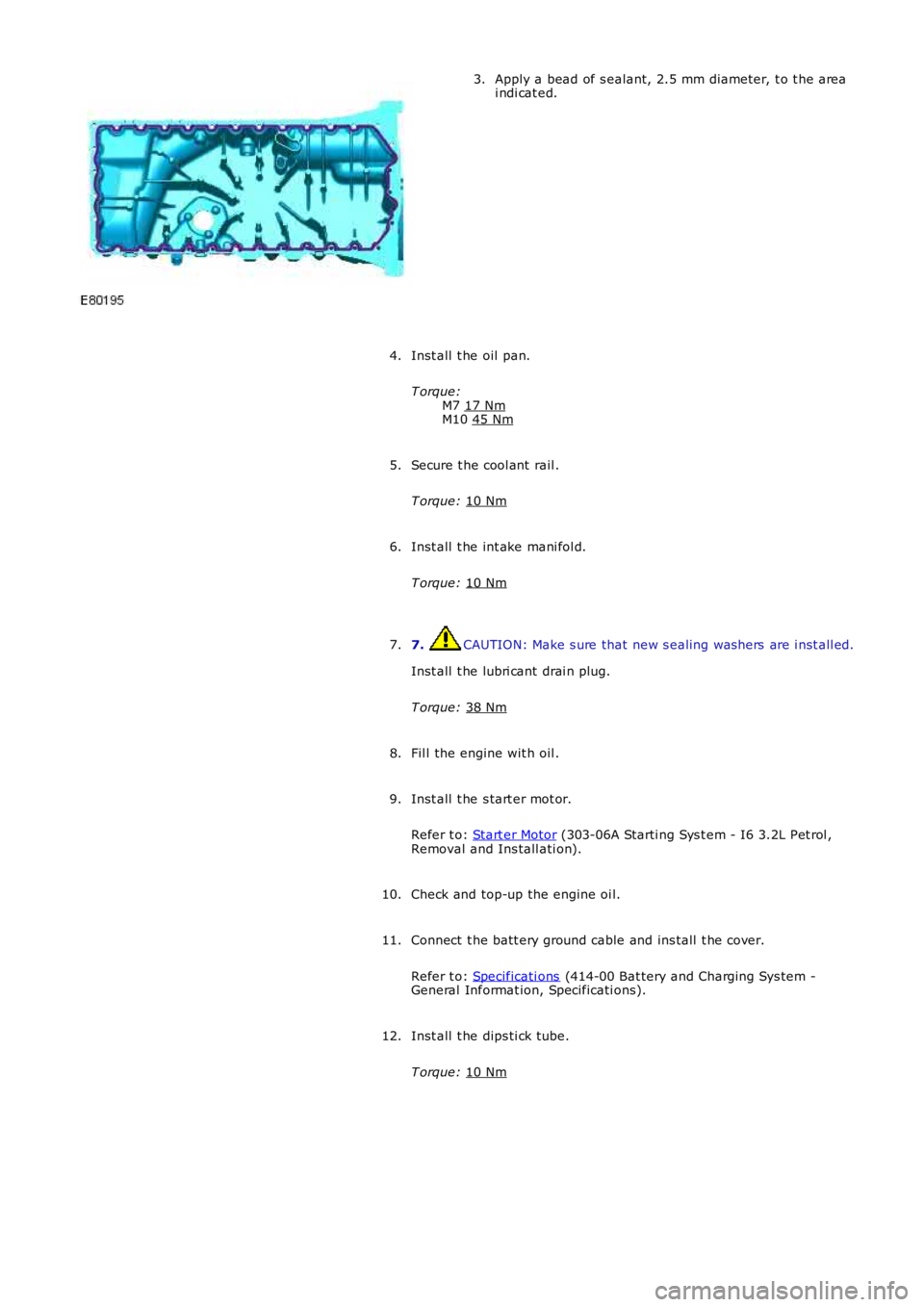

5. 6.

CAUTIONS: Make s ure that new cyli nder head bolt s are

i ns t alled. Take extra care not t o damage t he mati ng faces .

• NOTE: The cylinder head ti ght ening proces s is carri ed

out once to 45 Nm, then t he bolt s are loos ened and t he

final torque and angle appl ied.

• NOTE: The cylinder head ti ght ening proces s is carri ed

out once to 45 Nm, then t he bolt s are loos ened and t he

final torque and angle appl ied.

Tight en the cyli nder head bolt s in the sequence

s hown.

T orque: 45 Nm Check the cyli nder head bolt t orque in the

s equence s hown.

T orque: 45 Nm Tight en the cyli nder head bolt s in the sequence

s hown.

T orque: 90° Tight en the cyli nder head bolt s in the sequence

s hown.

T orque: 180° 6.

Page 690 of 3229

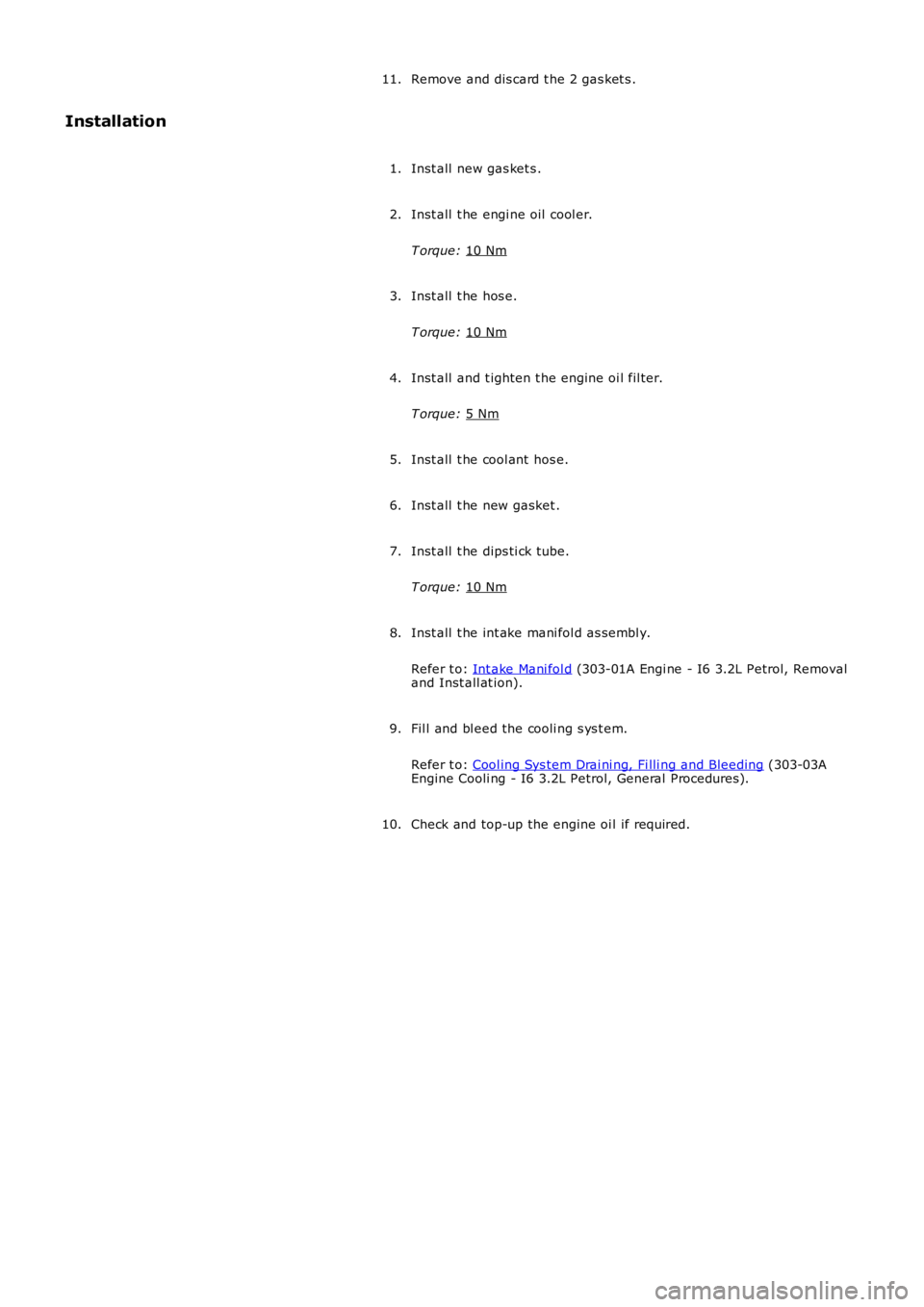

Apply a bead of s ealant, 2.5 mm diamet er, t o t he area

i ndi cat ed.

3.

Inst all t he oil pan.

T orque: M7 17 Nm M10

45 Nm 4.

Secure t he cool ant rail .

T orque: 10 Nm 5.

Inst all t he int ake mani fol d.

T orque: 10 Nm 6.

7. CAUTION: Make s ure that new s ealing was hers are i nst all ed.

Inst all t he lubri cant drai n plug.

T orque: 38 Nm 7.

Fil l the engine wit h oil .

8.

Inst all t he s tart er mot or.

Refer t o: Start er Motor (303-06A Starti ng Sys t em - I6 3.2L Pet rol ,

Removal and Ins tall ati on).

9.

Check and top-up the engine oi l.

10.

Connect t he batt ery ground cable and ins tall t he cover.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -

General Informat ion, Specificati ons).

11.

Inst all t he dips ti ck tube.

T orque: 10 Nm 12.

Page 696 of 3229

Remove and dis card t he 2 gas ket s .

11.

Installation

Inst all new gas ket s .

1.

Inst all t he engi ne oil cool er.

T orque: 10 Nm 2.

Inst all t he hos e.

T orque: 10 Nm 3.

Inst all and t ighten t he engine oi l fil ter.

T orque: 5 Nm 4.

Inst all t he cool ant hos e.

5.

Inst all t he new gasket .

6.

Inst all t he dips ti ck tube.

T orque: 10 Nm 7.

Inst all t he int ake mani fol d as sembl y.

Refer t o: Int ake Mani fol d (303-01A Engi ne - I6 3.2L Petrol, Removal

and Inst all at ion).

8.

Fil l and bl eed the cooli ng s ys t em.

Refer t o: Cool ing Sys tem Drai ni ng, Fi lli ng and Bleeding (303-03A

Engine Cooli ng - I6 3.2L Petrol, General Procedures).

9.

Check and top-up the engine oi l if required.

10.

Page 697 of 3229

Publi s hed: 11-May-2011

Engine - I6 3.2L Petrol - Oil Filter Element

Removal and Inst all ati on

Removal

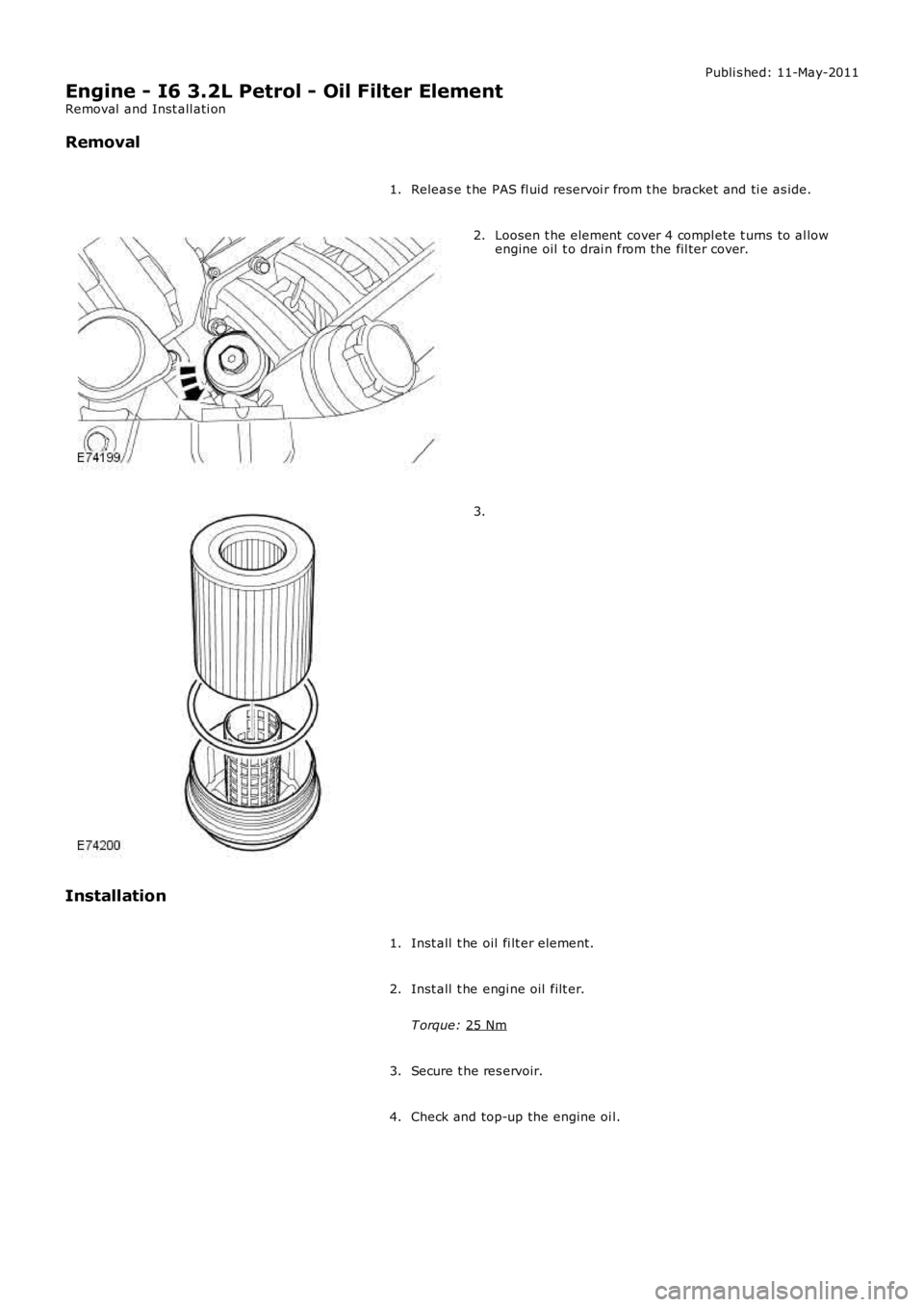

Releas e t he PAS fl uid reservoi r from t he bracket and ti e as ide.

1. Loosen t he element cover 4 compl ete t urns t o al low

engine oil t o drai n from the fil ter cover.

2. 3.

Installation Inst all t he oil fi lt er element.

1.

Inst all t he engi ne oil filt er.

T orque: 25 Nm 2.

Secure t he res ervoir.

3.

Check and top-up the engine oi l.

4.

Page 717 of 3229

Publi s hed: 11-May-2011

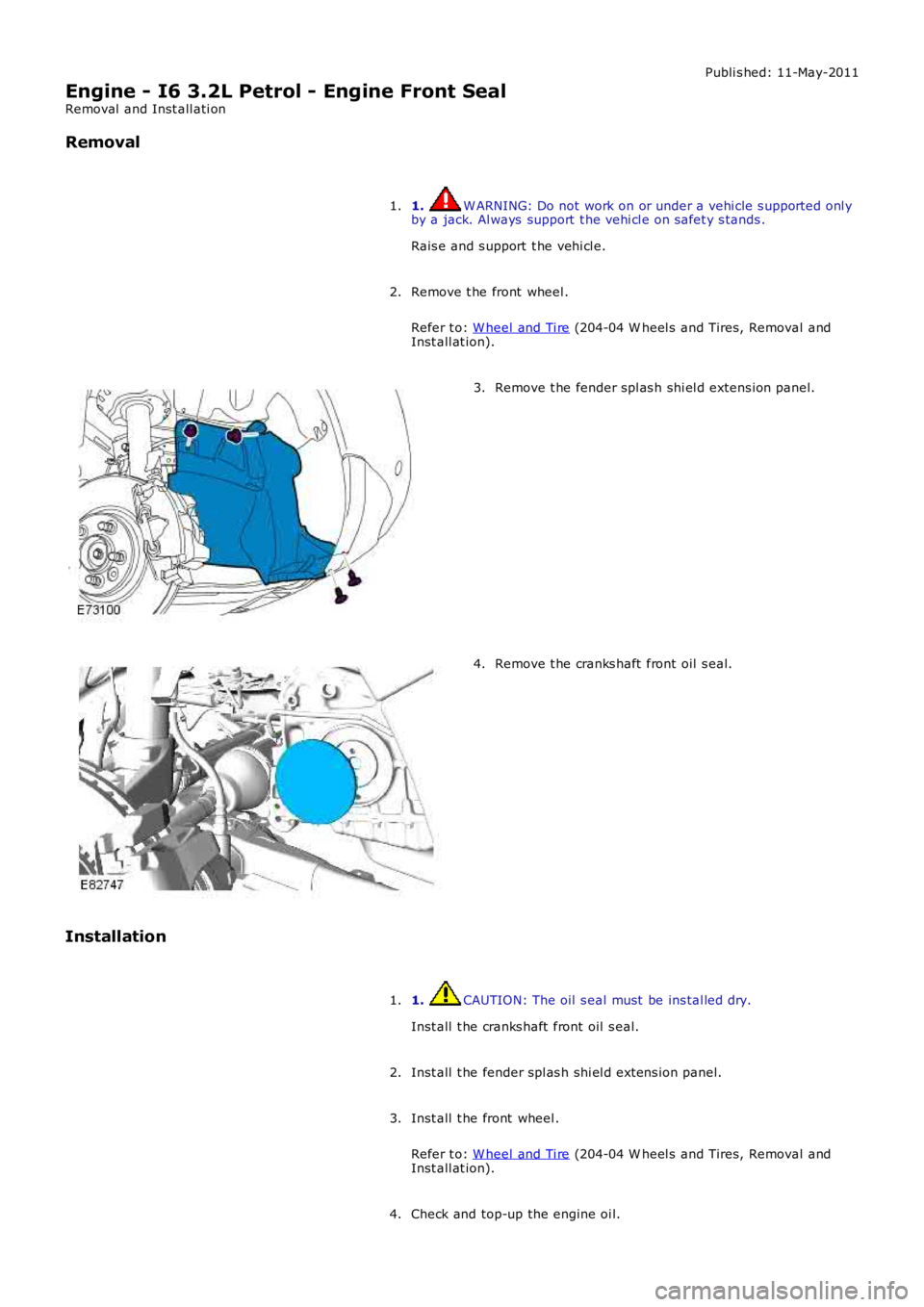

Engine - I6 3.2L Petrol - Engine Front Seal

Removal and Inst all ati on

Removal

1. W ARNING: Do not work on or under a vehi cle s upported onl yby a jack. Al ways support t he vehi cl e on s afet y s tands .

Rais e and s upport t he vehi cl e.

1.

Remove t he front wheel .

Refer t o: W heel and Ti re (204-04 W heel s and Tires, Removal andInst all at ion).

2.

Remove t he fender spl as h shi el d extens ion panel.3.

Remove t he cranks haft front oil s eal.4.

Installation

1. CAUTION: The oil s eal must be ins tal led dry.

Inst all t he cranks haft front oil s eal.

1.

Inst all t he fender spl as h shi el d extens ion panel.2.

Inst all t he front wheel .

Refer t o: W heel and Ti re (204-04 W heel s and Tires, Removal andInst all at ion).

3.

Check and top-up the engine oi l.4.

Page 752 of 3229

Publi s hed: 11-May-2011

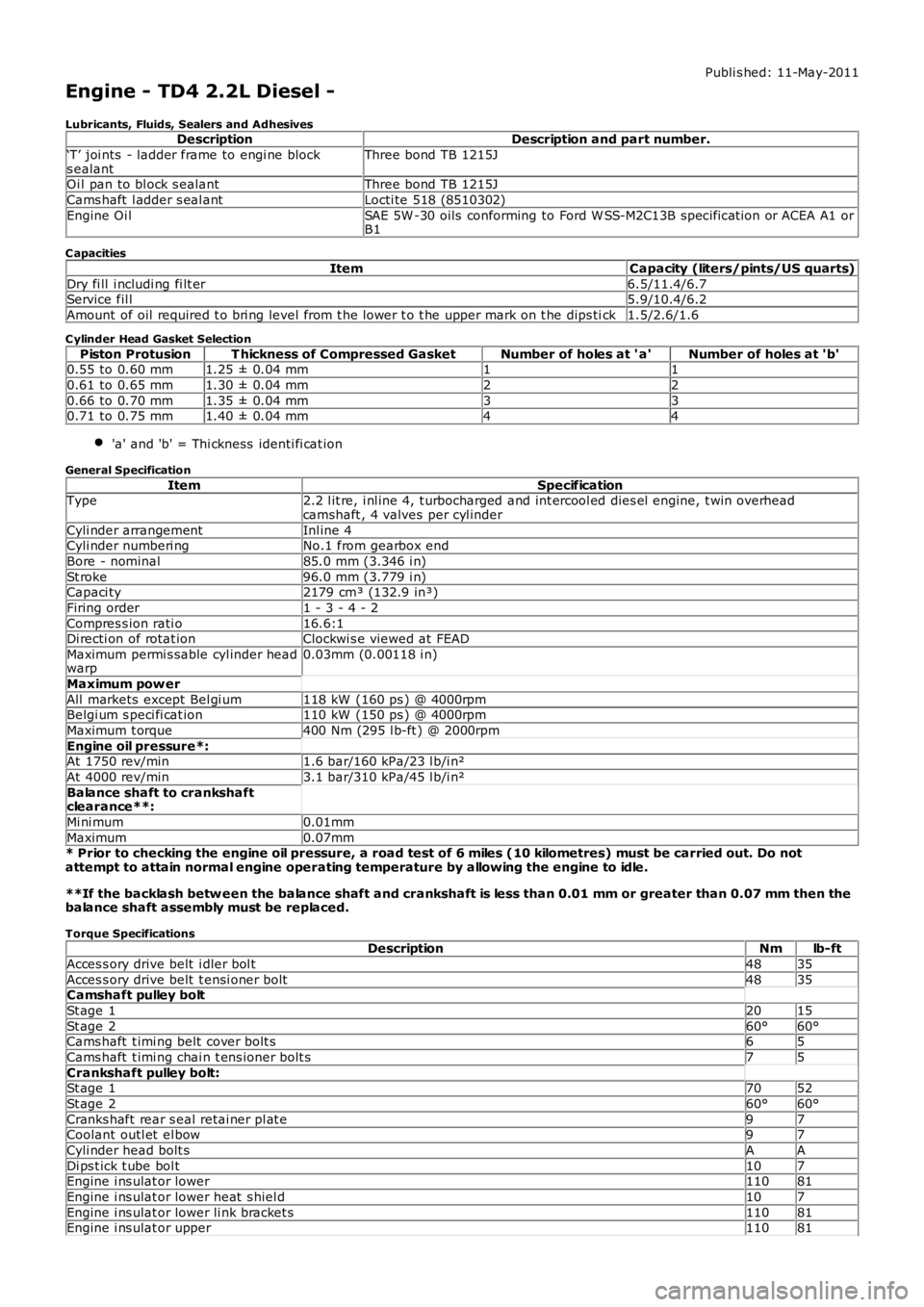

Engine - TD4 2.2L Diesel -

Lubricants, Fluids, Sealers and AdhesivesDescriptionDescription and part number.

‘T’ joi nts - ladder frame to engi ne blocks ealantThree bond TB 1215J

Oi l pan to bl ock s ealantThree bond TB 1215J

Cams haft l adder s eal antLocti te 518 (8510302)

Engine Oi lSAE 5W -30 oils conforming to Ford W SS-M2C13B specificat ion or ACEA A1 orB1

C apacities

ItemCapacity (liters/pints/US quarts)

Dry fi ll i ncludi ng fi lt er6.5/11.4/6.7Service fil l5.9/10.4/6.2

Amount of oil required t o bri ng level from t he lower t o t he upper mark on t he dips tick1.5/2.6/1.6

C ylinder Head Gasket Selection

Piston ProtusionT hickness of Compressed GasketNumber of holes at ' a'Number of holes at 'b'0.55 to 0.60 mm1.25 ± 0.04 mm11

0.61 to 0.65 mm1.30 ± 0.04 mm22

0.66 to 0.70 mm1.35 ± 0.04 mm330.71 to 0.75 mm1.40 ± 0.04 mm44

'a' and 'b' = Thi ckness identi fi cat ion

General Specification

ItemSpecificationType2.2 l it re, i nl ine 4, t urbocharged and int ercool ed dies el engine, t win overheadcamshaft , 4 valves per cyl inder

Cyli nder arrangementInl ine 4Cyli nder numberi ngNo.1 from gearbox end

Bore - nominal85.0 mm (3.346 i n)

St roke96.0 mm (3.779 i n)Capaci ty2179 cm³ (132.9 in³)

Firing order1 - 3 - 4 - 2

Compres s ion rati o16.6:1Di recti on of rotat ionClockwi s e viewed at FEAD

Maximum permi s sable cyl inder headwarp0.03mm (0.00118 i n)

Maximum pow er

All markets except Bel gi um118 kW (160 ps ) @ 4000rpmBelgi um s peci fi cat ion110 kW (150 ps ) @ 4000rpm

Maximum t orque400 Nm (295 l b-ft ) @ 2000rpm

Engine oil pressure*:At 1750 rev/min1.6 bar/160 kPa/23 l b/i n²

At 4000 rev/min3.1 bar/310 kPa/45 l b/i n²

Balance shaft to crankshaftclearance**:

Mi ni mum0.01mm

Maximum0.07mm* Prior to checking the engine oil pressure, a road test of 6 miles (10 kilometres) must be carried out. Do notattempt to attain normal engine operating temperature by allowing the engine to idle.

**If the backlash betw een the balance shaft and crankshaft is less than 0.01 mm or greater than 0.07 mm then thebalance shaft assembly must be replaced.

Torque SpecificationsDescriptionNmlb-ft

Acces s ory drive belt i dler bol t4835

Acces s ory drive belt t ensi oner bolt4835Camshaft pulley bolt

St age 12015

St age 260°60°Cams haft t imi ng belt cover bolt s65

Cams haft t imi ng chai n t ens ioner bolt s75

Crankshaft pulley bolt:St age 17052

St age 260°60°

Cranks haft rear s eal retai ner pl at e97Coolant outl et el bow97

Cyli nder head bolt sAA

Di ps t ick t ube bol t107Engine i ns ulat or lower11081

Engine i ns ulat or lower heat s hiel d107

Engine i ns ulat or lower li nk bracket s11081Engine i ns ulat or upper11081

Page 768 of 3229

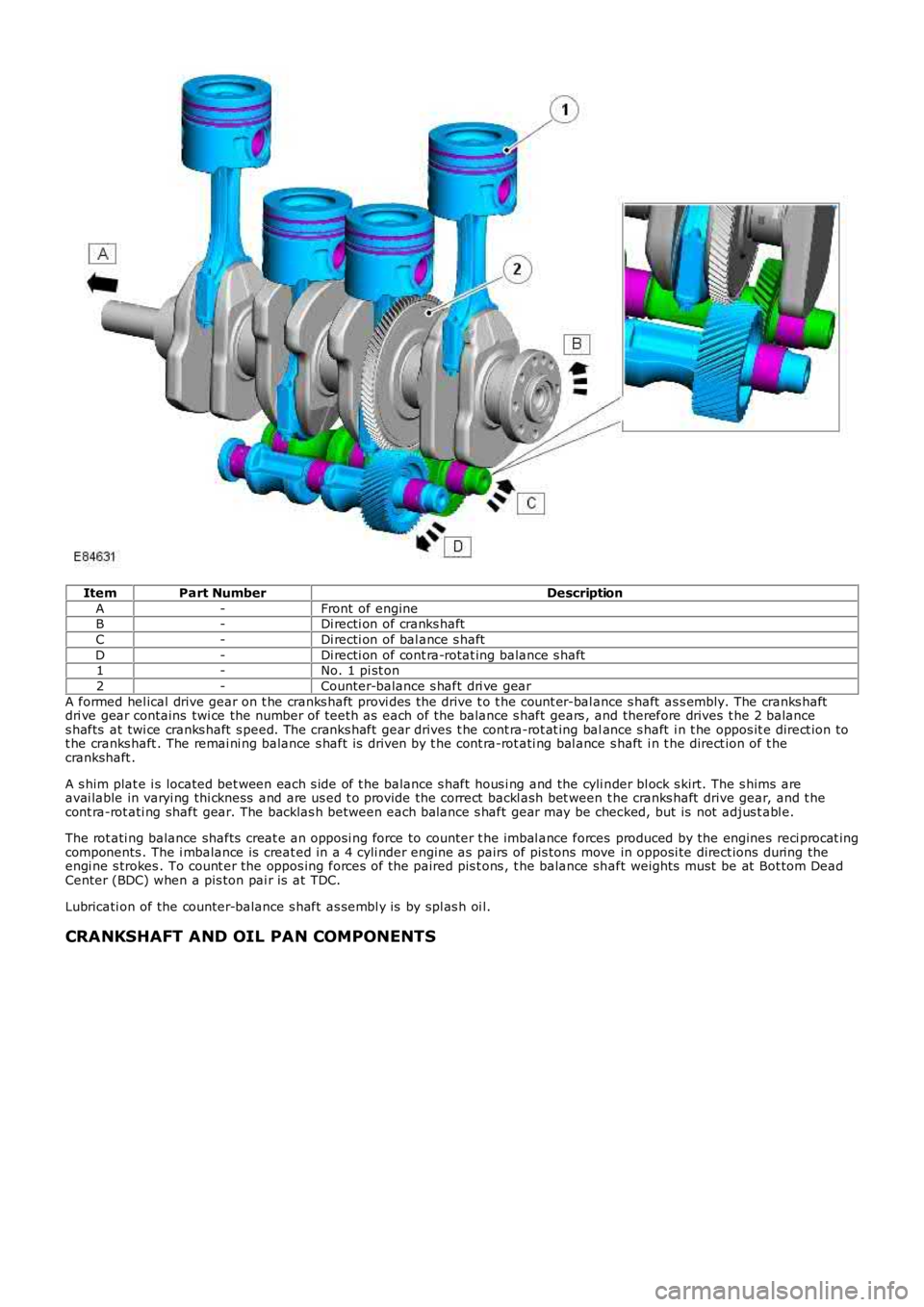

ItemPart NumberDescription

A-Front of engineB-Di recti on of cranks haft

C-Di recti on of bal ance s haft

D-Di recti on of cont ra-rotat ing balance s haft1-No. 1 pi st on

2-Counter-balance s haft dri ve gear

A formed hel ical drive gear on t he cranks haft provi des the drive t o t he count er-bal ance s haft as s embly. The cranks haftdri ve gear contains twi ce the number of teet h as each of the balance s haft gears , and therefore drives t he 2 balances hafts at twi ce cranks haft s peed. The cranks haft gear drives t he cont ra-rot at ing balance s haft i n t he oppos it e direct ion tot he cranks haft . The remai ni ng balance s haft is driven by t he cont ra-rot ati ng bal ance s haft i n t he direct ion of t hecrankshaft .

A s him plat e i s located bet ween each s ide of t he balance s haft hous i ng and the cyli nder bl ock s kirt. The s hims areavai lable in varyi ng thi ckness and are us ed t o provide the correct backl ash bet ween t he cranks haft drive gear, and t hecont ra-rot ati ng shaft gear. The backlas h between each balance s haft gear may be checked, but is not adjus t abl e.

The rot ati ng balance shafts creat e an opposi ng force to counter t he imbal ance forces produced by the engines reci procat ingcomponents . The i mbalance is creat ed in a 4 cyli nder engine as pairs of pis tons move in opposi te direct ions during theengi ne s trokes . To count er the oppos ing forces of the paired pis t ons , t he balance shaft weights must be at Bot tom DeadCenter (BDC) when a pis ton pai r is at TDC.

Lubricati on of the counter-balance s haft as sembl y is by spl as h oi l.

CRANKSHAFT AND OIL PAN COMPONENTS

Page 802 of 3229

Publi s hed: 11-May-2011

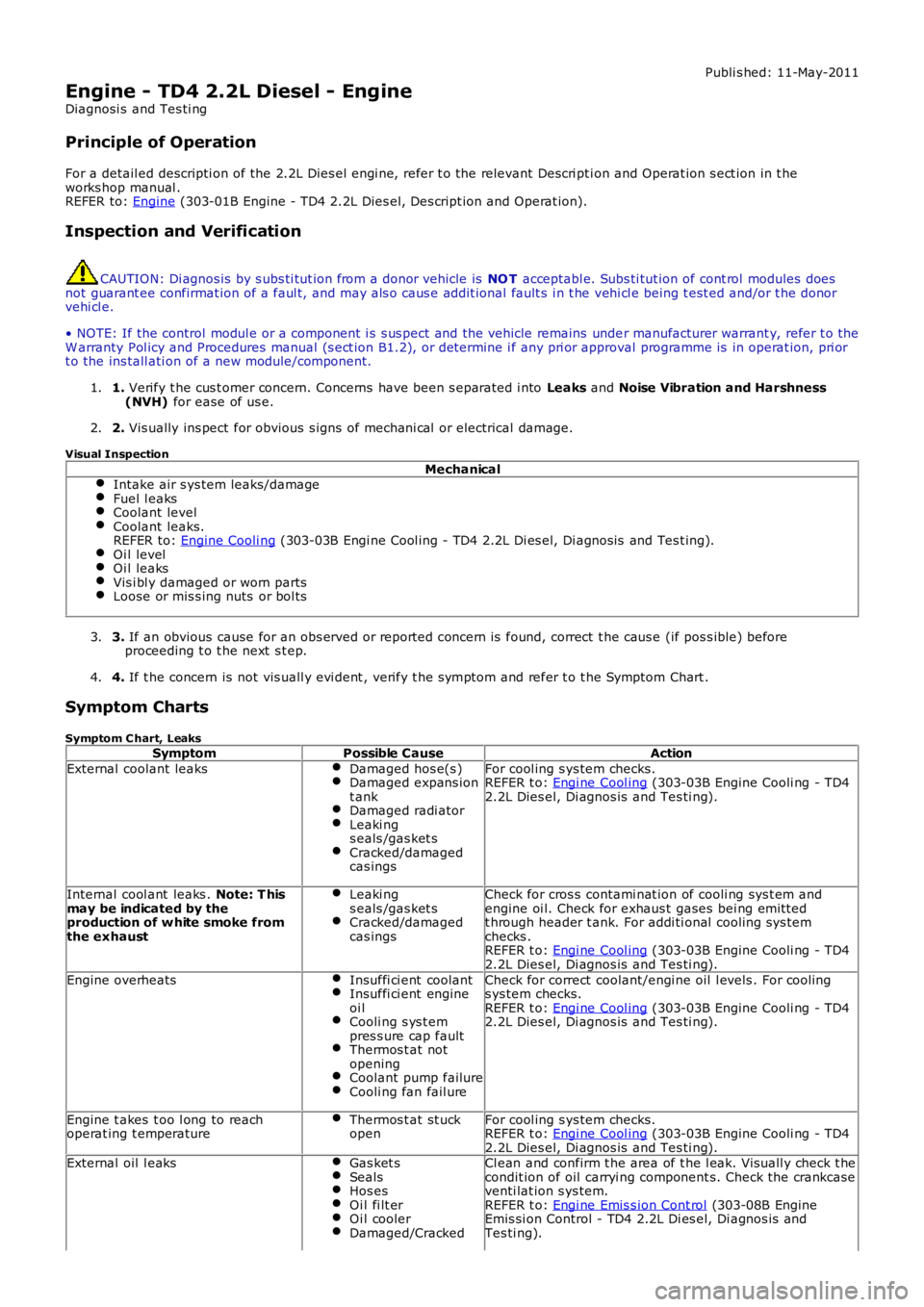

Engine - TD4 2.2L Diesel - Engine

Diagnosi s and Tes ti ng

Principle of Operation

For a detail ed descripti on of the 2.2L Dies el engi ne, refer t o the relevant Descri pti on and Operat ion s ect ion in t heworks hop manual .REFER to: Engine (303-01B Engine - TD4 2.2L Dies el, Des cript ion and Operat ion).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains under manufacturer warrant y, refer t o theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

1. Verify t he cus t omer concern. Concerns have been s eparated i nto Leaks and Noise Vibration and Harshness(NVH) for ease of us e.1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.2.

Visual Inspection

MechanicalIntake air s ys tem leaks/damageFuel l eaksCoolant levelCoolant leaks.REFER to: Engine Cooli ng (303-03B Engi ne Cool ing - TD4 2.2L Di es el, Di agnos is and Tes t ing).Oi l levelOi l leaksVis i bl y damaged or worn partsLoose or mis s ing nuts or bol ts

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep.3.

4. If t he concern is not vis uall y evi dent , verify t he s ymptom and refer t o t he Symptom Chart .4.

Symptom Charts

Symptom C hart, LeaksSymptomPossible CauseAction

External coolant leaksDamaged hos e(s )Damaged expans iont ankDamaged radi atorLeaki ngs eals /gas ket sCracked/damagedcas ings

For cool ing s ys tem checks.REFER t o: Engi ne Cool ing (303-03B Engine Cooli ng - TD42.2L Dies el, Di agnos is and Tes ti ng).

Internal cool ant leaks . Note: T hismay be indicated by theproduction of w hite smoke fromthe exhaust

Leaki ngs eals /gas ket sCracked/damagedcas ings

Check for cros s contami nat ion of cooli ng sys t em andengine oi l. Check for exhaus t gases bei ng emit tedt hrough header t ank. For addi ti onal cooling sys temchecks .REFER t o: Engi ne Cool ing (303-03B Engine Cooli ng - TD42.2L Dies el, Di agnos is and Tes ti ng).

Engine overheatsInsuffi ci ent coolantInsuffi ci ent engineoi lCooli ng s ys t empres s ure cap faultThermos t at notopeningCoolant pump failureCooli ng fan fail ure

Check for correct coolant/engi ne oil l evels . For cool ings ys tem checks.REFER t o: Engi ne Cool ing (303-03B Engine Cooli ng - TD42.2L Dies el, Di agnos is and Tes ti ng).

Engine t akes t oo l ong to reachoperat ing t emperatureThermos t at st uckopenFor cool ing s ys tem checks.REFER t o: Engi ne Cool ing (303-03B Engine Cooli ng - TD42.2L Dies el, Di agnos is and Tes ti ng).External oil l eaksGas ket sSealsHos esOi l fi lt erOi l coolerDamaged/Cracked

Cl ean and confirm t he area of t he l eak. Vis uall y check t hecondit ion of oil carryi ng component s. Check the crankcaseventi lat ion s ys tem.REFER t o: Engi ne Emis s ion Cont rol (303-08B EngineEmis si on Control - TD4 2.2L Di es el, Di agnos is andTes ti ng).

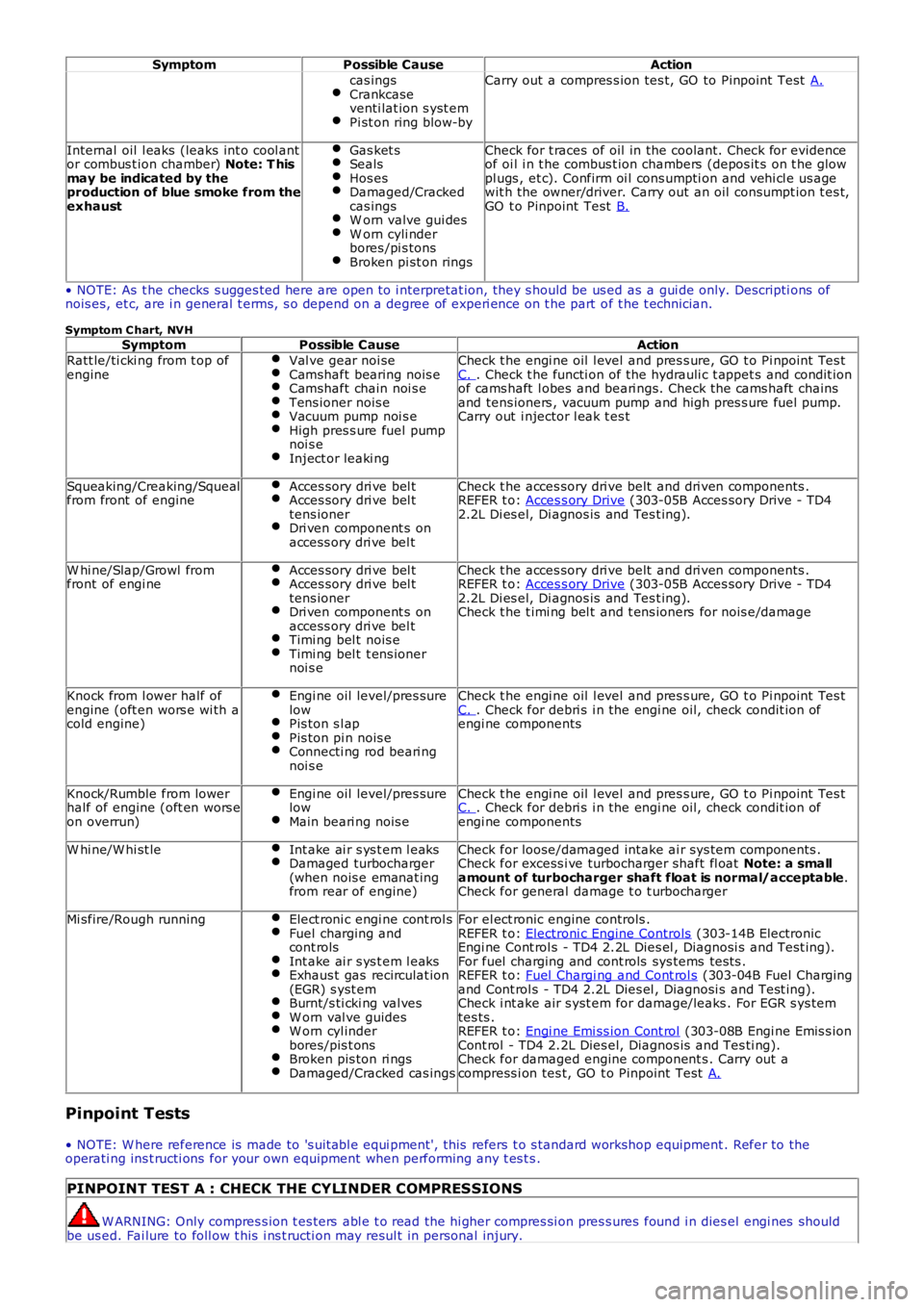

Page 803 of 3229

SymptomPossible CauseAction

cas ingsCrankcaseventi lat ion s yst emPi st on ring blow-by

Carry out a compres s ion tes t, GO to Pinpoint Test A.

Internal oil l eaks (leaks int o cool antor combus t ion chamber) Note: T hismay be indicated by theproduction of blue smoke from theexhaust

Gas ket sSealsHos esDamaged/Crackedcas ingsW orn valve gui desW orn cyli nderbores /pi s tonsBroken pi st on rings

Check for t races of oil in the coolant. Check for evidenceof oi l i n t he combus t ion chambers (depos it s on t he glowpl ugs , et c). Confirm oi l cons umpti on and vehi cl e us agewit h the owner/driver. Carry out an oil consumpt ion t es t,GO t o Pinpoint Test B.

• NOTE: As t he checks s ugges ted here are open to i nterpretat ion, they s hould be us ed as a gui de only. Descripti ons ofnois es, et c, are i n general t erms, s o depend on a degree of experi ence on t he part of t he t echnician.

Symptom C hart, NVHSymptomPossible CauseAction

Ratt le/ti cki ng from t op ofengineVal ve gear noi seCamshaft bearing nois eCamshaft chain noi s eTens ioner nois eVacuum pump noi s eHigh pres s ure fuel pumpnoi s eInject or leaki ng

Check t he engi ne oil l evel and pres s ure, GO t o Pi npoint Tes tC. . Check t he functi on of the hydrauli c t appet s and condit ionof cams haft l obes and beari ngs. Check the cams haft chainsand tens ioners , vacuum pump and high pres s ure fuel pump.Carry out i njector l eak t es t

Squeaking/Creaking/Squealfrom front of engineAcces sory dri ve bel tAcces sory dri ve bel ttens ionerDri ven component s onaccess ory dri ve bel t

Check t he acces sory dri ve belt and dri ven components .REFER t o: Acces s ory Drive (303-05B Acces sory Drive - TD42.2L Di es el, Di agnos is and Tes t ing).

W hi ne/Slap/Growl fromfront of engi neAcces sory dri ve bel tAcces sory dri ve bel ttens ionerDri ven component s onaccess ory dri ve bel tTimi ng bel t nois eTimi ng bel t t ens ionernoi s e

Check t he acces sory dri ve belt and dri ven components .REFER t o: Acces s ory Drive (303-05B Acces sory Drive - TD42.2L Di es el, Di agnos is and Tes t ing).Check t he t imi ng bel t and t ens ioners for nois e/damage

Knock from l ower half ofengine (oft en wors e wi th acold engine)

Engi ne oil level/pres surelowPis ton s l apPis ton pi n nois eConnecti ng rod beari ngnoi s e

Check t he engi ne oil l evel and pres s ure, GO t o Pi npoint Tes tC. . Check for debri s i n the engi ne oil, check condit ion ofengi ne components

Knock/Rumble from lowerhalf of engine (oft en wors eon overrun)

Engi ne oil level/pres surelowMain beari ng nois e

Check t he engi ne oil l evel and pres s ure, GO t o Pi npoint Tes tC. . Check for debri s i n the engi ne oil, check condit ion ofengi ne components

W hi ne/W hi st leInt ake ai r s ys t em l eaksDamaged turbocharger(when nois e emanat ingfrom rear of engine)

Check for loose/damaged intake ai r sys tem components .Check for excess i ve turbocharger shaft fl oat Note: a smallamount of turbocharger shaft float is normal/acceptable.Check for general damage t o t urbocharger

Mi sfire/Rough runningElect roni c engi ne cont rol sFuel charging andcont rolsInt ake ai r s ys t em l eaksExhaus t gas recirculat ion(EGR) s yst emBurnt/s ti cki ng val vesW orn val ve guidesW orn cyl inderbores/pis t onsBroken pis ton ri ngsDamaged/Cracked cas ings

For el ect ronic engine controls .REFER t o: Electroni c Engine Controls (303-14B ElectronicEngi ne Cont rol s - TD4 2.2L Dies el , Diagnosi s and Test ing).For fuel charging and cont rols sys tems tes ts .REFER t o: Fuel Chargi ng and Cont rol s (303-04B Fuel Chargingand Cont rol s - TD4 2.2L Dies el , Diagnosi s and Test ing).Check i nt ake air s yst em for damage/leaks . For EGR s ys temtes ts .REFER t o: Engi ne Emi ss ion Cont rol (303-08B Engi ne Emis s ionCont rol - TD4 2.2L Dies el, Diagnos is and Tes ti ng).Check for damaged engine component s . Carry out acompress i on tes t, GO t o Pinpoint Test A.

Pinpoint Tests

• NOTE: W here reference is made to 's uit abl e equi pment', this refers t o s tandard workshop equipment . Refer to theoperati ng ins t ructi ons for your own equipment when performing any t es t s .

PINPOINT TEST A : CHECK THE CYLINDER COMPRESSIONS

W ARNING: Only compres s ion t es ters abl e t o read the hi gher compres si on pres s ures found i n dies el engi nes shouldbe us ed. Fai lure to foll ow t his i ns t ructi on may resul t in personal injury.