check engine LAND ROVER FRELANDER 2 2006 Manual PDF

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 804 of 3229

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

1

2

3

4

5

6

7

8

9

• NOTE: W here pos si ble, compress i on tes t ing s houl d be carried out on an engine at normal operat ing temperat ure.

T ESTCONDIT IONSDET AILS/RESULT S/ACT IONS

A1: CARRY OUT A DRY CYLINDER COMPRESSION T EST

Make s ure t he parki ng brake is appl ied and t hat t he s elector l ever is in neutral (or park for vehi cl eswi th aut omati c transmis si on).

Set the ignit ion s t at us t o OFF.

Remove t he st art er rel ay.

Dis connect t he st art er motor s olenoid connect or.

Connect a s uit able remote st art er devi ce to the s t art er mot or s ol enoi d.

Remove t he glow pl ugs .REFER to: Gl ow Plugs (303-07B Glow Plug Sys tem, Removal and Ins tal lati on).

Ins t all s uit abl e adapt or in pl ace of t he glow plug i n t he fi rs t cyl inder to be tes t ed.

Connect a s uit able compres s ion t es ter t o the adapt or. See warni ng above.

Us ing t he remote s t art er device, crank t he engi ne a mi nimum of fi ve revoluti ons.

Record t he compres si on fi gure and t he number of revol uti ons taken to reach it .

Repeat s t eps 7 - 10 above for t he remai ning cylinders , cranking t he engine for a s imi lar number ofrevolut ions each ti me.

Compare the compres s ion figures acros s al l t he cylinders .

Are the compres s ion figures wit hi n 10% of each ot her?YesUnles s t he compres si on fi gures are uni vers al ly very low (experience wi ll indicat e thi s), check forother caus es for the cus tomer complaint .NoGO to A2.

A2: CARRY OUT A WET CYLINDER COMPRESSIO N T EST

CAUTION: If engi ne oil i s int roduced i nto the cyli nders, run t he engi ne at 2,000 rpm for a mi ni mum of t en mi nutesaft er compl eti ng tes t ing t o prevent damage to the catal yt ic convert ers . Fai lure to foll ow t his i nst ruct ion may res ul t indamage t o t he vehi cl e.

• NOTE: There is a combus ti on chamber i n the top of each pis ton. Make s ure that the oi l is not all owed t o run into thi schamber.Us ing a sui table oil can wit h a flexibl e s pout , int roduce a s mall amount of cl ean engi ne oil int o t hecyl inder jus t before tes t ing, such t hat the oi l i s able to run between t he pis t on and t he cyl inder bore.Repeat s t eps 7 - 10 from the tes t above, int roduci ng oil i nt o each cyl inder jus t before tes ti ng.

Compare the compres s ion figures acros s al l t he cylinders .

Is the compres s ion figure higher than t he dry tes t?YesA hi gher figure foll owing t he int roducti on of oi l may indi cat e a worn or damaged cyli nder bore, pi st onand/or pis t on ri ngs . Dis as s embl y would be required to confirm t his .NoIf the compres s ion figure is unaffect ed by t he int roducti on of oi l, but t he fi gure is s ti ll les s t han 90%of the ot her cyl inders , thi s may i ndi cat e a burnt and/or s t icking valve, leaking head gasket , et c.Dis as s embl y would be required to confirm t his .Clear any DTCs which may have been i nduced by t he tes t .

PINPOINT TEST B : OIL CONSUMPTION TEST

• NOTE: Oi l cons umpti on wil l vary, dependi ng on a number of fact ors . New engines will normall y us e more oil t han 'run-in'engines, once a cons umpt ion fi gure has been det ermined cont act Deal er Techni cal Support for furt her as s is t ance.T ESTCO NDIT IONSDET AILS/RESULT S/ACT IONS

B1: CHECK FOR EXCESSIVE OIL CONSUMPT IONStart the engine and al low it t o run unt il i t reaches normal operat ing temperat ure.

Make s ure t he vehi cl e i s parked on a l evel s urface and swi tch off.

All ow t o s et t le for at least five minutes .

Check t he oil l evel.

Correct t he level, i f necess ary, and record t he reading and mileage i n t he vehi cl e his t ory.

Make s ure t hat the owner/dri ver i s aware that a t est i s being carried out , and that t hey should nottop-up their oi l level for the durat ion of t he t est , but should check t he level every 160-240 Km(100-150 mil es ).

W hen t he oil l evel reaches the ADD mark, t he cust omer s houl d bri ng the vehicle in to be checked.

Top-up t he oil t o the level at t he beginning of t he tes t and record the amount of oil needed to dos o, and t he mi leage covered in the cours e of t he tes t .

From this , t he cons umpt ion can be calculated, and a decis ion made as to whet her or not t hecons umpti on is cons idered excess ive.Is the consumpt ion excess ive for the mil eage and/or us e? Contact Dealer Technical Support for furtherass is t ance.YesDis as sembl y wil l be required t o check t he components indicated i n t he s ympt om chart .NoNo furt her acti on is necess ary.

PINPOINT TEST C : CHECK THE ENGINE OIL PRESSU RE

• NOTE: The vehicle must be driven a minimum of 6 mil es (10 ki lometers ) prior t o t est ing t he oil press ure. Do not at temptt o att ain normal engi ne operati ng temperature by all owi ng t he engi ne to idle.

• NOTE: Check and, i f neces sary, t op-up t he engine oil l evel before begi nning t his test .

T EST CO NDIT IONSDET AILS/RESULT S/ACT IONSC1: CHECK FOR LOW ENGINE OIL PRESSURE

Page 805 of 3229

1

2

3

4

5

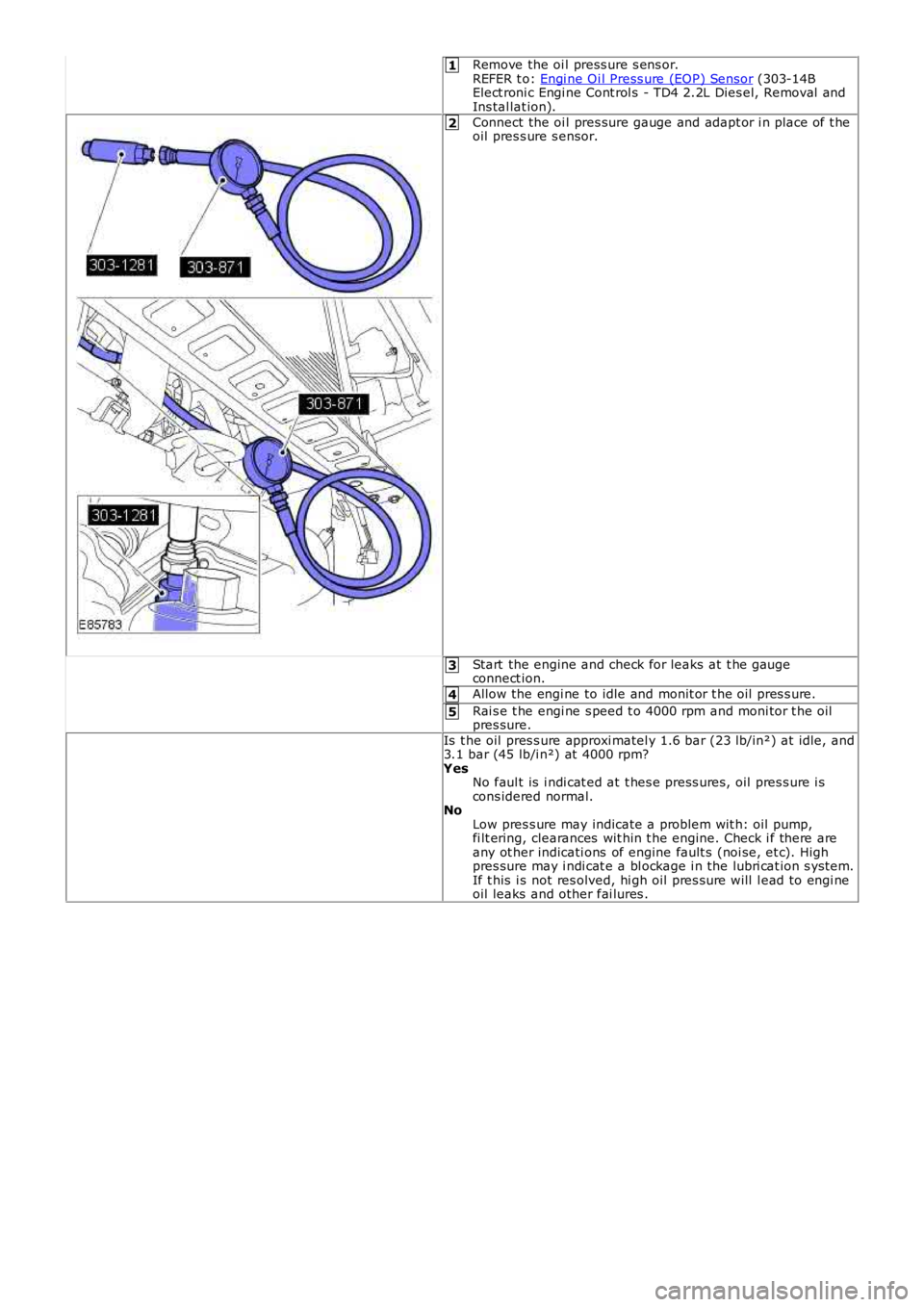

Remove the oi l press ure s ens or.REFER t o: Engi ne Oi l Press ure (EOP) Sensor (303-14BElect roni c Engi ne Cont rol s - TD4 2.2L Dies el, Removal andIns tal lat ion).

Connect the oi l pres sure gauge and adapt or i n place of t heoil pres s ure s ensor.

Start the engine and check for leaks at t he gaugeconnect ion.

Allow the engi ne to idle and monit or t he oil pres s ure.

Rai s e t he engi ne s peed t o 4000 rpm and moni tor t he oilpres sure.

Is t he oil pres s ure approxi matel y 1.6 bar (23 lb/in²) at idle, and3.1 bar (45 lb/i n²) at 4000 rpm?YesNo faul t is i ndi cat ed at t hes e press ures , oil pres s ure i scons idered normal.NoLow pres s ure may indicate a problem wit h: oil pump,fi lt ering, clearances wit hin t he engine. Check i f there areany ot her indicati ons of engine fault s (noi se, et c). Highpres sure may i ndi cat e a bl ockage i n the lubri cat ion s ys tem.If t his i s not res olved, hi gh oil pres s ure will l ead to engi neoil leaks and other fai lures .

Page 806 of 3229

Publi s hed: 11-May-2011

Engine - TD4 2.2L Diesel - Engine Oil Draining and Filling

General Procedures

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

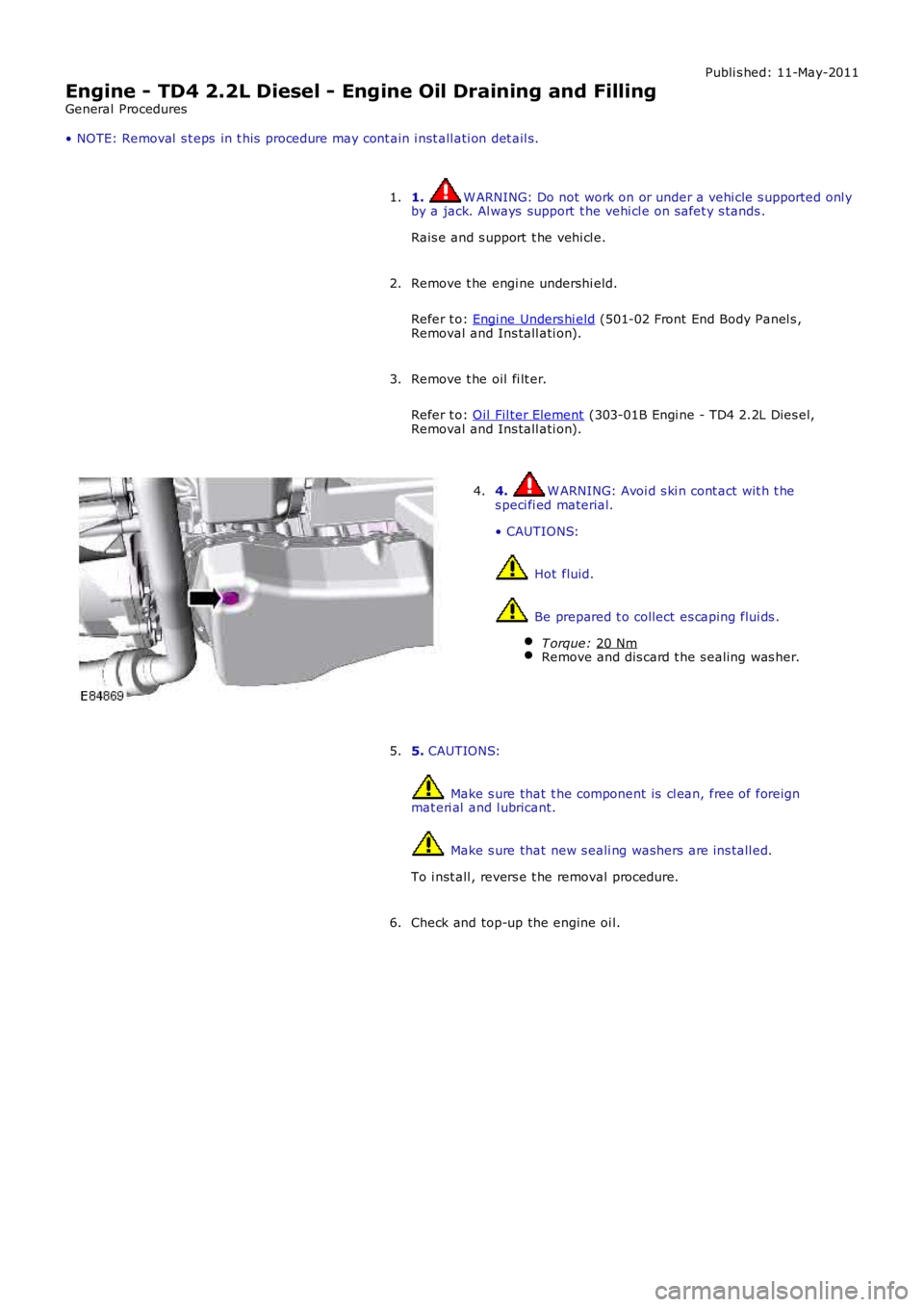

1. W ARNING: Do not work on or under a vehi cle s upported onl y

by a jack. Al ways support t he vehi cl e on s afet y s tands .

Rais e and s upport t he vehi cl e.

1.

Remove t he engi ne undershi eld.

Refer t o: Engi ne Unders hi eld (501-02 Front End Body Panel s ,

Removal and Ins tall ati on).

2.

Remove t he oil fi lt er.

Refer t o: Oil Fil ter Element (303-01B Engi ne - TD4 2.2L Dies el,

Removal and Ins tall ati on).

3. 4. W ARNING: Avoi d s ki n cont act wit h t he

s peci fi ed material.

• CAUTIONS: Hot fluid.

Be prepared t o collect es caping flui ds .

T orque: 20 Nm Remove and dis card t he s ealing was her.4.

5. CAUTIONS: Make s ure that t he component is cl ean, free of foreign

mat eri al and l ubricant. Make s ure that new s eali ng washers are ins tall ed.

To i nst all , revers e t he removal procedure.

5.

Check and top-up the engine oi l.

6.

Page 861 of 3229

T orque:

24 Nm

Inst all t he turbocharger s upport bracket , but do not fully

t ighten at t his st age. Tight en the support bracket to turbocharger bol t.

T orque: 24 Nm Tight en the support bracket to cyli nder bl ock bolt s .

T orque: 24 Nm 4.

5. CAUTIONS: Make s ure that t he area around the component i s clean and

free of foreign mat eri al. Make s ure that new s eali ng washers are ins tall ed.

Connect t he turbocharger oil feed line.

T orque: 24 Nm 5.

Inst all t he turbocharger outl et pi pe.

T orque: 25 Nm 6.

Inst all t he cat alyti c convert er.

Refer t o: Cat alyt ic Converter - Vehicles W it hout : Di es el Part iculate Fil ter (DPF) (309-00B Exhaus t Syst em - TD4 2.2L Di es el, Removal

and Inst all at ion).

7.

Inst all t he EGR cool er.

Refer t o: Exhaus t Gas Reci rculati on (EGR) Cooler (303-08B Engi ne

Emi ss i on Cont rol - TD4 2.2L Dies el, Removal and Ins tall ati on).

8.

Check and top-up the engine oi l.

9.

Page 866 of 3229

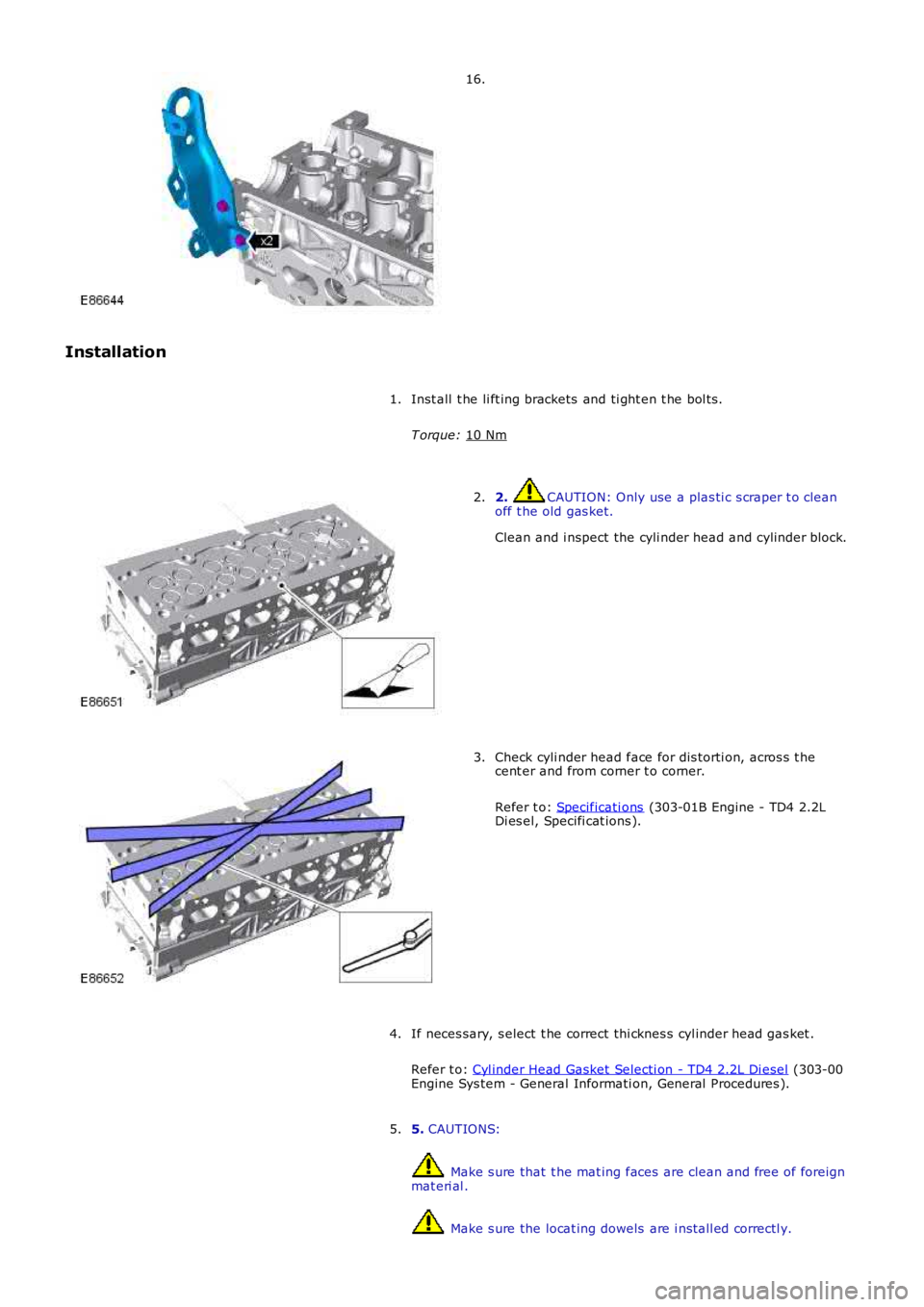

16.

Installation Inst all t he li ft ing brackets and ti ght en t he bol ts .

T orque: 10 Nm 1.

2. CAUTION: Only use a plas ti c s craper t o clean

off t he old gas ket.

Clean and i nspect the cyli nder head and cylinder block.

2. Check cyli nder head face for dis torti on, acros s t he

cent er and from corner t o corner.

Refer t o: Specificati ons (303-01B Engine - TD4 2.2L

Di es el, Specifi cat ions ).

3.

If neces sary, s elect t he correct thi cknes s cyl inder head gas ket .

Refer t o: Cyl inder Head Gasket Selecti on - TD4 2.2L Di esel (303-00

Engine Sys tem - General Informati on, General Procedures ).

4.

5. CAUTIONS: Make s ure that t he mat ing faces are clean and free of foreign

mat eri al . Make s ure the locat ing dowels are i nst all ed correctl y.

5.

Page 874 of 3229

Publi s hed: 11-May-2011

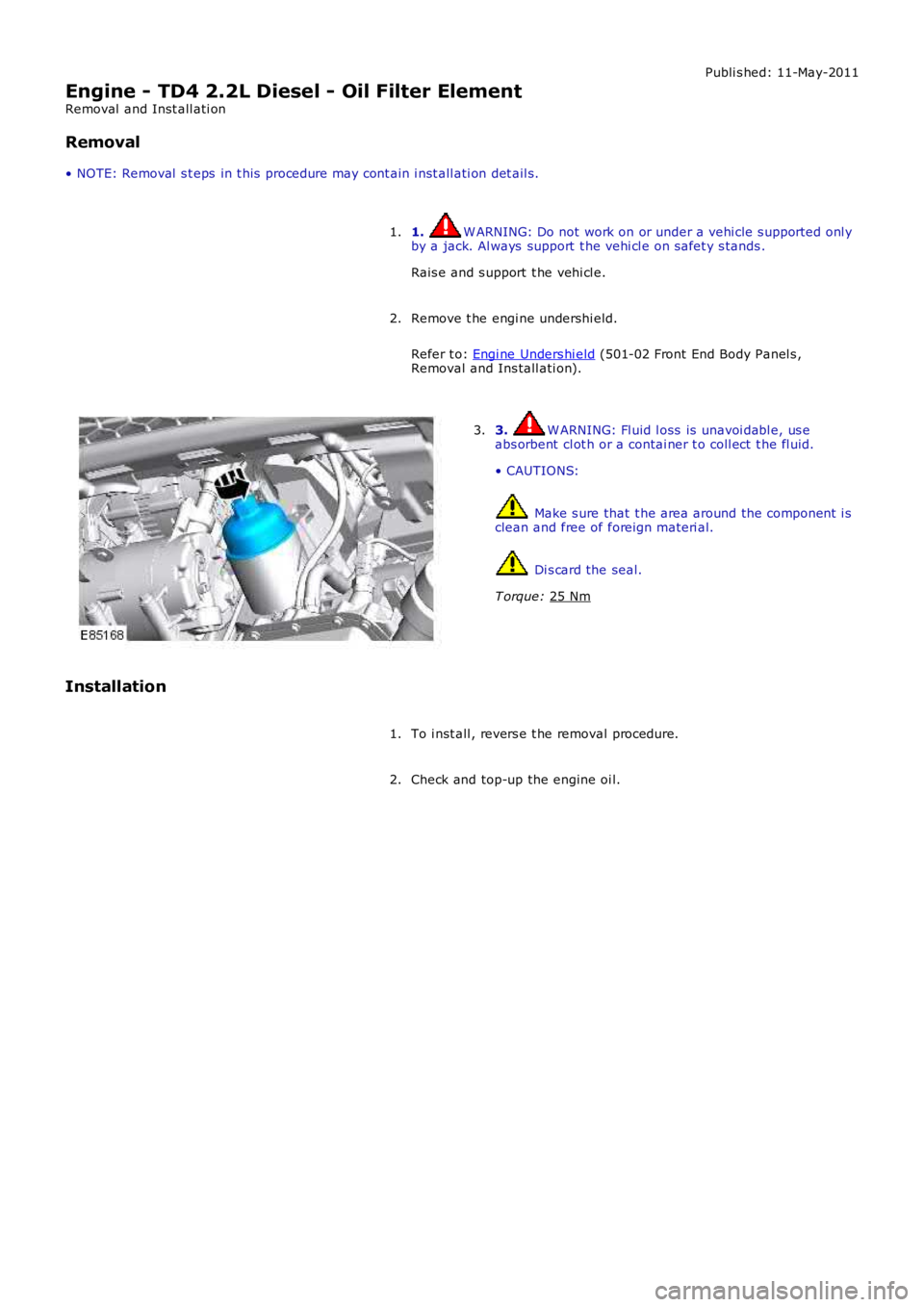

Engine - TD4 2.2L Diesel - Oil Filter Element

Removal and Inst all ati on

Removal

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

1. W ARNING: Do not work on or under a vehi cle s upported onl y

by a jack. Al ways support t he vehi cl e on s afet y s tands .

Rais e and s upport t he vehi cl e.

1.

Remove t he engi ne undershi eld.

Refer t o: Engi ne Unders hi eld (501-02 Front End Body Panel s ,

Removal and Ins tall ati on).

2. 3. W ARNING: Fl uid l oss is unavoi dabl e, us e

abs orbent cl ot h or a contai ner t o coll ect t he fl uid.

• CAUTIONS: Make s ure that t he area around the component i s

clean and free of foreign materi al. Di s card the seal.

T orque: 25 Nm 3.

Installation To i nst all , revers e t he removal procedure.

1.

Check and top-up the engine oi l.

2.

Page 888 of 3229

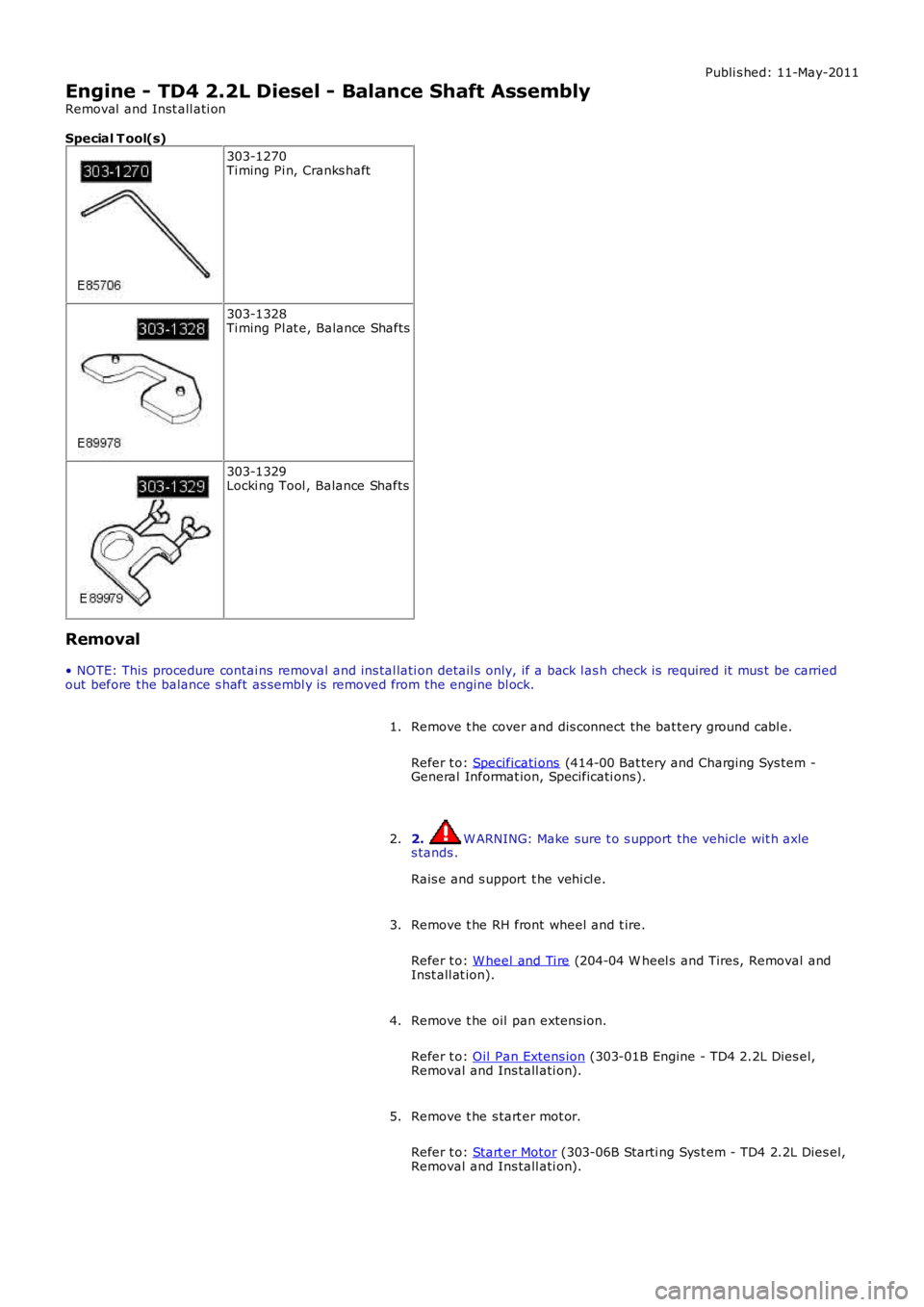

Publi s hed: 11-May-2011

Engine - TD4 2.2L Diesel - Balance Shaft Assembly

Removal and Inst all ati on

Special T ool(s)

303-1270Ti ming Pi n, Cranks haft

303-1328Ti ming Pl at e, Balance Shafts

303-1329Locki ng Tool , Balance Shafts

Removal

• NOTE: This procedure contai ns removal and ins tal lati on detail s only, if a back l ash check is required it mus t be carriedout before the balance s haft as sembl y is removed from the engine bl ock.

Remove t he cover and dis connect the bat tery ground cabl e.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -General Informat ion, Specificati ons).

1.

2. W ARNING: Make sure t o s upport the vehicle wit h axles tands .

Rais e and s upport t he vehi cl e.

2.

Remove t he RH front wheel and t ire.

Refer t o: W heel and Ti re (204-04 W heel s and Tires, Removal andInst all at ion).

3.

Remove t he oil pan extens ion.

Refer t o: Oil Pan Extens ion (303-01B Engine - TD4 2.2L Dies el,Removal and Ins tall ati on).

4.

Remove t he s tart er mot or.

Refer t o: Start er Motor (303-06B Starti ng Sys t em - TD4 2.2L Dies el,Removal and Ins tall ati on).

5.

Page 913 of 3229

Publi s hed: 11-May-2011

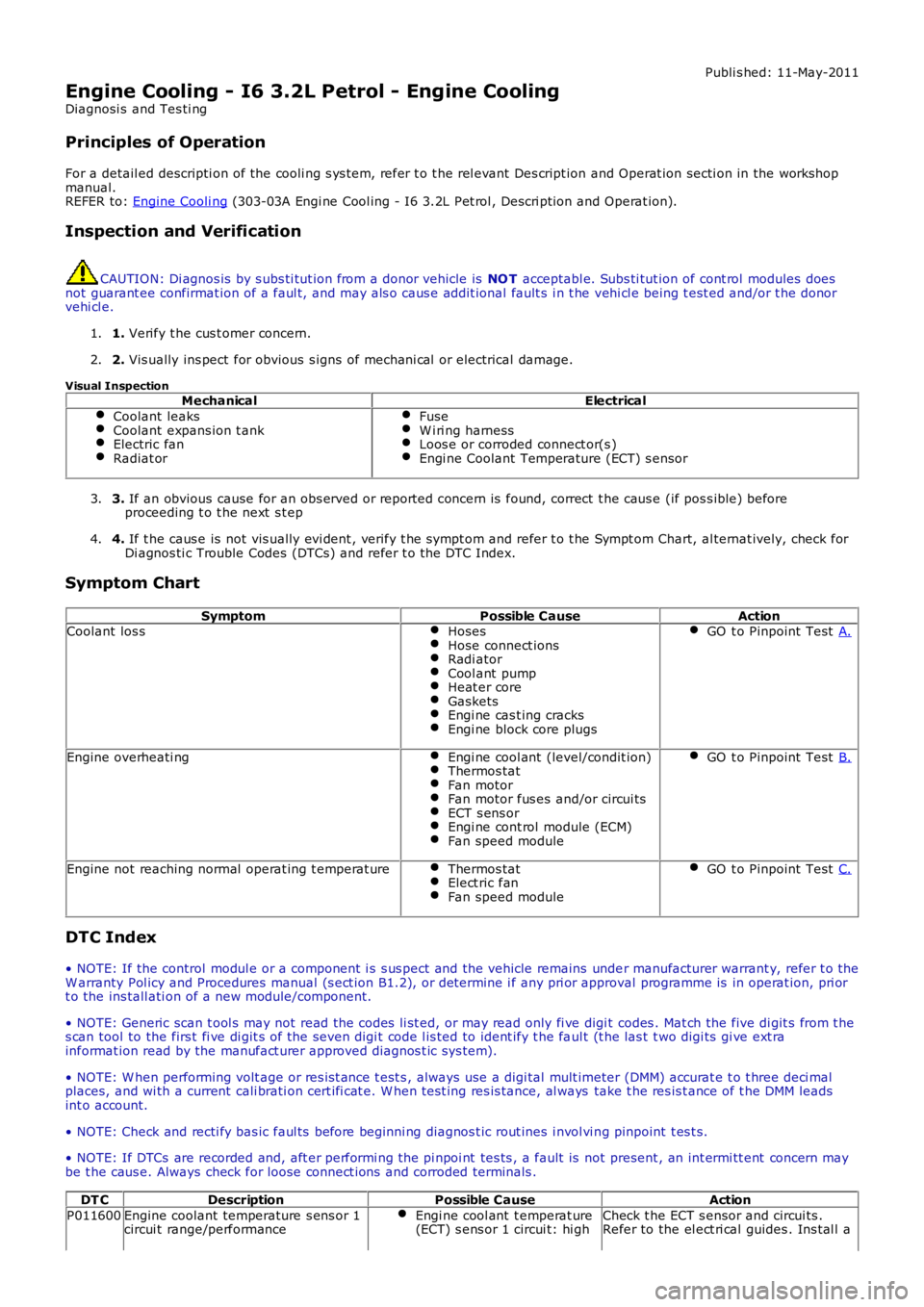

Engine Cooling - I6 3.2L Petrol - Engine Cooling

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the cooli ng s ys t em, refer t o t he rel evant Des cript ion and Operat ion secti on in the workshopmanual.REFER to: Engine Cooli ng (303-03A Engi ne Cool ing - I6 3.2L Pet rol , Descri pti on and Operat ion).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.2.

Visual InspectionMechanicalElectrical

Coolant leaksCoolant expans ion t ankElectric fanRadiat or

FuseW i ri ng harnessLoos e or corroded connect or(s )Engi ne Coolant Temperature (ECT) s ensor

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Chart, al ternat ively, check forDi agnos ti c Trouble Codes (DTCs) and refer t o t he DTC Index.4.

Symptom Chart

SymptomPossible CauseActionCoolant los sHosesHose connect ionsRadi atorCool ant pumpHeat er coreGasketsEngi ne cas t ing cracksEngi ne block core plugs

GO t o Pinpoint Test A.

Engine overheati ngEngi ne cool ant (level/condit ion)Thermos tatFan motorFan motor fus es and/or circui tsECT s ens orEngi ne cont rol module (ECM)Fan speed module

GO t o Pinpoint Test B.

Engine not reaching normal operat ing t emperat ureThermos tatElect ric fanFan speed module

GO t o Pinpoint Test C.

DTC Index

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains under manufacturer warrant y, refer t o theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve ext rainformat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces, and wi th a current cali brati on cert ifi cat e. W hen t est ing res is tance, al ways take t he res is t ance of t he DMM leadsint o account.

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

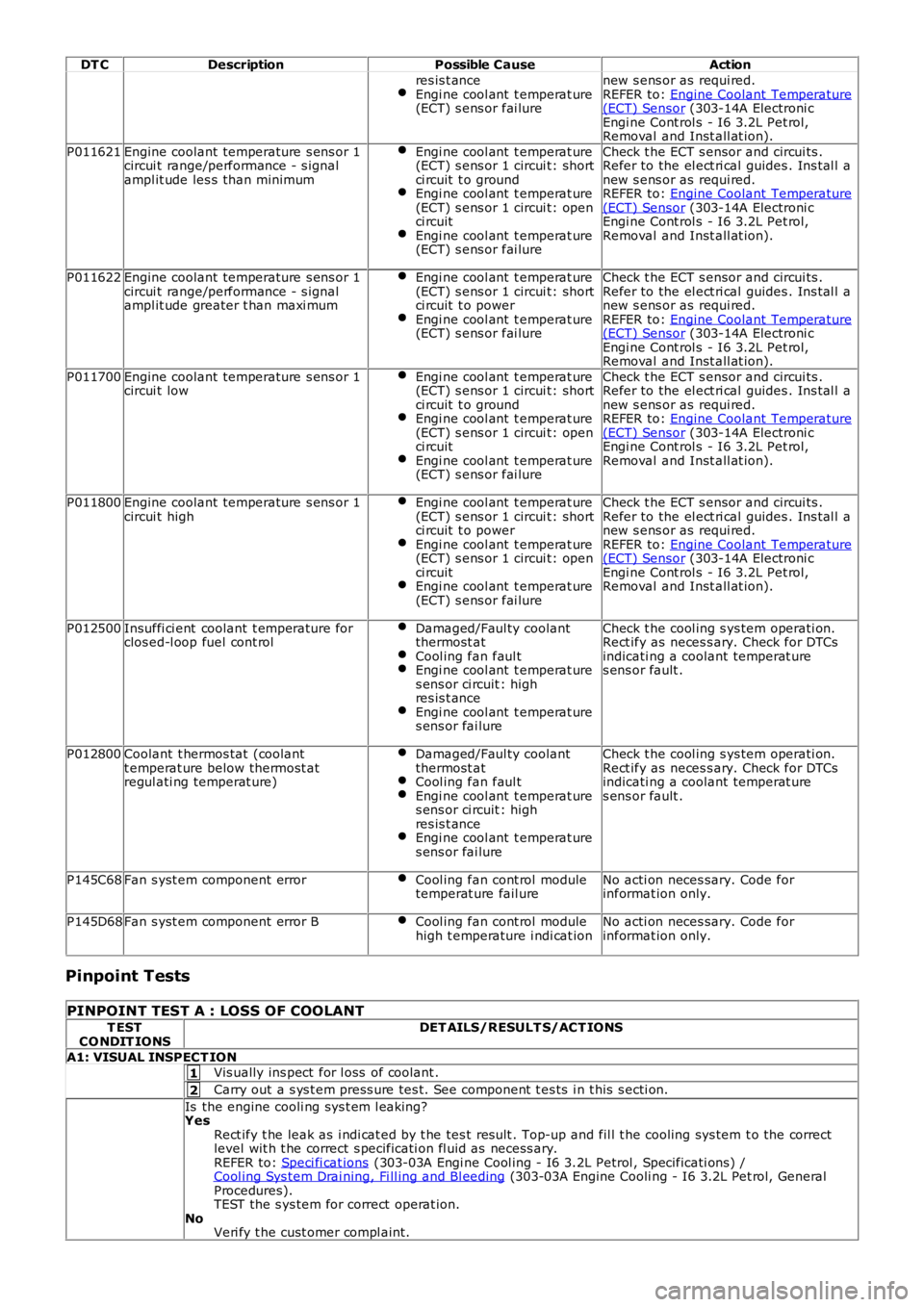

DT CDescriptionPossible CauseAction

P011600Engine coolant temperature s ens or 1circui t range/performanceEngi ne cool ant t emperat ure(ECT) s ens or 1 circui t: hi ghCheck t he ECT s ensor and circui ts .Refer to the el ect ri cal guides . Ins tal l a

Page 914 of 3229

1

2

DT CDescriptionPossible CauseAction

res is t anceEngi ne cool ant t emperat ure(ECT) s ens or fai lure

new s ens or as requi red.REFER to: Engine Coolant Temperature(ECT) Sensor (303-14A Electroni cEngi ne Cont rol s - I6 3.2L Pet rol,Removal and Inst all at ion).

P011621Engine coolant temperature s ens or 1circui t range/performance - s ignalampl it ude les s than minimum

Engi ne cool ant t emperat ure(ECT) s ens or 1 circui t: shortci rcuit t o groundEngi ne cool ant t emperat ure(ECT) s ens or 1 circui t: openci rcuitEngi ne cool ant t emperat ure(ECT) s ens or fai lure

Check t he ECT s ensor and circui ts .Refer to the el ect ri cal guides . Ins tal l anew s ens or as requi red.REFER to: Engine Coolant Temperature(ECT) Sensor (303-14A Electroni cEngi ne Cont rol s - I6 3.2L Pet rol,Removal and Inst all at ion).

P011622Engine coolant temperature s ens or 1circui t range/performance - s ignalampl it ude greater t han maxi mum

Engi ne cool ant t emperat ure(ECT) s ens or 1 circui t: shortci rcuit t o powerEngi ne cool ant t emperat ure(ECT) s ens or fai lure

Check t he ECT s ensor and circui ts .Refer to the el ect ri cal guides . Ins tal l anew s ens or as requi red.REFER to: Engine Coolant Temperature(ECT) Sensor (303-14A Electroni cEngi ne Cont rol s - I6 3.2L Pet rol,Removal and Inst all at ion).

P011700Engine coolant temperature s ens or 1circui t lowEngi ne cool ant t emperat ure(ECT) s ens or 1 circui t: shortci rcuit t o groundEngi ne cool ant t emperat ure(ECT) s ens or 1 circui t: openci rcuitEngi ne cool ant t emperat ure(ECT) s ens or fai lure

Check t he ECT s ensor and circui ts .Refer to the el ect ri cal guides . Ins tal l anew s ens or as requi red.REFER to: Engine Coolant Temperature(ECT) Sensor (303-14A Electroni cEngi ne Cont rol s - I6 3.2L Pet rol,Removal and Inst all at ion).

P011800Engine coolant temperature s ens or 1circui t highEngi ne cool ant t emperat ure(ECT) s ens or 1 circui t: shortci rcuit t o powerEngi ne cool ant t emperat ure(ECT) s ens or 1 circui t: openci rcuitEngi ne cool ant t emperat ure(ECT) s ens or fai lure

Check t he ECT s ensor and circui ts .Refer to the el ect ri cal guides . Ins tal l anew s ens or as requi red.REFER to: Engine Coolant Temperature(ECT) Sensor (303-14A Electroni cEngi ne Cont rol s - I6 3.2L Pet rol,Removal and Inst all at ion).

P012500Insuffi ci ent coolant t emperature forclos ed-l oop fuel cont rolDamaged/Faul ty coolantthermost atCool ing fan faul tEngi ne cool ant t emperat ures ens or ci rcuit : highres is t anceEngi ne cool ant t emperat ures ens or fai lure

Check t he cool ing s ys tem operati on.Rect ify as neces s ary. Check for DTCsindicati ng a coolant temperat ures ens or fault .

P012800Coolant t hermos tat (coolantt emperat ure below thermost atregul ati ng temperat ure)

Damaged/Faul ty coolantthermost atCool ing fan faul tEngi ne cool ant t emperat ures ens or ci rcuit : highres is t anceEngi ne cool ant t emperat ures ens or fai lure

Check t he cool ing s ys tem operati on.Rect ify as neces s ary. Check for DTCsindicati ng a coolant temperat ures ens or fault .

P145C68Fan s yst em component errorCool ing fan cont rol moduletemperat ure fail ureNo acti on neces sary. Code forinformat ion only.

P145D68Fan s yst em component error BCool ing fan cont rol modulehigh t emperature i ndi cat ionNo acti on neces sary. Code forinformat ion only.

Pinpoint Tests

PINPOINT TEST A : LOSS OF COOLANT

T ESTCO NDIT IONSDET AILS/RESULT S/ACT IONS

A1: VISUAL INSPECT IONVis ually ins pect for l oss of coolant .

Carry out a s ys t em press ure tes t. See component t es ts i n t his s ecti on.

Is the engine cooli ng sys t em l eaking?YesRect ify t he leak as i ndi cat ed by t he tes t res ult . Top-up and fil l t he cooling sys tem t o the correctlevel wit h t he correct s pecificati on fl uid as necess ary.REFER to: Speci fi cat ions (303-03A Engi ne Cool ing - I6 3.2L Petrol , Specificati ons) /Cool ing Sys tem Drai ning, Fi ll ing and Bl eeding (303-03A Engine Cooli ng - I6 3.2L Pet rol, GeneralProcedures).TEST the s ys tem for correct operat ion.NoVeri fy t he cust omer compl aint.

Page 915 of 3229

1

1

1

1

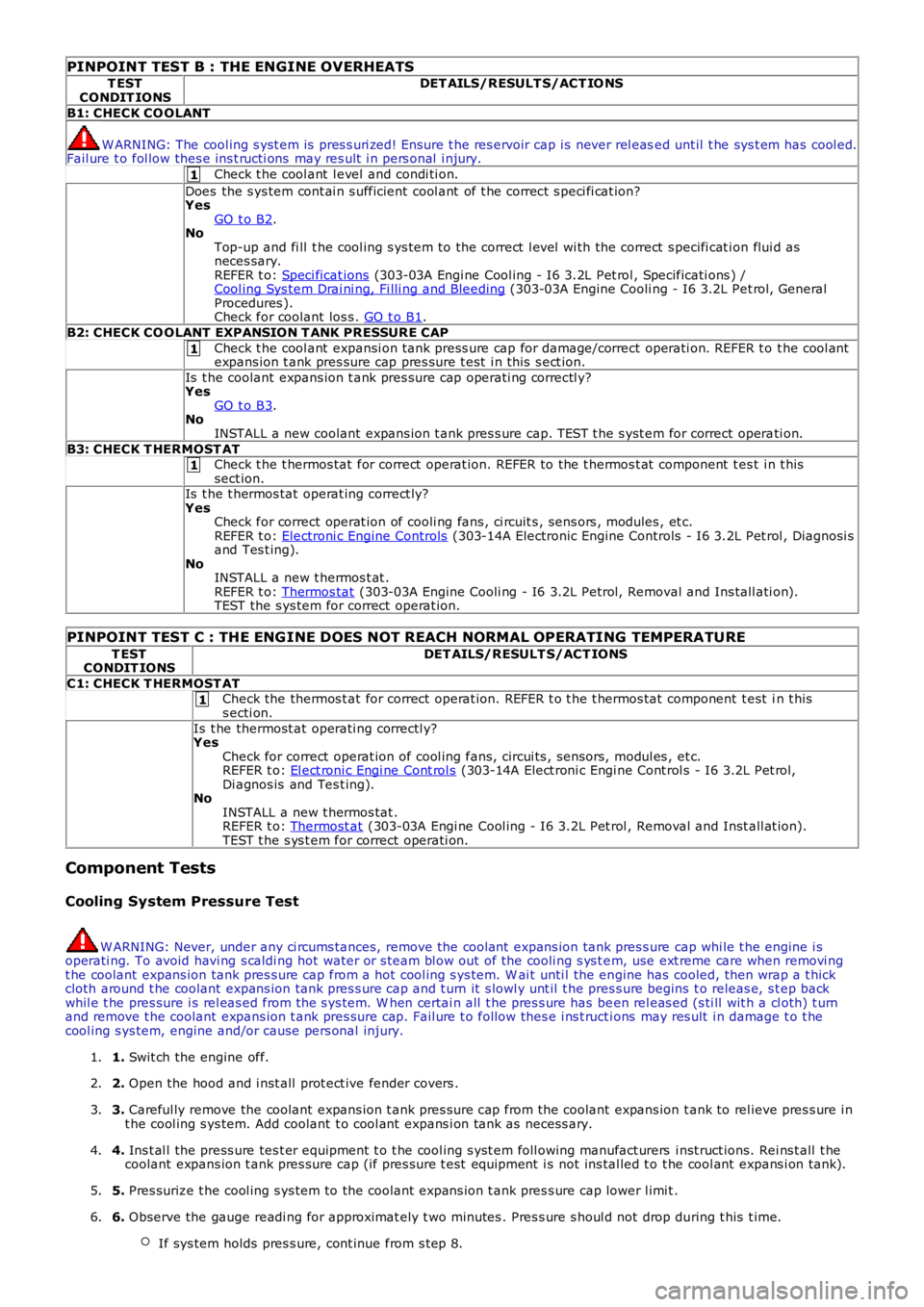

PINPOINT TEST B : THE ENGINE OVERHEATS

T ESTCONDIT IONSDET AILS/RESULT S/ACT IO NS

B1: CHECK CO OLANT

W ARNING: The cool ing s yst em is pres s uri zed! Ensure t he res ervoir cap i s never rel eased unt il t he sys t em has cool ed.Fail ure t o fol low thes e ins t ructi ons may res ult i n pers onal i njury.

Check t he cool ant l evel and condi ti on.

Does the s ys tem cont ai n s ufficient cool ant of t he correct s peci fi cat ion?YesGO t o B2.NoTop-up and fi ll t he cool ing s ys tem to the correct l evel wi th the correct s pecifi cat ion flui d asneces sary.REFER t o: Speci ficat ions (303-03A Engi ne Cool ing - I6 3.2L Pet rol , Specificati ons ) /Cool ing Sys tem Drai ni ng, Fi lli ng and Bleeding (303-03A Engine Cooli ng - I6 3.2L Pet rol, GeneralProcedures ).Check for coolant los s . GO t o B1.

B2: CHECK CO OLANT EXPANSION T ANK PRESSURE CAP

Check t he cool ant expansi on tank press ure cap for damage/correct operati on. REFER t o t he cool antexpans ion t ank pres sure cap pres sure t est i n t his s ect ion.

Is t he coolant expans ion t ank pres sure cap operati ng correctl y?YesGO t o B3.NoINSTALL a new coolant expans ion t ank pres s ure cap. TEST t he s yst em for correct operati on.

B3: CHECK T HERMOST ATCheck t he t hermos tat for correct operat ion. REFER to the t hermos t at component t es t in t hissect ion.Is t he t hermos tat operat ing correct ly?YesCheck for correct operat ion of cooli ng fans , ci rcuit s , sens ors , modules , et c.REFER t o: Electroni c Engine Controls (303-14A Electronic Engine Controls - I6 3.2L Pet rol , Diagnosi sand Tes t ing).NoINSTALL a new t hermos t at .REFER t o: Thermos tat (303-03A Engine Cooli ng - I6 3.2L Petrol, Removal and Ins tall ati on).TEST the s ys tem for correct operat ion.

PINPOINT TEST C : THE ENG INE DOES NOT REACH NORMAL OPERATING TEMPERATURE

T ESTCONDIT IONSDET AILS/RESULT S/ACT IONS

C1: CHECK T HERMOST ATCheck the thermos t at for correct operat ion. REFER t o t he t hermos tat component t est in t hiss ecti on.

Is t he thermost at operati ng correctl y?YesCheck for correct operat ion of cool ing fans, circui ts , s ensors, modul es , et c.REFER t o: El ect roni c Engi ne Cont rol s (303-14A Elect roni c Engi ne Cont rol s - I6 3.2L Pet rol,Di agnos is and Tes t ing).NoINSTALL a new t hermos tat .REFER t o: Thermost at (303-03A Engi ne Cool ing - I6 3.2L Pet rol , Removal and Inst all at ion).TEST t he s ys t em for correct operati on.

Component Tests

Cooling System Pressure Test

W ARNING: Never, under any ci rcums tances, remove the coolant expans ion tank pres s ure cap whi le t he engine i soperati ng. To avoid havi ng s caldi ng hot water or s team bl ow out of the cooli ng s ys t em, use ext reme care when removi ngt he coolant expans ion tank pres s ure cap from a hot cool ing s ys tem. W ai t unti l the engine has cooled, then wrap a t hickcloth around t he coolant expans ion tank pres s ure cap and t urn it s lowl y unt il t he pres s ure begins t o releas e, s t ep backwhil e t he pres sure i s rel eas ed from the s ys tem. W hen certai n all t he pres s ure has been rel eas ed (s ti ll wit h a cl oth) t urnand remove t he coolant expans ion t ank pres sure cap. Fail ure t o follow thes e i ns t ructi ons may res ult i n damage t o t hecool ing s ys tem, engine and/or cause pers onal injury.

1. Swit ch the engine off.1.

2. Open the hood and i nst all prot ect ive fender covers .2.

3. Careful ly remove the coolant expans ion t ank pres s ure cap from the coolant expans ion t ank to rel ieve pres s ure i nt he cool ing s ys tem. Add coolant t o cool ant expans i on tank as necess ary.3.

4. Ins t al l the press ure tes t er equipment t o t he cool ing s yst em foll owing manufact urers i nst ruct ions. Rei ns t all t hecoolant expans ion t ank pres sure cap (if pres s ure t est equipment i s not ins tal led t o t he cool ant expans i on tank).4.

5. Pres surize t he cool ing s ys tem to the coolant expans ion t ank pres s ure cap lower l imi t.5.

6. Observe the gauge readi ng for approximat ely t wo minutes . Pres s ure s houl d not drop during t his t ime.

If sys tem holds pres s ure, cont inue from s tep 8.

6.