engine LAND ROVER FRELANDER 2 2006 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 2883 of 3229

163

Maintenance

R

Topping up the oil

1. Unscrew the oil filler cap.

2. Add oil to maintain the level between the

MIN and MAX marks or notches on the

dipstick. Clean up any oil spilled during

topping-up.

3. Check the oil level again after 5 minutes.

It is essential to use the correct specification

oil, and to ensure it is suitable for the climatic

conditions in which the vehicle is to be

operated.

Note: The approximate quantity of oil required

to raise the level from MIN to MAX on the

dipstick is 0.8 litres (1.4 pints) - petrol models

or 1.5 litres (2.6 pi nts) - diesel models.

Engine oil specification

Land Rover recommends Castrol oils.

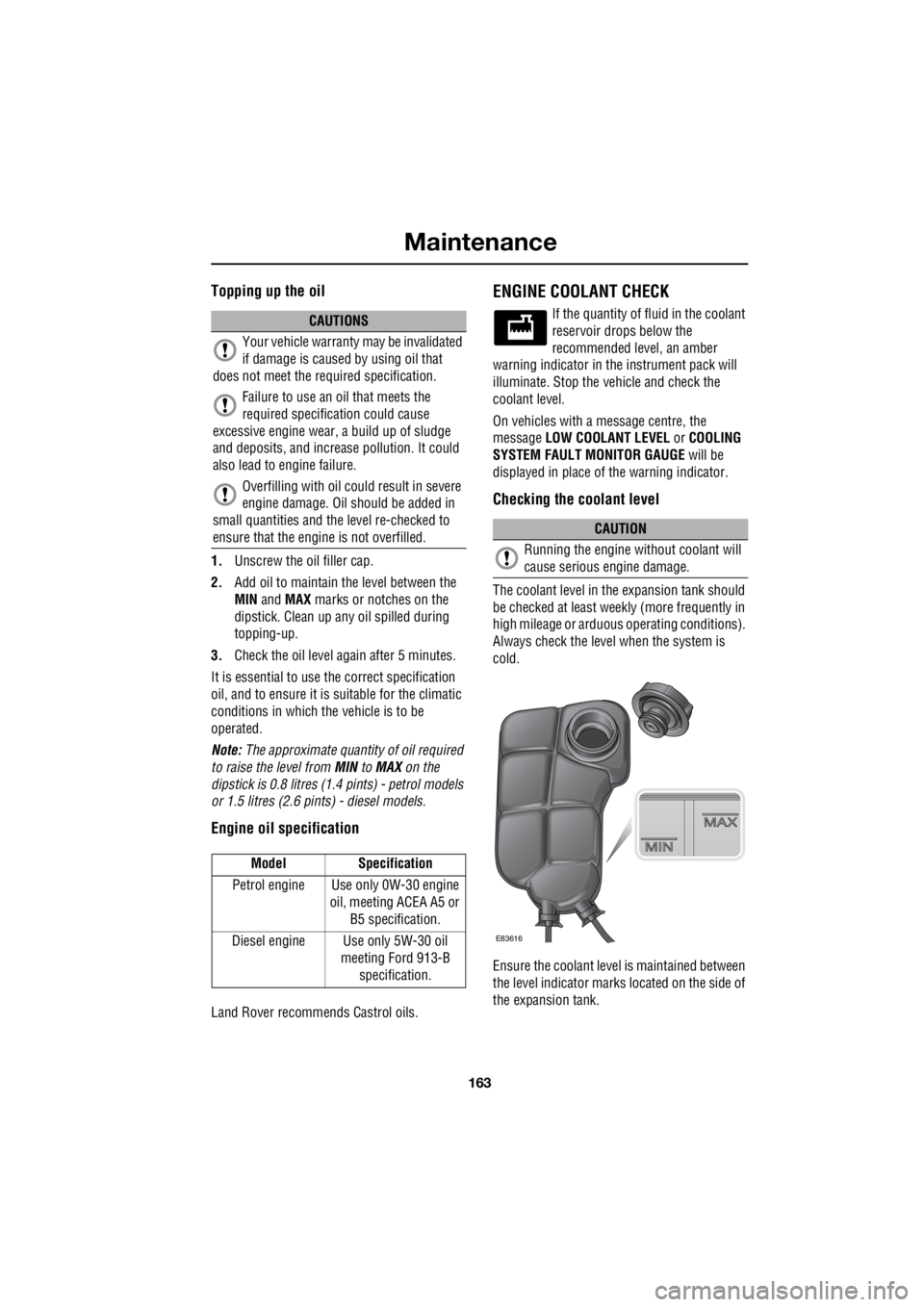

ENGINE COOLANT CHECK

If the quantity of fluid in the coolant

reservoir drops below the

recommended level, an amber

warning indicator in the instrument pack will

illuminate. Stop the vehicle and check the

coolant level.

On vehicles with a message centre, the

message LOW COOLANT LEVEL or COOLING

SYSTEM FAULT MONITOR GAUGE will be

displayed in place of the warning indicator.

Checking the coolant level

The coolant level in the expansion tank should

be checked at least week ly (more frequently in

high mileage or arduous operating conditions).

Always check the level when the system is

cold.

Ensure the coolant level is maintained between

the level indicator marks located on the side of

the expansion tank.

CAUTIONS

Your vehicle warranty may be invalidated

if damage is caused by using oil that

does not meet the required specification.

Failure to use an oil that meets the

required specification could cause

excessive engine wear, a build up of sludge

and deposits, and increase pollution. It could

also lead to engine failure.

Overfilling with oil could result in severe

engine damage. Oil should be added in

small quantities and the level re-checked to

ensure that the engine is not overfilled.

Model Specification

Petrol engine Use only 0W-30 engine oil, meeting ACEA A5 or

B5 specification.

Diesel engine Use only 5W-30 oil meeting Ford 913-B

specification.

CAUTION

Running the engine without coolant will

cause serious engine damage.

E83616

Page 2884 of 3229

Maintenance

164

L

If the level has fallen appreciably, suspect

leakage or overheatin g and arrange for the

vehicle to be exam ined by a qualified

technician.

Topping up the coolant

Top-up to the upper le vel indicator mark

located on the side of the expansion tank. Use

only a 50% mix of water and Texaco XLC

antifreeze.

Note: In an emergency - and only if the

approved antifreeze is unavailable - top-up the

cooling system with clea n water, but be aware

of the resultant reduction in frost protection.

Do not top-up or refill with conventional

antifreeze formulations. If in doubt consult a

qualified technician.

Ensure the cap is tightened fully after top-up is

completed by turning the cap until the ratchet

cap clicks. Antifreeze

Antifreeze contains important corrosion

inhibitors. The antifreeze content of the coolant

must be maintained at 50% ± 5% all year round

(not just in cold conditions). To ensure that the

anti-corrosion properties of the coolant are

retained, the antifreeze content should be

checked once a year and completely renewed

every ten years, regardless of distance

travelled. Failure to do so may cause corrosion

of the radiator and engine components.

The specific gravity of a 50% antifreeze

solution at 20°C (68°F) is 1.068 and protects

against frost down to -40°C (-40°F).

WARNINGS

Never remove the filler cap when the

engine is hot - escaping steam or

scalding water could ca use serious personal

injury.

Avoid spilling antifreeze onto a hot

engine - a fire may result.

Unscrew the filler cap slowly, allowing

the pressure to escape before removing

completely.

CAUTION

When travelling in territories where the

water supply contains salt, always

ensure you carry a supply of fresh (rain or

distilled) water. Topping up with salt water will

cause serious engine damage.

WARNINGS

Antifreeze is poisonous and can be fatal

if swallowed - keep containers sealed

and out of the reach of children. If accidental

consumption is suspec ted, seek medical

attention immediately.

If the fluid comes into contact with the

skin or eyes, rinse immediately with

plenty of water.

CAUTIONS

The use of non-approved antifreeze will

have an adverse ef fect on the engine

cooling system and therefore engine

durability.

Antifreeze will damage painted surfaces;

soak up any spillage with an absorbent

cloth immediately and wash the area with a

mixture of car shampoo and water.

Page 2885 of 3229

165

Maintenance

R

BRAKE AND CLUTCH FLUID CHECK

If the quantity of fluid in the

brake/clutch rese rvoir drops below

the recommended level, a red

warning indicator in the instrument pack will

illuminate or the message CHECK BRAKE

FLUID will be displayed in the message centre.

Note: If the warning indicator illuminates, or

the message is displayed while the vehicle is

being driven, stop the vehi cle as soon as safety

permits by gently applying the brakes.

Check and top-up the flui d level if necessary.

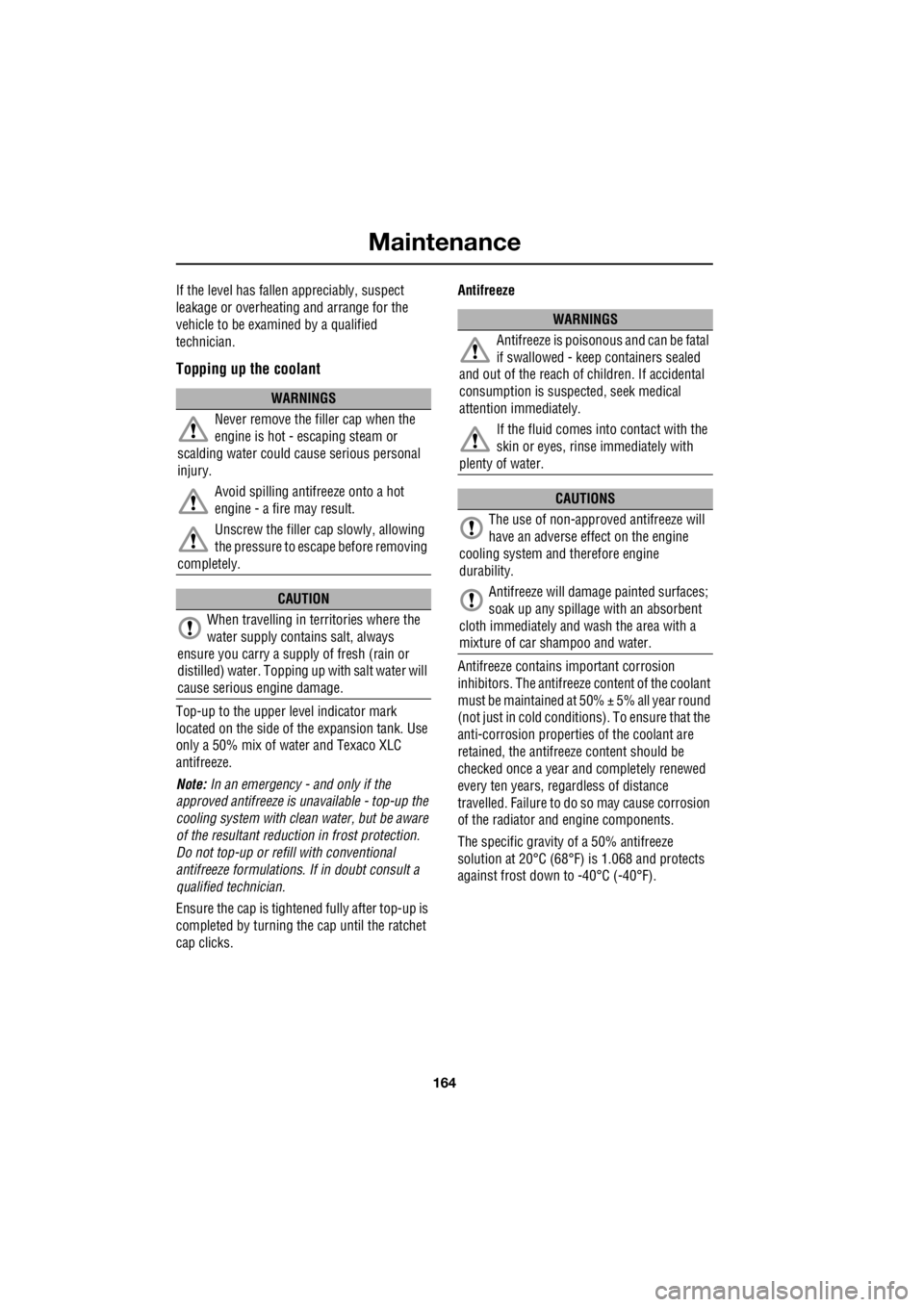

Checking the fluid level

With the vehicle on level ground, check the

fluid level at least every week (more frequently

in high mileage or arduous operating

conditions).

1. Release the two catches and lift the rear of

the cover.

2. Slide the cover forward and lift it off

completely.

1. Release the catch.

2. Remove the cover.

WARNINGS

Brake fluid is highly toxic - keep

containers sealed a nd out of the reach

of children. If accident al consumption of fluid

is suspected, seek medical attention

immediately.

If the fluid comes into contact with the

skin or eyes, rinse immediately with

plenty of water.

Take care not to spill the fluid onto a hot

engine - a fire may result.

Do not drive the vehicle with the fluid

level below the MIN mark.WARNING

Seek qualified assistance immediately if

brake pedal travel is unusually long or if

there is any significant loss of brake fluid.

Driving under such condi tions could result in

extended stopping distances or complete

brake failure.

E83617

2

11

E84161

21

Page 2886 of 3229

Maintenance

166

L

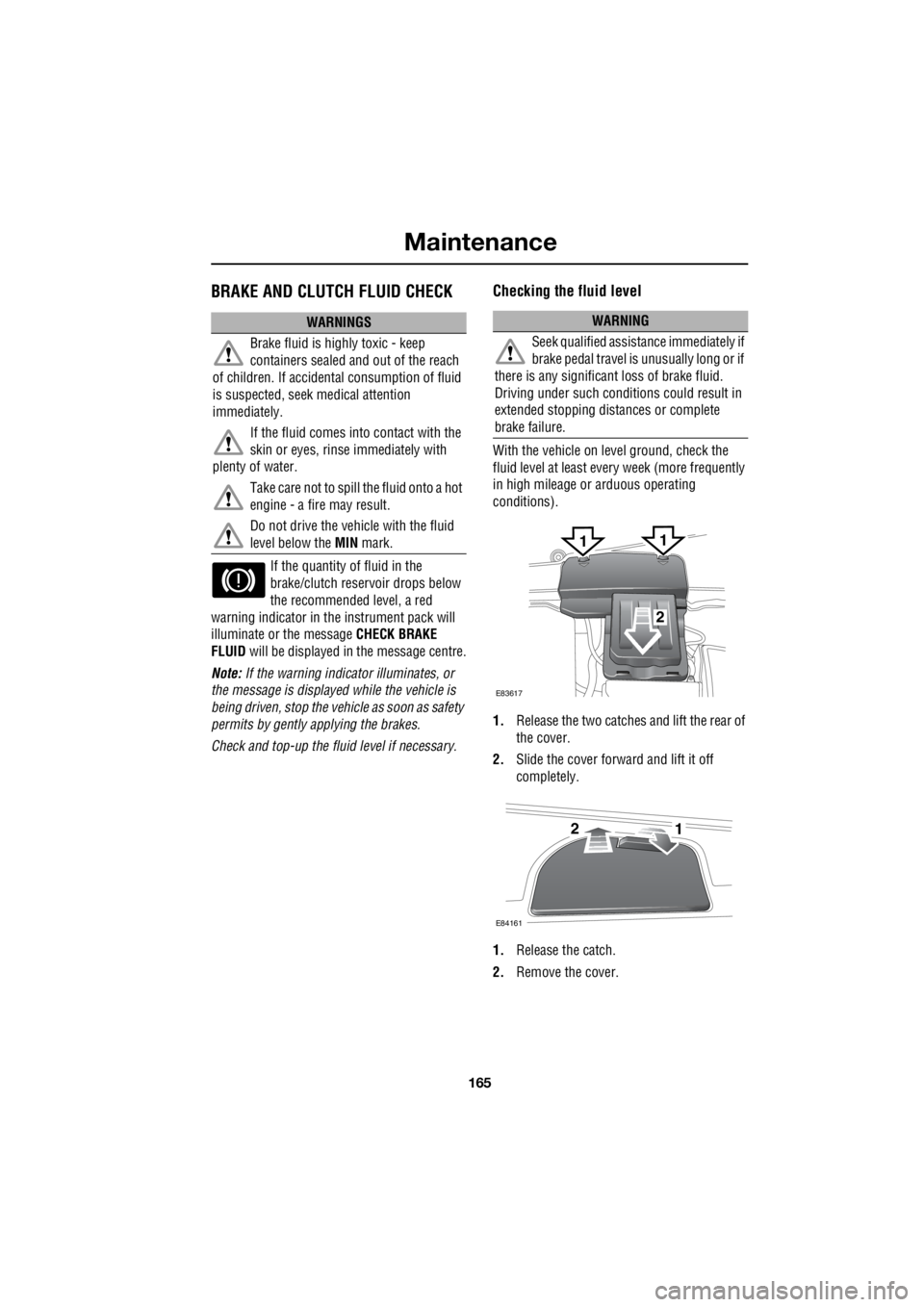

3. Clean the filler cap before removing to

prevent dirt from entering the reservoir.

4. Remove the filler cap.

5. The brake fluid level should be between the

MIN and the MAX marks.

The fluid level may drop slightly during normal

use as a result of brake pad wear but should

not be allowed to drop below the MIN mark.

Topping up the fluid

1.Top-up the reservoir to the MAX mark

using Shell DOT4 ESL brake fluid. If Shell

DOT4 ESL is not availa ble, a low viscosity

DOT4 brake fluid that meets ISO 4925

class 6 and Land Rover LRES22BF03

requirements ma y be used. 2.

Replace the cap.

3. Fit the reservoir cover in the reverse order

of removal.

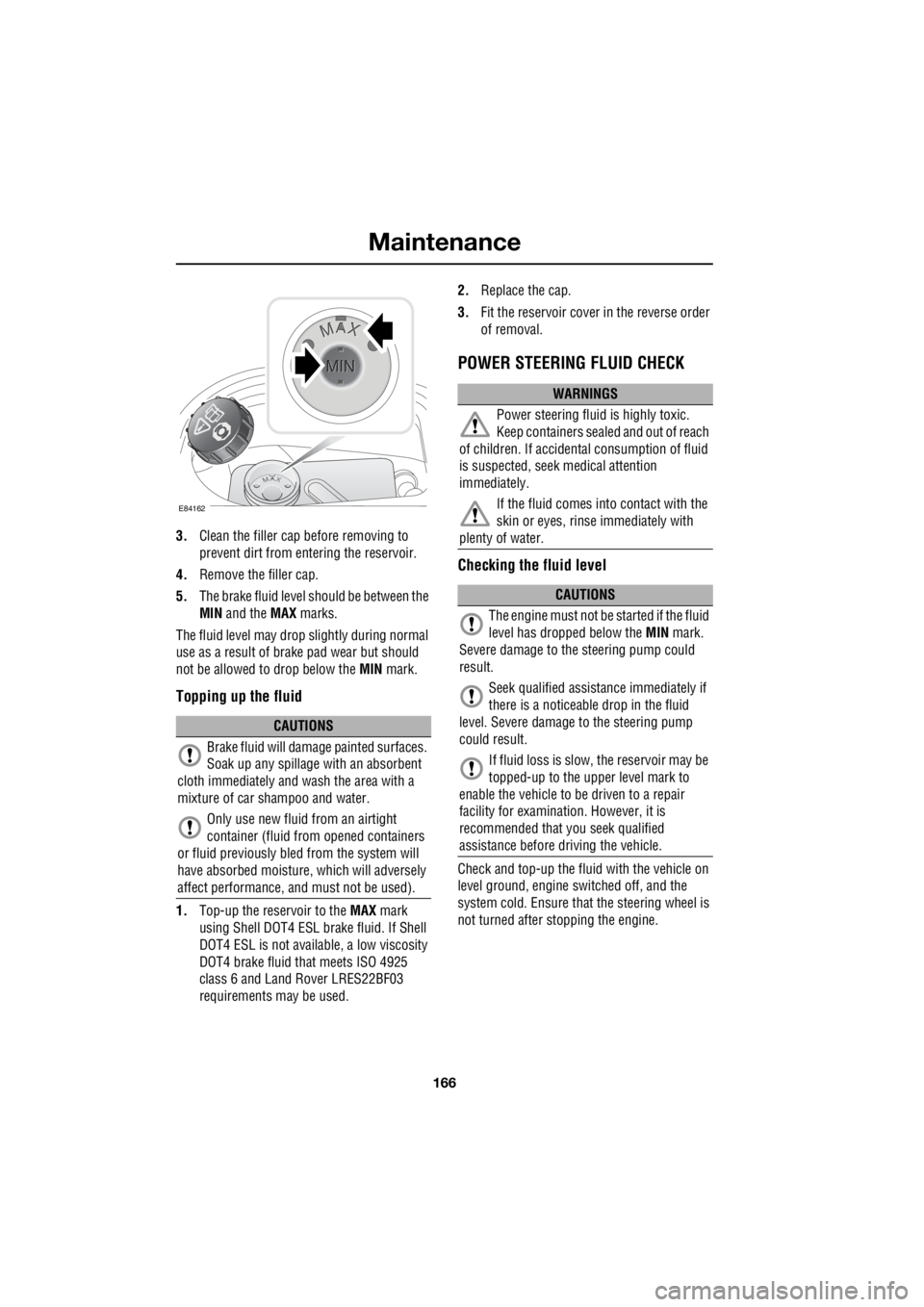

POWER STEERING FLUID CHECK

Checking the fluid level

Check and top-up the fluid with the vehicle on

level ground, engine switched off, and the

system cold. Ensure that the steering wheel is

not turned after stopping the engine.

CAUTIONS

Brake fluid will damage painted surfaces.

Soak up any spillage with an absorbent

cloth immediately and wash the area with a

mixture of car sh ampoo and water.

Only use new fluid from an airtight

container (fluid from opened containers

or fluid previously bled from the system will

have absorbed moisture, which will adversely

affect performance, and must not be used).

E84162

WARNINGS

Power steering fluid is highly toxic.

Keep containers sealed and out of reach

of children. If accidental consumption of fluid

is suspected, seek medical attention

immediately.

If the fluid comes into contact with the

skin or eyes, rinse immediately with

plenty of water.

CAUTIONS

The engine must not be started if the fluid

level has dropped below the MIN mark.

Severe damage to th e steering pump could

result.

Seek qualified assistance immediately if

there is a noticeable drop in the fluid

level. Severe damage to the steering pump

could result.

If fluid loss is slow, the reservoir may be

topped-up to the uppe r level mark to

enable the vehicle to be driven to a repair

facility for examinatio n. However, it is

recommended that you seek qualified

assistance before driving the vehicle.

Page 2889 of 3229

169

Maintenance

R

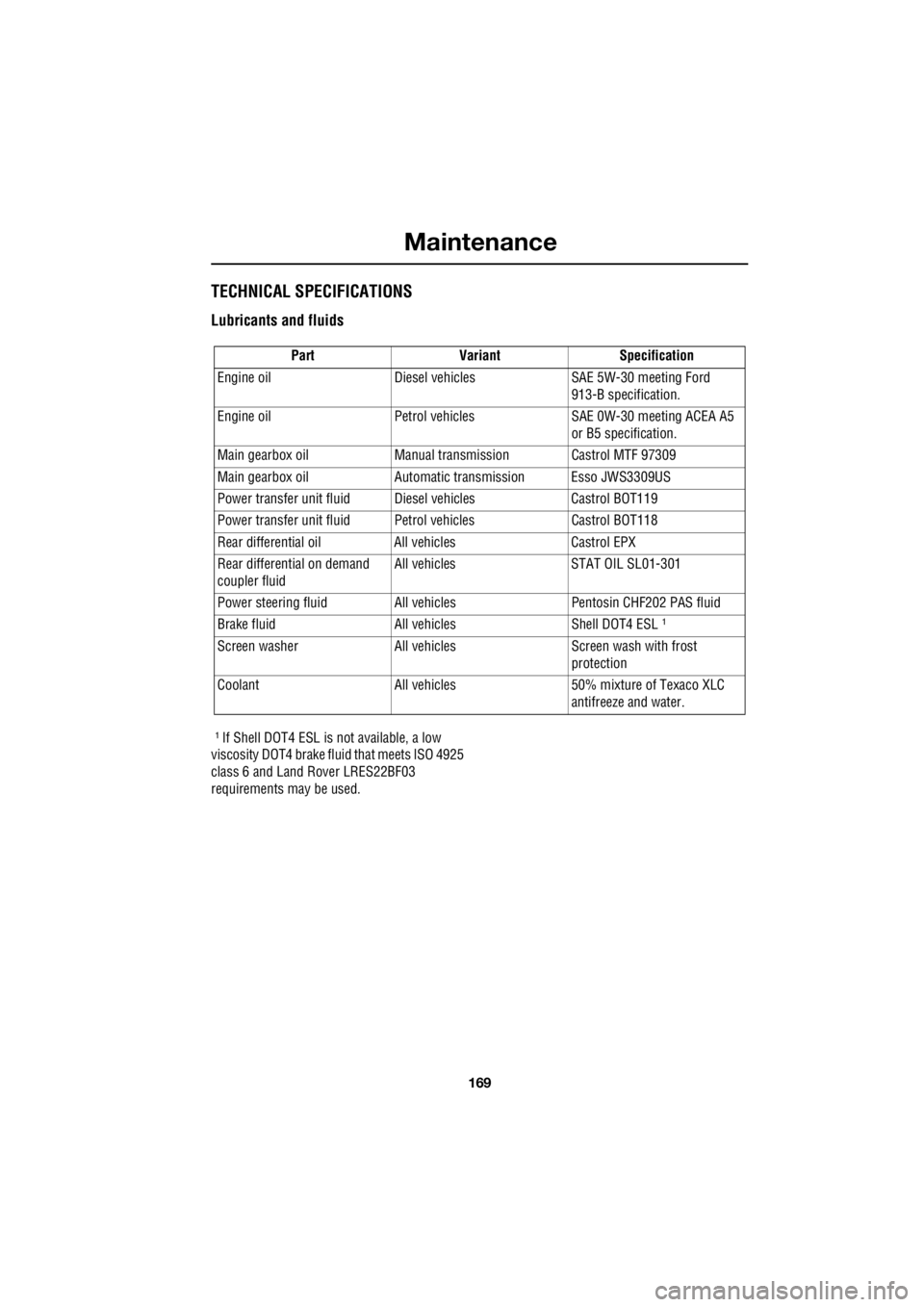

TECHNICAL SPECIFICATIONS

Lubricants and fluids

¹ If Shell DOT4 ESL is not available, a low

viscosity DOT4 brake fl uid that meets ISO 4925

class 6 and Land Rover LRES22BF03

requirements may be used. Part Variant Specification

Engine oil Diesel vehicles SAE 5W-30 meeting Ford 913-B specification.

Engine oil Petrol vehicles SA E 0W-30 meeting ACEA A5

or B5 specification.

Main gearbox oil Manual tr ansmission Castrol MTF 97309

Main gearbox oil Automatic transmission Esso JWS3309US

Power transfer unit fluid Die sel vehicles Castrol BOT119

Power transfer unit fluid Petrol vehicles Castrol BOT118

Rear differential oil All vehicles Castrol EPX

Rear differential on demand

coupler fluid All vehicles STAT OIL SL01-301

Power steering fluid All vehicl es Pentosin CHF202 PAS fluid

Brake fluid All vehicles Shell DOT4 ESL ¹

Screen washer All vehicles Screen wash with frost protection

Coolant All vehicles 50% mixture of Texaco XLC antifreeze and water.

Page 2890 of 3229

Maintenance

170

L

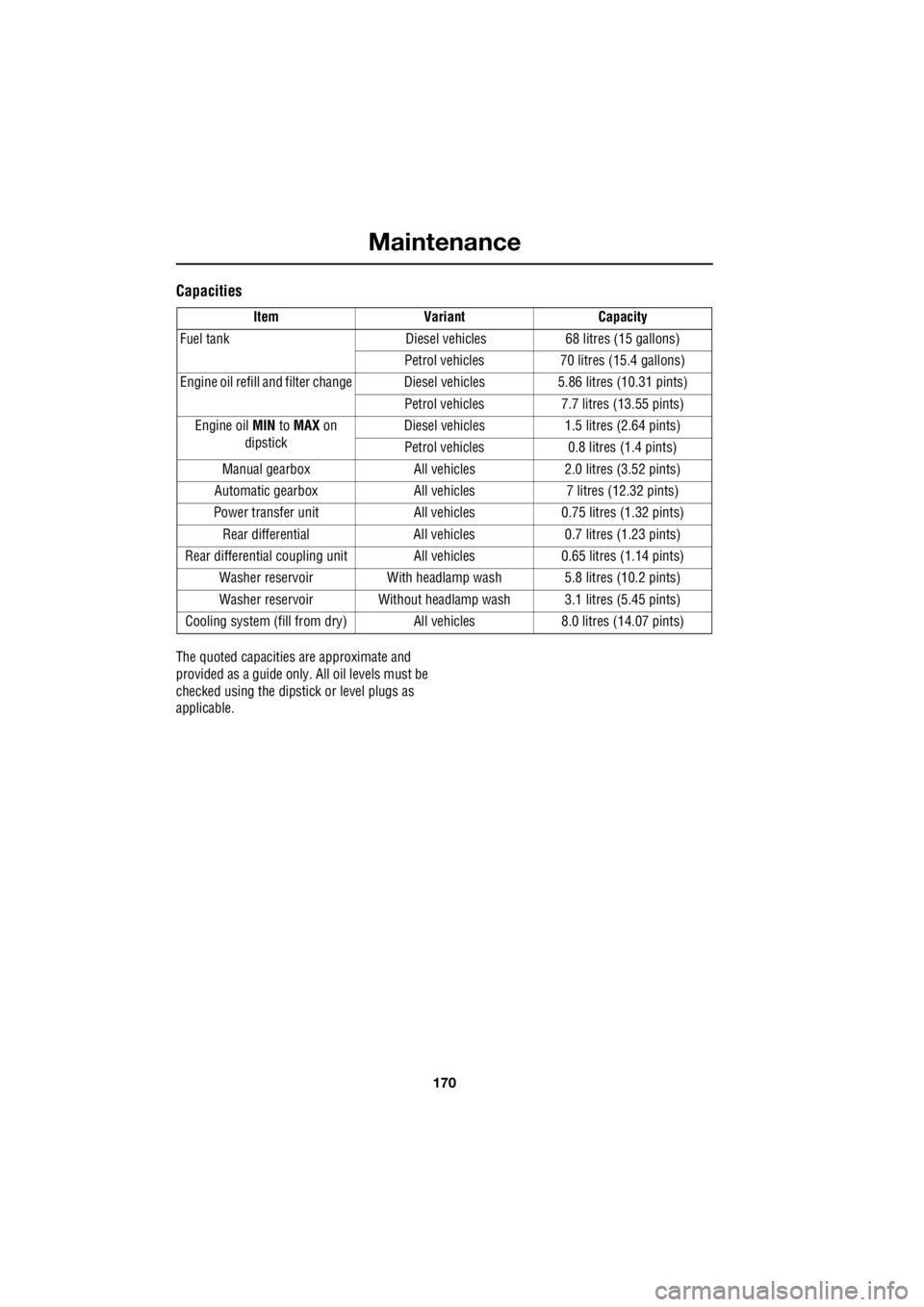

Capacities

The quoted capacities are approximate and

provided as a guide only. All oil levels must be

checked using the dipsti ck or level plugs as

applicable. Item Variant Capacity

Fuel tank Diesel vehi cles 68 litres (15 gallons)

Petrol vehicles 70 litres (15.4 gallons)

Engine oil refill and filter change Di esel vehicles 5.86 litres (10.31 pints)

Petrol vehicles 7.7 litres (13.55 pints)

Engine oil MIN to MAX on

dipstick Diesel vehicles 1.5

litres (2.64 pints)

Petrol vehicles 0.8 litres (1.4 pints)

Manual gearbox All vehicles 2.0 litres (3.52 pints)

Automatic gearbox All vehicl es 7 litres (12.32 pints)

Power transfer unit All vehi cles 0.75 litres (1.32 pints)

Rear differential All vehi cles 0.7 litres (1.23 pints)

Rear differential coupling unit All vehicles 0.65 litres (1.14 pints)

Washer reservoir With headlamp wash 5.8 litres (10.2 pints)

Washer reservoir Without headla mp wash 3.1 litres (5.45 pints)

Cooling system (fill from dry) Al l vehicles 8.0 litres (14.07 pints)

Page 2893 of 3229

173

Vehicle battery

R

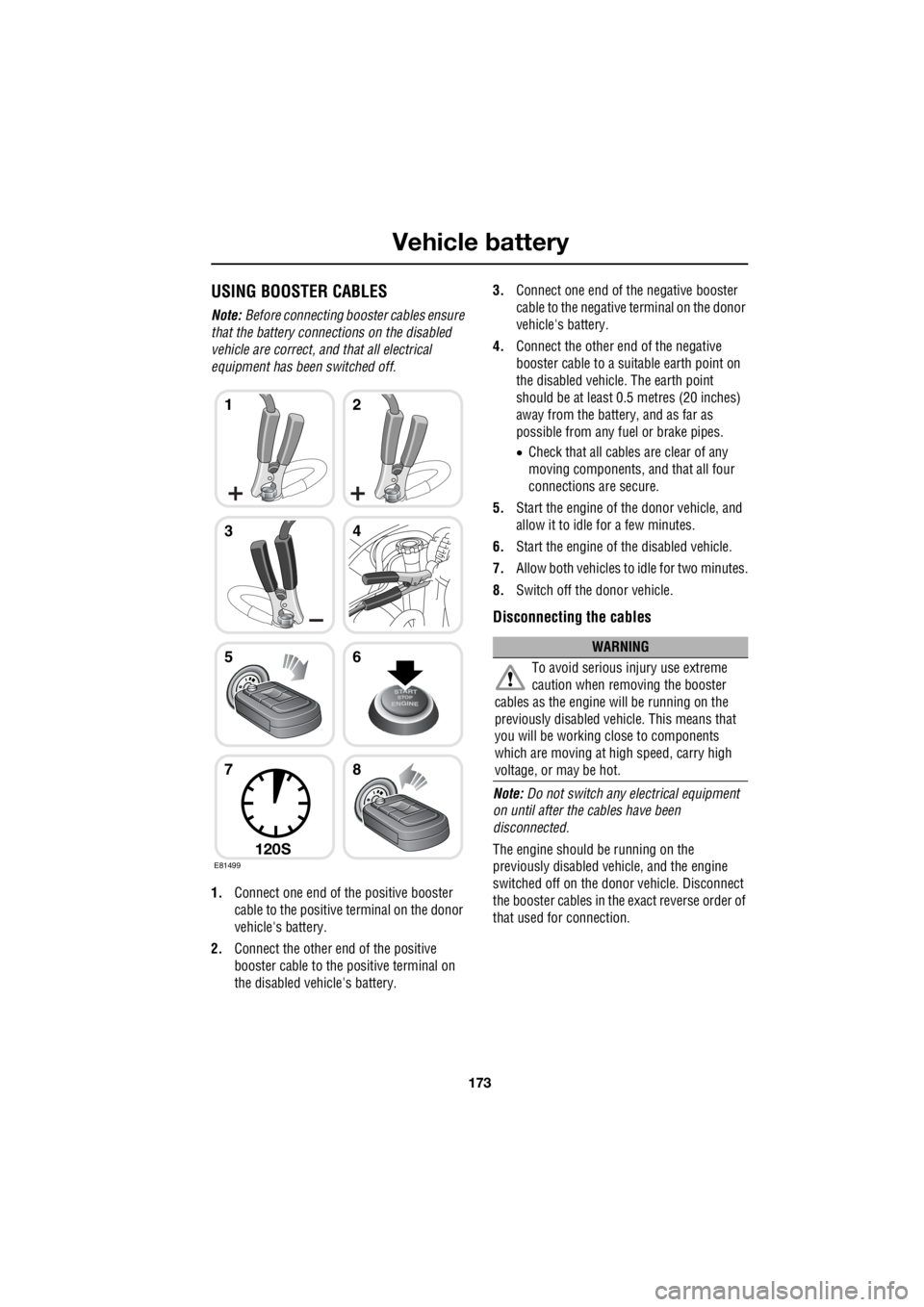

USING BOOSTER CABLES

Note: Before connecting boos ter cables ensure

that the battery connections on the disabled

vehicle are correct, and that all electrical

equipment has been switched off.

1. Connect one end of the positive booster

cable to the positive terminal on the donor

vehicle's battery.

2. Connect the other e nd of the positive

booster cable to the positive terminal on

the disabled vehicle's battery. 3.

Connect one end of the negative booster

cable to the negative terminal on the donor

vehicle's battery.

4. Connect the other en d of the negative

booster cable to a suit able earth point on

the disabled vehicle. The earth point

should be at least 0.5 metres (20 inches)

away from the battery, and as far as

possible from any fuel or brake pipes.

• Check that all cables are clear of any

moving components, and that all four

connections are secure.

5. Start the engine of the donor vehicle, and

allow it to idle for a few minutes.

6. Start the engine of the disabled vehicle.

7. Allow both vehicles to idle for two minutes.

8. Switch off the donor vehicle.

Disconnecting the cables

Note: Do not switch any electrical equipment

on until after the cables have been

disconnected.

The engine should be running on the

previously disabled ve hicle, and the engine

switched off on the donor vehicle. Disconnect

the booster cables in the exact reverse order of

that used for connection.

E81499

12

34

56

78

120S

WARNING

To avoid serious in jury use extreme

caution when removing the booster

cables as the engine will be running on the

previously disabled vehicle. This means that

you will be working close to components

which are moving at high speed, carry high

voltage, or may be hot.

Page 2894 of 3229

Vehicle battery

174

L

CHARGING THE VEHICLE BATTERY

1. Disconnect the battery and remove it from

the vehicle.

2. Connect the battery charger in accordance

with the charger manufacturer's

instructions.

3. Once the charge is complete switch off the

power to the charger.

4. Disconnect the charger cables from the

battery.

5. Allow the battery to stand for an hour

before connecting to the vehicle. This will

allow any explosive gasses to dissipate,

and reduce the risk of explosion.

CHANGING THE VEHICLE BATTERY

Disconnecting

1. Ensure that all electrical circuits are

switched off, all windows are closed, and

the alarm is disarmed.

2. Remove the remote control from the

vehicle and wait two minutes to allow the

systems to power down fully.

3. Undo the negative clam p, and lift the cable

and clamp clear of th e battery terminal.

4. Undo the positive clamp, and lift the cable

and clamp clear of th e battery terminal.

5. Undo the battery clamp and lift the battery

clear of the vehicle.

WARNINGS

Ensure that the charger used is of the

correct type and rating for the battery.

Using an unsuitable charger may damage the

battery, and could cause the battery to

explode.

Always charge the battery in a well

ventilated area away from any naked

flames, sparks or ot her ignition sources.

During charging the battery can produce a

highly explosive a nd flammable gas.

CAUTIONS

The battery must be disconnected and

removed from the vehicle before

charging. Failure to do so could result in

damage to the vehicle's electrical system.

Always follow the instructions supplied

with the battery charger. Failure to do so

may result in damage to the battery.

WARNINGS

Use caution when lifting the battery out

of, or into, the vehicl e. It is heavy, and

may cause injury when lifting, or if dropped.

Do not tip the battery when lifting or

moving as tilting the battery more than

45 degrees may damage the battery, and may

cause the electrolyte to leak out. Battery

electrolyte is highly corrosive, and toxic.

CAUTIONS

Do not rest the battery on any part of the

vehicle as it may ca use damage due to

it's weight.

Do not run the engine with the battery

disconnected. Doing so may damage the

charging system.

Page 2910 of 3229

Wheels and tyres

190

L

Using the Land Rover tyre repair kit

Note: All vehicle drivers and occupants should

be made aware that a temporary repair has

been made to a tyre fitted to the vehicle. They

should also be made aware of the special

driving conditions im posed when using a

repaired tyre. Repair procedure

1. Open the tyre repair kit and peel off the

maximum speed label. Attach the label to

the facia in the driver's field of view. Take

care not to obstruct any of the instruments

or warning lights.

2. Uncoil the compressor power cable and

the inflation hose.

3. Unscrew the orange cap from the sealant

bottle receiver, and the sealant bottle cap.

4. Screw the sealant bottle into the receiver

(clockwise) until tight.

• Screwing the bottle onto the receiver will

pierce the bottle's se al. Do not unscrew

a full, or partly us ed bottle from the

receiver. Doing so will result in the

sealant leaking from the bottle.

5. Remove the valve cap from the damaged

tyre.

6. Remove the protective cap from the

inflation hose, and c onnect the inflation

hose to the tyre valve. Ensure that the hose

is screwed on firmly.

7. Ensure that the compressor switch is in

the off ( O) position.

8. Insert the power cable connector into an

auxiliary power socket. See AUXILIARY

POWER SOCKETS (page 110).

9. Unless the vehicle is in an enclosed or

poorly ventilated area , start the engine.

10. Set the compressor switch to the on ( l)

position.

11. Inflate the tyre to a minimum of 1.8 bar (26

lb/in²) and a maximum of 3.5 bar (51

lb/in²).

†

WARNINGS

Avoid skin contact with the sealant

which contains natu ral rubber latex.

Do not unscrew the sealant bottle from the

receiver until it is empty, as sealant will leak

out.

If the tyre inflation pressure does not

reach 1.8 bar (26 lb/in²) within seven

minutes, the tyre may have suffered excessive

damage. A temporary repair will not be

possible, and the vehicle should not be driven

until the tyre has been replaced.

CAUTIONS

Before attempting a tyre repair, ensure

that the vehicle is parked safely, as far

away from passing traffic as possible.

Ensure that the parki ng brake is applied,

and P is selected if an automatic

transmission is fitted.

Do not attempt to remove foreign objects

such as nails, screws, etc from the tyre.

Always run the engine when using the

compressor, unless the vehicle is in an

enclosed, or poorly ventilated space.

To prevent overheating do not operate

the compressor continuously for longer

than ten minutes.

Page 2911 of 3229

191

Wheels and tyres

R

12. During the inflation, switch the

compressor off briefly to check the tyre

pressure using the gauge mounted on the

compressor.

• It should not take longer than seven

minutes to inflate the tyre. If after seven

minutes the tyre ha s not reached the

minimum pressure, the tyre should not

be used.

13. Once the tyre has been inflated switch off

the compressor. If desired the engine may

be turned off after the compressor has

been turned off.

14. Remove the power connector from the

auxiliary power socket.

15. Remove the inflation hose from the tyre

valve by unscrewing it as quickly as

possible (anti-clockwise).

16. Replace the inflation hose protective cap,

and the tyre valve cap.

17. Do not remove the sealant bottle from the

receiver.

18. Ensure that the tyre repair kit (including

the bottle, and receiver caps) are placed

securely in the vehicle. You will need to

use the kit to check the tyre pressure after

3km (2 miles) so ensure they are easily

accessible.

19. Immediately drive the vehicle for 3 km (2

miles) to allow the sealant to coat the inner

surface of the tyre and form a seal at the

puncture.

†When pumping the sealant through the tyre

valve, the pressure may rise up to 6 bar (87

lb/in²). The pressure will drop again after

approximately 30 seconds.

Checking the tyre pressure after a repair

1. Drive the vehicle for 3 km (2 miles) then

stop in a safe place. Carry out a visual

examination of the tyres condition.

2. Remove the protective cap from the

inflation hose.

3. Screw the inflation hos e connector firmly

onto the tyre valve.

4. Read the tyre pressure from the gauge.

5. If the pressure of the sealant filled tyre is

above 1.3 bar (19 lb/in²) adjust the

pressure to the correct value. See

TECHNICAL SPECIFICATIONS (page 194).

6. Ensure that the compressor switch is in

the off position ( O), and insert the power

cable connector into an auxiliary power

socket. See AUXILIARY POWER

SOCKETS (page 110).

7. If the vehicle is in a well ventilated area,

start the engine.

8. Switch on the compressor ( I), and inflate

the tyre to the correct pressure.

WARNINGS

When driving the vehicle, if you

experience vibr ations, abnormal

steering, or noises, re duce speed immediately.

Drive with extreme caution and reduced speed

to the first safe place to stop the vehicle.

Visually examine the tyre, and check it's

pressure. If there are any signs of damage or

deformity to the tyre, or the tyre pressure is

below 1.3 bar (19 lb/i n²) do not continue

driving.

Consult a tyre repair centre, or your

Land Rover Dealer/Authorised repairer

for advice concerning the replacement of a

tyre after using a tyre repair kit.