ABS LAND ROVER FRELANDER 2 2006 Manual Online

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 946 of 3229

Entrained gases i n t he cool ing s ys tem escape t hrough the t hermal control modul e degas l ine t o t he cool ant res ervoir.

The increas ing coolant temperature is felt at t he t hermos tat , and is regi s tered on the ins trument cl us t er coolantt emperature gage vi a t he ECM and ECT s ens or s i gnal.For addit ional informat ion, refer t o: Ins t rument Clus ter (413-01 Inst rument Cl us t er, Des cript ion and Operat ion).

Engine Normal Operating Temperature

W i th the coolant t emperature increas ing, at 83°C (181°F) t he t hermos tat reacts and commences openi ng. The by-pas svalve is progres s ively clos ed. Hot coolant ret urning from t he engi ne t o t he thermal control modul e i s now all owed to pas st hrough the t op hos e connecti on to the radiator. The fl ow of hot coolant t o t he radiat or now forces cold cool ant wi thi n t heradi at or and bot t om hos e t o fl ow t o t he thermal cont rol module.

Duri ng the thermos t at opening period t here i s an i nit ial temperat ure di fferenti al of t he coolant at bot h s ides of t het hermos tat . The thermos t at react s t o t he t emperature different ial and part iall y closes , whi le t he by-pas s val ve opensfurther. The thermos t at and by-pas s valve conti nue to oscil lat e whil e t he cool ant t emperat ure i ncreas es .

At a coolant temperat ure of 91°C (196°F) t he thermost at is full y opened and t he by-pas s valve i s ful ly clos ed. The returncool ant from t he engi ne is now ful ly circul ated t hrough t he radiat or and bot tom hose. Coolant flows t hrough the radiat orfrom the RH tank t o t he LH t ank, and i s cool ed by air pass i ng through the mat ri x. Ent rai ned gas es i n the radiat or es capet hrough the connect ed degas l ine t o t he cool ant res ervoir.

The increas ed cool ant volume created by heat expans ion caus es the coolant level to ri se through t he connecti ng res ervoirhose, and i nt o t he res ervoi r.

The t emperature of the cooli ng s ys t em i s cons t ant ly moni tored by t he ECM via the ECT s ens or s i gnal. The ECM uses t heECT s ignal to control operati on of the cooling fans , and to adjus t engine fueling. The ECM al so operates t he fans i nres ponse to input s from the aut omati c t ransmis s ion oil t emperat ure s ensor, Air Condit ioning (A/C) s ys tem cont rol s wit ch,and t he A/C pres sure s ens or. For addit ional i nformati on, refer to: El ect ronic Engine Cont rols - 2.2L Di es el (303-14Electroni c Engine Controls - 2.2L Dies el, Des cript ion and Operat ion).For addit ional informat ion, refer t o: Air Condit ioning (412-01 Cli mat e Cont rol , Descripti on and Operat ion).

The cool ing fan s peed is als o infl uenced by vehicle road s peed. The ECM adjus t s the speed of t he cool ing fans tocompens ate for t he ram air effect , us ing t he CAN bus road speed s ignal received from the Ant i-Lock Brake Sys tem (ABS)module.

W hen t he engine i s s hut down, t he coolant t emperature and volume decreas e. The thermos t at st art s t o clos e as t hecool ant t emperat ure decreas es to 89°C (192°F), and is fully cl osed at 81°C (178°F). The coolant level wit hin t he res ervoi rdecreas es as coolant is drawn from the res ervoi r to replenis h the s ys tem.

Followi ng engi ne s hut down when the coolant pump i s s tat ionary, the ECM may cont inue t o operat e t he cool ing fans for apre-det ermined peri od to maint ai n engine cooling.

Page 1021 of 3229

Publi s hed: 11-May-2011

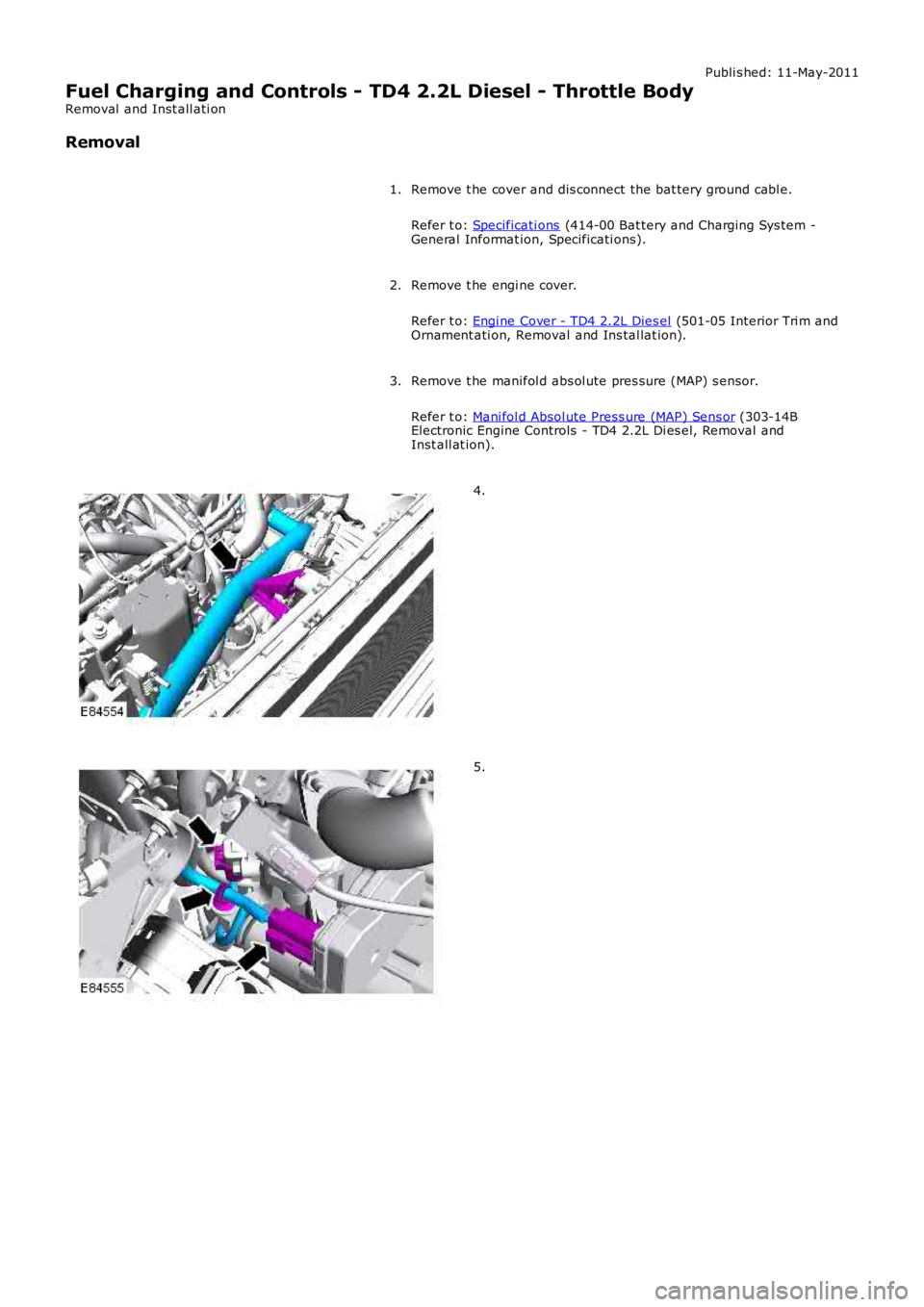

Fuel Charging and Controls - TD4 2.2L Diesel - Throttle Body

Removal and Inst all ati on

Removal

Remove t he cover and dis connect the bat tery ground cabl e.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -General Informat ion, Specificati ons).

1.

Remove t he engi ne cover.

Refer t o: Engi ne Cover - TD4 2.2L Dies el (501-05 Interior Tri m andOrnament ati on, Removal and Ins tal lat ion).

2.

Remove t he manifol d abs ol ute pres sure (MAP) s ens or.

Refer t o: Mani fol d Absol ute Press ure (MAP) Sens or (303-14BElectronic Engine Controls - TD4 2.2L Di es el, Removal andInst all at ion).

3.

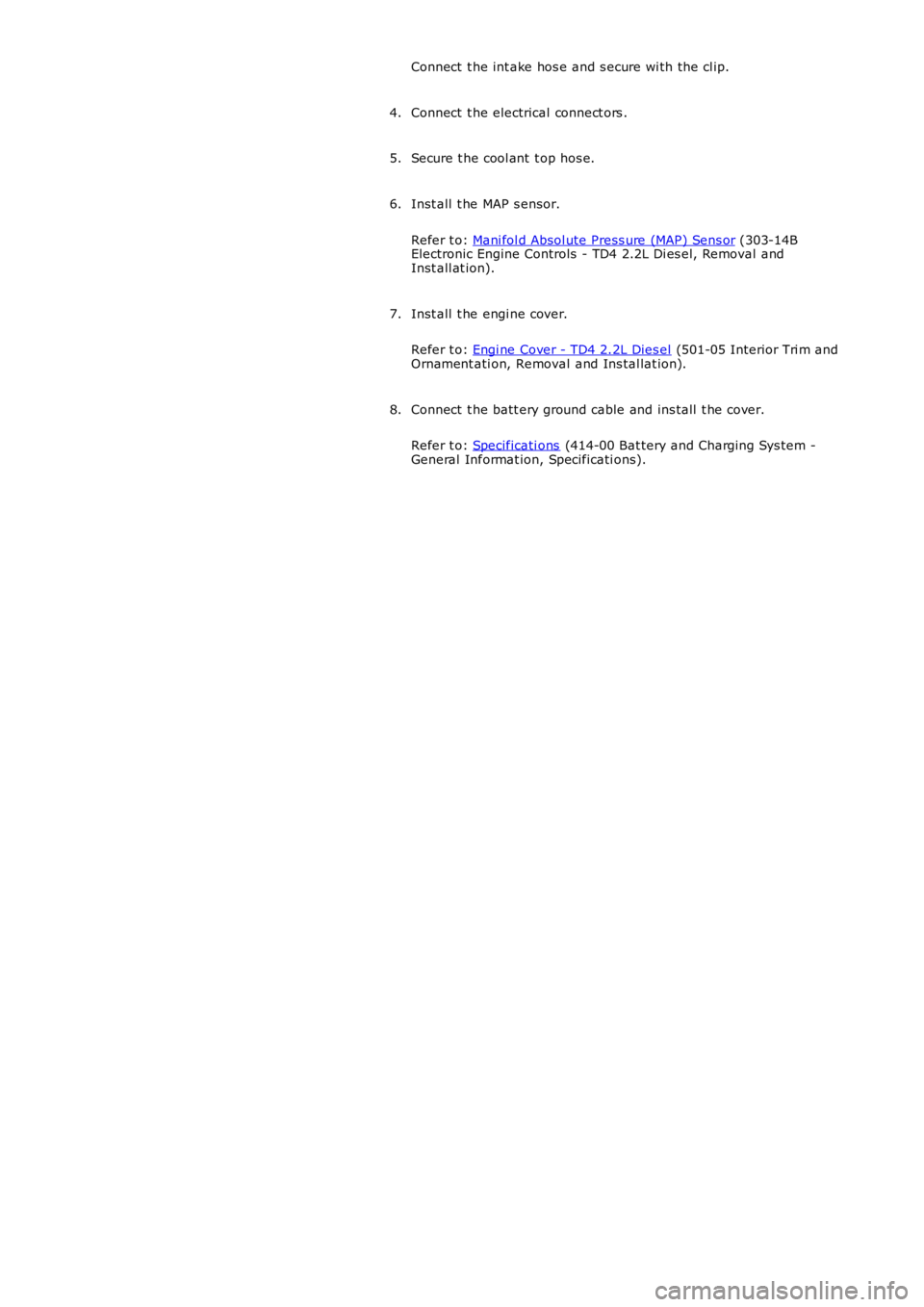

4.

5.

Page 1023 of 3229

Connect t he int ake hos e and s ecure wi th the cl ip.

Connect t he electrical connect ors .4.

Secure t he cool ant t op hos e.5.

Inst all t he MAP s ensor.

Refer t o: Mani fol d Absol ute Press ure (MAP) Sens or (303-14BElectronic Engine Controls - TD4 2.2L Di es el, Removal andInst all at ion).

6.

Inst all t he engi ne cover.

Refer t o: Engi ne Cover - TD4 2.2L Dies el (501-05 Interior Tri m andOrnament ati on, Removal and Ins tal lat ion).

7.

Connect t he batt ery ground cable and ins tall t he cover.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -General Informat ion, Specificati ons).

8.

Page 1079 of 3229

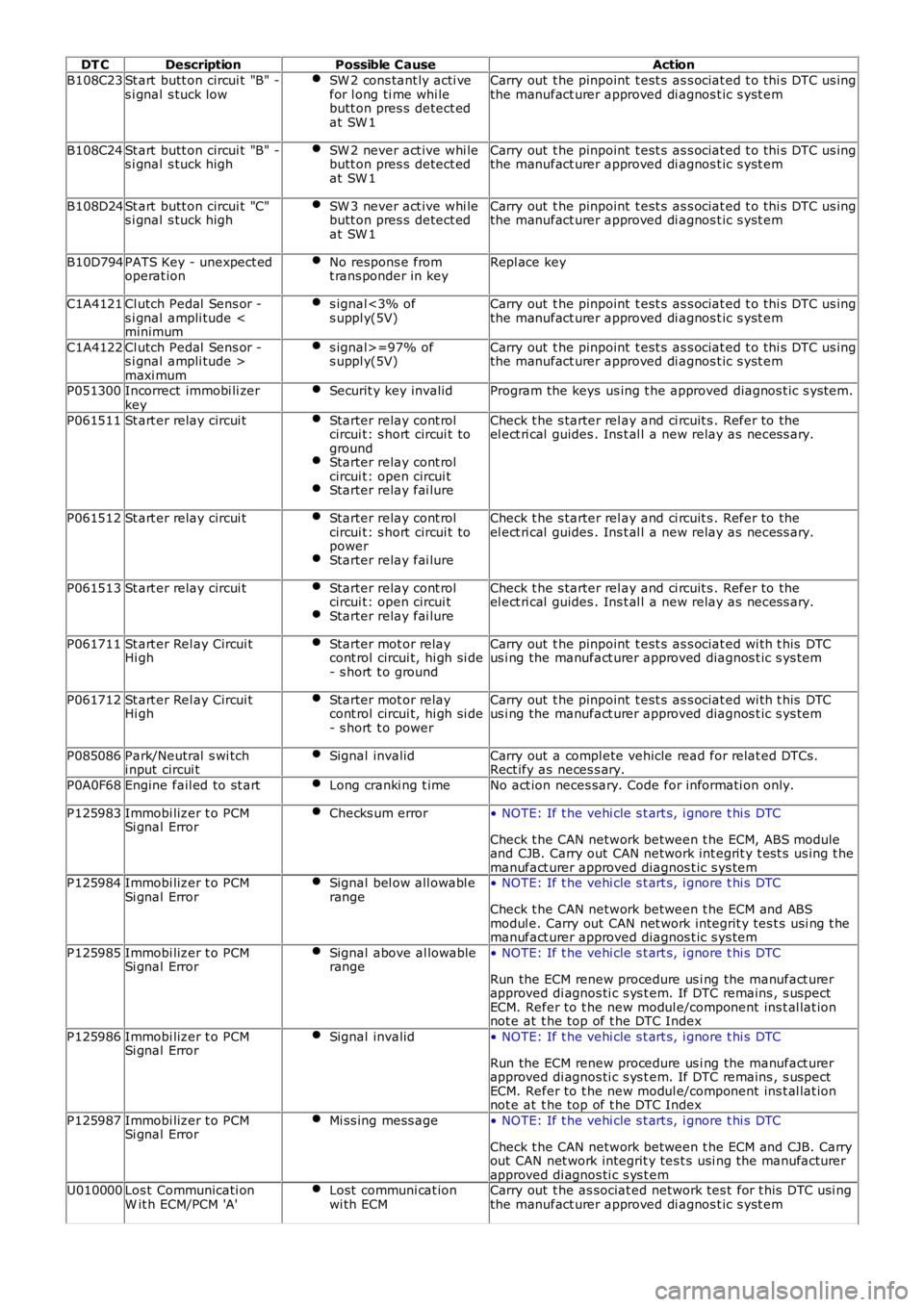

DT CDescriptionPossible CauseAction

B108C23St art butt on circui t "B" -s i gnal s tuck lowSW 2 cons tant ly acti vefor l ong ti me whi lebutt on pres s detect edat SW 1

Carry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B108C24St art butt on circui t "B" -s i gnal s tuck highSW 2 never act ive whi lebutt on pres s detect edat SW 1

Carry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B108D24St art butt on circui t "C"s i gnal s tuck highSW 3 never act ive whi lebutt on pres s detect edat SW 1

Carry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B10D794PATS Key - unexpect edoperat ionNo respons e fromt rans ponder in keyRepl ace key

C1A4121Cl utch Pedal Sens or -s i gnal ampli tude

C1A4122Cl utch Pedal Sens or -s i gnal ampli tude >maxi mum

s ignal>=97% ofs uppl y(5V)Carry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

P051300Incorrect immobi li zerkeySecurit y key invalidProgram the keys us ing t he approved diagnos t ic s yst em.

P061511St art er relay circui tStarter relay cont rolcircui t: s hort circui t togroundStarter relay cont rolcircui t: open circui tStarter relay fai lure

Check t he s tarter rel ay and ci rcuit s . Refer to theel ect ri cal guides . Ins t al l a new relay as neces s ary.

P061512St art er relay circui tStarter relay cont rolcircui t: s hort circui t topowerStarter relay fai lure

Check t he s tarter rel ay and ci rcuit s . Refer to theel ect ri cal guides . Ins t al l a new relay as neces s ary.

P061513St art er relay circui tStarter relay cont rolcircui t: open circui tStarter relay fai lure

Check t he s tarter rel ay and ci rcuit s . Refer to theel ect ri cal guides . Ins t al l a new relay as neces s ary.

P061711St art er Rel ay Circui tHi ghStarter mot or relaycont rol circui t, hi gh si de- s hort t o ground

Carry out t he pinpoint t est s as s ociat ed wi th t his DTCus i ng the manufact urer approved diagnos t ic s ys tem

P061712St art er Rel ay Circui tHi ghStarter mot or relaycont rol circui t, hi gh si de- s hort t o power

Carry out t he pinpoint t est s as s ociat ed wi th t his DTCus i ng the manufact urer approved diagnos t ic s ys tem

P085086Park/Neutral s wi tchi nput circui tSignal invalidCarry out a compl ete vehicle read for relat ed DTCs.Rect ify as neces s ary.

P0A0F68Engine fail ed to st artLong cranki ng t imeNo act ion neces sary. Code for informati on only.

P125983Immobi lizer t o PCMSi gnal ErrorChecks um error• NOTE: If t he vehi cle s t art s, i gnore t hi s DTC

Check t he CAN network between t he ECM, ABS moduleand CJB. Carry out CAN network int egrit y t est s us ing t hemanufact urer approved diagnos t ic s ys temP125984Immobi lizer t o PCMSi gnal ErrorSignal bel ow all owabl erange• NOTE: If t he vehi cle s t art s, i gnore t hi s DTC

Check t he CAN network between t he ECM and ABSmodul e. Carry out CAN net work integrit y tes t s usi ng t hemanufact urer approved diagnos t ic s ys tem

P125985Immobi lizer t o PCMSi gnal ErrorSignal above al lowablerange• NOTE: If t he vehi cle s t art s, i gnore t hi s DTC

Run the ECM renew procedure us i ng the manufact urerapproved di agnos ti c s ys t em. If DTC remains , s uspectECM. Refer to t he new modul e/component ins t al lat ionnot e at t he top of t he DTC Index

P125986Immobi lizer t o PCMSi gnal ErrorSignal invalid• NOTE: If t he vehi cle s t art s, i gnore t hi s DTC

Run the ECM renew procedure us i ng the manufact urerapproved di agnos ti c s ys t em. If DTC remains , s uspectECM. Refer to t he new modul e/component ins t al lat ionnot e at t he top of t he DTC Index

P125987Immobi lizer t o PCMSi gnal ErrorMi ss ing mess age• NOTE: If t he vehi cle s t art s, i gnore t hi s DTC

Check t he CAN network between t he ECM and CJB. Carryout CAN net work integrit y tes t s usi ng t he manufacturerapproved di agnos ti c s ys t emU010000Los t Communicati onW it h ECM/PCM 'A'Lost communi cat ionwi th ECMCarry out t he as sociat ed network tes t for t his DTC usi ngthe manufact urer approved di agnos t ic s yst em

Page 1098 of 3229

Publi s hed: 11-May-2011

Starting System - TD4 2.2L Diesel, Vehicles Built From: 01-03-2009 -

Starting System

Des cript ion and Operat ion

STOP/START SYSTEM

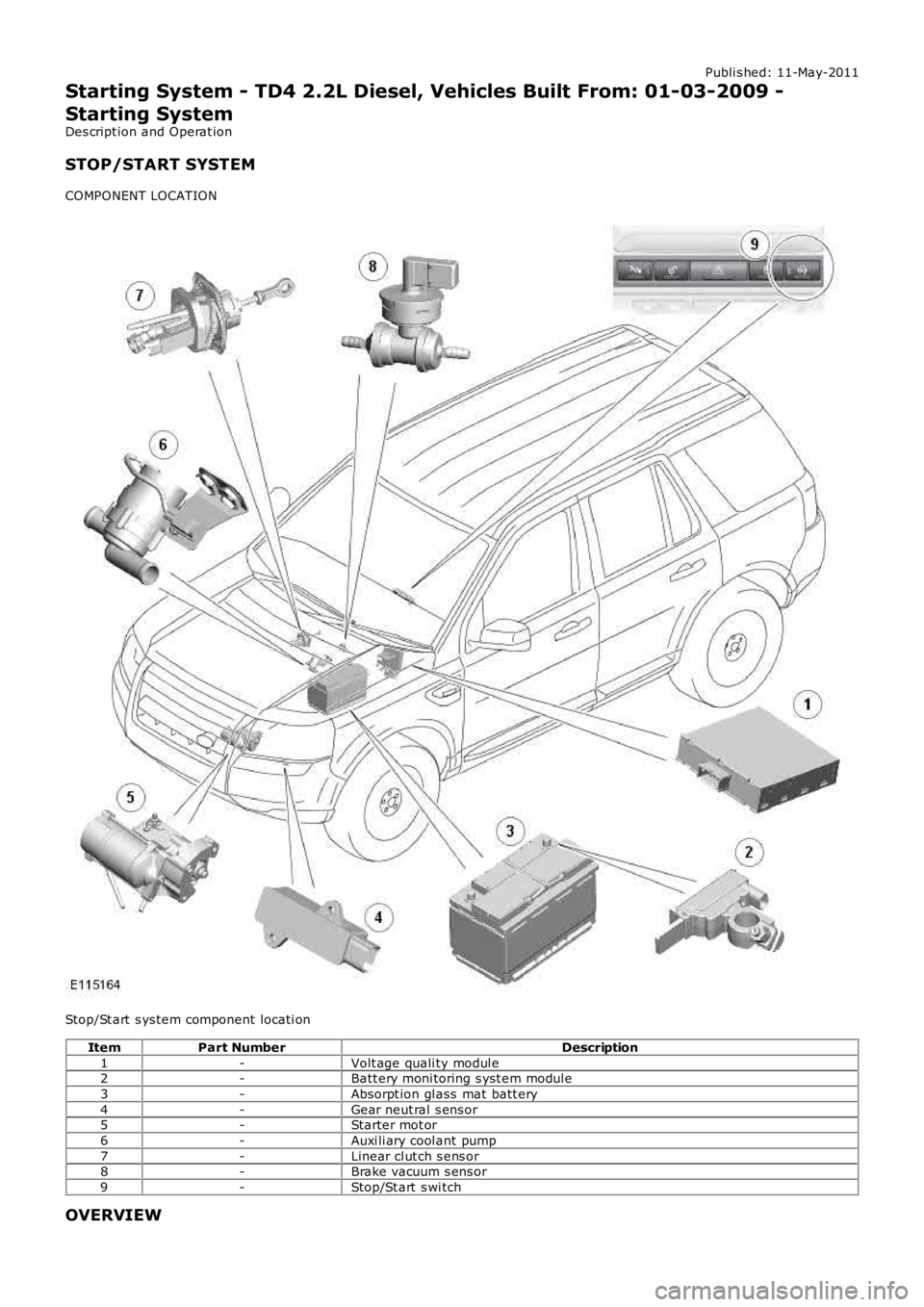

COMPONENT LOCATION

Stop/St art s ys tem component locati on

ItemPart NumberDescription

1-Volt age quali ty modul e2-Batt ery moni toring s yst em modul e

3-Absorpt ion gl ass mat batt ery

4-Gear neut ral s ens or5-Starter mot or

6-Auxi li ary cool ant pump

7-Linear cl ut ch s ens or8-Brake vacuum s ens or

9-Stop/St art s wi tch

OVERVIEW

Page 1101 of 3229

• NOTE: If aft er an uns ucces sful aut omati c res t art t he dri ver i s request ed t o res t art t he engi ne for example, by depres s ingt he cl utch. Thi s acti on has to be compl eted wi thi n 50 s econds , ot herwi se the St op/Start s yst em will deact ivat e and aconventi onal s tart wil l be required.

REFINEMENT AND DURABILITY

Engi ne operati ng refinement has been maint ai ned and in some cas es refined t o ens ure t he vehicle’s occupant s wit ness analmos t s eamles s operati on wi th regard t o engine s hutdown and rest art wit hi n a St op/St art cycle.

To reduce engine s hake when the engine is s hutt ing-down a revis ed t hrot tl e clos ing st rat egy i s i nt roduced, whi ch rampsdown t he fuel inject ion i n a more s moot h and cont rol led manner. At t he s ame t ime the generat or is t urned-off to reduceload on the engine.

ECM s oft ware changes and revis ed engine cali brati on further aid a s moother engi ne s hut down. Furthermore t he opti mizedengi ne mounti ng s trategy and t uni ng as si st s i n reducing engine s hake on engine s tart-up.

Component s direct ly i nvol ved wit h engine s tart-up and s hut-down have been ei ther upgraded or replaced to wit hst and t heincreas ed frequency of Stop/St art cycl es over t he l ifet ime of the vehicle. These enhanced and more robust component s aredis cus s ed i n thi s s ect ion.

CAUTION: To mai ntain the correct operat ion of t he St op/Start sys t em care must be taken when repl acingcomponents , t hat onl y approved parts are fit ted as some components from earl ier vehicl es wil l fi t the TD4_e.

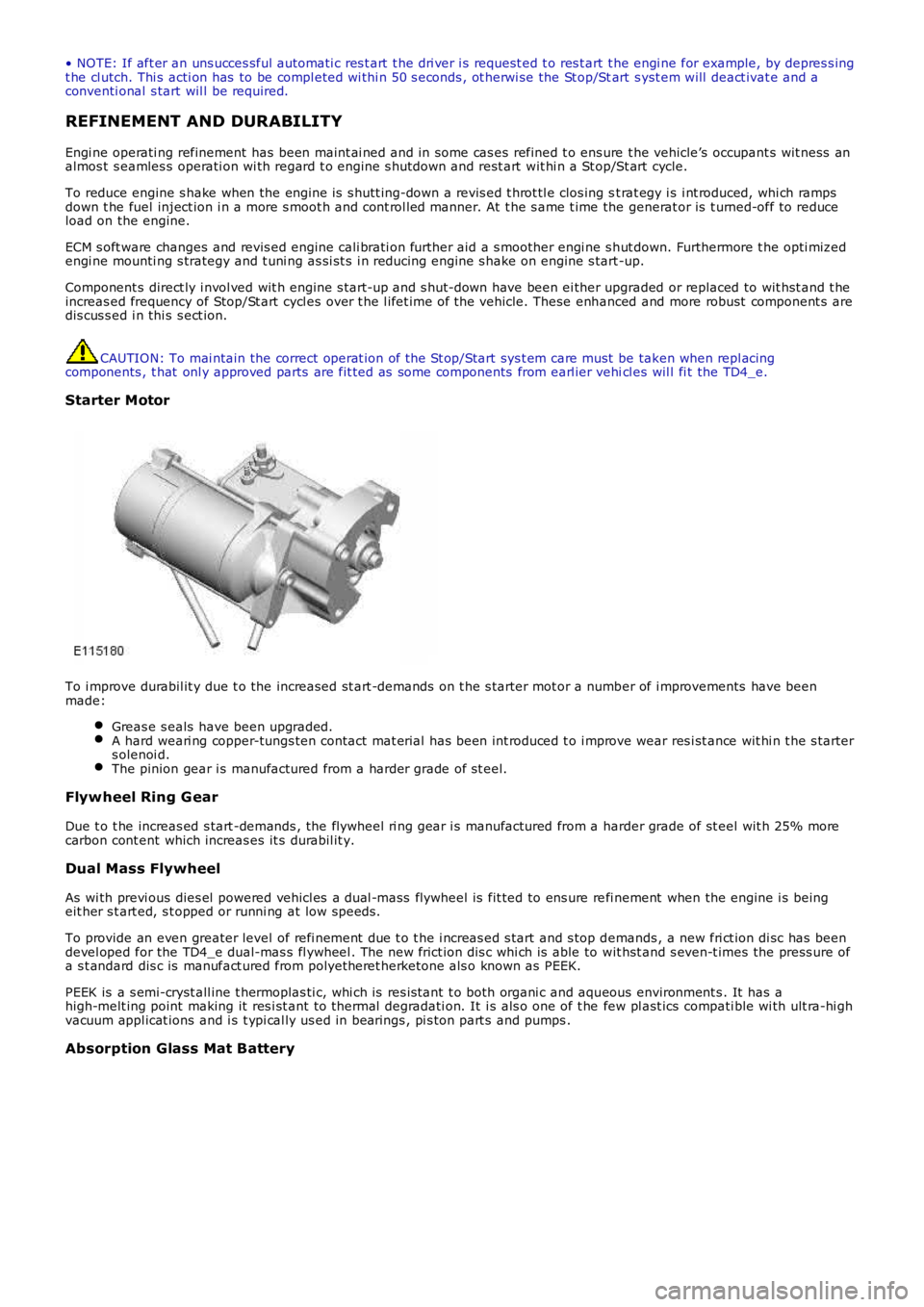

Starter Motor

To i mprove durabil it y due t o the increased st art -demands on t he s tarter mot or a number of i mprovements have beenmade:

Greas e s eals have been upgraded.A hard weari ng copper-tungs ten contact mat erial has been int roduced t o i mprove wear res i st ance wit hi n t he s tarters olenoi d.The pinion gear i s manufactured from a harder grade of st eel.

Flywheel Ring G ear

Due t o t he increas ed s tart -demands , the flywheel ri ng gear i s manufactured from a harder grade of st eel wit h 25% morecarbon cont ent which increas es it s durabil it y.

Dual Mass Flywheel

As wi th previ ous dies el powered vehicl es a dual -mass flywheel is fit ted to ens ure refi nement when the engine i s beingeit her s t art ed, s t opped or runni ng at low speeds.

To provide an even greater level of refi nement due t o t he i ncreas ed s tart and s top demands , a new fri ct ion di sc has beendevel oped for the TD4_e dual-mas s fl ywheel . The new frict ion dis c whi ch is able to wit hst and s even-t imes the press ure ofa s t andard dis c is manufact ured from polyetheret herketone als o known as PEEK.

PEEK is a s emi-cryst all ine t hermoplas ti c, whi ch is res is tant t o both organi c and aqueous environment s . It has ahigh-melt ing point making it res i st ant to thermal degradati on. It i s als o one of t he few pl ast ics compati ble wi th ult ra-hi ghvacuum appl icat ions and i s t ypi cal ly us ed in bearings , pi s ton part s and pumps .

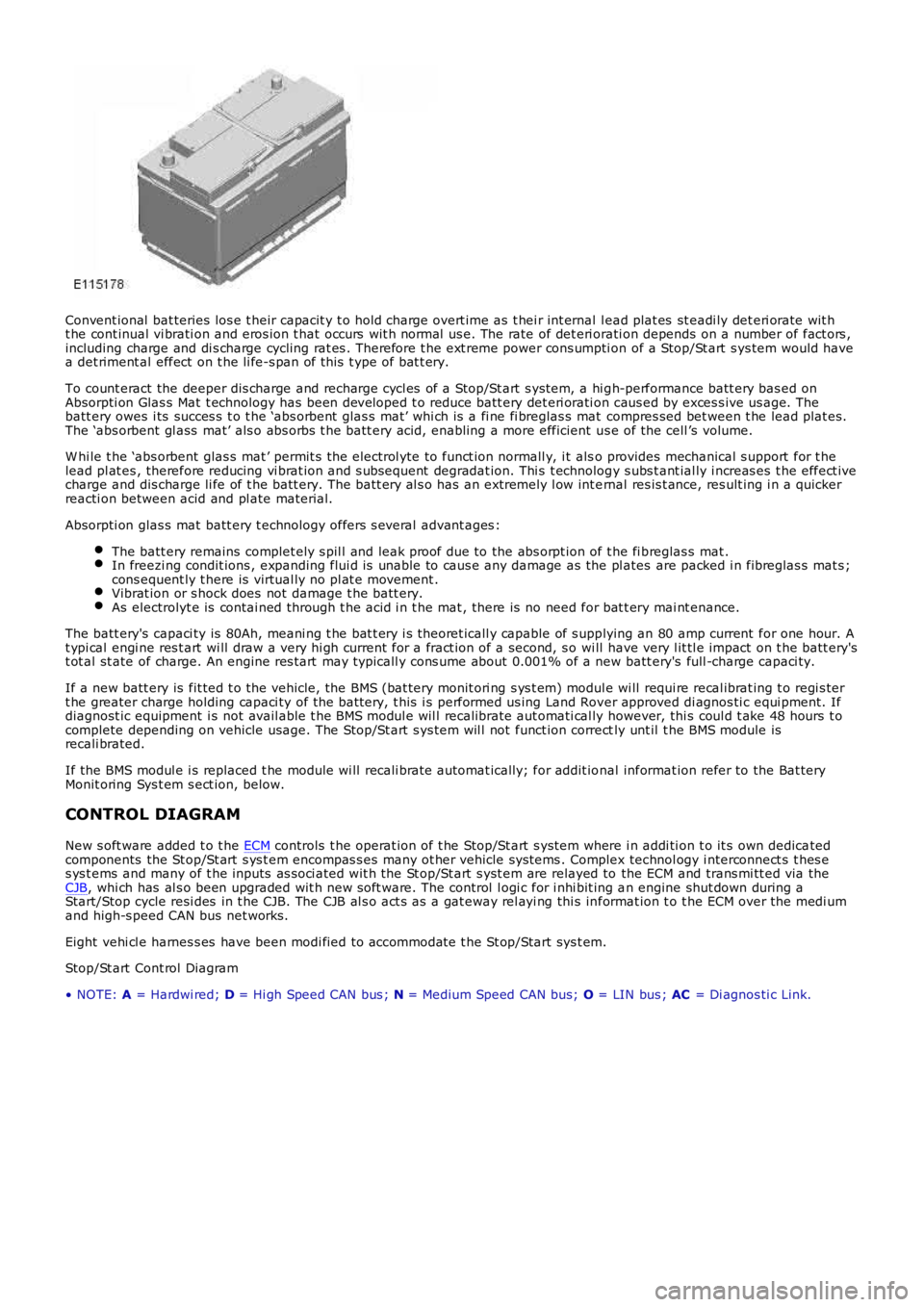

Absorption Glass Mat Battery

Page 1102 of 3229

Convent ional bat teries los e t heir capacit y t o hold charge overt ime as t hei r int ernal l ead plat es st eadi ly det eri orate wit ht he cont inual vi brati on and eros ion t hat occurs wit h normal us e. The rate of det eri orati on depends on a number of fact ors ,including charge and di s charge cycling rat es . Therefore t he ext reme power cons umpti on of a Stop/St art s ys tem would havea det riment al effect on t he li fe-s pan of t his t ype of bat t ery.

To count eract the deeper dis charge and recharge cycl es of a Stop/St art s ys tem, a hi gh-performance batt ery bas ed onAbsorpti on Glas s Mat t echnology has been developed t o reduce batt ery det eri orati on caus ed by exces s ive us age. Thebatt ery owes i ts succes s t o t he ‘abs orbent glas s mat’ whi ch is a fi ne fi breglas s mat compres sed bet ween t he lead plat es.The ‘abs orbent gl ass mat’ als o abs orbs t he batt ery acid, enabling a more efficient us e of the cell ’s volume.

W hi le t he ‘abs orbent glas s mat ’ permit s t he electrol yte to funct ion normall y, i t also provides mechanical s upport for t helead pl at es , therefore reducing vi brat ion and s ubsequent degradat ion. Thi s t echnology s ubs t ant ial ly i ncreas es t he effect ivecharge and dis charge li fe of t he batt ery. The batt ery al s o has an extremely l ow int ernal res is t ance, res ult ing i n a quickerreacti on between acid and pl ate material.

Absorpti on glas s mat batt ery t echnology offers s everal advant ages :

The batt ery remains complet ely s pil l and leak proof due to the abs orpt ion of t he fi breglas s mat .In freezi ng condit ions , expanding flui d is unable to caus e any damage as the pl ates are packed i n fibreglas s mat s ;cons equent ly t here is virtual ly no pl at e movement .Vibrat ion or s hock does not damage t he batt ery.As electrolyt e is contai ned through t he acid i n t he mat , there is no need for bat t ery mai nt enance.

The batt ery's capaci ty is 80Ah, meani ng t he bat t ery i s theoret icall y capable of s upplying an 80 amp current for one hour. At ypi cal engi ne res t art wi ll draw a very hi gh current for a fract ion of a second, s o wi ll have very l it tl e impact on t he batt ery'st ot al st ate of charge. An engine res tart may typicall y cons ume about 0.001% of a new batt ery's full -charge capaci ty.

If a new batt ery is fit ted t o t he vehicle, the BMS (bat tery monit ori ng s ys t em) module wi ll requi re recal ibrat ing t o regi s tert he greater charge holding capaci ty of the bat tery, t his i s performed us ing Land Rover approved di agnos ti c equi pment. Ifdiagnost ic equipment i s not avail able t he BMS modul e wil l recalibrate aut omati cal ly however, thi s coul d t ake 48 hours t ocomplete depending on vehicle usage. The Stop/St art s ys tem wil l not funct ion correctly unt il t he BMS module isrecali brated.

If the BMS modul e i s replaced t he module wi ll recali brat e automat ically; for addit ional informat ion refer to the Bat teryMonit oring Sys t em s ect ion, below.

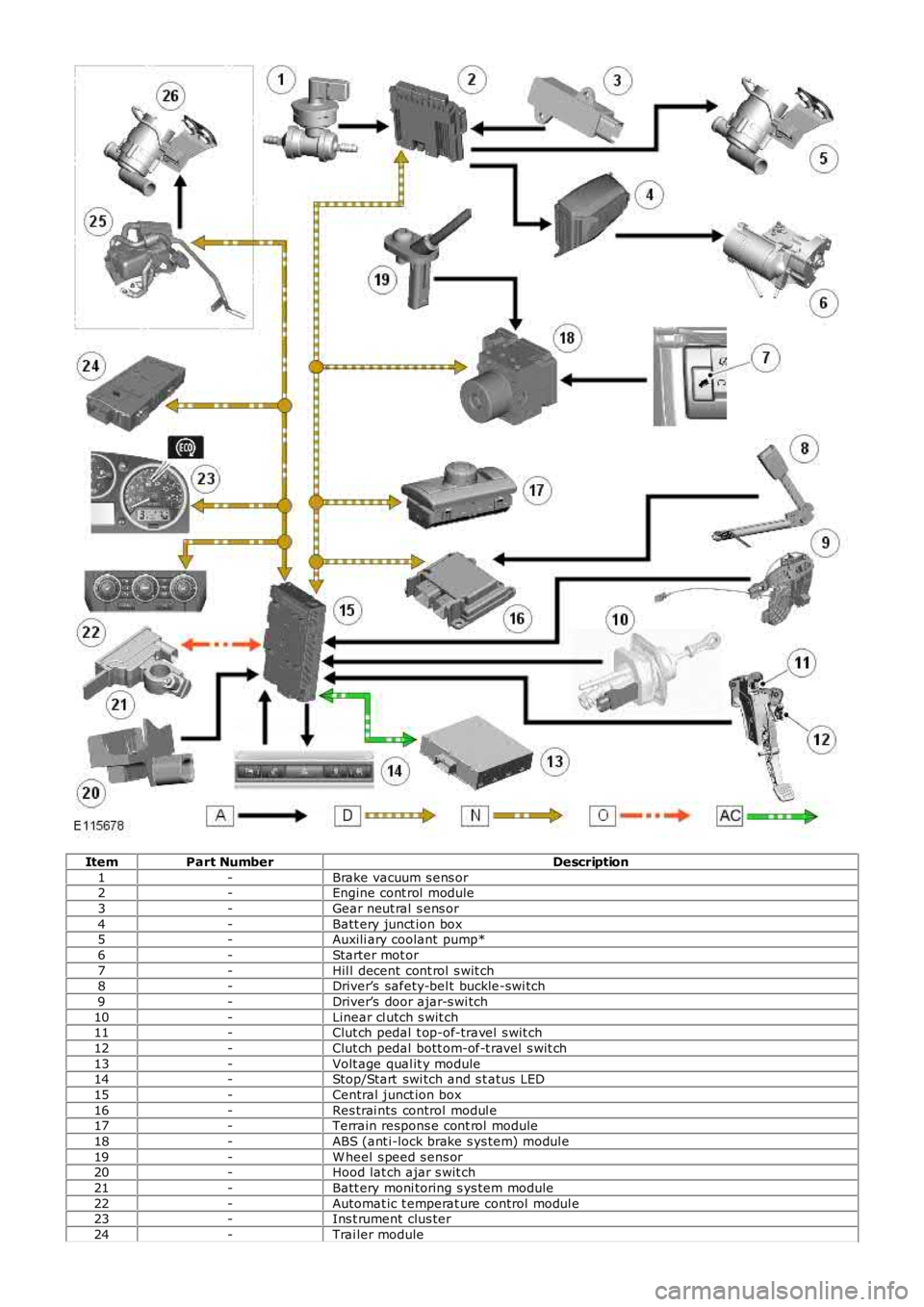

CONTROL DIAGRAM

New s oft ware added t o t he ECM controls t he operat ion of t he Stop/St art s yst em where i n addi ti on t o it s own dedicatedcomponents the St op/St art s ys t em encompas s es many ot her vehicle sys tems . Complex technol ogy i nterconnect s t hes es ys t ems and many of t he inputs as s oci ated wit h the St op/St art s yst em are relayed to the ECM and trans mi tt ed via theCJB, whi ch has al s o been upgraded wit h new s oft ware. The control l ogi c for i nhi bit ing an engine shut down during aStart/Stop cycle resi des in t he CJB. The CJB al s o act s as a gat eway rel ayi ng thi s informat ion t o t he ECM over the medi umand high-s peed CAN bus net works.

Eight vehi cl e harnes s es have been modi fied to accommodate t he St op/Start sys t em.

Stop/St art Cont rol Diagram

• NOTE: A = Hardwi red; D = Hi gh Speed CAN bus ; N = Medium Speed CAN bus; O = LIN bus ; AC = Di agnos ti c Link.

Page 1103 of 3229

ItemPart NumberDescription

1-Brake vacuum s ens or2-Engine cont rol module

3-Gear neut ral s ens or

4-Batt ery junct ion box5-Auxili ary coolant pump*

6-Starter mot or

7-Hil l decent cont rol s wit ch8-Driver’s safety-bel t buckle-swi tch

9-Driver’s door ajar-s wi tch

10-Linear cl utch s wit ch11-Clut ch pedal t op-of-travel s wit ch

12-Clut ch pedal bott om-of-t ravel s wit ch

13-Volt age qual it y module14-Stop/Start swi tch and s t atus LED

15-Central junct ion box

16-Res trai nts control modul e17-Terrain respons e cont rol module

18-ABS (ant i-lock brake s ys tem) modul e

19-W heel s peed s ens or20-Hood lat ch ajar s wit ch

21-Batt ery moni toring s ys tem module

22-Automat ic t emperat ure control modul e23-Ins t rument clus ter

24-Trai ler module

Page 1105 of 3229

Inhi bi tors ’ s ecti on, below.

The batt ery s t atus i nformat ion is t rans mit t ed from t he BMS modul e over t he LIN (l ocal i nt erconnect network) bus t o t heCJB which has a t wo-way communi cat ion wit h the BMS module. The cont rol l ogi c for i nhi bi ti ng engine s hutdown andini ti at ing an early engi ne res tart during a Start/Stop cycl e resi des in t he CJB. The CJB al so act s as t he gateway relayingt hi s informat ion t o t he ECM over the hi gh-s peed CAN bus.

Batt ery s t atus i nformat ion is al so trans mi tt ed from the CJB over the medi um-speed CAN bus t o t he ins t rument clus ter. Theins t rument clus ter dis plays batt ery charge warning mes s ages to indicate generat or or bat tery monit oring sys tem faul ts t ot he driver.

The BMS module cons tant ly computes t he s t at us of the el ect ri cal s ys tem on the bas is of the followi ng data:

batt ery det eriorati onbatt ery s t ate of chargebatt ery current demand.

If any of t hese factors s how a l ow meas urement, t he ECM s us pends t he Stop/Start feature unti l more bat tery power i savai lable. The fact ors are dis cus s ed below:

Batt ery det eriorati on

Alt hough fit t ed wit h a hi gh-performance batt ery bas ed on AGM (abs orpti on glas s mat ) technol ogy, t he charge holdingcapacit y of the bat tery wi ll s ti ll deteriorat e, however at a much s lower rat e t han a conventi onal bat tery. This degradat ionwil l reflect on the amount of charge t he bat t ery can hold unt il it reduces t o a condit ion where the bat tery wi ll needrepl acing.

The batt ery moni toring s yst em cal culat es t he condit ion of t he batt ery by obs erving a range of i nput s including:

ambient t emperaturecharge and dis charge act ivi tyvolt age andint ernal res is t ance.

The lat est condit ion value of t he batt ery i s s tored in the dedicated memory of t he BMS t o ens ure t he mos t accurat eforecas t of the bat teries condi ti on.

Stat e of charge

The BMS analys es how much charge has been drawn or repl enis hed to det ermi ne t he bat tery’s pres ent s tat e of charge.

Current demand

Duri ng a St op/Start cycle when vehicl e s ys t em us e i s in hi gh demand, for exampl e t he fol lowing are operat ing:

head li ght sclimate controlaudi o s yst em.

The batt ery wi ll dis charge more rapi dly due t o t he high current demand.

In thi s event t he BMS calculat es various fact ors t o determine how long t he batt ery can s upply a current at the presentlevel of demand. This calculat ion i s used by the CJB t o determine if t o authori ze whichever i s needed i n t he Stop/St artcycle, ei ther to:

prevent an engi ne s top, orini ti at e an engine res tart.

To provide this informati on t o t he CJB the BMS modul e calculates a range of batt ery variables , including:

s tat e of chargebatt ery s urface temperat ure to cal culat e t he int ernal temperat ureint ernal res is t ancevolt agecurrent flow into and from t he batt ery.

The batt ery moni toring s yst em cal culat es t hes e vari abl es agai nst programmed det ailed bat tery li fe model s t o determinehow l ong the gi ven current can be s upport ed.

Batt ery moni toring s ys tem modes

The batt ery moni toring s yst em has three di s ti nct modes :

Acti ve mode: during normal vehicle operat ion, batt ery dat a i s upl oaded and calculat ed every s econd.Sleep mode: duri ng ignit ion off, bat tery dat a i s uploaded every s econd and calculated every hour t o reduce i nacti vecurrent drai n.Trans port mode: bat t ery moni tori ng int ervals are mi nimi zed.

Batt ery replacement

If a new batt ery is fit ted t o t he vehicle, the BMS (bat tery monit ori ng s ys t em) module wi ll requi re recal ibrat ing t o regi s tert he greater charge holding capaci ty of the bat tery, t his i s performed us ing Land Rover approved di agnos ti c equi pment. If adiagnost ic s ys tem is not avail abl e t he BMS module will recal ibrat e automat icall y however, this could take 48 hours tocomplete depending on vehicle usage. The Stop/St art s ys tem wil l not funct ion correctly unt il t he BMS module isrecali brated.

If the BMS modul e i s replaced t he module wi ll re-calibrate aut omati cal ly.

Page 1161 of 3229

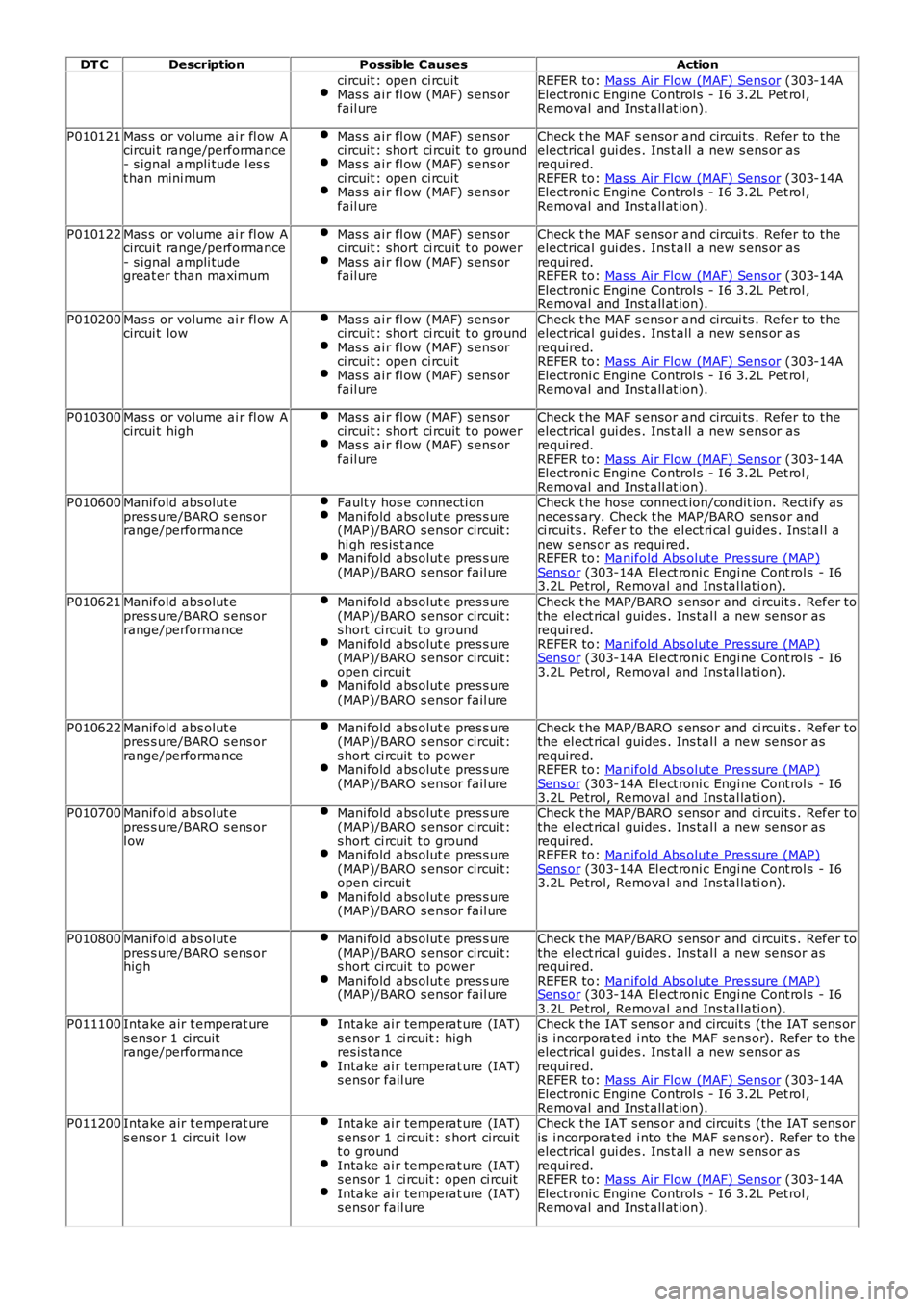

DT C

Description Possible Causes Action

ci rcuit : open ci rcuit

Mas s ai r fl ow (MAF) s ens or

fail ure REFER to:

Mas s Air Flow (MAF) Sens or (303-14A

Electroni c Engi ne Control s - I6 3.2L Pet rol ,

Removal and Inst all at ion).

P010121 Mas s or volume ai r fl ow A

circui t range/performance

- s ignal ampli tude l es s

t han mini mum Mas s ai r fl ow (MAF) s ens or

ci rcuit : short ci rcuit t o ground Mas s ai r fl ow (MAF) s ens or

ci rcuit : open ci rcuit Mas s ai r fl ow (MAF) s ens or

fail ure Check t he MAF s ensor and circui ts . Refer t o t he

electrical gui des . Ins t all a new s ens or as

required.

REFER to: Mas s Air Flow (MAF) Sens or (303-14A

Electroni c Engi ne Control s - I6 3.2L Pet rol ,

Removal and Inst all at ion).

P010122 Mas s or volume ai r fl ow A

circui t range/performance

- s ignal ampli tude

great er than maximum Mas s ai r fl ow (MAF) s ens or

ci rcuit : short ci rcuit t o power Mas s ai r fl ow (MAF) s ens or

fail ure Check t he MAF s ensor and circui ts . Refer t o t he

electrical gui des . Ins t all a new s ens or as

required.

REFER to: Mas s Air Flow (MAF) Sens or (303-14A

Electroni c Engi ne Control s - I6 3.2L Pet rol ,

Removal and Inst all at ion).

P010200 Mas s or volume ai r fl ow A

circui t low Mas s ai r fl ow (MAF) s ens or

ci rcuit : short ci rcuit t o ground Mas s ai r fl ow (MAF) s ens or

ci rcuit : open ci rcuit Mas s ai r fl ow (MAF) s ens or

fail ure Check t he MAF s ensor and circui ts . Refer t o t he

electrical gui des . Ins t all a new s ens or as

required.

REFER to: Mas s Air Flow (MAF) Sens or (303-14A

Electroni c Engi ne Control s - I6 3.2L Pet rol ,

Removal and Inst all at ion).

P010300 Mas s or volume ai r fl ow A

circui t high Mas s ai r fl ow (MAF) s ens or

ci rcuit : short ci rcuit t o power Mas s ai r fl ow (MAF) s ens or

fail ure Check t he MAF s ensor and circui ts . Refer t o t he

electrical gui des . Ins t all a new s ens or as

required.

REFER to: Mas s Air Flow (MAF) Sens or (303-14A

Electroni c Engi ne Control s - I6 3.2L Pet rol ,

Removal and Inst all at ion).

P010600 Manifold abs olut e

pres s ure/BARO s ens or

range/performance Fault y hos e connecti on Mani fold abs olut e pres s ure

(MAP)/BARO s ens or circui t:

hi gh res is t ance Mani fold abs olut e pres s ure

(MAP)/BARO s ens or fail ure Check t he hose connect ion/condit ion. Rect ify as

neces sary. Check t he MAP/BARO sens or and

ci rcuit s . Refer to the el ect ri cal guides . Ins tal l a

new s ens or as requi red.

REFER to: Manifold Abs olute Pres sure (MAP) Sens or (303-14A El ect roni c Engi ne Cont rol s - I6

3.2L Petrol, Removal and Ins tal lati on).

P010621 Manifold abs olut e

pres s ure/BARO s ens or

range/performance Mani fold abs olut e pres s ure

(MAP)/BARO s ens or circui t:

s hort ci rcuit t o ground Mani fold abs olut e pres s ure

(MAP)/BARO s ens or circui t:

open circui t Mani fold abs olut e pres s ure

(MAP)/BARO s ens or fail ure Check t he MAP/BARO s ens or and ci rcuit s . Refer to

the el ect ri cal guides . Ins tal l a new s ensor as

required.

REFER to: Manifold Abs olute Pres sure (MAP) Sens or (303-14A El ect roni c Engi ne Cont rol s - I6

3.2L Petrol, Removal and Ins tal lati on).

P010622 Manifold abs olut e

pres s ure/BARO s ens or

range/performance Mani fold abs olut e pres s ure

(MAP)/BARO s ens or circui t:

s hort ci rcuit t o power Mani fold abs olut e pres s ure

(MAP)/BARO s ens or fail ure Check t he MAP/BARO s ens or and ci rcuit s . Refer to

the el ect ri cal guides . Ins tal l a new s ensor as

required.

REFER to: Manifold Abs olute Pres sure (MAP) Sens or (303-14A El ect roni c Engi ne Cont rol s - I6

3.2L Petrol, Removal and Ins tal lati on).

P010700 Manifold abs olut e

pres s ure/BARO s ens or

l ow Mani fold abs olut e pres s ure

(MAP)/BARO s ens or circui t:

s hort ci rcuit t o ground Mani fold abs olut e pres s ure

(MAP)/BARO s ens or circui t:

open circui t Mani fold abs olut e pres s ure

(MAP)/BARO s ens or fail ure Check t he MAP/BARO s ens or and ci rcuit s . Refer to

the el ect ri cal guides . Ins tal l a new s ensor as

required.

REFER to: Manifold Abs olute Pres sure (MAP) Sens or (303-14A El ect roni c Engi ne Cont rol s - I6

3.2L Petrol, Removal and Ins tal lati on).

P010800 Manifold abs olut e

pres s ure/BARO s ens or

high Mani fold abs olut e pres s ure

(MAP)/BARO s ens or circui t:

s hort ci rcuit t o power Mani fold abs olut e pres s ure

(MAP)/BARO s ens or fail ure Check t he MAP/BARO s ens or and ci rcuit s . Refer to

the el ect ri cal guides . Ins tal l a new s ensor as

required.

REFER to: Manifold Abs olute Pres sure (MAP) Sens or (303-14A El ect roni c Engi ne Cont rol s - I6

3.2L Petrol, Removal and Ins tal lati on).

P011100 Intake air t emperat ure

s ensor 1 ci rcuit

range/performance Intake ai r temperat ure (IAT)

s ens or 1 ci rcuit : high

res is tance Intake ai r temperat ure (IAT)

s ens or fail ure Check t he IAT s ens or and circuit s (the IAT s ens or

is i ncorporated i nto the MAF sens or). Refer to the

electrical gui des . Ins t all a new s ens or as

required.

REFER to: Mas s Air Flow (MAF) Sens or (303-14A

Electroni c Engi ne Control s - I6 3.2L Pet rol ,

Removal and Inst all at ion).

P011200 Intake air t emperat ure

s ensor 1 ci rcuit l ow Intake ai r temperat ure (IAT)

s ens or 1 ci rcuit : s hort circuit

t o ground Intake ai r temperat ure (IAT)

s ens or 1 ci rcuit : open ci rcuit Intake ai r temperat ure (IAT)

s ens or fail ure Check t he IAT s ens or and circuit s (the IAT s ens or

is i ncorporated i nto the MAF sens or). Refer to the

electrical gui des . Ins t all a new s ens or as

required.

REFER to: Mas s Air Flow (MAF) Sens or (303-14A

Electroni c Engi ne Control s - I6 3.2L Pet rol ,

Removal and Inst all at ion).