ABS LAND ROVER FRELANDER 2 2006 Owners Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 1169 of 3229

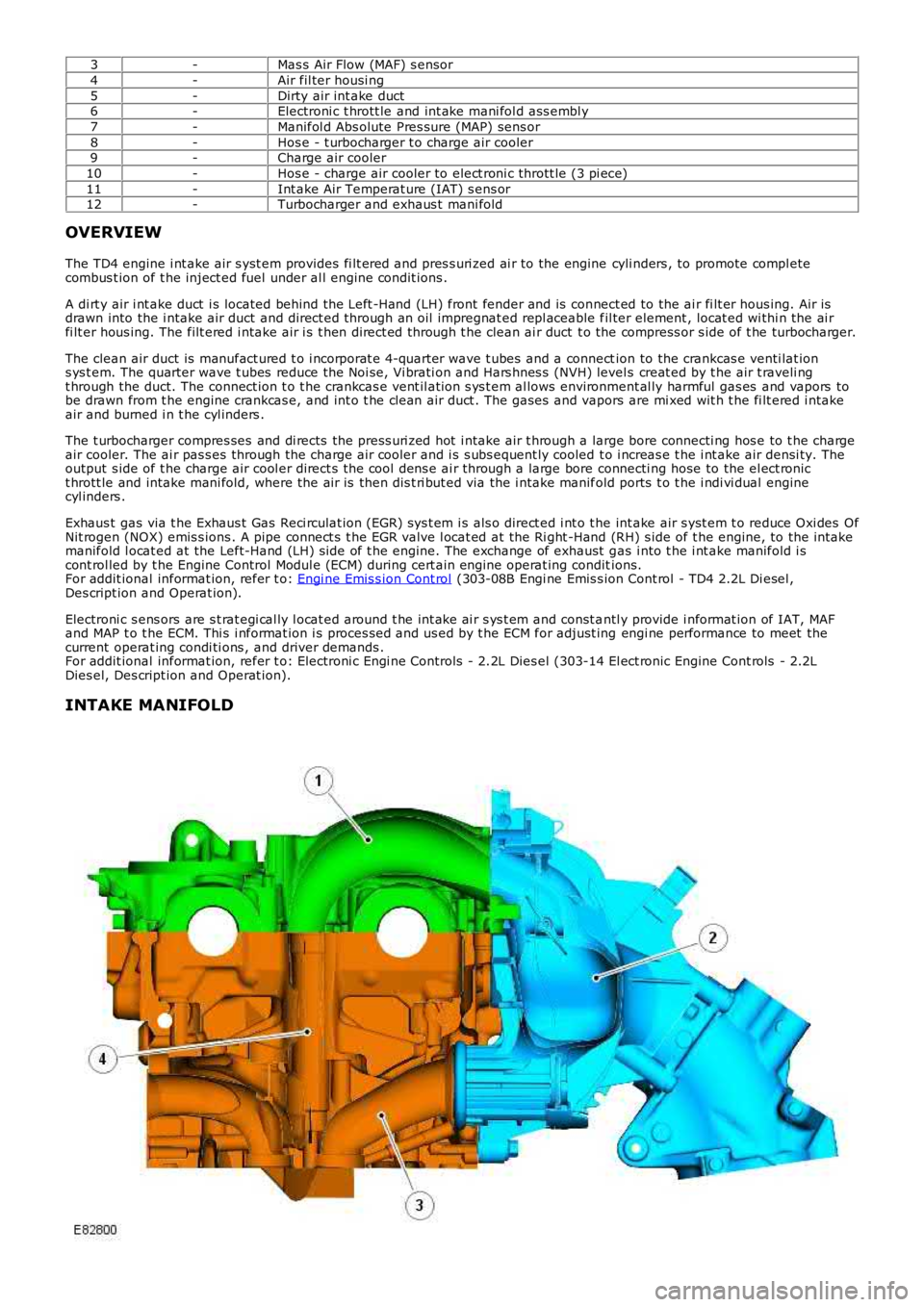

3-Mas s Air Flow (MAF) s ensor

4-Air fil ter housi ng

5-Dirty air int ake duct6-Electroni c t hrott le and int ake mani fol d ass embl y

7-Manifol d Abs olute Pres sure (MAP) sens or

8-Hos e - t urbocharger t o charge air cooler9-Charge air cooler

10-Hos e - charge air cooler to elect roni c thrott le (3 pi ece)

11-Int ake Air Temperat ure (IAT) s ens or12-Turbocharger and exhaus t mani fold

OVERVIEW

The TD4 engine i nt ake air s yst em provides fi lt ered and pres s uri zed ai r to the engine cyli nders , to promote compl etecombus t ion of t he inject ed fuel under al l engine condit ions .

A di rt y air i nt ake duct i s located behind the Left -Hand (LH) front fender and is connect ed to the ai r fi lt er hous ing. Air isdrawn into the i ntake air duct and direct ed through an oil impregnat ed repl aceable fil ter element , locat ed wi thi n the ai rfi lt er hous ing. The filt ered i ntake air i s t hen direct ed through t he clean ai r duct t o the compress or s ide of t he turbocharger.

The clean air duct is manufact ured t o i ncorporat e 4-quarter wave t ubes and a connection to the crankcas e venti lat ions ys t em. The quarter wave t ubes reduce the Noi se, Vi brati on and Hars hnes s (NVH) levels creat ed by t he air t raveli ngt hrough the duct. The connect ion t o t he crankcas e vent il ati on s ys t em al lows environment al ly harmful gas es and vapors tobe drawn from t he engine crankcas e, and int o t he cl ean air duct . The gases and vapors are mi xed wit h t he fi lt ered i ntakeair and burned i n t he cyl inders .

The t urbocharger compres ses and di rects the press uri zed hot i ntake air t hrough a large bore connecti ng hos e to t he chargeair cooler. The ai r pas s es through the charge ai r cooler and i s s ubs equent ly cooled t o i ncreas e t he i nt ake air densi ty. Theoutput s ide of t he charge air cool er direct s the cool dens e ai r through a large bore connecti ng hose to the el ect ronict hrott le and intake mani fold, where the ai r is then dis t ri but ed via the i ntake manifold ports t o t he i ndi vi dual enginecyl inders .

Exhaus t gas via t he Exhaus t Gas Reci rculat ion (EGR) sys t em i s als o direct ed i nt o t he int ake air s yst em t o reduce Oxi des OfNit rogen (NOX) emis s ions . A pipe connect s t he EGR valve l ocat ed at the Ri ght -Hand (RH) s ide of t he engine, to the i ntakemanifold l ocat ed at the Left-Hand (LH) s ide of t he engine. The exchange of exhaust gas i nto t he i nt ake manifold i scont rol led by t he Engine Control Modul e (ECM) during cert ain engine operat ing conditions.For addit ional informat ion, refer t o: Engi ne Emis s ion Cont rol (303-08B Engi ne Emis s ion Cont rol - TD4 2.2L Di esel ,Des cript ion and Operat ion).

Electroni c s ens ors are s t rat egi cal ly l ocat ed around t he int ake ai r s ys t em and const antl y provide i nformat ion of IAT, MAFand MAP t o t he ECM. Thi s i nformat ion i s proces sed and us ed by t he ECM for adjust ing engi ne performance to meet thecurrent operat ing condi ti ons , and driver demands .For addit ional informat ion, refer t o: Electroni c Engi ne Controls - 2.2L Dies el (303-14 El ect ronic Engine Cont rols - 2.2LDies el, Des cript ion and Operat ion).

INTAKE MANIFOLD

Page 1172 of 3229

Publi s hed: 11-May-2011

Intake Air Distribution and Filtering - TD4 2.2L Diesel - Intake Air

Distribution and Filtering

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the intake ai r di s tributi on and fi lt eri ng sys t em, refer t o t he rel evant Des cript ion and Operat ions ect ion i n t he works hop manual .REFER to: Intake Air Di s tributi on and Fil teri ng (303-12B Int ake Air Dis t ri but ion and Fi lt ering - TD4 2.2L Di esel , Des cri pti onand Operat ion).

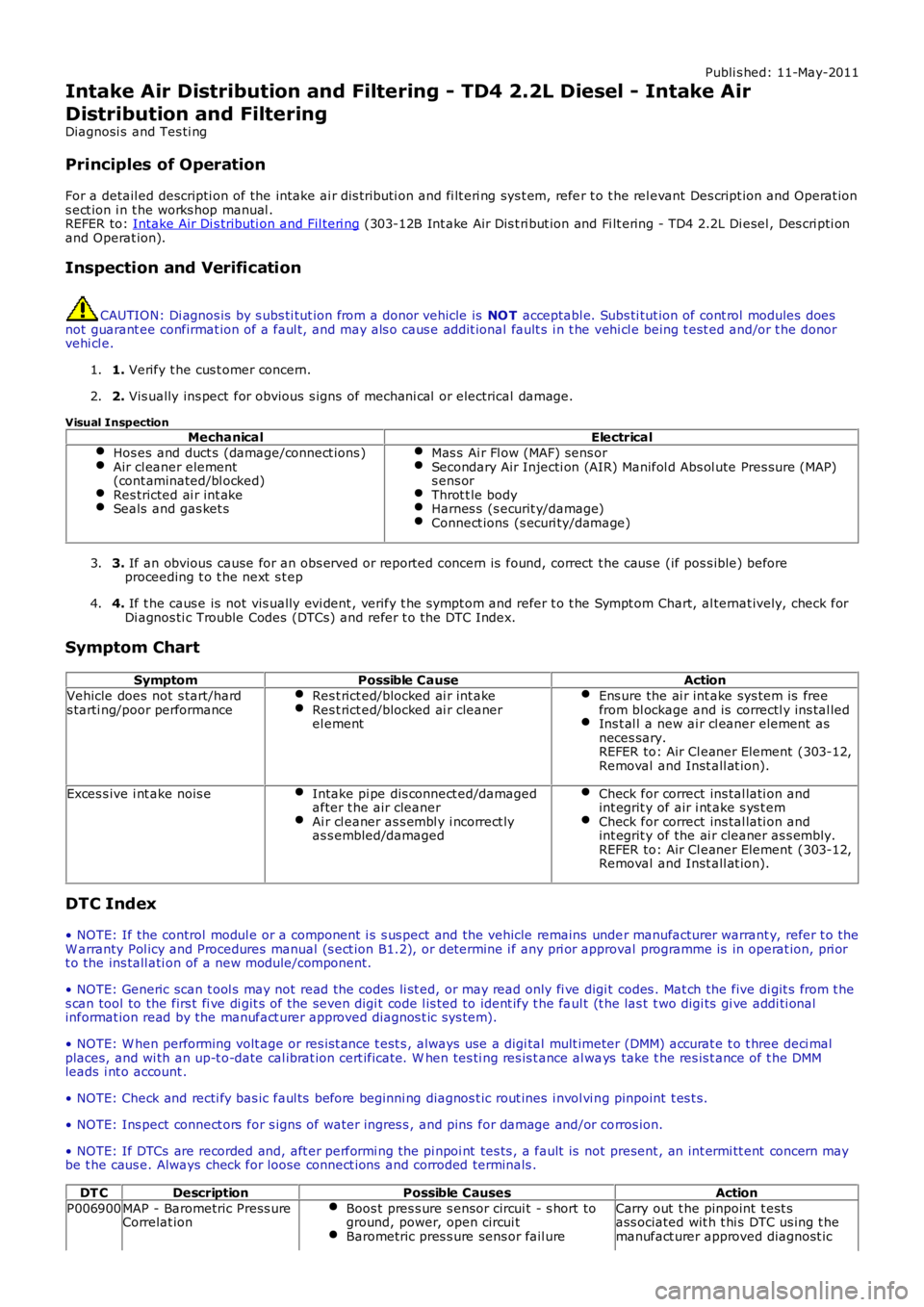

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.2.

Visual InspectionMechanicalElectrical

Hos es and duct s (damage/connect ions )Air cl eaner element(cont aminated/bl ocked)Res tricted ai r int akeSeals and gas ket s

Mas s Ai r Fl ow (MAF) sens orSecondary Air Injecti on (AIR) Manifol d Abs ol ute Pres sure (MAP)s ens orThrot t le bodyHarnes s (s ecurit y/damage)Connect ions (s ecuri ty/damage)

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Chart, al ternat ively, check forDi agnos ti c Trouble Codes (DTCs) and refer t o t he DTC Index.4.

Symptom Chart

SymptomPossible CauseAction

Vehicle does not s tart/hards tarti ng/poor performanceRes t rict ed/blocked ai r int akeRes t rict ed/blocked ai r cleanerel ement

Ens ure the ai r int ake sys tem is freefrom bl ockage and is correctl y ins tal ledIns t al l a new ai r cl eaner element asneces sary.REFER to: Air Cl eaner Element (303-12,Removal and Inst all at ion).

Exces s ive i nt ake nois eIntake pi pe dis connect ed/damagedafter t he air cleanerAi r cl eaner as s embl y i ncorrect lyas s embled/damaged

Check for correct ins tal lati on andint egrit y of air i nt ake s ys t emCheck for correct ins tal lati on andint egrit y of the ai r cleaner as s embly.REFER to: Air Cl eaner Element (303-12,Removal and Inst all at ion).

DTC Index

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains under manufacturer warrant y, refer t o theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve addi ti onalinformat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces, and wi th an up-t o-date cal ibrat ion cert ificate. W hen tes ti ng res is t ance al ways take t he res is t ance of t he DMMleads i nt o account .

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

DT CDescriptionPossible CausesAction

P006900MAP - Barometric Press ureCorrelat ionBoos t pres s ure s ensor circui t - s hort toground, power, open circui tBarometric pres s ure sens or fail ure

Carry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost ic

Page 1182 of 3229

5-Evaporati ve emis s ion canis ter - North Ameri can Specifi cat ion (NAS) deri vat ive

6-Fuel tank l eakage monit ori ng pump

7-Fuel tank l eakage monit ori ng pump filt er8-Fuel del ivery pi pe to engi ne

9-Evaporati ve emis s ion canis ter purge val ve

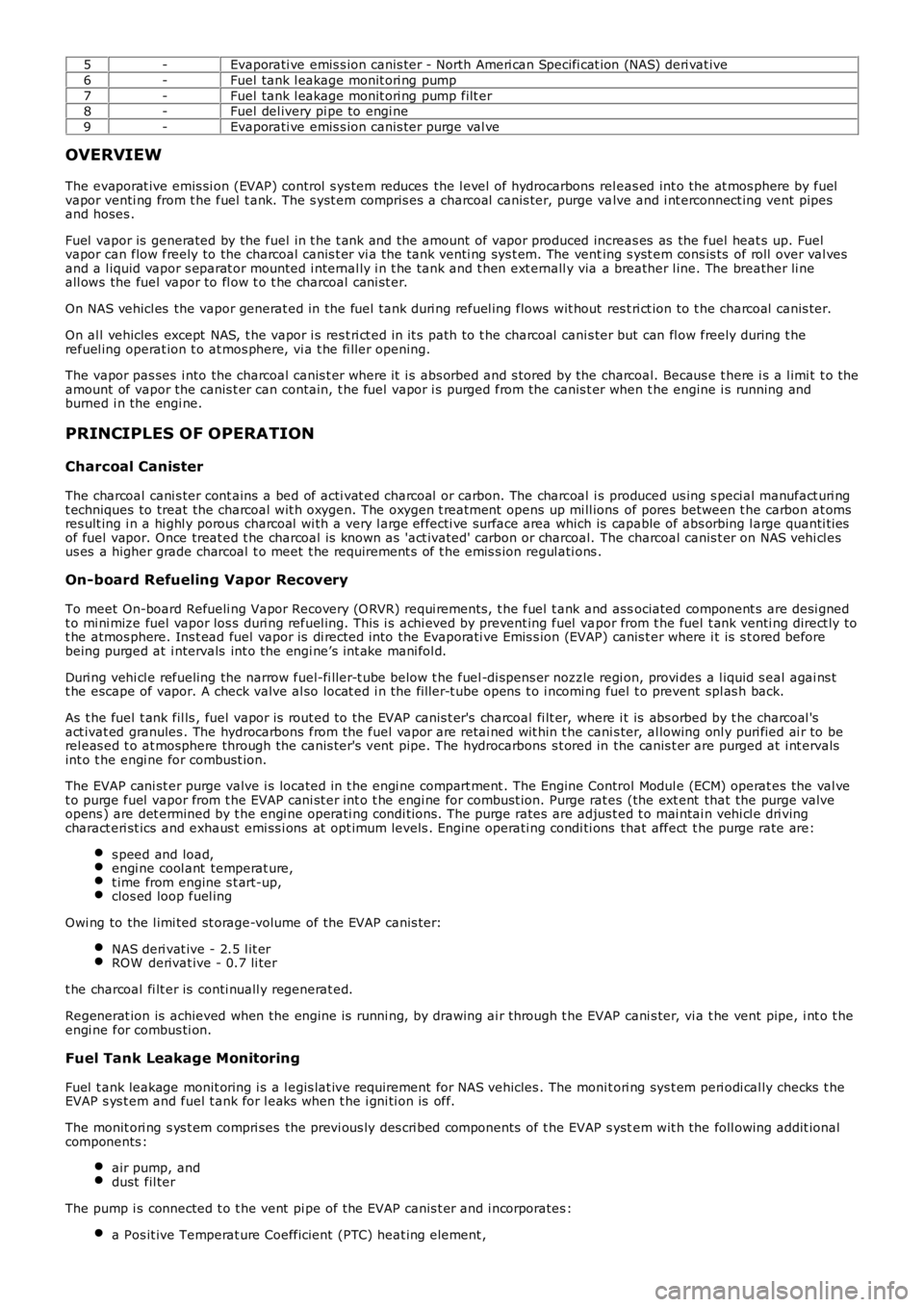

OVERVIEW

The evaporat ive emis si on (EVAP) control s ys tem reduces the l evel of hydrocarbons releas ed int o the at mos phere by fuelvapor venti ng from t he fuel t ank. The s yst em compris es a charcoal canis ter, purge valve and i nt erconnect ing vent pipesand hoses .

Fuel vapor is generated by the fuel in t he t ank and the amount of vapor produced increas es as the fuel heat s up. Fuelvapor can flow freely to the charcoal canis t er vi a the tank venti ng sys t em. The venting s yst em cons is ts of roll over val vesand a l iquid vapor s eparat or mounted i nternal ly i n t he tank and t hen ext ernall y via a breather l ine. The breather li neall ows the fuel vapor to fl ow t o t he charcoal cani st er.

On NAS vehicl es the vapor generat ed in the fuel tank duri ng refuel ing flows wit hout res t ri ct ion to t he charcoal canis ter.

On al l vehicles except NAS, t he vapor i s res t ri ct ed in it s path to t he charcoal canis ter but can fl ow freely during t herefuel ing operat ion t o at mos phere, vi a t he fi ller opening.

The vapor pas ses i nto the charcoal canis t er where it i s abs orbed and s tored by the charcoal. Becaus e t here i s a l imi t t o theamount of vapor the canis t er can contain, t he fuel vapor i s purged from the canis t er when t he engine i s running andburned i n the engi ne.

PRINCIPLES OF OPERATION

Charcoal Canister

The charcoal cani s ter cont ains a bed of acti vat ed charcoal or carbon. The charcoal is produced us ing s peci al manufact uri ngt echniques to treat the charcoal wit h oxygen. The oxygen t reatment opens up mi ll ions of pores between t he carbon at omsres ult ing i n a hi ghl y porous charcoal wi th a very l arge effecti ve surface area which is capable of abs orbing l arge quanti ti esof fuel vapor. Once treat ed t he charcoal is known as 'act ivated' carbon or charcoal. The charcoal canis t er on NAS vehi cl esus es a higher grade charcoal t o meet t he requirement s of t he emis s ion regul ati ons .

On-board Refueling Vapor Recovery

To meet On-board Refueli ng Vapor Recovery (O RVR) requi rement s, t he fuel t ank and associated component s are desi gnedt o mi ni mize fuel vapor los s duri ng refuel ing. This i s achi eved by prevent ing fuel vapor from t he fuel t ank venti ng direct ly tot he atmos phere. Ins t ead fuel vapor is di rected into the Evaporati ve Emis s ion (EVAP) canis t er where i t is s t ored beforebeing purged at i ntervals int o the engi ne’s int ake mani fol d.

Duri ng vehi cl e refueling the narrow fuel-fi ller-t ube below t he fuel -di spens er nozzle regi on, provi des a l iquid s eal agai ns tt he escape of vapor. A check valve al so locat ed i n the fi ller-t ube opens t o i ncomi ng fuel t o prevent spl as h back.

As t he fuel t ank fil ls , fuel vapor i s rout ed to the EVAP canis t er's charcoal fi lt er, where i t is abs orbed by t he charcoal 'sact ivat ed granules . The hydrocarbons from the fuel vapor are retai ned wit hin t he cani s ter, al lowing onl y puri fied ai r to berel eas ed t o at mosphere through the canis ter's vent pipe. The hydrocarbons s t ored in the canis t er are purged at i nt ervalsint o t he engi ne for combust ion.

The EVAP cani st er purge valve i s located i n t he engi ne compart ment . The Engine Control Modul e (ECM) operat es the val vet o purge fuel vapor from t he EVAP cani st er int o t he engi ne for combust ion. Purge rates (the ext ent that the purge valveopens ) are det ermined by t he engi ne operati ng condi ti ons . The purge rates are adjus ted t o mai ntai n vehi cl e dri vingcharact eri st ics and exhaus t emi ss i ons at opt imum levels . Engi ne operati ng condi ti ons that affect t he purge rate are:

s peed and load,engi ne cool ant temperat ure,t ime from engine s t art-up,clos ed loop fuel ing

Owi ng to the l imi ted st orage-volume of the EVAP canis ter:

NAS deri vat ive - 2.5 l it erROW derivat ive - 0.7 li ter

t he charcoal fi lt er is conti nuall y regenerat ed.

Regenerat ion is achieved when the engine is runni ng, by drawing ai r through t he EVAP cani s ter, vi a t he vent pipe, i nt o t heengi ne for combus ti on.

Fuel Tank Leakage Monitoring

Fuel t ank leakage monit oring i s a l egis lat ive requirement for NAS vehicles . The monit ori ng sys t em peri odi cal ly checks t heEVAP s ys t em and fuel t ank for l eaks when t he i gni ti on is off.

The monit ori ng s ys t em compri ses the previ ous ly des cri bed components of t he EVAP s ystem wit h the foll owing addit ionalcomponents :

air pump, anddust fil ter

The pump i s connected t o t he vent pi pe of the EVAP canis t er and i ncorporates :

a Pos it ive Temperat ure Coefficient (PTC) heat ing element ,

Page 1197 of 3229

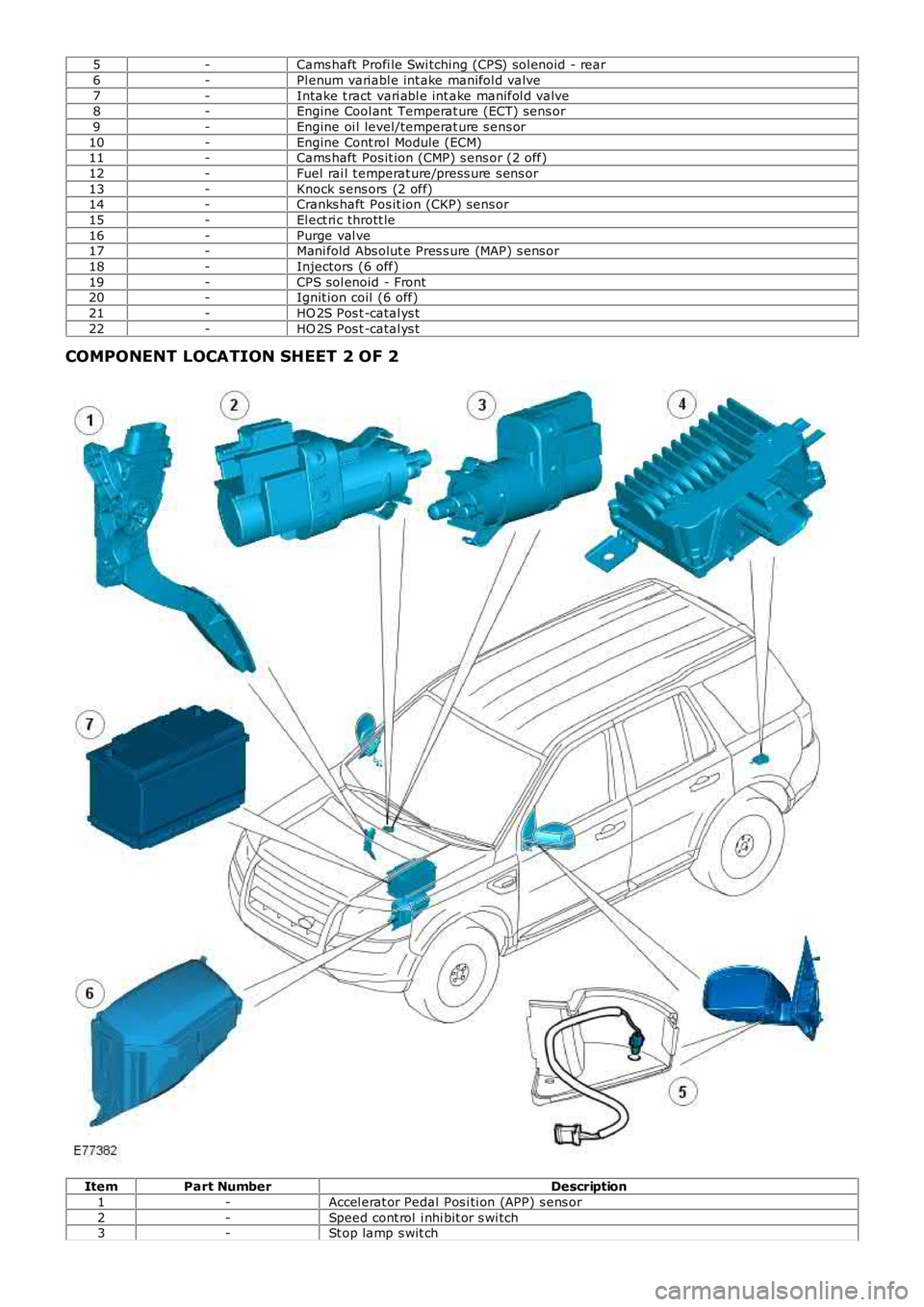

5-Cams haft Profi le Swi tching (CPS) sol enoid - rear

6-Pl enum variabl e int ake manifol d valve

7-Intake t ract vari abl e int ake manifol d valve8-Engine Cool ant Temperat ure (ECT) sens or

9-Engine oi l level/temperat ure s ens or

10-Engine Cont rol Module (ECM)11-Cams haft Pos it ion (CMP) s ens or (2 off)

12-Fuel rai l t emperat ure/press ure s ens or

13-Knock s ens ors (2 off)14-Cranks haft Pos it ion (CKP) sens or

15-El ect ri c thrott le

16-Purge val ve17-Mani fold Abs olut e Pres s ure (MAP) s ens or

18-Injectors (6 off)

19-CPS sol enoid - Front20-Ignit ion coil (6 off)

21-HO 2S Pos t -catal ys t

22-HO 2S Pos t -catal ys t

COMPONENT LOCATION SHEET 2 OF 2

ItemPart NumberDescription

1-Accel erat or Pedal Pos i ti on (APP) s ens or

2-Speed cont rol i nhi bit or s wi tch3-St op lamp s wit ch

Page 1198 of 3229

4-Fuel Pump Dri ver Module (FPDM)

5-Ambi ent ai r temperat ure sens or

6-Bat tery Juncti on Box (BJB)7-Bat tery

OVERVIEW

The Engi ne Control Module (ECM) controls t he fol lowing:

Engi ne fuel ingIgni ti on ti mingClos ed loop fuelingKnock controlIdl e s peed cont rolEmis s ion controlOn Board Diagnost icsSpeed cont rol.

The ECM controls engine fuel ing by provi ding s equent ial fuel inject ion t o al l cyli nders . Ignit ion i s cont rol led by a directignit ion sys tem, provi ded by 6 pl ug top coil s . The ECM is abl e t o detect and correct for i gni ti on knock on each cyl inder andadjus t the ignit ion t imi ng for each cyl inder to achieve opt imum performance.

The ECM us es a t orque-bas ed s trategy t o generate the t orque requi red by t he dri ver and ot her vehicle cont rol modules .The ECM us es various s ens ors t o determine t he t orque requi red from the engine. The ECM al so int erfaces wi th ot hervehi cl e elect ronic control modul es vi a t he high s peed Control ler Area Network (CAN) bus , to obt ain addit ional informat ion(for exampl e road speed from the Ant i-lock Brake Sys tem (ABS) module). The ECM proces ses t hese si gnal s and deci deshow much t orque t o generate. Torque i s t hen generat ed by us ing vari ous act uat ors to supply ai r, fuel and s park t o t heengi ne.

The ECM al so us es an el ect ronic throt tl e s yst em which compris es t he electric t hrot tle as sembl y and an Accel erator PedalPosi ti on (APP) s ensor.

The ECM al so interfaces wit h t he immobili zat ion sys tem t o help prevent t he vehi cl e being s t art ed wit hout properauthori zat ion.For addit ional informat ion, refer t o: Anti -Theft - Act ive (419-01, Des cri pt ion and Operati on).

CONTROL DIAGRAM SHEET 1 OF 2

• NOTE: A = Hardwi red; N = Medium s peed CAN bus; O = Local Int erconnect Network (LIN) bus

Page 1202 of 3229

12-Res trai nts Cont rol Module (RCM)

13-Knock sens ors (2 off)

14-Fuel rail t emperature/pres s ure s ens or15-Clockspring

16-Terrain respons e cont rol module

17-Trans mis s ion Cont rol Module (TCM)18-ABS module

19-Diagnos ti c socket

20-CJB

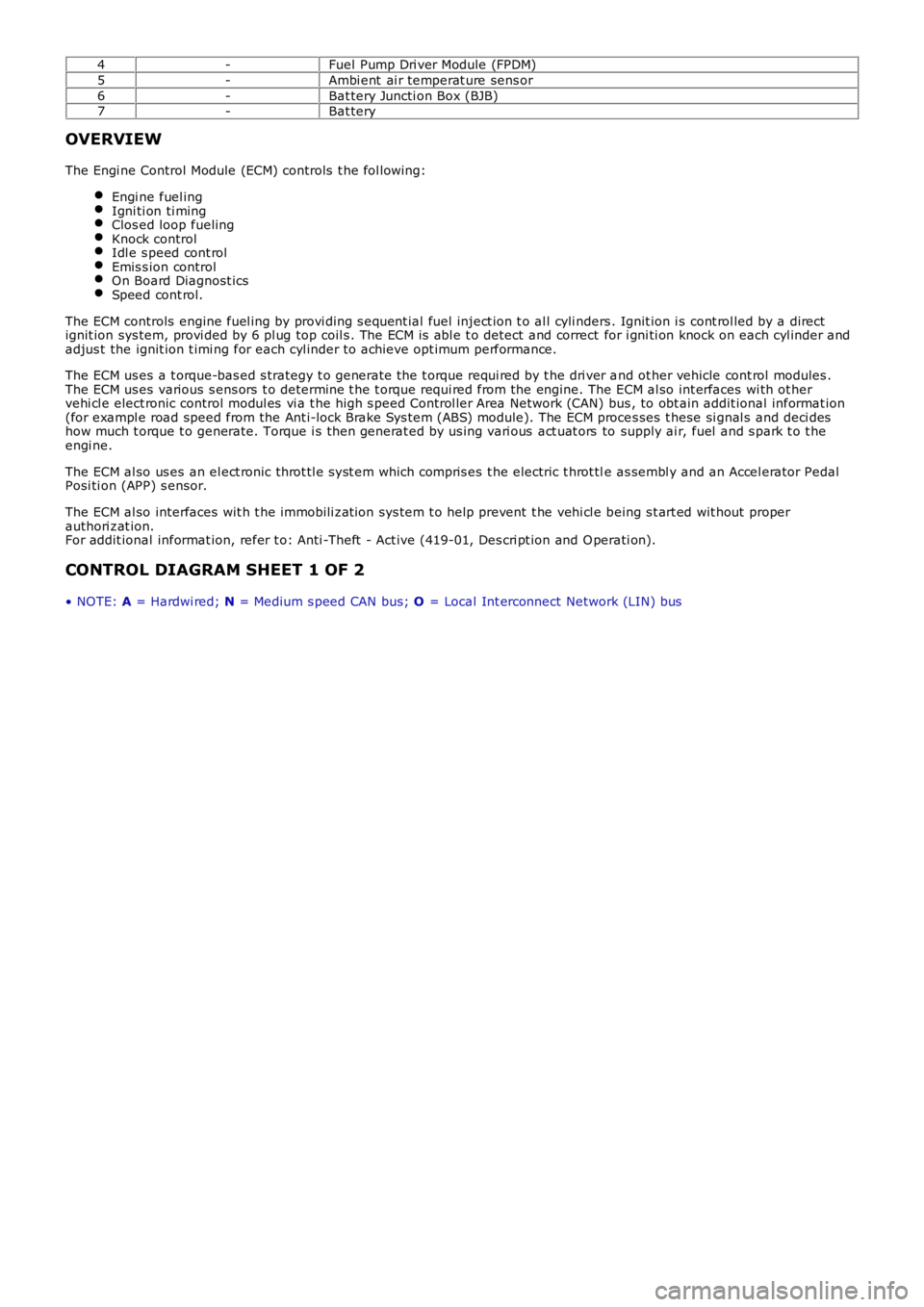

ENGINE CONTROL MODULE (ECM)

The ECM i s located on a bracket i n a central pos i ti on on the engi ne compartment firewal l. The ECM is at tached to ahous i ng and s ecured wit h 4 s crews . The hous i ng is l ocat ed in the bracket and locked in pos it ion.

The ECM i s s uppl ied wi th bat tery volt age from fuses l ocat ed in the BJB. A permanent batt ery s upply i s provided t o ens ureadapt ive dat a is not l ost when the engine i s s wit ched off.

A regul ator, locat ed wi thin the ECM, s upplies a 5V current t o i nt ernal components such as t he mi cro-proces s or unit . Ot hercomponents or funct ions requi ri ng ful l bat tery vol tage are cont rol led by ext ernal relays or int ernal power s t ages .

The mi cro-proces sor wi thi n the ECM receives s ignals from different component s and cont rol modules and us es a programwit hin the ECM software t o int erpret t he s ignal informat ion and i ss ue s ignals whi ch rel at e t o how the engine component sand functi ons should be cont rol led.

The ECM recei ves i nput s from the foll owing:

CMP s ensorsCKP s ensorFuel rail pres s ure s ensorMAF s ensorKnock s ens orsFuel rail t emperature/pres s ure s ensorECT s ens orEngi ne oil l evel/t emperature s ens orManifol d Abs olute Pres sure (MAP) sens orElectric t hrot tl e - Throt tl e Posi ti on (TP) s ens orAPP s ens orFuel t ank leakage monit oring modul e (NAS onl y)Cooling fan controlHeated Oxygen s ens ors (HO2S)Stop lamp s wi tch (via Central Juncti on Box (CJB))Speed cont rol inhibi t swi tchInt ake Air Temperat ure (IAT) s ens orAmbient Air Temperat ure (AAT) s ens orTrans mis s ion Cont rol Modul e (TCM).

The ECM s ends out puts to t he followi ng:

Main relayAir Condit ioning (A/C) relayFuel i njectorsIgni ti on coi lsEngi ne cool ing fan cont rolElectric t hrot tl eElectric fuel pump driver moduleVari abl e Cams haft Timing (VCT) s olenoidsStarter rel ay cont rolVari abl e int ake manifol d control valvesVari abl e inl et cam profile swit ching sol enoi d val vesTrans mis s ion Cont rol Modul e (TCM).

SENSORS

The ECM opt imi zes engine performance by interpreti ng s ignals from numerous vehicle sens ors and ot her i nput s. Some oft hes e s ignals are produced by t he act ions of t he dri ver, some are s uppli ed by s ens ors locat ed on and around t he engine

Page 1207 of 3229

The engi ne oil l evel s ens or us es an ult ras oni c puls e, which is refl ect ed back from the s urface of t he oil . The ti me i t takesfor t his s i gnal t o ret urn t o t he s ensor i s turned int o a PW M s ignal and is s ent to the ECM. The ECM det ermi nes the ti met aken for the ul trasonic pul se si gnal t o be recei ved and calculat es it i nto an oil level fi gure.

Engi ne Oi l Temperat ure Sens or

The engi ne oil t emperature s ensor i s a Pos it ive Temperat ure Co-effi ci ent (PTC) thermis t or el ement . The element res i st anceincreas es as t he sens or temperat ure decreas es. The ECM s uppli es t he sens or wit h a 5V reference vol tage and a ground andmeas ures t he ret urned s ignal as a t emperature. A low oil temperature wil l res ult in a l ow volt age bei ng ret urned t o t heECM and hi gh oil temperature wil l ret urn a hi gh volt age reading.

The ECM moni tors the engine oi l level/temperat ure sens or for fault s and can s tore faul t rel at ed codes . These can beret ri eved us i ng a Land Rover approved diagnos t ic s ys tem. If the sens or fail s , the ECM us es t he engine cool ant temperat ures ens or s ignal val ue as a s ubst it ute.

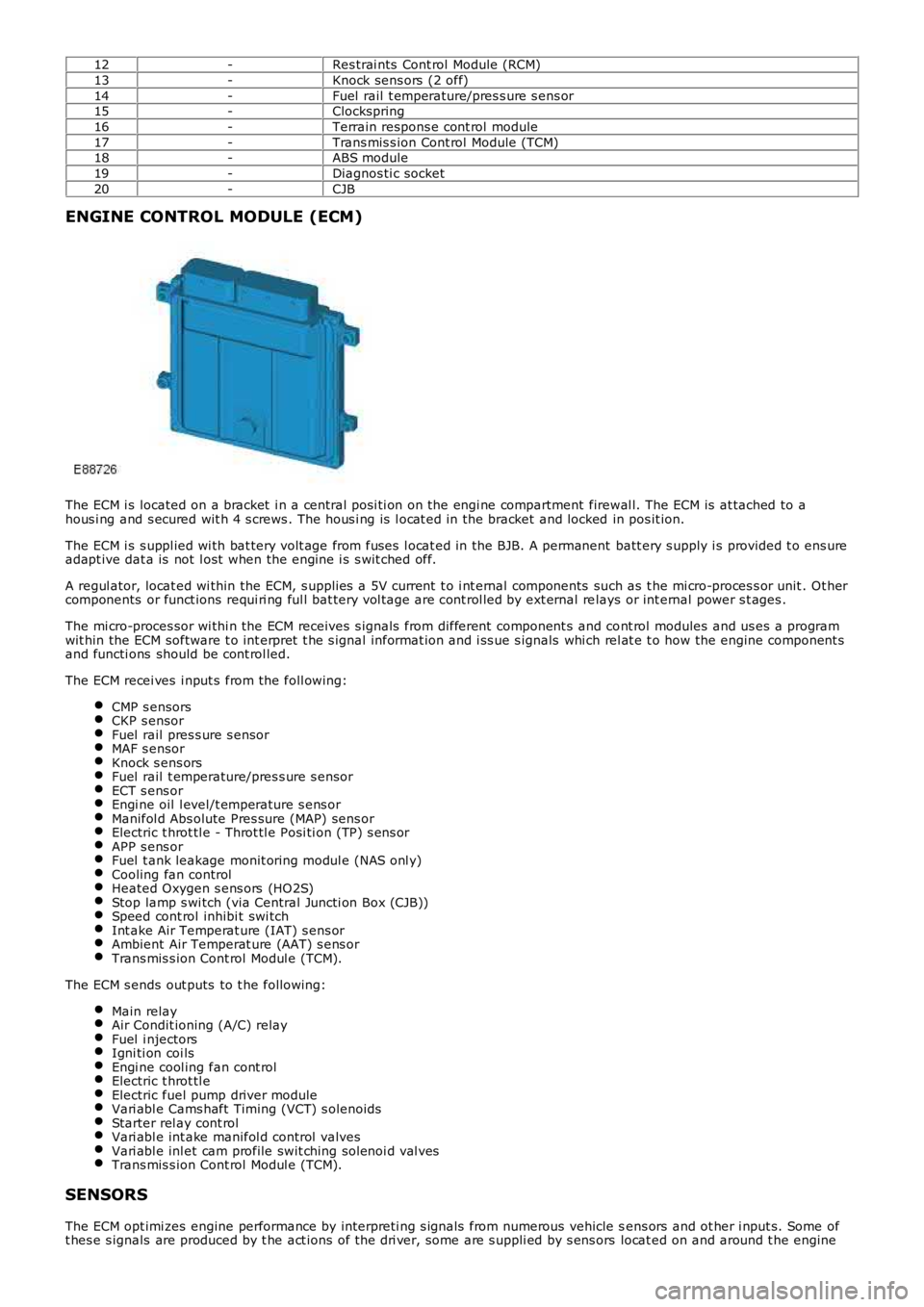

Manifold Absolute Pressure (MAP) Sensor

The MAP s ensor i s located i n t he lower part of t he int ake manifol d. The MAP s ens or meas ures t he abs olut e pres s ure in t heint ake manifol d. The sens or is a semi -conduct or type s ens or which responds t o pres s ure acti ng on a membrane wi thin thes ens or, al tering t he output volt age. The s ens or receives a 5V reference vol tage and a ground from t he ECM and returns as ignal of bet ween 0.5 - 4.5V t o t he ECM. A low pres sure ret urns a low vol tage s ignal to the ECM and a high press ureret urns a hi gh volt age.

The MAP s ensor det ect s quick pres s ure changes i n t he int ake mani fol d aft er the el ectri c thrott le. The s ignal is us ed inconjunct ion wi th the MAF sens or si gnal t o calculate the injecti on peri od.

The ECM moni tors the engine MAP s ens or for faul ts and can st ore fault related codes. Thes e can be ret ri eved us i ng a LandRover approved diagnost ic sys tem. If t he s ens or fai ls , the ECM uses t he MAF/IAT s ensor s i gnal value as a subs ti tut e.

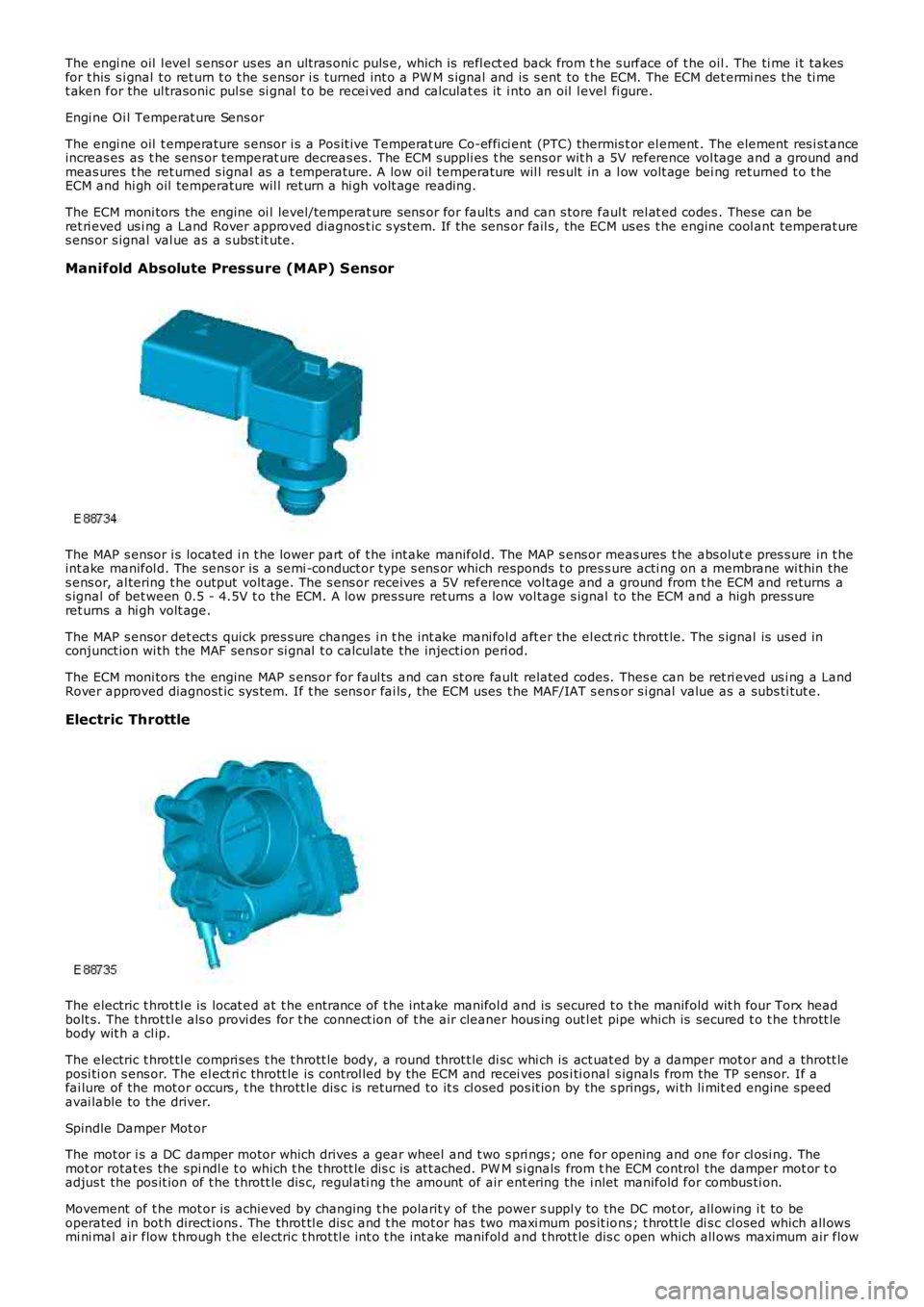

Electric Throttle

The electric t hrot tl e is locat ed at t he entrance of t he int ake manifol d and is secured t o t he manifold wit h four Torx headbolt s. The t hrot tl e als o provi des for t he connect ion of t he air cleaner hous ing out let pipe which is secured t o t he t hrott lebody wit h a cl ip.

The electric t hrot tl e compri ses t he t hrott le body, a round throt t le di sc whi ch is act uat ed by a damper mot or and a thrott leposi ti on s ens or. The el ect ri c thrott le is control led by the ECM and recei ves pos i ti onal s ignals from the TP s ens or. If afai lure of the mot or occurs , t he thrott le di s c is returned to it s cl osed pos it ion by the s prings, wi th li mit ed engine s peedavai lable to the driver.

Spindle Damper Mot or

The mot or i s a DC damper motor which drives a gear wheel and t wo s pri ngs ; one for opening and one for cl osi ng. Themot or rotat es the spi ndl e t o which t he t hrott le dis c is at t ached. PW M s i gnals from the ECM control the damper mot or t oadjus t the pos it ion of t he t hrott le dis c, regul ati ng the amount of air ent ering the i nlet manifold for combus ti on.

Movement of t he mot or is achieved by changing t he polarit y of the power s uppl y to the DC mot or, all owing i t to beoperated in bot h direct ions . The throt tl e dis c and t he mot or has two maxi mum pos it ions ; t hrott le di s c cl osed which all owsmi ni mal air flow t hrough t he electric t hrot tl e int o t he int ake manifol d and t hrott le dis c open which all ows maximum air flow

Page 1230 of 3229

Publi s hed: 11-May-2011

Electronic Engine Controls - I6 3.2L Petrol - Manifold Absolute Pressure

(MAP) Sensor

Removal and Inst all ati on

Removal

1. W ARNING: Do not work on or under a vehi cle s upported onl yby a jack. Al ways support t he vehi cl e on s afet y s tands .

Rais e and s upport t he vehi cl e.

1.

Remove t he engi ne undershi eld.

Refer t o: Engi ne Unders hi eld (501-02 Front End Body Panel s ,Removal and Ins tall ati on).

2.

3.

4.

5.

Page 1237 of 3229

Publi s hed: 11-May-2011

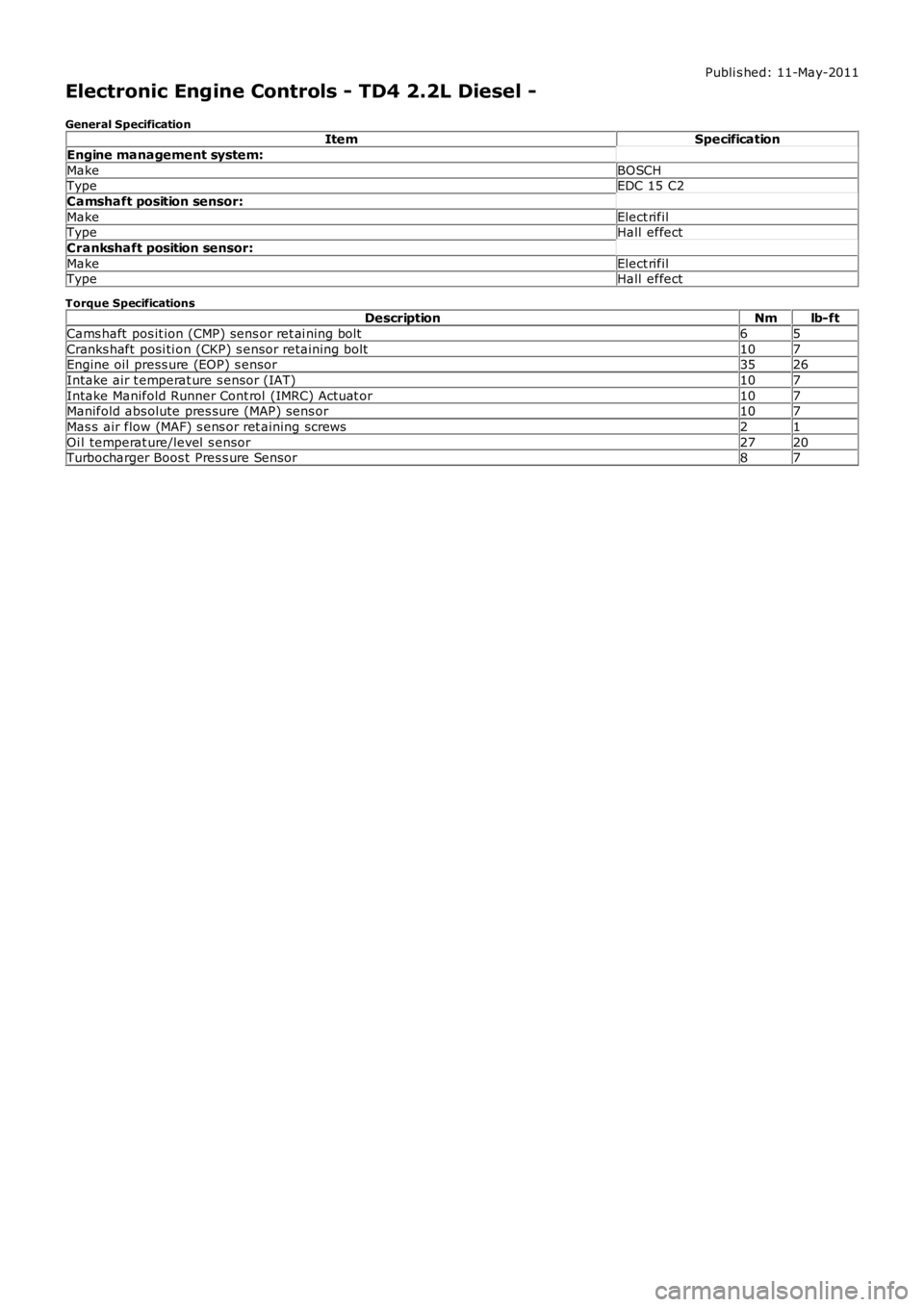

Electronic Engine Controls - TD4 2.2L Diesel -

General SpecificationItemSpecification

Engine management system:

MakeBOSCHTypeEDC 15 C2

Camshaft position sensor:

MakeElect rifilTypeHall effect

Crankshaft position sensor:

MakeElect rifilTypeHall effect

Torque SpecificationsDescriptionNmlb-ft

Cams haft pos it ion (CMP) sens or ret ai ning bolt65

Cranks haft posi ti on (CKP) s ensor retaini ng bolt107Engine oil press ure (EOP) s ensor3526

Intake air t emperat ure s ensor (IAT)107

Intake Manifold Runner Cont rol (IMRC) Actuat or107Manifold abs olute pres sure (MAP) sens or107

Mas s air flow (MAF) s ens or ret aining screws21

Oi l temperat ure/level s ensor2720Turbocharger Boos t Pres s ure Sensor87

Page 1238 of 3229

Publi s hed: 11-May-2011

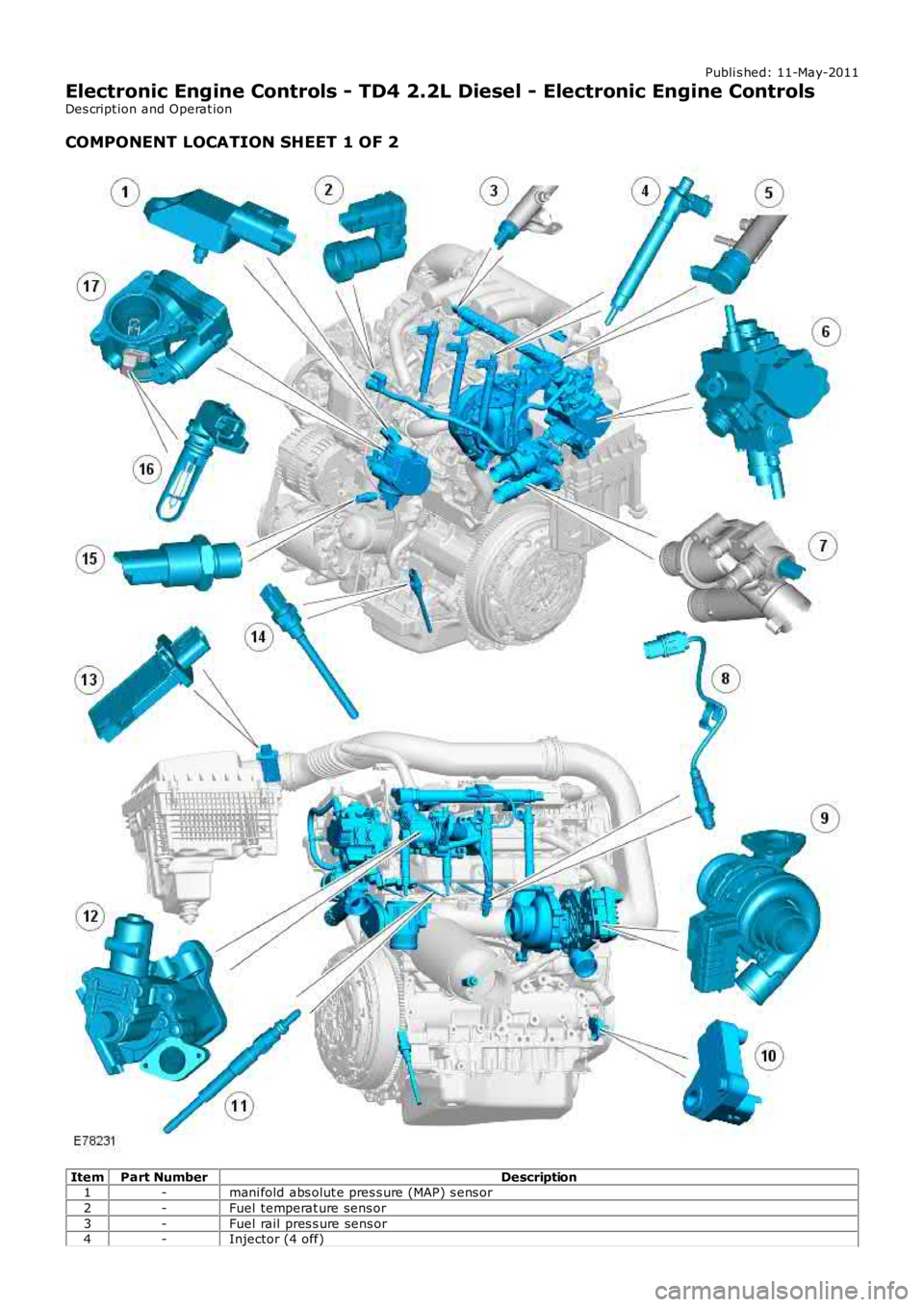

Electronic Engine Controls - TD4 2.2L Diesel - Electronic Engine Controls

Des cript ion and Operat ion

COMPONENT LOCATION SHEET 1 OF 2

ItemPart NumberDescription1-mani fold abs olut e pres s ure (MAP) s ens or

2-Fuel temperat ure sens or

3-Fuel rail pres s ure sens or4-Injector (4 off)