battery replacement LEXUS LS430 2003 Factory User Guide

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 364 of 4500

1.PERFORM ACTUATOR CHECK

a. Warm up the engine.

b. Set the actuator check mode (SEE ACTUATOR CHECK

).

c. Press the driver temperature up switch, and change to STEP operation.

d. Press the driver temperature up switch, and check the air flow by hand.

DISPLAY CODE - AIR FLOW POSITION

OK:

Cool air bypass damper changes in accordance with each display code.

NG: REPLACE AIR CONDITIONING AMPLIFIER (SEE REPLACEMENT

)

OK: Go to next step

2.INSPECT COOL AIR BYPASS SERVOMOTOR

a. Remove the cool air bypass servomotor.

b. Connect the positive (+) lead from the battery to terminal 4 and negative (-) lead to terminal 5, then

check that the lever turns to the "OPEN" position smoothly.

c. Connect the positive (+) lead from the battery to terminal 5 and negative (-) lead to terminal 4, then

check that the lever turns to the "SHUT" position smoothl

y.

Display codeAir flow position

0OPEN

1OPEN

2OPEN

3SHUT

4SHUT

5SHUT

6SHUT

7SHUT

8SHUT

9SHUT

Page 369 of 4500

Fig. 129: Cool Air Bypass Damper Control Servomotor Circuit (Passenger Side)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

INSPECTION PROCEDURE

1.PERFORM ACTUATOR CHECK

a. Warm up the engine.

b. Set the actuator check mode (SEE ACTUATOR CHECK

).

c. Press the driver temperature up switch, and change to STEP operation.

d. Press the driver temperature up switch, and check the air flow by hand.

Display code Air flow position

DISPLAY CODE AIR FLOW POSITION

OK:

Cool air bypass damper changes in accordance with each display code.

NG: REPLACE AIR CONDITIONING AMPLIFIER (SEE REPLACEMENT

)

OK: Go to next step

2.INSPECT COOL AIR BYPASS SERVOMOTOR

a. Remove the cool air bypass servomotor.

b. Connect the positive (+) lead from the battery to terminal 4 and negative (-) lead to terminal 5, then

check that the lever turns to the "OPEN" position smoothly.

c. Connect the positive (+) lead from the battery to terminal 5 and negative (-) lead to terminal 4, then

check that the lever turns to the "SHUT" position smoothly.

Display codeAir flow lever position

0OPEN

1OPEN

2OPEN

3SHUT

4SHUT

5SHUT

6SHUT

7SHUT

8SHUT

9SHUT

Page 375 of 4500

OK:

Water valve lever changes in accordance with each display code.

NG: REPLACE AIR CONDITIONING AMPLIFIER (SEE REPLACEMENT

)

OK: Go to next step

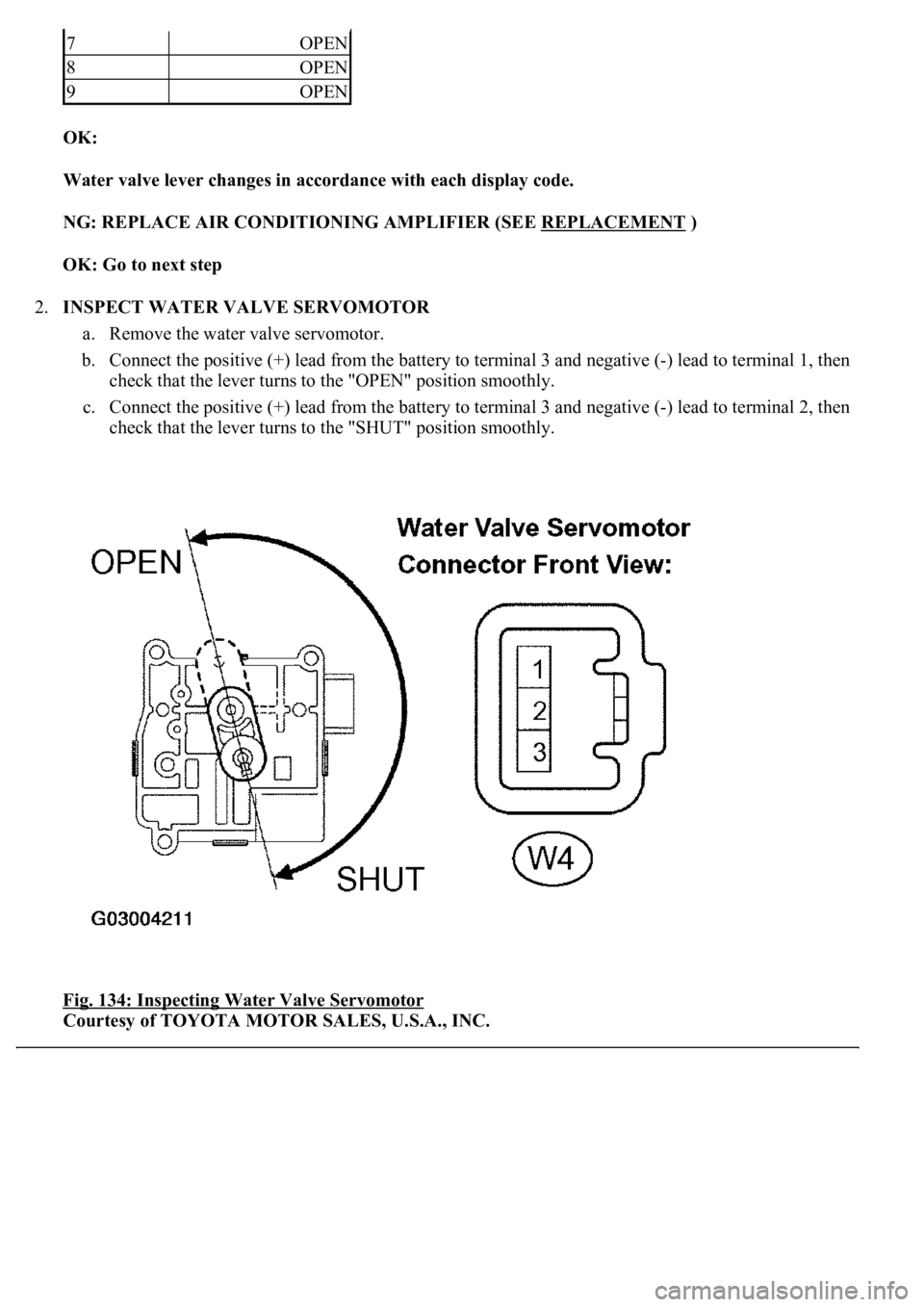

2.INSPECT WATER VALVE SERVOMOTOR

a. Remove the water valve servomotor.

b. Connect the positive (+) lead from the battery to terminal 3 and negative (-) lead to terminal 1, then

check that the lever turns to the "OPEN" position smoothly.

c. Connect the positive (+) lead from the battery to terminal 3 and negative (-) lead to terminal 2, then

check that the lever turns to the "SHUT" position smoothly.

Fig. 134: Inspecting Water Valve Servomotor

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

7OPEN

8OPEN

9OPEN

Page 550 of 4500

OK:Go to next step

2.INSPECT EXHAUST SOLENOID VALVE

a. Disconnect the exhaust solenoid valve connector.

b. Measure the resistance according to the value (s) in the table below.

TESTER CONNECTION STANDARD SPECIFIED CONDITION

c. Connect terminal 1 (SLEX) to the battery positive (+) terminal, and terminal 2 (GND) to the battery

negative (-) terminal.

d. Check the operating sound of the exhaust solenoid valve.

OK:

It should make an operating sound (click).

HINT:

When a malfunction is found in the exhaust solenoid valve, replace the height control compressor assy.

NG: REPLACE HEIGHT CONTROL COMPRESSOR ASSY (SEE REPLACEMENT

)

OK:Go to next step

Tester ConnectionSpecified Condition

1 (SLEX) - 2 (GND)10 to 14 ohms

Page 568 of 4500

POWER SOURCE CIRCUIT ) is displayed, carry out the necessary inspection. If they are output at the

same time, carry out the necessary inspection for DTC C1774 first.

NG: REPAIR CIRCUIT INDICATED BY OUTPUT CODE

OK:Go to next step

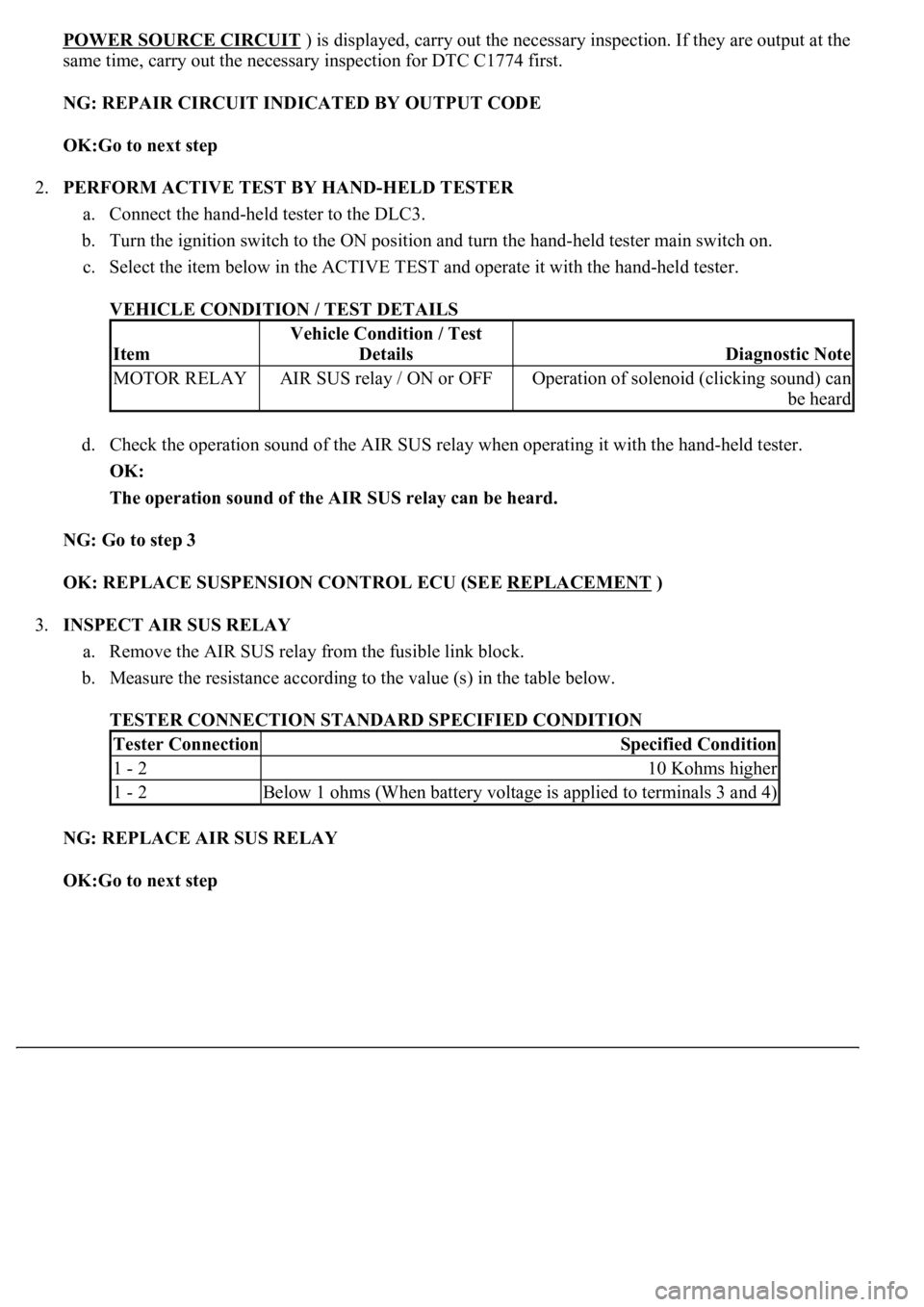

2.PERFORM ACTIVE TEST BY HAND-HELD TESTER

a. Connect the hand-held tester to the DLC3.

b. Turn the ignition switch to the ON position and turn the hand-held tester main switch on.

c. Select the item below in the ACTIVE TEST and operate it with the hand-held tester.

VEHICLE CONDITION / TEST DETAILS

d. Check the operation sound of the AIR SUS relay when operating it with the hand-held tester.

OK:

The operation sound of the AIR SUS relay can be heard.

NG: Go to step 3

OK: REPLACE SUSPENSION CONTROL ECU (SEE REPLACEMENT

)

3.INSPECT AIR SUS RELAY

a. Remove the AIR SUS relay from the fusible link block.

b. Measure the resistance according to the value (s) in the table below.

TESTER CONNECTION STANDARD SPECIFIED CONDITION

NG: REPLACE AIR SUS RELAY

OK:Go to next step

Item

Vehicle Condition / Test

Details

Diagnostic Note

MOTOR RELAYAIR SUS relay / ON or OFFOperation of solenoid (clicking sound) can

be heard

Tester ConnectionSpecified Condition

1 - 210 Kohms higher

1 - 2Below 1 ohms (When battery voltage is applied to terminals 3 and 4)

Page 572 of 4500

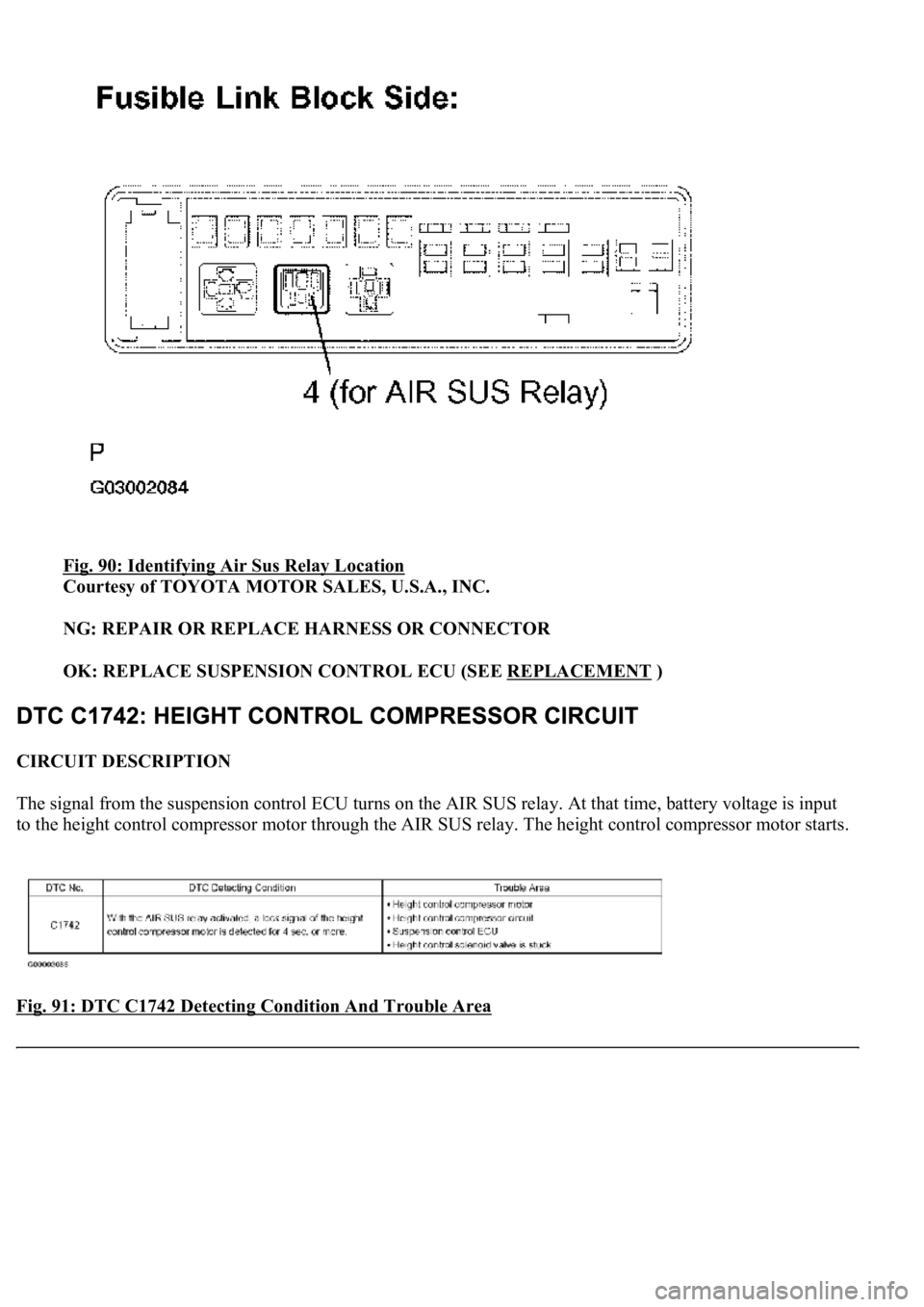

Fig. 90: Identifying Air Sus Relay Location

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR

OK: REPLACE SUSPENSION CONTROL ECU (SEE REPLACEMENT

)

CIRCUIT DESCRIPTION

The signal from the suspension control ECU turns on the AIR SUS relay. At that time, battery voltage is input

to the height control compressor motor through the AIR SUS relay. The height control compressor motor starts.

<0029004c004a00110003001c0014001d0003002700370026000300260014001a001700150003002700480057004800460057004c0051004a00030026005200510047004c0057004c005200510003002400510047000300370055005200580045004f004800

030024005500480044[

Page 574 of 4500

HINT:

If DTC C1741 (AIR SUS relay circuit) is displayed, carry out the inspection necessary (SEE DTC C1741

AIR SUS RELAY CIRCUIT ).

NG: REPAIR CIRCUIT INDICATED BY OUTPUT CODE

OK:Go to next step

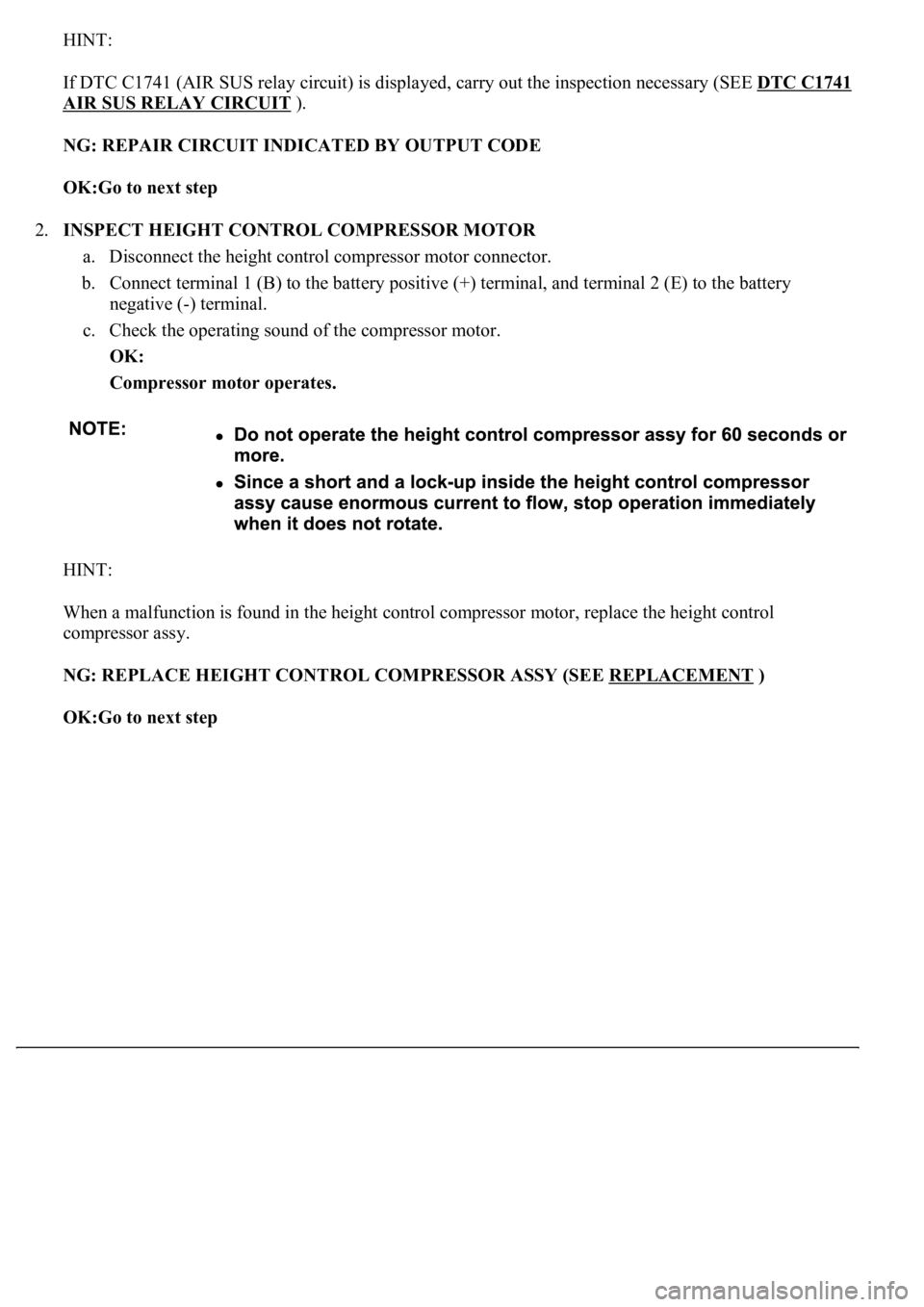

2.INSPECT HEIGHT CONTROL COMPRESSOR MOTOR

a. Disconnect the height control compressor motor connector.

b. Connect terminal 1 (B) to the battery positive (+) terminal, and terminal 2 (E) to the battery

negative (-) terminal.

c. Check the operating sound of the compressor motor.

OK:

Compressor motor operates.

HINT:

When a malfunction is found in the height control compressor motor, replace the height control

compressor assy.

NG: REPLACE HEIGHT CONTROL COMPRESSOR ASSY (SEE REPLACEMENT

)

OK:Go to next step

Page 585 of 4500

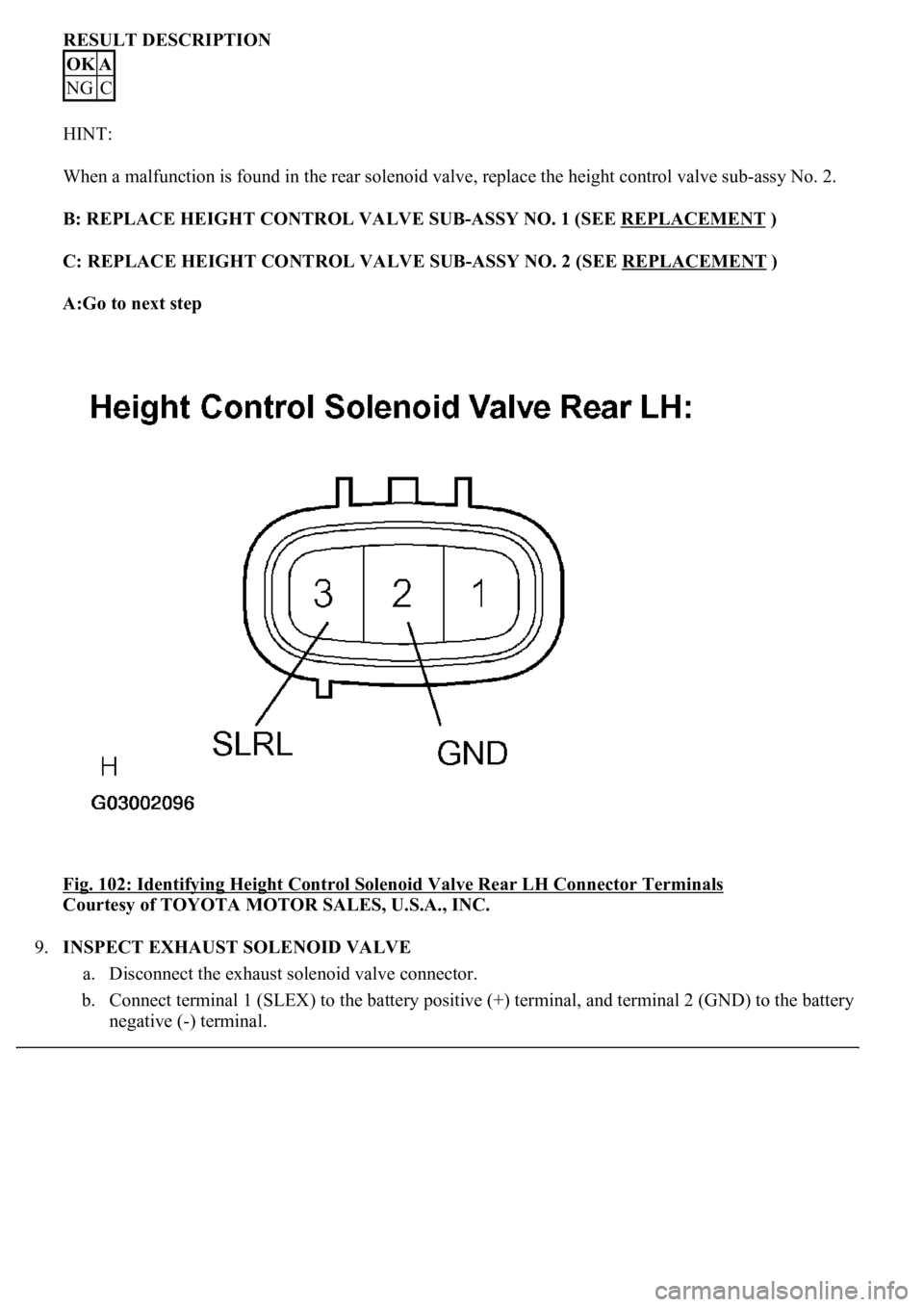

RESULT DESCRIPTION

HINT:

When a malfunction is found in the rear solenoid valve, replace the height control valve sub-assy No. 2.

B: REPLACE HEIGHT CONTROL VALVE SUB-ASSY NO. 1 (SEE REPLACEMENT

)

C: REPLACE HEIGHT CONTROL VALVE SUB-ASSY NO. 2 (SEE REPLACEMENT

)

A:Go to next step

Fig. 102: Identifying Height Control Solenoid Valve Rear LH Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

9.INSPECT EXHAUST SOLENOID VALVE

a. Disconnect the exhaust solenoid valve connector.

b. Connect terminal 1 (SLEX) to the battery positive (+) terminal, and terminal 2 (GND) to the battery

ne

gative (-) terminal.

OKA

NGC

Page 592 of 4500

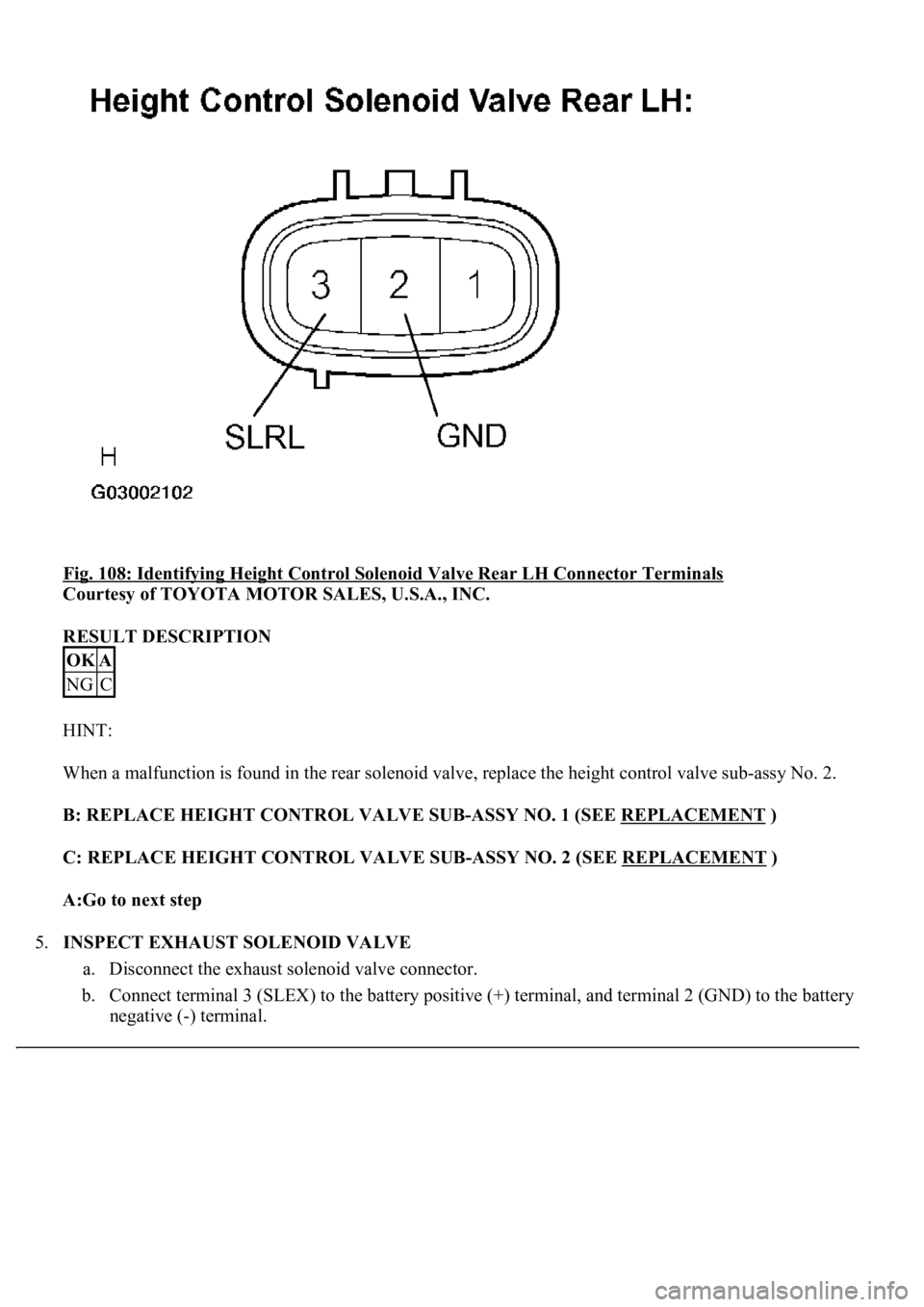

Fig. 108: Identifying Height Control Solenoid Valve Rear LH Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

RESULT DESCRIPTION

HINT:

When a malfunction is found in the rear solenoid valve, replace the height control valve sub-assy No. 2.

B: REPLACE HEIGHT CONTROL VALVE SUB-ASSY NO. 1 (SEE REPLACEMENT

)

C: REPLACE HEIGHT CONTROL VALVE SUB-ASSY NO. 2 (SEE REPLACEMENT

)

A:Go to next step

5.INSPECT EXHAUST SOLENOID VALVE

a. Disconnect the exhaust solenoid valve connector.

b. Connect terminal 3 (SLEX) to the battery positive (+) terminal, and terminal 2 (GND) to the battery

ne

gative (-) terminal.

OKA

NGC

Page 598 of 4500

Fig. 113: Identifying Suspension Control ECU Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: CHECK POWER SOURCE CIRCUIT (SEE DTC C1774 POWER SOURCE CIRCUIT

)

OK: REPLACE SUSPENSION CONTROL ECU (SEE REPLACEMENT

)

CIRCUIT DESCRIPTION

When the ignition switch is turned to the ON position, the D-IG1 relay is activated and battery voltage is

applied to terminal B of the suspension control ECU. When the ignition switch is turned off, the D-IG1 relay is

de-energized and the power source is cut off.

This power source energizes the suspension control actuator, height control solenoid valve, D-IG1 relay, each

IC and sensor.