check oil LEXUS LS430 2003 Factory User Guide

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 2163 of 4500

Tighten the nut using approximately 98 N.m (1,000 kgf.cm) of force and then tighten it further

while observing the preload.

d. Even if the nut tightening torque is greater than the specified maximum value, if the preload is less

than the specified minimum value, loosen the nut and check that the threads of the nut and drive

pinion are not stripped.

e. If the threads are not stripped, replace the spacer and apply hypoid gear oil LSD to the threads and

repeat the procedure.

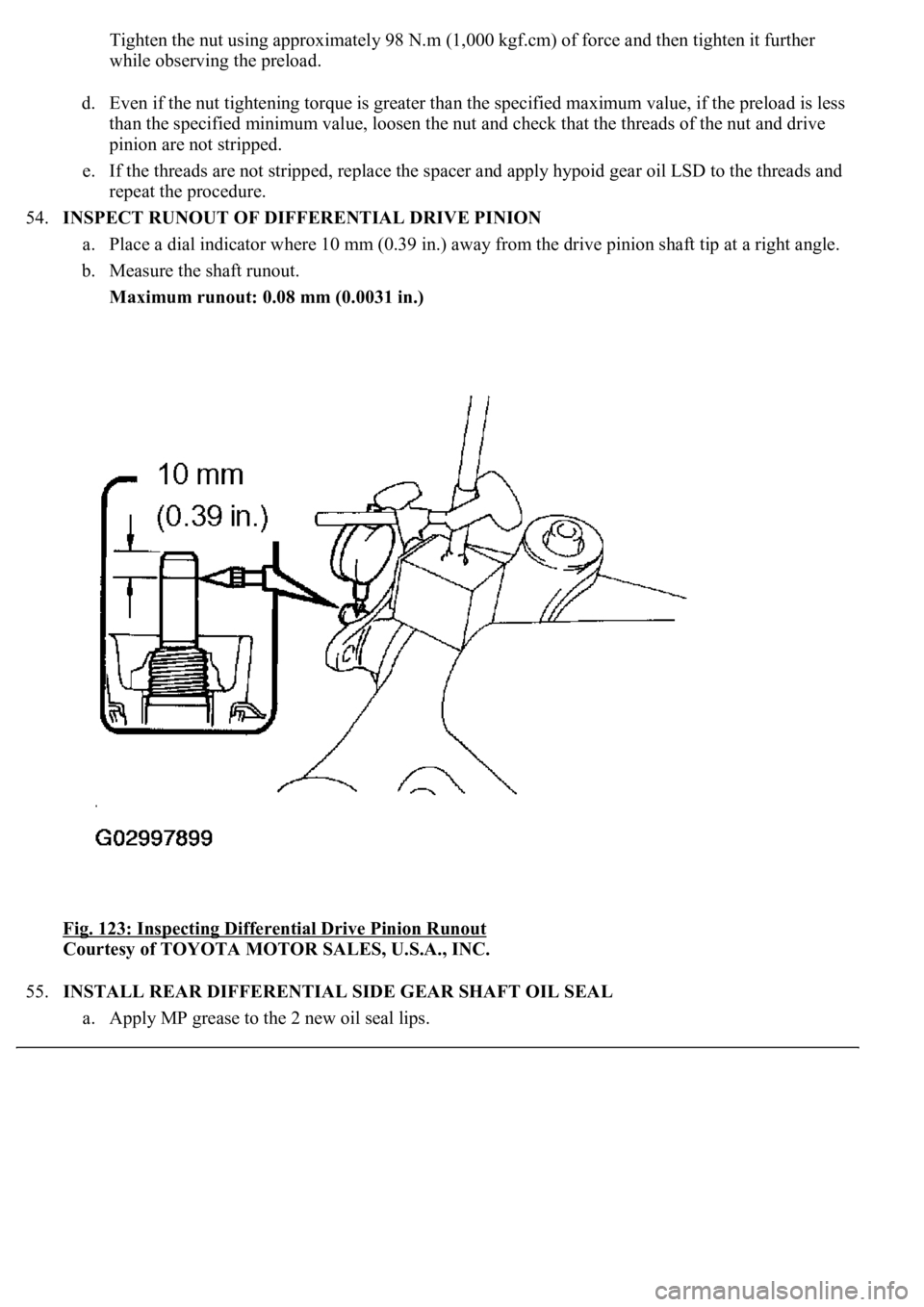

54.INSPECT RUNOUT OF DIFFERENTIAL DRIVE PINION

a. Place a dial indicator where 10 mm (0.39 in.) away from the drive pinion shaft tip at a right angle.

b. Measure the shaft runout.

Maximum runout: 0.08 mm (0.0031 in.)

Fig. 123: Inspecting Differential Drive Pinion Runout

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

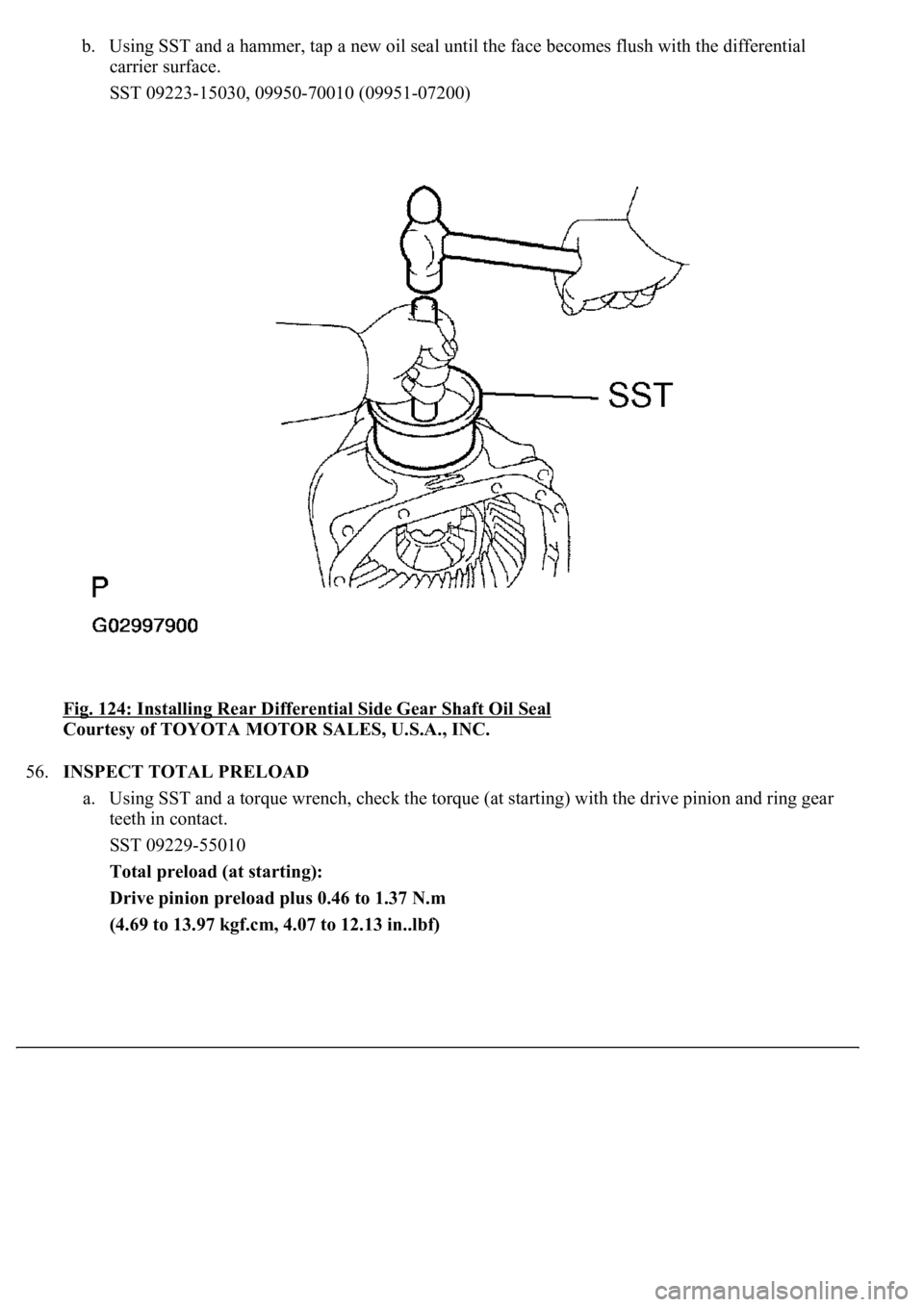

55.INSTALL REAR DIFFERENTIAL SIDE GEAR SHAFT OIL SEAL

a. Appl

y MP grease to the 2 new oil seal lips.

Page 2164 of 4500

b. Using SST and a hammer, tap a new oil seal until the face becomes flush with the differential

carrier surface.

SST 09223-15030, 09950-70010 (09951-07200)

Fig. 124: Installing Rear Differential Side Gear Shaft Oil Seal

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

56.INSPECT TOTAL PRELOAD

a. Using SST and a torque wrench, check the torque (at starting) with the drive pinion and ring gear

teeth in contact.

SST 09229-55010

Total preload (at starting):

Drive pinion preload plus 0.46 to 1.37 N.m

(4.69 to 13.97 kgf.cm, 4.07 to 12.13 in..lbf)

Page 2177 of 4500

a. Fill the rear differential carrier assy with differential gear oil equivalent.

Oil type: Differential synthetic gear oil GL-5 75W-90 or equivalent

Capacity: 1.35 +/- 0.05 liters (1.43 +/- 0.05 US qts, 1.19 +/- 0.04 Imp. qts)

67.INSPECT DIFFERENTIAL OIL (SEE ADJUSTMENT

)

68.INSTALL REAR DIFFERENTIAL FILLER PLUG

a. Using a hexagon wrench (10 mm), install the filler plug with a new gasket.

Torque: 49 N.m (500 kgf.cm, 36 ft.lbf)

69.INSTALL REAR DRIVE SHAFT ASSY LH (SEE REPLACEMENT

)

70.INSTALL REAR DRIVE SHAFT ASSY RH

HINT:

Installation procedure of the RH side is the same as that of the LH side.

71.INSTALL FRONT FLOOR HEAT INSULATOR NO.1

a. Install the front floor heat insulator No.1 with the 4 bolts.

Torque: 5.4 N.m (55 kgf.cm, 48 in..lbf)

72.INSTALL REAR WHEEL

a. Install the rear wheel with the 5 nuts.

Torque: 103 N.m (1,050 kgf.cm, 76 ft.lbf)

73. Install the ornament with the 10 bolts.

Torque: 20 N.m (204 kgf.cm, 15 ft.lbf)

74.INSTALL PROPELLER W/CENTER BEARING SHAFT ASSY (SEE OVERHAUL

)

75.FULLY TIGHTEN CENTER SUPPORT BEARING ASSY NO.1 (SEE OVERHAUL

)

SST 09922-10010

76.INSPECT AND ADJUST NO.2 AND NO.3 JOINT ANGLE (SEE OVERHAUL

)

77.INSTALL PROPELLER SHAFT HEAT INSULATOR (SEE OVERHAUL

)

78.INSTALL EXHAUST PIPE ASSY (SEE REPLACEMENT

)

79.INSTALL OXYGEN SENSOR (SEE REPLACEMENT

)

80.INSPECT AND ADJUST REAR WHEEL ALIGNMENT (SEE ADJUSTMENT

)

81.ADJUST VEHICLE HEIGHT (W/ AIR SUSPENSION) (SEE ON

-VEHICLE INSPECTION )

82.INSPECT HEADLIGHT AIM ONLY (SEE ADJUSTMENT

)

83.CHECK ABS SPEED SENSOR SIGNAL (SEE TEST MODE PROCEDURE

)

84.INSPECT AIR LEAK (W/ AIR SUSPENSION) (SEE REPLACEMENT

)

HINT:

Perform this operation onl

y when the rear differential mount cushion is replaced.

Page 2377 of 4500

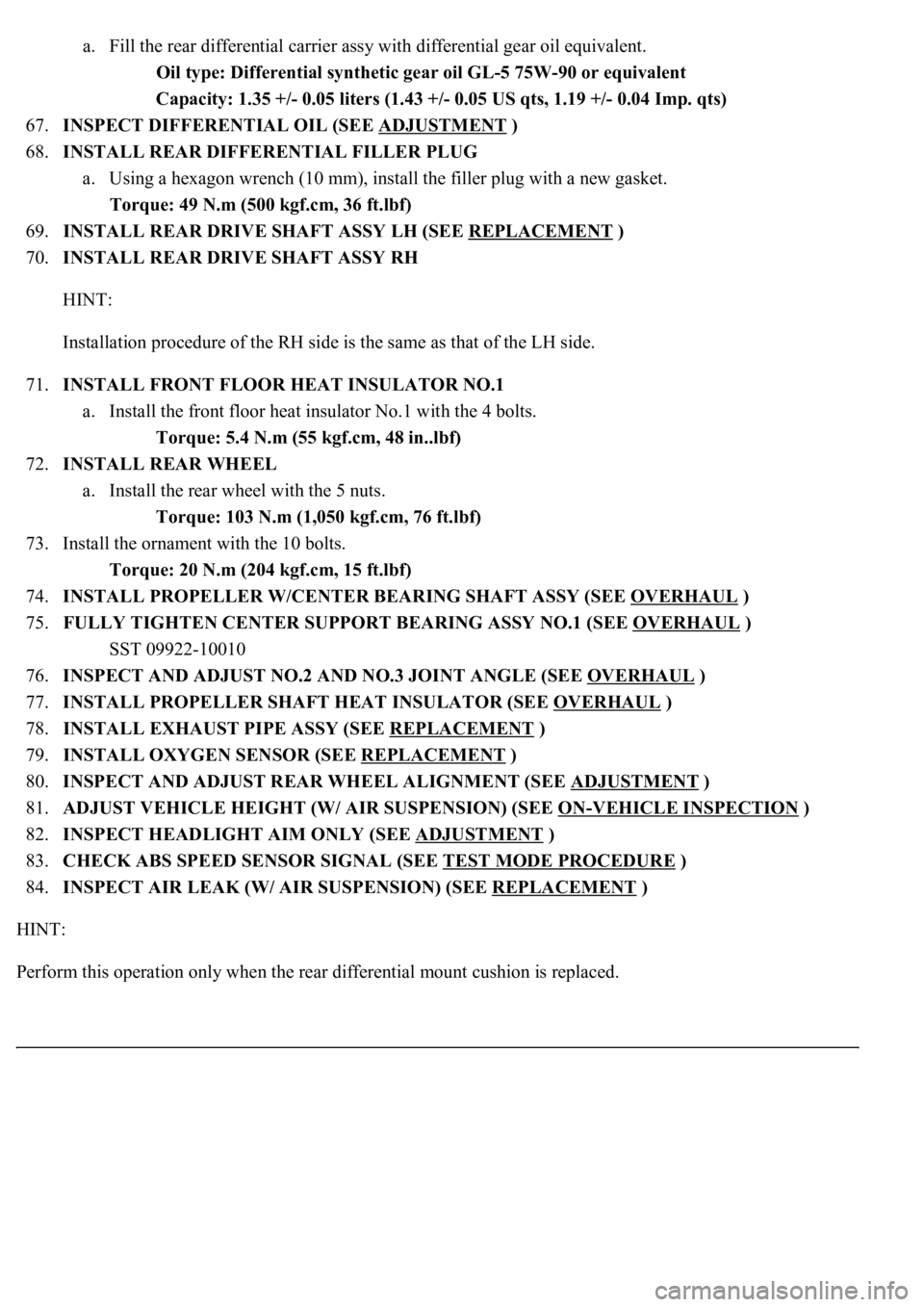

Fig. 71: Removing Rear Drive Shaft Assy LH

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

17.INSPECT REAR DRIVE SHAFT ASSY LH

a. Check that there is no excessive play in the outboard joint.

b. Check if the inboard joint slides smoothly in the thrust direction.

c. Check that there is no excessive play in the radial direction of the inboard joint.

d. Check the boots for damage.

18.INSTALL REAR DRIVE SHAFT ASSY LH

a. Coat the spline of the inboard joint shaft assy with gear oil.

b. Align the shaft splines, install the drive shaft assy LH with a brass bar and a hammer.

HINT:

Page 2745 of 4500

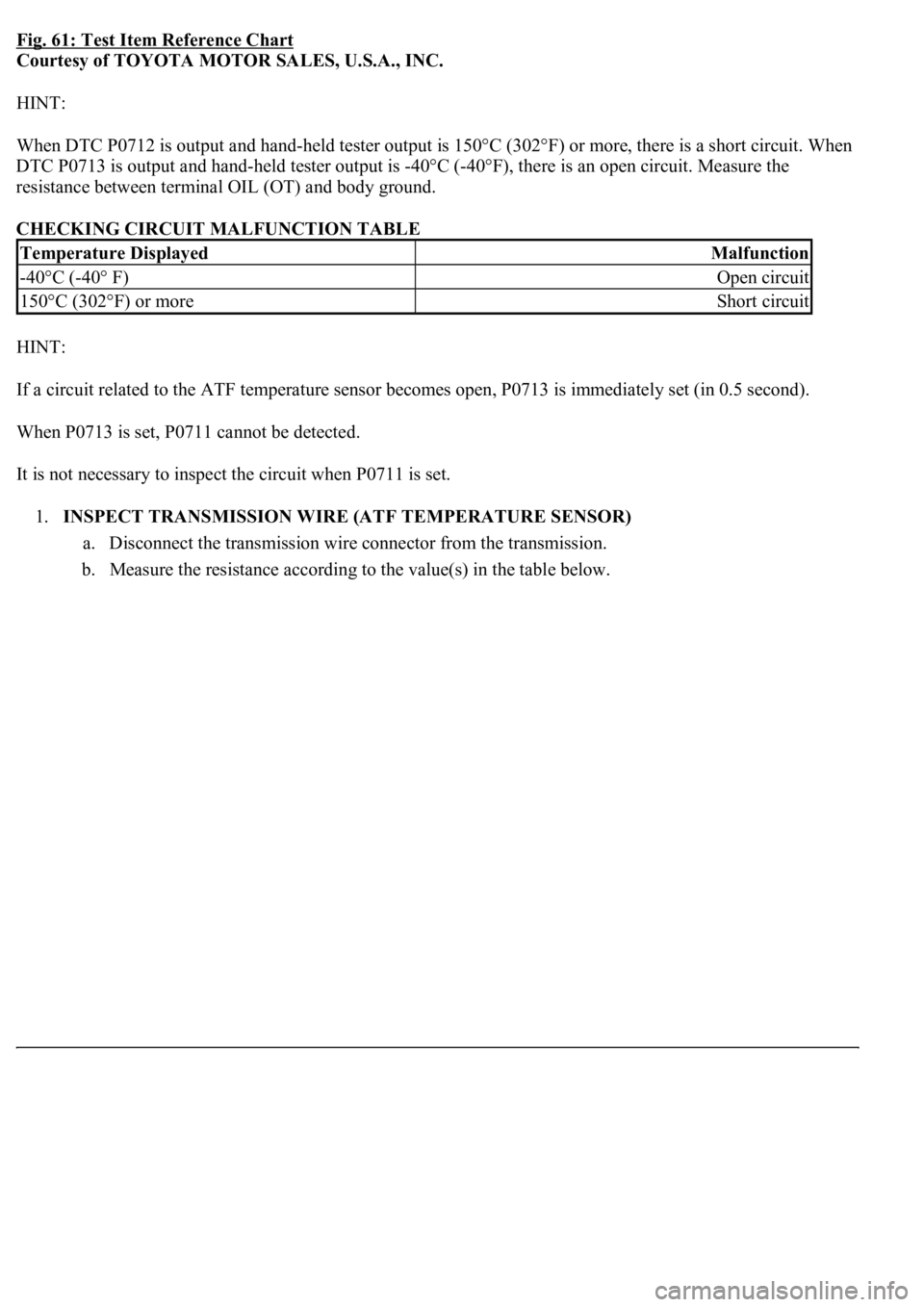

Fig. 61: Test Item Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

<003a004b004800510003002700370026000300330013001a001400150003004c0056000300520058005700530058005700030044005100470003004b0044005100470010004b0048004f004700030057004800560057004800550003005200580057005300

5800570003004c00560003001400180013008300260003000b[302°F) or more, there is a short circuit. When

DTC P0713 is output and hand-held tester output is -40°C (-40°F), there is an open circuit. Measure the

resistance between terminal OIL (OT) and body ground.

CHECKING CIRCUIT MALFUNCTION TABLE

HINT:

If a circuit related to the ATF temperature sensor becomes open, P0713 is immediately set (in 0.5 second).

When P0713 is set, P0711 cannot be detected.

It is not necessary to inspect the circuit when P0711 is set.

1.INSPECT TRANSMISSION WIRE (ATF TEMPERATURE SENSOR)

a. Disconnect the transmission wire connector from the transmission.

b. Measure the resistance according to the value(s) in the table below.

Temperature DisplayedMalfunction

-40°C (-40° F)Open circuit

150°C (302°F) or moreShort circuit

Page 2747 of 4500

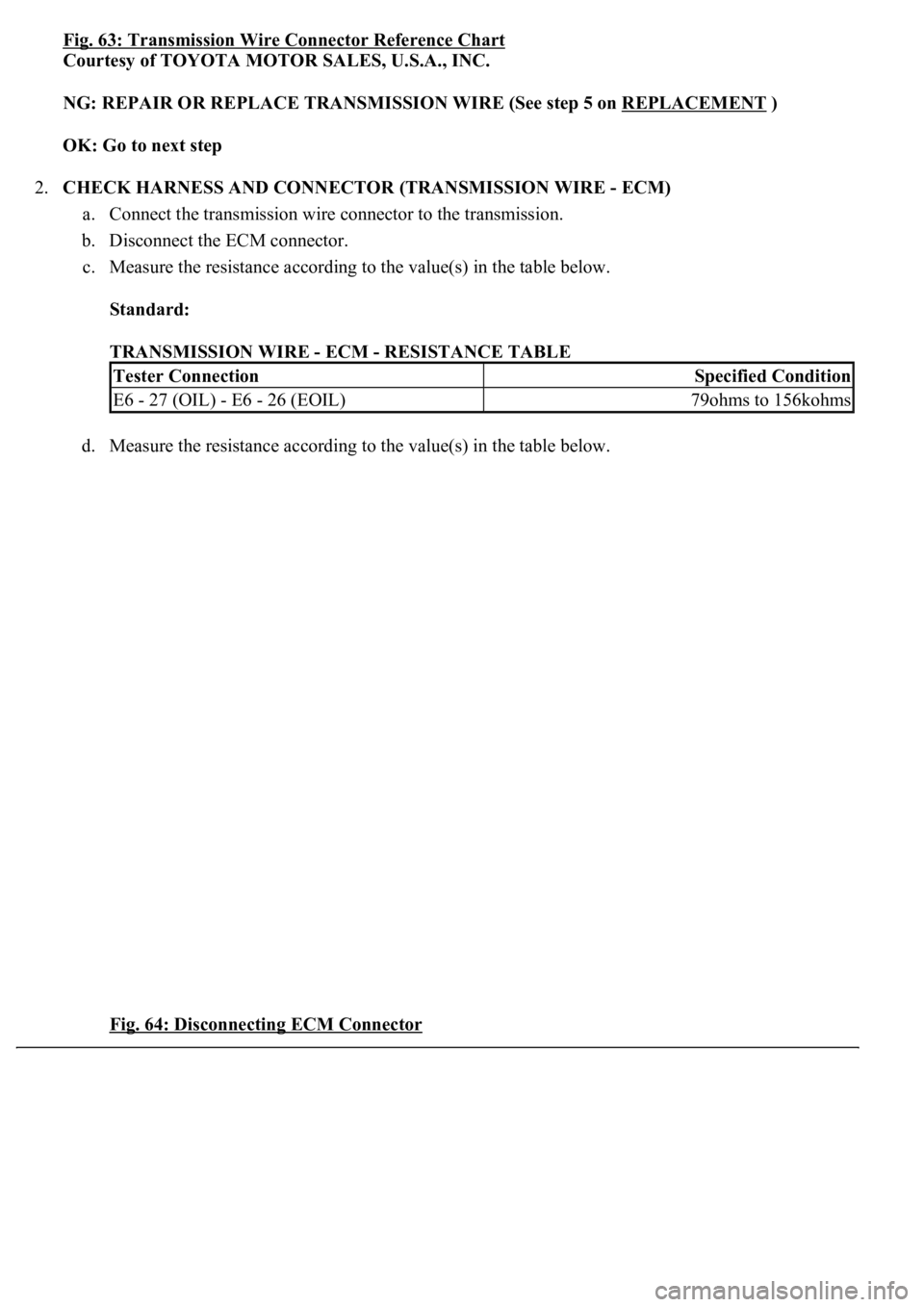

Fig. 63: Transmission Wire Connector Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPAIR OR REPLACE TRANSMISSION WIRE (See step 5 on REPLACEMENT

)

OK: Go to next step

2.CHECK HARNESS AND CONNECTOR (TRANSMISSION WIRE - ECM)

a. Connect the transmission wire connector to the transmission.

b. Disconnect the ECM connector.

c. Measure the resistance according to the value(s) in the table below.

Standard:

TRANSMISSION WIRE - ECM - RESISTANCE TABLE

d. Measure the resistance according to the value(s) in the table below.

Fig. 64: Disconnecting ECM Connector

Tester ConnectionSpecified Condition

E6 - 27 (OIL) - E6 - 26 (EOIL)79ohms to 156kohms

Page 2750 of 4500

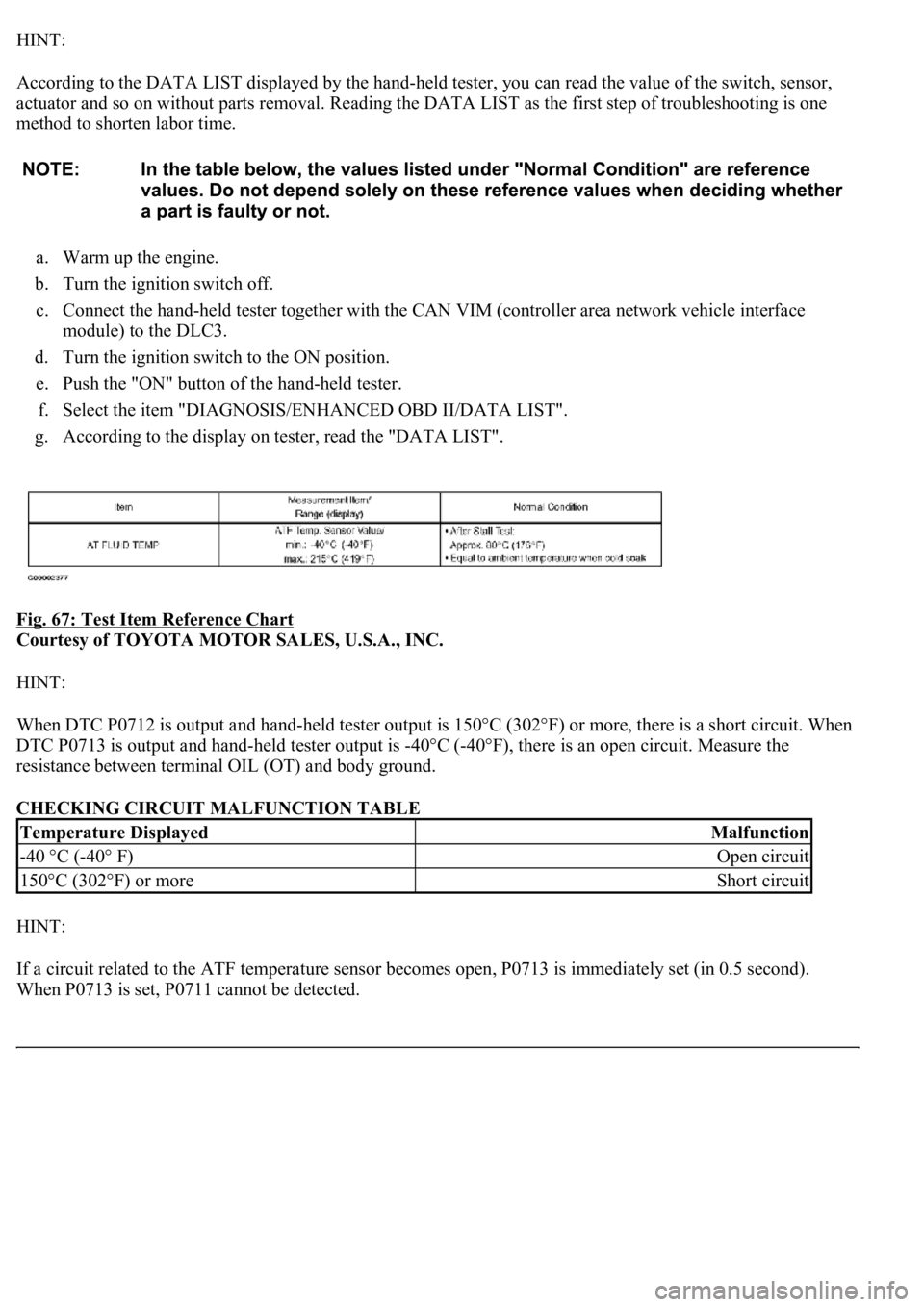

HINT:

According to the DATA LIST displayed by the hand-held tester, you can read the value of the switch, sensor,

actuator and so on without parts removal. Reading the DATA LIST as the first step of troubleshooting is one

method to shorten labor time.

a. Warm up the engine.

b. Turn the ignition switch off.

c. Connect the hand-held tester together with the CAN VIM (controller area network vehicle interface

module) to the DLC3.

d. Turn the ignition switch to the ON position.

e. Push the "ON" button of the hand-held tester.

f. Select the item "DIAGNOSIS/ENHANCED OBD II/DATA LIST".

g. According to the display on tester, read the "DATA LIST".

Fig. 67: Test Item Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

<003a004b004800510003002700370026000300330013001a001400150003004c0056000300520058005700530058005700030044005100470003004b0044005100470010004b0048004f004700030057004800560057004800550003005200580057005300

5800570003004c00560003001400180013008300260003000b[302°F) or more, there is a short circuit. When

DTC P0713 is output and hand-held tester output is -40°C (-40°F), there is an open circuit. Measure the

resistance between terminal OIL (OT) and body ground.

CHECKING CIRCUIT MALFUNCTION TABLE

HINT:

If a circuit related to the ATF temperature sensor becomes open, P0713 is immediately set (in 0.5 second).

When P0713 is set, P0711 cannot be detected.

Temperature DisplayedMalfunction

-40 °C (-40° F)Open circuit

150°C (302°F) or moreShort circuit

Page 2765 of 4500

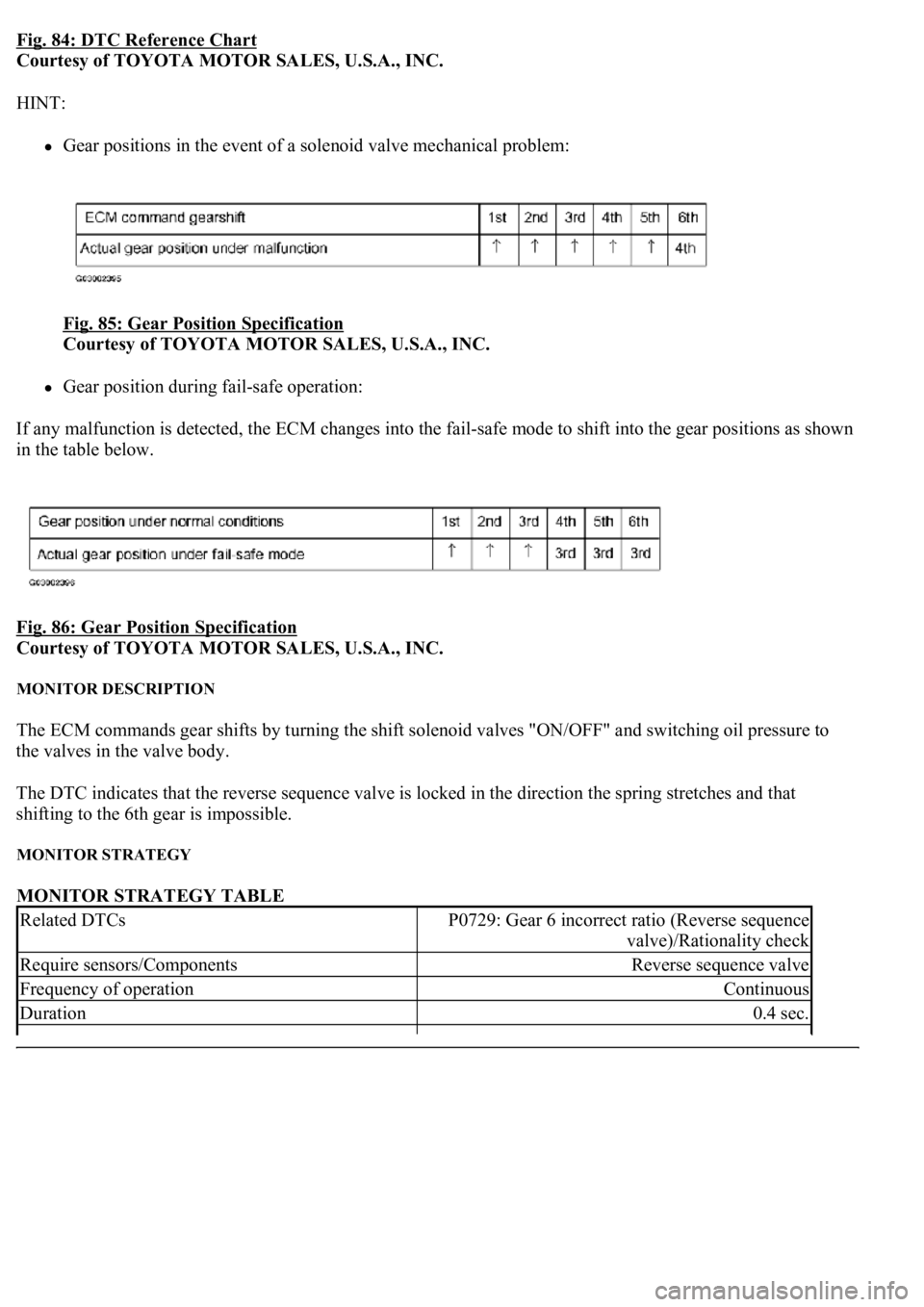

Fig. 84: DTC Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

Gear positions in the event of a solenoid valve mechanical problem:

Fig. 85: Gear Position Specification

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Gear position during fail-safe operation:

If any malfunction is detected, the ECM changes into the fail-safe mode to shift into the gear positions as shown

in the table below.

Fig. 86: Gear Position Specification

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF" and switching oil pressure to

the valves in the valve body.

The DTC indicates that the reverse sequence valve is locked in the direction the spring stretches and that

shifting to the 6th gear is impossible.

MONITOR STRATEGY

MONITOR STRATEGY TABLE

Related DTCsP0729: Gear 6 incorrect ratio (Reverse sequence

valve)/Rationality check

Require sensors/ComponentsReverse sequence valve

Frequency of operationContinuous

Duration0.4 sec.

Page 2820 of 4500

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF" and switching oil pressure to

the valves in the valve body.

The ECM calculates the "actual" transmission gear by comparing the signals from the input speed sensor (NT)

and the output speed sensor (SP2). The ECM can detect many mechanical problems in the shift solenoids, valve

body, and the transmission clutches, brakes, and gears. If the ECM detects that the actual gear position and the

commanded gear position are different, it will illuminate the MIL and store the DTC.

MONITOR STRATEGY

MONITOR STRATEGY TABLE

TYPICAL ENABLING CONDITIONS

The following items are common to all conditions below.

TYPICAL ENABLING CONDITIONS TABLE

Related DTCsP0781: Valve body/Rationality check

Required sensors/ComponentsValve body, Automatic transmission assembly

Frequency of operationContinuous

Duration<0026005200510047004c0057004c005200510003000b0024000c00030044005100470003000b0025000c00030013001100170003005600480046001100030026005200510047004c0057004c005200510003000b0026000c00030016000300560048004600

110003[

Condition (C) 1 sec.

MIL operation2 driving cycles

Sequence of operationNone

The monitor will run whenever this DTC is not

present.See LIST OF DISABLE A MONITOR

Turbine speed sensor circuitNot circuit malfunction

Output speed sensor circuitNot circuit malfunction

Shift solenoid valve S1 circuitNot circuit malfunction

Shift solenoid valve S2 circuitNot circuit malfunction

Shift solenoid valve S3 circuitNot circuit malfunction

Shift solenoid valve S4 circuitNot circuit malfunction

Shift solenoid valve SR circuitNot circuit malfunction

Shift solenoid valve SL1 circuitNot circuit malfunction

Shift solenoid valve SL2 circuitNot circuit malfunction

ECT (Engine coolant temperature) sensor circuitNot circuit malfunction

KCS sensor circuitNot circuit malfunction

ETCS (Electric throttle control system)Not system down

Transmission range"D"

ECT40°C (104°F) or more

Spark advance from Max. retard timing by KCS

control0° CA or more

EngineStarting

Page 2913 of 4500

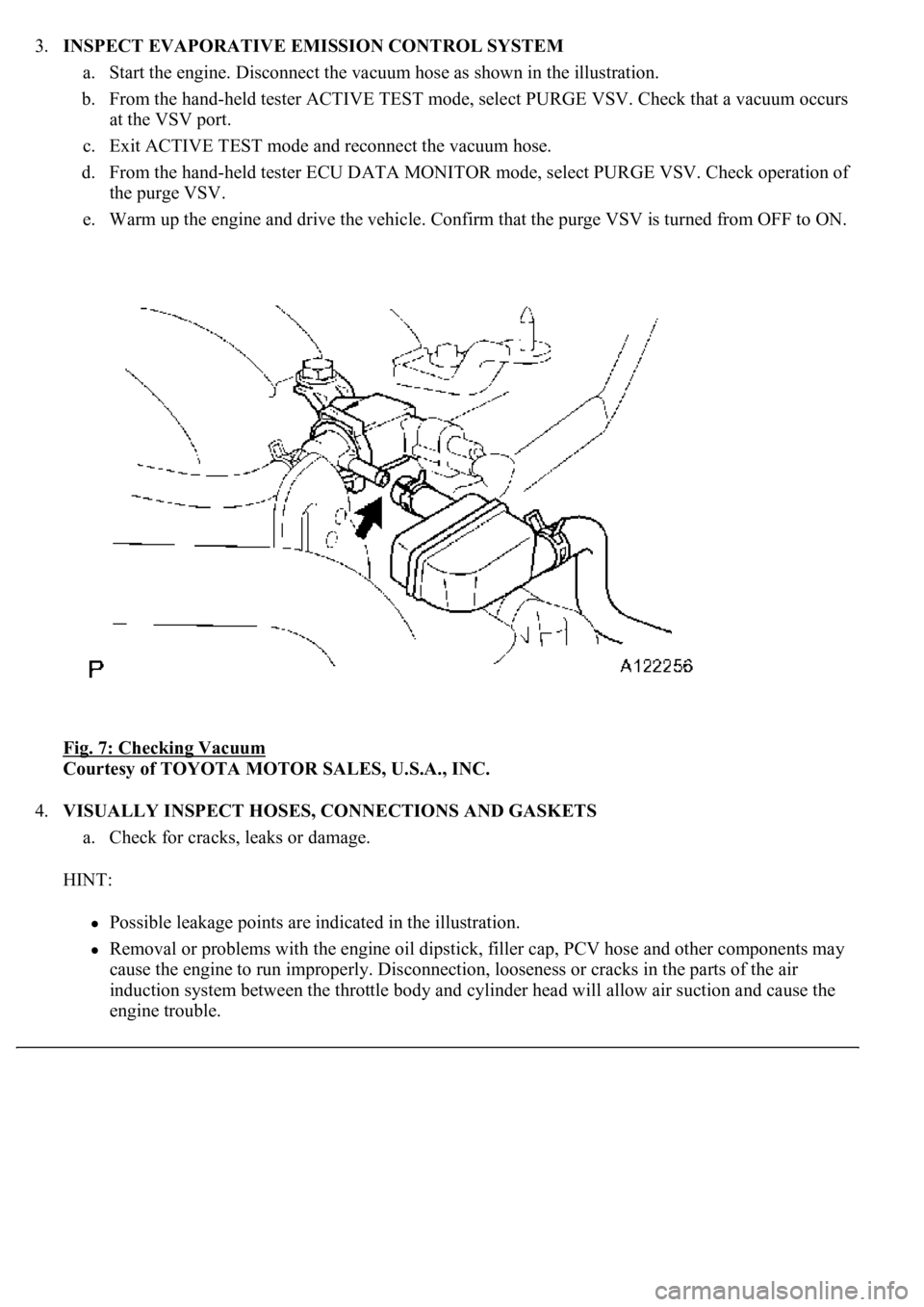

3.INSPECT EVAPORATIVE EMISSION CONTROL SYSTEM

a. Start the engine. Disconnect the vacuum hose as shown in the illustration.

b. From the hand-held tester ACTIVE TEST mode, select PURGE VSV. Check that a vacuum occurs

at the VSV port.

c. Exit ACTIVE TEST mode and reconnect the vacuum hose.

d. From the hand-held tester ECU DATA MONITOR mode, select PURGE VSV. Check operation of

the purge VSV.

e. Warm up the engine and drive the vehicle. Confirm that the purge VSV is turned from OFF to ON.

Fig. 7: Checking Vacuum

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

4.VISUALLY INSPECT HOSES, CONNECTIONS AND GASKETS

a. Check for cracks, leaks or damage.

HINT:

Possible leakage points are indicated in the illustration.

Removal or problems with the engine oil dipstick, filler cap, PCV hose and other components may

cause the engine to run improperly. Disconnection, looseness or cracks in the parts of the air

induction system between the throttle body and cylinder head will allow air suction and cause the

engine trouble.