LEXUS LS430 2003 Factory Repair Manual

LS430 2003

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57050/w960_57050-0.png

LEXUS LS430 2003 Factory Repair Manual

Page 2925 of 4500

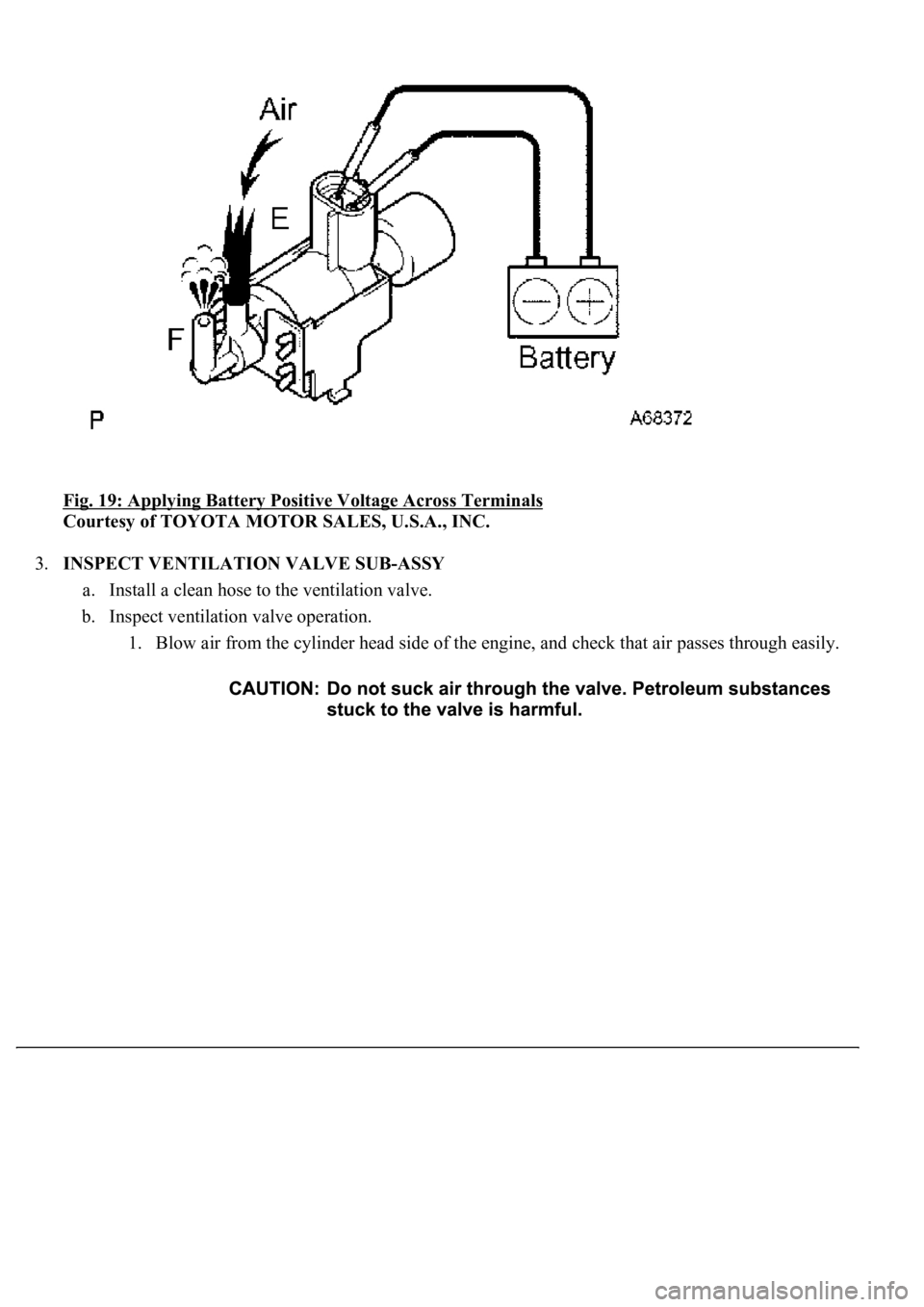

Fig. 19: Applying Battery Positive Voltage Across Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

3.INSPECT VENTILATION VALVE SUB-ASSY

a. Install a clean hose to the ventilation valve.

b. Inspect ventilation valve operation.

1. Blow air from the cylinder head side of the engine, and check that air passes through easily.

Page 2926 of 4500

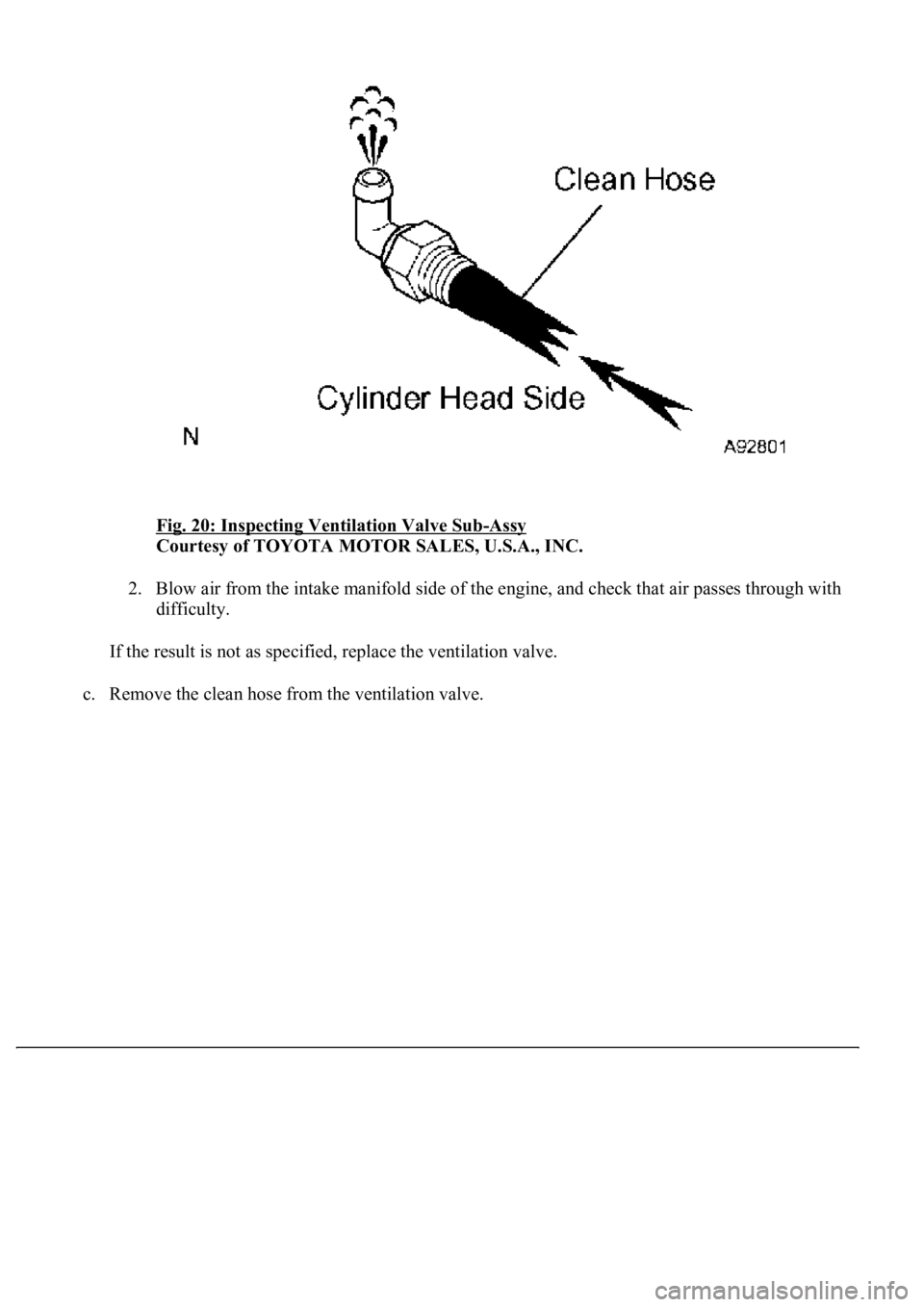

Fig. 20: Inspecting Ventilation Valve Sub-Assy

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

2. Blow air from the intake manifold side of the engine, and check that air passes through with

difficulty.

If the result is not as specified, replace the ventilation valve.

c. Remove the clean hose from the ventilation valve.

Page 2927 of 4500

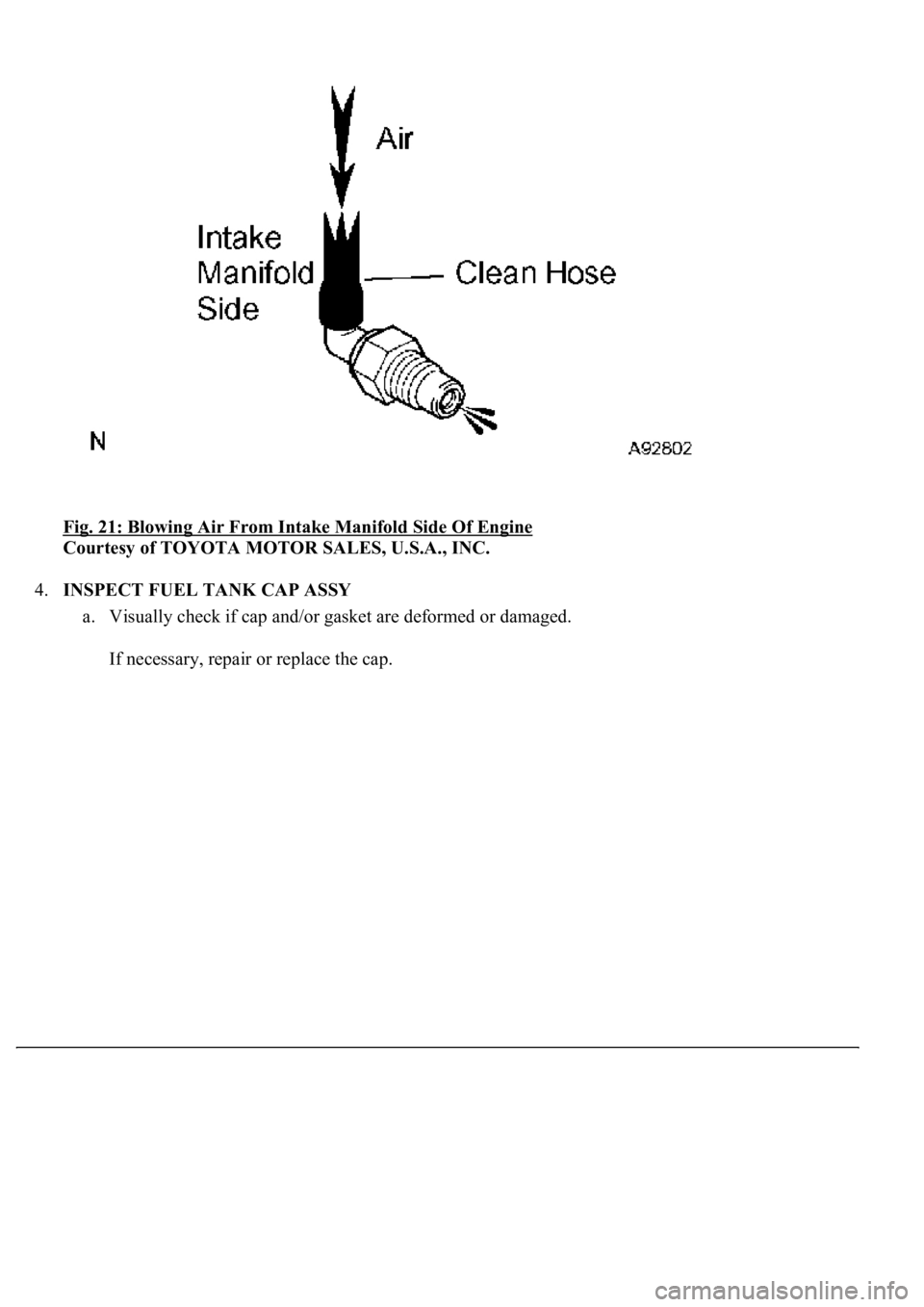

Fig. 21: Blowing Air From Intake Manifold Side Of Engine

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

4.INSPECT FUEL TANK CAP ASSY

a. Visually check if cap and/or gasket are deformed or damaged.

If necessar

y, repair or replace the cap.

Page 2941 of 4500

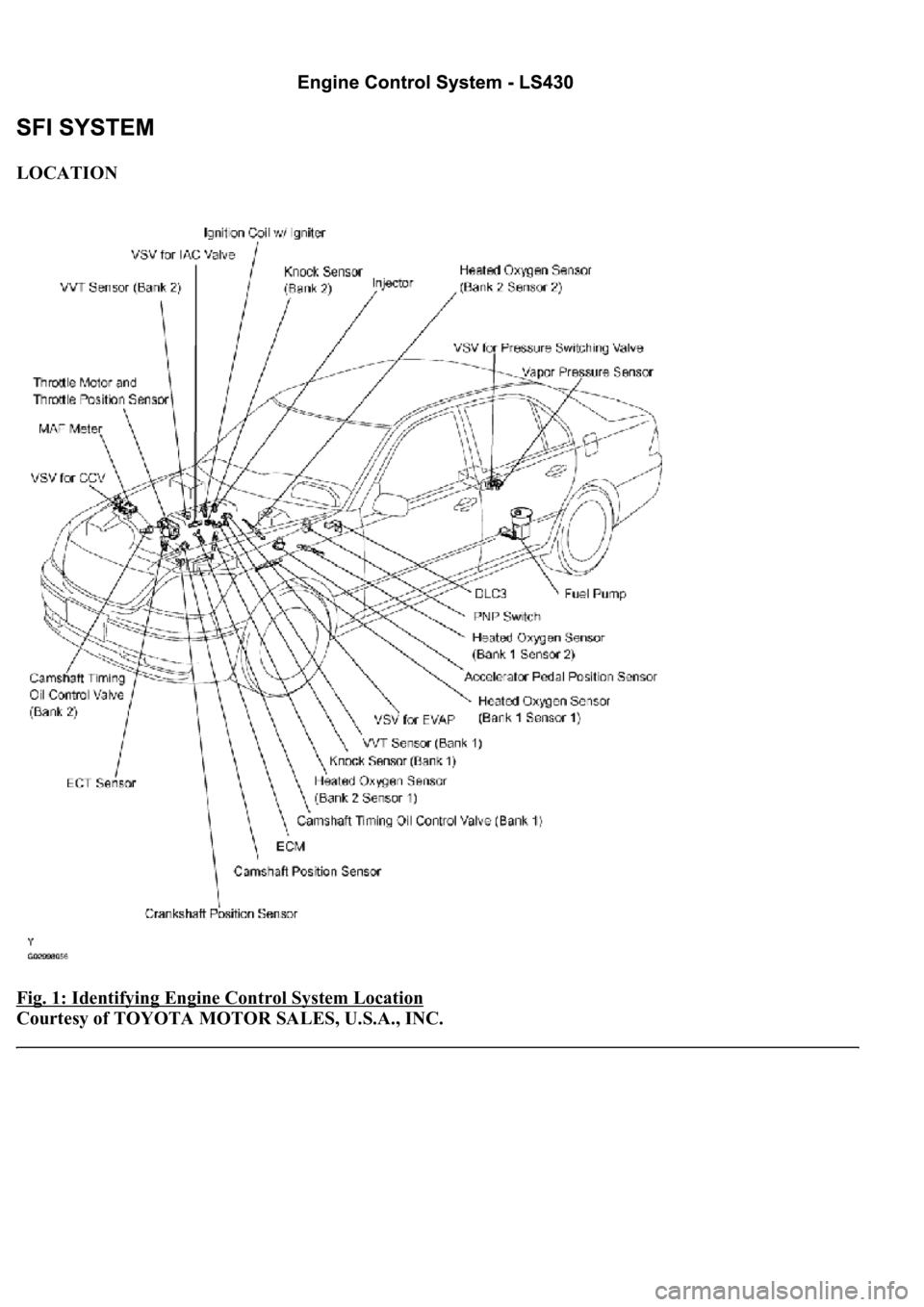

LOCATION

Fig. 1: Identifying Engine Control System Location

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 2942 of 4500

SYSTEM DIAGRAM

Engine control system is determined by the ECM based on signals from various sensors.

Fig. 2: Engine Control

- System Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 2945 of 4500

Standard: 0.6 to 1.0 V

If the result is not as specified, replace the accelerator pedal position sensor.

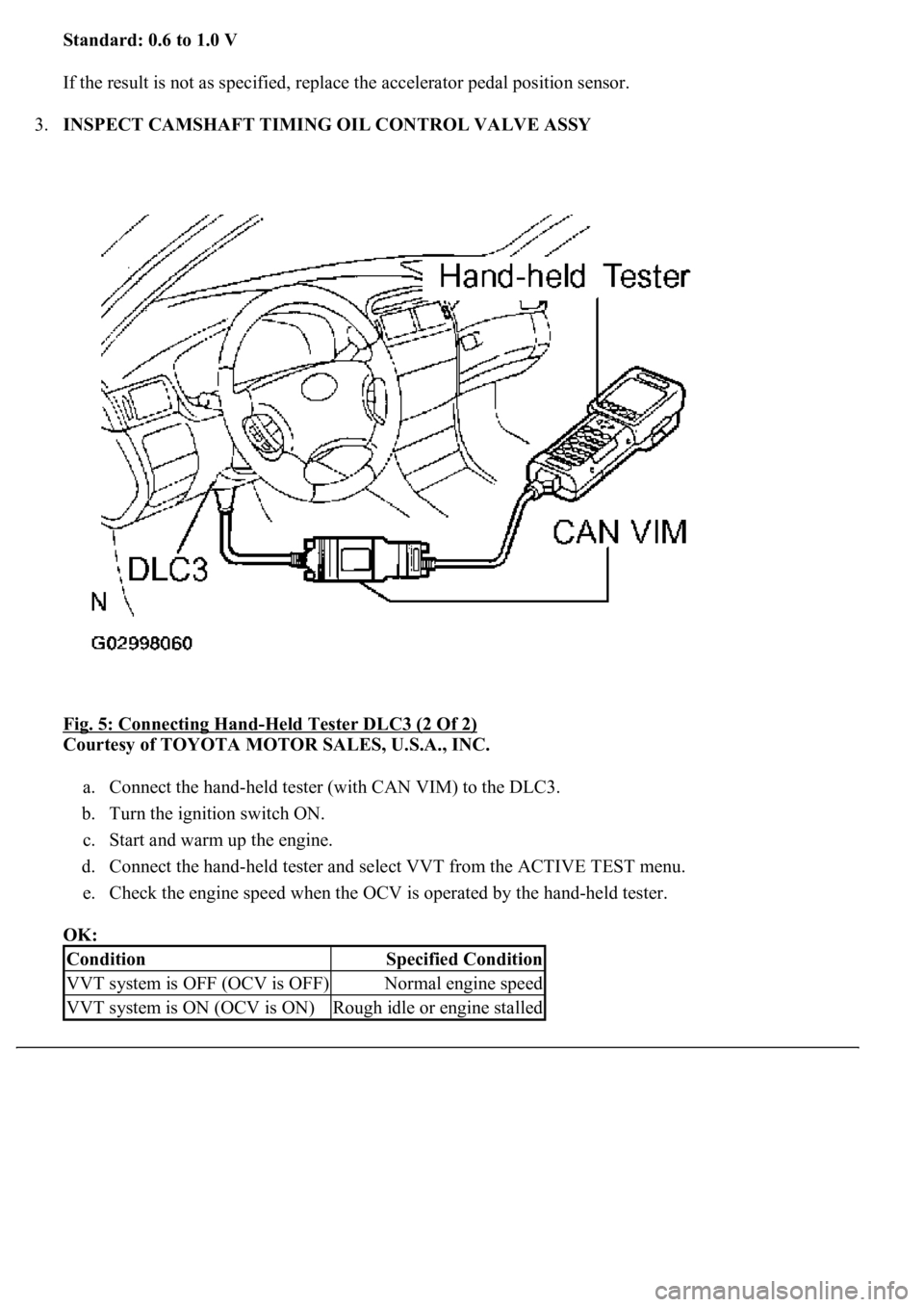

3.INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSY

Fig. 5: Connecting Hand

-Held Tester DLC3 (2 Of 2)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

a. Connect the hand-held tester (with CAN VIM) to the DLC3.

b. Turn the ignition switch ON.

c. Start and warm up the engine.

d. Connect the hand-held tester and select VVT from the ACTIVE TEST menu.

e. Check the engine speed when the OCV is operated by the hand-held tester.

OK:

ConditionSpecified Condition

VVT system is OFF (OCV is OFF)Normal engine speed

VVT system is ON (OCV is ON)Rough idle or engine stalled

Page 2950 of 4500

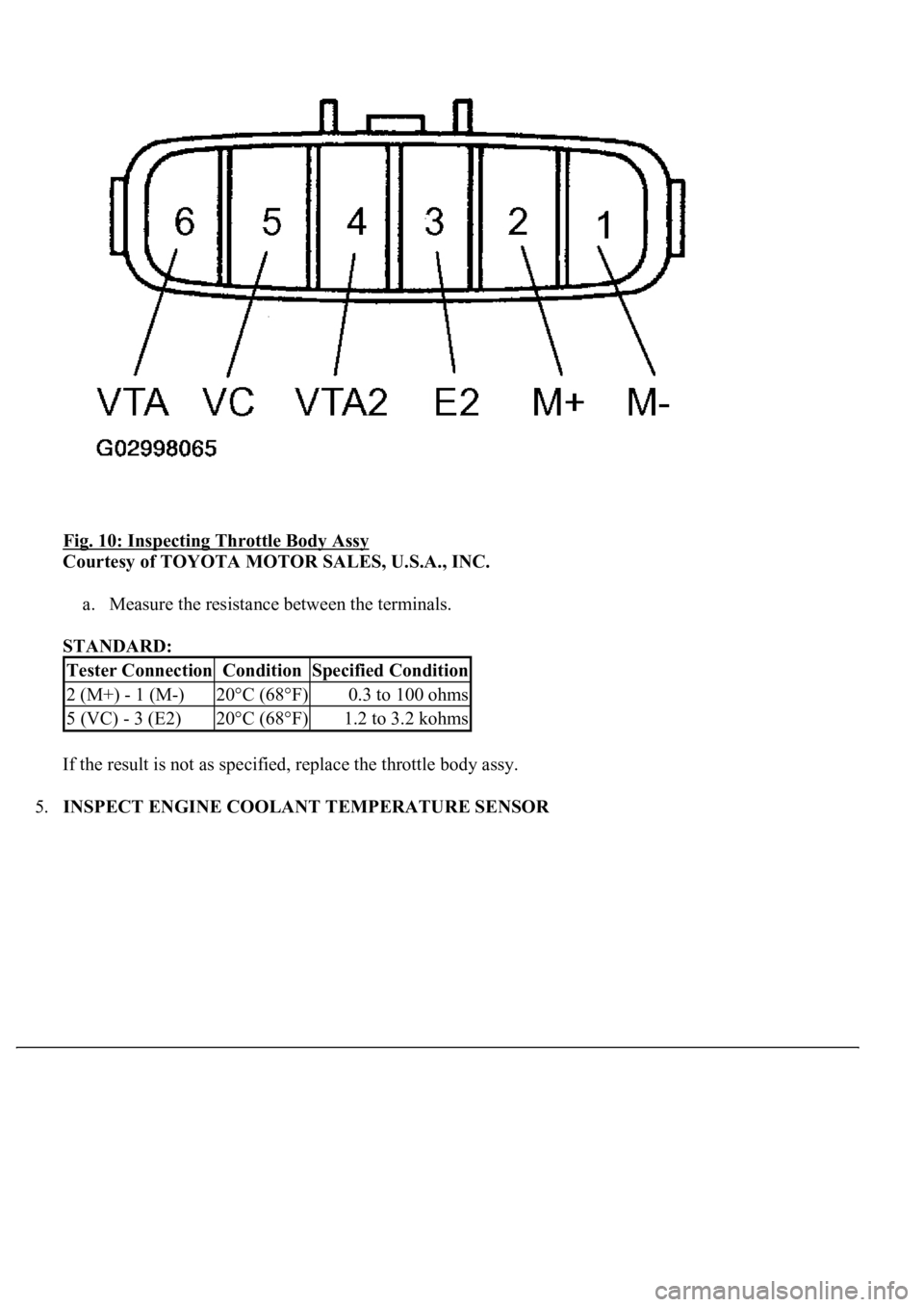

Fig. 10: Inspecting Throttle Body Assy

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

a. Measure the resistance between the terminals.

STANDARD:

If the result is not as specified, replace the throttle body assy.

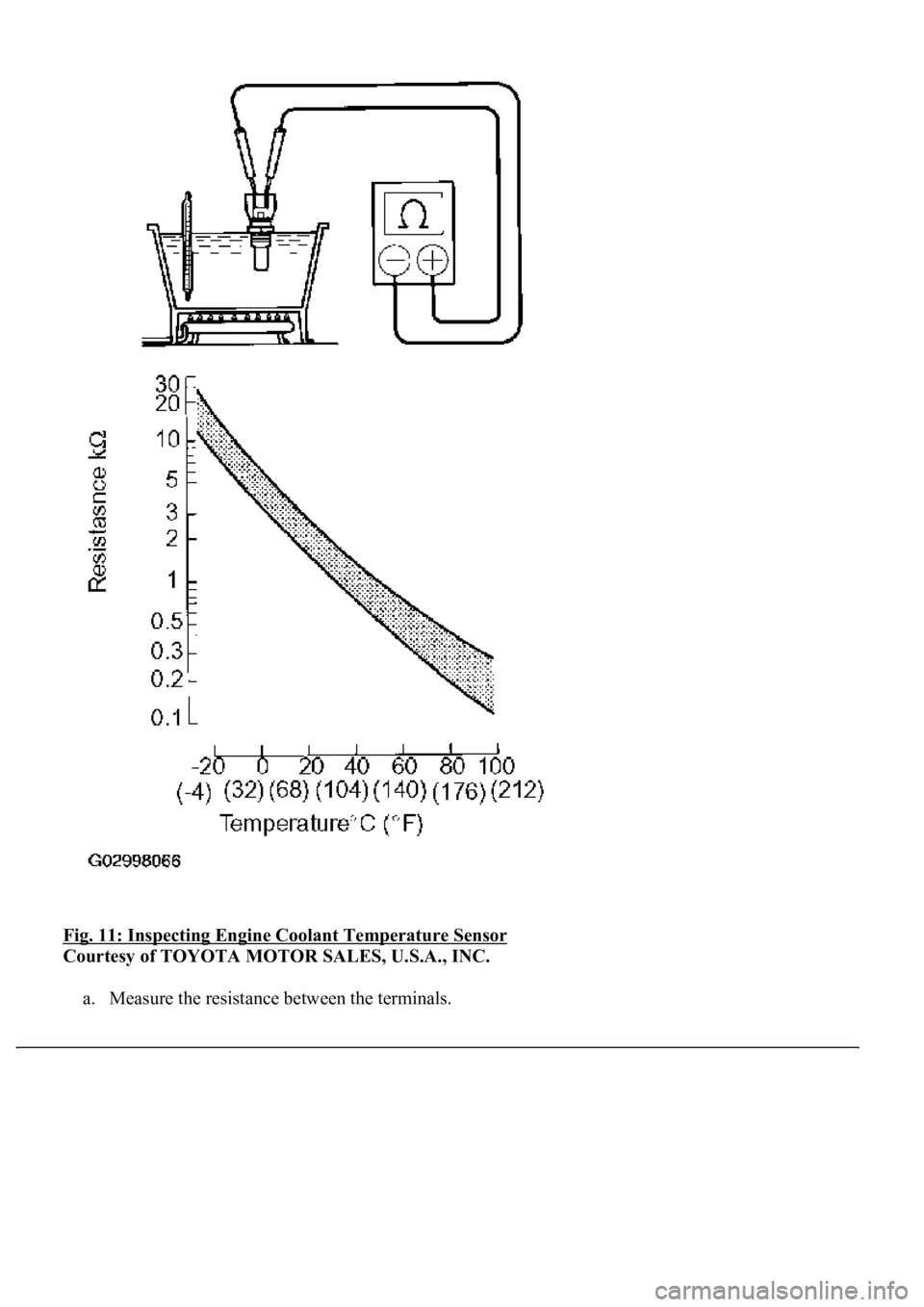

5.INSPECT ENGINE COOLANT TEMPERATURE SENSOR

Tester ConnectionConditionSpecified Condition

2 (M+) - 1 (M-)20°C (68°F)0.3 to 100 ohms

5 (VC) - 3 (E2)20°C (68°F)1.2 to 3.2 kohms

Page 2951 of 4500

Fig. 11: Inspecting Engine Coolant Temperature Sensor

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

a. Measure the resistance between the terminals.

Page 2953 of 4500

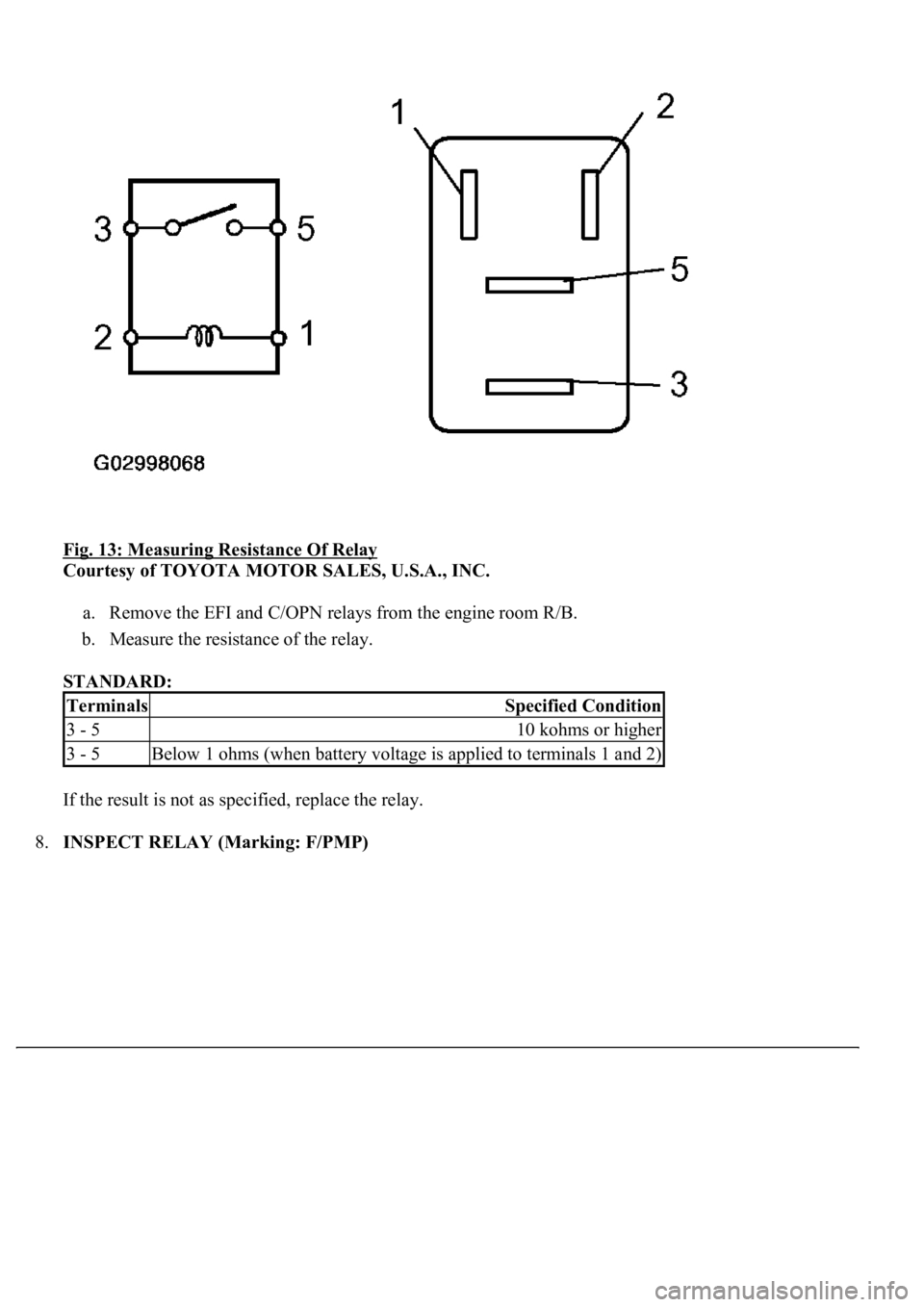

Fig. 13: Measuring Resistance Of Relay

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

a. Remove the EFI and C/OPN relays from the engine room R/B.

b. Measure the resistance of the relay.

STANDARD:

If the result is not as specified, replace the relay.

8.INSPECT RELAY (Marking: F/PMP)

TerminalsSpecified Condition

3 - 510 kohms or higher

3 - 5Below 1 ohms (when battery voltage is applied to terminals 1 and 2)

Page 2954 of 4500

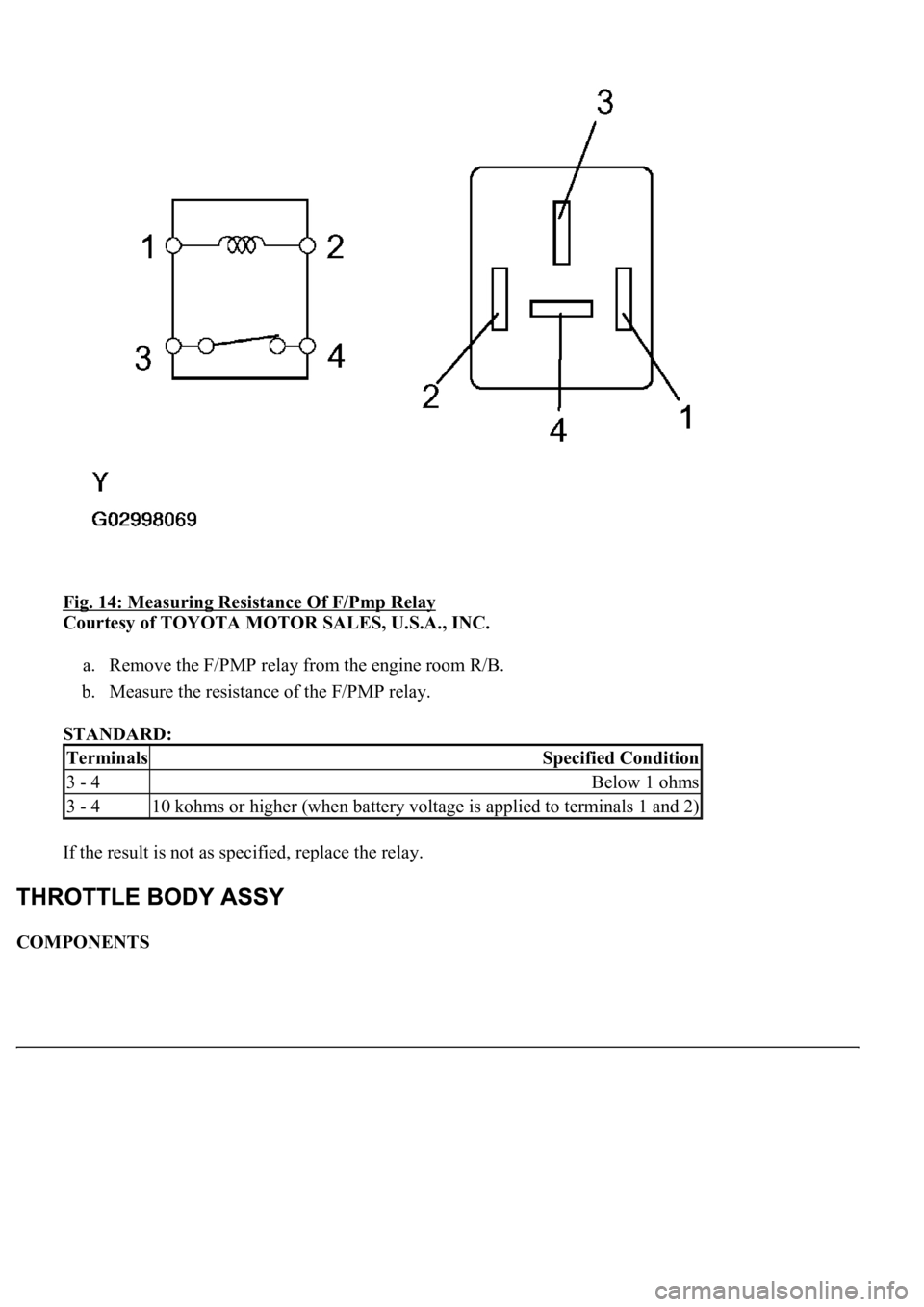

Fig. 14: Measuring Resistance Of F/Pmp Relay

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

a. Remove the F/PMP relay from the engine room R/B.

b. Measure the resistance of the F/PMP relay.

STANDARD:

If the result is not as specified, replace the relay.

COMPONENTS

TerminalsSpecified Condition

3 - 4Below 1 ohms

3 - 410 kohms or higher (when battery voltage is applied to terminals 1 and 2)