sensor LEXUS LS430 2003 Factory Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 4056 of 4500

Fig. 64: Installing Height Control Sensor Link Sub-Assy Front (Air Suspension)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

9.INSTALL LOWER BALL JOINT ASSY FRONT LH (See LOWER BALL JOINT ASSY FRONT

LH REPLACEMENT )

10.STABILIZE SUSPENSION (See REPLACEMENT

or REPLACEMENT )

11.FULLY TIGHTEN FRONT SUSPENSION LOWER ARM ASSY LH

a. Fully tighten the nut.

Torque: 137 N.m (1,395 kgf.cm, 101 ft.lbf)

Page 4059 of 4500

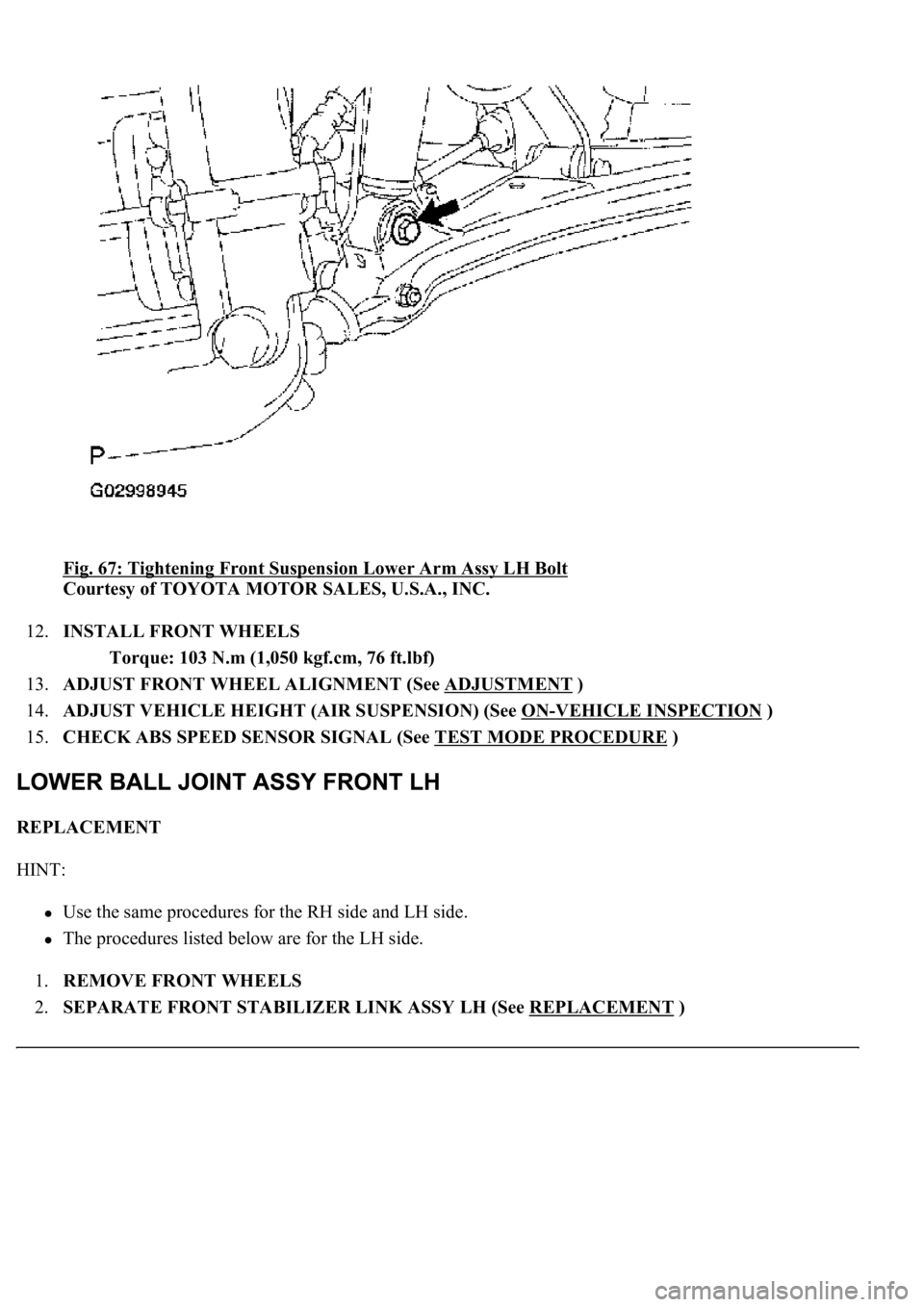

Fig. 67: Tightening Front Suspension Lower Arm Assy LH Bolt

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

12.INSTALL FRONT WHEELS

Torque: 103 N.m (1,050 kgf.cm, 76 ft.lbf)

13.ADJUST FRONT WHEEL ALIGNMENT (See ADJUSTMENT

)

14.ADJUST VEHICLE HEIGHT (AIR SUSPENSION) (See ON

-VEHICLE INSPECTION )

15.CHECK ABS SPEED SENSOR SIGNAL (See TEST MODE PROCEDURE

)

REPLACEMENT

HINT:

Use the same procedures for the RH side and LH side.

The procedures listed below are for the LH side.

1.REMOVE FRONT WHEELS

2.SEPARATE FRONT STABILIZER LINK ASSY LH (See REPLACEMENT

)

Page 4060 of 4500

3.SEPARATE SKID CONTROL SENSOR WIRE (See REPLACEMENT )

4.REMOVE DISC BRAKE CYLINDER ASSY LH (See step 8 in OVERHAUL

)

5.REMOVE FRONT DISC (See step 14 in OVERHAUL

)

6.REMOVE FRONT AXLE HUB SUB-ASSY LH (See step 5 in REPLACEMENT

)

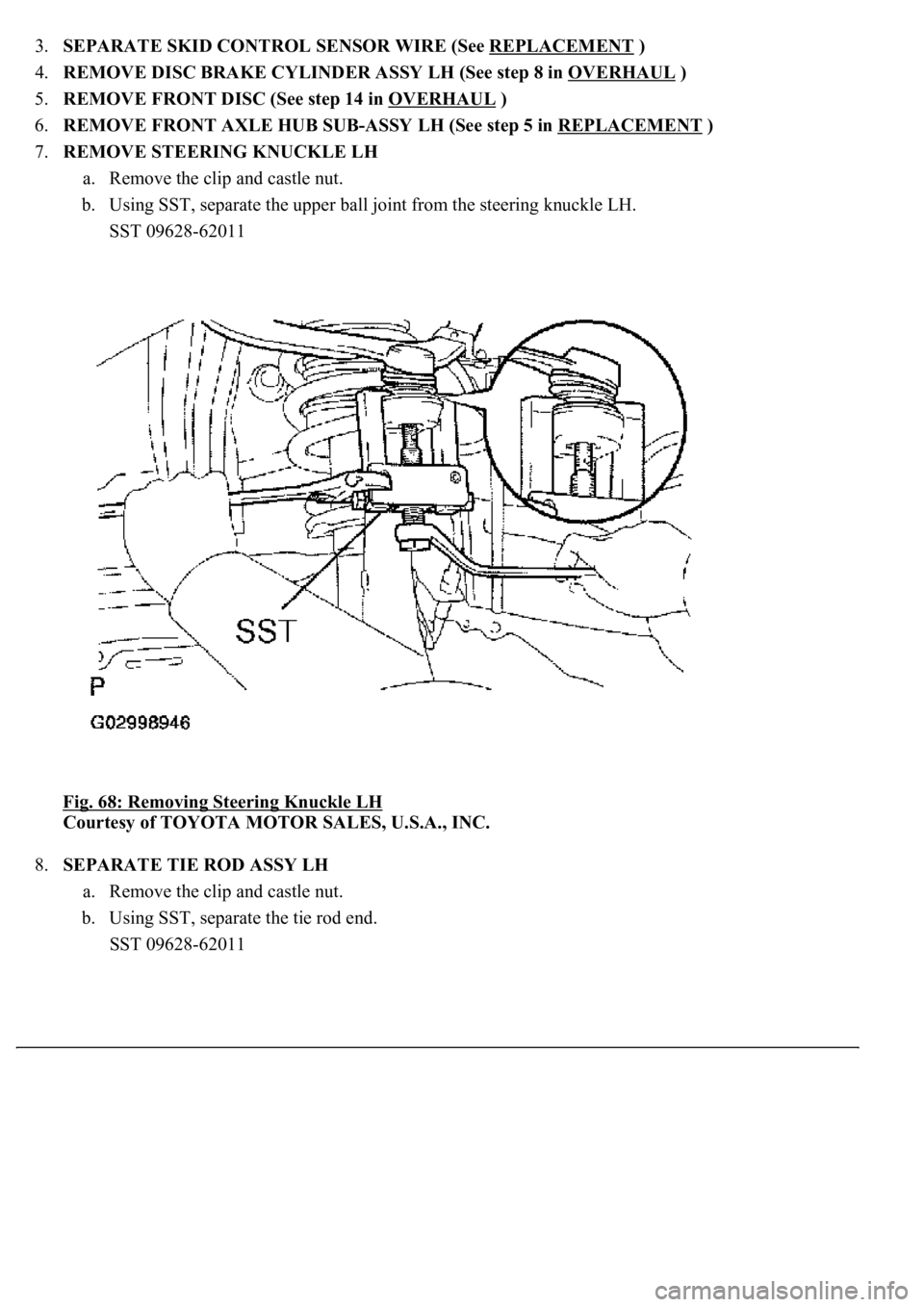

7.REMOVE STEERING KNUCKLE LH

a. Remove the clip and castle nut.

b. Using SST, separate the upper ball joint from the steering knuckle LH.

SST 09628-62011

Fig. 68: Removing Steering Knuckle LH

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

8.SEPARATE TIE ROD ASSY LH

a. Remove the clip and castle nut.

b. Using SST, separate the tie rod end.

SST 09628-62011

Page 4064 of 4500

b. Install a new cotter pin on the steering knuckle.

14.INSTALL FRONT AXLE HUB SUB-ASSY LH (See step 8 in REPLACEMENT

)

15.INSTALL FRONT DISC (See step 15 in OVERHAUL

)

16.INSTALL DISC BRAKE CYLINDER ASSY LH (See step 21 in OVERHAUL

)

17.INSTALL SKID CONTROL SENSOR WIRE (See step 11 in REPLACEMENT

)

18.INSTALL FRONT STABILIZER LINK ASSY LH (See REPLACEMENT

)

19.INSTALL FRONT WHEELS

Torque: 103 N.m (1,050 kgf.cm, 76 ft.lbf)

20.CHECK ABS SPEED SENSOR SIGNAL (See TEST MODE PROCEDURE

)

REPLACEMENT

1.REMOVE FRONT WHEELS

2.REMOVE FRONT STABILIZER LINK ASSY LH

a. Support the suspension lower arm assy with a jack using a wood block to avoid damage.

b. Remove the bolt and nut to separate the front stabilizer link assy LH.

c. Remove the nut and front stabilizer link assy LH.

Page 4082 of 4500

3.INSPECT BATTERY VOLTAGE

Standard: 11 to 14 V

If voltage is below 11 V, recharge the battery before proceeding.

1.DATA LIST

HINT:

Using the hand-held tester's DATA LIST allows switch, sensor, actuator and other item values to be read

without removing any parts. Reading the DATA LIST early in troubleshooting is one way to save time.

a. Connect the hand-held tester (with CAN VIM) to the DLC3.

b. Turn the ignition switch ON.

c. Read the DATA LIST on the tester's screen.

Driver side J/B ECU:

DRIVER SIDE J/B ECU

2.ACTIVE TEST

HINT:

Performing the hand-held tester's ACTIVE TEST allows relay, VSV, actuator and other items to be

operated without removing any parts. Performing the ACTIVE TEST early in troubleshooting is one way

to save time. The DATA LIST can be displayed during the ACTIVE TEST.

a. Connect the hand-held tester (with CAN VIM) to the DLC3.

b. Turn the ignition switch ON.

c. Perform the ACTIVE TEST accordin

g to the display on the tester.

Symbols (Terminals No.)Terminal DescriptionConditionSpecified condition

SIL (7) - SG (5)Bus "+" lineDuring transmissionPulse generation

CG (4) - Body groundChassis groundAlwaysBelow 1 ohms

SG (5) - Body groundSignal groundAlwaysBelow 1 ohms

BAT (16) - Body groundBattery positiveAlways11 to 14 V

ItemMeasurement

Item/Display (Range)Normal ConditionDiagnostic

Note

FUEL LID

OPN SWFuel lid opener switch

signal /ON or OFFON: Fuel lid opener switch is pushed OFF:

Fuel lid opener switch is not pushed-

Page 4100 of 4500

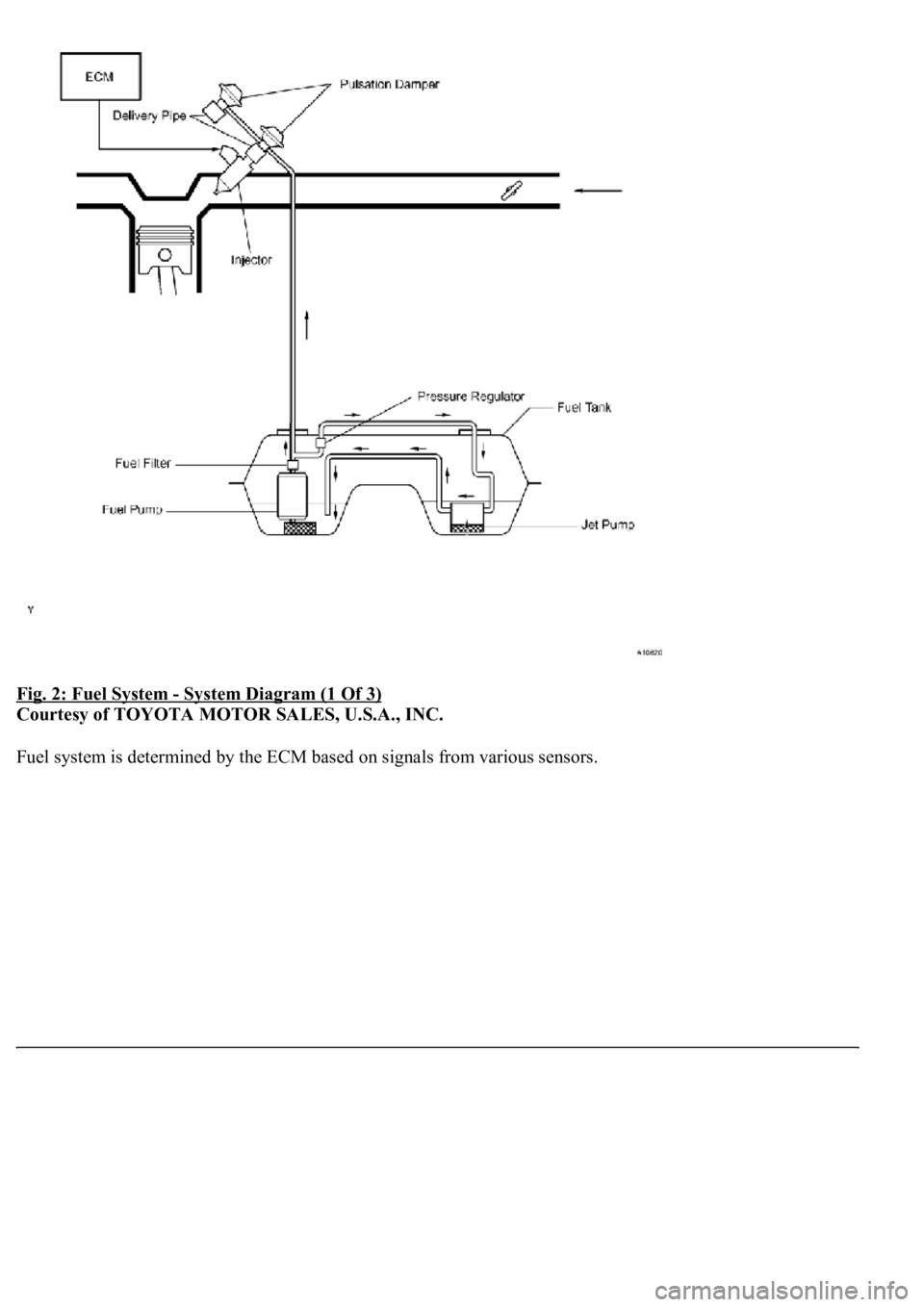

Fig. 2: Fuel System - System Diagram (1 Of 3)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Fuel s

ystem is determined by the ECM based on signals from various sensors.

Page 4211 of 4500

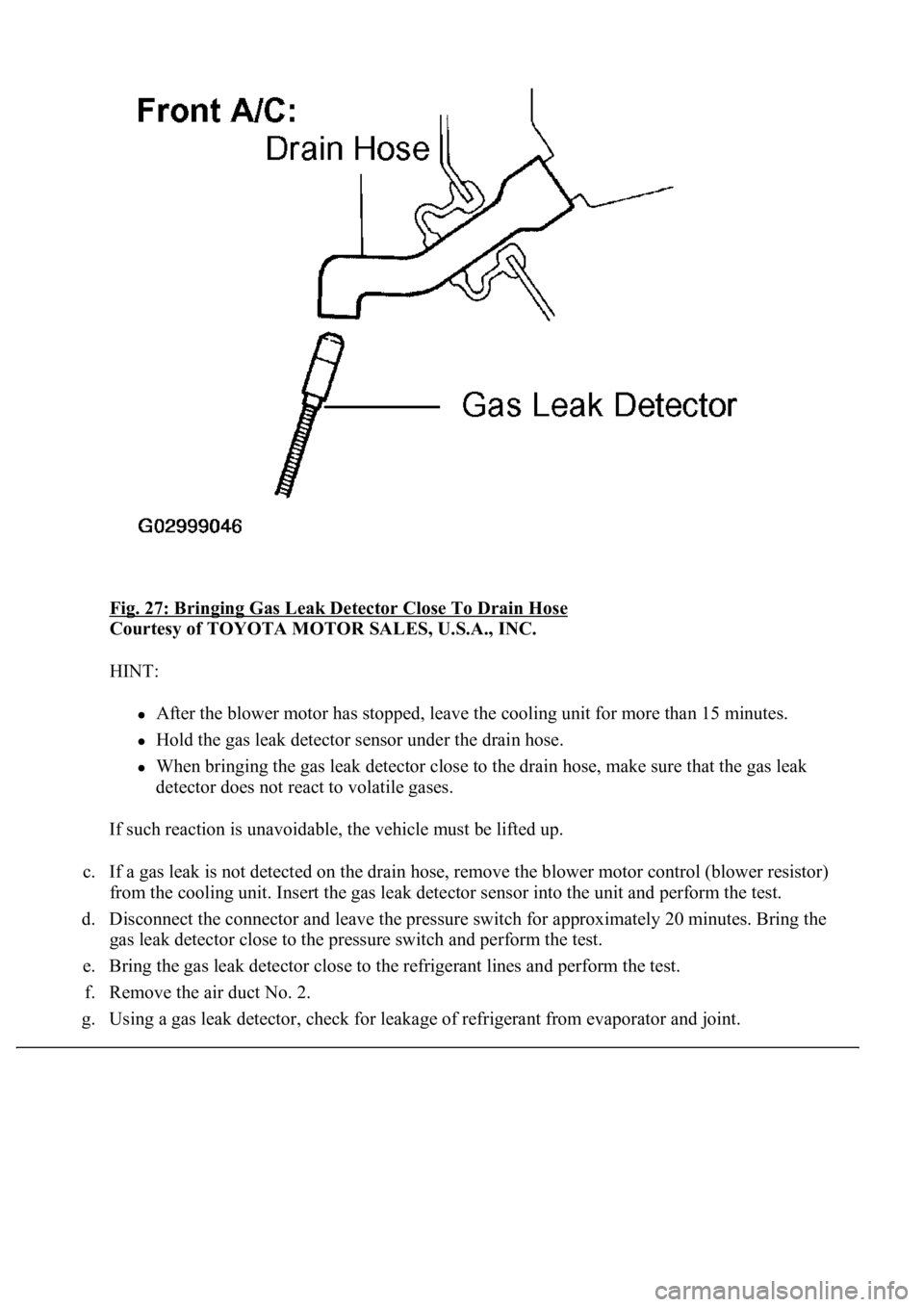

Fig. 27: Bringing Gas Leak Detector Close To Drain Hose

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

<0024004900570048005500030057004b004800030045004f0052005a004800550003005000520057005200550003004b0044005600030056005700520053005300480047000f0003004f004800440059004800030057004b00480003004600520052004f00

4c0051004a000300580051004c005700030049005200550003[more than 15 minutes.

Hold the gas leak detector sensor under the drain hose.

When bringing the gas leak detector close to the drain hose, make sure that the gas leak

detector does not react to volatile gases.

If such reaction is unavoidable, the vehicle must be lifted up.

c. If a gas leak is not detected on the drain hose, remove the blower motor control (blower resistor)

from the cooling unit. Insert the gas leak detector sensor into the unit and perform the test.

d. Disconnect the connector and leave the pressure switch for approximately 20 minutes. Bring the

gas leak detector close to the pressure switch and perform the test.

e. Bring the gas leak detector close to the refrigerant lines and perform the test.

f. Remove the air duct No. 2.

g.Using a gas leak detector, check for leakage of refrigerant from evaporator and joint.

Page 4227 of 4500

INSPECTION

1.CHECK EVAPORATOR AND HEATER RADIATOR FINS FOR FOREIGN MATTER

If foreign matter is attached to the fin, blow it off with compressed air.

2.CHECK FITTINGS FOR CRACKS OR SCRATCHES

a. Repair as necessary.

3.INSPECT EVAPORATOR TEMPERATURE SENSOR CIRCUIT (See DTC B1413:

EVAPORATOR TEMPERATURE SENSOR CIRCUIT )

4.INSPECT COOL AIR BYPASS DAMPER POSITION SENSOR CIRCUIT (DRIVER SIDE) (See

DTC B1434: MAX COOL DAMPER POSITION SENSOR CIRCUIT (DRIVER SIDE)

)

5.INSPECT COOL AIR BYPASS DAMPER CONTROL SERVOMOTOR CIRCUIT (DRIVER

SIDE) (See COOL AIR BYPASS DAMPER CONTROL SERVOMOTOR CIRCUIT (DRIVER

SIDE) )

6.INSPECT COOL AIR BYPASS DAMPER POSITION SENSOR CIRCUIT (PASSENGER SIDE)

(See COOL AIR BYPASS DAMPER CONTROL SERVOMOTOR CIRCUIT (PASSENGER

SIDE) )

7.INSPECT COOL AIR BYPASS DAMPER CONTROL SERVOMOTOR CIRCUIT (PASSENGER

SIDE) (SEE COOL AIR BYPASS DAMPER CONTROL SERVOMOTOR CIRCUIT

(PASSENGER SIDE) )

8.INSPECT WATER VALVE CONTROL SERVOMOTOR CIRCUIT (See WATER VALVE

CONTROL SERVOMOTOR CIRCUIT )

9.INSPECT AIR VENT MODE DAMPER CONTROL SERVOMOTOR CIRCUIT (See AIR VENT

MODE DAMPER CONTROL SERVOMOTOR CIRCUIT )

10.INSPECT AIR MIX DAMPER CONTROL SERVOMOTOR CIRCUIT (See AIR MIX DAMPER

CONTROL SERVOMOTOR CIRCUIT )

OVERHAUL

HINT:

Installation is in the reverse order of removal.

See COMPONENTS .

1.DISCONNECT NEGATIVE TERMINAL CABLE FROM BATTERY

2.EVACUATE REFRIGERANT HFC-134A (R134A) (See REPLACEMENT

)

3.DRAIN ENGINE COOLANT FROM RADIATOR

HINT:

It is not necessar

y to drain out all coolant.

Page 4238 of 4500

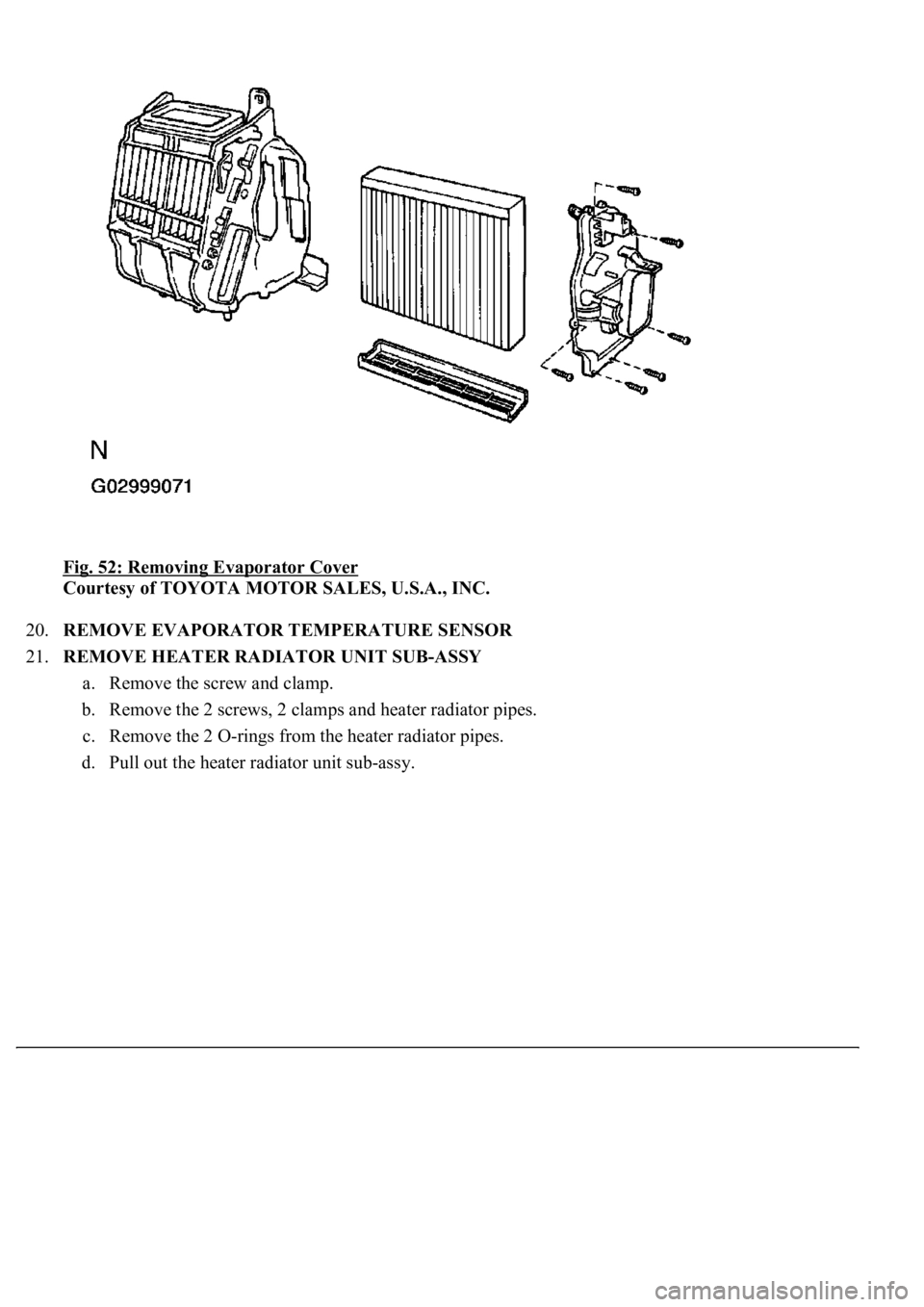

Fig. 52: Removing Evaporator Cover

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

20.REMOVE EVAPORATOR TEMPERATURE SENSOR

21.REMOVE HEATER RADIATOR UNIT SUB-ASSY

a. Remove the screw and clamp.

b. Remove the 2 screws, 2 clamps and heater radiator pipes.

c. Remove the 2 O-rings from the heater radiator pipes.

d. Pull out the heater radiator unit sub-assy.

Page 4277 of 4500

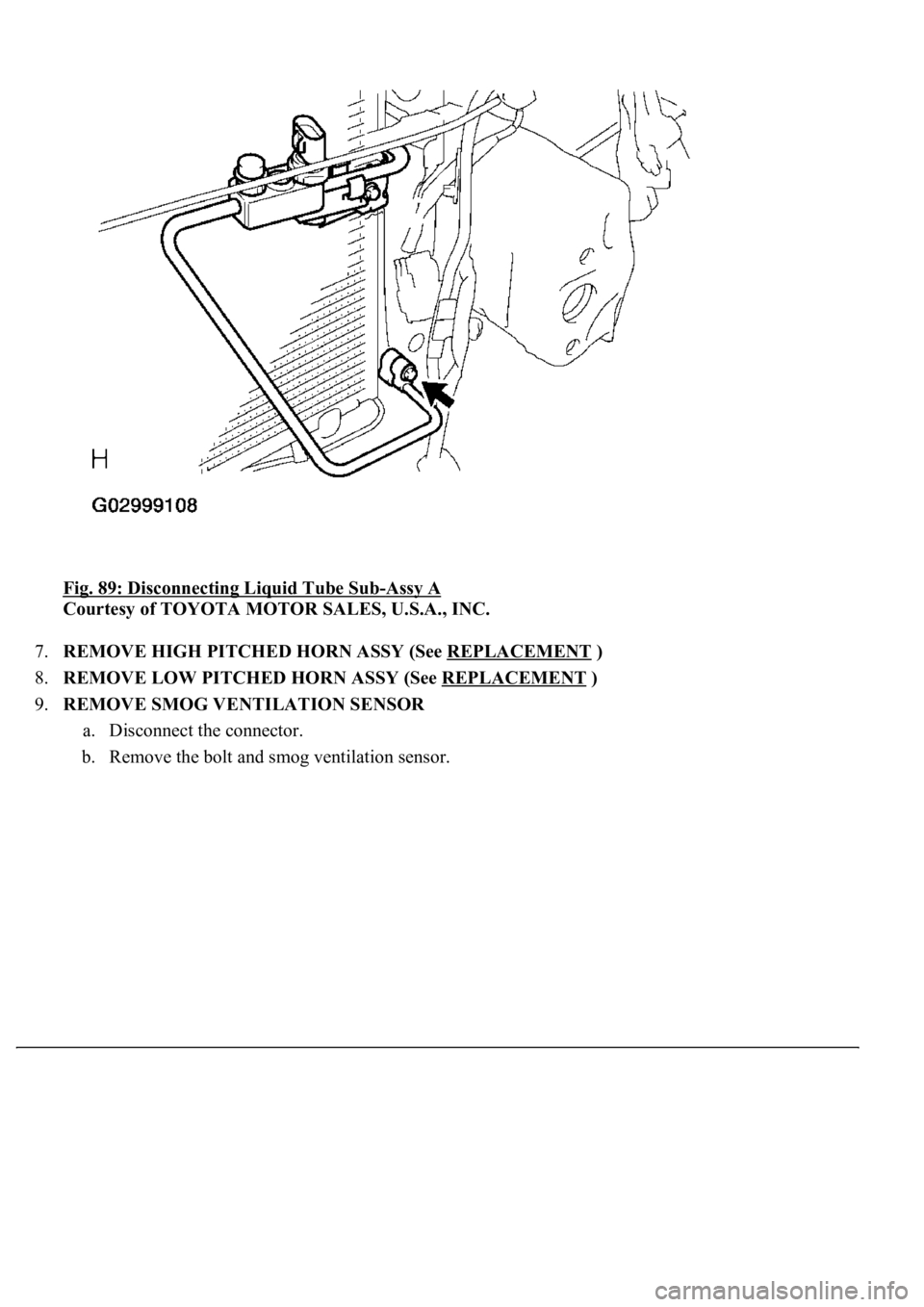

Fig. 89: Disconnecting Liquid Tube Sub-Assy A

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

7.REMOVE HIGH PITCHED HORN ASSY (See REPLACEMENT

)

8.REMOVE LOW PITCHED HORN ASSY (See REPLACEMENT

)

9.REMOVE SMOG VENTILATION SENSOR

a. Disconnect the connector.

b. Remove the bolt and smog ventilation sensor.