ESP LEXUS LS430 2003 Factory Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 34 of 4500

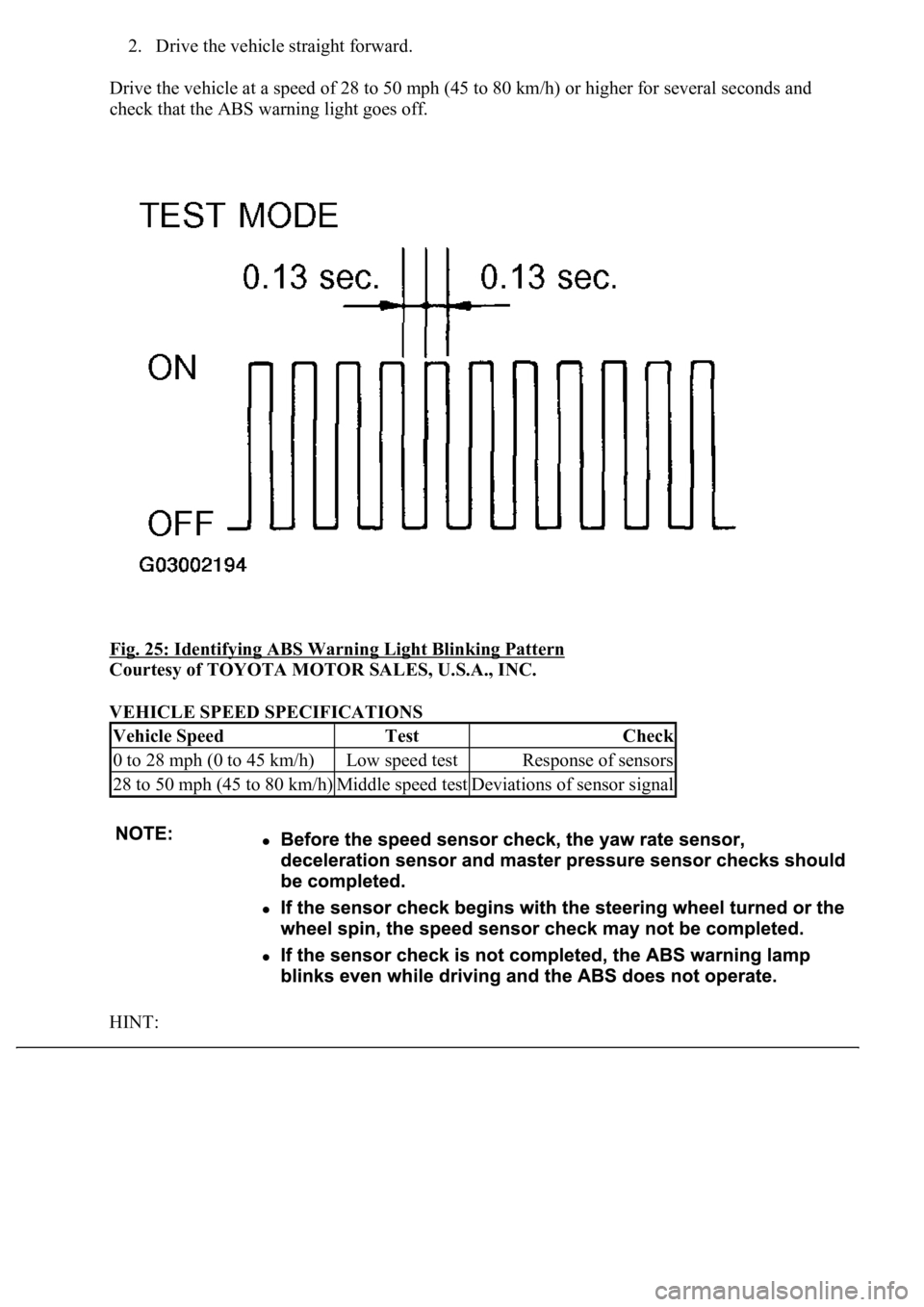

2. Drive the vehicle straight forward.

Drive the vehicle at a speed of 28 to 50 mph (45 to 80 km/h) or higher for several seconds and

check that the ABS warning light goes off.

Fig. 25: Identifying ABS Warning Light Blinking Pattern

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

VEHICLE SPEED SPECIFICATIONS

HINT:

Vehicle SpeedTestCheck

0 to 28 mph (0 to 45 km/h)Low speed testResponse of sensors

28 to 50 mph (45 to 80 km/h)Middle speed testDeviations of sensor signal

Page 60 of 4500

CIRCUIT DESCRIPTION

The speed sensor detects wheel speed and sends the appropriate signals to the ECU. These signals are used to

control the ABS control system. The front and rear rotors have 48 serrations respectively.

When the rotors rotate, the magnetic field emitted by the permanent magnet in the speed sensor generates an

AC voltage. Since the frequency of this AC voltage changes in direct proportion to the speed of the rotor, the

frequenc

y is used by the ECU to detect the speed of each wheel.

Page 62 of 4500

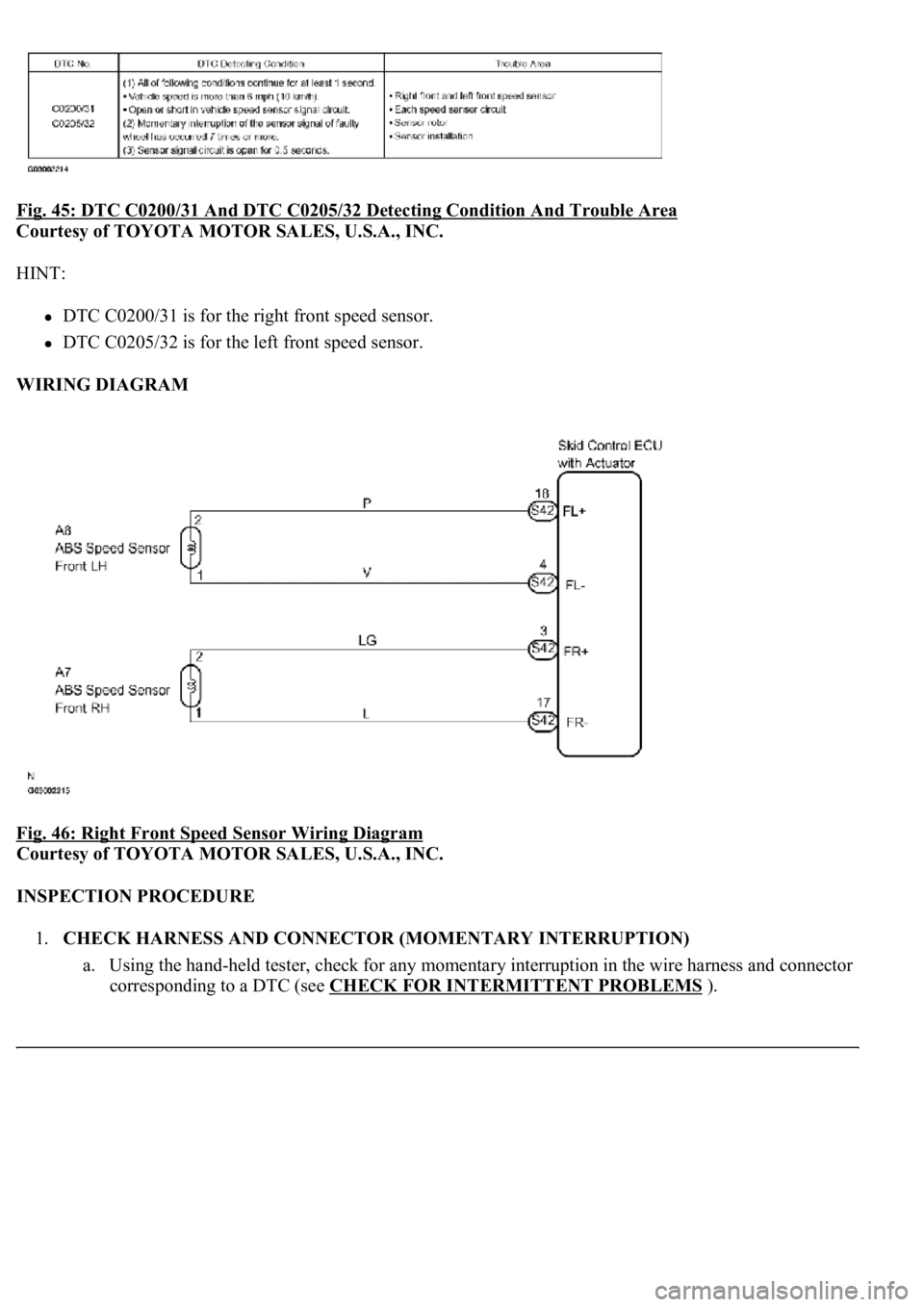

Fig. 45: DTC C0200/31 And DTC C0205/32 Detecting Condition And Trouble Area

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

DTC C0200/31 is for the right front speed sensor.

DTC C0205/32 is for the left front speed sensor.

WIRING DIAGRAM

Fig. 46: Right Front Speed Sensor Wiring Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

INSPECTION PROCEDURE

1.CHECK HARNESS AND CONNECTOR (MOMENTARY INTERRUPTION)

a. Using the hand-held tester, check for any momentary interruption in the wire harness and connector

corresponding to a DTC (see CHECK FOR INTERMITTENT PROBLEMS

).

Page 75 of 4500

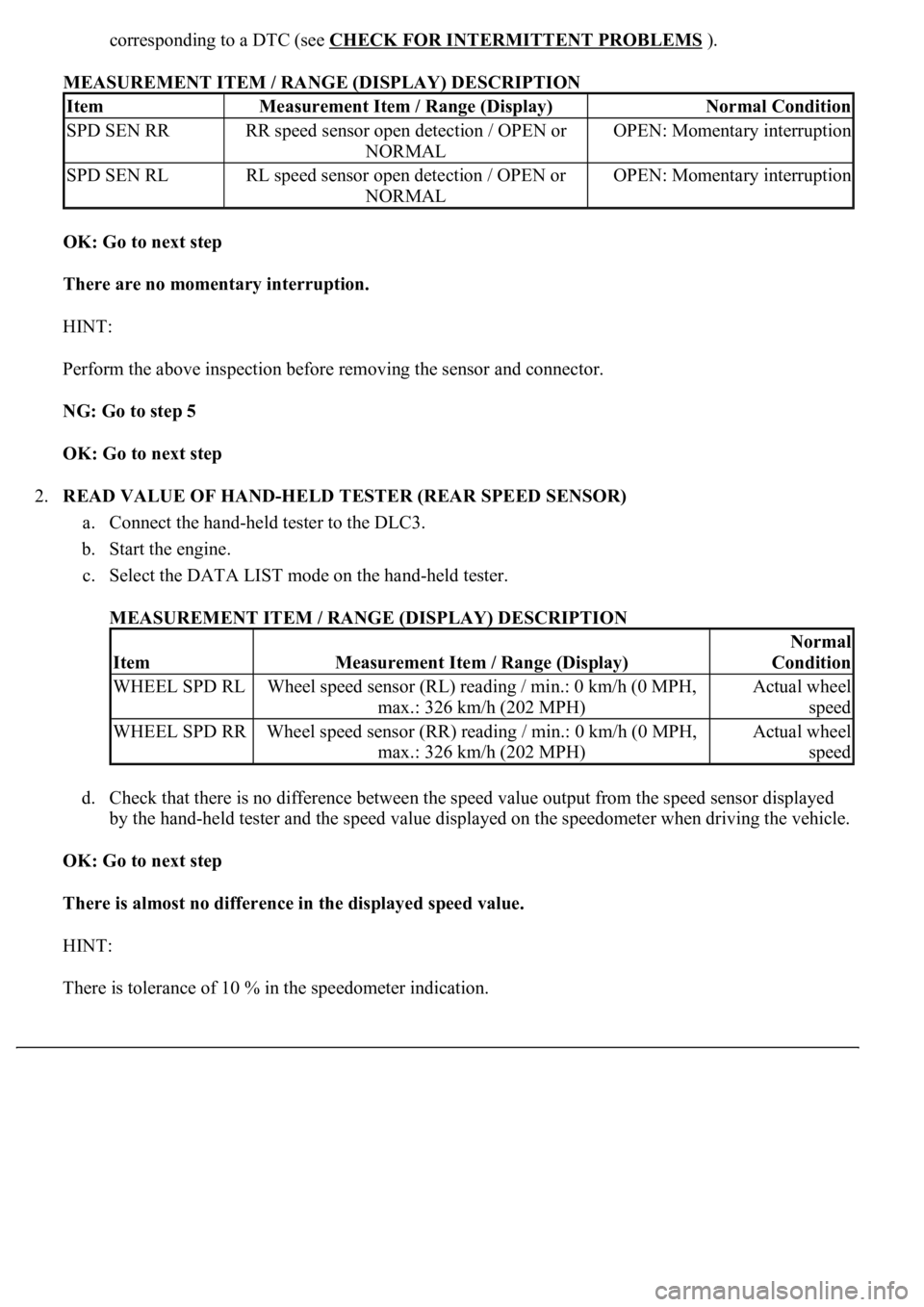

corresponding to a DTC (see CHECK FOR INTERMITTENT PROBLEMS ).

MEASUREMENT ITEM / RANGE (DISPLAY) DESCRIPTION

OK: Go to next step

There are no momentary interruption.

HINT:

Perform the above inspection before removing the sensor and connector.

NG: Go to step 5

OK: Go to next step

2.READ VALUE OF HAND-HELD TESTER (REAR SPEED SENSOR)

a. Connect the hand-held tester to the DLC3.

b. Start the engine.

c. Select the DATA LIST mode on the hand-held tester.

MEASUREMENT ITEM / RANGE (DISPLAY) DESCRIPTION

d. Check that there is no difference between the speed value output from the speed sensor displayed

by the hand-held tester and the speed value displayed on the speedometer when driving the vehicle.

OK: Go to next step

There is almost no difference in the displayed speed value.

HINT:

There is tolerance of 10 % in the speedometer indication.

ItemMeasurement Item / Range (Display)Normal Condition

SPD SEN RRRR speed sensor open detection / OPEN or

NORMALOPEN: Momentary interruption

SPD SEN RLRL speed sensor open detection / OPEN or

NORMALOPEN: Momentary interruption

ItemMeasurement Item / Range (Display)

Normal

Condition

WHEEL SPD RLWheel speed sensor (RL) reading / min.: 0 km/h (0 MPH,

max.: 326 km/h (202 MPH)Actual wheel

speed

WHEEL SPD RRWheel speed sensor (RR) reading / min.: 0 km/h (0 MPH,

max.: 326 km/h (202 MPH)Actual wheel

speed

Page 102 of 4500

HINT:

It is suspect that the DTCs output was caused by the poor connection on the connector terminal.

OK: REPLACE ABS & TRACTION ACTUATOR ASSY (SEE REPLACEMENT

)

CIRCUIT DESCRIPTION

If trouble occurs in the engine control system, the ECM transmits the abnormality to the skid control ECU. The

skid control ECU sets this DTC and the skid control ECU prohibits TRAC and VSC control.

DTC DETECTING CONDITION DESCRIPTION

INSPECTION PROCEDURE

1.CHECK HARNESS AND CONNECTOR (MOMENTARY INTERRUPTION)

a. Using the hand-held tester, check for any momentary interruption in the wire harness and connector

corresponding to a DTC (see CHECK FOR INTERMITTENT PROBLEMS

).

MEASUREMENT ITEM / RANGE (DISPLAY) DESCRIPTION

OK: Go to next step

There are no momentary interruptions.

HINT:

Perform the above inspection before removing the sensor and connector.

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR (ECM - SKID CONTROL ECU)

OK: Go to next step

2.CHECK DTC FOR ENGINE

a. Check if the normal code is recorded for en

gine control system.

DTC No.DTC Detecting ConditionTrouble Area

C1201/51At the engine speed of 500 RPM, a trouble signal in the engine

control system continues for 5 secs, or more.Engine control

system

ItemMeasurement Item / Range (Display)Normal Condition

EFI COMEFI communication open detectionOPEN: Momentary interruption

Page 478 of 4500

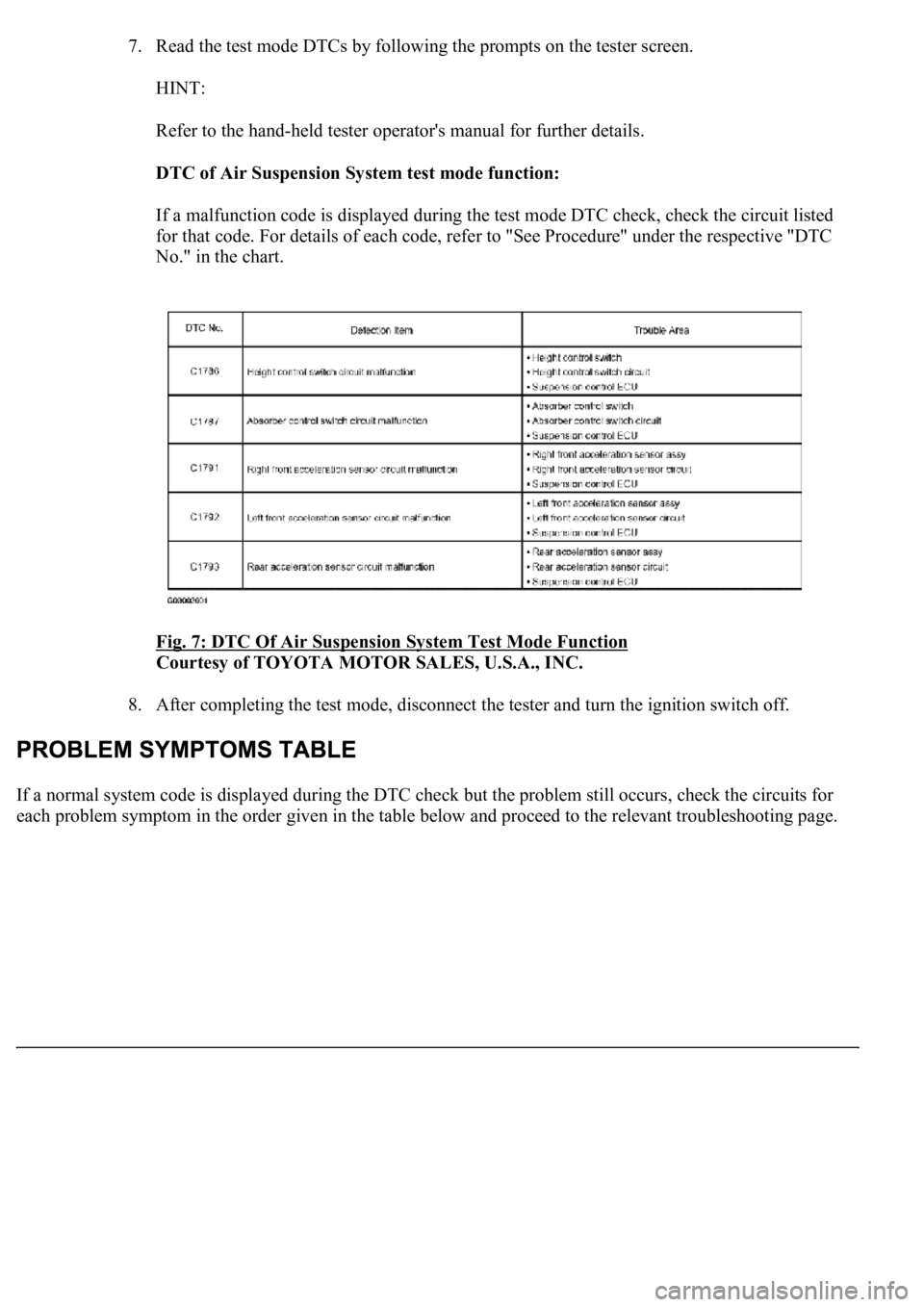

7. Read the test mode DTCs by following the prompts on the tester screen.

HINT:

Refer to the hand-held tester operator's manual for further details.

DTC of Air Suspension System test mode function:

If a malfunction code is displayed during the test mode DTC check, check the circuit listed

for that code. For details of each code, refer to "See Procedure" under the respective "DTC

No." in the chart.

Fig. 7: DTC Of Air Suspension System Test Mode Function

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

8. After completing the test mode, disconnect the tester and turn the ignition switch off.

If a normal system code is displayed during the DTC check but the problem still occurs, check the circuits for

each problem s

ymptom in the order given in the table below and proceed to the relevant troubleshooting page.

Page 525 of 4500

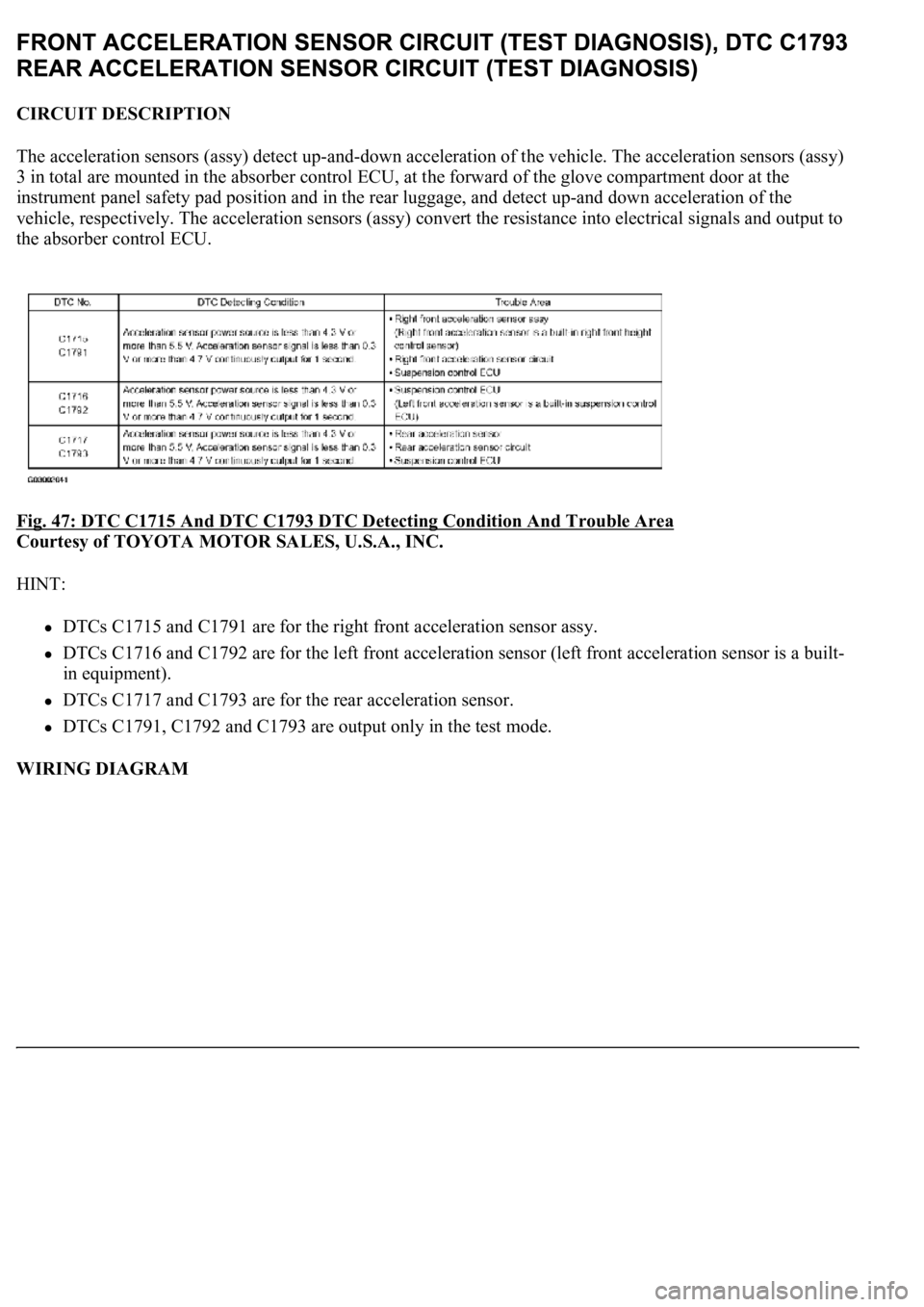

CIRCUIT DESCRIPTION

The acceleration sensors (assy) detect up-and-down acceleration of the vehicle. The acceleration sensors (assy)

3 in total are mounted in the absorber control ECU, at the forward of the glove compartment door at the

instrument panel safety pad position and in the rear luggage, and detect up-and down acceleration of the

vehicle, respectively. The acceleration sensors (assy) convert the resistance into electrical signals and output to

the absorber control ECU.

Fig. 47: DTC C1715 And DTC C1793 DTC Detecting Condition And Trouble Area

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

DTCs C1715 and C1791 are for the right front acceleration sensor assy.

DTCs C1716 and C1792 are for the left front acceleration sensor (left front acceleration sensor is a built-

in equipment).

DTCs C1717 and C1793 are for the rear acceleration sensor.

DTCs C1791, C1792 and C1793 are output only in the test mode.

WIRING DIAGRAM

Page 723 of 4500

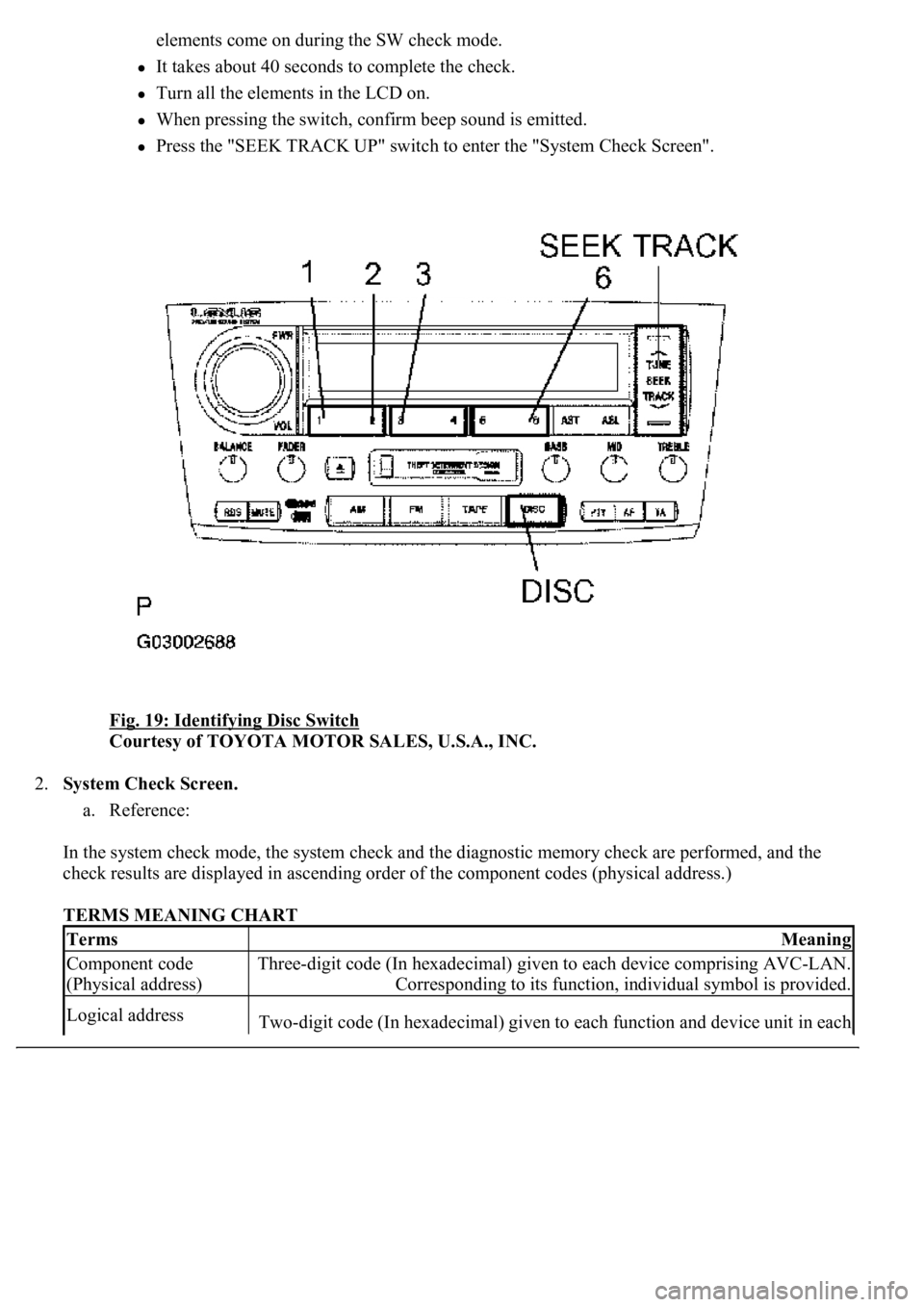

elements come on during the SW check mode.

It takes about 40 seconds to complete the check.

Turn all the elements in the LCD on.

When pressing the switch, confirm beep sound is emitted.

Press the "SEEK TRACK UP" switch to enter the "System Check Screen".

Fig. 19: Identifying Disc Switch

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

2.System Check Screen.

a. Reference:

In the system check mode, the system check and the diagnostic memory check are performed, and the

check results are displayed in ascending order of the component codes (physical address.)

TERMS MEANING CHART

TermsMeaning

Component code

(Physical address)Three-digit code (In hexadecimal) given to each device comprising AVC-LAN.

Corresponding to its function, individual symbol is provided.

Logical addressTwo-digit code (In hexadecimal) given to each function and device unit in each

Page 726 of 4500

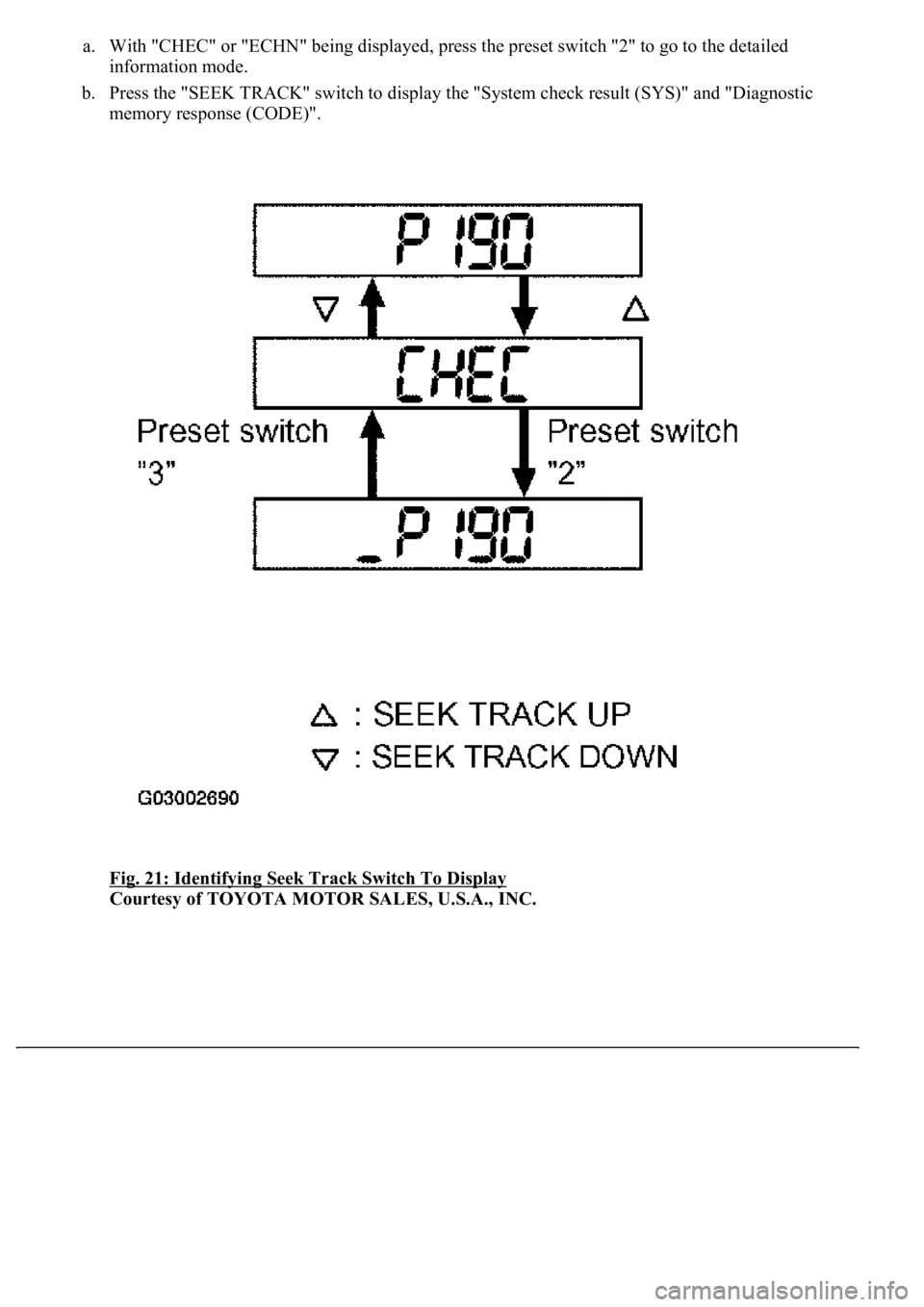

a. With "CHEC" or "ECHN" being displayed, press the preset switch "2" to go to the detailed

information mode.

b. Press the "SEEK TRACK" switch to display the "System check result (SYS)" and "Diagnostic

memory response (CODE)".

Fig. 21: Identifying Seek Track Switch To Display

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 818 of 4500

PRECAUTION

1. The automatic transmission is composed of highly precision-finished parts which need careful inspection

before reassembly because even a small nick could cause fluid leakage or affect performance. The

instructions here are organized so that you work on only one component group at a time. This will help

avoid confusion from similar-looking parts of different sub-assemblies being on your workbench at the

same time. The component groups should be inspected and repaired from the converter housing side.

Inspect, repair and reassemble as much as possible before proceeding to the next component group. If a

defect is found in a certain component group during reassembly, inspect and repair this group

immediately. If a component group cannot be assembled because parts are being ordered, be sure to keep

all parts of the group in a separate container while proceeding with disassembly, inspection, repair and

reassembly of other component groups. Recommended ATF: ATF WS

2. All disassembled parts should be washed clean and any fluid passages and holes should be blown through

with compressed air.

3. Dry all parts with compressed air. Never use shop rags.

4. When using compressed air, be careful not to not aim at yourself to prevent accidentally spraying ATF or

kerosene on your face.

5. Only recommended automatic transaxle fluid or kerosene should be used for cleaning.

6. After cleaning, the parts should be arranged in the correct order for efficient inspection, repairs, and

reassembly.

7. When disassembling a valve body, be sure to match each valve together with the corresponding spring.

8. New discs for the brakes and clutches that are to be used for replacement must be soaked in ATF for at

least 15 minutes before reassembly.

9. All oil seal rings, clutch discs, clutch plates, rotating parts, and sliding surfaces should be coated with

ATF prior to reassembly.

10. All gaskets and rubber O-rings should be replaced.

11. Do not apply adhesive cements to gaskets or similar parts.

12. Make sure that the ends of a snap ring are not aligned with one of the cutouts and are installed in the

groove correctly.

13. When replacing a worn bushing, the sub-assembly containing the bushing must also be replaced.

14. Check thrust bearings and races for wear or damage. Replace them as necessary.

15. Use petroleum jelly to keep parts in place.

16. When working with FIPG material, perform the following: Using a razor blade and a gasket scraper,

remove all the old packing (FIPG) material from the gasket surface.

Thoroughly clean all components to remove any loose material.