pcv LEXUS LS430 2003 Factory Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 2010 of 4500

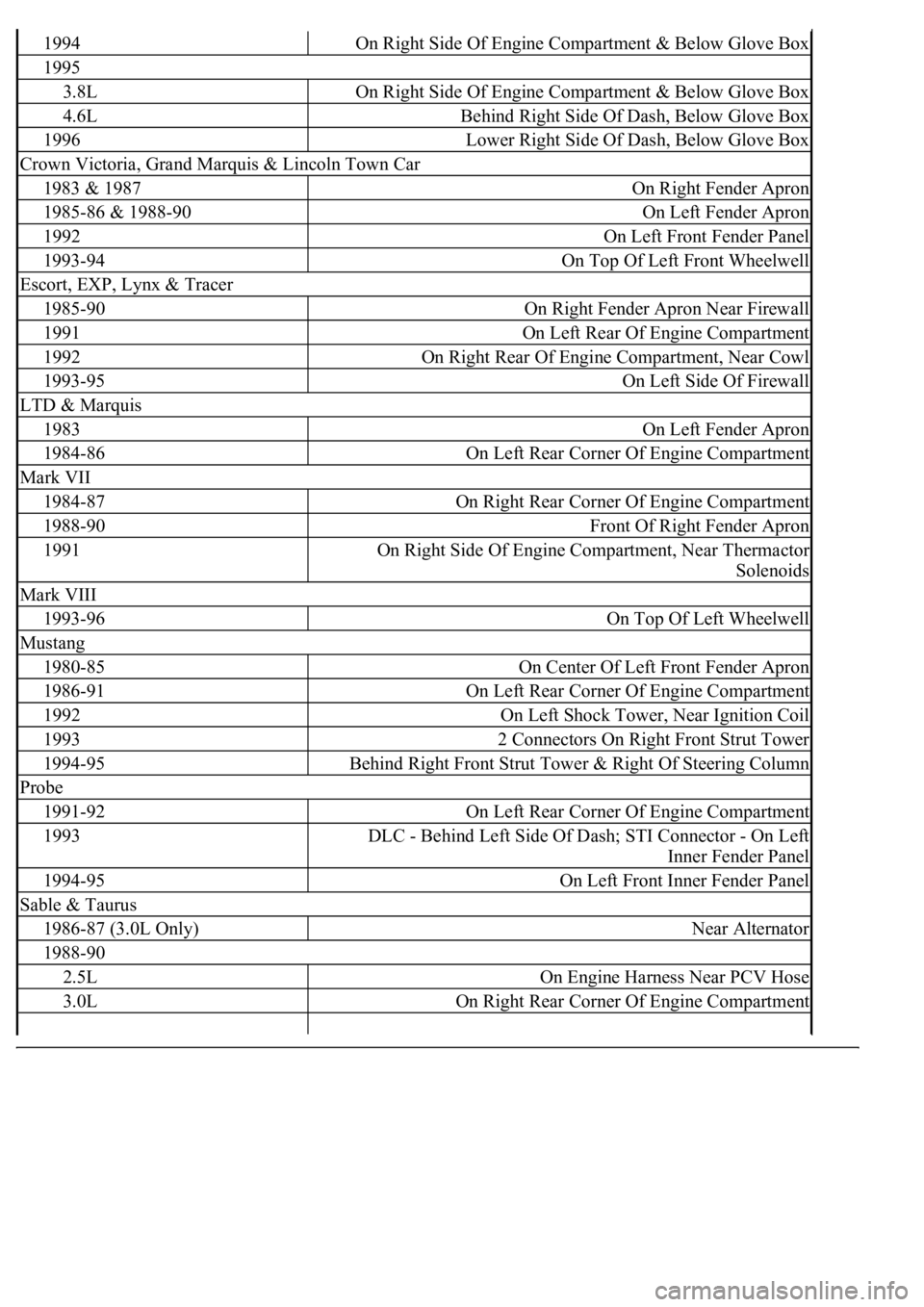

1994On Right Side Of Engine Compartment & Below Glove Box

1995

3.8LOn Right Side Of Engine Compartment & Below Glove Box

4.6LBehind Right Side Of Dash, Below Glove Box

1996Lower Right Side Of Dash, Below Glove Box

Crown Victoria, Grand Marquis & Lincoln Town Car

1983 & 1987On Right Fender Apron

1985-86 & 1988-90On Left Fender Apron

1992On Left Front Fender Panel

1993-94On Top Of Left Front Wheelwell

Escort, EXP, Lynx & Tracer

1985-90On Right Fender Apron Near Firewall

1991On Left Rear Of Engine Compartment

1992On Right Rear Of Engine Compartment, Near Cowl

1993-95On Left Side Of Firewall

LTD & Marquis

1983On Left Fender Apron

1984-86On Left Rear Corner Of Engine Compartment

Mark VII

1984-87On Right Rear Corner Of Engine Compartment

1988-90Front Of Right Fender Apron

1991On Right Side Of Engine Compartment, Near Thermactor

Solenoids

Mark VIII

1993-96On Top Of Left Wheelwell

Mustang

1980-85On Center Of Left Front Fender Apron

1986-91On Left Rear Corner Of Engine Compartment

1992On Left Shock Tower, Near Ignition Coil

19932 Connectors On Right Front Strut Tower

1994-95Behind Right Front Strut Tower & Right Of Steering Column

Probe

1991-92On Left Rear Corner Of Engine Compartment

1993DLC - Behind Left Side Of Dash; STI Connector - On Left

Inner Fender Panel

1994-95On Left Front Inner Fender Panel

Sable & Taurus

1986-87 (3.0L Only)Near Alternator

1988-90

2.5LOn Engine Harness Near PCV Hose

3.0LOn Right Rear Corner Of Engine Compartment

Page 2905 of 4500

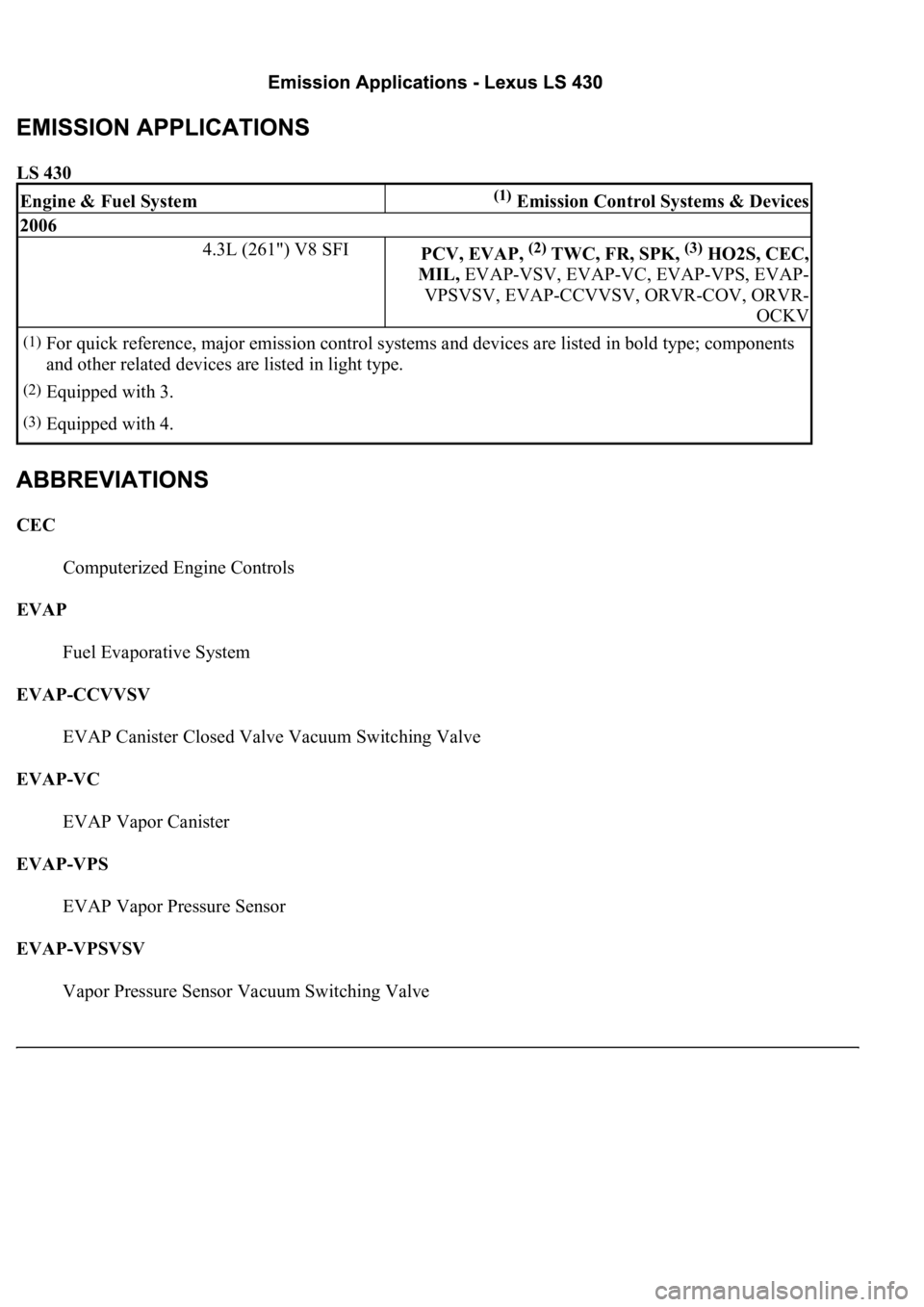

LS 430

CEC

Computerized Engine Controls

EVAP

Fuel Evaporative System

EVAP-CCVVSV

EVAP Canister Closed Valve Vacuum Switching Valve

EVAP-VC

EVAP Vapor Canister

EVAP-VPS

EVAP Vapor Pressure Sensor

EVAP-VPSVSV

Vapor Pressure Sensor Vacuum Switching Valve

Engine & Fuel System(1) Emission Control Systems & Devices

2006

4.3L (261") V8 SFIPCV, EVAP, (2) TWC, FR, SPK, (3) HO2S, CEC,

MIL, EVAP-VSV, EVAP-VC, EVAP-VPS, EVAP-

VPSVSV, EVAP-CCVVSV, ORVR-COV, ORVR-

OCKV

(1)For quick reference, major emission control systems and devices are listed in bold type; components

and other related devices are listed in light type.

(2)Equipped with 3.

(3)Equipped with 4.

Page 2906 of 4500

EVAP-VSV

EVAP Vacuum Switching Valve

FR

Fill Pipe Restrictor

HO2S

Heated Oxygen Sensor

MIL

Malfunction Indicator Light

ORVR-COV

On-Board Refueling Vapor Recovery Cut-Off Valve

ORVR-OCKV

On-Board Refueling Vapor Recovery Overfill Check Valve

PCV

Positive Crankcase Ventilation

SFI

Sequential Multiport Fuel Injection

SPK-CC

SPK Computer Controlled

TWC

Three-Way Catalytic Converter

WU-TWC

Warm-Up Three-Wa

y Catalytic Converter

Page 2913 of 4500

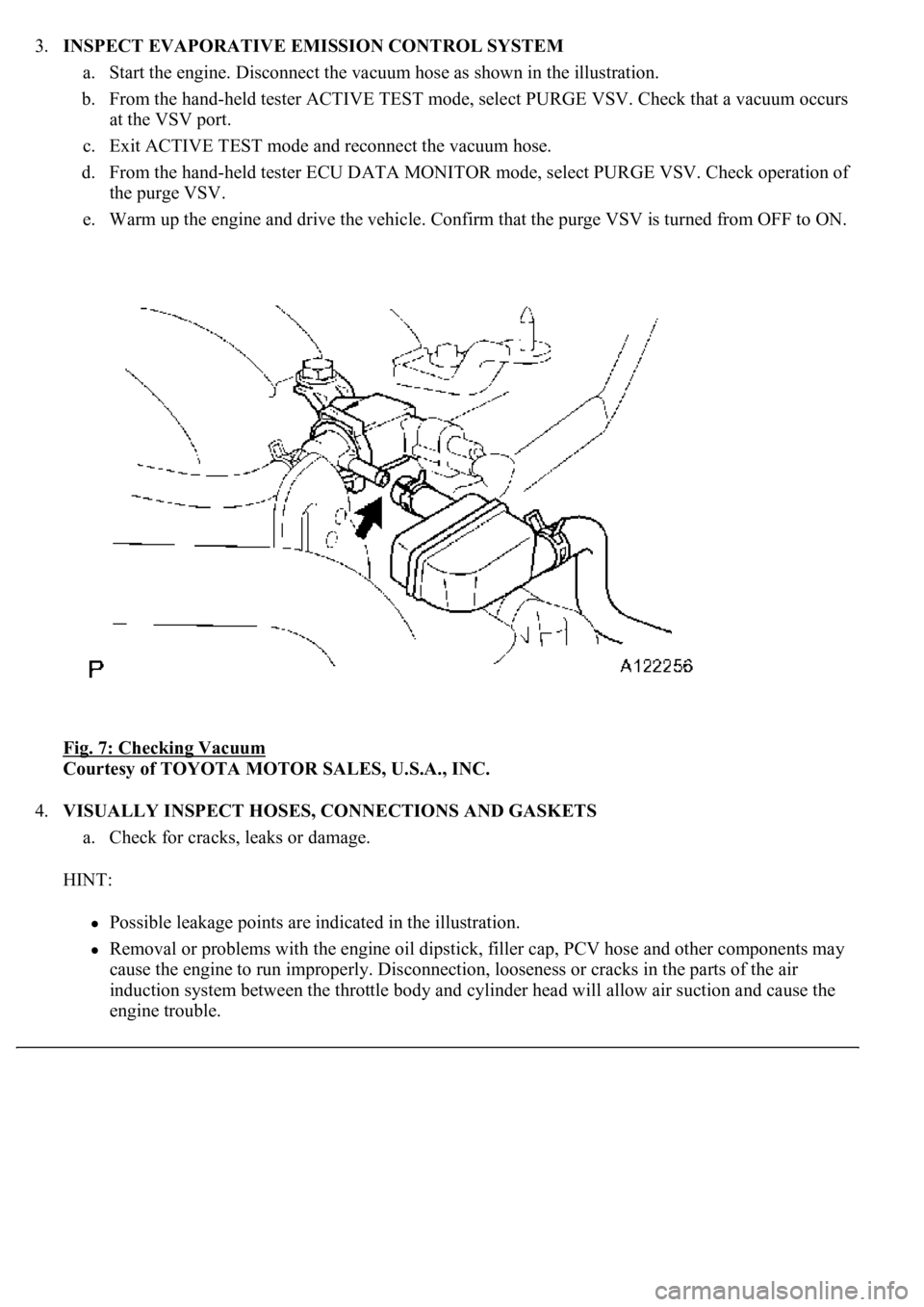

3.INSPECT EVAPORATIVE EMISSION CONTROL SYSTEM

a. Start the engine. Disconnect the vacuum hose as shown in the illustration.

b. From the hand-held tester ACTIVE TEST mode, select PURGE VSV. Check that a vacuum occurs

at the VSV port.

c. Exit ACTIVE TEST mode and reconnect the vacuum hose.

d. From the hand-held tester ECU DATA MONITOR mode, select PURGE VSV. Check operation of

the purge VSV.

e. Warm up the engine and drive the vehicle. Confirm that the purge VSV is turned from OFF to ON.

Fig. 7: Checking Vacuum

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

4.VISUALLY INSPECT HOSES, CONNECTIONS AND GASKETS

a. Check for cracks, leaks or damage.

HINT:

Possible leakage points are indicated in the illustration.

Removal or problems with the engine oil dipstick, filler cap, PCV hose and other components may

cause the engine to run improperly. Disconnection, looseness or cracks in the parts of the air

induction system between the throttle body and cylinder head will allow air suction and cause the

engine trouble.

Page 4408 of 4500

6.REMOVE THROTTLE BODY ASSY

a. Disconnect the connector from the throttle body.

b. Disconnect the PCV hose.

c. Disconnect the 2 water by-pass hoses.

HINT:

It is not necessary to disconnect the water by-pass hose that has both ends connected to the throttle

body.

d. Remove the 2 bolts, 2 nuts and throttle body.

7.REMOVE V-BANK COVER BRACKET NO. 1

a. Remove the bolt and cover bracket.

8.REMOVE V-BANK COVER BRACKET NO. 2

a. Remove the bolt and cover bracket.

9.REMOVE V-BANK COVER BRACKET NO. 3

a. Remove the bolt and cover bracket.

10.REMOVE V-BANK COVER BRACKET NO. 4

a. Remove the 2 nuts and cover bracket.

11.REMOVE VACUUM SWITCHING VALVE ASSY FOR EVAP

a. Disconnect the VSV connector.

b. Disconnect the 2 hoses from the VSV.

c. Remove the bolt and VSV.

12.DISCONNECT FUEL PIPE SUB-ASSY NO. 2

a. Using SST, disconnect the fuel main hose.

SST 09023-38401

Page 4412 of 4500

a. Install the cover bracket with the bolt.

Torque: 7.5 N.m (76 kgf.cm, 66 in.lbf)

23.INSTALL THROTTLE BODY ASSY

a. Install the throttle body with the 2 bolts and 2 nuts.

b. Connect the water by-pass hose.

c. Connect the PCV hose.

d. Connect the connector to the throttle body.

24.INSTALL INTAKE AIR CONNECTOR PIPE

a. Install the intake air connector pipe with the bolt and hose clamp.

Torque:

4.0 N.m (40 kgf.cm, 35 in.lbf) for hose clamp

5.0 N.m (50 kgf.cm, 44 in.lbf) for bolt

b. Connect the air hose and ventilation hose No. 1 together.

25.INSTALL AIR CLEANER INLET NO. 1

26.INSPECT FUEL PUMP OPERATION AND CHECK FOR FUEL LEAKS

27.INSTALL V-BANK COVER

a. Install the V-bank cover with the 2 nuts.

Torque: 5.0 N.m (50 kgf.cm, 44 in.lbf)

28.REFILL ENGINE COOLANT

29.CHECK FOR ENGINE COOLANT LEAKS

a. Check for engine coolant leaks.

If leaks are present, find the leak and repair or replace parts as necessar

y.