replacement LEXUS LS430 2003 Factory Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 1 of 4500

LS430 SPECIFICATIONS INDEX

SystemSpecification/Procedure

Air Conditioning

ServiceSERVICE DATA

TorqueTORQUE SPECIFICATION

Axle Nut/Hub Nut

Front69 N.m (700 kgf.cm, 51 ft.lbf)

Rear290 N.m (2,960 kgf.cm, 214 ft.lbf)

BatteryNA

Brakes

Bleeding

SequenceBLEEDING

Disc BrakesSERVICE DATA

TorqueTORQUE SPECIFICATION

Charging

GeneratorSERVICE DATA

TorqueTORQUE SPECIFICATION

Drive Belts

AdjustmentREPLACEMENT

Belt RoutingDRIVE BELT

Engine Cooling

General Service

SpecificationsSERVICE DATA

Radiator Cap

PressureStandard Value

93 to 123 kPa (0.95 to 1.25 kgf/cm

2 , 13.5 to 17.8 psi)

Minimum Standard Value

78 kPa (0.8 kgf/cm

2 , 11.4 psi)

Thermostat R & ITHERMOSTAT

Water Pump R &

IWATER PUMP

Engine Mechanical

CompressionSERVICE DATA

Oil Pressureat idle, 29 kPa (0.3 kgf.cm2 , 43 psi) or more

at 3,000 rpm, 294 to 588 kPa (3.0 to 6.0 kgf.cm

2 , 43 to 85 psi)

OverhaulSERVICE DATA

TorqueTORQUE SPECIFICATION

Page 65 of 4500

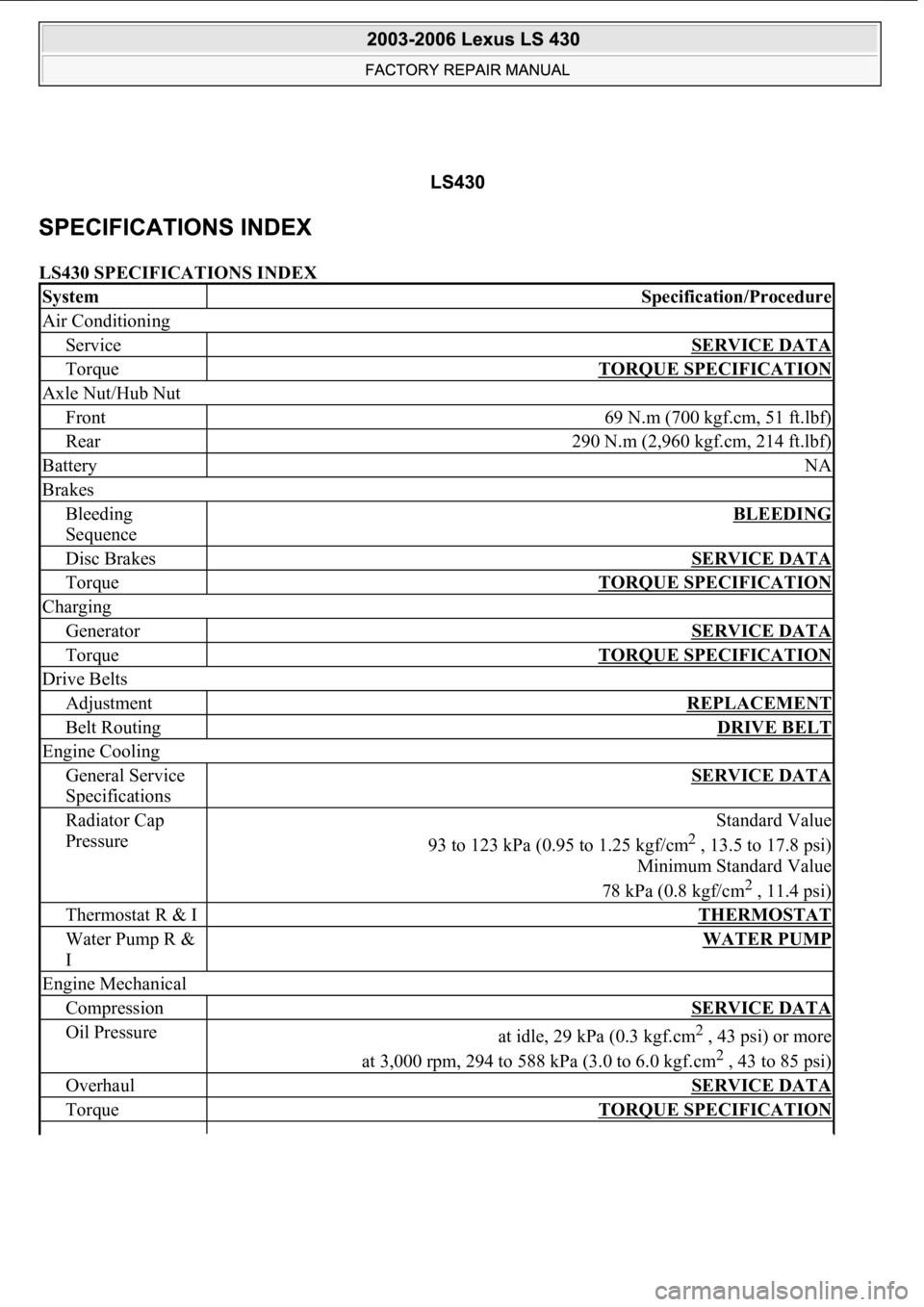

Fig. 47: Normal Signal Waveform

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OK: REPLACE ABS & TRACTION ACTUATOR ASSY (SEE REPLACEMENT

)

4.INSPECT FRONT SPEED SENSOR

Page 68 of 4500

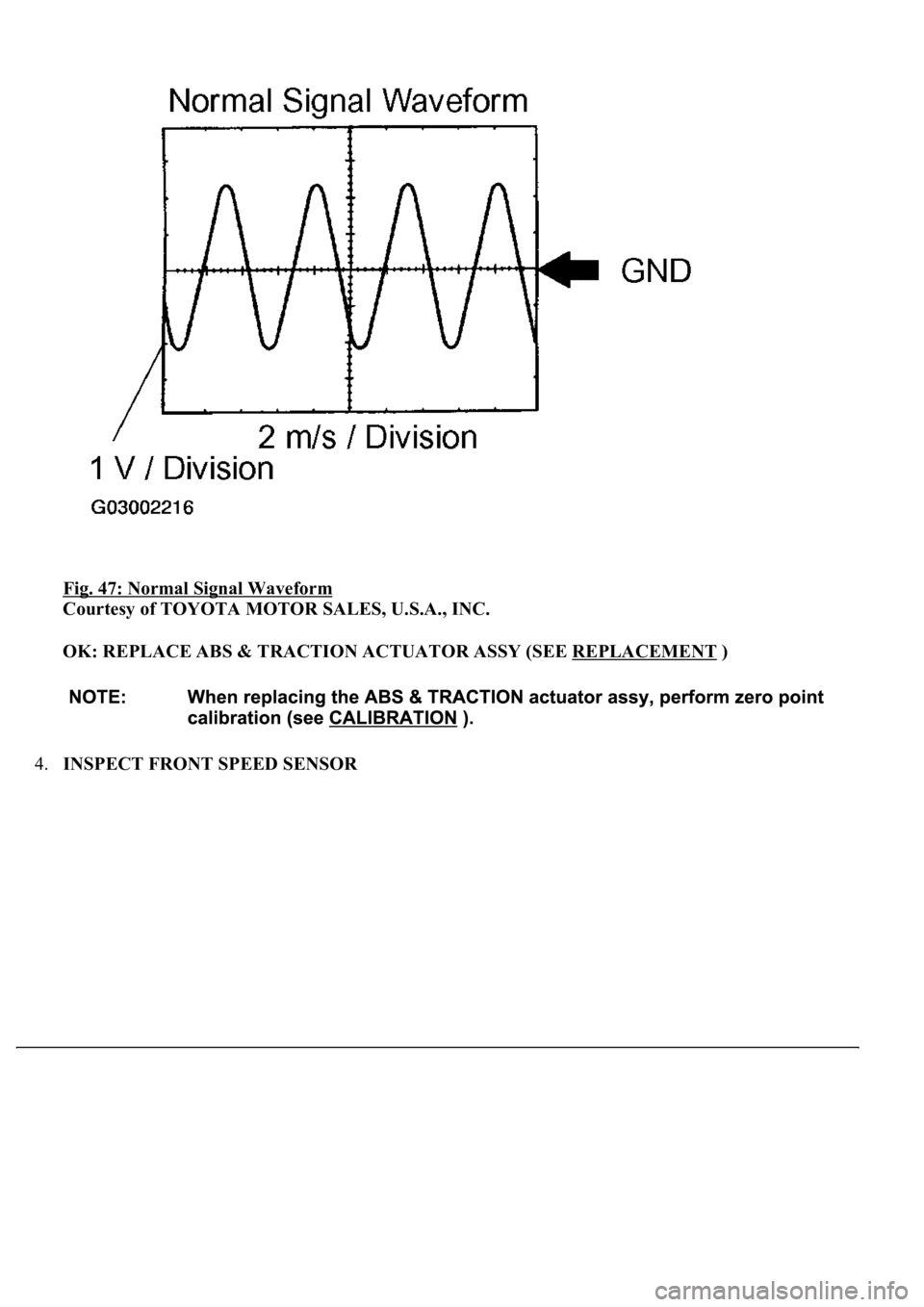

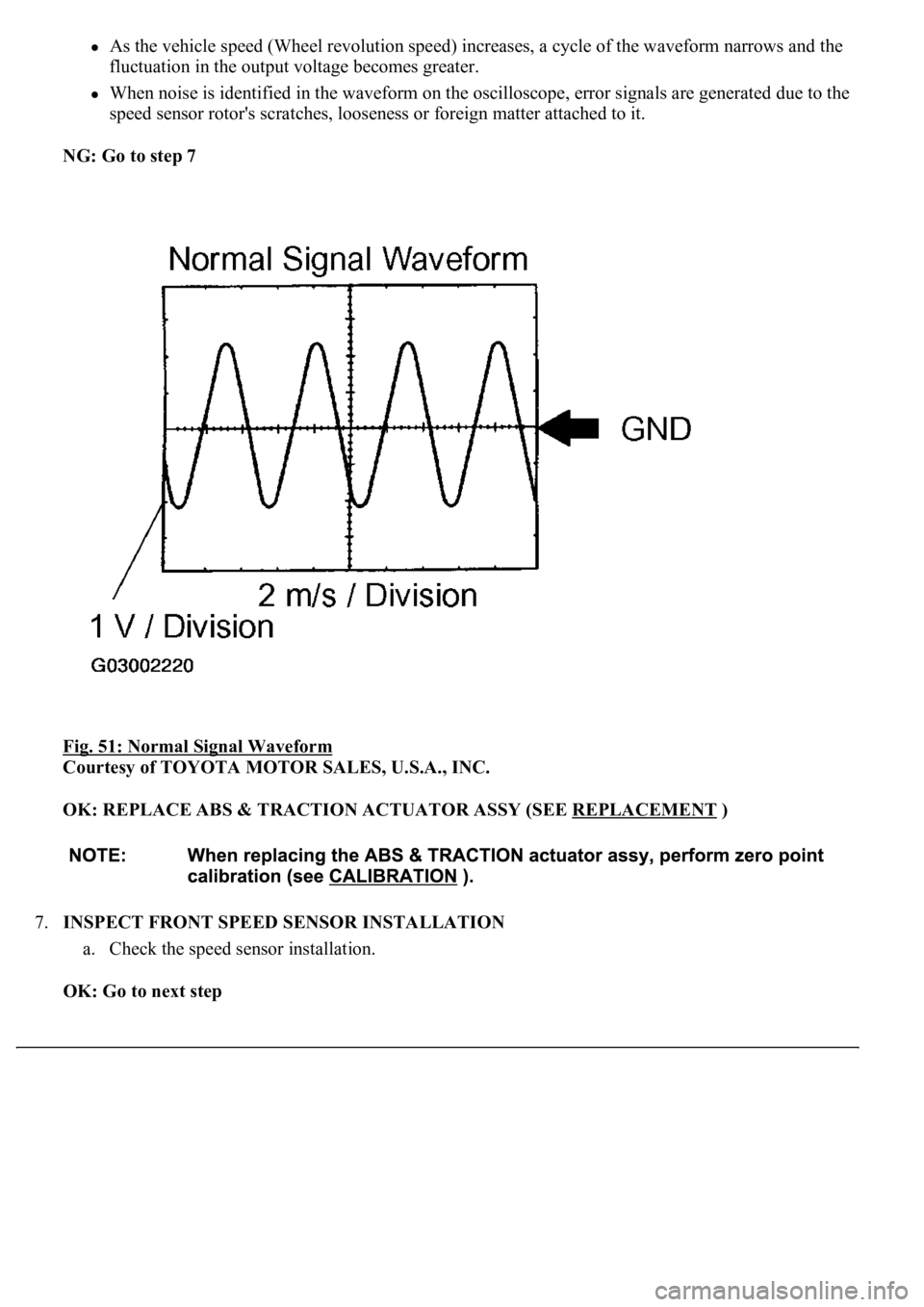

f. Measure the resistance according to the value (s) in the table below.

Standard:

TESTER CONNECTION SPECIFIED CONDITION LH:

TESTER CONNECTION SPECIFIED CONDITION RH:

NG: REPLACE FRONT SPEED SENSOR (SEE REPLACEMENT

)

Tester ConnectionSpecified Condition

(Connector A-1) - Body ground1 Mohms or higher

(Connector A-2) - Body ground1 Mohms or higher

Tester ConnectionSpecified Condition

(Connector A-1) - Body ground1 Mohms or higher

(Connector A-2) - Body ground1 Mohms or higher

Page 72 of 4500

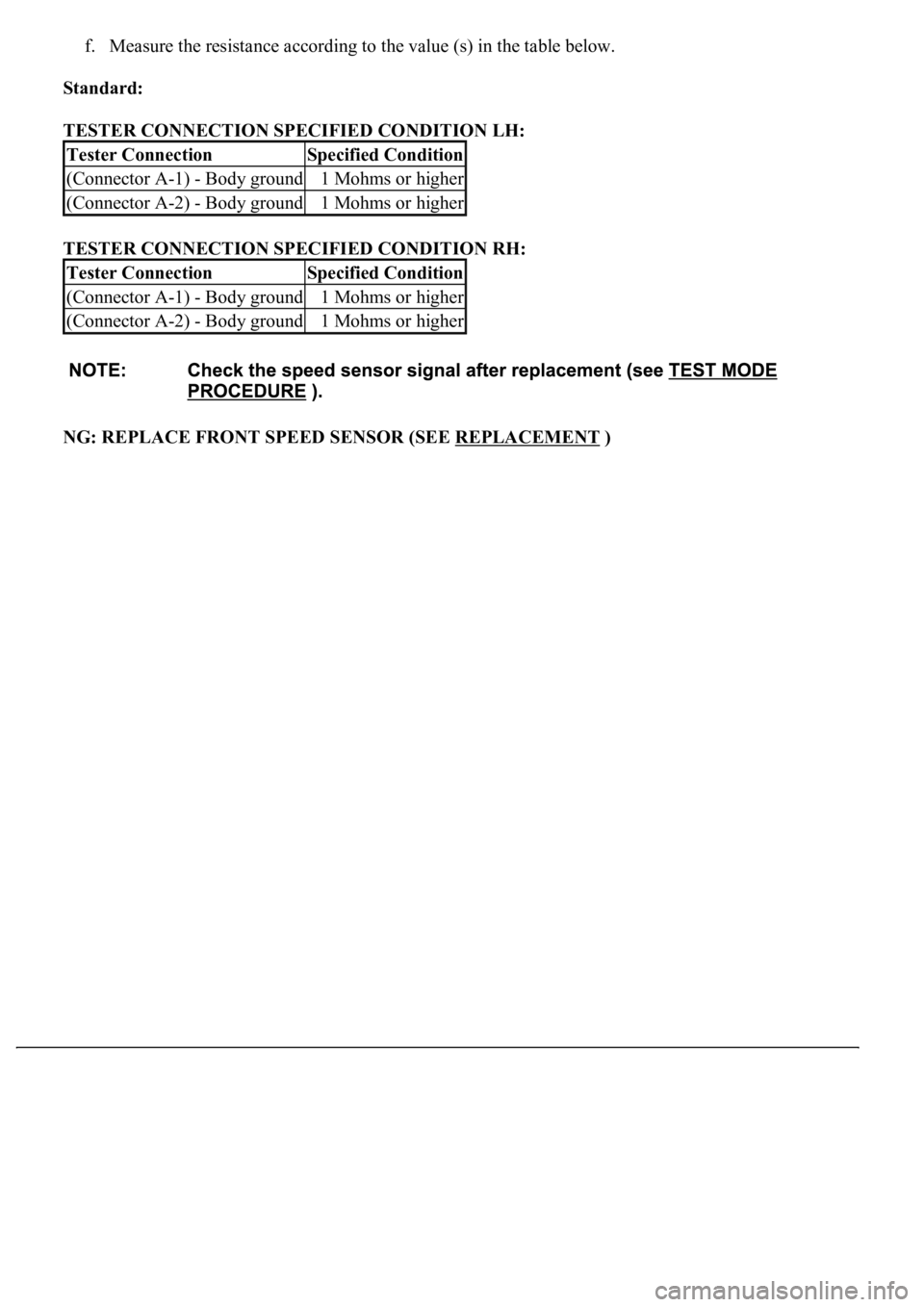

As the vehicle speed (Wheel revolution speed) increases, a cycle of the waveform narrows and the

fluctuation in the output voltage becomes greater.

When noise is identified in the waveform on the oscilloscope, error signals are generated due to the

speed sensor rotor's scratches, looseness or foreign matter attached to it.

NG: Go to step 7

Fig. 51: Normal Signal Waveform

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OK: REPLACE ABS & TRACTION ACTUATOR ASSY (SEE REPLACEMENT

)

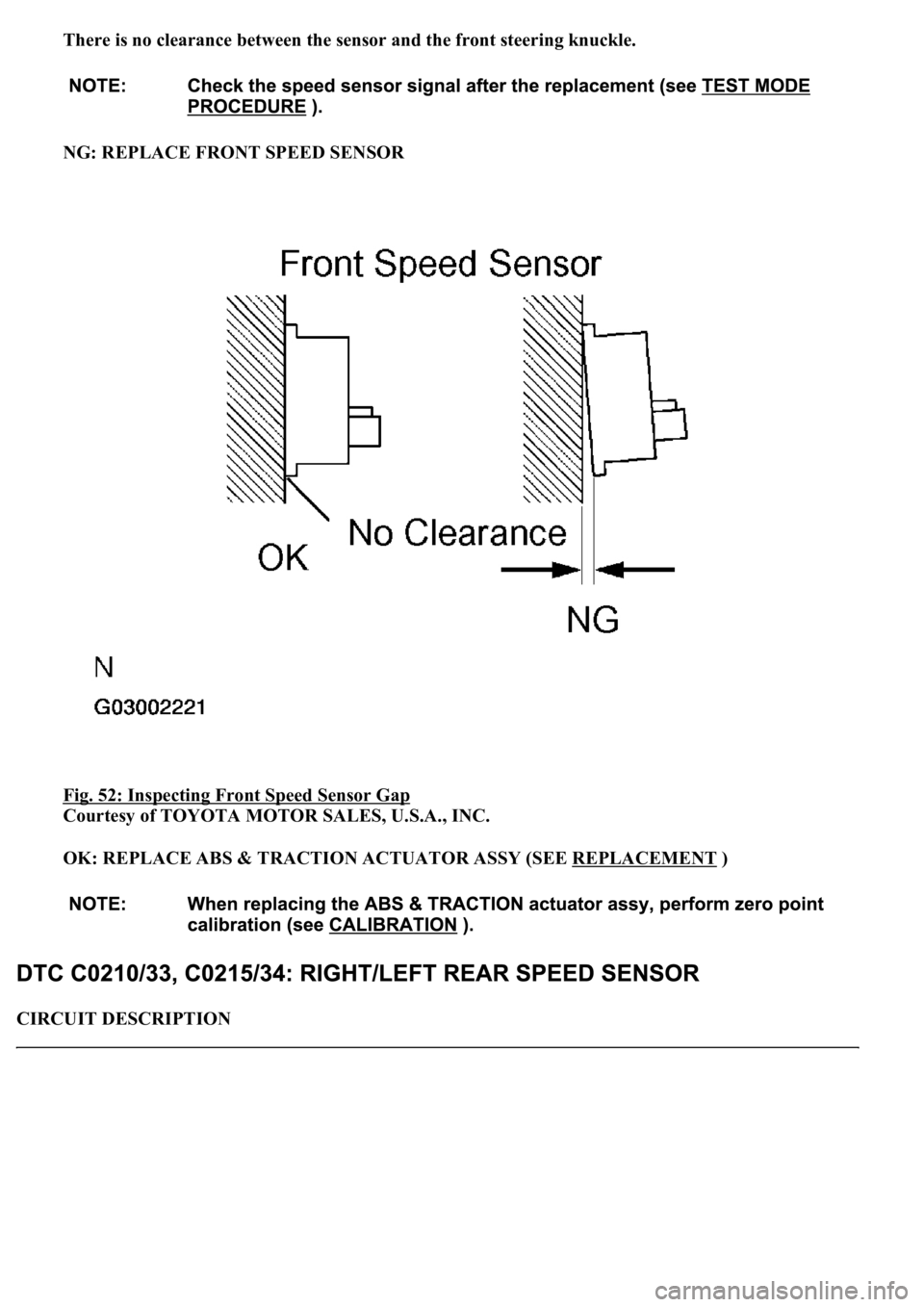

7.INSPECT FRONT SPEED SENSOR INSTALLATION

a. Check the speed sensor installation.

OK: Go to next step

Page 73 of 4500

There is no clearance between the sensor and the front steering knuckle.

NG: REPLACE FRONT SPEED SENSOR

Fig. 52: Inspecting Front Speed Sensor Gap

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OK: REPLACE ABS & TRACTION ACTUATOR ASSY (SEE REPLACEMENT

)

CIRCUIT DESCRIPTION

Page 77 of 4500

fluctuation in the output voltage becomes greater.

When noise is identified in the waveform on the oscilloscope, error signals are generated due to the

speed sensor rotor's scratches, looseness or foreign matter attached to it.

NG: Go to step 7

OK: REPLACE ABS & TRACTION ACTUATOR ASSY (SEE REPLACEMENT

)

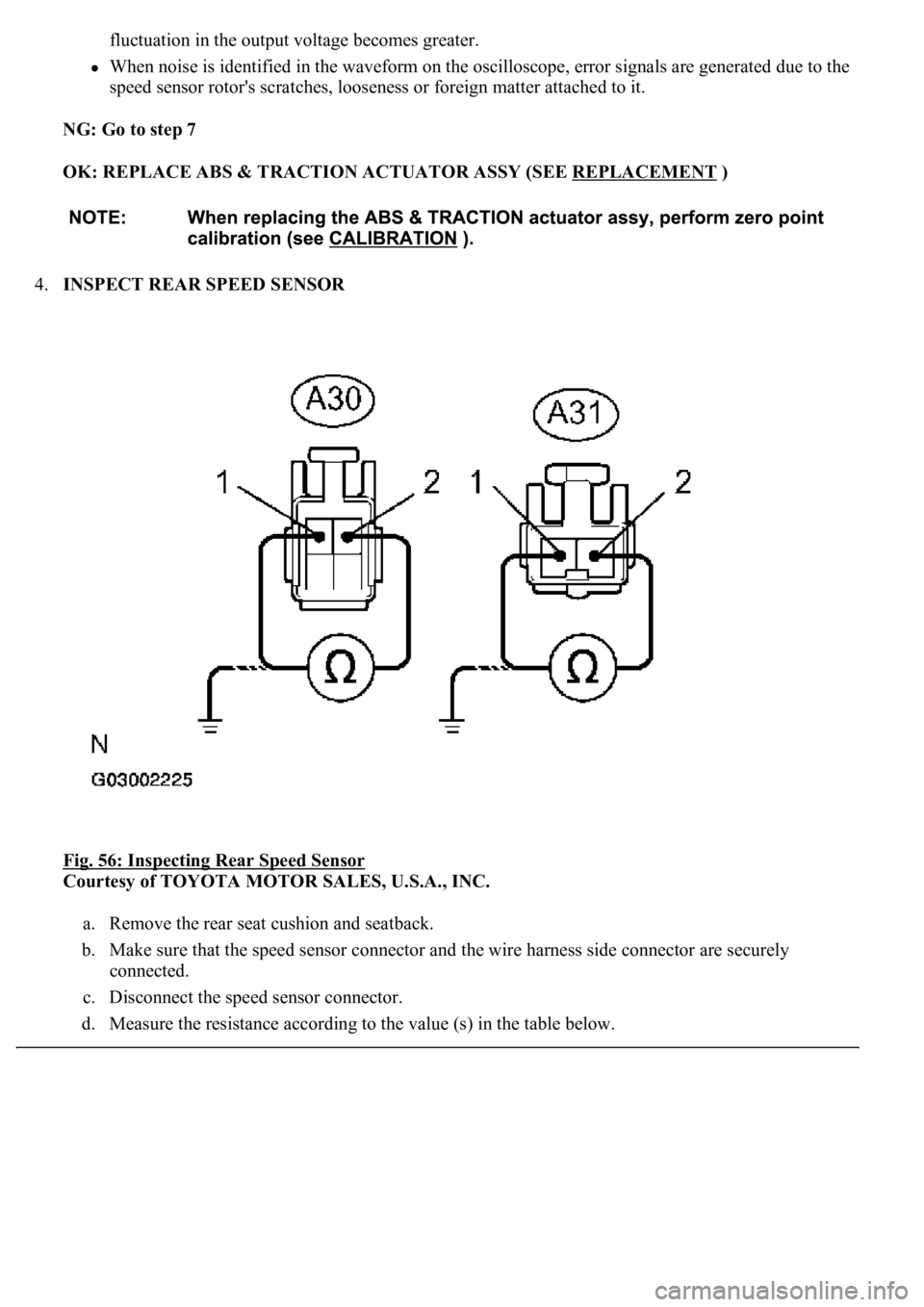

4.INSPECT REAR SPEED SENSOR

Fig. 56: Inspecting Rear Speed Sensor

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

a. Remove the rear seat cushion and seatback.

b. Make sure that the speed sensor connector and the wire harness side connector are securely

connected.

c. Disconnect the speed sensor connector.

d. Measure the resistance accordin

g to the value (s) in the table below.

Page 78 of 4500

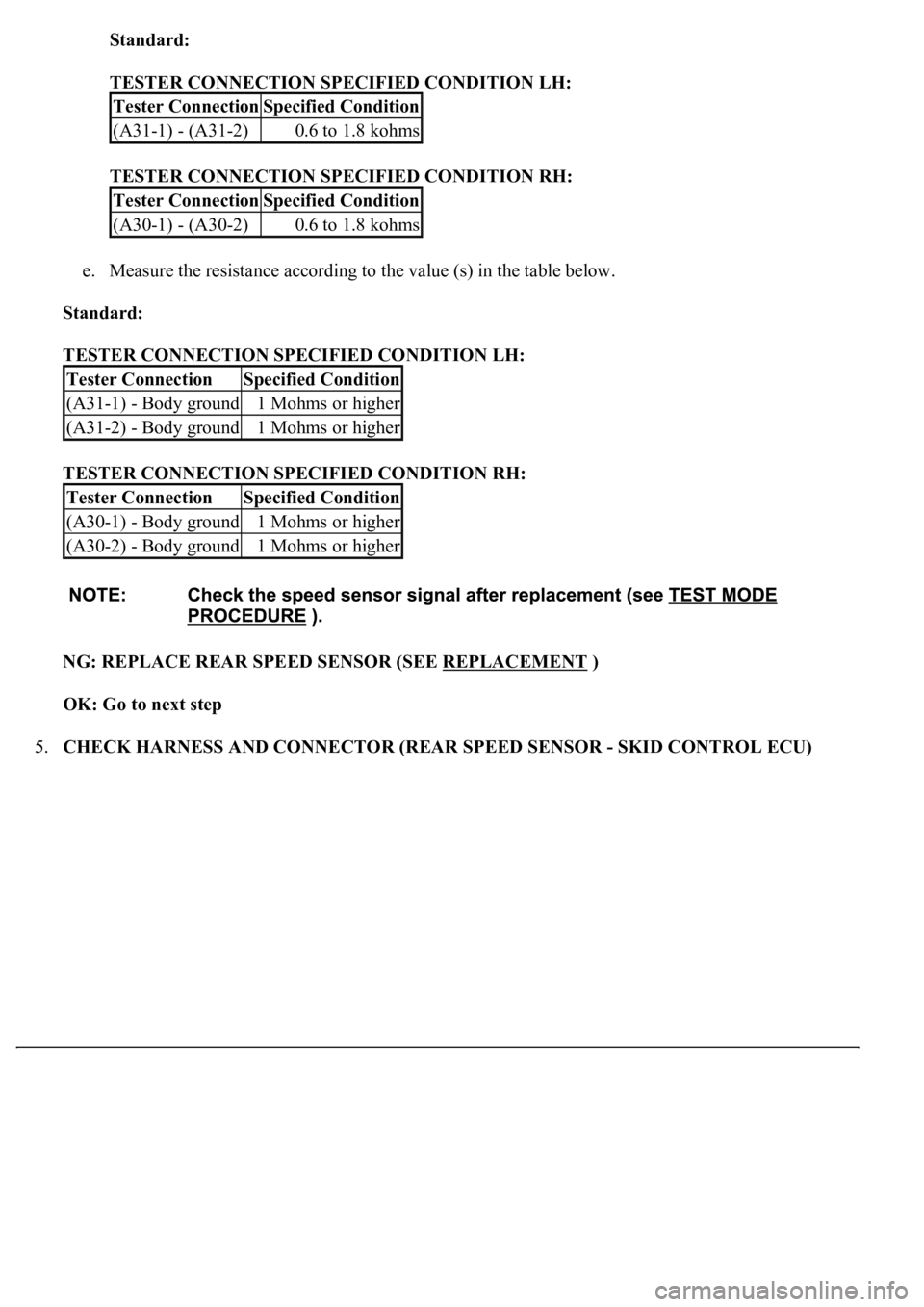

Standard:

TESTER CONNECTION SPECIFIED CONDITION LH:

TESTER CONNECTION SPECIFIED CONDITION RH:

e. Measure the resistance according to the value (s) in the table below.

Standard:

TESTER CONNECTION SPECIFIED CONDITION LH:

TESTER CONNECTION SPECIFIED CONDITION RH:

NG: REPLACE REAR SPEED SENSOR (SEE REPLACEMENT

)

OK: Go to next step

5.CHECK HARNESS AND CONNECTOR (REAR SPEED SENSOR - SKID CONTROL ECU)

Tester ConnectionSpecified Condition

(A31-1) - (A31-2)0.6 to 1.8 kohms

Tester ConnectionSpecified Condition

(A30-1) - (A30-2)0.6 to 1.8 kohms

Tester ConnectionSpecified Condition

(A31-1) - Body ground1 Mohms or higher

(A31-2) - Body ground1 Mohms or higher

Tester ConnectionSpecified Condition

(A30-1) - Body ground1 Mohms or higher

(A30-2) - Body ground1 Mohms or higher

Page 82 of 4500

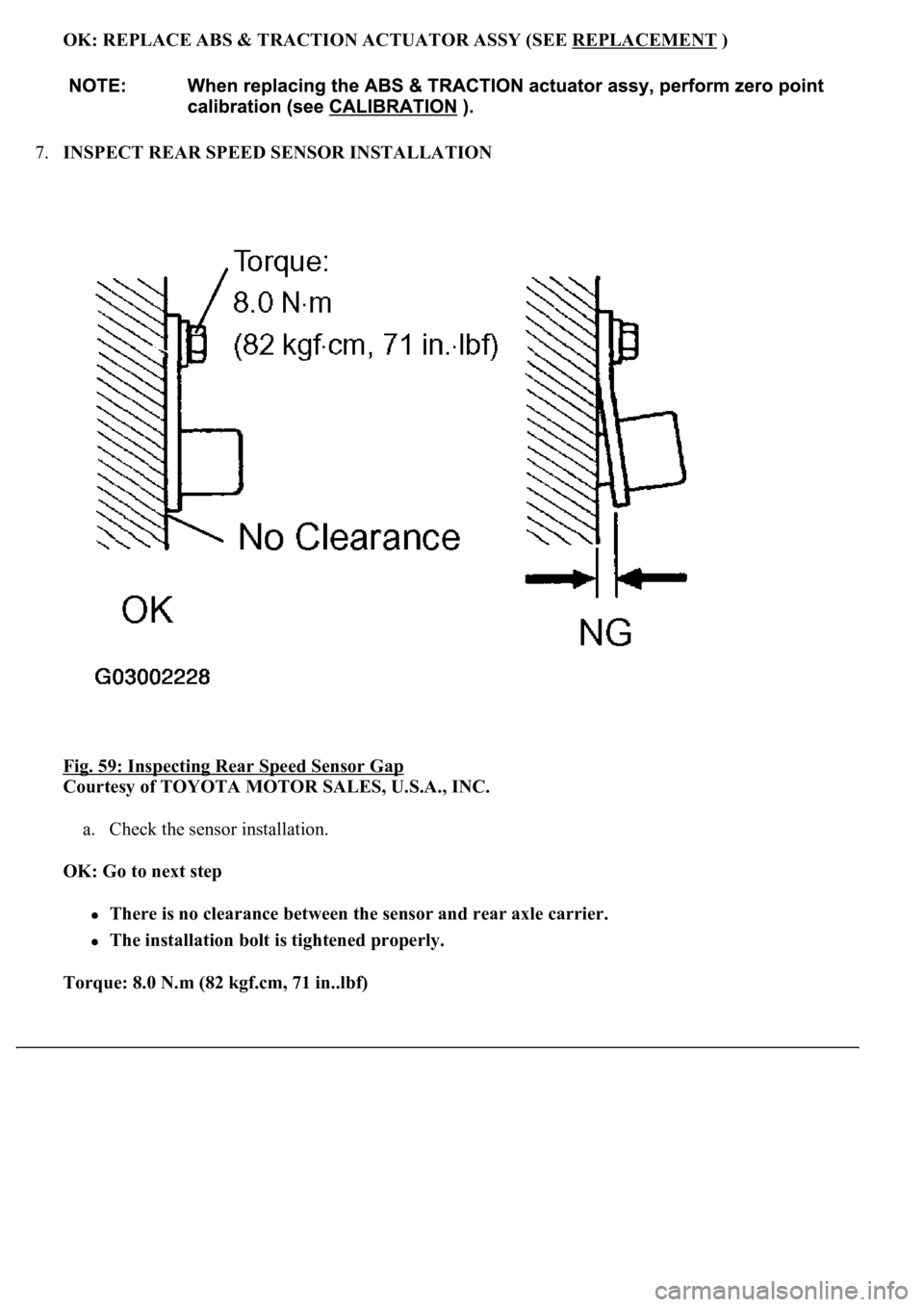

OK: REPLACE ABS & TRACTION ACTUATOR ASSY (SEE REPLACEMENT )

7.INSPECT REAR SPEED SENSOR INSTALLATION

Fig. 59: Inspecting Rear Speed Sensor Gap

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

a. Check the sensor installation.

OK: Go to next step

There is no clearance between the sensor and rear axle carrier.

The installation bolt is tightened properly.

Torque: 8.0 N.m (82 kgf.cm, 71 in..lbf)

Page 83 of 4500

NG: REPLACE REAR SPEED SENSOR

OK: REPLACE ABS & TRACTION ACTUATOR ASSY (SEE REPLACEMENT

)

CIRCUIT DESCRIPTION

<0037004b004c0056000300560052004f004800510052004c00470003005700580055005100560003005200510003005a004b0048005100030056004c004a00510044004f0056000300440055004800030055004800460048004c0059004800470003004900

550052005000030057004b0048000300280026003800030044[nd controls the pressure acting on the wheel

c

ylinders to control the braking force.

Page 86 of 4500

OK: Go to next step

The same DTC is recorded.

NG: PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS

TABLE

OK: REPLACE ABS & TRACTION ACTUATOR ASSY (SEE REPLACEMENT

)

CIRCUIT DESCRIPTION

The ABS motor relays consist of 2 relays are included in the engine room No.3 R/B.

The ABS cut relay is turned on after turning the ignition switch to the ON position. If the DTCs in the

ABS pump motor circuit are memorized, the ABS cut relay cuts off the power supply to the ABS motor

relay and performs the fail safe.

While any of the ABS, BA, TRAC and VSC is operating, the skid control ECU (included in the actuator)

<0057005800550051005600030057004b00480003002400250036000300500052005700520055000300550048004f0044005c0003005200510003005700520003005200530048005500440057004800030057004b0048000300440046005700580044005700

52005500030053005800500053000300500052005700520055[.

If the voltage applied to the ABS motor relays (+BM) drops below the condition that detects the DTCs

due to the shorta

ge of the battery or alternator output, the DTCs may be memorized.