LEXUS SC400 1991 Service Repair Manual

Manufacturer: LEXUS, Model Year: 1991,

Model line: SC400,

Model: LEXUS SC400 1991

Pages: 4087, PDF Size: 75.75 MB

LEXUS SC400 1991 Service Repair Manual

SC400 1991

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57051/w960_57051-0.png

LEXUS SC400 1991 Service Repair Manual

Trending: water pump, set clock, oil change, maintenance schedule, exhaust, wiper blades, transmission oil

Page 1911 of 4087

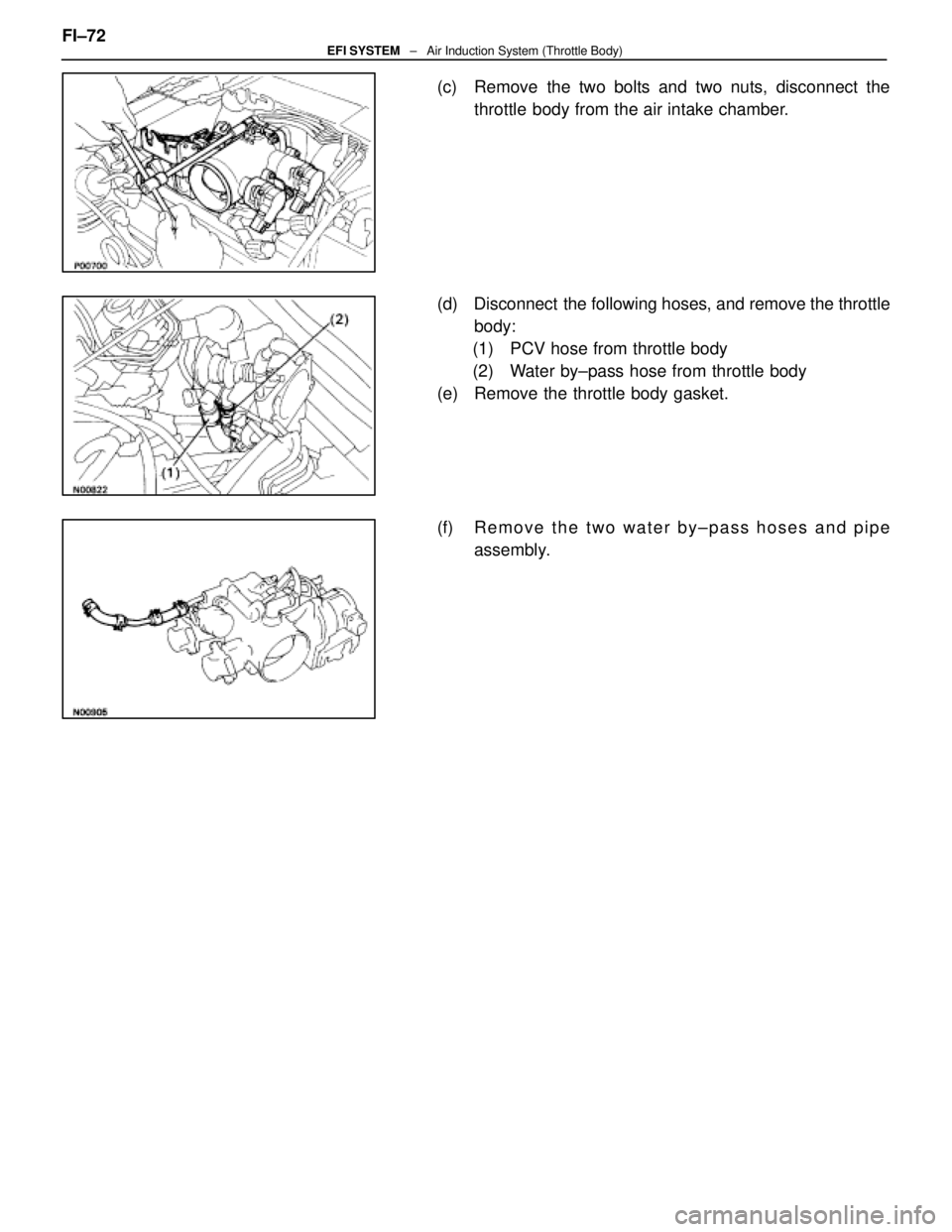

(c) Remove the two bolts and two nuts, disconnect thethrottle body from the air intake chamber.

(d) Disconnect the following hoses, and remove the throttle body:

(1) PCV hose from throttle body

(2) Water by±pass hose from throttle body

(e) Remove the throttle body gasket.

(f) R e m o v e t h e t w o w a t e r b y ±pass hoses and pipe

assembly.

FI±72

EFI SYSTEM

± Air Induction System (Throttle Body)

WhereEverybodyKnowsYourName

Page 1912 of 4087

INSPECTION OF THROTTLE BODY

1. CLEAN THROTTLE BODY(a) Using a soft brush and carburetor cleaner, clean the cast

parts.

(b) Using compressed air, clean all the passages and apertures.

NOTICE: To prevent deterioration, do not clean the

throttle position sensor and DP.

2. INSPECT THROTTLE VALVE AND THROTTLE POSI TION

SENSOR

A. Inspect throttle valve Check that there is no clearance between the throttle stop

screw and throttle lever when the throttle valve is fully closed.

B. Inspect throttle position sensor (a) Insert a 40 mm (0.016 in.) or 0.65 mm (0.026 in.) feelergauge between the throttle stop screw and stop lever.

(b) Using an ohmmeter, measure the resistance between each terminal.

Clearance betweenClearance between

lever and stop screwBetween terminalsResistancelever and stop screwBetween terminalsResistance

0 mm (0 in.)VTA1±E20.2±0.8 �

0.40 mm (0.016 in.)IDL1±E22.3 k� or less

0.65 mm (0.026 in.)IDL1±E2Infinity

Throttle valve fully

openVTA1±E23.3±10.0 k �

±VC±E24.0±9.0 k�

C. If necessary, adjust throttle position sensor

(a) Loosen the two set screws of the sensor. FI±73

EFI SYSTEM

± Air Induction System (Throttle Body)

WhereEverybodyKnowsYourName

Page 1913 of 4087

(b) Insert a 0.40 mm (0.016 in.) feeler gauge, between thethrottle stop screw and stop lever.

(c) Connect the test probe of an ohmmeter to the terminals

IDL1 and E2 of the sensor.

(d) Gradually turn the sensor clockwise until the ohmmeter deflects, and secure it with the two set screws.

(e) Recheck the continuity between terminals IDL1 and E2.

Clearance between

lever and stop screwContinuity (IDL1±E2)

0.40 mm (0.016 in.)Continuity

0.65 mm (0.026 in.)No continuity

3. (w/ TRAC) INSPECT SUB±THROTTLE ACTUATOR, SUBTHROTTLE

VALVE AND SUB±THROTTLE POSITION SENSOR

A. Inspect sub±throttle actuator Using an ohmmeter, measure the resistance between the ter-

minals (ACM±A and �, BCM±B and B).

Resistance: 0.5±1.0 �

If the resistance is not as specified, replace the actuator

valve.

B. Inspect sub±throttle actuator Remove the three screws and sub±throttle actuator.

FI±74

EFI SYSTEM

± Air Induction System (Throttle Body)

WhereEverybodyKnowsYourName

Page 1914 of 4087

C. Inspect sub±throttle valveCheck that there is no clearance between the throttle stop

screw and throttle valve gear when the sub±throttle valve is

fully closed.

D. Inspect sub±throttle position sensor (a) Insert a 0.30 mm (0.012 in.) or 0.50 mm (0.020 in.) feeler

gauge between the throttle stop screw and throttle valve

gear.

(b) Using an ohmmeter, measure the resistance between each terminal.

Clearance between

lever and stop screwBetween terminalsResistance

0 mm (0 in.)VTA2±E20.2±0.8 �

0.30 mm (0.012 in.)IDL2±E22.3 k� or less

0.50 mm (0.020 in.)IDL2±E2Infinity

Throttle valve fully

openVTA2±E23.3±10.0 k �

±VC±E24.0±9.0 k�

E. If necessary, adjust sub±throttle position sensor

(a) Loosen the two set screws of the sensor.

(b) Insert a 0.30 mm (0.012 in.) feeler gauge, between thethrottle stop screw and throttle valve gear.

(c) Connect the test probe of an ohmmeter to the terminals IDL2 and E2 of the sensor. FI±75

EFI SYSTEM

± Air Induction System (Throttle Body)

WhereEverybodyKnowsYourName

Page 1915 of 4087

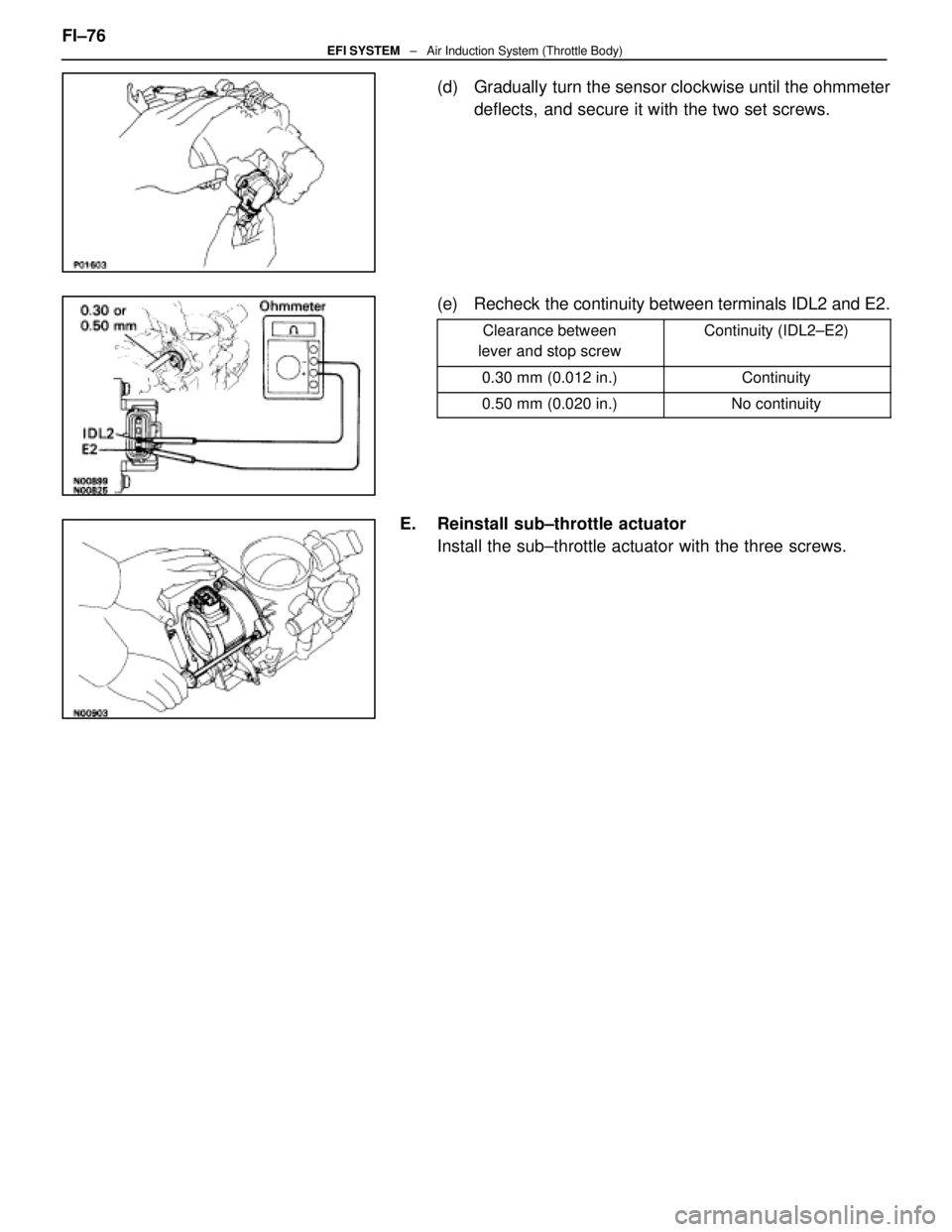

(d) Gradually turn the sensor clockwise until the ohmmeterdeflects, and secure it with the two set screws.

(e) Recheck the continuity between terminals IDL2 and E2.

Clearance between

lever and stop screwContinuity (IDL2±E2)

0.30 mm (0.012 in.)Continuity

0.50 mm (0.020 in.)No continuity

E. Reinstall sub±throttle actuator Install the sub±throttle actuator with the three screws.

FI±76

EFI SYSTEM

± Air Induction System (Throttle Body)

WhereEverybodyKnowsYourName

Page 1916 of 4087

INSTALLATION OF THROTTLE BODY

(See Components o page FI±69)

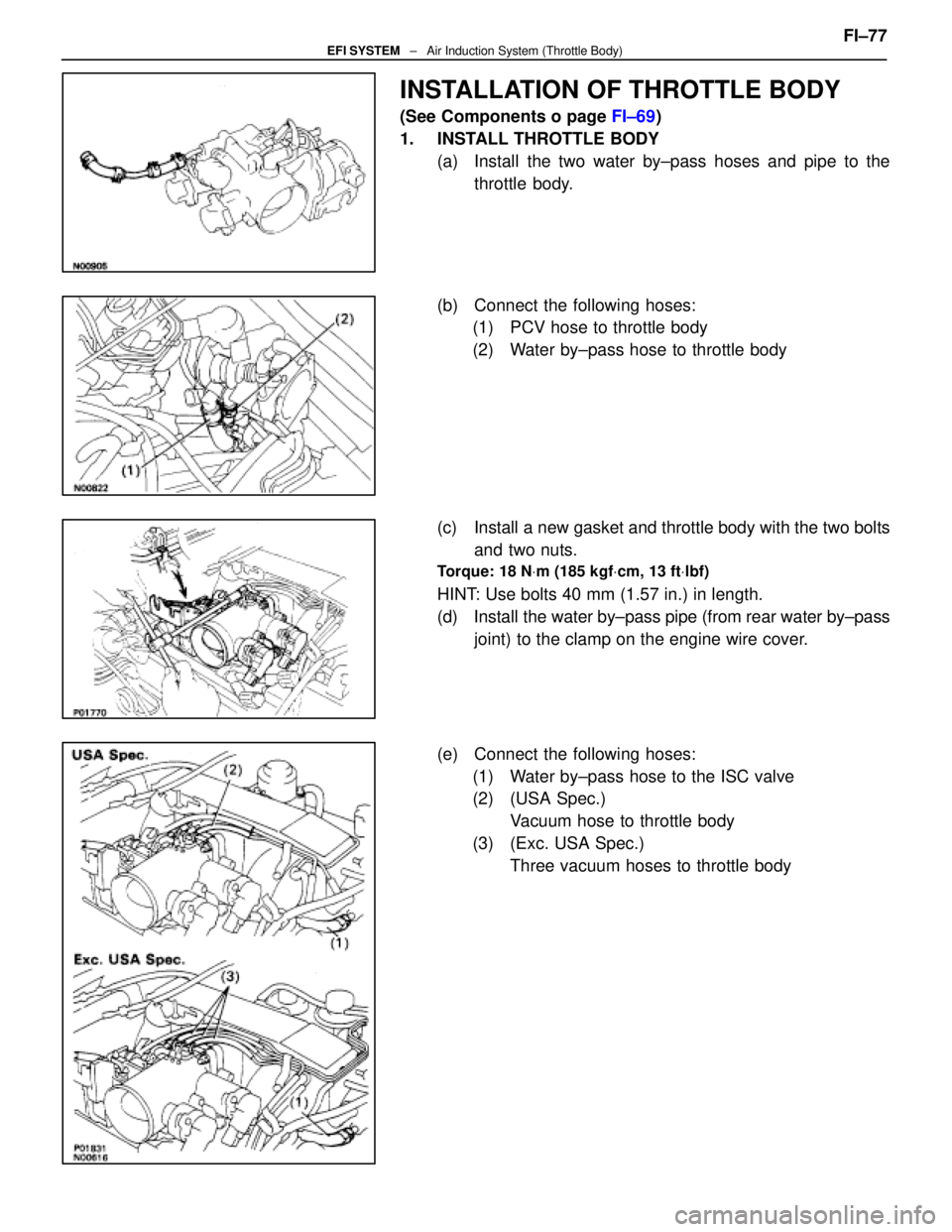

1. INSTALL THROTTLE BODY (a) Install the two water by±pass hoses and pipe to thethrottle body.

(b) Connect the following hoses: (1) PCV hose to throttle body

(2) Water by±pass hose to throttle body

(c) Install a new gasket and throttle body with the two bolts and two nuts.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

HINT: Use bolts 40 mm (1.57 in.) in length.

(d) Install the water by±pass pipe (from rear water by±pass

joint) to the clamp on the engine wire cover.

(e) Connect the following hoses: (1) Water by±pass hose to the ISC valve

(2) (USA Spec.) Vacuum hose to throttle body

(3) (Exc. USA Spec.) Three vacuum hoses to throttle body FI±77

EFI SYSTEM

± Air Induction System (Throttle Body)

WhereEverybodyKnowsYourName

Page 1917 of 4087

(4) Heater water hose to heater water valve

(f) Connect the following connectors: (1) Throttle position sensor connector

(2) (w/ TRAC)

Sub±throttle position sensor connector

(3) (w/ TRAC) Sub±throttle actuator connector

2. INSTALL UPPER HIGH±TENSION CORD COVER (a) Fit portion A of the upper high±tension cover, matchingit with the top of the lower high±tension cord cover.

(b) Push the front side of the high±tension cord cover, and connect the front side claw groove of the upper

high±tension cord cover to the claw of the lower

high±tension cord cover.

(c) Install the upper high±tension cord cover with the two bolts.

3. INSTALL INTAKE AIR CONNECTOR (a) Connect the end portions of the intake air connector tothe throttle body and air cleaner hose.

(b) Tighten the two hose clamps.

(c) Install the bolt holding the intake air connector to the

cylinder head cover.

FI±78

EFI SYSTEM

± Air Induction System (Throttle Body)

WhereEverybodyKnowsYourName

Page 1918 of 4087

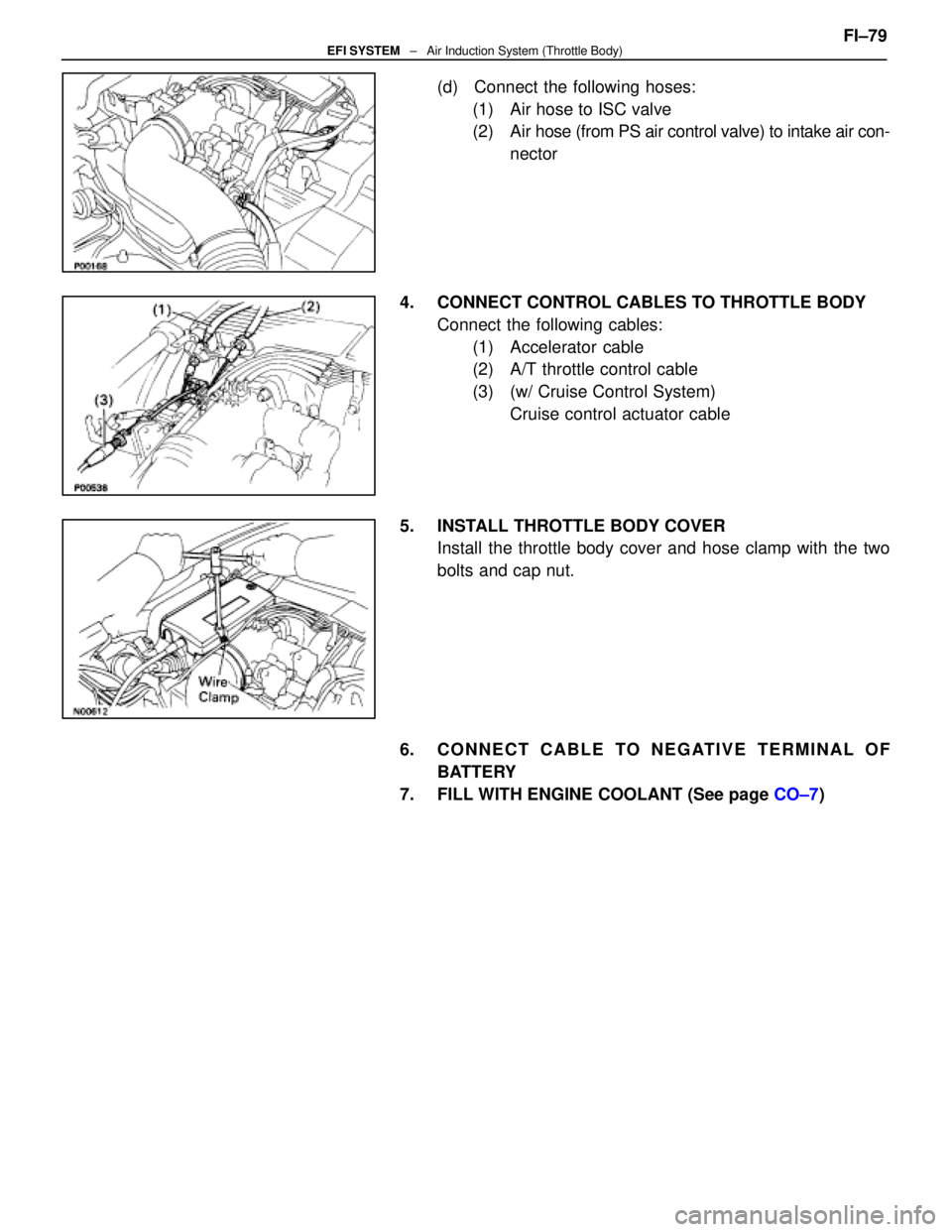

(d) Connect the following hoses:(1) Air hose to ISC valve

(2) Air hose (from PS air control valve) to intake air con-

nector

4. CONNECT CONTROL CABLES TO THROTTLE BODY Connect the following cables:(1) Accelerator cable

(2) A/T throttle control cable

(3) (w/ Cruise Control System) Cruise control actuator cable

5. INSTALL THROTTLE BODY COVER Install the throttle body cover and hose clamp with the two

bolts and cap nut.

6. CONNECT CABLE TO NEGATIVE TERMINAL OF BATTERY

7. FILL WITH ENGINE COOLANT (See page CO±7)FI±79

EFI SYSTEM

± Air Induction System (Throttle Body)

WhereEverybodyKnowsYourName

Page 1919 of 4087

11. RECONNECT DRIVER BELTInstall the drive belt by turning the drive belt tensioner clock-

wise.

12. RECONNECT CABLE FROM NEGATIVE TERMINAL OF BATTERY

13. REFILL WITH ENGINE COOLANT

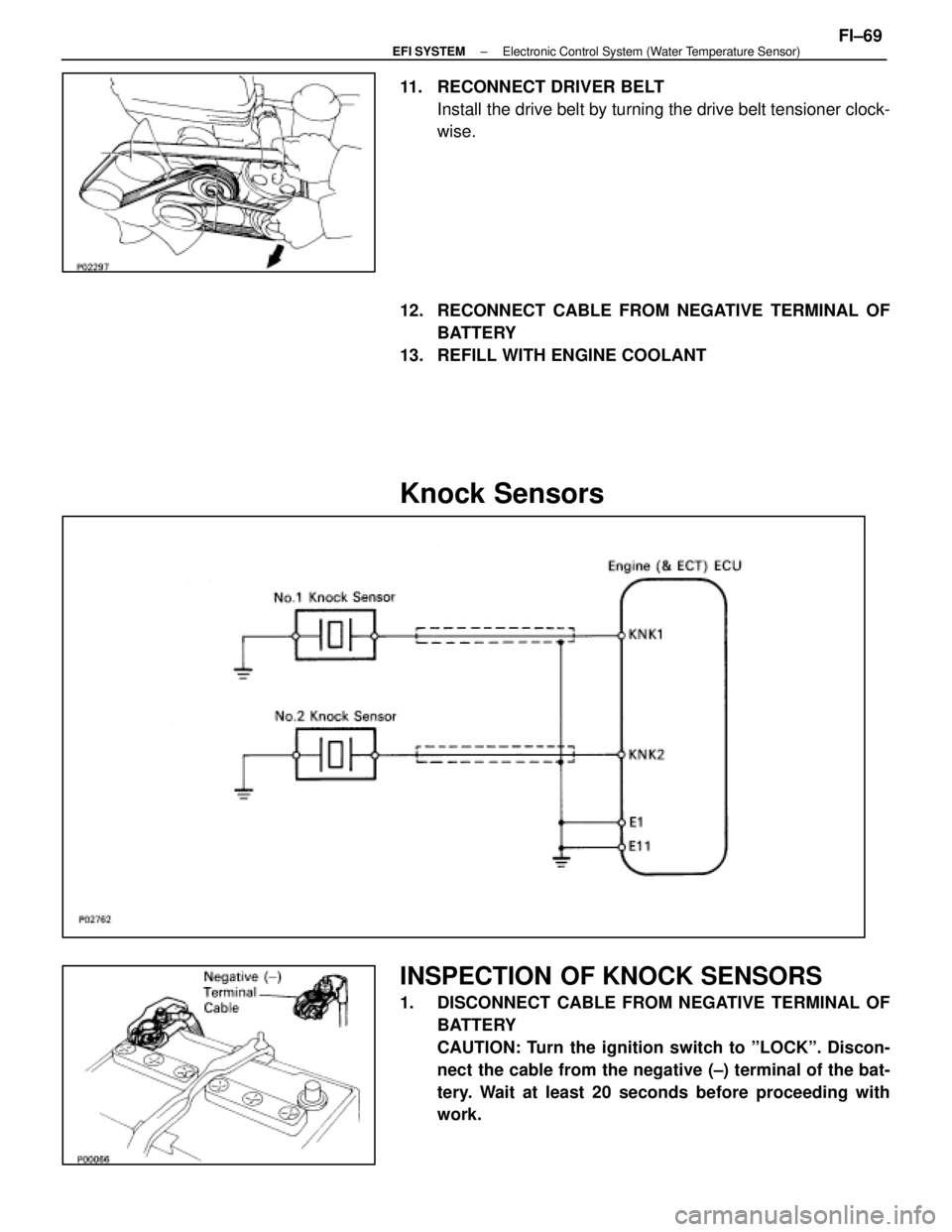

Knock Sensors

INSPECTION OF KNOCK SENSORS

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OF BATTERY

CAUTION: Turn the ignition switch to ºLOCKº. Discon-

nect the cable from the negative (±) terminal of the bat-

tery. Wait at least 20 seconds before proceeding with

work.

±

EFI SYSTEM Electronic Control System (Water Temperature Sensor)FI±69

WhereEverybodyKnowsYourName

Page 1920 of 4087

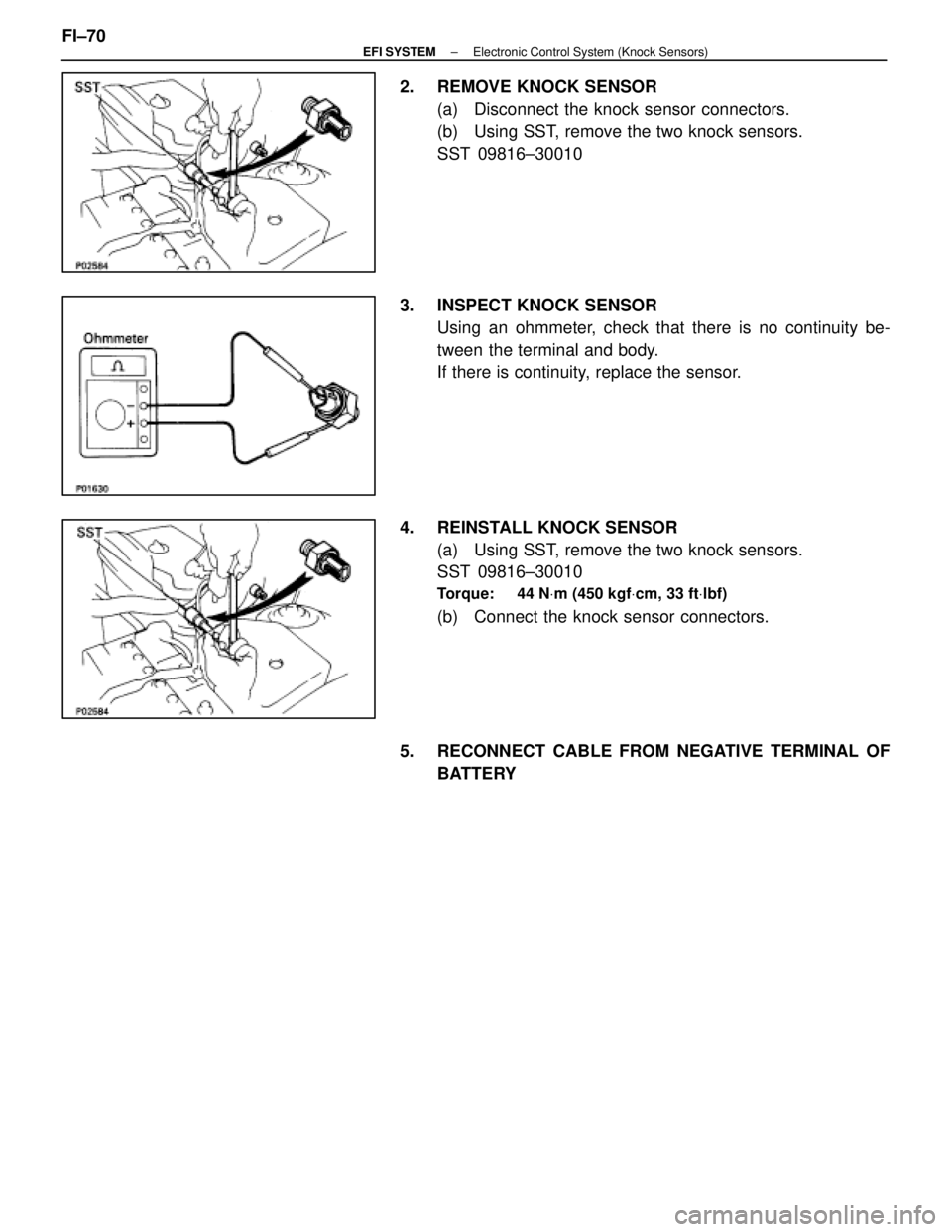

2. REMOVE KNOCK SENSOR(a) Disconnect the knock sensor connectors.

(b) Using SST, remove the two knock sensors.

SST 09816±30010

3. INSPECT KNOCK SENSOR Using an ohmmeter, check that there is no continuity be-

tween the terminal and body.

If there is continuity, replace the sensor.

4. REINSTALL KNOCK SENSOR (a) Using SST, remove the two knock sensors.

SST 09816±30010

Torque: 44 N Vm (450 kgf Vcm, 33 ft Vlbf)

(b) Connect the knock sensor connectors.

5. RECONNECT CABLE FROM NEGATIVE TERMINAL OF BATTERY

FI±70

±

EFI SYSTEM Electronic Control System (Knock Sensors)

WhereEverybodyKnowsYourName

Trending: ignition switch, roof rack, manual transmission, transmission oil, headrest, hood release, fuel cap release