LEXUS SC400 1991 Service Repair Manual

Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 2391 of 4087

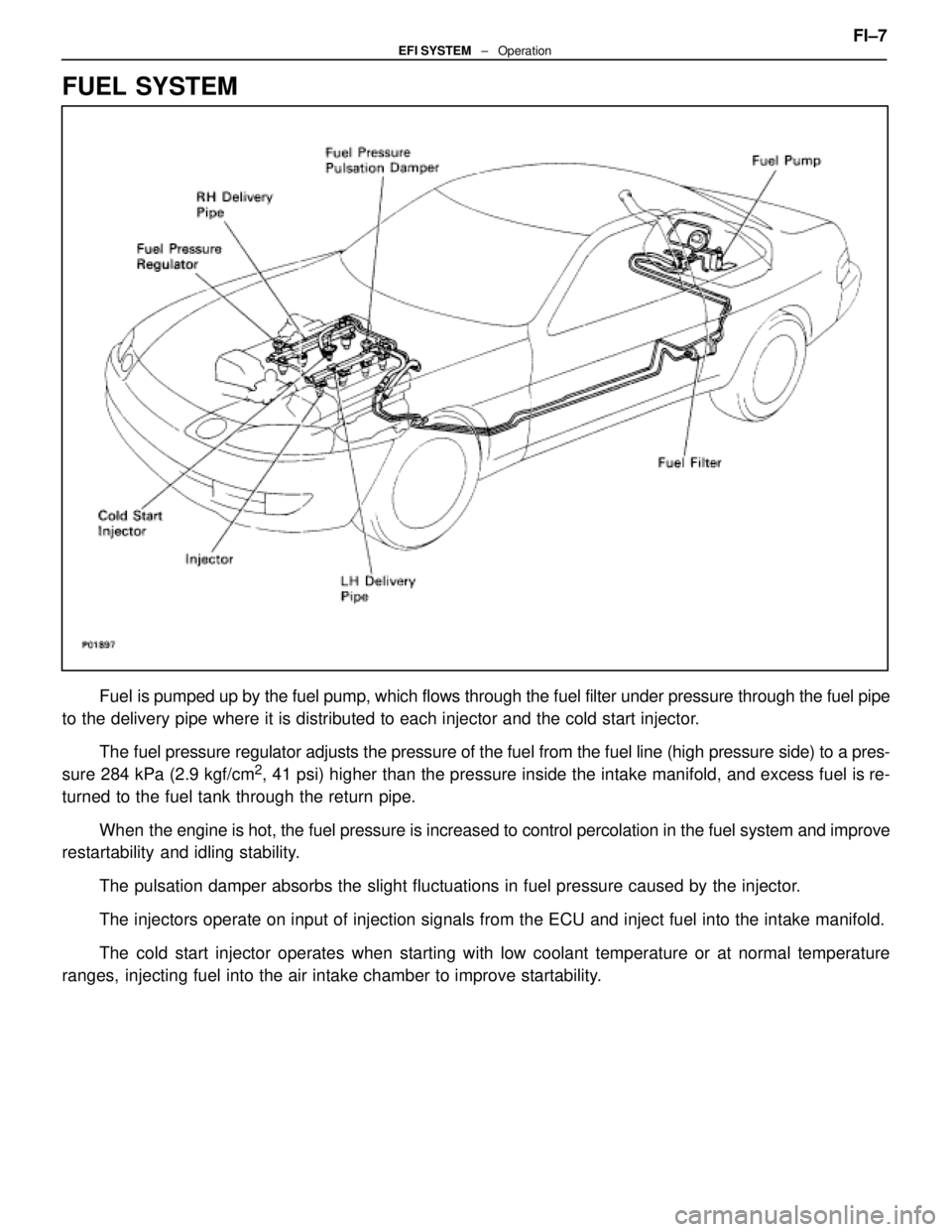

FUEL SYSTEM

Fuel is pumped up by the fuel pump, which flows through the fuel filter under pr\

essure through the fuel pipe

to the delivery pipe where it is distributed to each injector and the cold\

start injector.

The fuel pressure regulator adjusts the pressure of the fuel from the fuel \

line (high pressure side) to a pres-

sure 284 kPa (2.9 kgf/cm

2, 41 psi) higher than the pressure inside the intake manifold, and exce\

ss fuel is re-

turned to the fuel tank through the return pipe.

When the engine is hot, the fuel pressure is increased to control percolatio\

n in the fuel system and improve

restartability and idling stability.

The pulsation damper absorbs the slight fluctuations in fuel pressure ca\

used by the injector.

The injectors operate on input of injection signals from the ECU and inj\

ect fuel into the intake manifold.

The cold start injector operates when starting with low coolant temperature or at normal temperature

ranges, injecting fuel into the air intake chamber to improve startability. FI±7

EFI SYSTEM

± Operation

WhereEverybodyKnowsYourName

Page 2392 of 4087

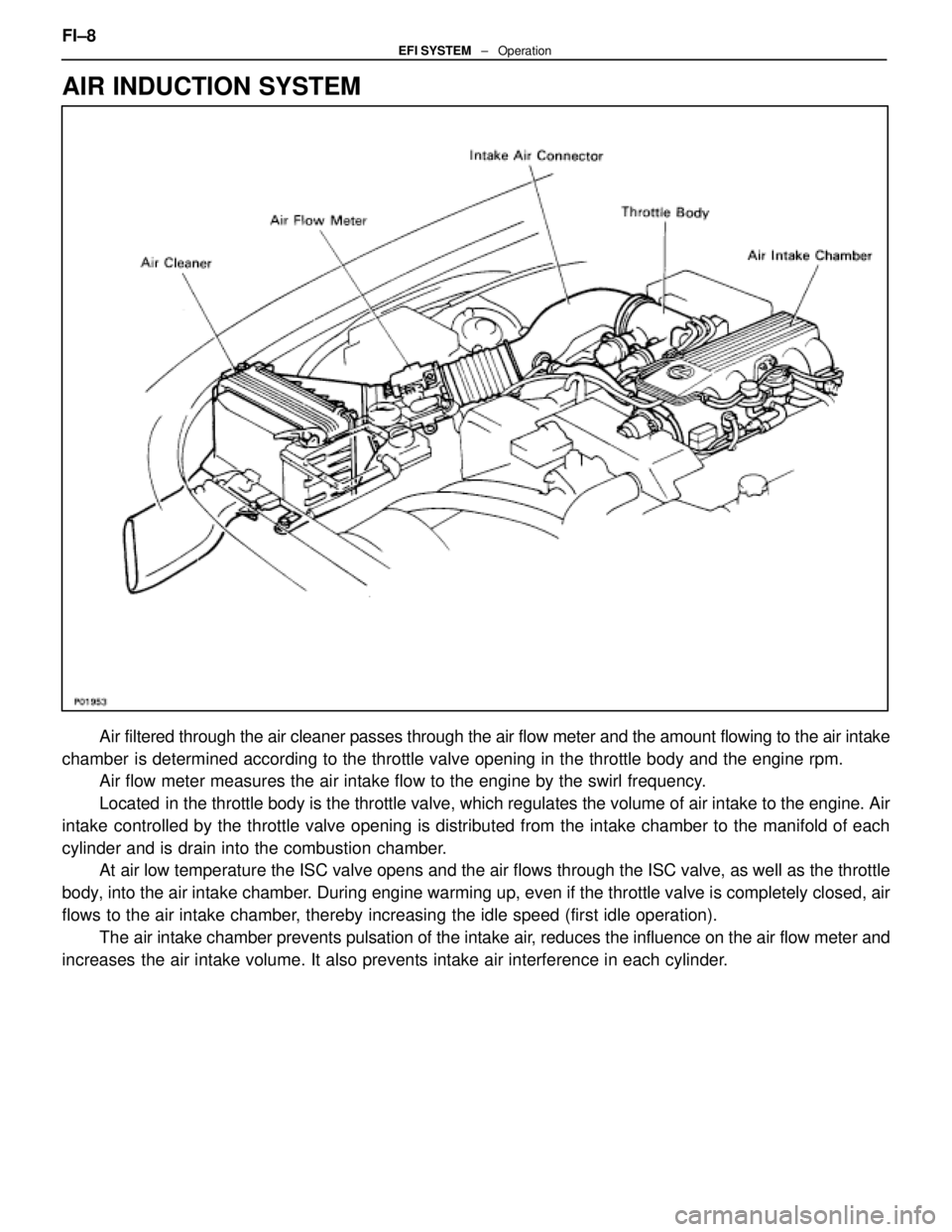

AIR INDUCTION SYSTEM

Air filtered through the air cleaner passes through the air flow meter and \

the amount flowing to the air intake

chamber is determined according to the throttle valve opening in the throttle b\

ody and the engine rpm. Air flow meter measures the air intake flow to the engine by the swirl f\

requency.

Located in the throttle body is the throttle valve, which regulates the volume \

of air intake to the engine. Air

intake controlled by the throttle valve opening is distributed from the intake\

chamber to the manifold of each

cylinder and is drain into the combustion chamber. At air low temperature the ISC valve opens and the air flows through the I\

SC valve, as well as the throttle

body, into the air intake chamber. During engine warming up, even if the throttle valve is completely clo\

sed, air

flows to the air intake chamber, thereby increasing the idle speed (first idle operation). The air intake chamber prevents pulsation of the intake air, reduces the influence on the air flow meter and

increases the air intake volume. It also prevents intake air interference in each\

cylinder. FI±8

EFI SYSTEM ± Operation

WhereEverybodyKnowsYourName

Page 2393 of 4087

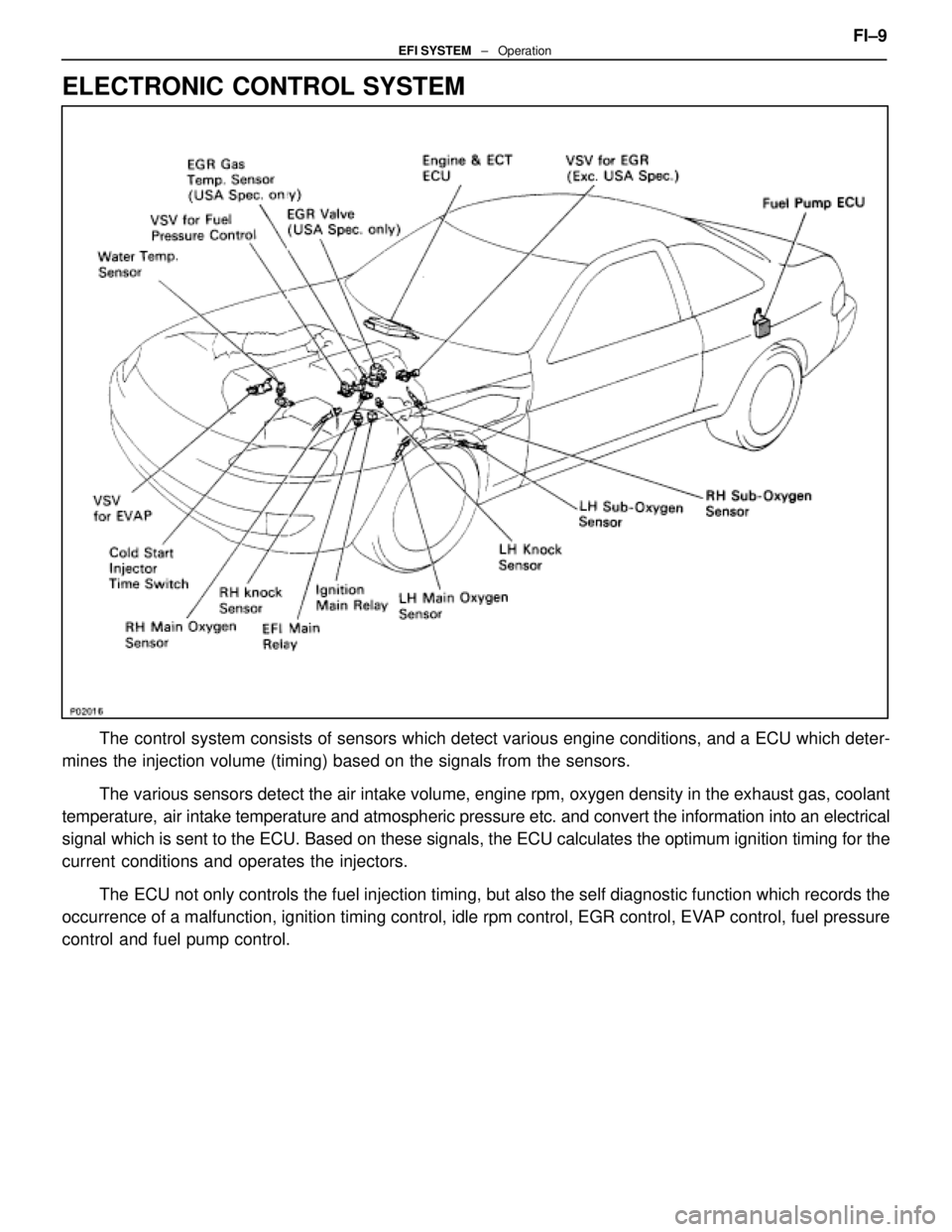

ELECTRONIC CONTROL SYSTEM

The control system consists of sensors which detect various engine conditions, and a ECU which deter\

-

mines the injection volume (timing) based on the signals from the sens\

ors.

The various sensors detect the air intake volume, engine rpm, oxygen densit\

y in the exhaust gas, coolant

temperature, air intake temperature and atmospheric pressure etc. and convert the in\

formation into an electrical

signal which is sent to the ECU. Based on these signals, the ECU calculates th\

e optimum ignition timing for the

current conditions and operates the injectors.

The ECU not only controls the fuel injection timing, but also the self diag\

nostic function which records the

occurrence of a malfunction, ignition timing control, idle rpm control, \

EGR control, EVAP control, fuel pressure

control and fuel pump control. FI±9

EFI SYSTEM

± Operation

WhereEverybodyKnowsYourName

Page 2394 of 4087

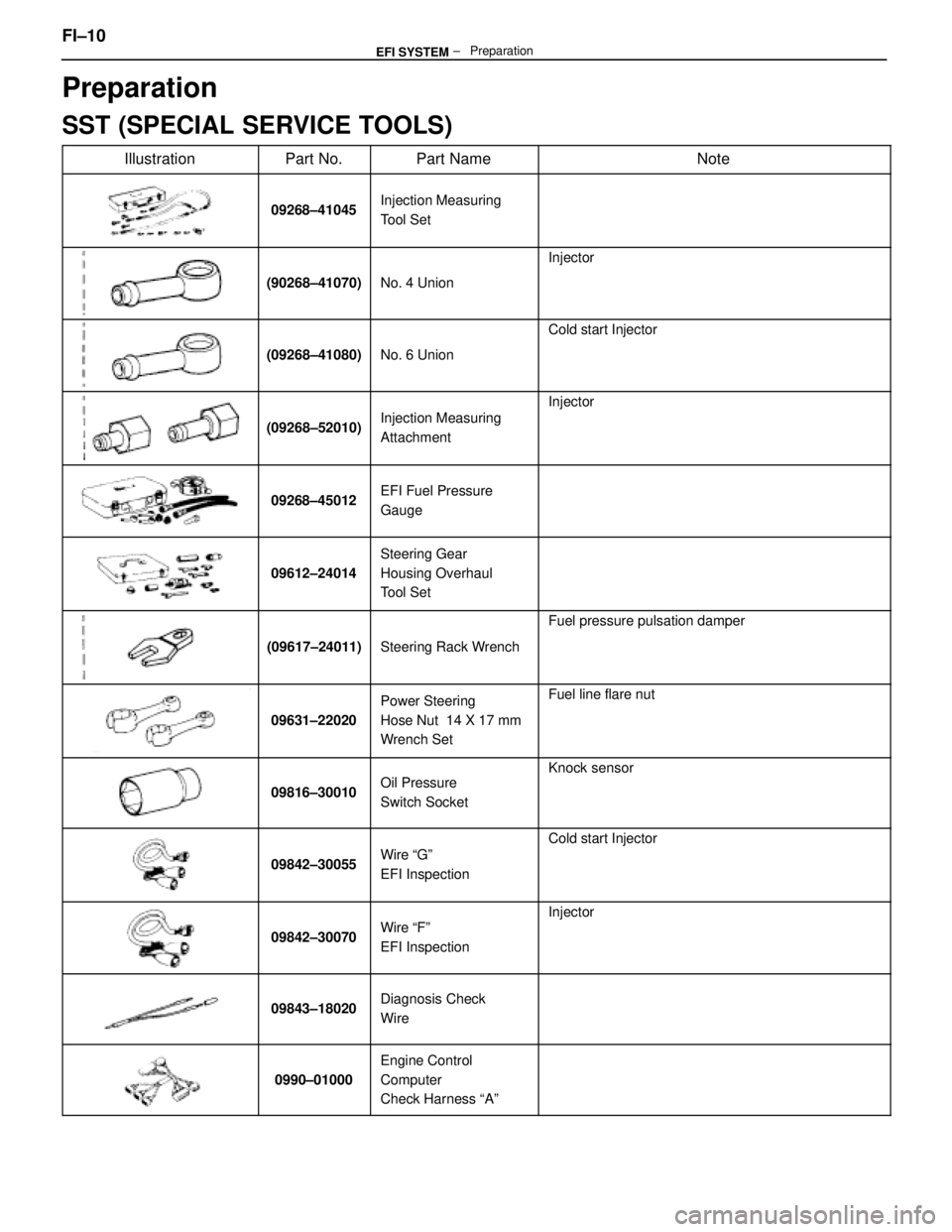

Preparation

SST (SPECIAL SERVICE TOOLS)

IllustrationPart No.Part NameNote

09268±41045Injection Measuring

Tool Set

(90268±41070)No. 4 Union

Injector

(09268±41080)No. 6 Union

Cold start Injector

(09268±52010)Injection Measuring

Attachment

Injector

09268±45012EFI Fuel Pressure

Gauge

09612±24014

Steering Gear

Housing Overhaul

Tool Set

(09617±24011)Steering Rack Wrench

Fuel pressure pulsation damper

09631±22020

Power Steering

Hose Nut 14 X 17 mm

Wrench SetFuel line flare nut

09816±30010Oil Pressure

Switch SocketKnock sensor

09842±30055Wire ªGº

EFI Inspection

Cold start Injector

09842±30070Wire ªFº

EFI Inspection

Injector

09843±18020Diagnosis Check

Wire

0990±01000

Engine Control

Computer

Check Harness ªAº

FI±10 ± PreparationEFI SYSTEM

WhereEverybodyKnowsYourName

Page 2395 of 4087

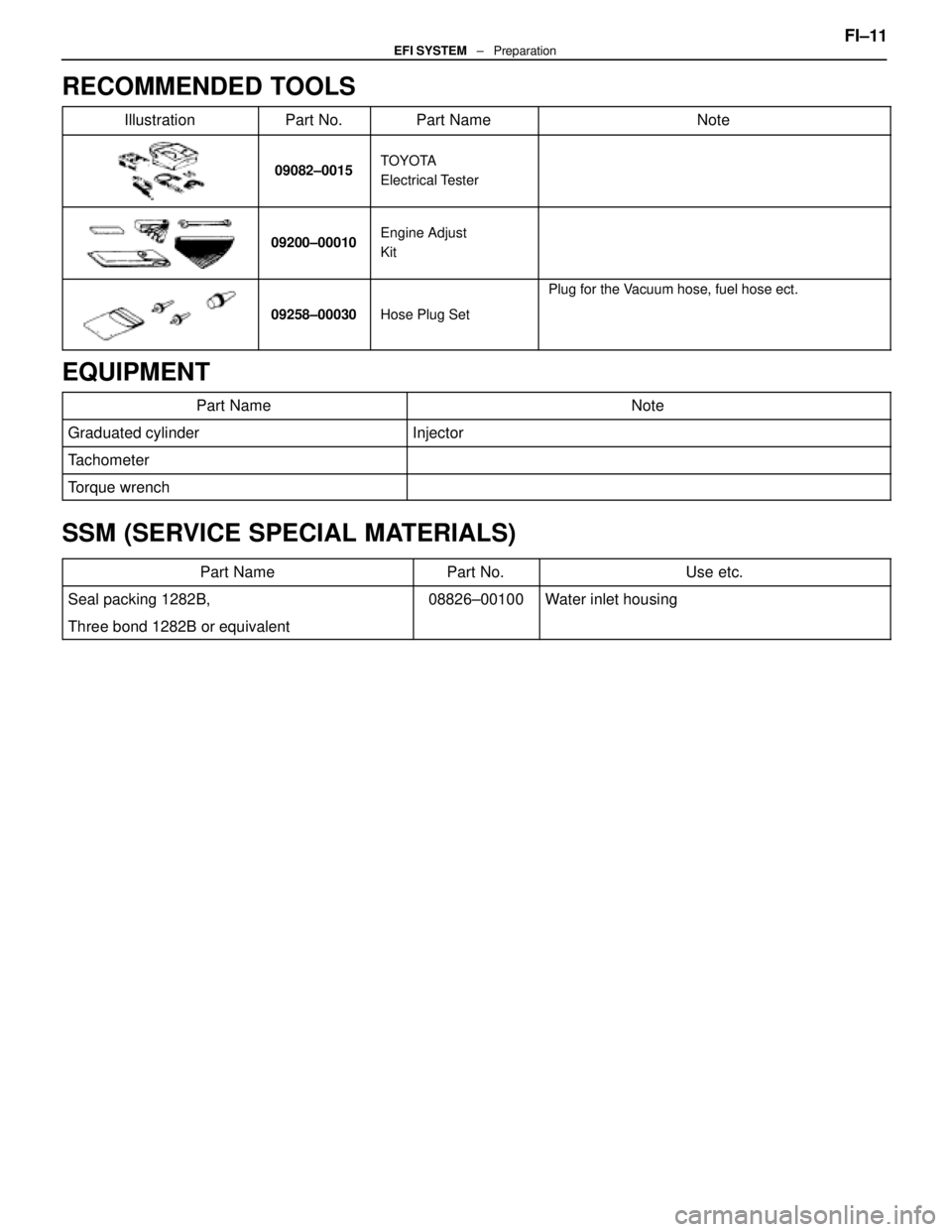

RECOMMENDED TOOLS

IllustrationPart No.Part NameNote

09082±0015TOYOTA

Electrical Tester

09200±00010Engine Adjust

Kit

09258±00030Hose Plug Set

Plug for the Vacuum hose, fuel hose ect.

EQUIPMENT

Part NameNote

Graduated cylinderInjector

Tachometer

Torque wrench

SSM (SERVICE SPECIAL MATERIALS)

Part NamePart No.Use etc.

Seal packing 1282B,08826±00100Water inlet housing

Three bond 1282B or equivalent

FI±11EFI SYSTEM ± Preparation

WhereEverybodyKnowsYourName

Page 2396 of 4087

PRECAUTIONS

1. Before working on the fuel system, disconnect the cablefrom negative (±) terminal of the battery.

HINT: Any diagnostic code retained by the computer will be

erased when the battery terminal is removed. Therefore, if

necessary, read the diagnosis before removing the battery

terminal.

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and negative (±) terminal

cable is disconnected from the battery.

2. Do not smoke or work on open flame when working on the fuel system.

3. Keep gasoline away from rubber or leather parts.

INSPECTION PRECAUTIONS

MAINTENANCE PRECAUTIONS

1. CHECK CORRECT ENGINE TUNE±UP (See page EM±8)

2. PRECAUTIONS WHEN CONNECTING GAUGE (a) Use the battery as the power source for the timing light,tachometer, etc.

(b) Connect the test probe of a tachometer to the terminal IG of the check connector.

3. IN EVENT OF ENGINE MISFIRE, FOLLOWING PRECAUTIONS SHOULD BE TAKEN

(a) Check proper connection of battery terminals, etc.

(b) Handle high±tension cords carefully.

(c) After repair work, check that the ignition coil terminalsand all other ignition system lines are reconnected

securely.

(d) When cleaning the engine compartment, be especially careful to protect the electrical system from water.

4. PRECAUTIONS WHEN HANDLING OXYGEN SENSOR (a) Do not allow oxygen sensor to drop or hit against anobject.

(b) Do not allow the sensor to come into contact with water.

FI±12

± Precautions, Inspection PrecautionsEFI SYSTEM

WhereEverybodyKnowsYourName

Page 2397 of 4087

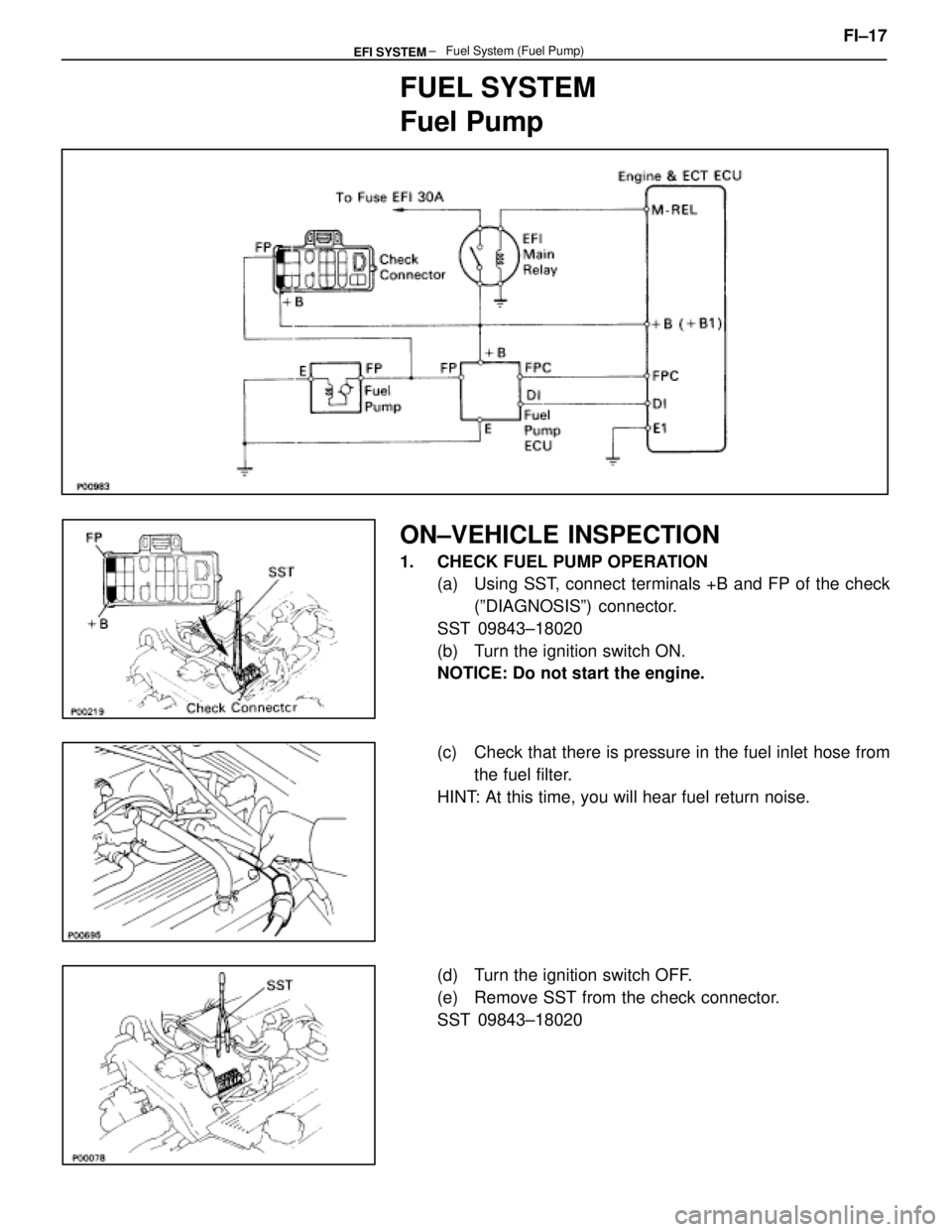

FUEL SYSTEM

Fuel Pump

ON±VEHICLE INSPECTION

1. CHECK FUEL PUMP OPERATION(a) Using SST, connect terminals +B and FP of the check

(ºDIAGNOSISº) connector.

SST 09843±18020

(b) Turn the ignition switch ON.

NOTICE: Do not start the engine.

(c) Check that there is pressure in the fuel inlet hose from the fuel filter.

HINT: At this time, you will hear fuel return noise.

(d) Turn the ignition switch OFF.

(e) Remove SST from the check connector.

SST 09843±18020 FI±17

± Fuel System (Fuel Pump)EFI SYSTEM

WhereEverybodyKnowsYourName

Page 2398 of 4087

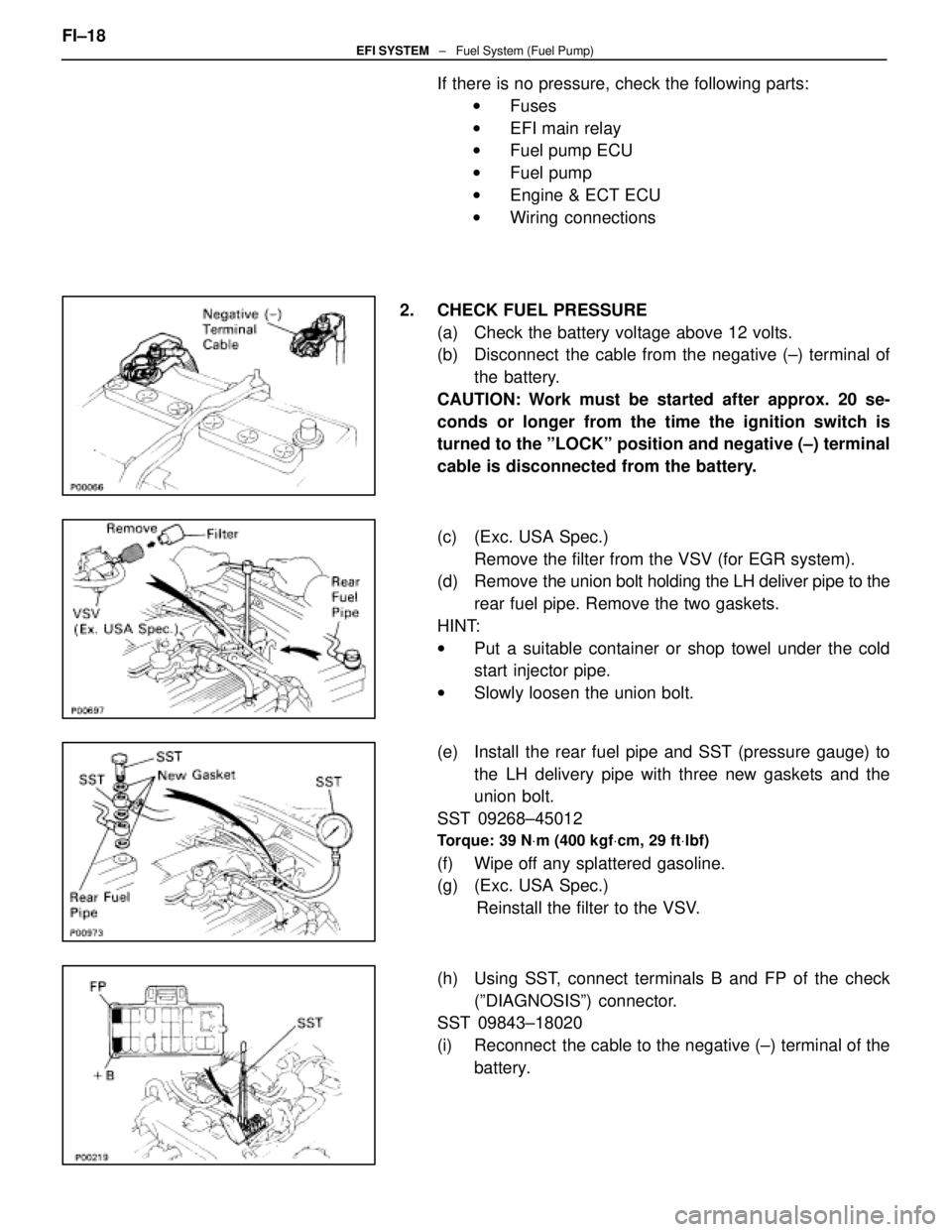

If there is no pressure, check the following parts:w Fuses

w EFI main relay

w Fuel pump ECU

w Fuel pump

w Engine & ECT ECU

w Wiring connections

2. CHECK FUEL PRESSURE (a) Check the battery voltage above 12 volts.

(b) Disconnect the cable from the negative (±) terminal ofthe battery.

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and negative (±) terminal

cable is disconnected from the battery.

(c) (Exc. USA Spec.) Remove the filter from the VSV (for EGR system).

(d) Remove the union bolt holding the LH deliver pipe to the

rear fuel pipe. Remove the two gaskets.

HINT:

w Put a suitable container or shop towel under the cold

start injector pipe.

w Slowly loosen the union bolt.

(e) Install the rear fuel pipe and SST (pressure gauge) to the LH delivery pipe with three new gaskets and the

union bolt.

SST 09268±45012

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

(f) Wipe off any splattered gasoline.

(g) (Exc. USA Spec.)

Reinstall the filter to the VSV.

(h) Using SST, connect terminals B and FP of the check (ºDIAGNOSISº) connector.

SST 09843±18020

(i) Reconnect the cable to the negative (±) terminal of the

battery.

FI±18

EFI SYSTEM

± Fuel System (Fuel Pump)

WhereEverybodyKnowsYourName

Page 2399 of 4087

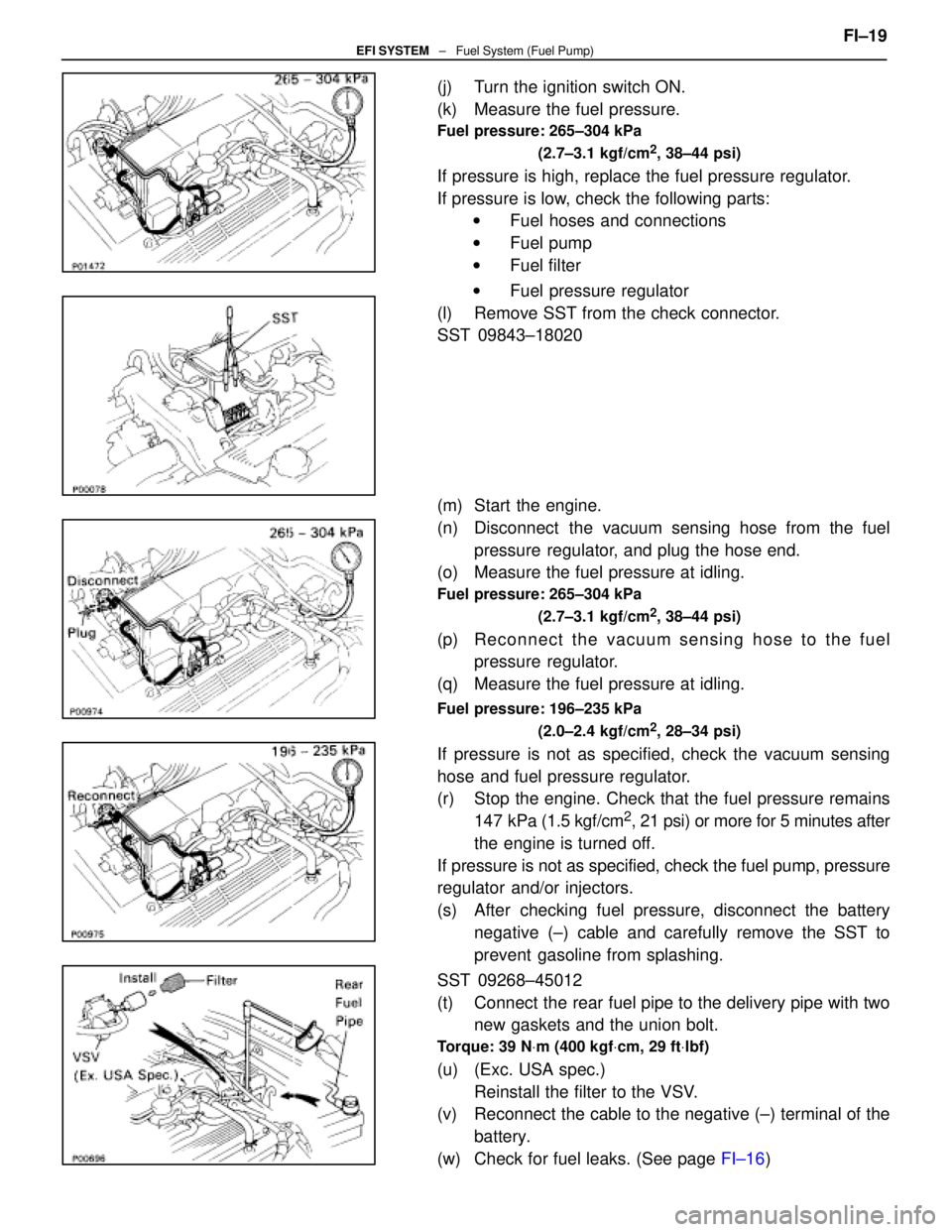

(j) Turn the ignition switch ON.

(k) Measure the fuel pressure.

Fuel pressure: 265±304 kPa(2.7±3.1 kgf/cm

2, 38±44 psi)

If pressure is high, replace the fuel pressure regulator.

If pressure is low, check the following parts:w Fuel hoses and connections

w Fuel pump

w Fuel filter

w Fuel pressure regulator

(l) Remove SST from the check connector.

SST 09843±18020

(m) Start the engine.

(n) Disconnect the vacuum sensing hose from the fuel pressure regulator, and plug the hose end.

(o) Measure the fuel pressure at idling.

Fuel pressure: 265±304 kPa

(2.7±3.1 kgf/cm

2, 38±44 psi)

(p) Re connect the vacuum sensing hose to the fuel

pressure regulator.

(q) Measure the fuel pressure at idling.

Fuel pressure: 196±235 kPa

(2.0±2.4 kgf/cm

2, 28±34 psi)

If pressure is not as specified, check the vacuum sensing

hose and fuel pressure regulator.

(r) Stop the engine. Check that the fuel pressure remains147 kPa (1.5 kgf/cm

2, 21 psi) or more for 5 minutes after

the engine is turned off.

If pressure is not as specified, check the fuel pump, pressure

regulator and/or injectors.

(s) After checking fuel pressure, disconnect the battery negative (±) cable and carefully remove the SST to

prevent gasoline from splashing.

SST 09268±45012

(t) Connect the rear fuel pipe to the delivery pipe with two new gaskets and the union bolt.

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

(u) (Exc. USA spec.)

Reinstall the filter to the VSV.

(v) Reconnect the cable to the negative (±) terminal of the

battery.

(w) Check for fuel leaks. (See page FI±16) FI±19

EFI SYSTEM

± Fuel System (Fuel Pump)

WhereEverybodyKnowsYourName

Page 2400 of 4087

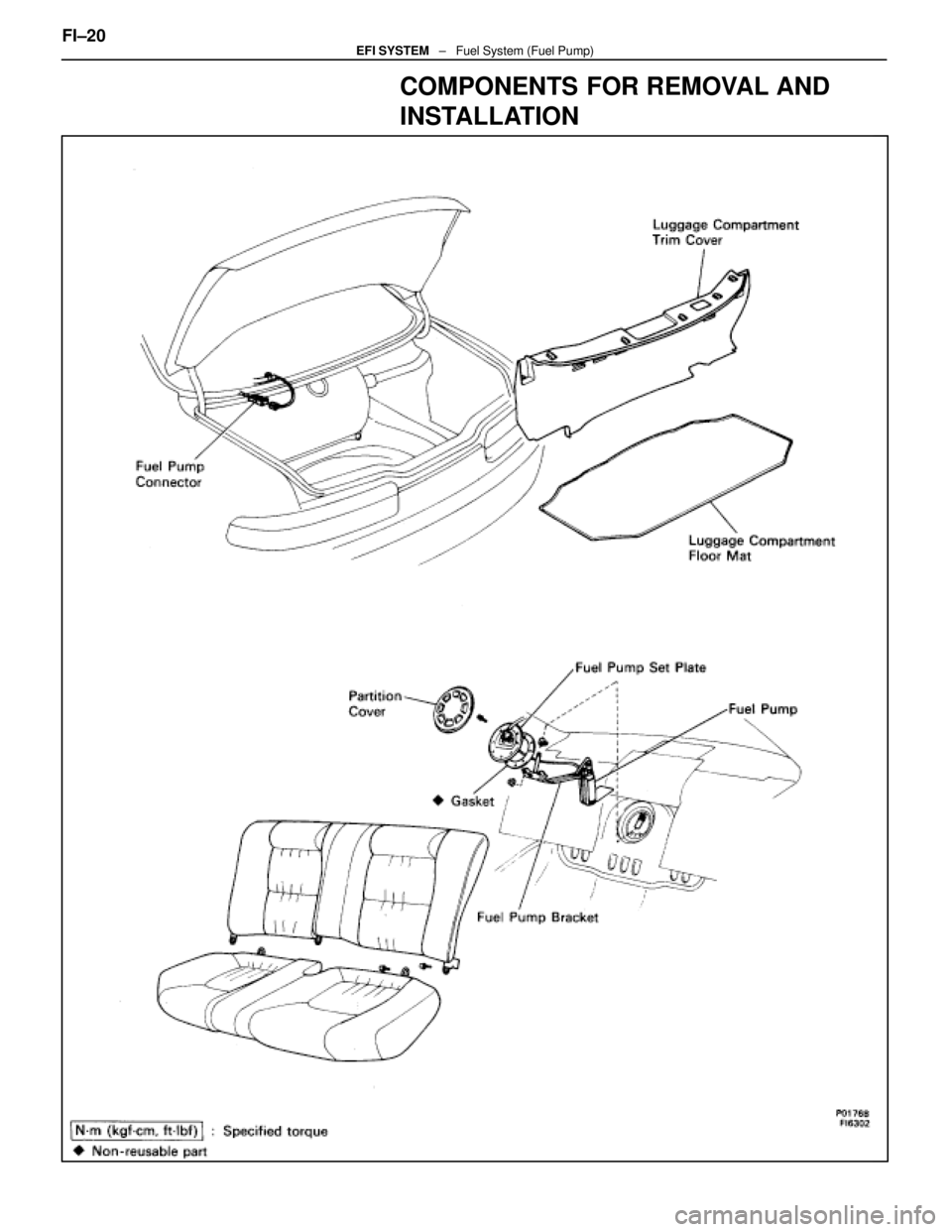

COMPONENTS FOR REMOVAL AND

INSTALLATION

FI±20EFI SYSTEM ± Fuel System (Fuel Pump)

WhereEverybodyKnowsYourName