LEXUS SC400 1991 Service Repair Manual

Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 2431 of 4087

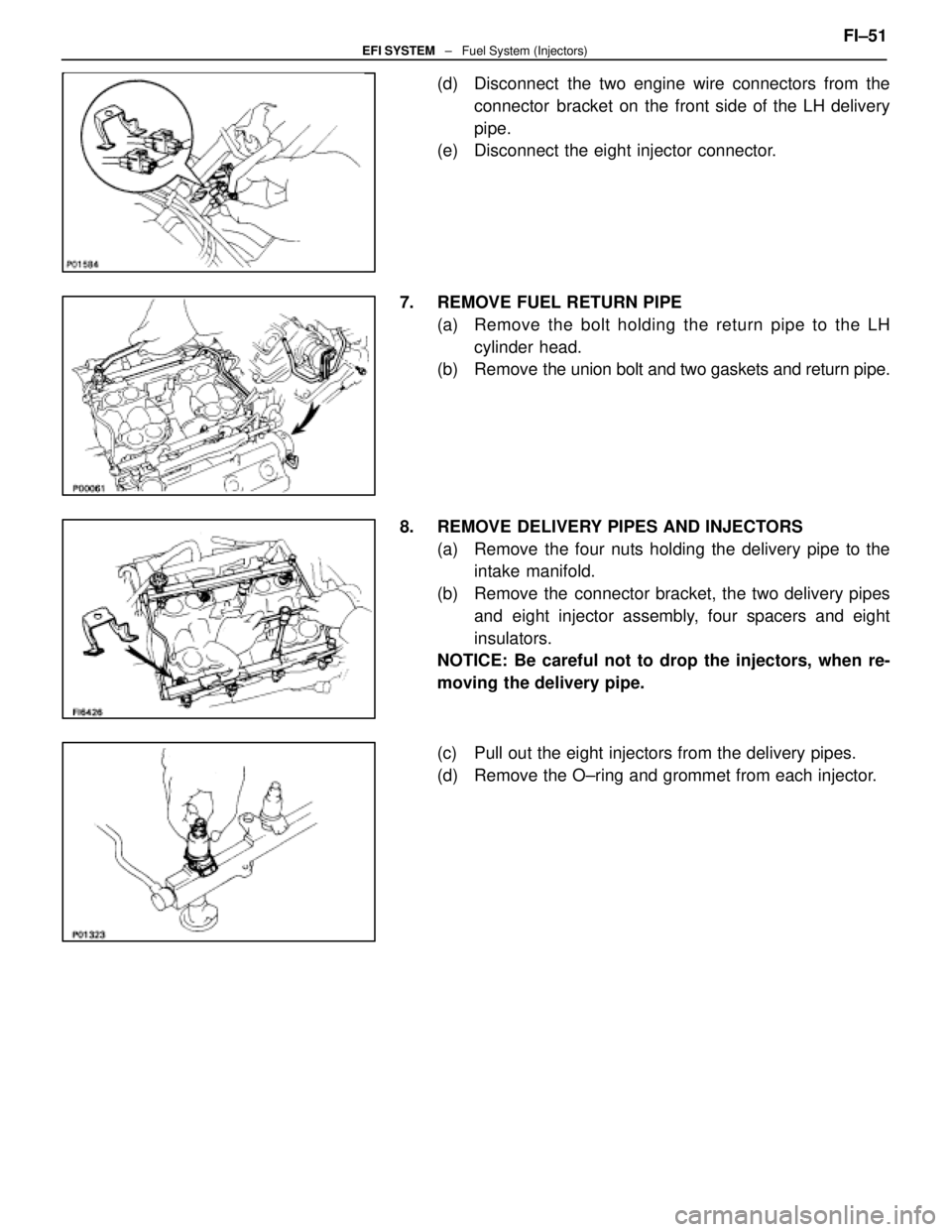

(d) Disconnect the two engine wire connectors from theconnector bracket on the front side of the LH delivery

pipe.

(e) Disconnect the eight injector connector.

7. REMOVE FUEL RETURN PIPE (a) Remove the bolt holding the return pipe to the LHcylinder head.

(b) Remove the union bolt and two gaskets and return pipe.

8. REMOVE DELIVERY PIPES AND INJECTORS (a) Remove the four nuts holding the delivery pipe to theintake manifold.

(b) Remove the connector bracket, the two delivery pipes and eight injector assembly, four spacers and eight

insulators.

NOTICE: Be careful not to drop the injectors, when re-

moving the delivery pipe.

(c) Pull out the eight injectors from the delivery pipes.

(d) Remove the O±ring and grommet from each injector. FI±51

EFI SYSTEM

± Fuel System (Injectors)

WhereEverybodyKnowsYourName

Page 2432 of 4087

INSPECTION OF INJECTORS

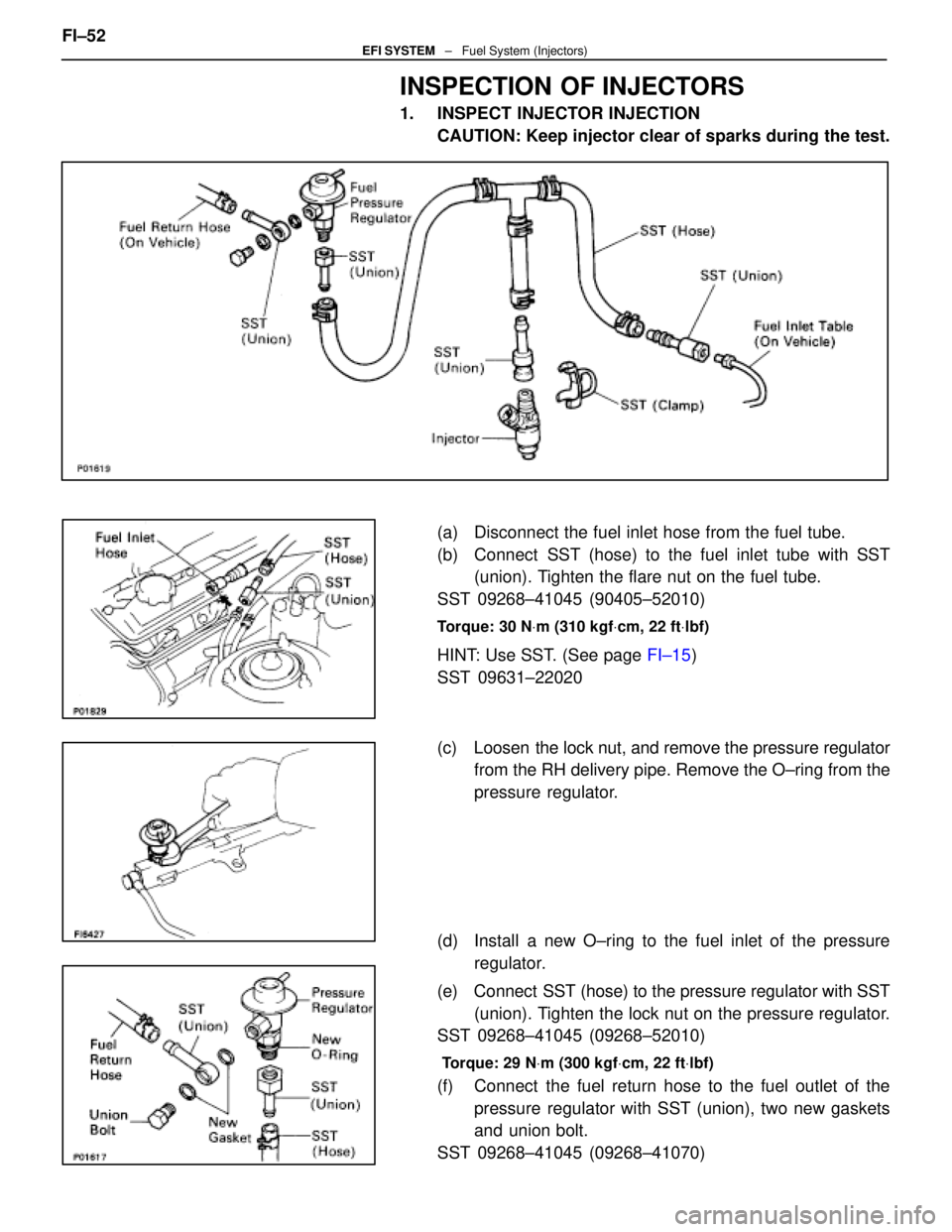

1. INSPECT INJECTOR INJECTIONCAUTION: Keep injector clear of sparks during the test.

(a) Disconnect the fuel inlet hose from the fuel tube.

(b) Connect SST (hose) to the fuel inlet tube with SST(union). Tighten the flare nut on the fuel tube.

SST 09268±41045 (90405±52010)

Torque: 30 N Vm (310 kgf Vcm, 22 ft Vlbf)

HINT: Use SST. (See page FI±15)

SST 09631±22020

(c) Loosen the lock nut, and remove the pressure regulator from the RH delivery pipe. Remove the O±ring from the

pressure regulator.

(d) Install a new O±ring to the fuel inlet of the pressure regulator.

(e) Connect SST (hose) to the pressure regulator with SST (union). Tighten the lock nut on the pressure regulator.

SST 09268±41045 (09268±52010)

Torque: 29 N Vm (300 kgf Vcm, 22 ft Vlbf)

(f) Connect the fuel return hose to the fuel outlet of the

pressure regulator with SST (union), two new gaskets

and union bolt.

SST 09268±41045 (09268±41070)

FI±52EFI SYSTEM ± Fuel System (Injectors)

WhereEverybodyKnowsYourName

Page 2433 of 4087

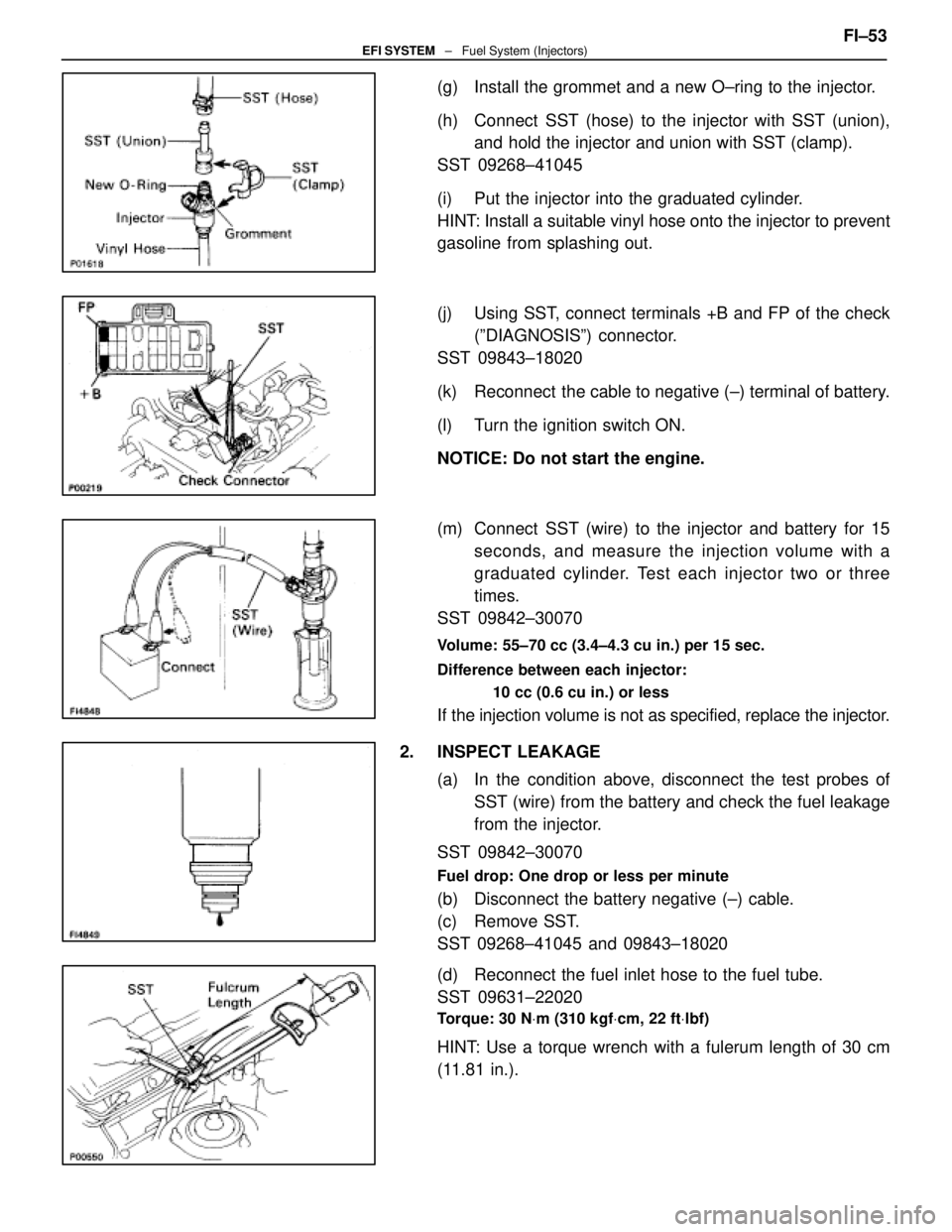

(g) Install the grommet and a new O±ring to the injector.

(h) Connect SST (hose) to the injector with SST (union),and hold the injector and union with SST (clamp).

SST 09268±41045

(i) Put the injector into the graduated cylinder.

HINT: Install a suitable vinyl hose onto the injector to prevent

gasoline from splashing out.

(j) Using SST, connect terminals +B and FP of the check (ºDIAGNOSISº) connector.

SST 09843±18020

(k) Reconnect the cable to negative (±) terminal of battery.

(l) Turn the ignition switch ON.

NOTICE: Do not start the engine.

(m) Connect SST (wire) to the injector and battery for 15 seconds, and measure the injection volume with a

graduated cylinder. Test each injector two or three

times.

SST 09842±30070

Volume: 55±70 cc (3.4±4.3 cu in.) per 15 sec.

Difference between each injector:

10 cc (0.6 cu in.) or less

If the injection volume is not as specified, replace the injector.

2. INSPECT LEAKAGE (a) In the condition above, disconnect the test probes ofSST (wire) from the battery and check the fuel leakage

from the injector.

SST 09842±30070

Fuel drop: One drop or less per minute

(b) Disconnect the battery negative (±) cable.

(c) Remove SST.

SST 09268±41045 and 09843±18020

(d) Reconnect the fuel inlet hose to the fuel tube.

SST 09631±22020

Torque: 30 N Vm (310 kgf Vcm, 22 ft Vlbf)

HINT: Use a torque wrench with a fulerum length of 30 cm

(11.81 in.). FI±53

EFI SYSTEM

± Fuel System (Injectors)

WhereEverybodyKnowsYourName

Page 2434 of 4087

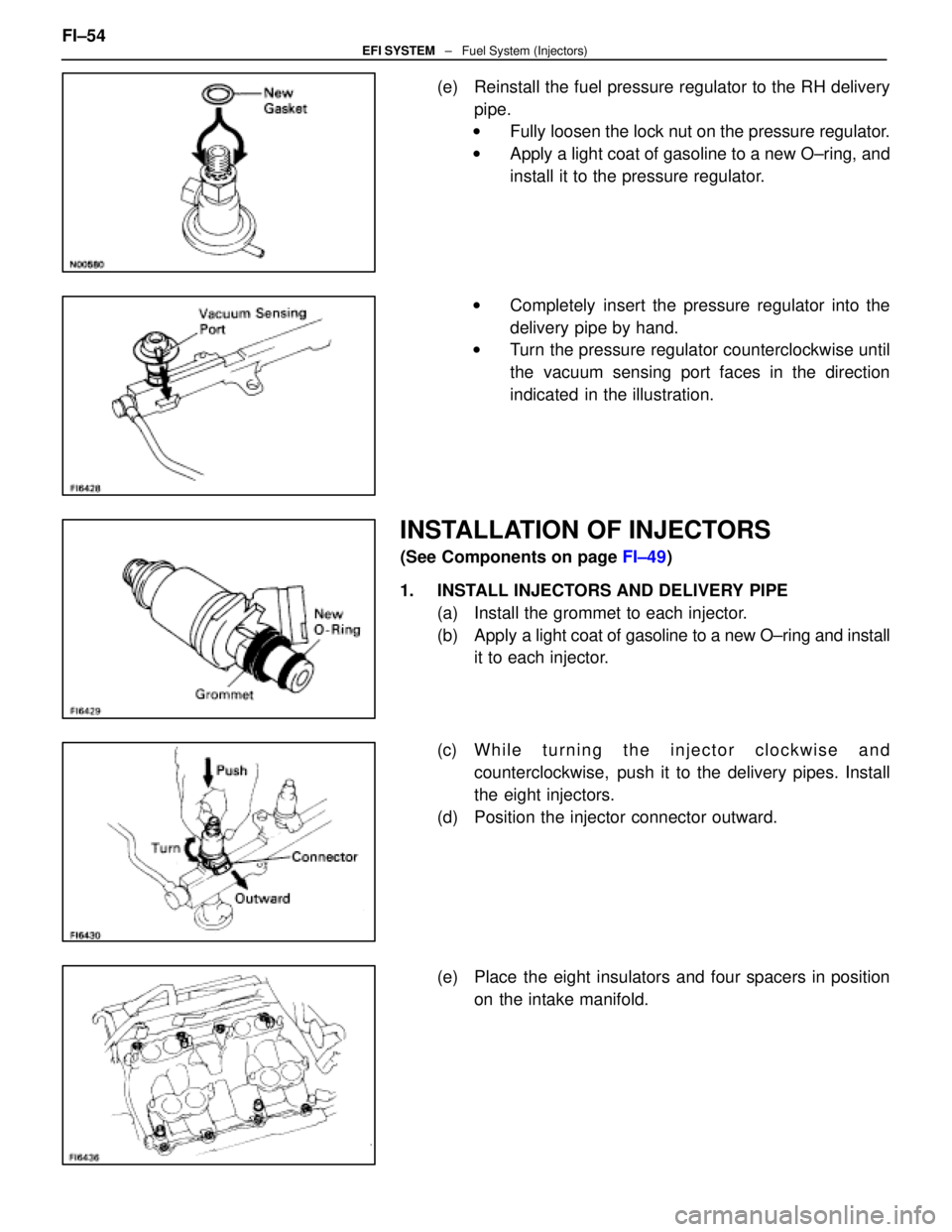

(e) Reinstall the fuel pressure regulator to the RH deliverypipe.

w Fully loosen the lock nut on the pressure regulator.

w Apply a light coat of gasoline to a new O±ring, and

install it to the pressure regulator.

w Completely insert the pressure regulator into the

delivery pipe by hand.

w Turn the pressure regulator counterclockwise until

the vacuum sensing port faces in the direction

indicated in the illustration.

INSTALLATION OF INJECTORS

(See Components on page FI±49)

1. INSTALL INJECTORS AND DELIVERY PIPE (a) Install the grommet to each injector.

(b) Apply a light coat of gasoline to a new O±ring and install

it to each injector.

(c) W h i l e t u r n i n g t h e i n j e c t o r c l o c k w i s e a n d counterclockwise, push it to the delivery pipes. Install

the eight injectors.

(d) Position the injector connector outward.

(e) Place the eight insulators and four spacers in position on the intake manifold.

FI±54

EFI SYSTEM

± Fuel System (Injectors)

WhereEverybodyKnowsYourName

Page 2435 of 4087

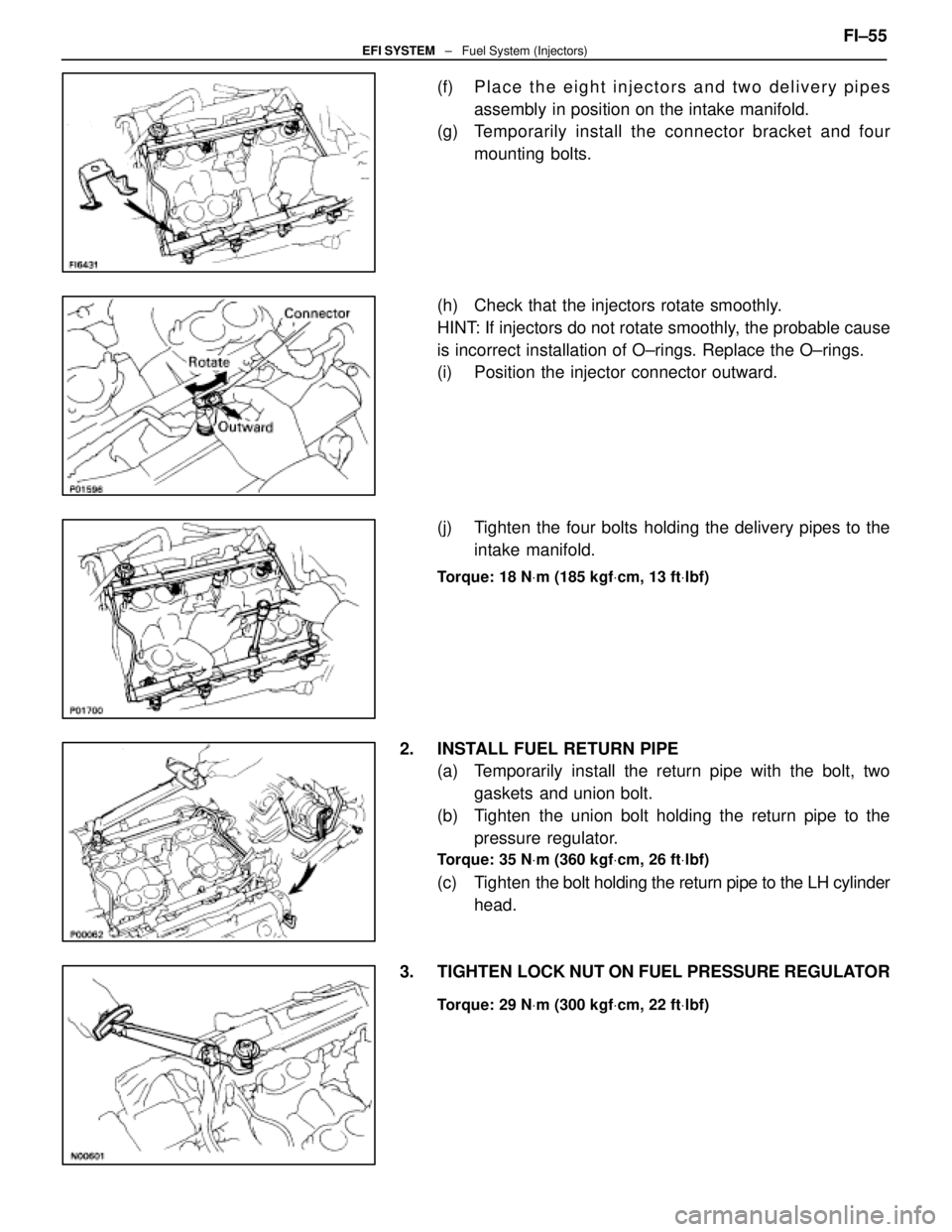

(f) Place the eight injectors and two delivery pipesassembly in position on the intake manifold.

(g) Temporarily install the c onnector bracket and four

mounting bolts.

(h) Check that the injectors rotate smoothly.

HINT: If injectors do not rotate smoothly, the probable cause

is incorrect installation of O±rings. Replace the O±rings.

(i) Position the injector connector outward.

(j) Tighten the four bolts holding the delivery pipes to the intake manifold.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

2. INSTALL FUEL RETURN PIPE

(a) Temporarily install the return pipe with the bolt, two

gaskets and union bolt.

(b) Tighten the union bolt holding the return pipe to the pressure regulator.

Torque: 35 N Vm (360 kgf Vcm, 26 ft Vlbf)

(c) Tighten the bolt holding the return pipe to the LH cylinder

head.

3. TIGHTEN LOCK NUT ON FUEL PRESSURE REGULATOR

Torque: 29 N Vm (300 kgf Vcm, 22 ft Vlbf)

FI±55EFI SYSTEM ± Fuel System (Injectors)

WhereEverybodyKnowsYourName

Page 2436 of 4087

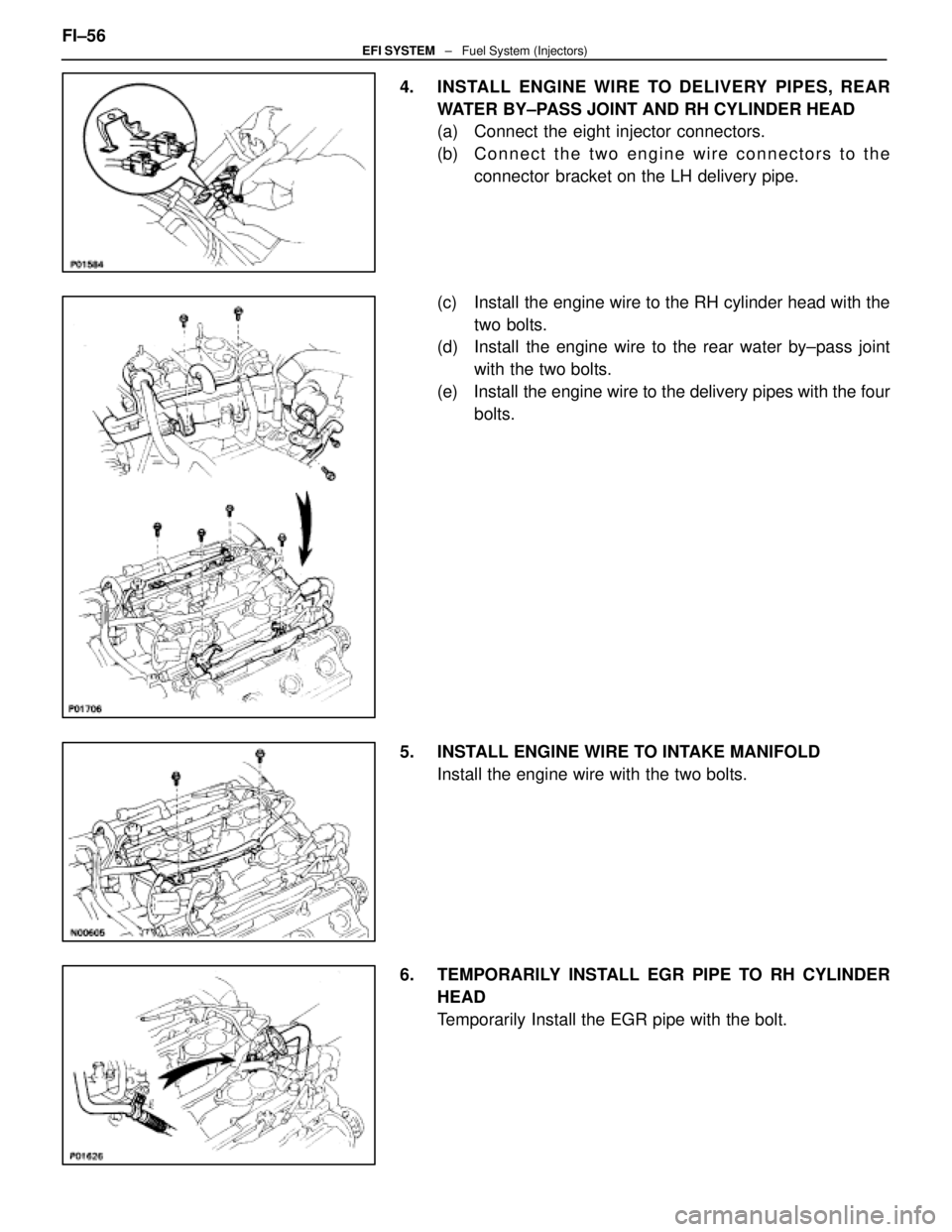

4. INSTALL ENGINE WIRE TO DELIVERY PIPES, REARWATER BY±PASS JOINT AND RH CYLINDER HEAD

(a) Connect the eight injector connectors.

(b) C onnect the two engine wire connectors to the

connector bracket on the LH delivery pipe.

(c) Install the engine wire to the RH cylinder head with the two bolts.

(d) Install the engine wire to the rear water by±pass joint

with the two bolts.

(e) Install the engine wire to the delivery pipes with the four bolts.

5. INSTALL ENGINE WIRE TO INTAKE MANIFOLD Install the engine wire with the two bolts.

6. TEMPORARILY INSTALL EGR PIPE TO RH CYLINDER HEAD

Temporarily Install the EGR pipe with the bolt.

FI±56

EFI SYSTEM

± Fuel System (Injectors)

WhereEverybodyKnowsYourName

Page 2437 of 4087

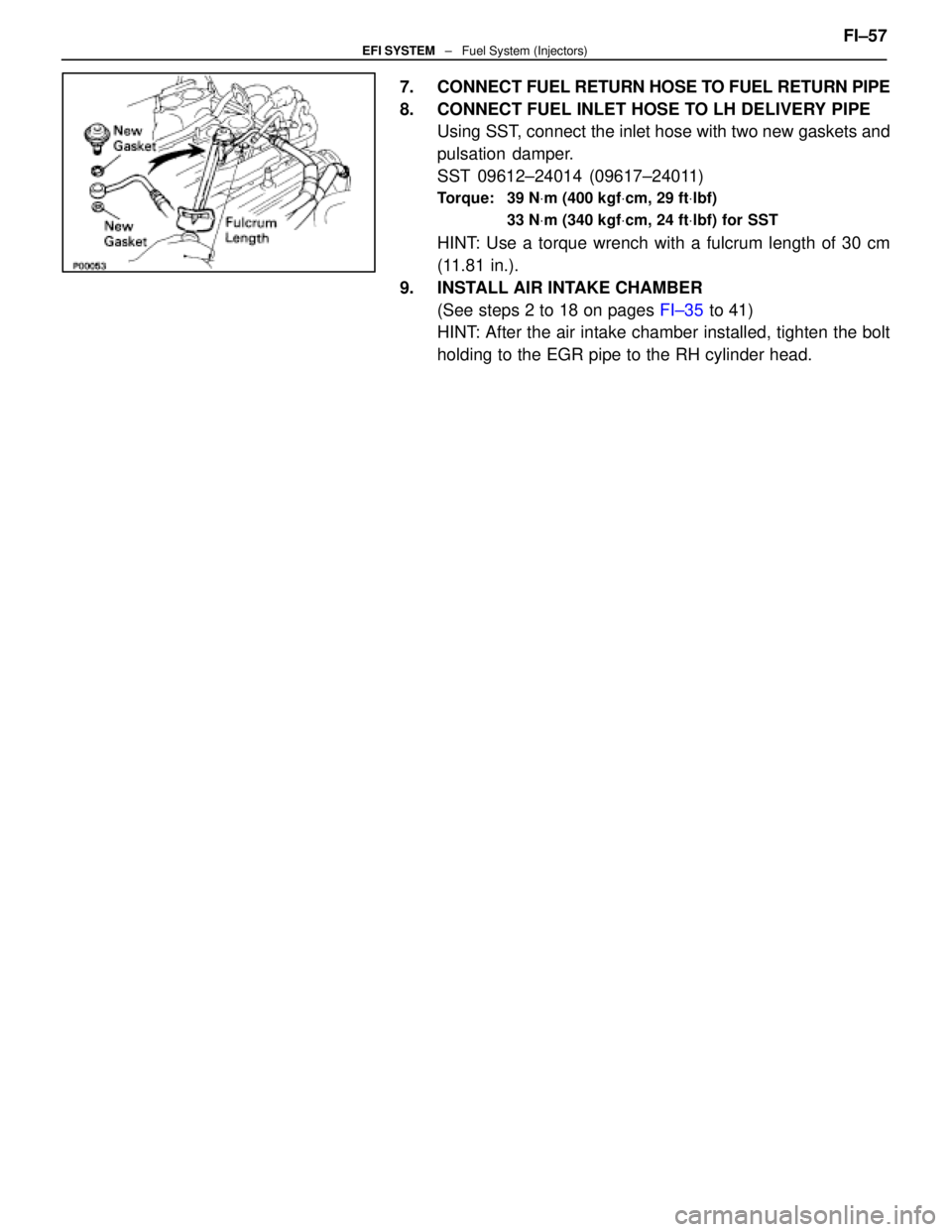

7. CONNECT FUEL RETURN HOSE TO FUEL RETURN PIPE

8. CONNECT FUEL INLET HOSE TO LH DELIVERY PIPE Using SST, connect the inlet hose with two new gaskets and

pulsation damper.

SST 09612±24014 (09617±24011)

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

33 N Vm (340 kgf Vcm, 24 ft Vlbf) for SST

HINT: Use a torque wrench with a fulcrum length of 30 cm

(11.81 in.).

9. INSTALL AIR INTAKE CHAMBER (See steps 2 to 18 on pages FI±35 to 41)

HINT: After the air intake chamber installed, tighten the bolt

holding to the EGR pipe to the RH cylinder head. FI±57

EFI SYSTEM

± Fuel System (Injectors)

WhereEverybodyKnowsYourName

Page 2438 of 4087

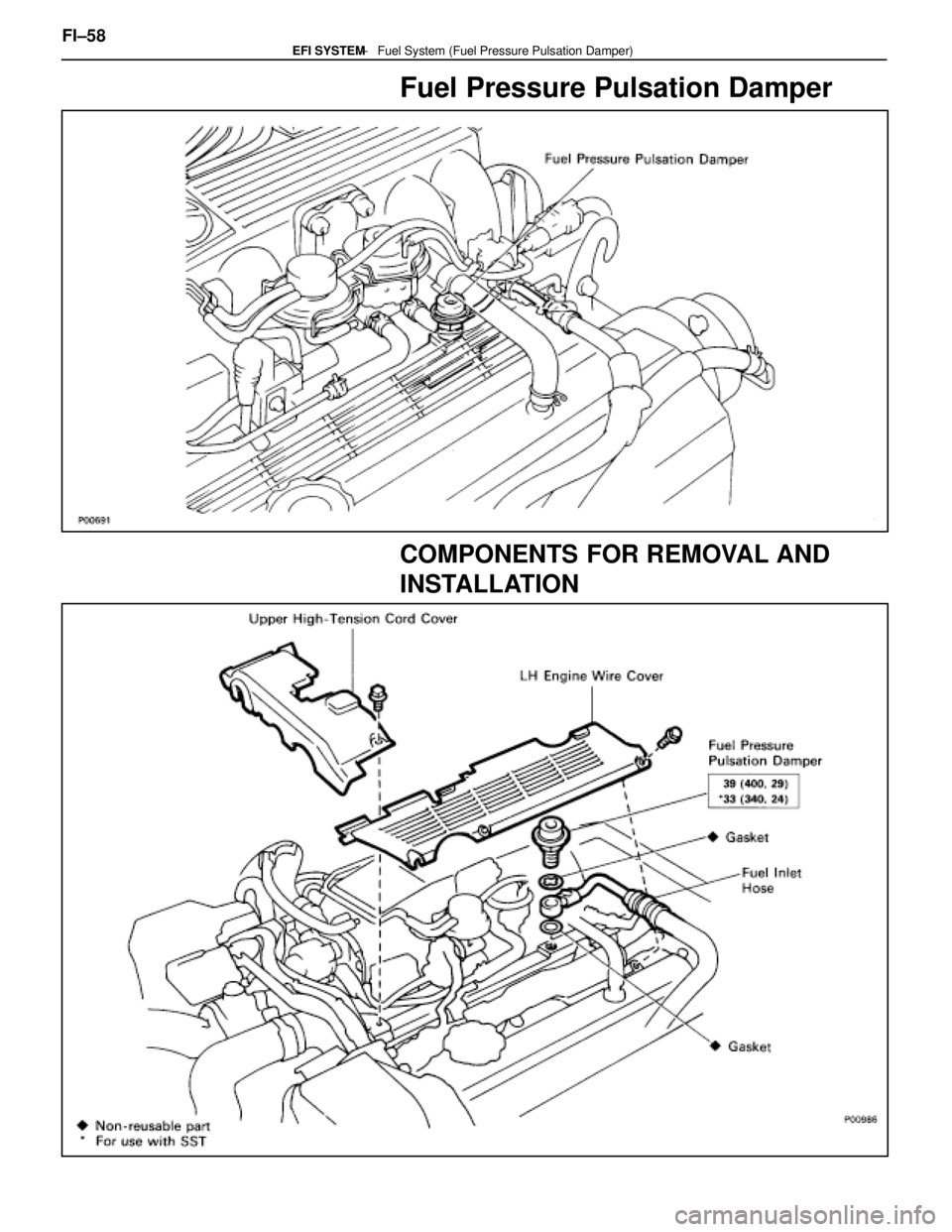

Fuel Pressure Pulsation Damper

COMPONENTS FOR REMOVAL AND

INSTALLATION

FI±58 ± Fuel System (Fuel Pressure Pulsation Damper)EFI SYSTEM

WhereEverybodyKnowsYourName

Page 2439 of 4087

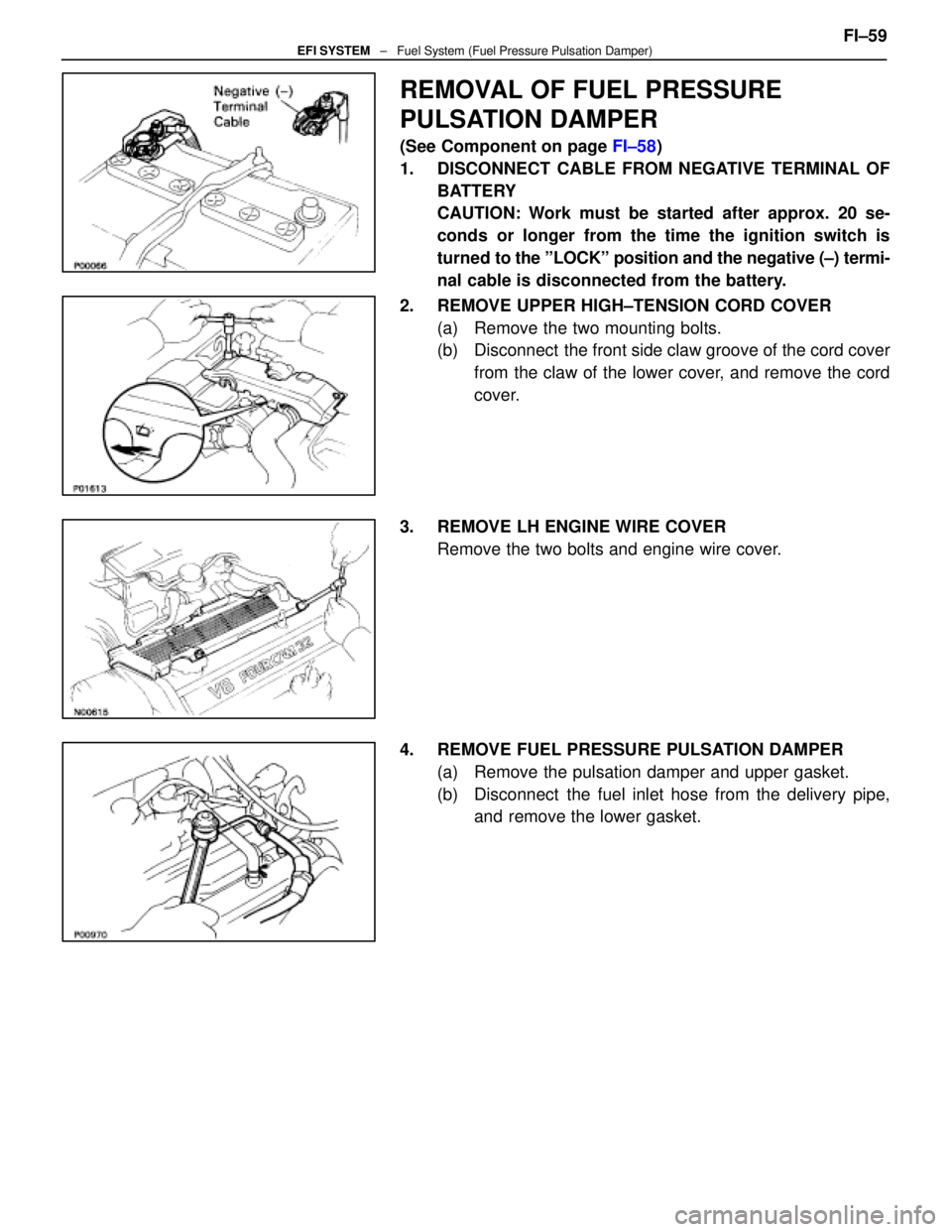

REMOVAL OF FUEL PRESSURE

PULSATION DAMPER

(See Component on page FI±58)

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OF BATTERY

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and the negative (±) termi-

nal cable is disconnected from the battery.

2. REMOVE UPPER HIGH±TENSION CORD COVER (a) Remove the two mounting bolts.

(b) Disconnect the front side claw groove of the cord coverfrom the claw of the lower cover, and remove the cord

cover.

3. REMOVE LH ENGINE WIRE COVER Remove the two bolts and engine wire cover.

4. REMOVE FUEL PRESSURE PULSATION DAMPER (a) Remove the pulsation damper and upper gasket.

(b) Disconnect the fuel inlet hose from the delivery pipe,and remove the lower gasket. FI±59

EFI SYSTEM

± Fuel System (Fuel Pressure Pulsation Damper)

WhereEverybodyKnowsYourName

Page 2440 of 4087

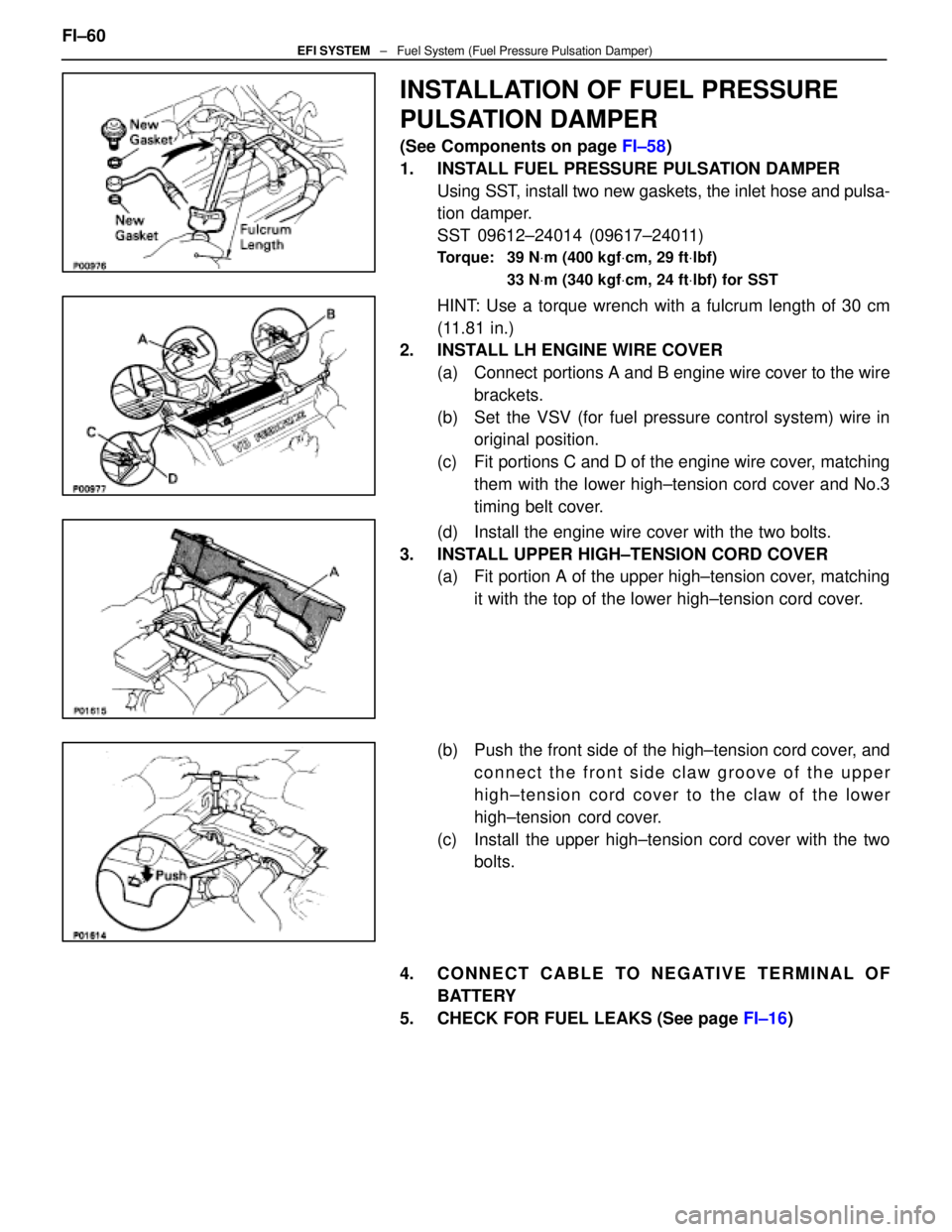

INSTALLATION OF FUEL PRESSURE

PULSATION DAMPER

(See Components on page FI±58)

1. INSTALL FUEL PRESSURE PULSATION DAMPER Using SST, install two new gaskets, the inlet hose and pulsa-

tion damper.

SST 09612±24014 (09617±24011)

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

33 N Vm (340 kgf Vcm, 24 ft Vlbf) for SST

HINT: Use a torque wrench with a fulcrum length of 30 cm

(11.81 in.)

2. INSTALL LH ENGINE WIRE COVER

(a) Connect portions A and B engine wire cover to the wirebrackets.

(b) Set the VSV (for fuel pressure control system) wire in original position.

(c) Fit portions C and D of the engine wire cover, matching them with the lower high±tension cord cover and No.3

timing belt cover.

(d) Install the engine wire cover with the two bolts.

3. INSTALL UPPER HIGH±TENSION CORD COVER (a) Fit portion A of the upper high±tension cover, matching

it with the top of the lower high±tension cord cover.

(b) Push the front side of the high±tension cord cover, and connect the front side claw groove of the upper

high±tension cord cover to the claw of the lower

high±tension cord cover.

(c) Install the upper high±tension cord cover with the two bolts.

4. CONNECT CABLE TO NEGATIVE TERMINAL OF BATTERY

5. CHECK FOR FUEL LEAKS (See page FI±16)

FI±60

EFI SYSTEM

± Fuel System (Fuel Pressure Pulsation Damper)

WhereEverybodyKnowsYourName