LEXUS SC400 1991 Service Repair Manual

Manufacturer: LEXUS, Model Year: 1991,

Model line: SC400,

Model: LEXUS SC400 1991

Pages: 4087, PDF Size: 75.75 MB

LEXUS SC400 1991 Service Repair Manual

SC400 1991

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57051/w960_57051-0.png

LEXUS SC400 1991 Service Repair Manual

Trending: set clock, exhaust, seat adjustment, wiper blades, light, brake sensor, headrest

Page 381 of 4087

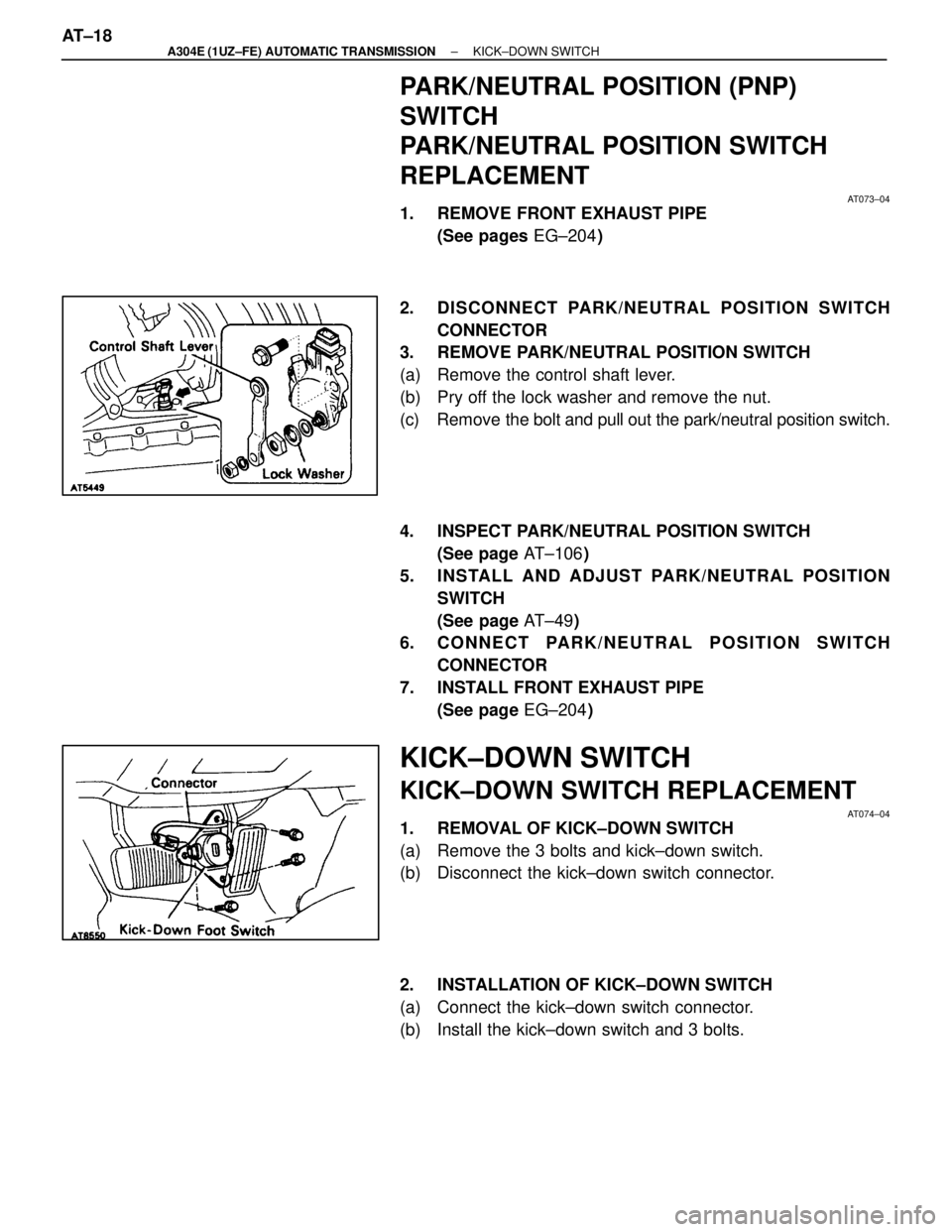

PARK/NEUTRAL POSITION (PNP)

SWITCH

PARK/NEUTRAL POSITION SWITCH

REPLACEMENT

AT073±04

1. REMOVE FRONT EXHAUST PIPE(See pages EG±204)

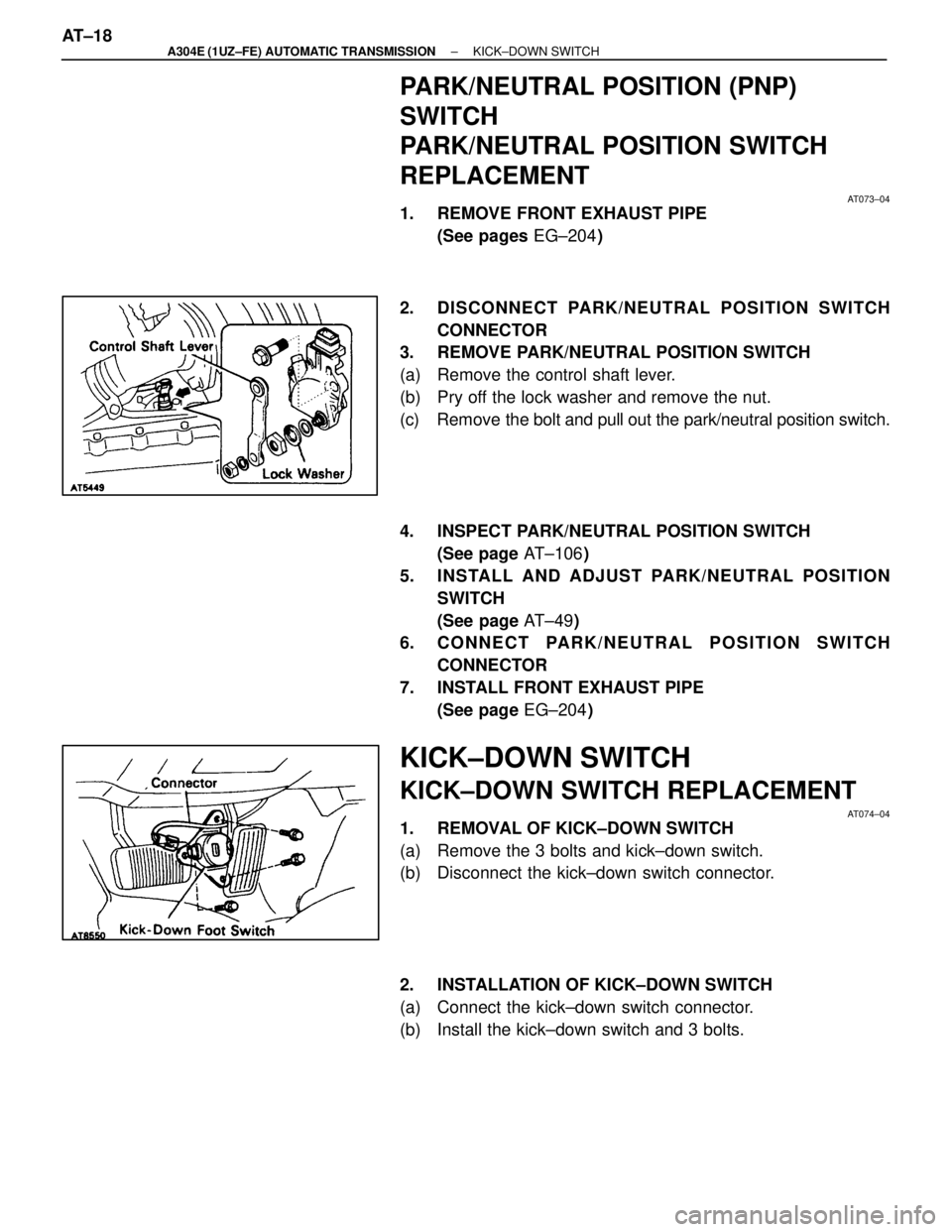

2. DISCONNECT PARK/NEUTRAL POSITION SWITCH CONNECTOR

3. REMOVE PARK/NEUTRAL POSITION SWITCH

(a) Remove the control shaft lever.

(b) Pry off the lock washer and remove the nut.

(c) Remove the bolt and pull out the park/neutral position switch.

4. INSPECT PARK/NEUTRAL POSITION SWITCH

(See page AT±106)

5. INSTALL AND ADJUST PARK/NEUTRAL POSITION SWITCH

(See page AT±49)

6. CONNECT PARK/NEUTRAL POSITION SWITCH

CONNECTOR

7. INSTALL FRONT EXHAUST PIPE (See page EG±204)

KICK±DOWN SWITCH

KICK±DOWN SWITCH REPLACEMENT

AT074±04

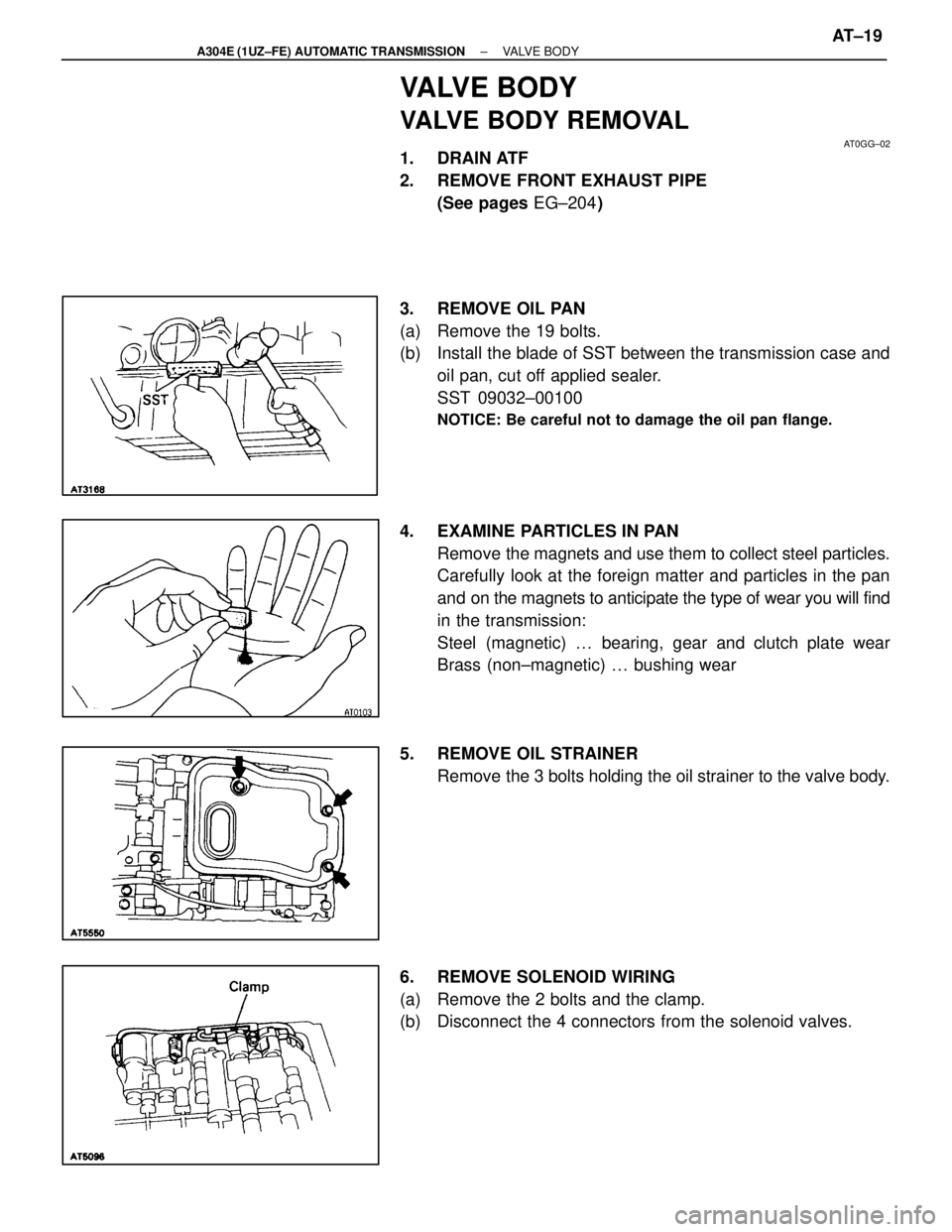

1. REMOVAL OF KICK±DOWN SWITCH

(a) Remove the 3 bolts and kick±down switch.

(b) Disconnect the kick±down switch connector.

2. INSTALLATION OF KICK±DOWN SWITCH

(a) Connect the kick±down switch connector.

(b) Install the kick±down switch and 3 bolts.

AT±18

±

A304E (1UZ±FE) AUTOMATIC TRANSMISSION KICK±DOWN SWITCH

WhereEverybodyKnowsYourName

Page 382 of 4087

VALVE BODY

VALVE BODY REMOVAL

AT0GG±02

1. DRAIN ATF

2. REMOVE FRONT EXHAUST PIPE(See pages EG±204)

3. REMOVE OIL PAN

(a) Remove the 19 bolts.

(b) Install the blade of SST between the transmission case and oil pan, cut off applied sealer.

SST 09032±00100

NOTICE: Be careful not to damage the oil pan flange.

4. EXAMINE PARTICLES IN PANRemove the magnets and use them to collect steel particles.

Carefully look at the foreign matter and particles in the pan

and on the magnets to anticipate the type of wear you will find

in the transmission:

Steel (magnetic) 0 bearing, gear and clutch plate wear

Brass (non±magnetic) 0 bushing wear

5. REMOVE OIL STRAINER Remove the 3 bolts holding the oil strainer to the valve body.

6. REMOVE SOLENOID WIRING

(a) Remove the 2 bolts and the clamp.

(b) Disconnect the 4 connectors from the solenoid valves.

±

A304E (1UZ±FE) AUTOMATIC TRANSMISSION VALVE BODYAT±19

WhereEverybodyKnowsYourName

Page 383 of 4087

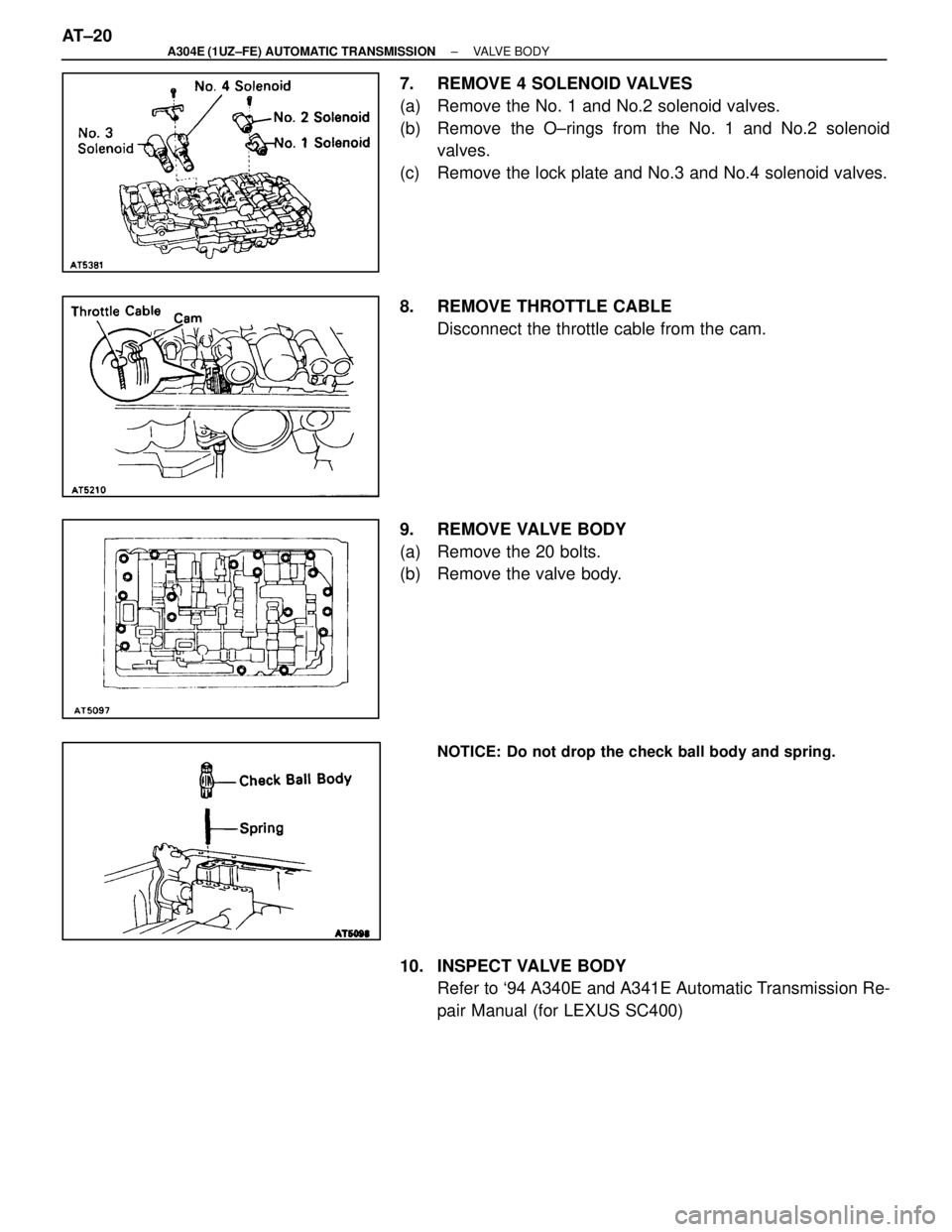

7. REMOVE 4 SOLENOID VALVES

(a) Remove the No. 1 and No.2 solenoid valves.

(b) Remove the O±rings from the No. 1 and No.2 solenoidvalves.

(c) Remove the lock plate and No.3 and No.4 solenoid valves.

8. REMOVE THROTTLE CABLE Disconnect the throttle cable from the cam.

9. REMOVE VALVE BODY

(a) Remove the 20 bolts.

(b) Remove the valve body.

NOTICE: Do not drop the check ball body and spring.

10. INSPECT VALVE BODY Refer to `94 A340E and A341E Automatic Transmission Re-

pair Manual (for LEXUS SC400)

AT±20

±

A304E (1UZ±FE) AUTOMATIC TRANSMISSION VALVE BODY

WhereEverybodyKnowsYourName

Page 384 of 4087

VALVE BODY INSTALLATION

AT0GH±02

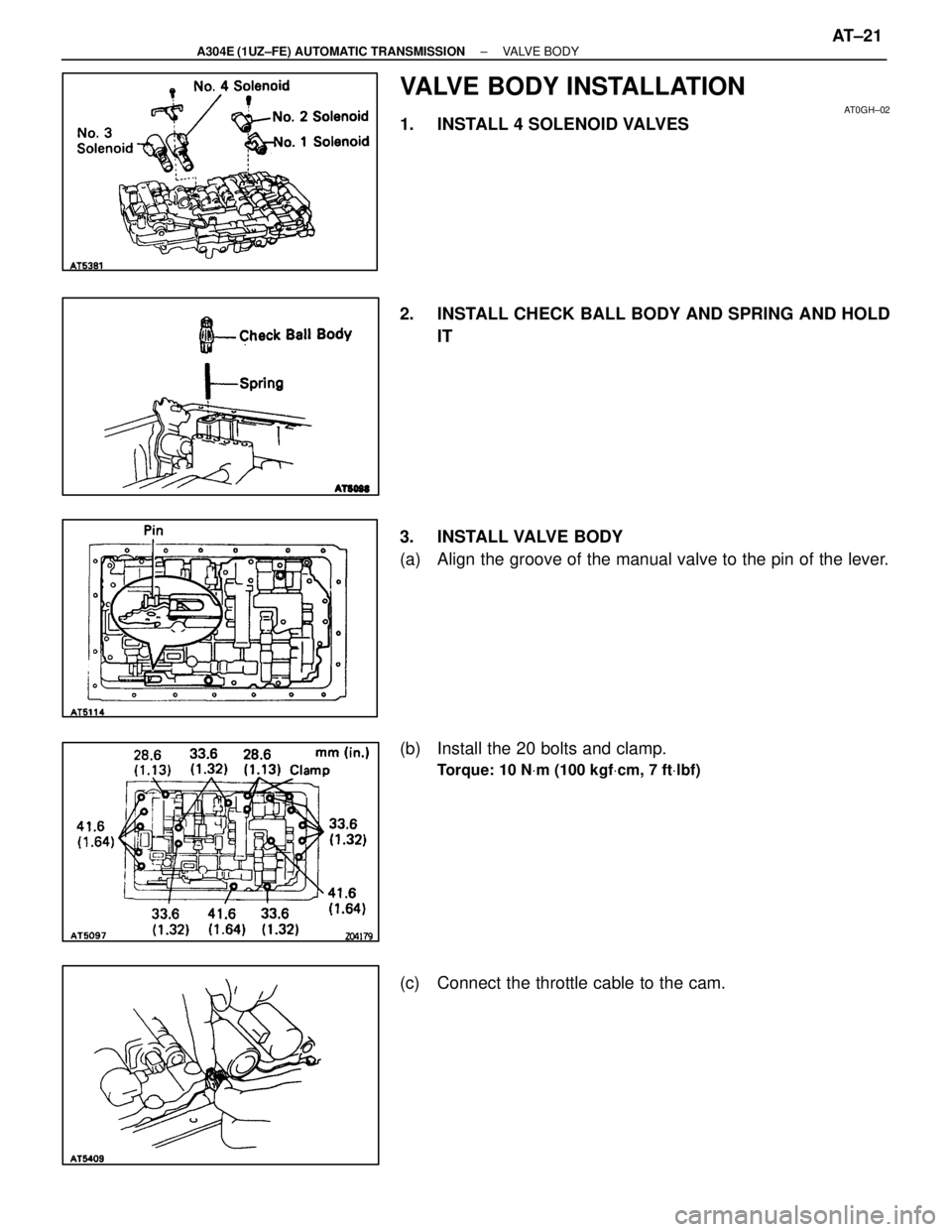

1. INSTALL 4 SOLENOID VALVES

2. INSTALL CHECK BALL BODY AND SPRING AND HOLDIT

3. INSTALL VALVE BODY

(a) Align the groove of the manual valve to the pin of the lever.

(b) Install the 20 bolts and clamp.

Torque: 10 N Vm (100 kgf Vcm, 7 ft Vlbf)

(c) Connect the throttle cable to the cam.

±

A304E (1UZ±FE) AUTOMATIC TRANSMISSION VALVE BODYAT±21

WhereEverybodyKnowsYourName

Page 385 of 4087

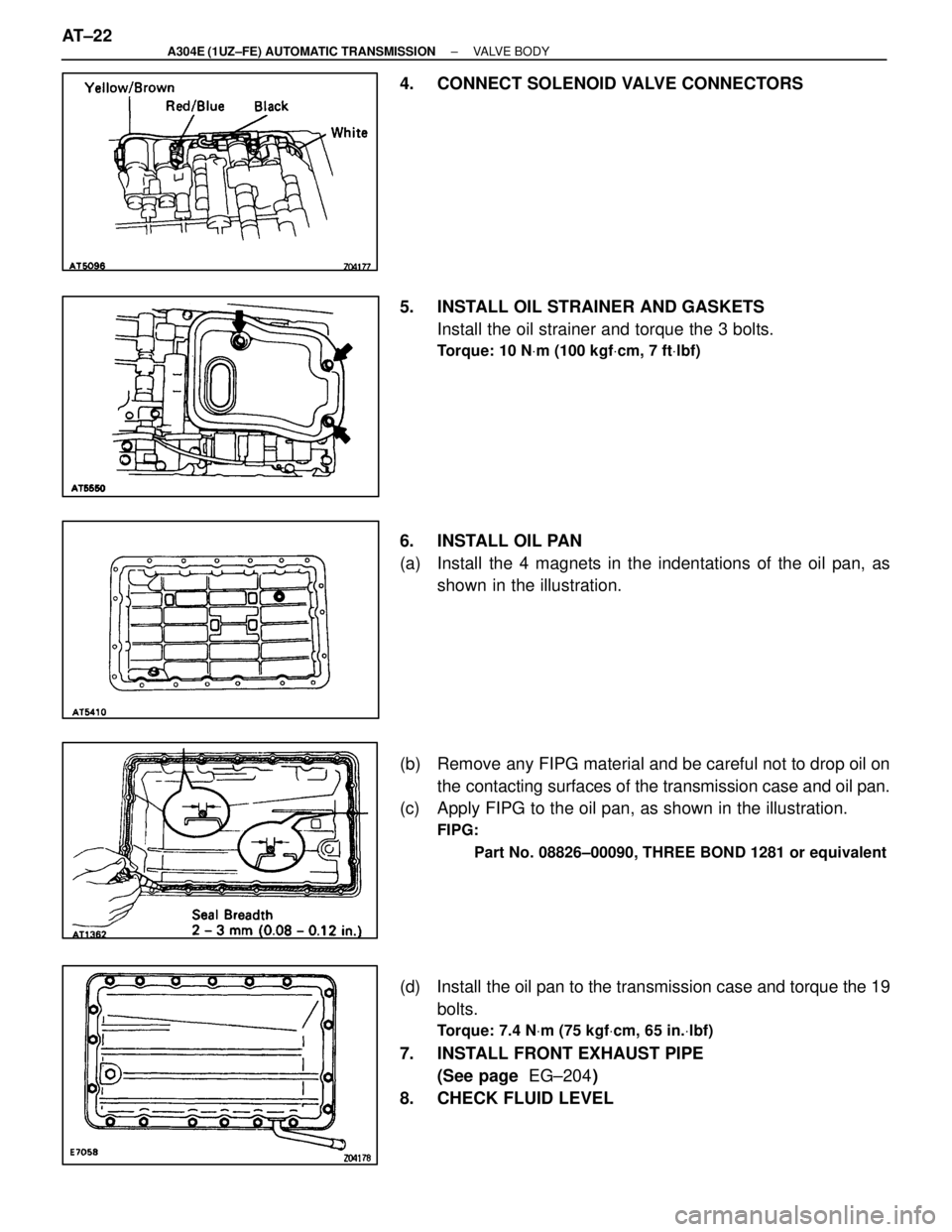

4. CONNECT SOLENOID VALVE CONNECTORS

5. INSTALL OIL STRAINER AND GASKETSInstall the oil strainer and torque the 3 bolts.

Torque: 10 N Vm (100 kgf Vcm, 7 ft Vlbf)

6. INSTALL OIL PAN

(a) Install the 4 magnets in the indentations of the oil pan, as

shown in the illustration.

(b) Remove any FIPG material and be careful not to drop oil on the contacting surfaces of the transmission case and oil pan.

(c) Apply FIPG to the oil pan, as shown in the illustration.

FIPG:

Part No. 08826±00090, THREE BOND 1281 or equivalent

(d) Install the oil pan to the transmission case and torque the 19bolts.

Torque: 7.4 N Vm (75 kgf Vcm, 65 in. Vlbf)

7. INSTALL FRONT EXHAUST PIPE

(See page EG±204)

8. CHECK FLUID LEVEL

AT±22

±

A304E (1UZ±FE) AUTOMATIC TRANSMISSION VALVE BODY

WhereEverybodyKnowsYourName

Page 386 of 4087

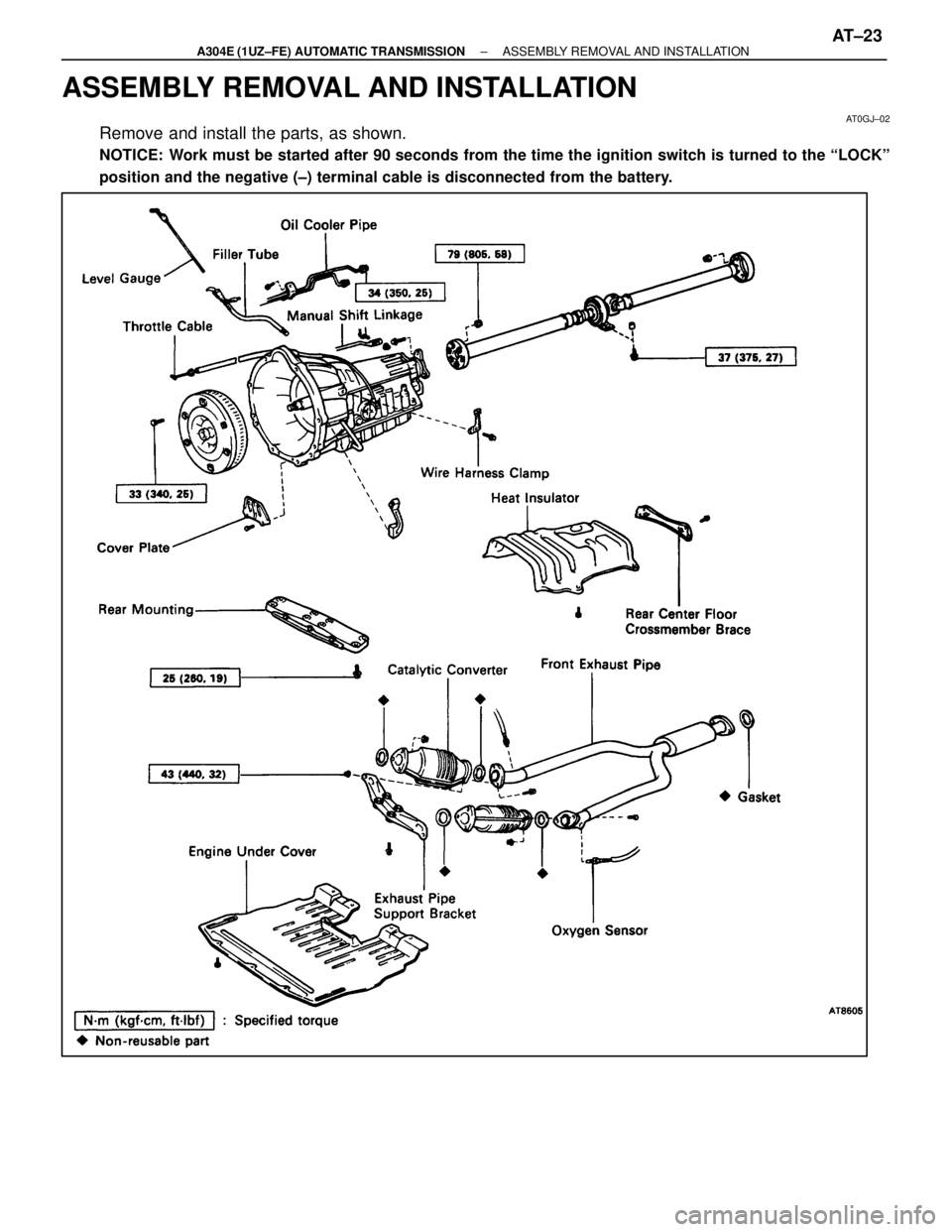

ASSEMBLY REMOVAL AND INSTALLATION

AT0GJ±02

Remove and install the parts, as shown.

NOTICE: Work must be started after 90 seconds from the time the ignition switch i\

s turned to the ªLOCKº

position and the negative (±) terminal cable is disconnected from t\

he battery.

±

A304E (1UZ±FE) AUTOMATIC TRANSMISSION ASSEMBLY REMOVAL AND INSTALLATIONAT±23

WhereEverybodyKnowsYourName

Page 387 of 4087

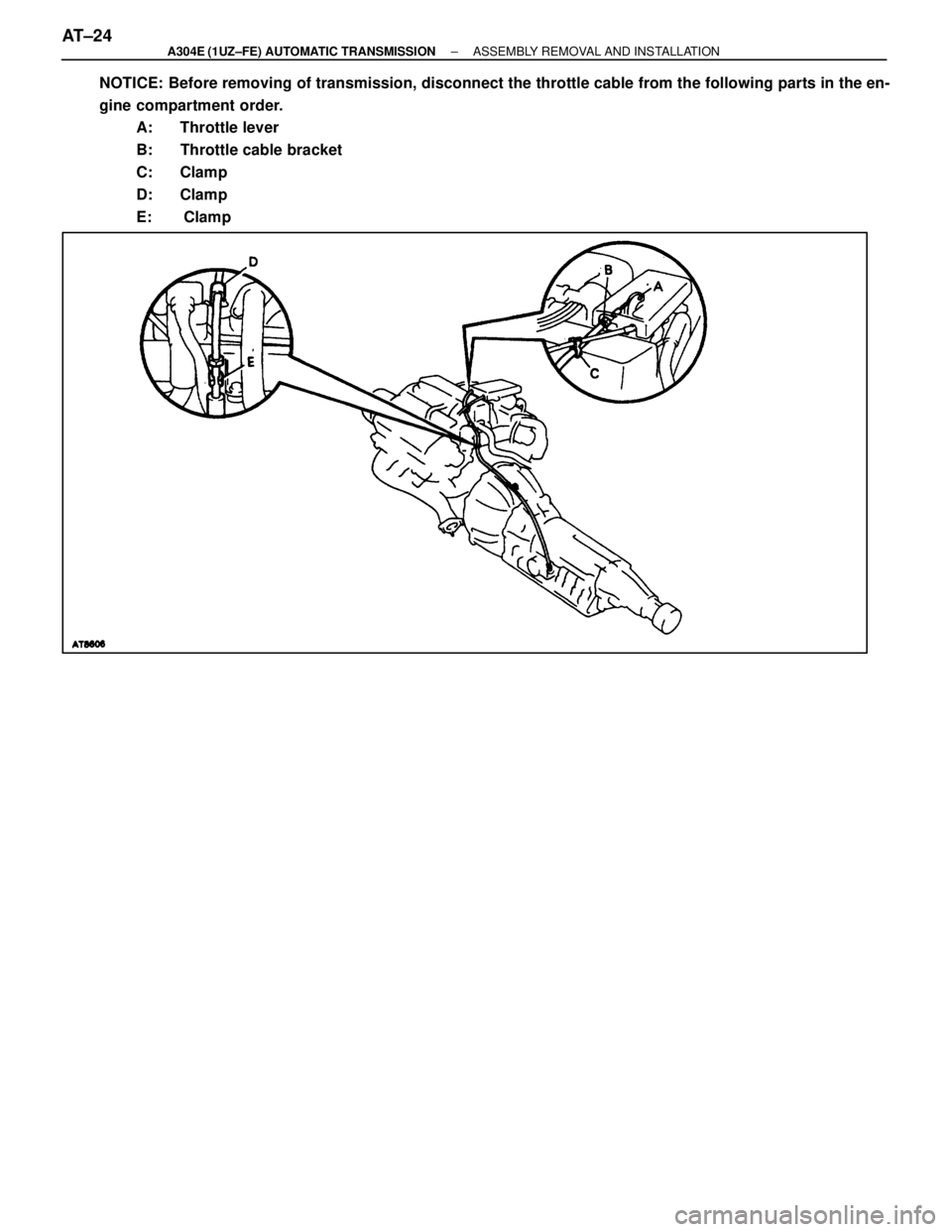

NOTICE: Before removing of transmission, disconnect the throttle cable from the\

following parts in the en-

gine compartment order.A: Throttle lever

B: Throttle cable bracket

C: Clamp

D: Clamp

E: Clamp

AT±24±

A304E (1UZ±FE) AUTOMATIC TRANSMISSION ASSEMBLY REMOVAL AND INSTALLATION

WhereEverybodyKnowsYourName

Page 388 of 4087

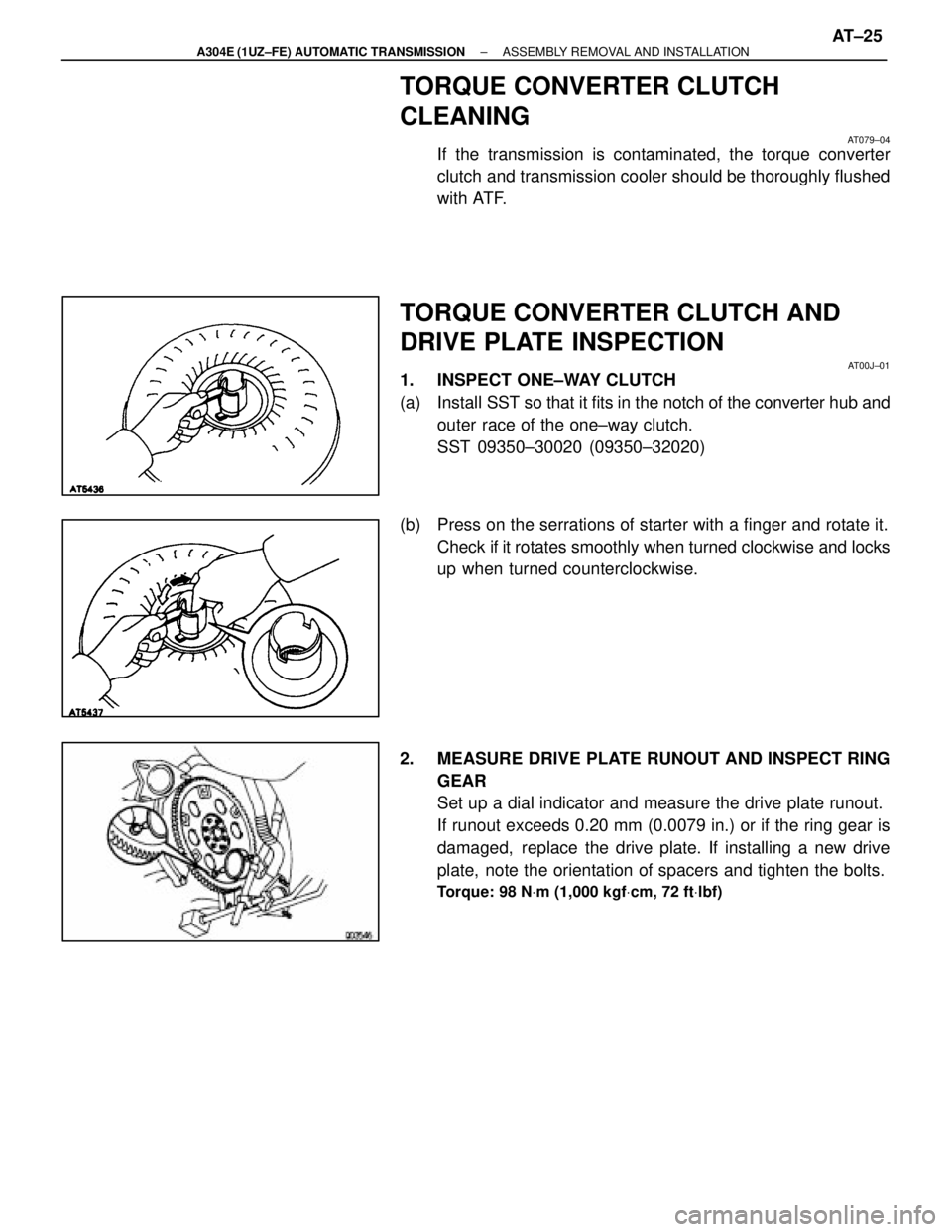

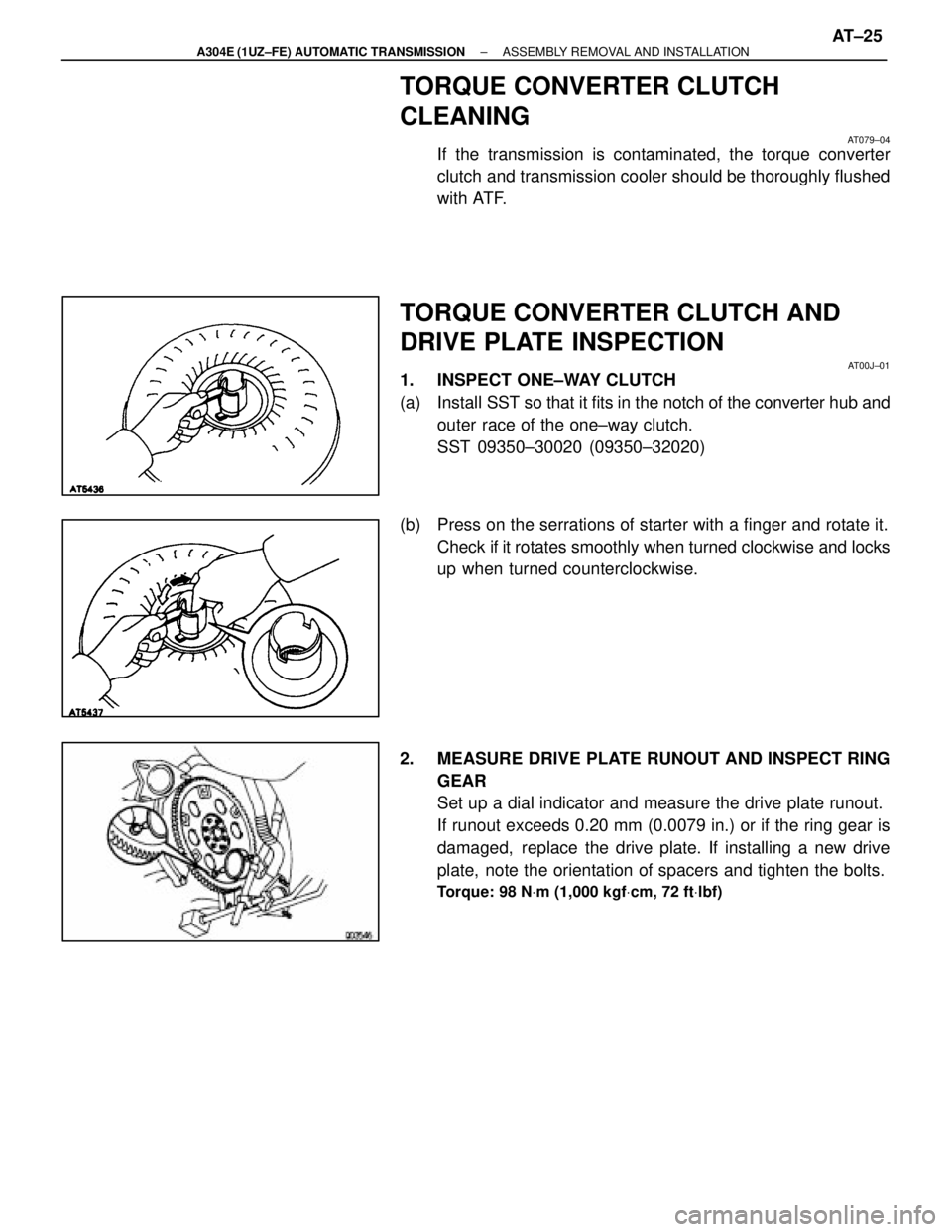

TORQUE CONVERTER CLUTCH

CLEANING

AT079±04

If the transmission is contaminated, the torque converter

clutch and transmission cooler should be thoroughly flushed

with ATF.

TORQUE CONVERTER CLUTCH AND

DRIVE PLATE INSPECTION

AT00J±01

1. INSPECT ONE±WAY CLUTCH

(a) Install SST so that it fits in the notch of the converter hub and

outer race of the one±way clutch.

SST 09350±30020 (09350±32020)

(b) Press on the serrations of starter with a finger and rotate it. Check if it rotates smoothly when turned clockwise and locks

up when turned counterclockwise.

2. MEASURE DRIVE PLATE RUNOUT AND INSPECT RING GEAR

Set up a dial indicator and measure the drive plate runout.

If runout exceeds 0.20 mm (0.0079 in.) or if the ring gear is

damaged, replace the drive plate. If installing a new drive

plate, note the orientation of spacers and tighten the bolts.

Torque: 98 N Vm (1,000 kgf Vcm, 72 ft Vlbf)

±

A304E (1UZ±FE) AUTOMATIC TRANSMISSION ASSEMBLY REMOVAL AND INSTALLATIONAT±25

WhereEverybodyKnowsYourName

Page 389 of 4087

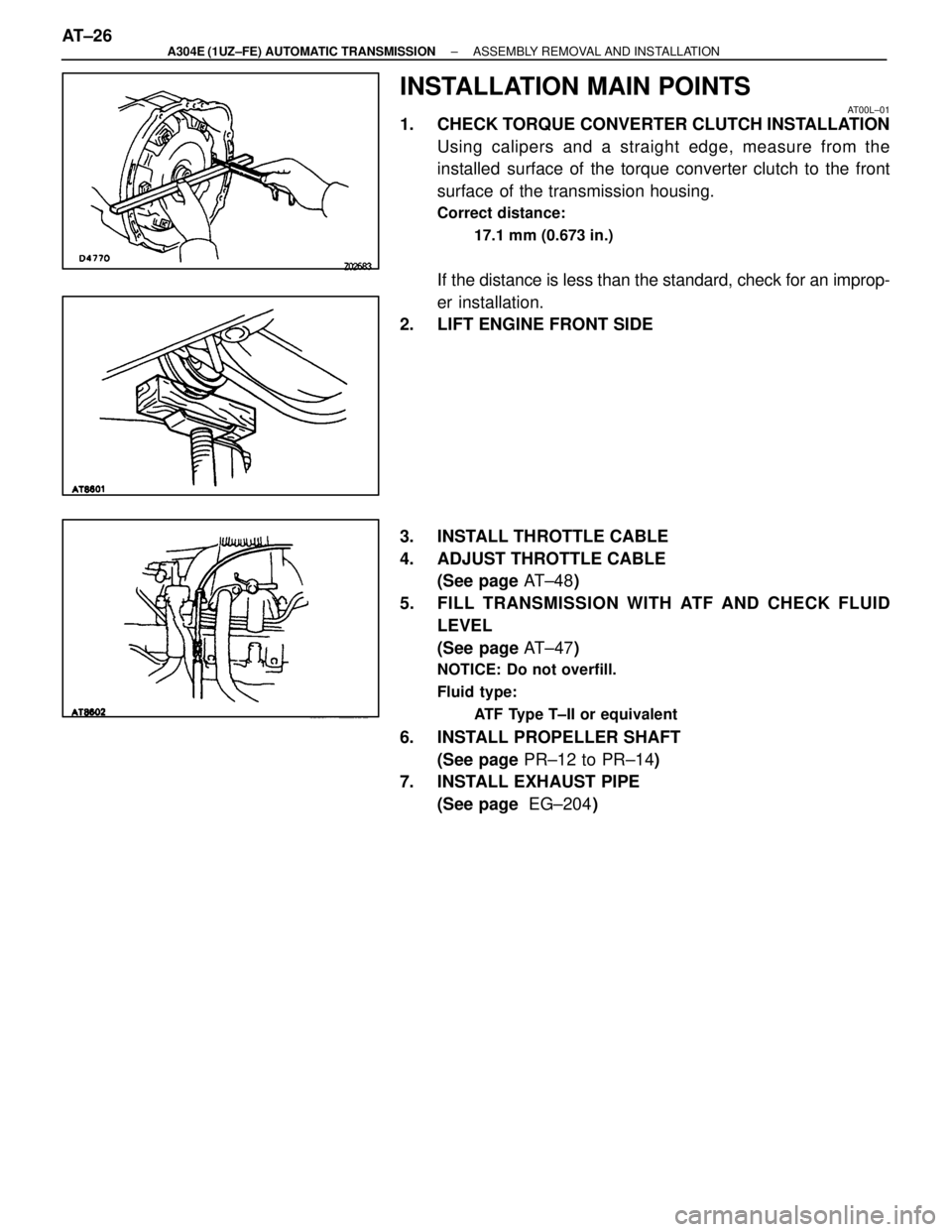

INSTALLATION MAIN POINTS

AT00L±01

1. CHECK TORQUE CONVERTER CLUTCH INSTALLATIONUsing calipers and a straight edge, measure from the

installed surface of the torque converter clutch to the front

surface of the transmission housing.

Correct distance:

17.1 mm (0.673 in.)

If the distance is less than the standard, check for an improp-

er installation.

2. LIFT ENGINE FRONT SIDE

3. INSTALL THROTTLE CABLE

4. ADJUST THROTTLE CABLE (See page AT±48)

5. FILL TRANSMISSION WITH ATF AND CHECK FLUID LEVEL

(See page AT±47)

NOTICE: Do not overfill.

Fluid type:

ATF Type T±II or equivalent

6. INSTALL PROPELLER SHAFT(See page PR±12 to PR±14 )

7. INSTALL EXHAUST PIPE

(See page EG±204)

AT±26

±

A304E (1UZ±FE) AUTOMATIC TRANSMISSION ASSEMBLY REMOVAL AND INSTALLATION

WhereEverybodyKnowsYourName

Page 390 of 4087

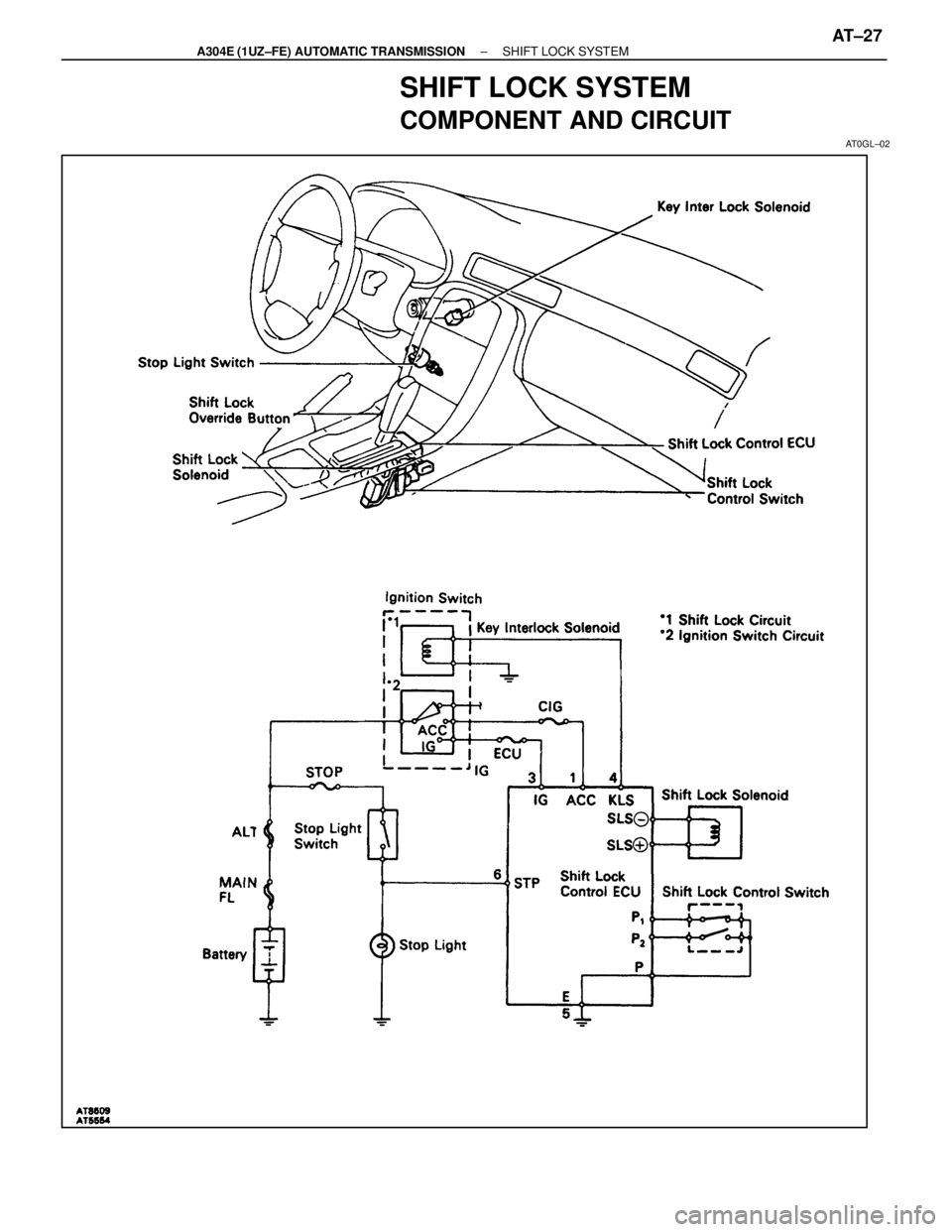

SHIFT LOCK SYSTEM

COMPONENT AND CIRCUIT

AT0GL±02

±

A304E (1UZ±FE) AUTOMATIC TRANSMISSION SHIFT LOCK SYSTEMAT±27

WhereEverybodyKnowsYourName

Trending: check engine, fuel, lock, buttons, fuel type, wire pin out, tire type