engine coolant MAZDA 232 1990 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 93 of 677

E OUTLINE

OUTLINE

OUTttNE OF CONSTRUCTION

The cooling system in the 323 4WD model is basically the same as in the 323 2WD model.

Although there is no fundamental change from the BP DOHC of the 2WD model, the coolant circulation

path has been changed to direct coolant to the water-cooied turbocharger.

A two-stage thermostat is used in the BP DUHC turbocharged engine to stabilize the engine coolant tem-

peratu re.

The radiator and cooling fan specifications are different. The BP DOHC turbocharged engine of the 4WD

model uses a two-speed electric cooling fan.

93GOEX-704

COOLANT FLOW CHART (BP DOHC TURBO)

E-4

Page 94 of 677

![MAZDA 232 1990 Suplement User Guide SPECIFICATlONS

-

km

Cootlng system

Coolant camacltv

EnginelTtansaxte

lrters [US Qt. Imo at)

8P SOHC ] 8P DOW Turbo

MTX ATX

I MTX

Water-cooled, forced crrculation

5.0 (5.3, 4.4)

I 6.0 t&3,5 MAZDA 232 1990 Suplement User Guide SPECIFICATlONS

-

km

Cootlng system

Coolant camacltv

EnginelTtansaxte

lrters [US Qt. Imo at)

8P SOHC ] 8P DOW Turbo

MTX ATX

I MTX

Water-cooled, forced crrculation

5.0 (5.3, 4.4)

I 6.0 t&3,5](/img/28/57056/w960_57056-93.png)

SPECIFICATlONS

-

km

Cootlng system

Coolant camacltv

EnginelTtansaxte

lrters [US Qt. Imo at)

8P SOHC ] 8P DOW Turbo

MTX ATX

I MTX

Water-cooled, forced crrculation

5.0 (5.3, 4.4)

I 6.0 t&3,5.3) -

1 Type

Water puma 1

I Water seal Centrifugal

Unified mechanical

seal

: Type I Wax,single stage”‘, Wax, two-stage*’ 1 Wax, two-stage

80.5-83.5 (177-182)“1

Opening temperature

“C (OF)

Main: 86.5-89.5 (188-l 93) *’ Main: 86.5-89.5 (lSS--193)

The:mosta! 1 Sub : 83.5-86.5 (182-188) Sub 83.G86.5 (182-188)

1 Full-open temperature OC

(OF) 95 (203)*‘, 100 (212)*’ i 100 (212)

L I

“...Except cold area, *2...Cotd area only

1 r 1 93GOEX-706 j Full-open lift mm (in) 8.5 (0.335) or more’l

Main: 8.0 (0.31).mln.‘2

Sub : 1.5 10.061 min * Main: 8.0 (0.31) min.

Sub : I.5 (0.06) mm.

Radiator 1 Type

Cap vaive opening-pressure ’

kPa (kglcm2, psi) Corrugated fin

74-l 03 (0.75-I .05, 11-l 5) j Tvm?

EIectnc I

Coohg fan f Outer drameter mm (in) 320 (12.6) 340 (13.4)

Blade

Number 4 5

Motor

/ Current A

6.6 * 1 Hi : 13.3 + 10% max.

Lo: 8.8 + 10% max. E-5

Page 95 of 677

E OUTlANE

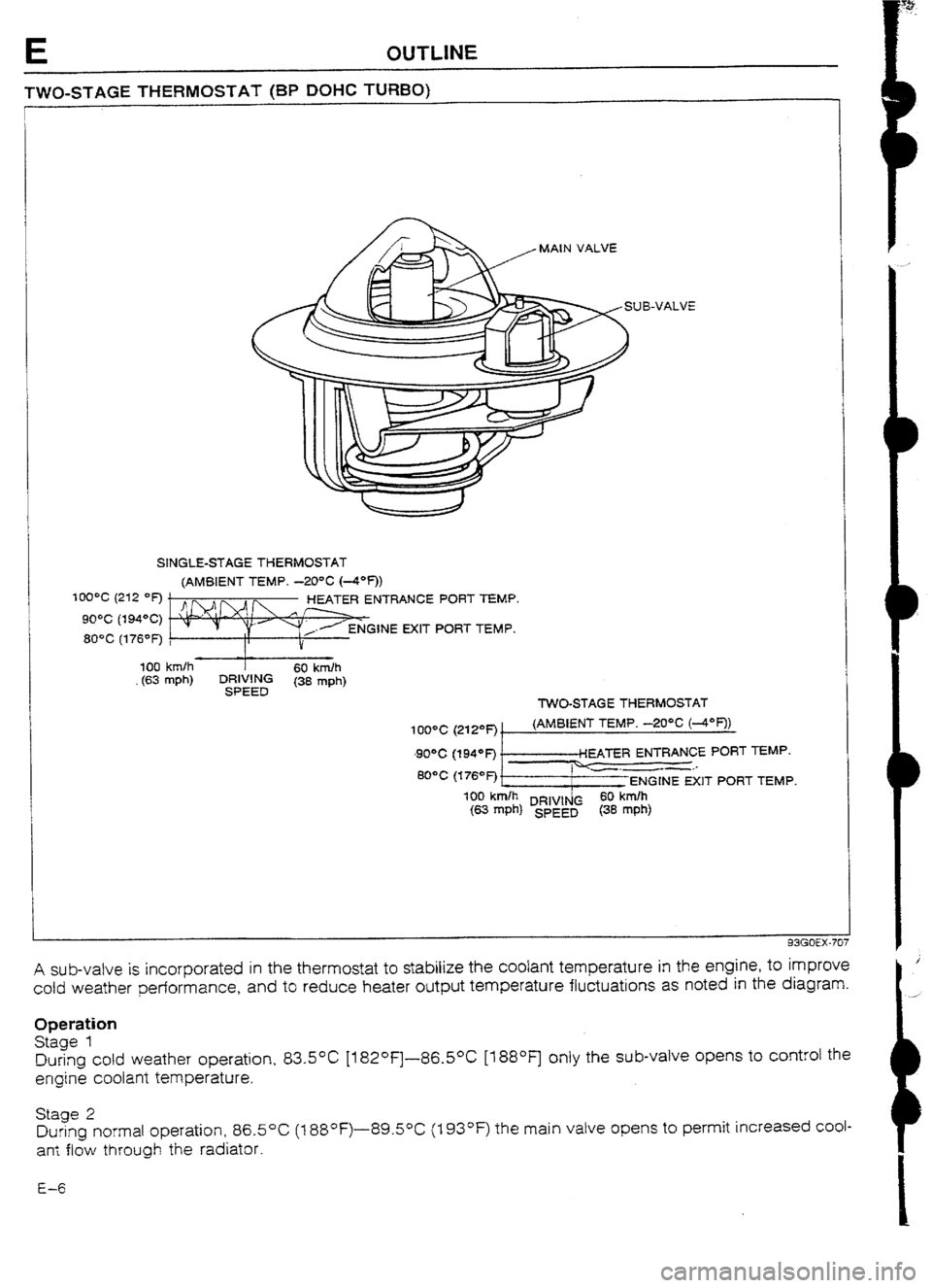

TWO-STAGE THERMOSTAT (BP DOHC TURBO)

MAIN VALVE

SINGLE-STAGE THERMOSTAT

(AMBIENT fEMP. -20% (4*f))

NTRANCE PORT TEMP

GINE EXIT PORT TEMP.

- 100 km/h

60 kndh

(63 mph) ~~~~~ (38 mph)

TWO-STAGE THERMOSTAT

A sub-valve is incorporated in the thermostat to stabilize the coolant temperature in the engine, to improve

cold weather performance, and to reduce heater output temperature fluctuations as noted in the diagram.

Operation

Stage 1

During cold weather operation, 83.5*C [182°F]-86.50C [t 88OF] only the sub-valve opens to control the

engine coolant temperature.

Stage 2

During normal operation, 86.5OC (1 88°F)-89.50C (I 93OF) the main valve opens to permit increased coul-

an: flow through the radiator.

E-6

Page 99 of 677

E ELECTRIC COOLING FAN SYSTEM

ELECTRIC COOLING FAN SYSTEM (BP

DUHC TURBO)

SYSTEM ClRCUIT

r

WITH A/C

r-- _______ ------

I ADDITIONAL

1 FAN

I PRESSL

SWITCH

I WATER

THERMOSWfTCtl

ABOVE 87OC (207OF): ON

RADlATOjl THERMOSWITCH

ABOVE 105*C (221 “I=): ON

8 93GOEX-719

-

%

J--- QY- -THERMOME?ERsi-=i

--

--------L-

93GOEX-7 i 2

E-10 SYSTEM INSPECTION

1. Jump across the test fan (TFA) terminal and the ground

(GN D) terminal of the diagnosis connector.

2. Turn the ignition switch ON and verify that the fan operates.

If the fan does not operate, inspect the cooling fan system

components and wiring harness.

3. Remove the radiator cap and place a thermometer in the

radiator filler neck.

4. Start the engine.

5. Verify that the fan operates when the coolant temperature

reaches approx. 97*C (207°F).

If it does, check the water thermoswitch.

(Refer to page

E--i I.)

Page 139 of 677

![MAZDA 232 1990 Suplement User Guide F2 CONTROL SYSTEM

KNOCK CONTROL SYSTEM [BP TURBO]

This svstem retards the ignition timina when enaine knocking occurs because of usage of low octane fuel, etc.

1NTAKE

MANIFO

KNOCK SENSOR

(INSTAL MAZDA 232 1990 Suplement User Guide F2 CONTROL SYSTEM

KNOCK CONTROL SYSTEM [BP TURBO]

This svstem retards the ignition timina when enaine knocking occurs because of usage of low octane fuel, etc.

1NTAKE

MANIFO

KNOCK SENSOR

(INSTAL](/img/28/57056/w960_57056-138.png)

F2 CONTROL SYSTEM

KNOCK CONTROL SYSTEM [BP TURBO]

This svstem retards the ignition timina when enaine knocking occurs because of usage of low octane fuel, etc.

1NTAKE

MANIFO

KNOCK SENSOR

(INSTALLED BETWEEN No.2 AND

No.3 CYLINDER)

IGNITER

KNOCK iX?NTROL

UNIT

Operation

When the engine vibrates, the knock sensor generates a slight voltage signal that is the sent to the knock

control unit. The knock control unit determines whether the signal is a knocking signal. If it is a knocking

signal, the ignition spark is retarded according to the intensity of the knock to a maximum of 4O.

Inhibition of spark retardation

In order to improve drivability and fuel economy, the ECU inhibits the above spark retardation when the

‘engine load Ls light, the coolant temperature is below O°C (32OF), the engine is cranking during engine test

conditions.

Note

l The knock ~ensur and knock control unit cannot be inspected individually.

When a matfunction code number 05 is indicated, replace the knock controt unit or sensor

only after inspecting the related wiring and connectors.

F2-22

Page 140 of 677

![MAZDA 232 1990 Suplement User Guide CONTROL SYSTEM F2

t OXYGEN SENSOR [BP TURBO]

I

CERAMlC HEATER

93GOF2-733

Because the temperature of the exhaust gas is inherently low in turbocharged engines, the BP Turbo model

uses a rapid hea MAZDA 232 1990 Suplement User Guide CONTROL SYSTEM F2

t OXYGEN SENSOR [BP TURBO]

I

CERAMlC HEATER

93GOF2-733

Because the temperature of the exhaust gas is inherently low in turbocharged engines, the BP Turbo model

uses a rapid hea](/img/28/57056/w960_57056-139.png)

CONTROL SYSTEM F2

t OXYGEN SENSOR [BP TURBO]

I

CERAMlC HEATER

93GOF2-733

Because the temperature of the exhaust gas is inherently low in turbocharged engines, the BP Turbo model

uses a rapid heating ceramic heater to detect the air/fuel ratio,

PRESSURE REGULATOR CONTROL SYSTEM [BP TURBO]

PRESSURE

REGULATOR

I SOLENOID VALVE

(PRESSURE REGULATOR CONTROL)

FUEL

+ (FROM

DELIVERY PIPE1

II

FUEL INJ I

RELAY

(MAIN REU\Y)

I

II Ir

-__. _ - -’ VACUUM

CT0 DYNAMIC

Ill

CHAMBER)

BATTERY -

c

FUEL

(TO FUEL TANK)

nme*rn -.-a

To prevent percolation of the fuel during hot restart idle, vacuum to the pressure regulator k cut for 180

sec., and the fuel injection pressure is increased to slightly more than 284 kPa (2.90 kg/cm’, 41.2 psi).

Operating condition

l Coolant temperature: Above 90°C (194OF)

l Intake air temperature: Above 58OC (136OF)

g No-load condition

FZ-23

Page 164 of 677

TURSUCHARGER CONTROL SYSTEM F2

Removal I InstaIlation

Caution

l Be carefui of following points after turbocharger removal.

l Do not carry the turbocharger by the actuator rod or actuator hose.

l Do not drop the turbocharger.

l Set the turbocharger down with the turbine shaft horizontal.

9 Cover the intake, exhaust, and oil passages to prevent dirt or other materia1 from entering.

l Use the specified new studs when installing the turbocharger.

1. Disconnect the negative battery cable.

2. Lift up the vehicle.

3.

Remove the undercover.

4. Drain

the engine coolant.

5. Remove in

the order shown in the figure.

6. fnstall in the reverse order of removat, referring to Installation Note.

7.8-l 1 N-m (80-l 10 cm-kg, 69-95 in-lb)

G I’

/

43-61 (4.4-6.2, 3245)

36-42 (3.94.3, 28-

7.8-1 1 N-m (80-110 cm-kg, 6

cm-kg, 69-95

indb)

26-31

12.7~g-2. 20-231

w

19-26 (l-9-2.6, 14-19)

7.6-17 N-m (80-7 t d cm-kg, 69-95 in-lb)

N-m (m-kg, Mb]

I 93GOF2-762

F2-47

Page 179 of 677

F2 CONTROLSYSTEM

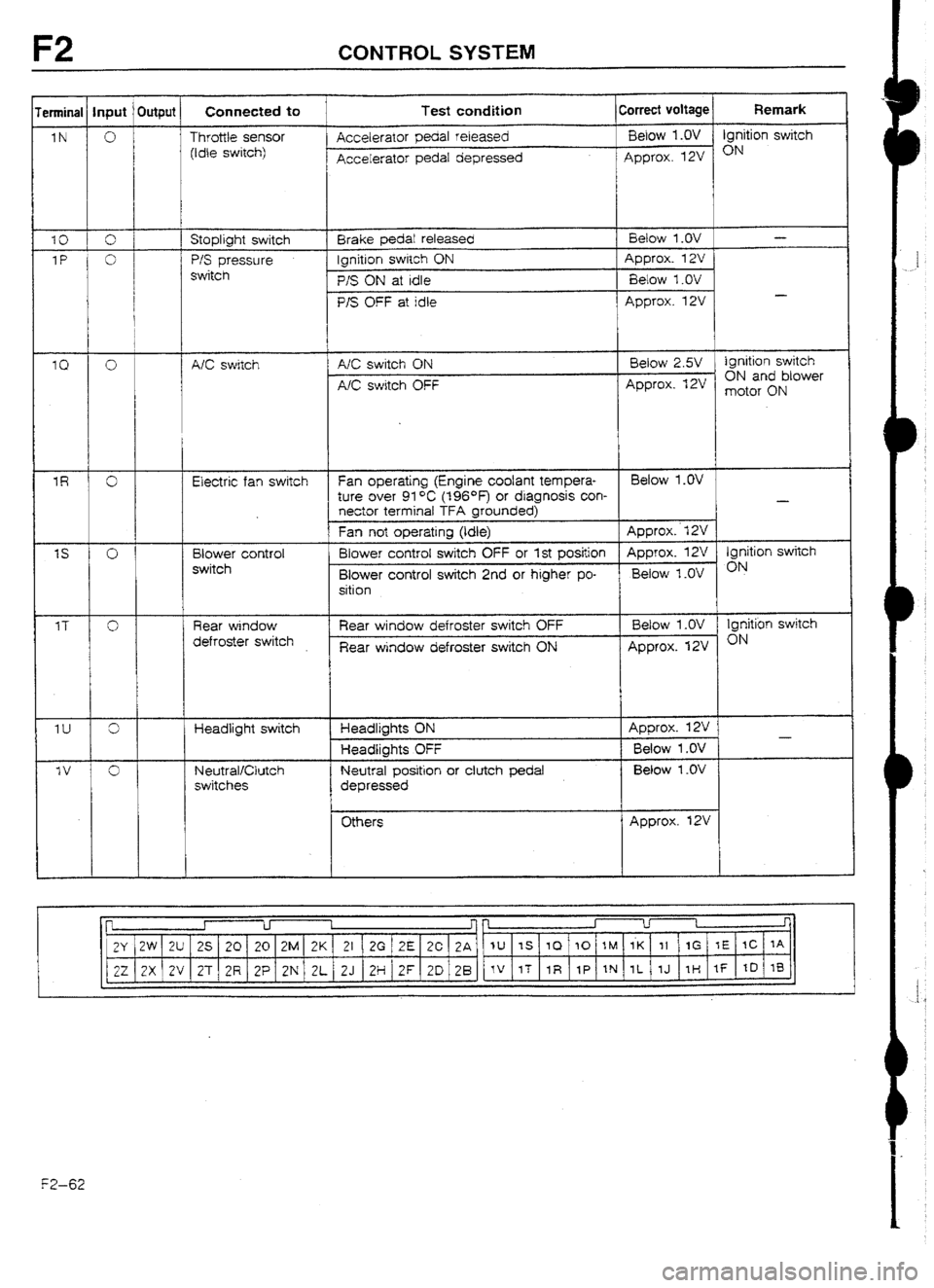

erminat Input ’ Output Connected to Test condition Correct voltage Remark

1N 0 I Throttle sensor Accelerator pedal released &low l.OV j Ignition switch

(Idle switch)

Accelerator pedal depressed Approx. 12V *N

IO I 0 j [ Stoplight switch Brake pedal released Betow 1 .OV -

1P j 0 1 i P/S pressure lgnitlon switch ON Approx. 12V

I

switch

f/S ON at idle Below 1 .UV

I

P/S OFF at idle Approx. 12V -

I

to 0 A/C switch A/C switch ON

NC switch OFF Beiow 2.W ignition switch

ON and blower

Approx* t2V motor ON

i

1R 0 Electric fan switch Fan operating (Engine coolant tempera- Betow l.OV

ture over 91 *C (t96*F) or diagnosis con-

-

nector terminal TFA grounded)

Fan not operating (Idle) Approx.. f 2V

IS 0 Blower control Blower controf switch OFF or 1st position Approx. 13 Ignition switch

switch

Blower control switch 2nd or higher po- Below 7 .OV ON

sition

IT

Cl Rear window

defroster switch Rear window defroster switch OFF

Rear window defroster switch ON Below 1 .OV Ignition switch

Approx. 12V ON

1u 3 Headlight switch Headlights ON Approx. 12V

-

Headlights OFF Below 1 .OV

-Iv Cl ’ Neutral/Clutch

Neutral position or clutch pedal Below I .OV

switches

depressed

Others Approx. 12V

l-7 I r

f

2V 2W 2U 25 20 20 2M 2K 21 2G IZE 2C 2A IU IS 10 10 IM 1K 11 1G rE tC IA

22 2X (2V 2T 2R 2P 2N 2L 2J 2H’ZF 20 2B fV 1T 1R IP IN 1L 7J III If ItI 1B l F2-62

Page 181 of 677

F2 CUNTRULSYSTEM

‘erminal Input Output i Connected to Test condition Correct voltage Remark

2A - - ’ Ground {Injector)

Constant OV -

2B - - I Ground (Output)

Constant OV -

2c , - - 1 Ground (CPU)

Constant OV - 20

-i- Ground (Input) Constant

OV -

2E ’ 0 1 Distributor I

Ignition switch ON Approx. OV

(Ne-signal)

or 5v -

Idle Approx. 2V

2F -j- - - - -

2G 0

Distributor ignition switch ON Approx. OV

(G-stgnal) or 5V

Idle Approx. I.3

2t-I - - -

- - -

21 - - - - - -

2J C

Knock control unit

Idle Approx. 4. OV -

2K 0

Thronle sensor/ Constant . 4.5--5.W

Airflow meter

-

2L

- -

- - - -

I

2M 0 Throttle sensor

Accelerator pedal released Approx. 0.W

-

Accelerator pedal fully depressed Approx. 4.W

2N 0

20 0

2P 0

1

2Q ! 0

2R Oxygen sensor

Airflow meter

Intake air

thermosensor

Water

thermosensor 0

’ Turbocharge

indicator Ignition switch ON

f OV

Idle (Cold engine) ov

Idle (After warm-up) O-l .ov -

Increasing engine speed [After warm-up) 0.5-I .ov

Deceleration o-0.4v

ignition switch ON

’ Idle Approx. 3.8V

-

Approx. 3.OV

Ambient air temperature 20°C (68OF) Approx. 2SV In airflow meter

Engine coolant temperature 20°C (68OF) Approx. 2.5V

-

After warm-up

Below 03

Ignition switch ON

Approx. f2V

-

F2-64

Page 183 of 677

F2 CONTROLSYSTEM

Terminal I Input Output Connected to Test condition Correct voltage Remark

25 0

Overboost warning lgnltion switch ON Approx. 12V

-

buzzer

2T 0 1 Solenoid valve 180 seconds atter engine started when Below 1 SV

(Pressure regulator) engine coolant temperature above 90%

(I 94OF) and Intake air temperature above -

58OC (13WF)

1 Other condition at Idle Approx. 12V

2u 0 Injector (Nos. I 1 3) Ignrtion switch ON Approx. 12V * Engine Signal

Idle Approx. 12V’ Monitor: Green

and red lamps

Engrne speed above 2,000 rpm on de- Approx. f2V

flash

celeratlon (Atter warm-up)

2v 0 Injector (Nos. 2, 4) lgnitlon swrtch ON Approx. 12V

Idle Approx. 12V’

Engine speed above 2,000 rpm on de- Approx. 12V

ceieration (After warm-up)

2W 0

ISC valve Ignition switch ON Approx. 7V

-

Idle Approx. 9V

2x 0 Solenoid valve Ignition switch ON Approx. 12V

(Purge control)

t Idle -

Approx. f2V

t

2Y 0 Cmxit opening Ignition switch UN Approx. 12V

-

relay

Idle Below 1 .OV

22 - - - - - -

-L J

u-

v I U-1 l-

2y 2w 2u 2s 20 20 2M 2K 21 2G 2E 2C

2A 1U 1S IQ 10 1M 1K 11 1G 1E IC 1A

22 2X 2V 2T 2R 2P 2N 2L 2.J i’t-( 2F 2D 2B 1V 1T 1R tP IN IL I..! ItI IF

tD 18

F2-66