MAZDA 323 1992 Suplement Owner's Manual

Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 21 of 279

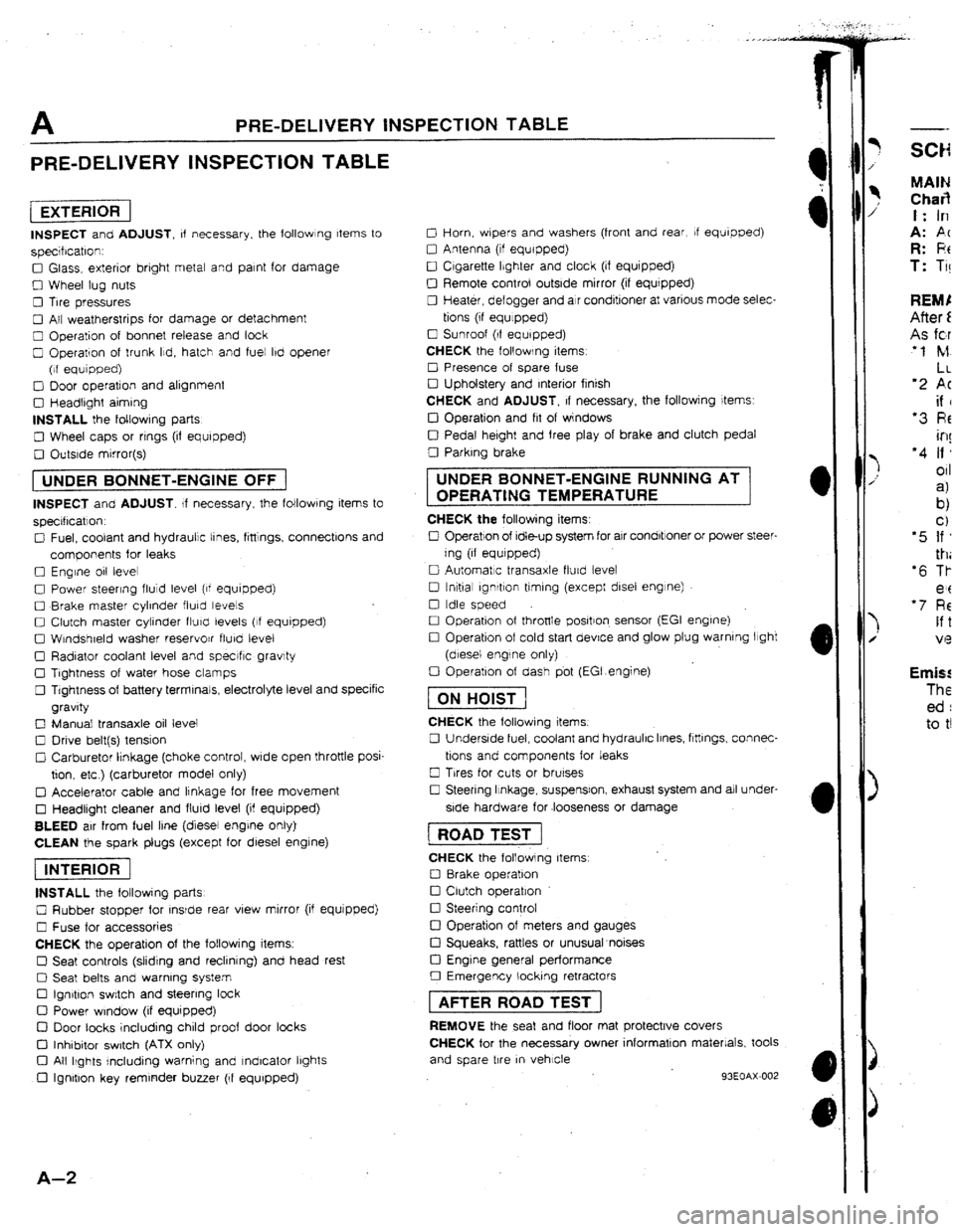

A PRE-DELIVERY INSPECTION TABLE

PRE-DELIVERY INSPECTION TABLE

[EXTERlORI

INSPECT and ADJUST, of necessary. the followlng Items to

specrfrcatron:

0 Glass, exterior bright metal and paint for damage

0 Wheel lug nuts

0 Tire pressures

0 All weatherstrips for damage or detachment

0 Operation of bonnet release and look

0 Operation of trunk Ild, hatch and fuel lbd opener

(of equipped)

0 Door operation and alignment

0 Headtrght aiming

INSTALL the foltowrng parts

0 Wheel caps or rrngs (if equipped)

0 Outsrde mirror(s)

1 UNDER BONNET-ENGINE OFF j

INSPECT and ADJUST. If necessary, the following items to

specrflcatlon.

0 Fuel, coolant and hydraulic tines, fittings, connectlons and

components for leaks

0 Engine 011 level

0 Power steering fluid level (of equipped)

0 Brake master cylinder fluky levels

0 Clutch master cylinder fturcl levels (If equipped)

0 Wtndshreld washer reservojr flurd level

0 Radiator coolant level and specrfic gravity

0 Tightness of water hose clamps

0 Tightness of battery terminals, electrolyte level and specific

gravity

0 Manual transaxle oil level

0 Drive belt(s) tension

Cl Carburetor lrnkage (choke control, wrde open throttle posi-

tion. etc ) (carburetor model only)

q Accelerator cable and linkage for free movement

0 Headlight cleaner and flurd level (if equipped)

BLEED air from fuel line (diesel engrne only)

CLEAN the spark plugs (except for diesel engine)

piEi6F]

INSTALL the following parts

0 Rubber stopper for rnsrde rear view mirror (if equjpped)

0 Fuse for accessories

CHECK the operation of the following items.

0 Seat controls (sliding and reclining) and head rest

0 Seat belts and warning system

Cl Ign&on switch and steering lock

0 Power window (if equipped)

D Door tacks including child proof door locks

Cl Inhibitor switch (ATX only)

Cl All Ikghts rncluding warning and Indicator lbghts

0 Ignition key reminder buzzer (If equipped)

A-Z

0 Horn, wbpers and washers (front and rear, If equipped)

0 Antenna (tf equipped)

0 Cigarette Ibghter and clock (if equipped)

0 Remote control outside mirror (if equrpped)

0 Heater, defogger and air conditioner at various mode selec-

tions (if equlppedj

0 Sunroof (If equipped)

CHECK the following items

0 Presence of spare fuse

0 Upholstery and Interior finish

CHECK and ADJUST, If necessary, the followjng items:

IJ Operation and fit of windows

0 Pedal height and free play of brake and clutch pedal

0 Parking brake UNDER BONNET-ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

0 Operation of Idle-up system for air condbtroner or power steer-

ing (if equrpped)

0 Automatic transaxle flurd levet

0 tnltial ignrtlon timing (except disel engine)

0 Idle speed

0 Operation of throttle positron. sensor (EGI engrne)

0 Operation of cold start device and glow plug warning light

(diesel engine only)

0 Operation of dash pbt (EGI.engine)

fTiGGJ

CHECK the following items.

0 Underside fuel, coolant and hydraulic Irnes, ftttlngs, connec-

tions and components for leaks

0 Trres for cuts or brurses

0 Steering Itnkage, suspensron, exhaust system and all under-

side hardware for .looseness or damage 1 ROAD TEST j

CHECK the following items

0 8rake operation

0 Clutch operation

0 Steering control

!ZI Operation of meters and gauges

Cl Squeaks, rattles or unusual noises

Cl Engine general performance

0 Emergency locking retractors 1 AFTER ROAD TEST ]

REMOVE the seat and floor mat protective covers

CHECK for the necessary owner information materials, took

and spare tire

m vehicle

93EOAX-002

-- MAIN Char3 t: In

A: PC R: F!t T: Ti! Emis! The ed : to t!

Page 22 of 279

SCHEDULED MAINTENANCE SERVICES A

SCHEDULED MAINTENANCE SERVICES

MAINTENANCE TABLE

Chafi symbols:

1 : Inspect: Visual examination and/or functional measurement of system’s operation or

performance , A: Adjust: Examination resulting in adjustment or replacement

n

R: Replace or change

T: Tighten

REMARKS

After 80,000 km or 48 months, continue to follow the described maintenance at the recommended intervals.

As for * marked items in this maintenance chart, note the following points.

+ 1 Major service interval at 12 months/20,000 km (12,000 miles).

Lubrication service based on distance only 10,000 km (6,000 miles) not time.

l 2 Adjust or inspect alternator and water pump drive belt, and power steering and air conditioner drive belt

if equipped.

‘3 Replacement of the timing belt is required at every 100,000 km (60,000 mile). Failure to replace the tim-

ing bett may result in damage to the engine.

‘4 tf the vehicle is operated under any of the following conditions, it is suggested that the engine oil and

oil filter be changed more often than the recommended intervals.

a) Driving in dusty conditions. I

:

b) Extended periods of idling or low speed operation. i

i!

c) Driving for a prolonged periods in cold temperatures or regularly driving onty short distances.

*5 If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more often

than at usual recommended intervals.

l 6 This IS a full function check of all electrical systems, i.e, atl

ltghts. washers (including condition of blades)

electric windows, sunroof, horn etc.

‘7 Replace every two years. $1

‘I

If there has been continuous hard driving, mountain

drivtng, or if the brakes are used extensively or the

vehicle is operated in extremely humid climates, the brake fluid should be changed annually.

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the-emission control and relat-

ed system, as well as for efficient engine operation. It is strongly recommended that all servicing related

to these systems be done by your Authorised Mazda Dealer.

13EOAX-302 -4

I!

A-3

Page 23 of 279

A SCHEDULED MAtNTENANCE SERVtCES (Europe)

Maintenance Number of months or km (miles), whichever comes first

Months” - 6 12 18 24 30 36 42 48

Kllometers 1,000 10,000 20,000 30,000 40,000 50,000 60,000 70,000 80,000

{Miles)

(600) (6,000) f[t2,000) (18,000) (24,000) (3U,OOO) (36,000) (42,000) {48,000), Engine

Intake and exhaust manrfold nuts (Bolts)

Drive belts”

i Engine trmlng beltW3

Engine oil (Turbo)‘4

01 filter

l *

Cool!ng system (Includtng

coolant level adlustment)

Engrne coolant T T T

A A A

A A

Replace every 100,000 km (60,000 miles)

Replace every 5,000 km (3,000 miles) or 6 months

R R R R R 1 R R R

I I I I

I

Replace every 2 years Fuel system

Idle speed

Air cleaner element * 5

Fuel

falter

Fuel Ilnes and hoses Ignition system

A f 1

I R I R

R R

I I f t I ~

lnlttal rgnrtloh trmlng 1 I I I I I I I I

Spark plugs A

A. A A

Spark plugs (Only for Sweden) Adjust every 30.000 km (t8.000 mrls) Evaporative emission control system

Throttle sensor Throttle sensor (Only for Sweden)

Evaporative system

Evaporatrve system (Only for Sweden) 1 A 1 1 A 1 1 A 1 ) A

Adjust every 80,000 km (48,000 miles)

1 I 1 1 I’ 1 1 I 1 1 I

Inspect every 80,000 km (48,000 mites) Electrical system

Battery electrolyte level and specific gravity 1 I f I I I

All Electrical system

l ’ 1 I

I 1 I I I

1 . 1 I I

Headlight alrgnment 1 A A A . A. Chassis and body

t 3EOAX-303

A-4 Chas

SW31 Rear

Tires

Hing

Seat

Page 24 of 279

![MAZDA 323 1992 Suplement Owners Manual SCHEDULED MAINTENANCE SERVICES (Europe) A

Maintenance Number of months or km (miles), whichever comes first

Months’ ’

- 6 12 18 1 24 30 36 ] 42 48

Kllometers 1,000

10,000 20,000 30,000 1 40,0 MAZDA 323 1992 Suplement Owners Manual SCHEDULED MAINTENANCE SERVICES (Europe) A

Maintenance Number of months or km (miles), whichever comes first

Months’ ’

- 6 12 18 1 24 30 36 ] 42 48

Kllometers 1,000

10,000 20,000 30,000 1 40,0](/img/28/57055/w960_57055-23.png)

SCHEDULED MAINTENANCE SERVICES (Europe) A

Maintenance Number of months or km (miles), whichever comes first

Months’ ’

- 6 12 18 1 24 30 36 ] 42 48

Kllometers 1,000

10,000 20,000 30,000 1 40,000 50,000 60,000 1 70,000

80,000

(Miles) (600)

(6,000) j(12,000)~(18,000)~(24,000) (30,000) (36,000)~(42,000) (48,000)

Chassis and body (Cont’d)

Steering and front suspension

I ’ I

I 1 I

MTX oil A R

Rear axle oil

I R A A R

A A A R I

Trabsfercarrier oil R A 1 A

R A A A R

Bolts, nuts on chassis and body T T 1

T , T T

Body condltlon (Visual only) Inspect annually

Exhaust system heat shields I 1 I

Tires (Including spare tjresj with inflation

pressure adjustment I

I I I

Hinges and catches A A

A 1 A

Underside of vehicle I

I i 1 I I

Seat belt I

I f

I ’ I

Dnveshafl dust boots I I 1 I I

13EOAX.304

A-5

Page 25 of 279

B2

ENGINE

(DOHC)

1 FEATURES j

OUTLINE ................................................

B2- 2

OUTLINE OF CONSTRUCTION..

.............. B2- 2

SPEClFICATlONS

..................................

82- 2

INTERCHANGEABILITY ..........................

B2- 3

PISTON ...............................................

82- 4

CONNECTING ROD ...............................

82- 5

CRANKSHAFT PULLEY ..........................

B2- 6

EXHAUST VALVE ..................................

B2- 7

INSTRUCTION FOR HANDLING METALLIC

SODllJM~FlLLED EXHAUST VALVE .........

82- 8

SUPPLEMENTAL SERVICE INFORMATION 820 9

4

13E082-301

Page 26 of 279

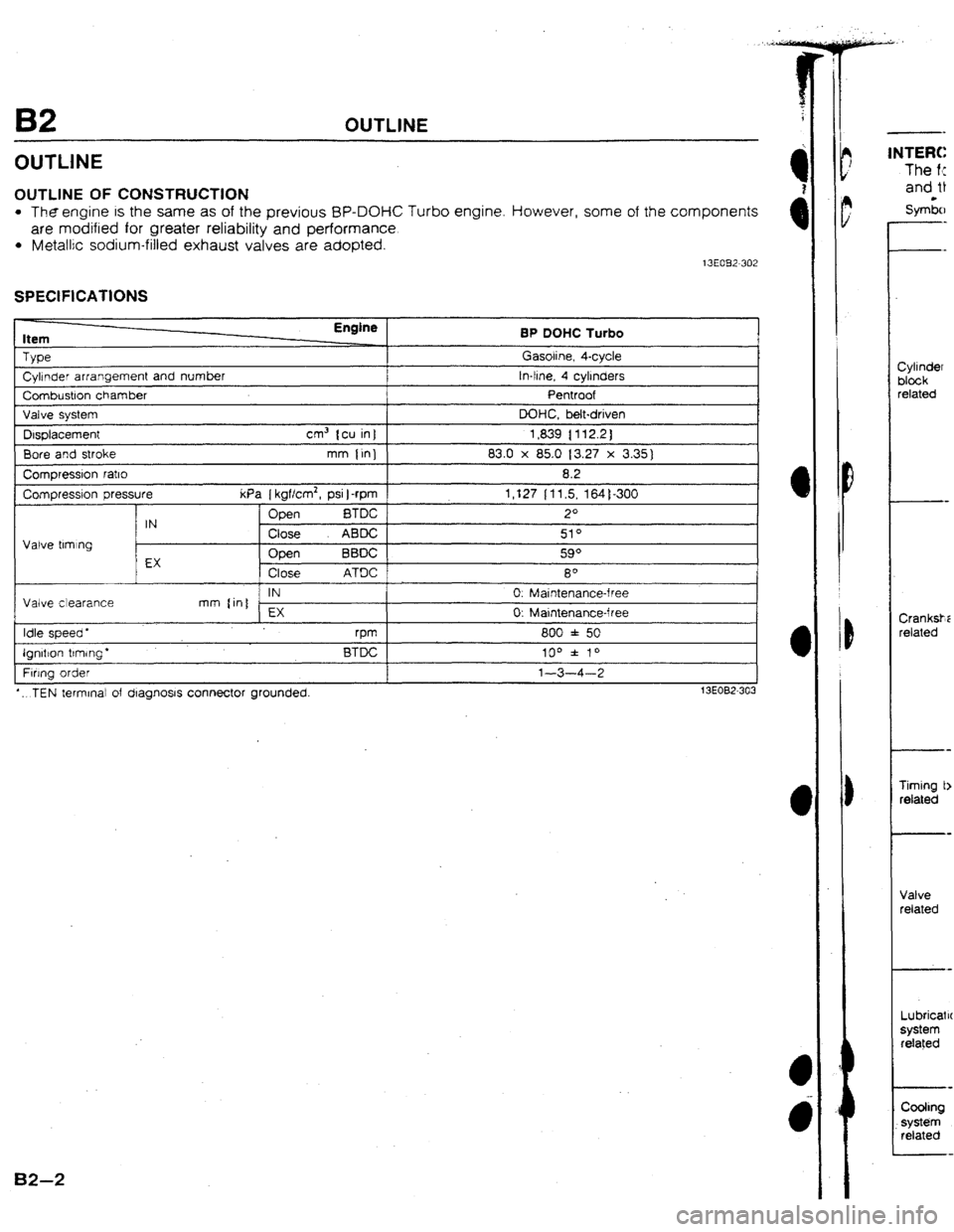

B2 OUTLINE

OUTLINE

OUTLINE OF CONSTRUCTION

l Theengine is the same as of the previous BP-DOHC Turbo engine. However, some of the components

are modified for greater reliability and performance.

l Metallic sodium-filled exhaust valves are adopted. 13E032-302

SPECtFlCATIONS

Item

TYPe

Cyhnder arrangement and number

Combustion chamber

Valve system

Displacement cm3 tcu in]

Bore and stroke mm {in)

Compressron ratio

Compressron pressure kPa [ kgf/cm2, psi 1

-rpm

Open

BTDC

IN

Close ABDC

Valve tlmlng

EX Open BBDC

Close ATDC

IN

Valve clearance mm (in]

EX

Idle speed *

rpm

Ignltlon trmrng’ BTDC

Fwng order

*.. TEN terminal of dragnosrs connector grounded. Gasoline, 4-cycle

tn-line, 4 cyljnders

Pentroof

DOHC, belt-driven

1,839 { 112.2)

83.0 x 85.0 13.27 x 3.35)

8.2

1,127 lt1.5, 164)-300

2O

510

590

8O

0. Maintenance-free

0: Maintenance-free

800 f 50

100 f 70

l-3-4-2

13EOB2-303

82-2

1NTERC

The f<

and 0

S ym&l

-

Cytinder

block

related

Crank&;

related

Timing b

related

Vatve

related

Lubricatrc

system related

Coohng

. . system

related

Page 27 of 279

The following chart shows interchangeability of the main parts of the previous BP DOHC Turbo engine

and the new BP DOHC Turbo engine for 4WD models.

S ymiols: 0 _. lnterc hangeable X . . . Not Interchangeable

Part name tnterchangeability

Remark

Cytlnder head 0

Camshaft 011 seal 0

Cvllnder head bolt 0

CB :

Cyh nder

blcck

related

Crankshaft

related

Timing belt

related

Valve

related

Lubrication

system

related Cylrnder head gasket 0

Wnder head cover 0

Cylinder head cover gasket

Cylinder block

MaEn bearina cao 0

0

0

Ma+n bearino suo~oFt elate I

0 I ” ,I I

Oil pan

Timrno belt cover I X

0 I

Turbocharger oil return pipe hole increased from

13mm IO.51 in) to 17mm IO.67 in)

Seal elate

Front orl seal I 0 I

I I 0

1

Rear 011 seal 0

Crankshaft 0

Marn bearina 0

Thrust bearing

Connectmg rod

Connecting rod beartng

Piston 0

;J

X

Shape different

Piston skirt shortened

I Piston pm cl

Tw

X Sectional shape different

Piston rrng Piston ring end gap increased from 0:?5--0.30mm

Second

X ~0.006-0.011 in ) to 0.35-0.50mm IO.01 4-0.019

in ] (Measured In cylinder)

Crankshaft pulley Shape different

Rear cover ;5

Flywheel

I 0

Flywheel bolt 0

Tbmlng belt 0

Timing belt crank pulley 0

Camshaft pulley 0

Timing belt tensioner and spring

0

Idler 0

Camshaft 0

AA

Valve Intake

Exhaust

cl

0

X Metallic sodium-filled valve

Valve spring Intake

I 0

and seat

Exhaust 0

Vatve wide I 0

Valve seal

Oil pump 0

Oil pump gasket 0

oil strainer 0

Oil strainer gasket 0

Oil cooler

X Heat dissi patlon capacity increased

Oil jet

Oil filter Shape different

1 Water pump 0

Coohng Thermostat 0

system

related Radiator 0

Cooling fan 0

I 3EO32.304

BZ-3.

Page 28 of 279

![MAZDA 323 1992 Suplement Owners Manual B2 OUTl1NE

COOUNG CHANNEL RtNG CARRtER

61.5mm i 2.42 in ] - 56.5mm (2.22 in

Piston diameter Piston diameter

Measured at 90* Measured at 90°

to pin bore axis I+ to pin bore axis

and t6.5mm and 1 MAZDA 323 1992 Suplement Owners Manual B2 OUTl1NE

COOUNG CHANNEL RtNG CARRtER

61.5mm i 2.42 in ] - 56.5mm (2.22 in

Piston diameter Piston diameter

Measured at 90* Measured at 90°

to pin bore axis I+ to pin bore axis

and t6.5mm and 1](/img/28/57055/w960_57055-27.png)

B2 OUTl1NE

COOUNG CHANNEL RtNG CARRtER

61.5mm i 2.42 in ] - 56.5mm (2.22 in

Piston diameter Piston diameter

Measured at 90* Measured at 90°

to pin bore axis I+ to pin bore axis

and t6.5mm and 11 .Omm

IO.650 in 1 below 10.433 in 1 below

oil rmg groove. oil ring groove.

COOLING CHANNEL

*IL YTLET

OIL t NiET

l The piston skirt is shortened for reduced weight and friction. l A cast iron ring carrier is installed in the piston to reduce piston-ring groove wear. l A cooling channel is incorporated in the body of the piston. The 011 jet squirts oil into this cootrng channel

and the or! absorbs

the heat from around the ring lands, reducing piston ring and cylinder wat! wear

Bz-4

Page 29 of 279

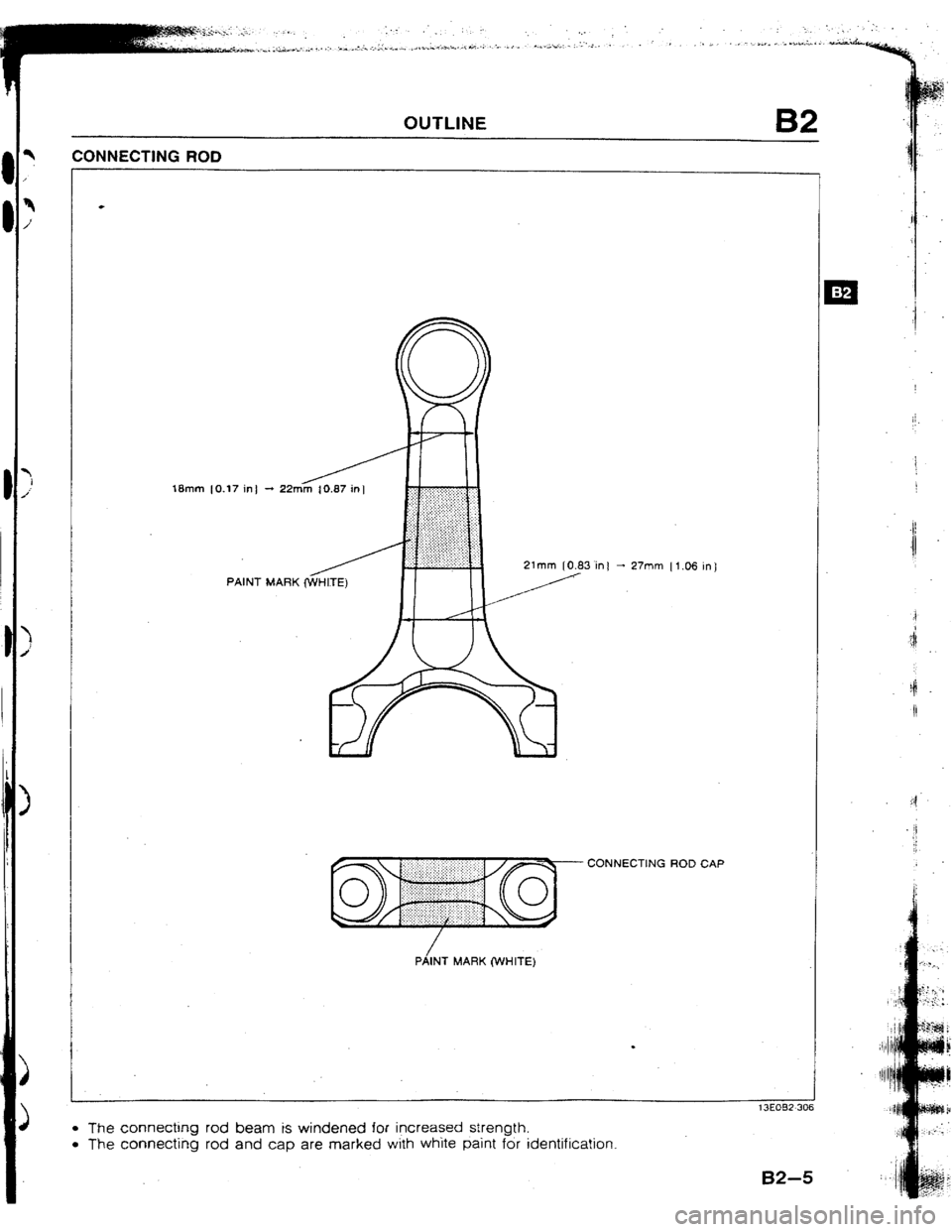

OUTLINE B2

CONNECTING ROD

18mm 10.17 in!

PAINT

MARK @VHITE) in t - 27mm Il.06 ml

CONNECTING ROD CAP

PiINT MARK (WHITE)

l The connecting rod beam is windened for increased strength.

l The connecting rod and cap are marked with white paint for identification.

Page 30 of 279

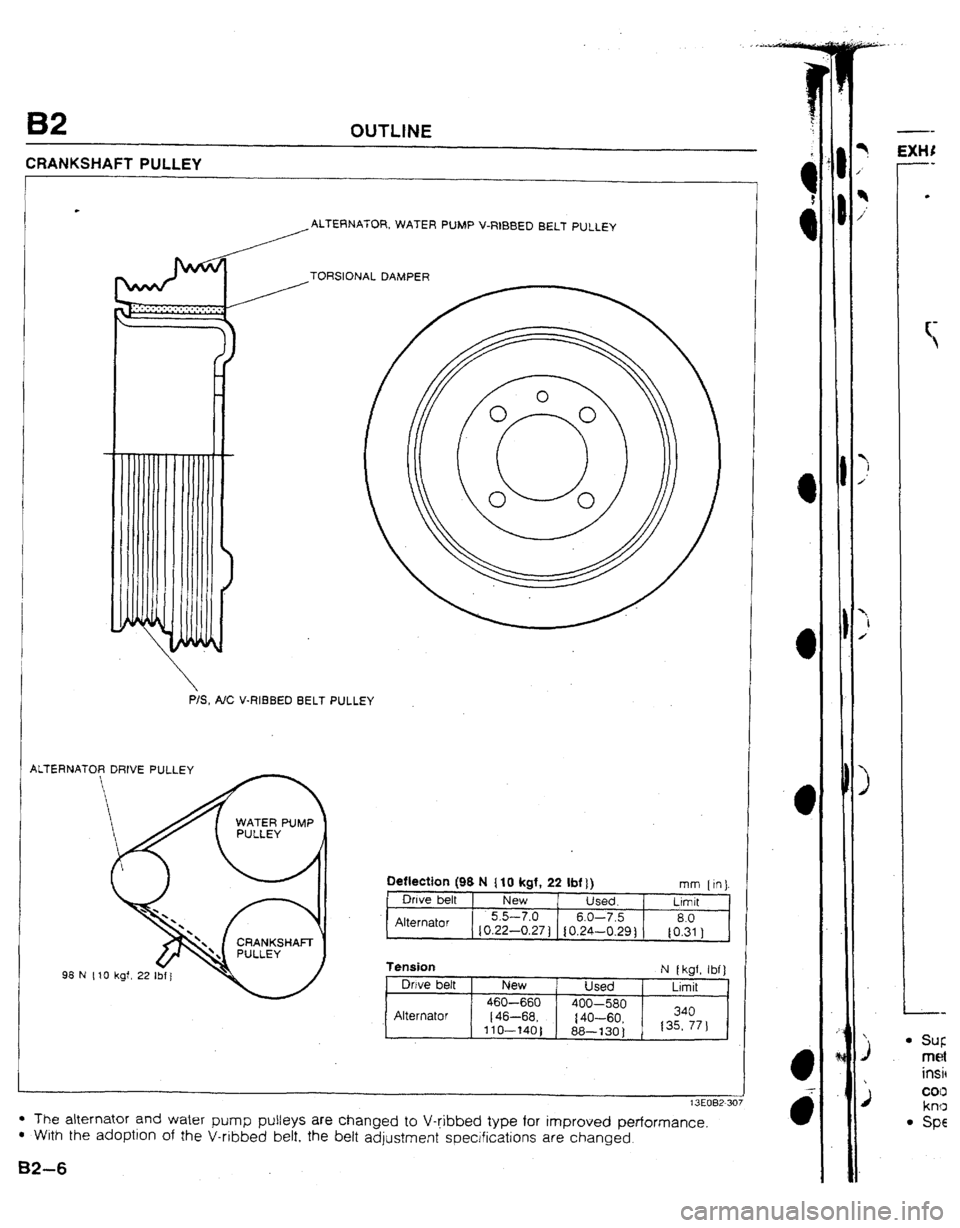

B2 CXJTUNE

CRANKSHAFT PULLEY

ALTERNATOR, WATER PUMP V-RIBBED BELT PULLEY

/TORSIONAL DAMPER

P/S, A/C V-RI3BED BELT PULLEY

ALTERNATOR DRIVE PULLEY

Deflectton (98 N ( 10 kgf, 22 Ibf f ) mm ftn)

Owe belt New Used. Lrmlt

Alternator 5.5-7.0 6.0-7.5 8.0

{0.22-0.27 ) IO.24-0.29) to.31 )

fension

Owe belt

Alternator New

460-660

(46-68,

llO--140) Used

400-580

{‘IO-60,

88-130 1 N I kgf, Ibf]

Ltmit

340

135, 771

l The alternator and water pump pulleys are changed to V-ribbed type for improved performance l With the adoptjon of the V-ribbed betf. the belt adjustment specifications are changed.

B2-6