MAZDA 323 1992 Suplement User Guide

Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 11 of 279

. _ .

GI JACK AND SAFETY STAND POSlTiOtWVEHlCLE LIFT (2-SUPPORT TYPE) POSlTlONS

JACK AND SAFETY STAND POSITIONS

FRONT END

JacKposition:

At the front crossmember Safety stand positions:

On both sides of the body frame

REAR END

Jack position:

At the center of the rear crossmember Safety stand positions:

On both sides of the body frame

At the rear differential (4WD)

--

03UGW80

VEHICLE LIFT (2-SUPPORT TYPE) POSITIONS

FRONT END, REAR END

Frame Frame

Side sills Side sills

9MuGIX 010 9MVGtX 01

Page 12 of 279

MAlNTENANCE NOTE GI

.

FREE ROLLER

I t 3EGlX-304

MAlNTENANCE NOTE

SPEEDOMETER TESTER CHECK

Caution

l Do not clutch abruptly.

l Do not attempt rabbit starts or accelerate quickly. 13EGIX-302

[Front wheel free-roller method]

1. Set the free roller securely on the floor under the front wheels

by matching it to the wheel base and front tread.

2. Place the vehicle softly on the tester and free roller.

3. Start the engine, and engage the clutch softly at a low speed

in 2nd gear; then gradually increase the speed.

4. Upon completion of the test, stop the engine by gradually

decelerating with soft braking.

[Front wheel jack-up method1

1’. Place the rear wheels on the roller.

2. Jack up the front wheels and mount on a safety stand.

3. Start the engine, and engage the clutch softly at a low speed

in 2nd gear; then gradually increase the speed.

Caution

l When using either the front wheel free-roller meth-

od or front wheel jack-up method, secure the vehi-

cle to prevent forward and lateral movement by

attaching towing hardware (chain or wire) to the

front and rear tow hook or tie-down hook.

BRAKE TESTER CHECK

Caution

. To stabilize the drag force of the viscous coupling,

conduct the brake test after the speedometer test.

1. Place the wheels to be tested (front or rear) on the roller.

2. Shift itit0 NEUTRAL.

3. Drive the tester roller and check.

a-9

Page 13 of 279

GI MAINTENANCE NOTE

VIEWED

.OM BELOW

‘REE

13EGfX-307

I

I t3EGIX-308 CHASSIS DYNAMOMETER CHECK

Caution

l Do not clutch abruptly. l Do not attempt rabbit starts or accelerate quickly.

1. Remove the propeller shaft.

2. Lock the center differential (2WD).

3. Place the front wheets on the roller.

4. Lock the rear wheels and apply the parking brake.

5. Drive the tester roller and check.

6. Upon completion of the test, gradually decelerate with soft

braking and stop the engine.

7. When the test is done, return the differential lclck rod to the

free condition (4WD) and reinstall the propeller shaft.

WHEEL BALANCER (On-the-car Balance)

1.

Jack up all four wheels. Support the wheels to be checked

(front or rear) with the wheel balancer sensor stand and the

remainrng wheels with safety stands.

2. Set the on-the-car balancer. With the center differential in

free condition, drove the tires with the engine; then check.

Page 14 of 279

MAINTENANCE NOTE

TOWlNG

Caution

g Use method @I to tow vehicles having problems in the steering system or drivetrain.

Towing method

0 Rope towing items to confirm

Parking brake Transaxle shtft posttton Remarks

Released Neutral

@ Towlng with front wheels off

ground

Released Neutral Remove propeller shaft

@ Towtng by wrecker truck

Released Neutral

Rempve propetler shaft

@Towing or hauling with all wheels

off ground

Engaged Any posItIon

13EGIX.30

TIE-DOWN HOOKS - FRONT TIE-DOWN HOOKS

- REAR (HATCHBACK)

!

Page 15 of 279

GI IDENTIFICATION NUMBER tOCATlONS/UNlTS/ABBREVIATlONS

IDENTIFICATION NUMBER LOCATIONS

VEHICLE tDENTtRCATtUN NUM8ER (VIM) ENGINE MODEL AND NUMBER

I

UNITS

N.rn { kgf m or kgfcm,

f-t&f or tn.lbf 1 . . . . . . . . . . . . . . . . Torque

rpm ._ . . . Revolutions per minute

A.. ,_...___.... Ampere(s)

v I... Volt(s)

$2 . .._..__......_.....__... Ohm(s) (resls‘tance)

kPa { kgflcm*, psr] . . . . . . . Pressure

{usually positive)

mmHg I inl-lg ] . . . . . . . . . Pressure

(usually negatrve)

W . . . ._ .._.__ .._ . . . . . . ..,......... Watt

titers [US qt, Imp qt 1 . V&me

mm { rn 1 . . . . . . . . . . . . . . . . . . . . . . . Length

89UOGX-006

ABBREWATIONS

ABDC _. . . . . . . . . . . After bottom dead

center

A/C . . . . . . . ._.. _. . . . . . . . . Air conditioner

ACC .__ . . . . . . . Accessones

ATX .._ ._ . . . . . . . . . . . . . . Automate transaxle

ATDC _.. __ _. . . . . After top dead center

ATF ,... ._....__._.. Automatic transmission

fluid

BAC ._ . . . . . . . . . . . . . . ,. Bypass air control

BBDC _. . . . . . . . . . . . . .._. Before bottom dead

center

BTDC ., ._._... . . . Before top dead center

CPU . . . . . . . . . Central processrng unit EC-AT

........................... Electronrcally-controlled

automatic transmlsslon

ECU ._ ....................... Engine control unit

EG 1 ..................... Electronc gasoll ne

injectron

E/L. ............................ Electrrcal load

EX .............................. Exhaust

IC ................................ Integrated clrcult

IGN ........................... lgnrtlon

IN ..... ........................ Intake

INT

............................... Intermittent

ISC ............................ Idle speed control

U-l ................................

Left hand

M..

........................... Motor

MIL

........ ...................... MatfunctIon Indicator

iamp

MTX. ........................... Manual transaxle

00.. .............................. Overdnve

Of F .............................. Swrtch off

ON

............................... Switch

on

PCV .............................. Positive crankcase

ventilation

PRC .......................... Pressure regulator

control

P/S ............................. Power steerrng

P/W ............................

Power window

RH ............................... Rlght hand

SST

............................. Special service tool

ST.. ............................... Starl

SW.. ............................. Switch

TDC. ............................ Top dead center

4WD .............................

4-wheel drive

03UGIX-802

INS7

If a t’

and

Whe

1, II-!

2. II-!

3. E-

4. Dr

W-1 2

Page 16 of 279

CAUTION Gl

CAUTlUN

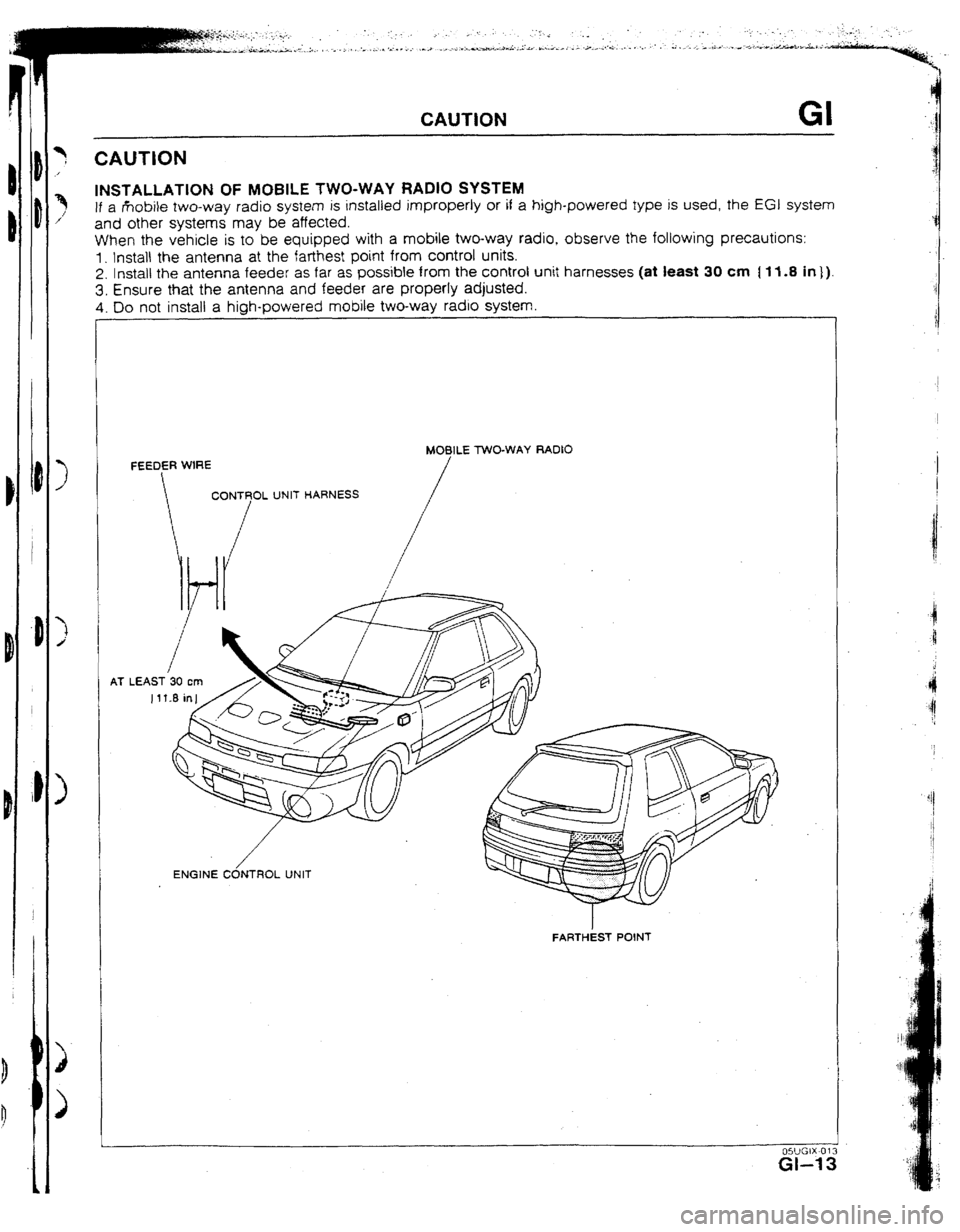

INSTALLATION OF MOBILE TWO-WAY RADIO SYSTEM

If a rkobile two-way radio system is installed improperly or if a high-powered type is used, the EGI system

and other systems may be affected.

When the vehicle is to be equipped with a mobile two-way radio, observe the following precautions:

1. Install the antenna at the farthest point from control units.

2. lnstatt the antenna feeder as far as possible from the control unit harnesses (at least 30 cm [ If .8 in 1).

3. Ensure that the antenna and feeder are properly adjusted.

4. Do not instali a high-powered mobile two-way radio svstem.

AT MOBlLE TWO-WAY RADIO

FARTHEST POINT

Page 17 of 279

..,. .

a

._

GI CAUTKN

PRECAUTIONS TO TAKE WHEN SERVICING AN ELECTRICAL SYSTEM l Note the following items when servicing the electrical system.

l Do not alter the wiring or electrical equipment in any way; this may damage the vehicle or cause a fire

from short-circuiting a circuit or overloading it.

l The negatrve (-) battery cable must be removed first and

rnstalled last. l Do not reptace with fuses exceedrng specified capacity

Cautron

l 8e sure that the ignitton and other switches are off

before disconnectrng or connecting the battery cables.

Failure to do so may damage the semrconductor

components. Caution l Repfacing a fuse with one of a larger capacrty than

desrgnated may damage components or cause a frre.

l Secure harnesses with provrded clamps to take up slack. l Tape areas of the harness

that may rub or bump l When mounting

components, be sure the

against sharp edges to

protect rt from damage. harness IS not caught or

damaged.

Caution

l Clamp all harnesses near vibratrng components (for

example, the engine) to remove slack and to prevent

contact resultrng from vibration. i Drsconnect heatsensitive l Make sure that the

parts (for example, relays

and ECU) when performing connectors are securely

connected when installed.

l Do not handle electrical components roughly or drop

them. maintenance (such as

weldrng) where

temperatures may exceed

80°C [176OFj.

-*

HI

Page 18 of 279

CAUTION GI

HANDLING CONNECTORS

Caution

*‘Be sure to grasp the connectors, not the wires, when disconnecting them.

1. Raise the rear

2. Lift the tab with a

thin piece of metal

and remove the

poor termrnat contact.

Lift the tab with a thin

When using a matching Make sure the termmals

male terminal, make are

not pushed out of

sure there

IS no

c Round connectors >

1. Raise the cover.

2. Lift the termrnal to

3. Make sure the

terminal is securely

mounted in the

Pull lightty on individual

wires to check that they

are secured rn the 1. Raise the cover.

2. Remove A.

3. Lift the tab with a

thin piece of metal

and remove the

Page 19 of 279

:

.

GI CAUTION

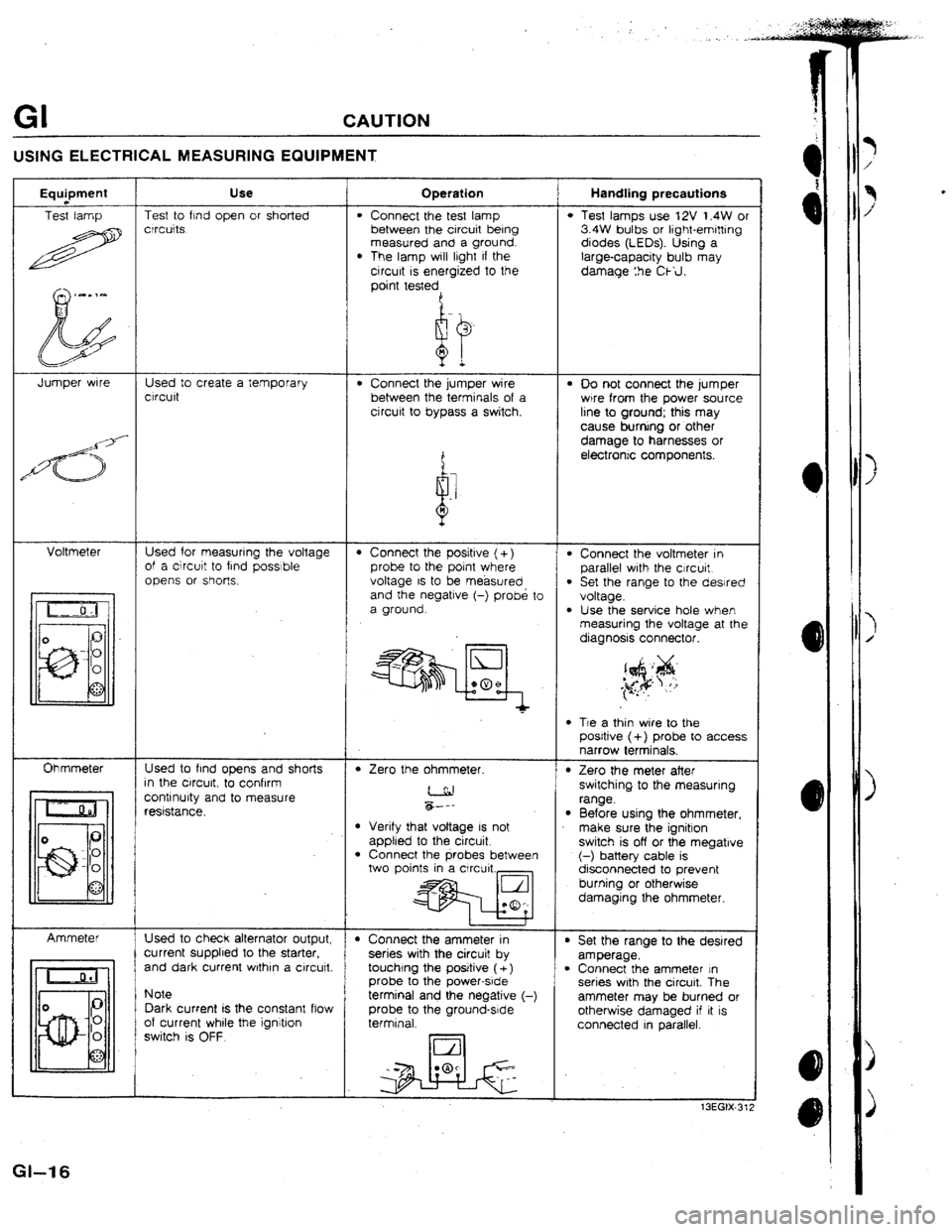

USING ELECTRICAL MEASURING EQUIPMENT

Use Handling precautions Operation Equpment

Test lamp Test to find open or shorted

crrcuits

l Connect the test lamp

between the circuit being

measured and a ground.

l The lamp will lrght if the

circurt is energized to the

point testedA

l Test lamps use 12V t.4W or

3.4W bulbs or light-emitting

diodes (LEOs). Using a

large-capacity bulb may

damage :he Ckil.

Jumper wrre Used to create a temporary

ctrcult . Connect the jumper wire

between the terminals of a

cjrcurt to bypass a switch. l 00 not connect the lumper

wrre from the power source

line to ground; this may

cause burning or other

damage to harnesses or

electrontc components.

Voltmeter Used for measuring the voltage

of a circutt to find possible

opens or shot-k.

l Connect the voltmeter in

parallel wrth the cjrcurt.

l Set the range to the dewed

voltage.

l Use the service hole when measuring the voltage at the

diagnosis connector.

l Connect the positive (+)

probe to the point where

voltage IS to be. measured

and the negatrve (-) probe to

a ground.

l Tie a thin wire to the

posrtive (+) probe to access

narrow terminals.

Ohmmeter Used to find opens and shorts

In the ctrcurt, to confrrm

contrnurty and to measure

reststance.

l Zero the ohmmeter. l Zero the meter after

switching to the measuring

range.

l Before using the ohmmeter,

make sure the ignitron

switch is off or the megatrve

(-) battery cable is

disconnected to prevent

burning or otherwise

damaging the ohmmeter. &--- l Verify that voltage IS not

applied to the circuit

l Connect the probes between

two points in a Circuit.,

t I t

+ Connect the ammeter in

series with the circuit by

touchtng the positive ( +)

probe to the power-srde

terminal and the negative (-

probe to the ground-srde

terminal. Ammeter

Used to check alternator output,

current supplied to the starter.

and dark current wrthrn a circutt. l Set the range to the desired

amperage.

l Connect the ammeter In

series with the circuit. The

ammeter may be burned or

otherwise damaged if it IS

connected in parallel. Note

Dark current IS the constant flow

of current whrle

the ignitron

switch is OFF.

13EGIX-31;

Gl-t 6

Page 20 of 279

c

PRE-DELIVERY INSPECTION

AND

SCHEDULED MAINTENANCE

SERVICES

ME-DELIVERY INSPECTION TABLE . . . . . . . . . . A- 2

SCHEDULED MAINTENANCE SERVICES . . . . . A- 3

MAINTENANCE TABLE ..*.*.............,....**a,. A- 3

REMARKS . ..*...*...............**~.*...*.....t...*... A- 3

13EOAX.301