battery MAZDA 323 1992 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 81 of 279

F3 CONTROL SYSTEM

Ve: Battery voltage

Termina

1N ’

10

1P

IQ

IR

IS

1T

tlJ

IV Jnput Outpul

0

0

0

0

0

0

0

0

0 Connected to

Throttle sensor

(idle switch) Test condition

Correct voltage Remark

Accelerator pedal released

Below 1.0V

lgnltlon switch

Accelerator pedal depressed

VI3 ON

Foglrght relay

P/S pressure

switch Fogtight switch ON

Fogfight switch OFF

Ignition switch ON

P/S pressure switch ON at Idle

PIS pressure switch OFF at idle Va

ov

V3

Below 1 .OV

VB -

-

A/C switch A/C switch ON

A/C switch OFF Below 23 Ignition switch

Va ’ ON and blower

motor ON

1 f Ekctrtc cooltng fan Fan operating (coolant temperature over

Below 1 .OV

switch

97OC 1207OF 1 or diagnosis connector

terminal TFA grounded) -

Fan not operating (Idle)

VI3

Blower control Blower control switch OFF or 1st position

.Va

swbtch Ignitton switch

Blower control switch 2nd or hjgher po-

Below 1 .OV ON

sition

Rear window

defroster switch Rear window defroster OFF

Rear window defroster ON Below 1 .OV Ignition switch

V0 ON

Headlight switch

Headfights ON Va

Headlights OFF -

Below 1.OV

Neutral/Clutch

Neutral position or clutch pedal

9eJow I .OV

switches

depressed

Others

Va

7

r u-.

I-I-I

f

2y 2w 2u 2s 20 20 2M 2K 21 2G 2E 2C 2A 1U 1s 10 10 1M 1K 11 rG IE tC ;A

22 2% 2V 2T 2R 2P ZN 2L 25 2H 2F 2D 28 tV 1T ‘IR IF 1N It ;J. IH IF ID 18

i

A

F3-48

-- Alwa@

Always

Always

Always

--

Always

--

Always

--

Always

--

Always

--

Always

(electric

--

Alway<;

--

Always

-e

Afway?;

I .ov

Always

--

Always

--

Alway:;

--

Page 82 of 279

-. _.. . . . . . _ - ._.

-w

CONTROL SYSTEM F3

I .

-.

Ve: Battery voltaae I

Incorrect voltage

Atwafi below 1 .OV

Always VB

Always VS (foglight switch OK)

Always below 1 .OV

Always below 1 .OV

Always Vs

Always

below 23 (blower fan OK)

Always VB (blower fan OK)

Always below 1 .OV

(electric cooling fan OK) -

1-

Possible cause

l Throttle sensor mrsadjustment l Short circuit in wtrrng from throttle sensor to ECU terminal 1 N l ECU malfunction

l Throttle sensor mrsadjustment l Open circuit in wiring from throttle sensor to ECU terminal fN l Open circuit in mnng from throttle sensor to ECU terminal 20

l Foglight relay malfunctron

l Foglrght relay malfunction

l P/S pressure switch maltunctron l Short crrcurt In wrrlng from P/S pressure switch to ECU terminal 1 P l ECU malfunction

l P/S pressure switch malfunction l Open circuit in wlnng from P/S pressure switch to ECU terminal 7 P l Open circuit in wiring from P/S pressure switch to ground

l A/C switch malfunctron l Short circuit tn wiring from A/C switch to ECU terminal 1Q l Poor connection at ECU connector l ECU malfunction

l #C swatch malfunction l Open circuit in wiring from A/C switch to ECU terminal 1Q l Open circuit in wiring from A/C switch to blower control switch

l Open or short circuit in wiring from fan relay to ECU terminal 1R l ECU matfunction

Always below 1 .OV (blower fan OK}

Always Vs (btower fan OK)

Always betow illumination lamp

1 .ov ON when rear

window defroster

switch ON

Illumination lamp

never ON

Atways below 1 .OV (headttghts OK)

l Short circuit in wrrtng from blower control switch to ECU terminal IS l Poor connection at ECU connector l ECU m&function

l Open crrcuit in wrrrng from blower control switch to ECU terminal 1s

l Open or short crrcuit In wiring from rear window defroster switch to ECU

terminal t T

l Open circuit in wiring from ignitron switch to rear window defroster switch l Rear window defroster switch malfunction

l Open or short circuit in wiring from headlight relay to ECU terminal 1 U

Always below 1 .OV

l Neutral switch malfunction l Clutch switch malfunction l Short circuit in wiring from ECU terminal IV to neutral or clutch switch

Always VB

l Neutral switch malfunction l Clutch switch malfunction l Open circuit in wiring from ECU terminal 1V to neutral or clutch swdch l Poor connection at ECU connector

13FOl=3-36 .

F3-49

.:i

Page 83 of 279

F3 CONTROL SYSTEM

Vs: Battery voltage

‘erminat Input Output Connected to Test condition

Correct voltage Remark

2A’ - - Ground (i nlector) Constant CIV -

26 - - Ground (output) Constant ov -

2C - - Ground (CPU) Constant ov -

2D - - Ground (input) Constant ov -

2E 0 Distributor Ignition switch ON QV or 5v

{NE-slgnal) -

f

r ldte

Approx. 2V

2F - - - -

- -

2G 0 Dstributor Ignition switch ON

ov or 5v

(G signal)

ldte Approx. 1.5V

a-l -I- - -

- -

21 - - - - - -

23 0 Knock control unit Idle Approx. 4.W -

I

2K 0 Throttle sensor/ Constant 4.5--5SV

Airflow meter

-

2L cl

2M 0 Speedometor

sensor

Throttle sensor Ignition switch UN

Accelerator pedal released

Accelerator pedal fully depressed 0 or 5V

Approx. 0.W

Approx. 4.W

-

2N 0

20 0

2P 0

2Q 0

2R Oxygen sensor Ignition switch ON ov

Idle (cold engine) ov

Idle (after warm-up) o- 1 .ov -

Increasing engine speed (after warm-up) 0.5-l .ov

Deceleration o--0.w

Airflow meter ignition switch ON Approx. 3.W

-

Idle Approx. 3.OV

Intake air Ambient air temperature 2O*C (68*F) Approx. 2.5V In arrflow meter

thermosensor

Water Engine’cooiant temperature 20°C (68OF) Approx. 2.W

thermosensor -

After warm-up Below 0.5V

0 Turbocharge Ignition switch ON VS

indicator -

7

r u-l 7 c Ul I-'

2y ?A’ 2u 25 20 20 2M 2K 21 ?G 2E 2C 2A 1u 1s 10 10 1M ?K 11 1G 1E 1C 1A

22 2x zv 2T 2R 2P 2N 2L 2J 2H 2F 20 28 1V 1T tR tP 1N IL 1.1 1~ qF 10 1~

F3-50

L --

4b&e (

--

Alway:

-a

--

Always

--

--

--

Always

--

Always

--

Below L

-I

--

Always

--

Alway:,

Alway:;

Alway:;

--

Alway:;

--

Always

--

Always

--

Always

Always

Page 84 of 279

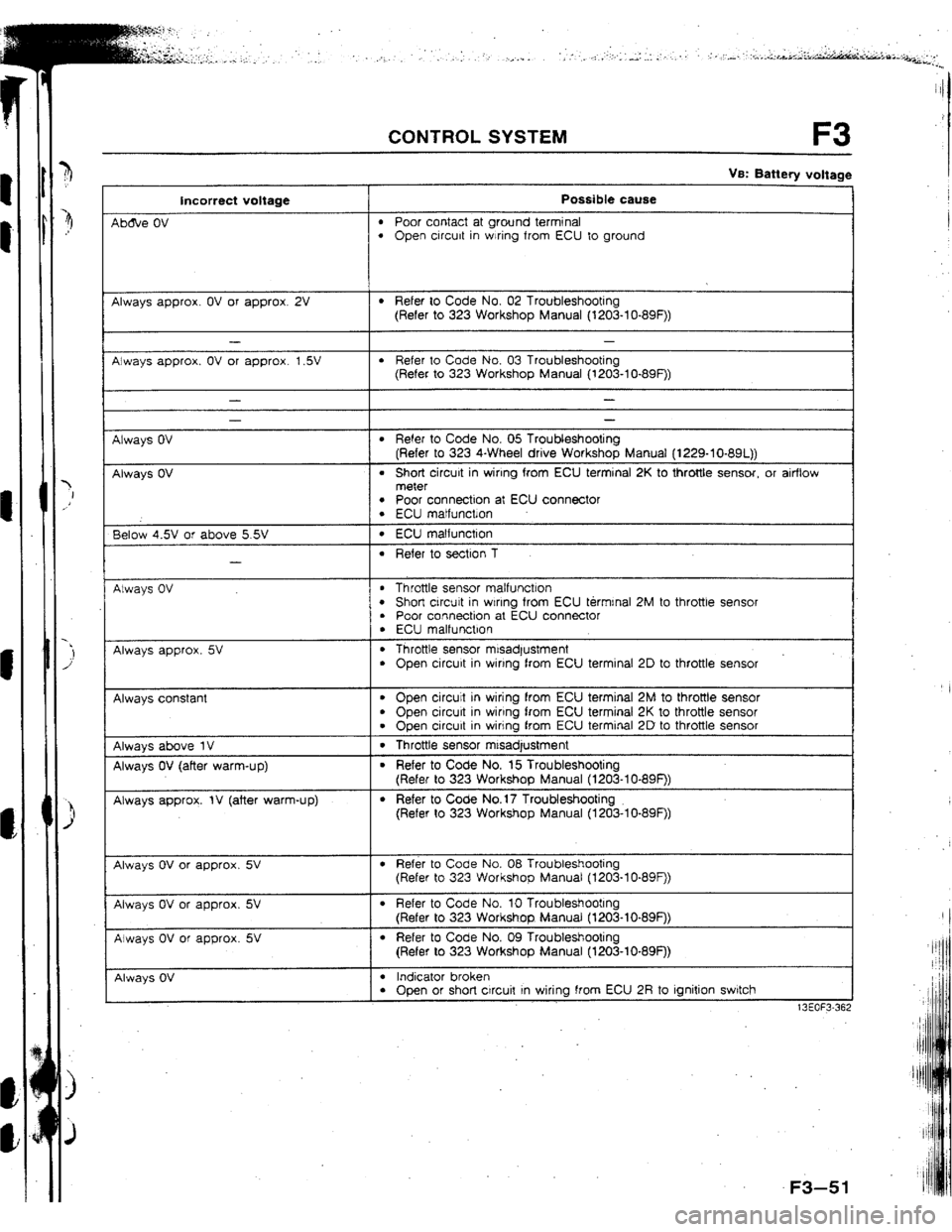

CONTROL SYSTEM F3

VS: Battery voltage

Incorrect voltage Possible cause

Ab&e OV

l Poor contact at ground terminal l Open circuit in wiring from ECU to ground

Always approx. OV or approx. 2V

l Refer to Code No. 02 Troubleshooting

(Refer to 323 Workshop Manual (l203-lo-89F))

Always approx. OV or approx. 1.5V

l Refer to Code No, 03 Troubleshooting

(Refer to 323 Workshop Manual (1203-lo-89F))

Always OV

Always OV

- -

l Refer to Code No. 05 Troubleshooting

(Refer to 323 4-Wheel drive Workshop Manual (1229-10-891))

l Short circuit in wiring from ECU terminal 2K to throttle sensor, or airflow

meter

l Poor connection at ECU connector l ECU matfunctlon

Below 4.5V or above 5.5V

-

l ECU matfunction

l Refer to section 1

Always OV

l Throttle sensor malfunction l Short circuit in wlnng from ECU termrnal 2M to throttle sensot l Poor connection at ECU connector

. ECU malfunction

Always approx. 5V . Throttle sensor misadjustment

l Open circuit in wiring from ECU terminal 2D to throttle sensor

Always constant

l Open circuit in wiring from ECU terminal 2M to throttle sensor

. Open circurt in wiring from ECU terminal 2K to throttle sensor

l Open circuit in wiring from ECU terminal 2D to throttle sensor

Always above 1V 1 . Throttle sensor mtsadjustment

Always OV (after warm-up)

Always approx. IV (after warm-up)

l Refer to Code No. 15 Troubleshooting

(Refer to 323 Workshop Manual (1203-I O-89F))

l Refer to Code No.17 Troubleshooting

(Refer to 323 Workshop Manual (1203-lo-89F))

Always OV or approx. 5V

l Refer to Code No. 08 Troubleshooting

(Refer to 323 Workshop Manual (t203-lo-89F))

Always OV or approx. 5V

Always OV or approx. 5V

l Refer to Code No. 10 Troubleshooting

(Refer to 323 Workshop Manual (l203-lo-89F))

l Refer to Code No. 09 Troubleshooting

(Refer to 323 Workshop Manual (1203-10.89F))

Always OV

I

l Indicator broken l Open or short circuit In wiring from ECU 2R to ignition switch

13EOF3-36;

F3

Page 85 of 279

F3 CONTROL SYSTEM

Terminal Input Dutpui

2s - 0

2T 0

2U 0

2v 0

2w 0

2x 0

2Y 0

22 0 t

I, Ve: Battery voltage I I I Connected to Test condition

Correct voltage Remark

Overboost warning lgnitron switch ON

VB

-

buzzer

Solenoid valve

(PRC low temp.) 180 sec. after engrne started with coolant Below 1.W No-load engine

temperature is above 9O*C { 194*F ] and condition

intake air temperature IS between 40°C

1104*FJ and 50°C {122OF

f Other condition at idle

I VS

tnjector {Nos. 1, 3) Ignition switch ON VS

Idle V0’

I Engine speed above 2,000 rpm during

I Ve

deceleration (after warm-up)

Injector (Nos 2, 4) Ignition switch

ON VS

Idle VS’ * Engine Signal

Monrtor: Green

and red lamps

flash

ISC valve Engine speed above 2,000 rpm during VS

deceleration (after warm-up)

Ignition switch ON Approx. 7V

-

Idle 1 Approx. 9V

Solenoid valve

(purge control) Ignition switch ON

Idle V0

-

VB

Ci rcuit-opening

relay ignition switch ON

tdle 1 VB

I 8elow l.OV -

Solenotd valve

(PRC high temp.) 210 sec. after engine started wrth coolant Below 1.5V

temperature above 90°C ]194*F] and

Intake atr temperature above 50°C

f t22*F1 No-load engine

cond$on

1 Other condition at idle

I VB

I -

7 I PI

I l-1 t

r

2'f 2W 2U 25 iQ 20 &A 2K 21 2G 2E 2C 2A 1U 1s 10 10 1M 1K 11 tG If 1C 1A

F3-52 --

A/w&

--

Alway

--

Alway

--

Alway

--

Alwaj

--

Alwa f

--

Alwas]

--

Alwa I’

Page 86 of 279

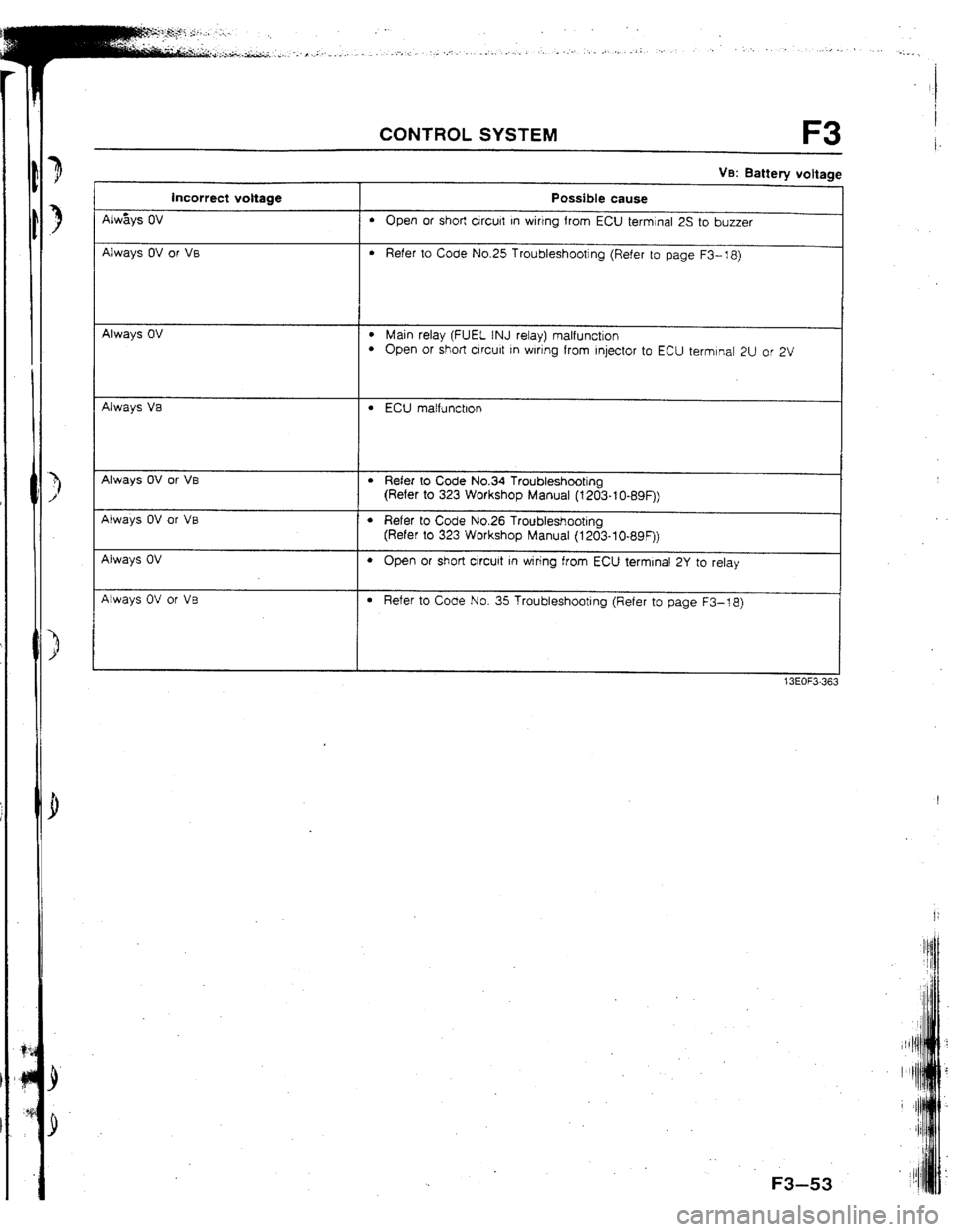

VB: Battery voltage

Incorrect voltage Possible cause

Always OV

l Open or short &curt in wirtng from ECU terminal 25 to buzzer

Always OV or VB

l Refer to Code No.25 Troubleshooting (Refer to page F3-18)

-

Always OV l Main relay (FUEL INJ relay) malfunction l Open or short crrcult rn wlnng from Injector to ECU termtnal 2U or 2V

Always Va

l ECU matfunctlon

Always OV or VB

Always OV or VB

Always OV

Atways OV or VB

l Refer to Code No.34 Troubleshooting

(Refer to 323 Workshop Manual (1203-t O-89F))

l Refer to Code No.26 Troubleshooting

(Refer to 323 Workshop Manual (1203-lO-89F))

l Open or short circuit in wiring from ECU terminal 2Y to relay

l Refer to Code No. 35 Troubleshooting (Refer to page F3-18)

F3-53

Page 160 of 279

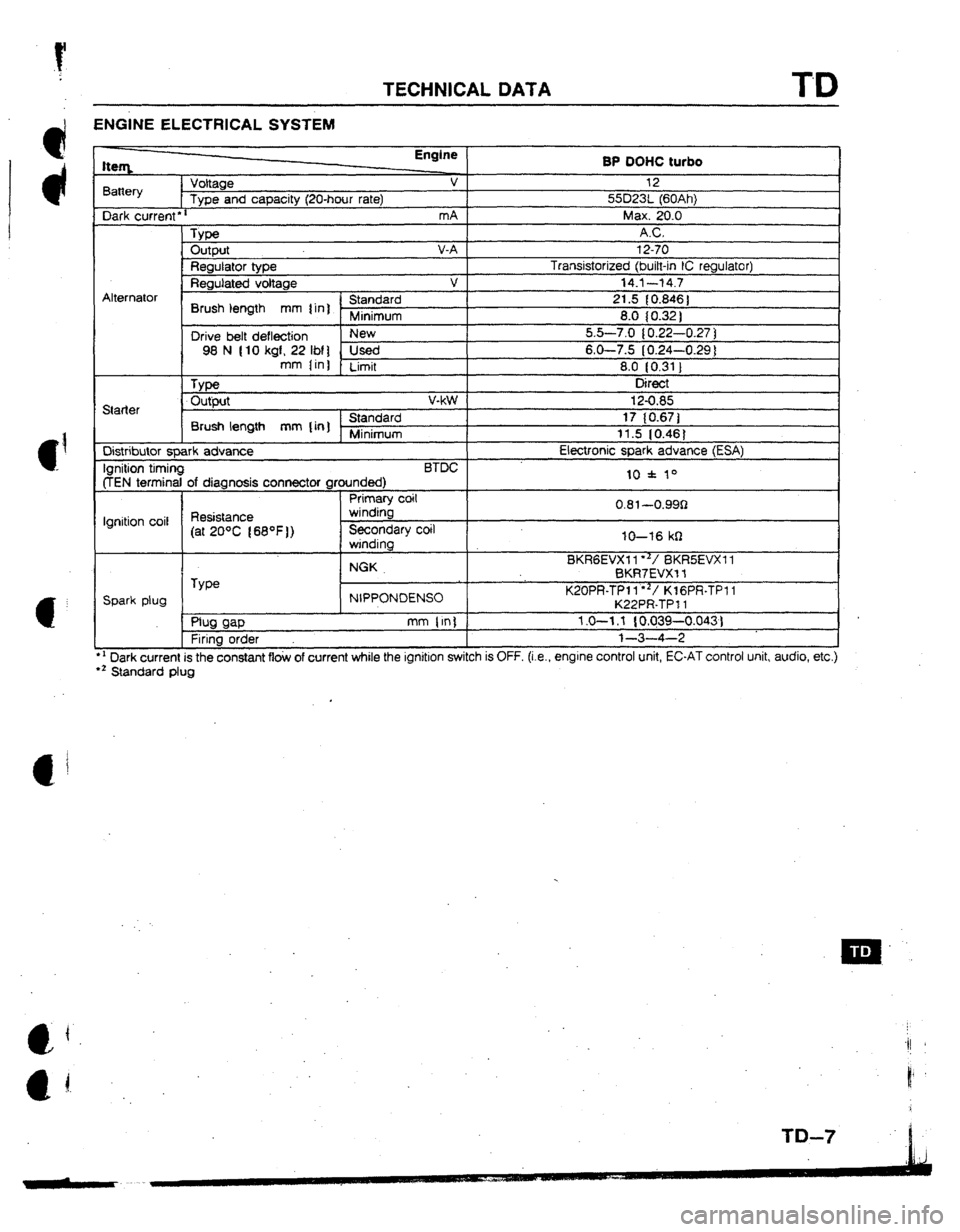

TECHNICAL DATA TD

ENGINE ELECTRICAL SYSTEM

l ’ Dark current is the constant flow of current while the ignition switch is OFF. (i.e., engrne control unit, EC-AT control unit, audio, etc.)

l z Standard plug tteq Engine

BP OOHC turbo

Battery Voltage v 12

Type and capacity (2U-hour rate) 55D23t (60Ah)

Dark current

l r mA Max. 20.0

_ Type AC.

Output V-A 12-70

Regulator type Transistorized (bitt-in IC regulator)

Regutated voltage v 14.1--t4.7

Alternator

’ Standard

Brush length mm 1 in] r 21.5 { 0.846 ]

Minimum 8.0 (0.32 )

Drive belt deflection New 5.5-7.0 10.22-0.27 ]

98 N (10 kgf, 22 IM] Used 6-O-7.5 (0.24-0.29 1

mm Iin)

Limit 8.0 IO.31 1

, Type Direct

Starter Output v-kW

Standard

Brush length mm {in] Minimum

Distributor spark advance

Ignition timing BTDC

(TEN terminal of diagnosis connector grounded)

Primary coit

Ignition coil Resistance winding

(at 20°C 168OF)) Secondary coil

winding

NGK

TYW

Spark plug NIPPONDENSO

, ml WP mm (in)

Firing order 12-0.85

17 (0.671

11.5 IO.481

Etectronic spark advance (ESA)

10 f 10

0.81~-0.99Q

IO-16 kfI

BKRGEVXI I**/ BKRSEVXI 1

BKR7EVX-f f

K20PR-TPl l”‘/ KlGPR-TPI 1

K22PR-TP 11

1.0-l .f { 0.039-0.043)

l-3-4-2

Page 183 of 279

GI Wiring Diagrams

Contents of wiring diagrams

l This document comprises the 8 groups shown below. The main components are summarized in the

components location diagram at the

end of the document.

I I Gi General information A how-to on using and reading wiring diagrams, 1

using test equipment, checking harnesses and

connectors, and findrng trouble spots

Y , Ground points

- Ground routes from and to the battery

W Electrical wiring Shows main fuses and other fuses for each

schematics system

A-U Circuit diagrams for

~ individual systems Shows circuit and connector diagrams and

component and connector location diagrams

X Common connectors Shows connectors common throughout system

~ JB i Joint box complete

wiring system

I Shows internal circuits and connectors

PL Parts location

Pi index Shows location of major electrical parts

Gives page number of circuit diagram for each

component

Using wiring diagrams

l The use of the wiring diagram depends on its application. Application

-or checking

:ircuits of

ndividual

systems

For checking

ground circuit

of individual

systems Use

II Application For checking

fuse

connections

Open to page with circuit diagram and

harness routing to be used and fold out

common connector diagram or joint box

diagram.

II

For finding

page numbers

of systems and

components

Open to page with ground point diagram

and fold out common connector diagram

or joint box diagram. Use

3pen to electrical wiring schematic.

Parts Index System Index

or

Open to parts index or system index.

Page 189 of 279

GI Reading Wiring Diagrams

Symbols

Symbol Meaning Symbol Meaning

Battery

l Generates electricity through

Resistance 0 A resistor with a constant value.

chemical reaction. l Mainly used to protect electrical

l Supplies direct current to circuits. components in circuits by maintaining

rated voltage.

l Reading resistance values.

Ground (1)

l Connecting point to vehicle body or No.1 color band other ground wire where current flows No.2 color band

-A-

from positive to negative terminal of No.3 mbr band

battery. No.4 color band

1 l Ground (1) indicates a ground point to

body through wire harness.

Ground (2)

l Gound (2) indicates point where

component is grounded directly to

body.

Remarks

l Current will not flow through a circuit if

ground is faulty.

Fuse (1)

0 Melts when current flow exceeds that

specified for circuit, interrupts current

I__q/y)__ now.

Precautions

(box)

l Do not replace with fuses exceeding

Fuse (2) specified capacity.

(Cartridge)

Main fuse/Fusible

Transistor (1)

l Electrical switching component. l Turns on when voltage is applied to Motor

0 Converts electrical energy into

mechanical energy.

Transistor (2)

0 Reading code. a Pulls in and discharges gases and

liquids.

Number of temtinak

Lamp l Emits light and generates heat when Current flows through filament. Cigarette lighter l Electrical coil that generates heat.

Page 191 of 279

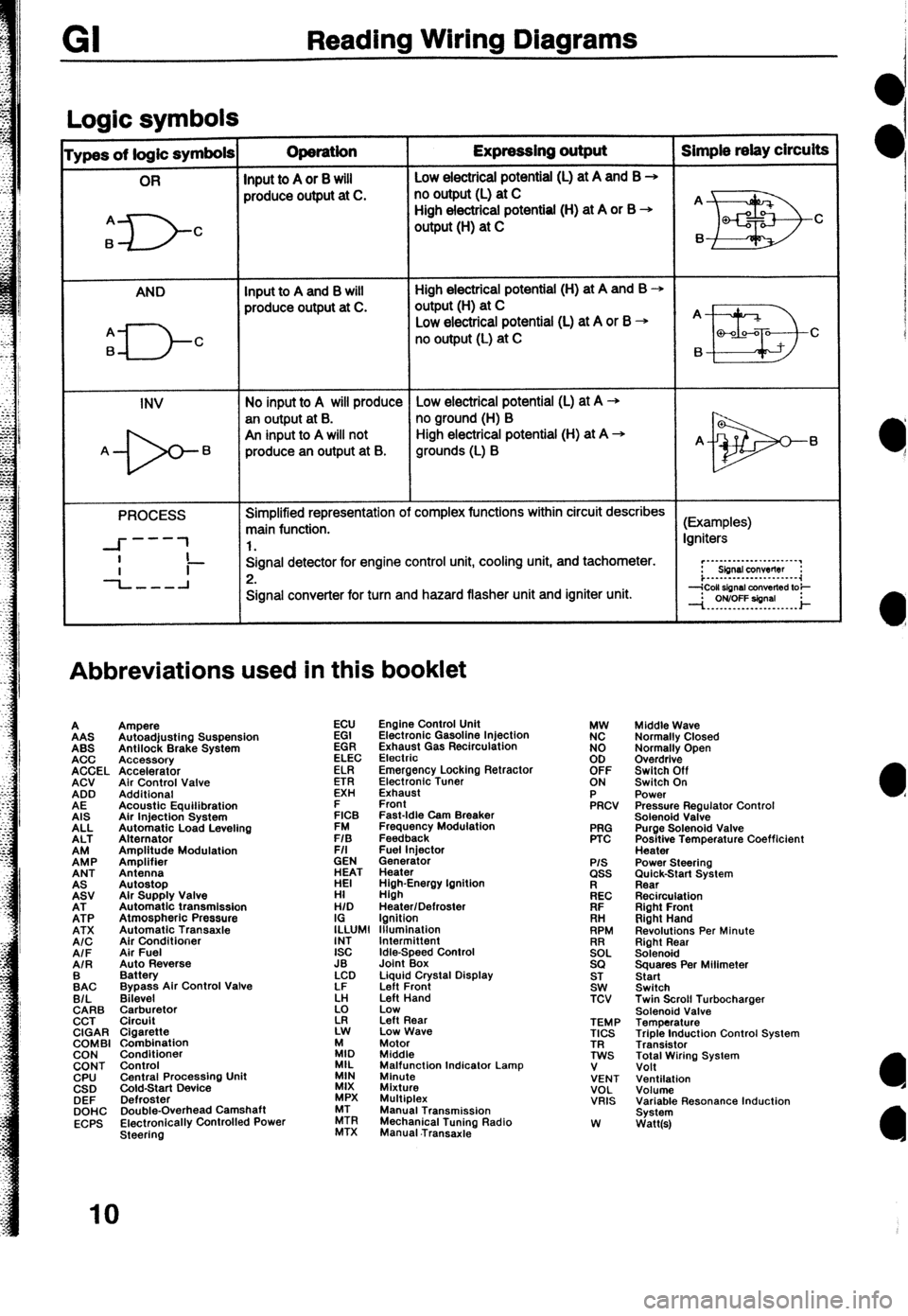

Reading Wiring Diagrams

Loaic symbols I

ypes of logic symbols Operation Expressing output Simple relay circuits

OR

Input to A or 8 will Low electricai potential (L) at A and B +

produce output at C. no output (L) at C

A

6

D- High electrical potential (H) at A or B +

C output (H) at C

AND Input to A and B will High electrical potential (H) at A and B +

produce output at C. output(H) at C

q---J-c

Low electrical potential (L) at A or B + A

no output (L) at C

B a-00-a C

6

INV No input to A will produce Low electrical potential (L) at A -+

an output at B. no ground (H) B

An input to A will not High electrical potential (H) at A +

A- 6 produce an output at B. grounds (L) B A- 6

PROCESS Simplified representation of complex functions within circuit describes

main function. (Examples)

---

--I- 1 1. Igniters

I

-L-l Signal detector for engine control unit, cooling unit, and tachometer.

Ii- 2. r”~“-‘-‘-““‘~~‘.“’

Sbnsl conwflw :

i...-..--.---......-.~~

Signal converter for turn and hazard flasher unit and igniter unit.

Abbreviations used in this booklet

A

AAS

ABS

ACC

ACCEL

ACV

ADD

AE

AIS

ALL

ALT

EP

ANT

EV

EP

ATX

A/C

AIF

AIR

:AC

B/L

CARB

CCT

CIGAR

COMBI

CON

CONT

CPU

CSD

DEF

DOHC

ECPS Ampere

Autoadjusting Suspension

Antilock Brake System

Accessory

Accelerator

Air Control Valve

Additional

Acoustic Equilibration

Air Injection System

Automatic Load Leveling

Alternator

Amplitude Modulation

Amplifier

Antenna

Autostop

Alr Supply Valve

Automatic transmission

Atmospheric Pressure

Automatic Transaxle

Air Conditioner

Air Fuel

Auto Reverse

Battery

Bypass Air Control Valve

Bilevel

$rr$:,tor

Cigarette

Combination

Conditioner

Control

Central Procassino Unit

&Id-Start Device -

Defroster

Double-Overhead Camshaft

Electronically Controlled Power

Steering ECU

EGI

EGR

ELEC

ELR

ETR

EXH

E

FICB

FM

F/S

F/I

GEN

ET

HI

H/D

I;LUMl

INT

ISC

JB

LCD

LF

k!

z Engine Control Unit

Electronic Gasoline Injection

Exhaust Gas Recirculation

Electrio

Emergency Locking Retractor

Electronic Tuner

Exhaust

Front

Fast-Idle Cam Breaker

Frequency Modulation

Feedback

Fuel lniector

Generator

Heater

High-Energy Ignition

High

Heater/Defroster

Ignition

lllumlnation

Idle-Speed Control

Joint Box

Liquid Crystal Display

Left Front

Left Hand

Low

Left Rear

Low Wave

:I, Motor

Middle

MIL

MIN Malfunction Indicator Lamp

Minute

MIX

Mixture

MPX Multiplex

ZR Manual Transmission

MTX Mechanical Tuning Radio

Manual .Transaxie PRG

PTC

P/S ass

kc

FIF

. . .

RH

RPM

!2EL

SQ

ST

SW

TCV

TEMP

TICS

TR

TWS

V

VENT

VOL

VRIS

W Middle Wave

Normally Closed

Normally Open

Overdrive

Switch Off

Switch On

Power

Pressure Regulator Control

Solenoid Valve

Purge Solenoid Valve

Positive Temperature Coefficient

Heater

Power Steering

;im&k-Start System

Recirculation

Right Front

Right Hand

Revolutions Per Minute

Right Rear

Solenoid

Squares Per Milimeter

Start

Switch

Twin Scroll Turbocharger

Solenoid Valve

Temperature

Triple Induction Control System

Transistor

Total Wiring System

Volt

Ventilation

Volume

Variable Resonance Induction

System

Watt(s)

IO