wheel MAZDA 323 1992 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 102 of 279

M FRONT AXLE

13EOMX-320

L 13EOMX-321

i . 13EOMX-32 13EOMX-322

3

Dust cover

1. Mark the new dust cover as the one removed.

2. Align the marks of the new dust cover and the steering

knuckle.

3. install the dust cover by using a steet plate and the SST.

Wheef bearing

lnstail the new wheel bearing by using the SST.

Front wheel hub assembly

1. Install the front wheel hub assembly by using the SST.

2. Verify that the wheel hub rotates smoothly.

Oil seal

Caution

l Use a new oil seal, and apply grease to the lip of

the seal.

‘0 tnstatt the oil seat flush with the steering knuckle.

Install the new oil seal by using the SST,

REA

PREP.

SST *

49 FO:

Pulter.

49 GOi

Hand E

(Part 3

49 GOi

49 FOE

Attach r

(Part 01

49 FOZ

--

49 FO2

Attach n

68 & 7’

(Part of

49 FO:!

--

49 FO:!’

t nstaller

bearing

--

49 GO3

Matter

49 G03:

lnstallef,

XW3

1

I 13EOMX-324 M--l 0

Page 103 of 279

_.:__ _:

M

I

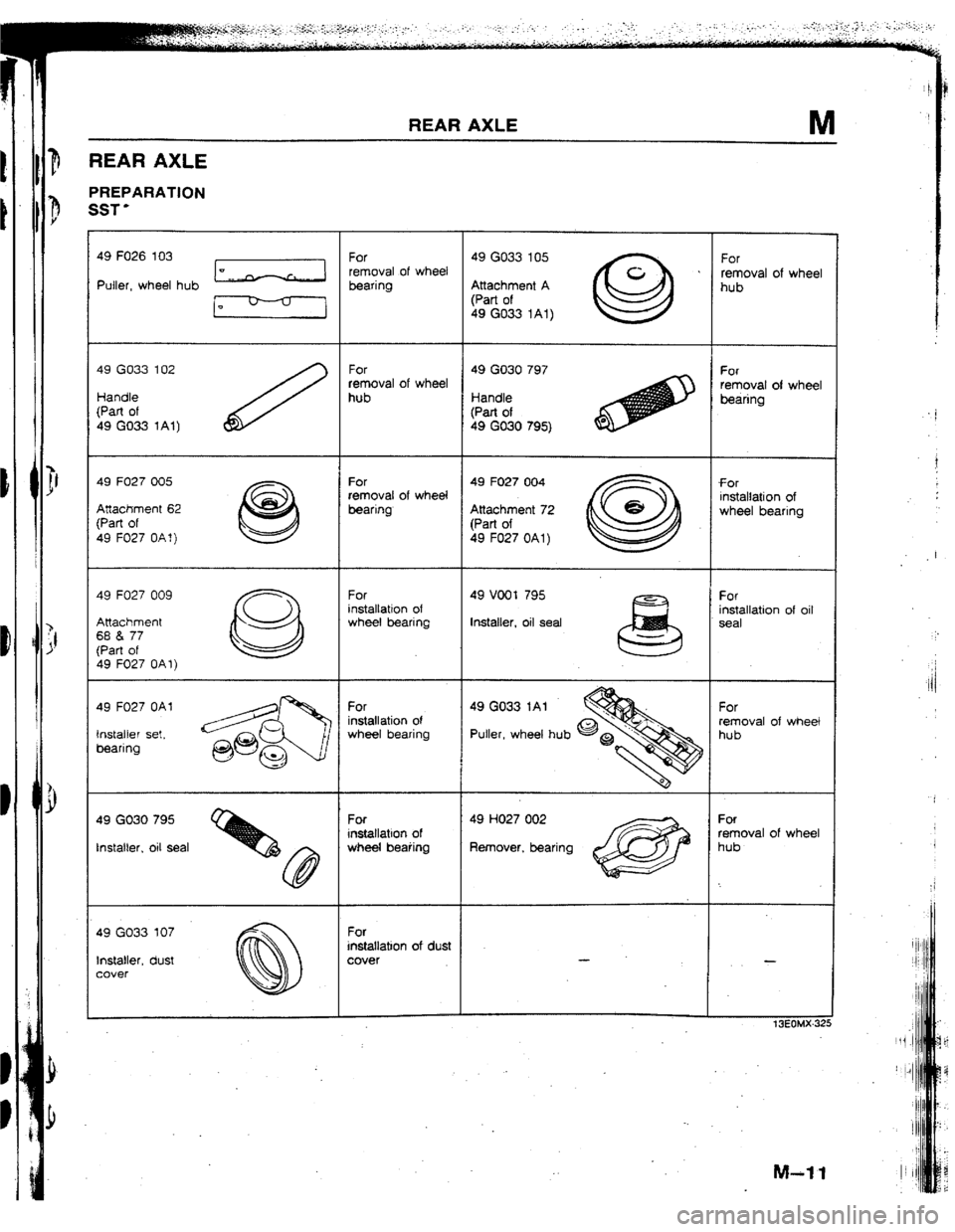

REAR AXLE

REAR

AXLE

PREPARATlON

SST’

49 FO26 103

Puller, wheel hub [cl Ei;;l of wheel ~a~~e~~~ ’ i!ovat of wheel

I- (Part of

49 GO33 1Al)

49 GO33 102

Handle

(Part of

49 GO33 1At) FC?r 49 GO30 797 For

removal of wheel removal of wheel

hub ktandte

bearing

(Part of

49 GO30 795)

49 FO27 005

Attachment 62

(Part of

49 FU27 OAf)

49 F027 009

Attachment

68 & 77 For 49 F027 004

f Of

removal of wheel installation of

bearing Attachment 72 wheel bearing

(Part of

49 F027 OAl)

installation of oil

Installer, oit seat

Instatter, oil seat Remover, bearing oval of wheel

49 GO33 107

Installer, dust

cover installation of dust

t3EOMX-32!

F

. i

t

I

Ii/

I

1

1

Page 104 of 279

REAR AXLE

WHEEL HUB, KNUCKLE

Removal I Inspection / installation

1. Remove in the order shown in the figure, referring to

Removal Note. 2. Inspect all parts and repair or replace as necessary.

3. Install in the reverse order of removal, referring to Installation Note.

Caution

l Loosely tighten the shock absorber bolts. Lower the vehicle and tighten the bolts to the specified

torque with the vehicle unladen.

4. Adiust the rear wheel alianment.

16-22 1?.6-2.3, 12-16 I

7

IO.o-13.0,

66-66.7 1 1. Wheel and tire

2. Locknut

Removal Note..; . . . . . . . . , . . . . ,.......- -.. page M-f 3

Installation Note .._...,.,...._.__........ page M-13

I$ Brake caliper assembly

Service . . . . . . . . . . . ..e......._......... ,.,...,....

Section P

4. Disc plate

‘Service ..I....................__....... . . . . . . . . . Section P 5. Af3S wheel speed sensor (if equipped)

6. Wheel hub, knuckle

Disassembly I Inspect& /

Assem bty . . . . . . . ..I..........*..*.*...-... page M-14

Inspect wheel hub and knuckle for damage

or cracks

Inspect dust cover for damage or defor-

mation

M-12

Page 106 of 279

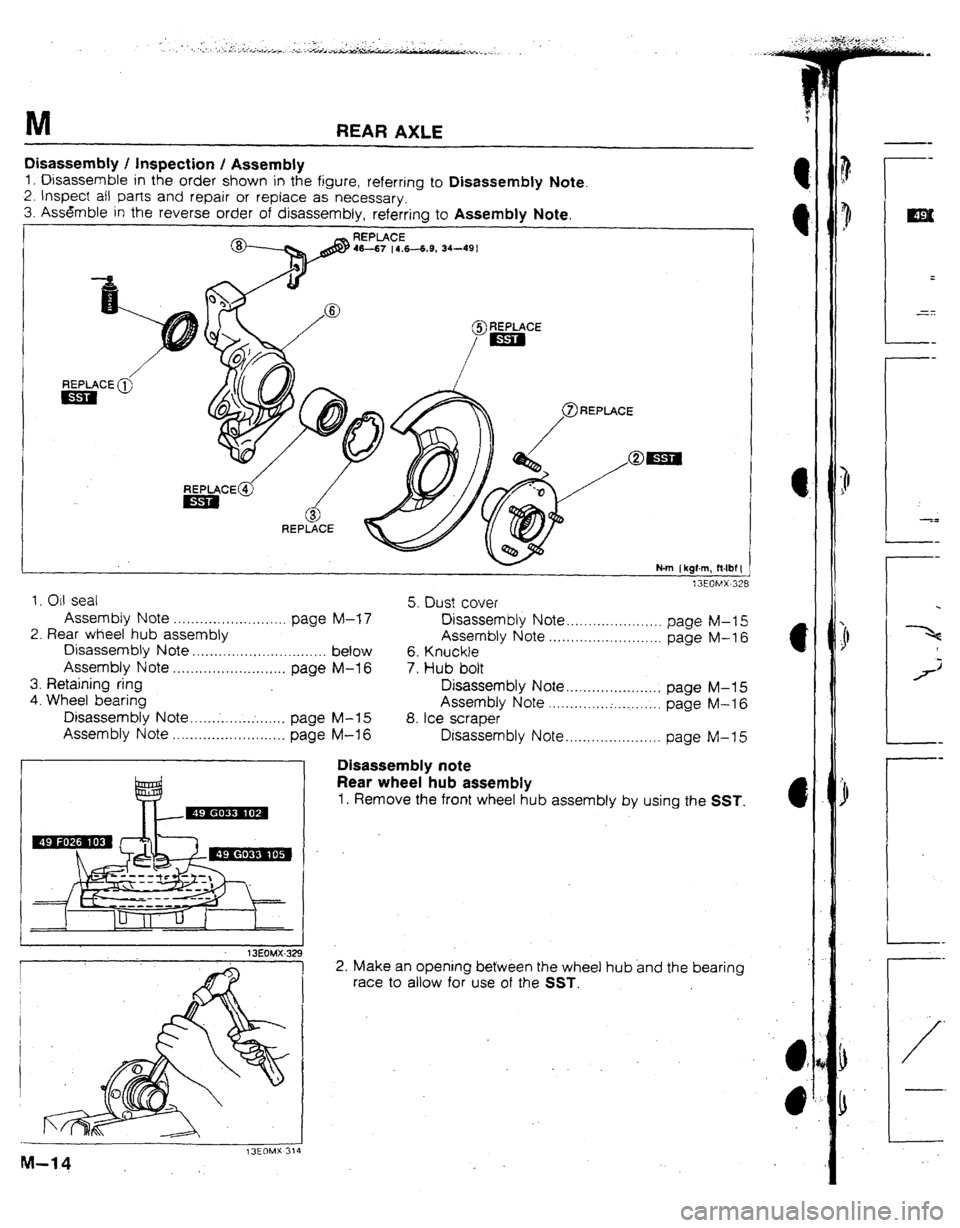

M REAR AXLE

Disassembly ! Inspection ! Assembly

1, Disassemble in the order shown in the figure, referring to Disassembly Note.

2. Inspect ail parts and repair of replace as necessary.

3. Assemble in the reverse order of disassembly, referring to Assembly Note.

13EOMX-328

L

1. CM seal

Assembfy Note . . . . . . . . . . . . . . . . . . . . . . . . . . page M-f 7

2. Rear wheel hub assembly

Disassembly Note. . . . . . . . . . . , , ,...... . . . . . . . . , . . below

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . page M-l 6

3. Retaining ring

4. Wheel bearing

Disassembly Note .,.... ~ . . . . ..=........ page M-15

Assembly Note .+.................. _ . . . . . page M-l 6 5. Dust cover

Disassembly Note . . . . . . . . . . . . . . . . . . . . . page M-t 5

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . page M-16

6. Knuckle

7. Hub bolt

Disassembly Note . . . . . . . . . . . . ..‘....... page M-l 5

Assembly Note k.. . . . . . . . . . . . :. . . . . . . . . . . page M-l 6

8. tee scraper

Disassembly Note . . . . . . . . . . . . . . . . . . . . . . page M-f 5

13EOMX-32 9

r

I

I

1

13EOMX 314

M-14 Disassembly note

Rear wheel hub assembly

1. Remove the front wheel hub assembly by using the SST.

2. Make an opening between the wheel hub and the bearing

race to allow for use of the SST.

--

ma

=

-zt:

--

--

5=

--

--

I

1

j

-a

--

--

/-

Page 107 of 279

REAR AXLE

13EOMX-330

13EOMX-331

I

t3EOMX.318

. _.

-.

3. Press out the bearing race by using the SST.

Wheel bearing

Remove the wheel bearing by using the SST.

Dust cover

Caution

l Do not remove the dust cover if not necessary.

l Do not reuse-the dust cover if removed.

1. Mark the dust cover and steering knuckle for proper reas- *

sembly.

2. Remove the dust cover by using a chisel.

Ice scraper

Caution

l Do not remove the ice scraper if not necessary.

. If it is removed, use a new bolt applied specified

thread locking compound.

Hub bolt

caution

l Do not remove the hub bolts if not necessary.

i Do not reuse the hub bolts if removed.

Remove the hub bolts by using a press.

.

M-q.5

Page 108 of 279

M REAR AXLE

.

I

I

13EOMX-319

I

1 SEOMX -3;

13EOMX-33

1

M-16 f3EOMX-32:

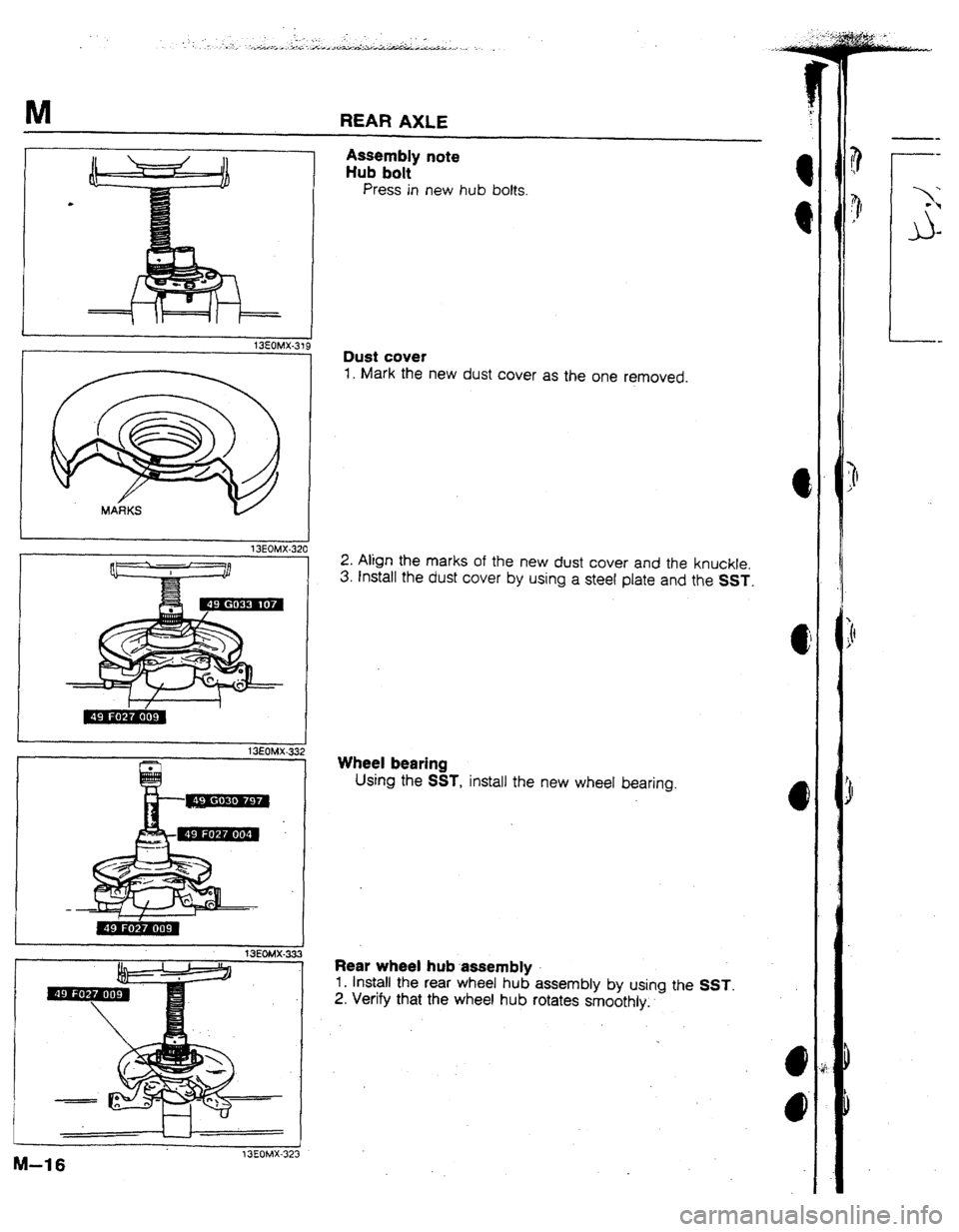

Assembly note

Hub bolt

Press in new hub bolts.

Dust cover

1. Mark the new dust cover as the one removed.

2. Align the marks of the new dust cover and the knuckle.

3. Install the dust cover by using a steel plate and the SST.

Wheel bearing

Using the SST, install the new wheel bearing.

Rear wheel hub assembly

1. Install the rear wheel hub assembly by using the SST.

2. Verify that the wheel hub rotates smoothly..

Page 111 of 279

N OUTLJNE

UUTLJNE

OUTLINE Of CONSTRUCTION

l EncJine speed sensing power steering (ESPS) is standard equipment for all models. The construction and

operation are basically the same as for previous models.

l The lock-to-lock specification of the steering wheel is reduced from 2.76 to 2.51.

13EONX-302

SPECIFICATIONS

hem Specifications

Steermg wheel Outer diameter mm {in] 370 { 14.57)

Lock-to-lock turns :i-‘~~:~.~~~~~~:~~;~~~~ :;‘:.. .‘:I .:::::.::~::::,:.:::.i: ,,,,.,:, :‘,:,,.:,: .,: I. . ..- :.~6:.n.:::;,:~~:~~~~~~~.~::~,:~:.: :: :

” .: ‘-.: .:.:::~:‘::.‘.::‘:‘:.I;:.‘,.: >.. .: :” 3 :. ,;:.+..i<.I. ‘_ : ; t:

. . ..: :: ::.:. .:::. ::r .;

. . . . . . . . . .y : :.: ,. .: ,_ : ., :

Me Collapsible

Steering shaft and joint Joint type

Tilt stroke

J 2-cross joint

mm {in] 30 11.18)

Type Rack-and-pinion

I

Steering gear Gear ratio

Rack stroke mm [in] 00 (infinite)

121 f4.761

Capacity

Power steertng fluid 1 (US qt Imp qt) 018 (0.85, 0.701

We ATF DexrorPlI or M-ID

,

Shaded area rndicates new specrfcatlon. t3EONX-303

N-2

Page 114 of 279

OUTLlNE P

OUTLfNE

OUTLINE OF CONSTRUCTION

l The brake system remains similar to that of the previous model. l However, because all new models use a higher-horsepower engine, the brake system is enlarged as a whole.

l Vehicles without ABS use a portless-type master cylinder

13EOPX-303

SPECIFICATIONS

Brake pedal

Master cylinder

Front drsc brake

Rear disc brake

Power brake unit

Braking force control device

Brake fluid

Parking brake Item Specification

Type Suspended

I

PedaJ lever ratio 4.1

Max. stroke mm [in] 140 j5.511

I,

Type Tandem

Cylinder inner diameter mm {in] Without ABS: 25.4 j 1 .UO ]

With ABS: 23.8 to.941 3-

Type Ventilated disc ?

Cylinder bore mm [in)

57.2 12.253

Pad dimensions (area x thickness)

mm2 {rn2) xmm [In) 5,200 (8.OSl x 10 (0.39)

Disc plate dimensions mm (in]

(outer diameter x thickness) 274x24 (10.79x0.94)

Type Solid disc

Cylinder bore mm Jon]

34.9 j 1.37 ]

Pad dimensions (area x thrckness)

mm’ (in21 xmm [in) 3,200 I4.961 x8 (0.31)

DISC plate dimensions mm t,n]

(outer diameter x thickness) 280x10 (tl.02xu.39]

il

Type Without ABS: Vacuum multIplier

With ABS: Hydraulrc muttiplier

Diameter mm Iln]

(without ABS) 188.4 17.42) +215.2 t8.47)

We Without ABS: Dual proportioning valve

With ASS: Proportioning valve

FMVSS 116, DOT-3, SAE J1703

Mechanical twGrear-wheel control

Type

Operation system Center lever

13EOPX.304 t

Page 121 of 279

P CONVENTIONAL BRAKE SYSTEM

FRONT BRAKE (DISC)

t nspection (on-ve hicte)

Disc pad

t. Jack up the front of the vehicle and support it with safety

stands.

2. Remove the wheels.

3. Sight through the caliper inspection hole and inspect the

remaining thickness of the pads.

1

Thickness: 2.Omm f 0.08 in ] min.

I LlL”r *-cl , a 4. Replace the pads as a set (right and left wheels) if either

is at br ‘less than the mintmum thickness.

Removal / inspection I installation

1. Remove in the order shown in the figure.

2. Inspect all parts and repair or replace as necessary.

3. Install in the reverse order of removal, referring to InstaHation Note.

4. After installation, perform the following.

(1) Add fluid and bleed the air.

(2) Check for fluid leakage.

(3) Depress the pedal a few times, then verify that the brakes do not drag while rotating the wheel by hand.

102-137 (10.4-14.0,

22-29 (2.2-3.0, 16-21)

75.3-1011

1. Flexible hose 7. Outer shim

2. Bolt 8. Inner shim

3. Callper 9. Guide plate

Disassembly I t nspection / IO. Mounting support

Assembly . _. . . . . _. ._. . . . . . . . . . . . , i.. . . ,:, . page P-l 2 t 1. Disc plate

4. Boot Inspection . . . . . . . . . . . . . . . . . . . . . . . . .,......_.. page P-1 2

5. V-spring

6. Disc pad

Inspection . . . . . . . . . . . . . . . . . . . . .._.__....._........... above InstaUation Note . . . . . . . . . . . . . . . . . .._...... page P-l 1 DlSC PAC

Reptacem

I. Remove

2. tnstatl in

1; Em

2. V-spring

3. Disc paa

fnstatle

Page 125 of 279

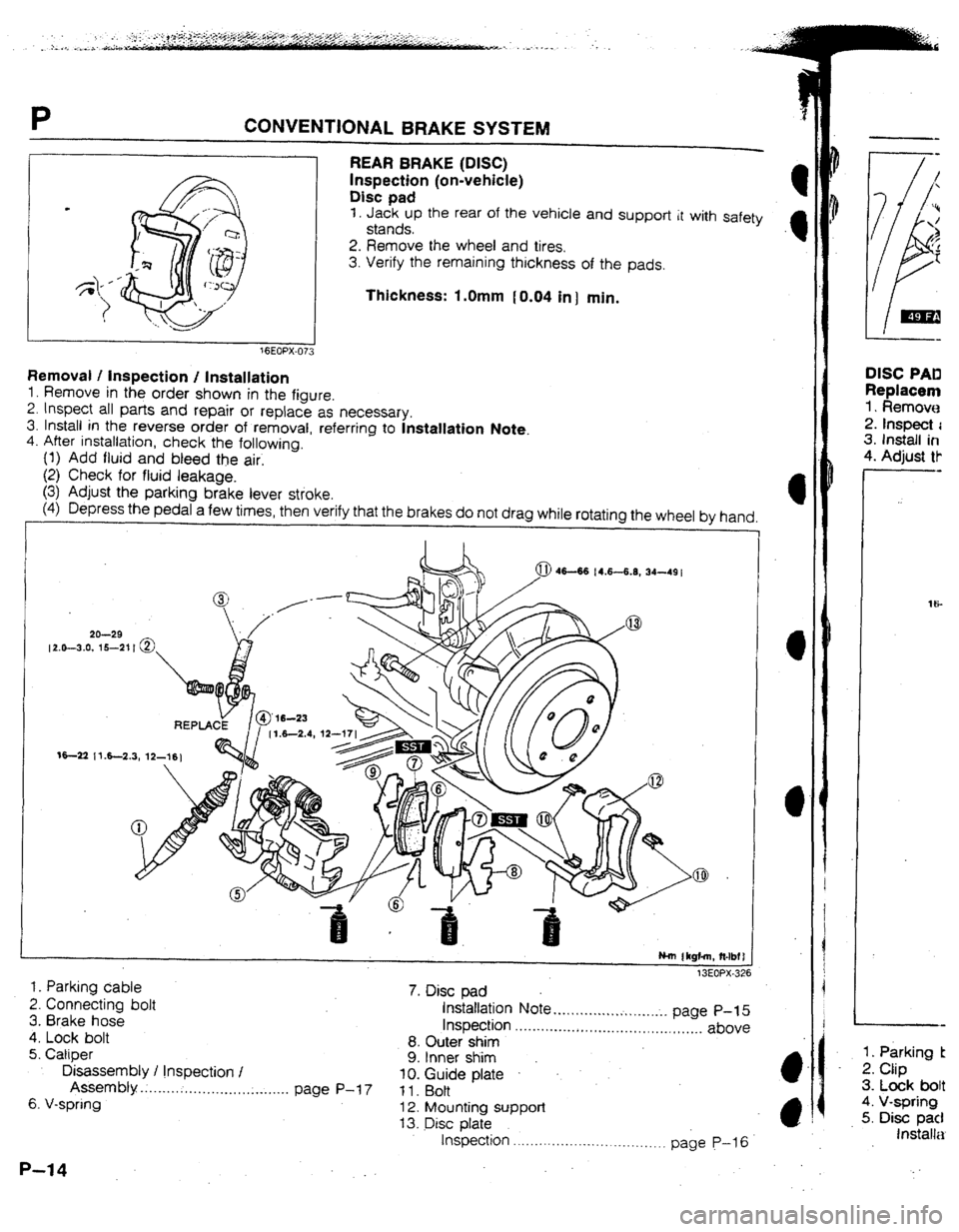

P CONVENTIONAL BRAKE SYSTEM

f 6EOPX-073

REAR BRAKE (DISC)

inspection (on-vehicle)

Disc pad

1, Jack up the rear of the vehicle and support it with safety

stands.

2, Remove the wheel and tires.

3. Verify the remaining thickness of the pads.

Thickness: f .Omm fU.04 in) min.

Removal I Inspection / Installation

1. Remove in the order shown in the figure.

2. Inspect all parts and repair or replace as necessary.

3. Install in the reverse order of removal, referring to Installation Note.

4. After instaHation, check the following.

(1) Add fluid and bteed the air.

(2) Check for fluid leakage.

(3) Adjust the parking brake lever stioke.

(4) Depress the pedal a few times, then verify that the brakes do not drag while rotating the wheel bv hand,

1. Parking cable

7. Disc pad

13EOPX-32f page P-15 ,..

. . ..I...... above 2. Connecting bolt installation

3. Brake hose Note . ..*. 1 ,...... I.r. . . . . .

4. Lock bolt Inspection . ..-f...........III.I.......,,.

8. Outer shim

5. Caliper 9. Inner shim

Disassembly I Inspection I

Assem bty IO. Guide plate .

-. . . _. . . . . . . . . . . . . . . . . , . . . . . . . . . . . page P-l 7

Il. Bolt

6, V-spring 12. Mounting support

I 3. Disc plate

Inspection . . . . . . . . . . . . . . . . . . . .._...._.~

P-1 4 . . . page p-16 DISC PAD

Replacem

1 s Remove

2. Inspect

i 3. Install in

4. Adjust tF

1. Parking t

2. Ciip

3. Lock bolt

4. V-spring

5. Disc pad

Installa