engine coolant MAZDA 323 1992 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 21 of 279

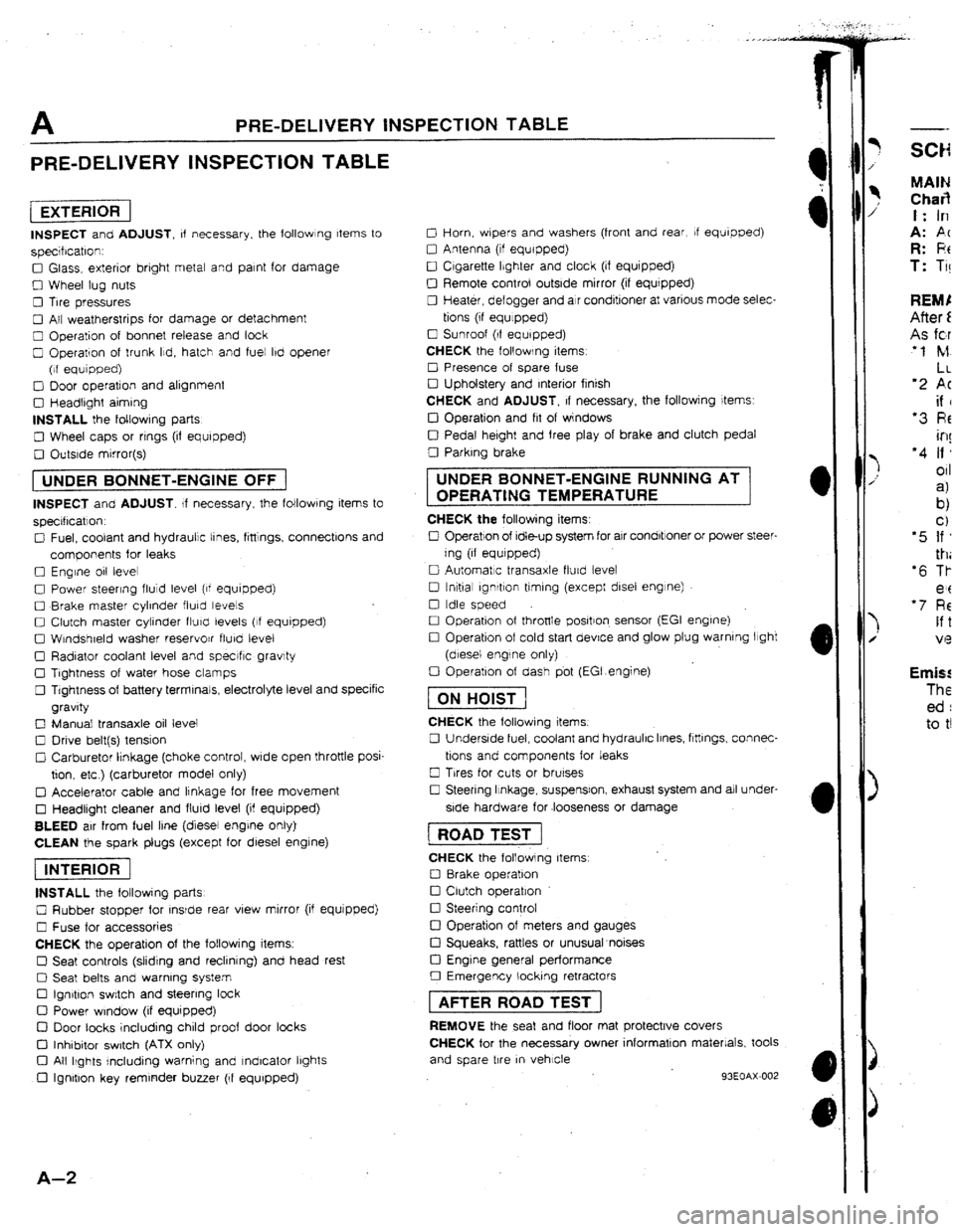

A PRE-DELIVERY INSPECTION TABLE

PRE-DELIVERY INSPECTION TABLE

[EXTERlORI

INSPECT and ADJUST, of necessary. the followlng Items to

specrfrcatron:

0 Glass, exterior bright metal and paint for damage

0 Wheel lug nuts

0 Tire pressures

0 All weatherstrips for damage or detachment

0 Operation of bonnet release and look

0 Operation of trunk Ild, hatch and fuel lbd opener

(of equipped)

0 Door operation and alignment

0 Headtrght aiming

INSTALL the foltowrng parts

0 Wheel caps or rrngs (if equipped)

0 Outsrde mirror(s)

1 UNDER BONNET-ENGINE OFF j

INSPECT and ADJUST. If necessary, the following items to

specrflcatlon.

0 Fuel, coolant and hydraulic tines, fittings, connectlons and

components for leaks

0 Engine 011 level

0 Power steering fluid level (of equipped)

0 Brake master cylinder fluky levels

0 Clutch master cylinder fturcl levels (If equipped)

0 Wtndshreld washer reservojr flurd level

0 Radiator coolant level and specrfic gravity

0 Tightness of water hose clamps

0 Tightness of battery terminals, electrolyte level and specific

gravity

0 Manual transaxle oil level

0 Drive belt(s) tension

Cl Carburetor lrnkage (choke control, wrde open throttle posi-

tion. etc ) (carburetor model only)

q Accelerator cable and linkage for free movement

0 Headlight cleaner and flurd level (if equipped)

BLEED air from fuel line (diesel engrne only)

CLEAN the spark plugs (except for diesel engine)

piEi6F]

INSTALL the following parts

0 Rubber stopper for rnsrde rear view mirror (if equjpped)

0 Fuse for accessories

CHECK the operation of the following items.

0 Seat controls (sliding and reclining) and head rest

0 Seat belts and warning system

Cl Ign&on switch and steering lock

0 Power window (if equipped)

D Door tacks including child proof door locks

Cl Inhibitor switch (ATX only)

Cl All Ikghts rncluding warning and Indicator lbghts

0 Ignition key reminder buzzer (If equipped)

A-Z

0 Horn, wbpers and washers (front and rear, If equipped)

0 Antenna (tf equipped)

0 Cigarette Ibghter and clock (if equipped)

0 Remote control outside mirror (if equrpped)

0 Heater, defogger and air conditioner at various mode selec-

tions (if equlppedj

0 Sunroof (If equipped)

CHECK the following items

0 Presence of spare fuse

0 Upholstery and Interior finish

CHECK and ADJUST, If necessary, the followjng items:

IJ Operation and fit of windows

0 Pedal height and free play of brake and clutch pedal

0 Parking brake UNDER BONNET-ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

0 Operation of Idle-up system for air condbtroner or power steer-

ing (if equrpped)

0 Automatic transaxle flurd levet

0 tnltial ignrtlon timing (except disel engine)

0 Idle speed

0 Operation of throttle positron. sensor (EGI engrne)

0 Operation of cold start device and glow plug warning light

(diesel engine only)

0 Operation of dash pbt (EGI.engine)

fTiGGJ

CHECK the following items.

0 Underside fuel, coolant and hydraulic Irnes, ftttlngs, connec-

tions and components for leaks

0 Trres for cuts or brurses

0 Steering Itnkage, suspensron, exhaust system and all under-

side hardware for .looseness or damage 1 ROAD TEST j

CHECK the following items

0 8rake operation

0 Clutch operation

0 Steering control

!ZI Operation of meters and gauges

Cl Squeaks, rattles or unusual noises

Cl Engine general performance

0 Emergency locking retractors 1 AFTER ROAD TEST ]

REMOVE the seat and floor mat protective covers

CHECK for the necessary owner information materials, took

and spare tire

m vehicle

93EOAX-002

-- MAIN Char3 t: In

A: PC R: F!t T: Ti! Emis! The ed : to t!

Page 23 of 279

A SCHEDULED MAtNTENANCE SERVtCES (Europe)

Maintenance Number of months or km (miles), whichever comes first

Months” - 6 12 18 24 30 36 42 48

Kllometers 1,000 10,000 20,000 30,000 40,000 50,000 60,000 70,000 80,000

{Miles)

(600) (6,000) f[t2,000) (18,000) (24,000) (3U,OOO) (36,000) (42,000) {48,000), Engine

Intake and exhaust manrfold nuts (Bolts)

Drive belts”

i Engine trmlng beltW3

Engine oil (Turbo)‘4

01 filter

l *

Cool!ng system (Includtng

coolant level adlustment)

Engrne coolant T T T

A A A

A A

Replace every 100,000 km (60,000 miles)

Replace every 5,000 km (3,000 miles) or 6 months

R R R R R 1 R R R

I I I I

I

Replace every 2 years Fuel system

Idle speed

Air cleaner element * 5

Fuel

falter

Fuel Ilnes and hoses Ignition system

A f 1

I R I R

R R

I I f t I ~

lnlttal rgnrtloh trmlng 1 I I I I I I I I

Spark plugs A

A. A A

Spark plugs (Only for Sweden) Adjust every 30.000 km (t8.000 mrls) Evaporative emission control system

Throttle sensor Throttle sensor (Only for Sweden)

Evaporative system

Evaporatrve system (Only for Sweden) 1 A 1 1 A 1 1 A 1 ) A

Adjust every 80,000 km (48,000 miles)

1 I 1 1 I’ 1 1 I 1 1 I

Inspect every 80,000 km (48,000 mites) Electrical system

Battery electrolyte level and specific gravity 1 I f I I I

All Electrical system

l ’ 1 I

I 1 I I I

1 . 1 I I

Headlight alrgnment 1 A A A . A. Chassis and body

t 3EOAX-303

A-4 Chas

SW31 Rear

Tires

Hing

Seat

Page 31 of 279

EXHAUST ViitVE

EXHAUST SIDE

VALVE GUIDE

METALLIC SODIUM

(ABOUT 30% VOLUME)

VALVE STEM

.‘.‘*

:::I

:::I

VALVE HEAD

CYttNDER HEAD

IDENTlFtCATION OF METALLIC SODIUM-FILLED EXHAUST VALVE

l Superior he& dissipating .metallic sodium-filled exhaust valves are adopted. During engine operation, the

metalic sodium inside the valve stem melts. As the valve moves up and down, the sodium splashes around

inside the valve and helps to absorb heat from the cylinder head and to transfer it back to the engine

coolant through the valve guide. In this way, the combustion chamber temperature is reduced, reducing

knocking and improving fuel efficeincy.

l Special handling of sodium filled valves is required for personal safety. (See next page.)

B2-7

Page 47 of 279

F3 CONTROL SYSTEM

PRESSURE REGULATOR CONTROL SYSTEM

SOLENOID VALVE TO MAIN RELAY

(PRC HIGH TEYP.)

t ECU

I

PRESSURE REGULATOR

// VACUUM

IJ WATER

THERMOSENSOR

F----------- lNTAKE AIR

THERMOSENSOR

SWITCH SOLEltolD VALVE

(PRC LOW TEMP.)

TO FUEL TANK

13EOF3-31 To prevent vaporlock in the fuel system during hot restart idle, a two-stage pressure regulator is adoped

to the new 323 4WD.

Low temperature operation: The vacuum to the pressure regulator (A and B ports) is cut (solenoid valve

[low temp.] UN), and the fuel injection pressure is increased to 284 kPa (2.90 kgf/cm2, 41 psi ) ,

High temperature operation: The vacuum to the pressure regulator (A port) is cut (solenoid valve [high

temp.] ON), and the fuel injection pressure is increased to 343 kPa [ 3.5 kgf/cm2, 49 psi 1.

Condition and operation

Condition Operation

1

coolant Intake alt Solenoid vrlve Solenoid vatve Opemtlon

I temperature temperature Engine (Idw temp.)

(high temp.) time Operation 40% [fU40f)-

Above 90°C 5U°C (t22OFI ON OFF 180s Low temp.

f f940Fj No load

Above 5O*C

I122OF) OFF ON 210s t-ltgh temp.

3

t3EOF3-319

F3-14 Wast

l Ins fuel

l In:; InJeci

l In:;

l Vol Injecl

l In:;

Presr

l SCI Engir

l InsI

Page 64 of 279

TROUSLESHOOTING GUIDE F3

10 ROUGH IDLE/ENGINE STALLS AT IDLE - AmER WARM-UP

DESCRIP- -Engine runs normalty at idle during warm-up but engine stalls or vibrates excessively after warm

TlO#

TROUBLESHOOTING HINTS]

3 Idle-speed control system malfunction

3 Air/Fuel mixture too lean

l Air leakage

*Low fuel line pressure

TEP

INSPECTION

1

ts “00” dlsplayed on Se\-Diagnosis Checker

with ignition switch ON?

SYSTEM SELECT: 1 @ Air/Fuel mixture too rich

l Fuel injection control malfunctlon

(correction for coolant tem$eratuie)

@ Poor ignition

@ Low engine compresslon

ACTION

YES Go to next step

No Service

Code No. displayed

Check for cause (Refer to specified

check sequence)

w page F3-16

“88” flashes Check ECU terminal IF voltage w page F345

Voltage: Battery voltage

(ignition switch ON)

W: SELF TEST e !f UK, replace ECU

w page F3-3 c3 ff not OK, check wiring

(ECU - Self-Diagnosis Checker)

2 Are ECU termrnal voltages OK Yes Go to next step

(especially 20, 20, and 2Q)?

w page F3-45 No

Check for cause

3 Disconnect each high-tension lead at idle; does Yes Go to next step

engine speed decrease equally at each cylinder?

NO Go to Step 9

4 Is intake manifold vacuum correct at idle? Yes Go to next step

Vacuum: More than 450 mmHg f 17.7 InHg )

NO Check for air leakage of intake air sys-

tem components

5 Is air cleaner element clean? Yes Go to next step

No Replace air cleaner element

F3-3 1

Page 70 of 279

F3 II TURBOCHARGER CONTROL SYSTEM ‘1

1’

:j

TURBOCHARGER CONTROL

SYSTEM

TURBOCHARGER

Re’inovaf / Installation

Caution

l Be careful of the following points after turbocharger removal.

l Do not carry the turbocharger by the actuator rod or actuator hose.

l Do not drop the turbocharger.

l Set the turbocharger down with the turbine shaft horizontat.

l Cover the intake, exhaust, and oil passages to prevent dirt or other material from entering

the turbocharger.

l Use the specified new studs when installing the turbocharger.

1, Disconnect the negative battery cable.

2. Raise the vehicle and support it on safety stands.

3. Remove the undercover.

4. Orain the engine coolant.

5. Remove in the order shown in the figure, referring to Removal Note.

6. Install in the reverse order of removal, referring to Installation Note.

I-- 7.8-1 1 N-m ~80-110 kgfcm. 69-96 idbf j

3946 13.94.7, 2% 3842 13.94.3, 28-

31--46 13.2-4.7, 23-341

T, REPLACE .

12-18 1 f-2-1.8, 8.7-13 I

GASKET, REPLACE

19-26 1 t .9-2.6, 14-19 1

7.6-11 Mm t80-?lO kgfcm, 69-95 hlbfl

~-t-n 1 kgf-m, Wlbt]

13EOF3 3.31

F3-3i

Page 85 of 279

F3 CONTROL SYSTEM

Terminal Input Dutpui

2s - 0

2T 0

2U 0

2v 0

2w 0

2x 0

2Y 0

22 0 t

I, Ve: Battery voltage I I I Connected to Test condition

Correct voltage Remark

Overboost warning lgnitron switch ON

VB

-

buzzer

Solenoid valve

(PRC low temp.) 180 sec. after engrne started with coolant Below 1.W No-load engine

temperature is above 9O*C { 194*F ] and condition

intake air temperature IS between 40°C

1104*FJ and 50°C {122OF

f Other condition at idle

I VS

tnjector {Nos. 1, 3) Ignition switch ON VS

Idle V0’

I Engine speed above 2,000 rpm during

I Ve

deceleration (after warm-up)

Injector (Nos 2, 4) Ignition switch

ON VS

Idle VS’ * Engine Signal

Monrtor: Green

and red lamps

flash

ISC valve Engine speed above 2,000 rpm during VS

deceleration (after warm-up)

Ignition switch ON Approx. 7V

-

Idle 1 Approx. 9V

Solenoid valve

(purge control) Ignition switch ON

Idle V0

-

VB

Ci rcuit-opening

relay ignition switch ON

tdle 1 VB

I 8elow l.OV -

Solenotd valve

(PRC high temp.) 210 sec. after engine started wrth coolant Below 1.5V

temperature above 90°C ]194*F] and

Intake atr temperature above 50°C

f t22*F1 No-load engine

cond$on

1 Other condition at idle

I VB

I -

7 I PI

I l-1 t

r

2'f 2W 2U 25 iQ 20 &A 2K 21 2G 2E 2C 2A 1U 1s 10 10 1M 1K 11 tG If 1C 1A

F3-52 --

A/w&

--

Alway

--

Alway

--

Alway

--

Alwaj

--

Alwa f

--

Alwas]

--

Alwa I’

Page 135 of 279

R OUTLINE

OUTLINE

OUTLtNE OF CONSTRUCTION

l The%onstruction and operation of the suspension system are basically the same as for previous models.

l The coil spring and shock absorber specifications are changed.

l The stabilizer specifications are changed.

SPECIFICATIONS

13EORX-302

Front suspension

Suspension type

Sprmg type

Shock absorber

Stabrlmr

Specifications

Strut

Coil spring

Oil filled Total toe-rn

Front

wheel

atignment

(‘Unladen)

Rear suspension

Suspensron type

Sprmg type

Shock absorber

Stabrlrzer

Rear wheei

alrgnment

(‘Unladen) Maximum steering 38* f 3*

309 f 30

-0045 f 45’

2035’ f 45’

KIngpin angle degree

12*to’

We Oil fifled

Damprng force N [ kgl Ibf 1 .‘? .@g,$g&;qJ&,$. ‘: ‘., . . ” ‘, : :,

at 0.3 m 112

]ls I Contraction ;. ~ .. . . . . .__. ..:, .. .. ,I. ._ :. . . f: ; _... .:

Type Torsion bar

Diameter mm. f in ]

19.t (0.751

Total toe-in mm fin!

2.h 3 (0.08 f 0.121

degree

O”12’ f 18’

Camber angle degree -0°20’ f 45’

13EORX-303

l Fuel tank full, radrator coolant and engine oil at speclfled levels; and spare tire, jack, and tools in designated positions. Front Coil Spring Specifications

1 Identification mark color Wire diameter Coif .center

M l l

I Free length A a2 mm lin)

diameter mm [in) . mm 1 in) Coil number Rear Coil Spring Speci?ications

ldentlfication mark color M” Wire diameter Coil center

Free length

mm {in) diameter mm 1 in J

mm {in) Coil number

*’ Maln Identlfcatlon mark on second cgil from bottom.

*’ Auxrllary &entificatton mark on thrrd coil from bottom.

Shaded areas tndcate

new specifrcat+ons 13EORXCS05

(I .f

Page 158 of 279

TECHNICAL DATA TD

Engine

Item BP DOHC turbo

Engine oii

Total (dry engine} 4.0 14.2, 3.5)

Capacity

L IUS qt, Imp qtl Ott pan 3.6 (3.8, 3.2)

011 filter 0.17 (0.18, 0.15)

Grade API Service SD, SE, SF or SG

Above 30°C (86*F) SAE 40

O*C-40*C ~32°F-1040F 1 SAE 30

-1 OOC--2O*C [ 14OF-68OF ] SAE 2OW-20

Viscosity Above -10% [14*Fj SAE ZOW-40 or 2OW-50

number -25*C--3O*C I-1 3OF-86OF ] SAE 1 OW-30

Above -25OC (-13*F1 SAE low-40 or low-50

Below O*C (32*F] SAE 5W-30

Below -2O*C I-4*F] SAE 5W-20

COOLING SYSTEM

L

item

Zooling method - 1 Engine

BP DUHC turbo

I Water-cooled, forced crrcutation

water pump

Type

mpeller diameter

Number of impeller blades

Speed ratio

tiater seal type

rhermostat

bfpe

Opening temperature

Full-open temperature

Full-open lift mm [in)

OC (OF)

*C j*FJ

mm (in] Centrifugal, V-belt driven

75 12.95)

6

1 : 1.05

Unified mechanical seal

Wax, two-stage

Marn: 86.5-89.5 [ 788-I 93 1

Sub: 83.5-86.5 [182-i 88)

loo (212)

Main: 8.0 (0.31 1 min.

Sub: 1.5 IO.061 min.

Radbtor

Type

Cap valve opening pressure kPa { kgflcm2, psi)

Cooling circuit checkrng pressure kPa ( kgflcm2, psi 1

Cooling fan

Type

Number of blades

Outer diameter mm {in 1

Capacity w-v

Current A

Water thermoswitch

OFF-+ON “C 1°F) 1

Radiator thermoswitch

OFFdON OC (OF]

Coolant

Capacity LWS qt,

Imp qt) Coolant protection

Above -16*C (3OF]

Antifreeze solutron

.Above -26*C t-1 5*F ) -

Above -4UOC I-40°F) Corrugated fin

74-103 {0.75--1.05, 11-15)

103 11.05, 15)

Electric

5

340 (13.41

160-12

Hi: 13.3+ 10% max., Lo: 8.8+ 10% max.

97 f207)

105 [221)

6.0 16.3, 5.3)

Specific gravity at 20*C (68*f)

1.054

1.066

1.078 -.ep

1

Page 216 of 279

Ve:BenyVdhfp

Test condttton

-roliqc lblwk

lgnhn switch ON

VI3

- bmtm

2A

28

x

2D

2E

2F

26

2H

21

2J

2K

21

2M

2N

20

2P

20

2R Test condtthw

ranabla

2s

2T

2u

2v

2W

2x

2Y

arm-up)

P

P

8°F) P

ov

ov

ov

ov

ov of sv

Approx. 2v

-

ov or 5v

tpplox. 1.5

- connected to

oveftmost warning

tluzz.af

I

I

i”e started wilh cootanl 1 Below 1.5V 1 No&ad engine 1Bo sec. alter eng

temperature is above 90% 1194°F ) and

CondilkJn

iniake air temperature is between 40%

I l@i°F) and So% (122OFj

Other condition at idle

VB

lgrition switch ON

L VE ‘Engine Signd

Idle

VFJ’ Monitor: Green

Engine speed above 2.ooO rpm during

VE and red lamps

Nash Sde”&d valve

m kw tap.)

deceteralion (alter warm-up) -

-

0 -

lanition switch ON -

-

-

-

0 lnjedor (Nos. 1. 3) -

Ignition switch ON

Idle

injector (Nos 2. 4) IgrMon switch ON

I -3 Va

I

ISC valve -

-

0

0

-

0

0

0

0

-

0

0

-

- Idle -

Lpprox. 4.01

4.!--5sv

0 of 5v Knock control unit

Engine speed above 2,GOD rf

Thio#e sensor/

Airllow mder Constant -

0 Solenoid valve

(purge conlro4) Ignition switch ON

II

-

I* I “la I

lgnitlon switch ON .-.- ._

lgnitiin swilch ON VB

-

Idle Below 1.w

210 sec. alter engine started with coolant Below 1.5V No&d engine

temperature above 90% ( 194OF) and

cofditlon

intake air temperature above 50°C

/122OF)

Other condition al idle Va - 0

0 Qrcuit-oparing

relay

sdenoid valve

(PRC high temp.) Accelerator pedal released

Accelerator pedal lully depfesw ,pprox. 0.5L

.pprox. 4.oi 22 -

1 J

Is- r,

L-7 r

2Y Zw 2U 2s 20 20 ZM 2K 21 2G 2E 2C ZA 1U IS 10 10 1M tK I, tG 1E ,C ,A

22 2X ZV 2T ZR 2P 2N 2L 2J 2H ZF 20 28 1V IT IF! ,P IN 1L 1J t” 1F 10 19 lamlion switch ON

Idle (cold engine)

Idle (alter warm-up) ov

o-l.OV

0.5-l.OV

o-0.4v

xpprox. 3.8

tipprox. 3.0

tpprox 2.5

bpprox. 2.5

Bdow 0.5v

V8 -

lncreasmg engine speed (after w

Deceleralion

lgnltro” switch ON Airllow meter -

n airflow meter intake aa

Ambient air temperalure 20°C (6

ErlQl”l? codant temperature 200(

Alter warm-up

Ignition switch ON Water

thermosensor

To&charge

rndlcator

1 I

UI “I

u-1 r

-

2Y ZW ZU ZS 20 20 2M ZK 21 2G 2E 2C ZA lU IS 10 10 1f.I 1K 11 1G 1E tC 1A

22 2X 2V 27 2P 2P 2N 2L 2J 2H ZF 2D 28 IV IT IA 1P IN IL 1.1 1H 1F ID It3

35