lock MAZDA 6 2002 Suplement Owners Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 790 of 909

LIFTGATE

S–9

S

9. To remove the stay damper, remove the bolt B.

10. Install in the reverse order of removal.

End Of Sie

LIFTGATE DISASSEMBLY/ASSEMBLYA6E772262010202WGN

1. Disconnect the negative battery cable.

2. Remove the liftgate lower trim.

3. To remove the liftgate outer handle and liftgate key cylinder, remove the rear finisher.

4. To remove the stud ball, separate the stud ball and the stay damper.

5. Disassemble in the order indicated in the table.

6. Assemble in the reverse order of disassembly.

.

BOLT B

HINGE

STAY DAMPER

BOLT A

NUT

LIFTGATE

N·m {kgf·cm, in·lbf} 8.8—12.7

{90—130,

78—112}

32.4—48.5 N·m

{3.3—4.9 kgf·m,

24—35 ft·lbf} 7.8—10.8

{80—110, 70—95}

A6E77221102

A

2

N·m {kgf·cm, in·lbf}

A

31

B

6.90—9.80

{70—100,

60.8—86.7}

4.0—5.8

{39.8—60.1,

34.6—52.2}

4

B

16—23 N·m

{1.6—2.4 kgf·m,

12—17 ft·lbf}3.9—5.9

{39.8—60.1,

34.6—52.2}

5

7

6

A6A7722W103

1 Liftgate latch and lock actuator

2 Liftgate outer handle

3 Liftgate key cylinder

4Clip5Stud ball

6 Liftgate

7 Stopper

Page 817 of 909

T–6

MULTIPLEX COMMUNICATION SYSTEM

ON-BOARD DIAGNOSTIC FUNCTIONA6E811155430205Outline

•The on-board diagnostic function is incorporated into the PCM, TCM, ABS (ABS/TCS) HU/CM (with ABS (ABS/

TCS)), DSC HU/CM (with DSC), 4WD control module, and instrument cluster. This function can narrow down

CAN system malfunction locations.

•Due to the adoption of the TCM and the 4WD CM, some DTCs and PID/data monitor items have been added.

Other functions are the same as those of the current Mazda6 (GG) model.

Block Diagram

.

Fail-Safe Function

•When the failure detection function detemines that there is a malfunction, the fail-safe function illuminates a

warning light to advise the driver of the malfunction.

1

3

24

5

6

A6E81111103

1PCM

2 TCM (JA5AX-EL)

3 ABS (ABS/TCS) HU/CM or DSC HU/CM4 4WD control module (4WD)

5 Instrument cluster

6Twist pair

Module Fail-safe function

PCM•MIL illuminated

TCM•AT warning light illuminated

•ABS (ABS/TCS) HU/CM (with ABS (ABS/TCS))

•DSC HU/CM (with DSC)•ABS (ABS/TCS) suspended (with ABS (ABS/TCS))

•DSC suspended (with DSC)

•ABS warning light illuminated

•DSC/TCS indicator light illuminated

•DSC OFF light illuminated

•TCS OFF light illuminated

4WD control module•4WD indicator light illuminated

Instrument cluster•Speedometer, tachometer, water temperature gauge: 0 displayed

Page 826 of 909

LOCATION INDEX

T–15

T

POWER SYSTEMA6E810001072201

.

End Of Sie

EXTERIOR LIGHTING SYSTEMA6E810001052201

.

LOCATION INDEX

1

A6E81101124

1 Main fuse block

(See T–19 RELAY LOCATION)

(See T–19 RELAY INSPECTION)

11

2

A6E81121162

1 High-mount brake light

(See T–20 HIGH-MOUNT BRAKE LIGHT

REMOVAL/INSTALLATION)2 Rear auto leveling sensor (4WD)

(See T–20 REAR AUTO LEVELING SENSOR

REMOVAL/INSTALLATION)

Page 844 of 909

AIR BAG SYSTEM

T–33

T

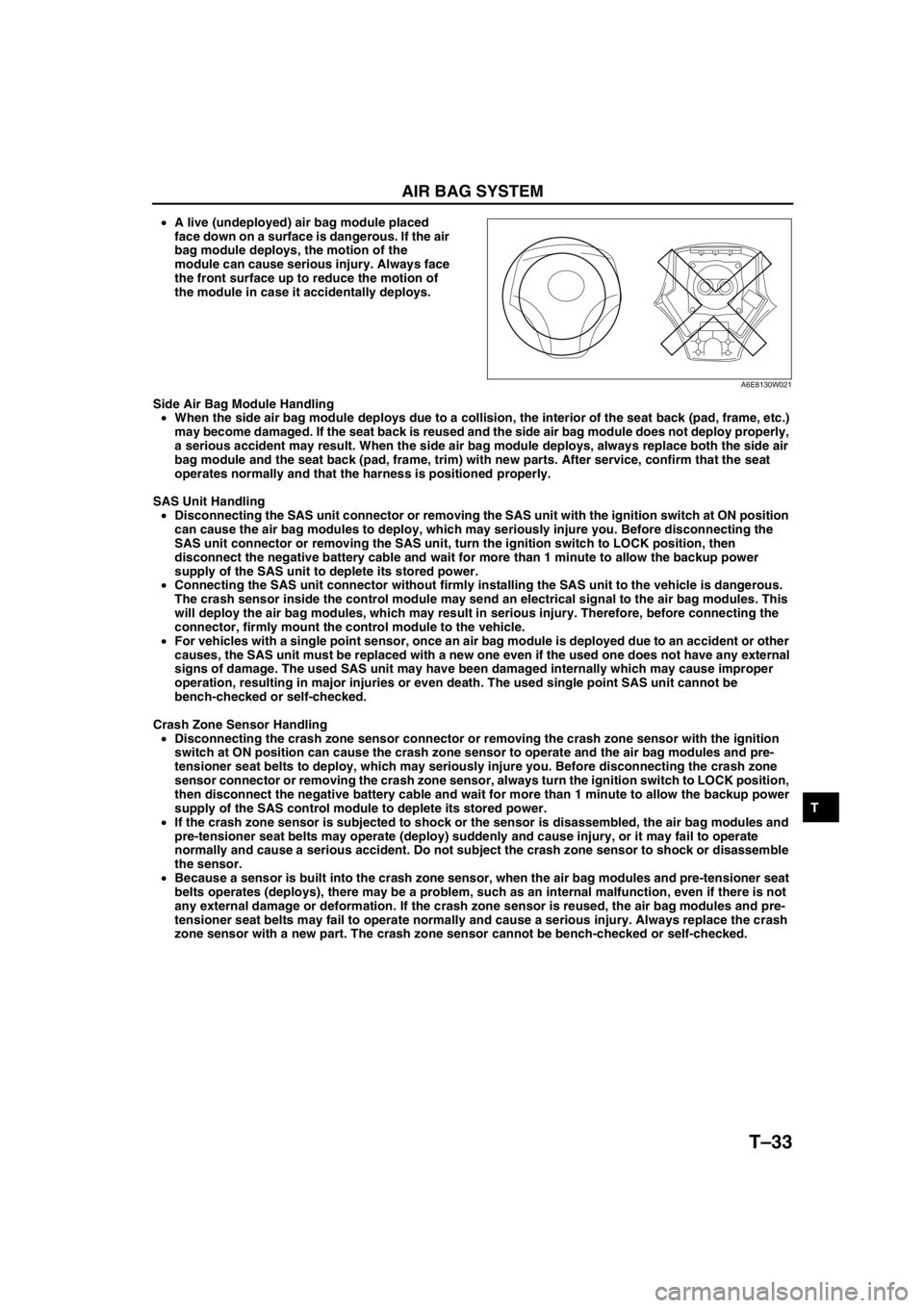

•A live (undeployed) air bag module placed

face down on a surface is dangerous. If the air

bag module deploys, the motion of the

module can cause serious injury. Always face

the front surface up to reduce the motion of

the module in case it accidentally deploys.

Side Air Bag Module Handling

•When the side air bag module deploys due to a collision, the interior of the seat back (pad, frame, etc.)

may become damaged. If the seat back is reused and the side air bag module does not deploy properly,

a serious accident may result. When the side air bag module deploys, always replace both the side air

bag module and the seat back (pad, frame, trim) with new parts. After service, confirm that the seat

operates normally and that the harness is positioned properly.

SAS Unit Handling

•Disconnecting the SAS unit connector or removing the SAS unit with the ignition switch at ON position

can cause the air bag modules to deploy, which may seriously injure you. Before disconnecting the

SAS unit connector or removing the SAS unit, turn the ignition switch to LOCK position, then

disconnect the negative battery cable and wait for more than 1 minute to allow the backup power

supply of the SAS unit to deplete its stored power.

•Connecting the SAS unit connector without firmly installing the SAS unit to the vehicle is dangerous.

The crash sensor inside the control module may send an electrical signal to the air bag modules. This

will deploy the air bag modules, which may result in serious injury. Therefore, before connecting the

connector, firmly mount the control module to the vehicle.

•For vehicles with a single point sensor, once an air bag module is deployed due to an accident or other

causes, the SAS unit must be replaced with a new one even if the used one does not have any external

signs of damage. The used SAS unit may have been damaged internally which may cause improper

operation, resulting in major injuries or even death. The used single point SAS unit cannot be

bench-checked or self-checked.

Crash Zone Sensor Handling

•Disconnecting the crash zone sensor connector or removing the crash zone sensor with the ignition

switch at ON position can cause the crash zone sensor to operate and the air bag modules and pre-

tensioner seat belts to deploy, which may seriously injure you. Before disconnecting the crash zone

sensor connector or removing the crash zone sensor, always turn the ignition switch to LOCK position,

then disconnect the negative battery cable and wait for more than 1 minute to allow the backup power

supply of the SAS control module to deplete its stored power.

•If the crash zone sensor is subjected to shock or the sensor is disassembled, the air bag modules and

pre-tensioner seat belts may operate (deploy) suddenly and cause injury, or it may fail to operate

normally and cause a serious accident. Do not subject the crash zone sensor to shock or disassemble

the sensor.

•Because a sensor is built into the crash zone sensor, when the air bag modules and pre-tensioner seat

belts operates (deploys), there may be a problem, such as an internal malfunction, even if there is not

any external damage or deformation. If the crash zone sensor is reused, the air bag modules and pre-

tensioner seat belts may fail to operate normally and cause a serious injury. Always replace the crash

zone sensor with a new part. The crash zone sensor cannot be bench-checked or self-checked.

A6E8130W021

Page 845 of 909

T–34

AIR BAG SYSTEM

Side Air Bag Sensor Handling

•Disconnecting the side air bag sensor connector or removing the side air bag sensor with the ignition

switch at ON position can cause the side air bag sensor to operate and the side air bag module to

deploy, which may seriously injure you. Before disconnecting the side air bag sensor connector or

removing the side air bag sensor, always turn the ignition switch to LOCK position, then disconnect the

negative battery cable and wait for more than 1 minute to allow the backup power supply of the SAS

control module to deplete its stored power.

•If the side air bag sensor is subjected to shock or the sensor is disassembled, the side air bag module

may operate (deploy) suddenly and cause injury, or it may fail to operate normally and cause a serious

accident. Do not subject the side air bag sensor to shock or disassemble the sensor.

•Because a sensor is built into the side air bag sensor, when the side air bag module operates (deploys),

there may be a problem, such as an internal malfunction, even if there is not any external damage or

deformation. If the side air bag sensor is reused, the side air bag module may fail to operate normally

and cause a serious injury. Always replace the side air bag sensor with a new part. The side air bag

sensor cannot be bench-checked or self-checked.

Pre-tensioner Seat Belt Inspection

•Inspecting a pre-tensioner seat belt using an

ohmmeter can deploy the pre-tensioner seat

belt, which can cause serious injury. Do not

use an ohmmeter to inspect the pre-tensioner

seat belt. Always use the on-board diagnostic

to diagnose the pre-tensioner seat belt for

malfunctions.

Component Handling

•Oil, grease, water, etc on components may cause the air bag modules and pre-tensioner seat belts to

fall to deploy in an accident, which may cause serious injury. Do not allow oil, grease, water, etc., on

components.

•Inserting a screwdriver, etc., into the

connector of an air bag module or a pre-

tensioner seat belt may damage the connector

and cause the air bag module or the pre-

tensioner seat belt to deploy improperly,

which may cause serious injury. Do not insert

any foreign objects into the connector.

Component Reuse

•Even if an air bag module or a pre-tensioner seat belt does not deploy in a collision and does not have

any external signs of damage, it may have been damaged internally, which may cause improper

operation. Improper operation may cause serious injury. Always self-check the undamaged air bag

module or pre-tensioner seat belt to determine whether it can be reused.

End Of Sie

A6E8130W025

A6E8130W023

Page 846 of 909

AIR BAG SYSTEM

T–35

T

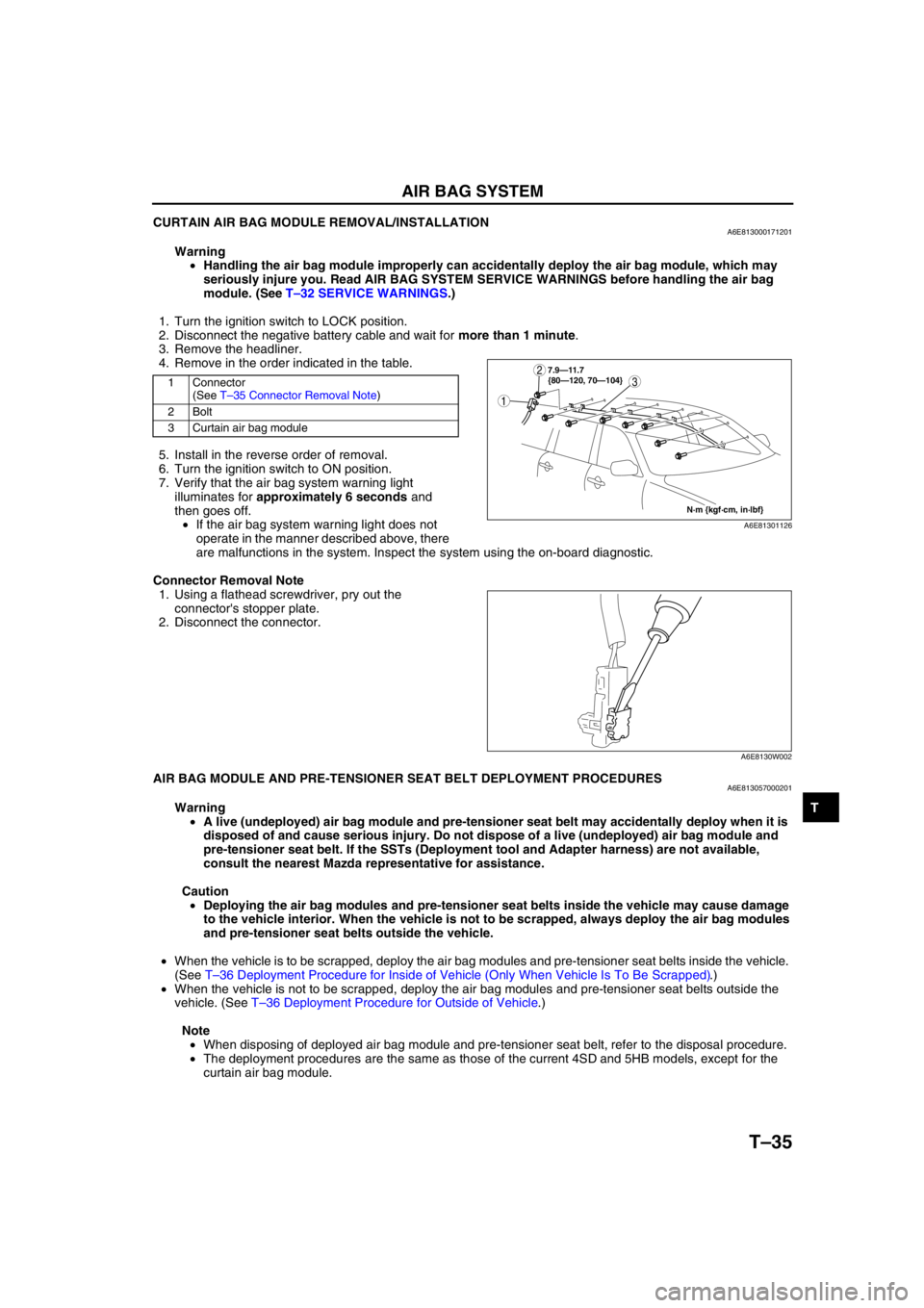

CURTAIN AIR BAG MODULE REMOVAL/INSTALLATIONA6E813000171201

Warning

•Handling the air bag module improperly can accidentally deploy the air bag module, which may

seriously injure you. Read AIR BAG SYSTEM SERVICE WARNINGS before handling the air bag

module. (See T–32 SERVICE WARNINGS.)

1. Turn the ignition switch to LOCK position.

2. Disconnect the negative battery cable and wait for more than 1 minute.

3. Remove the headliner.

4. Remove in the order indicated in the table.

5. Install in the reverse order of removal.

6. Turn the ignition switch to ON position.

7. Verify that the air bag system warning light

illuminates for approximately 6 seconds and

then goes off.

•If the air bag system warning light does not

operate in the manner described above, there

are malfunctions in the system. Inspect the system using the on-board diagnostic.

Connector Removal Note

1. Using a flathead screwdriver, pry out the

connector's stopper plate.

2. Disconnect the connector.

End Of SieAIR BAG MODULE AND PRE-TENSIONER SEAT BELT DEPLOYMENT PROCEDURESA6E813057000201

Warning

•A live (undeployed) air bag module and pre-tensioner seat belt may accidentally deploy when it is

disposed of and cause serious injury. Do not dispose of a live (undeployed) air bag module and

pre-tensioner seat belt. If the SSTs (Deployment tool and Adapter harness) are not available,

consult the nearest Mazda representative for assistance.

Caution

•Deploying the air bag modules and pre-tensioner seat belts inside the vehicle may cause damage

to the vehicle interior. When the vehicle is not to be scrapped, always deploy the air bag modules

and pre-tensioner seat belts outside the vehicle.

•When the vehicle is to be scrapped, deploy the air bag modules and pre-tensioner seat belts inside the vehicle.

(See T–36 Deployment Procedure for Inside of Vehicle (Only When Vehicle Is To Be Scrapped).)

•When the vehicle is not to be scrapped, deploy the air bag modules and pre-tensioner seat belts outside the

vehicle. (See T–36 Deployment Procedure for Outside of Vehicle.)

Note

•When disposing of deployed air bag module and pre-tensioner seat belt, refer to the disposal procedure.

•The deployment procedures are the same as those of the current 4SD and 5HB models, except for the

curtain air bag module.

1 Connector

(See T–35 Connector Removal Note)

2Bolt

3 Curtain air bag module3

1

2

N·m {kgf·cm, in·lbf} 7.9—11.7

{80—120, 70—104}

A6E81301126

A6E8130W002

Page 847 of 909

T–36

AIR BAG SYSTEM

Deployment Procedure for Inside of Vehicle (Only When Vehicle Is To Be Scrapped)

1. Inspect the SST (Deployment tool).

2. Move the vehicle to an open space, away from strong winds, and close all the doors and windows.

3. Turn the ignition switch to LOCK position.

4. Disconnect the negative battery cable and wait for more than 1 minute.

5. Follow the appropriate procedure for deploying the driver-side air bag module, passenger-side air bag module,

side air bag module, curtain air bag module, or pre-tensioner seat belt.

Curtain air bag module (WGN)

1. Remove the headliner.

2. Disconnect the curtain air bag module connector.

3. Connect the SST (Adapter harness) to the curtain

air bag module.

4. Connect the SST (Deployment tool) to the SST

(Adapter harness).

5. Connect the red clip of the SST (Deployment tool)

to the positive battery terminal and the black clip

to the negative battery terminal.

6. Verify that the red light on the SST (Deployment

tool) is illuminated.

7. Make sure all persons are standing at least 6 m

{20 ft} from the vehicle.

8. Press the activation switch on the SST

(Deployment tool) to deploy the curtain air bag

module.

Deployment Procedure for Outside of Vehicle

1. Inspect the SST (Deployment tool).

2. Turn the ignition switch to LOCK position.

3. Disconnect the negative battery cable and wait for more than 1 minute.

4. Follow the appropriate procedure for deploying the driver-side air bag module, passenger-side air bag module,

side air bag module, curtain air bag module, or pre-tensioner seat belt.

49 L066 002

CURTAIN

AIR BAG MODULE

CONNECTOR

A6E81301112

49 L066 002

49 H066 002

A6E8130W151

49 H066 002

ACTIVATION

SWITCH

A6E8130W028

Page 851 of 909

![MAZDA 6 2002 Suplement Owners Manual T–40

ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

Flowchart

•Use the following flowchart to verify the cause of the trouble.

End Of Sie

Repair the malfunctioning part by

following the DT MAZDA 6 2002 Suplement Owners Manual T–40

ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

Flowchart

•Use the following flowchart to verify the cause of the trouble.

End Of Sie

Repair the malfunctioning part by

following the DT](/img/28/57057/w960_57057-850.png)

T–40

ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

Flowchart

•Use the following flowchart to verify the cause of the trouble.

End Of Sie

Repair the malfunctioning part by

following the DTC inspection.A

Inspect the power supply and the ground circuits for any units

that do not respond.

Are they normal?

Repair the malfunctioning part.A

A

B START

Using the SST (WDS or equivalent), verify if DTCs are displayed for PCM, TCM, ABS (ABS/TCS) HU/CM (with ABS (ABS/TCS)),

DSC HU/CM (with DSC), 4WD control module and instrument cluster.

Are any DTCs displayed?

Ye s

Are any DTCs other than the following displayed?

PCM: U0073, U0101, U0121, U0155

TCM: U0073, U0100

ABS (ABS/TCS) HU/CM, DSC HU/CM,

Instrument cluster: U1900, U2516

4WD control module: U0100, U0101, U0121

NoEND No

No Ye s

Are any of the following DTCs displayed?

PCM: U0073, U0101, U0121, U0155

TCM: U0073, U0100

ABS (ABS/TCS) HU/CM, DSC HU/CM,

Instrument cluster: U1900, U2516

4WD control module: U0100, U0101, U0121

Ye s

Ye s Narrow down CAN system malfunction location.

Using the SST (WDS or equivalent), verify if DTCs are displayed

for PCM, TCM, ABS (ABS/TCS) HU/CM, DSC HU/CM, 4WD

control module and instrument cluster.

Are any DTCs displayed?

No

Using the SST (WDS or equivalent), clear DTCs stored in

each module.

END

Ye s

No

Turn the ignition switch to the LOCK position.

Inspect the wiring harness and connector between

any unit that does not respond and the DLC-2.

PCM

—DLC-2 (except MZR-CD (RF Turbo))

2R—CAN_L

2U—CAN_H

PCM—DLC-2 (MZR-CD (RF Turbo))

39—CAN_L

13—CAN_H

TCM—DLC-2

2J—CAN_L

2M—CAN_H

ABS (ABS/TCS) HU/CM—DLC-2

X—KLN

DSC HU/CM—DLC-2

AB—KLN

4WD control module—DLC-2

H—CAN_L

G—CAN_H

Instrument cluster—DLC-2

2W—CAN_L

2X—CAN_H

Are the wiring harnesses and connectors normal? Is there a response from the PCM, TCM, ABS (ABS/TCS) HU/CM,

DSC HU/CM, 4WD control module and/or instrument cluster?

No Ye s

No

Ye s Repair the malfunctioning part by following the DTC inspection.

Repair the malfunctioning part.

A6E8162L101

Page 852 of 909

![MAZDA 6 2002 Suplement Owners Manual ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

T–40–1

T

T–40BODY ELECTRICAL SYSTEM

End Of Sie

ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

Connect each unit connector.

Turn the ig MAZDA 6 2002 Suplement Owners Manual ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

T–40–1

T

T–40BODY ELECTRICAL SYSTEM

End Of Sie

ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

Connect each unit connector.

Turn the ig](/img/28/57057/w960_57057-851.png)

ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

T–40–1

T

T–40BODY ELECTRICAL SYSTEM

End Of Sie

ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

Connect each unit connector.

Turn the ignition switch to the ON position.

Measure the voltage between DLC-2 terminals CAN_L and CAN_H.

Is the voltage 2.0—3.0 V?

Turn the ignition switch to the LOCK position.

Measure the resistance between DLC-2 terminals CAN_L and

CAN_H.

Is the resistance 59—65 ohms?

Replace any units that

do not respond.Disconnect the PCM connector.

Measure the resistance between PCM

connector terminals 2R and 2U

(except MZR-CD (RF Turbo)) or 13 and

39 (MZR-CD (RF Turbo)).

Is the resistance 118—130 ohms?

Replace the PCM.

Disconnect the instrument cluster connector.

Measure the resistance between instrument cluster connector

terminals 2W and 2X.

Is the resistance 118—130 ohms?

Replace the instrument

cluster.Turn the ignition switch to the LOCK position.

Disconnect the connector of any unit that does not respond.

(If there are two or more units that do not respond,

disconnect only one of the units.)

Turn the ignition switch to the ON position.

Measure the voltage between DLC-2 terminals CAN_L and

CAN_H.

Is the voltage 2.0—3.0 V?

The disconnected unit or the

related wiring harness may

have a malfunction.

Replace the disconnected unit. Replace the related wiring harness.The disconnected

unit is normal.

Are all units that do not respond disconnected?

Inspect if the related wiring harnesses (CAN_L

and/or CAN_H) have been shorted (to power

supply or ground).

If a short is found, replace the related wiring

harness. Ye sNo B

A A A AA

A

Turn the ignition switch to the LOCK position.

Verify the continuity between the following connector terminals of any disconnected unit.

PCM connector (except MZR-CD (RF Turbo)): 2R (CAN_L)—other terminals,

2U (CAN_H)—other terminals

PCM connector (MZR-CD (RF Turbo)): 39 (CAN_L)—other terminals,

13 (CAN_H)—other terminals

TCM connector: 2J (CAN_L)—other terminals, 2M (CAN_H)—other terminals

ABS (ABS/TCS) HU/CM connector: R (CAN_L)—other terminals,

O (CAN_H)—other terminals

DSC HU/CM connector: AF (CAN_L)—other terminals, AG (CAN_H)—other terminals

4WD control module connector: H (CAN_L)—other terminals, G (CAN_H)—other terminals

Instrument cluster connector: 2W (CAN_L)—other terminals, 2X (CAN_H)—other terminals

Is there continuity?

Ye s

No

Ye s

No

Ye sNo

Ye sNo

Ye sNo

Ye sNo

A6E8162L102

Page 865 of 909

U–2

OUTLINE

OUTLINE OF CONSTRUCTIONA6E850201038201•The construction and operation of the air conditioner system is essentially carried over from that of the previous

Mazda6 (GG) model, except for the following features. (See Mazda6 Training Manual 3359-1*-02C.)

End Of Sie

FEATURESA6E850201038202Improved Comfort

•The water heater system has been adopted. (For MZR-CD (RF Turbo) European (L.H.D.) specs.)

End Of Sie

SPECIFICATIONSA6E850201038203Manual Air Conditioner

OUTLINE

ItemSpecification

L3, L8, LF MZR-CD (RF Turbo)

Heating capacity (kW {kcal/h}) 4.400 {3,784}4.400 {3,784} (L.H.D.)

5.120 {4,403} (R.H.D.)

Airflow volume

(during heater operation)Blower motor

(m

3/h)310 (L.H.D.)

300 (R.H.D.)

Electricity consumption

(during heater operation)Blower motor (W) 184

Cooling capacity (kW {kcal/h}) 4.200 {3,612}

Airflow volume (during air

conditioner operation)Blower motor

(m

3/h)460

Electricity consumption

(during air conditioner

operation)Blower motor (W) 225

Magnetic clutch (W) 46 45

Fan type Blower motor Sirocco fan

RefrigerantType R-134a

Regular amount

(approximate quantity)470 {16.6} (L.H.D.)

430 {15.2} (R.H.D.)

(g {oz})

A/C compressorType Vane-rotary

Discharge capacity

120 {120, 4.06}

(ml {cc, fl oz})

Max. allowable speed

6,400

(rpm)

Lube

oilType ATMOS GU10

Sealed volume

(approximate quantity)

120 {120, 4.06} 150 {150, 5.07}

(ml {cc, fl oz})

Magnetic clutch clearance

0.3—0.5 {0.012—0.019}

(mm {in})

CondenserType Multiflow (sub-cooling type)

Radiated heat (kW {kcal/h})4.69 {4,030}: European (L.H.D.) specs.

5.96 {5,130}: European (U.K.), GCC specs.

Receiver/drier

capacity(ml {cc, fl oz}) 190 {190, 6.42}

Desiccant Synthetic zeolite

Expansion valve Type Block type

Evaporator Type Double-tank drawn cup