warning MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 739 of 909

P–6

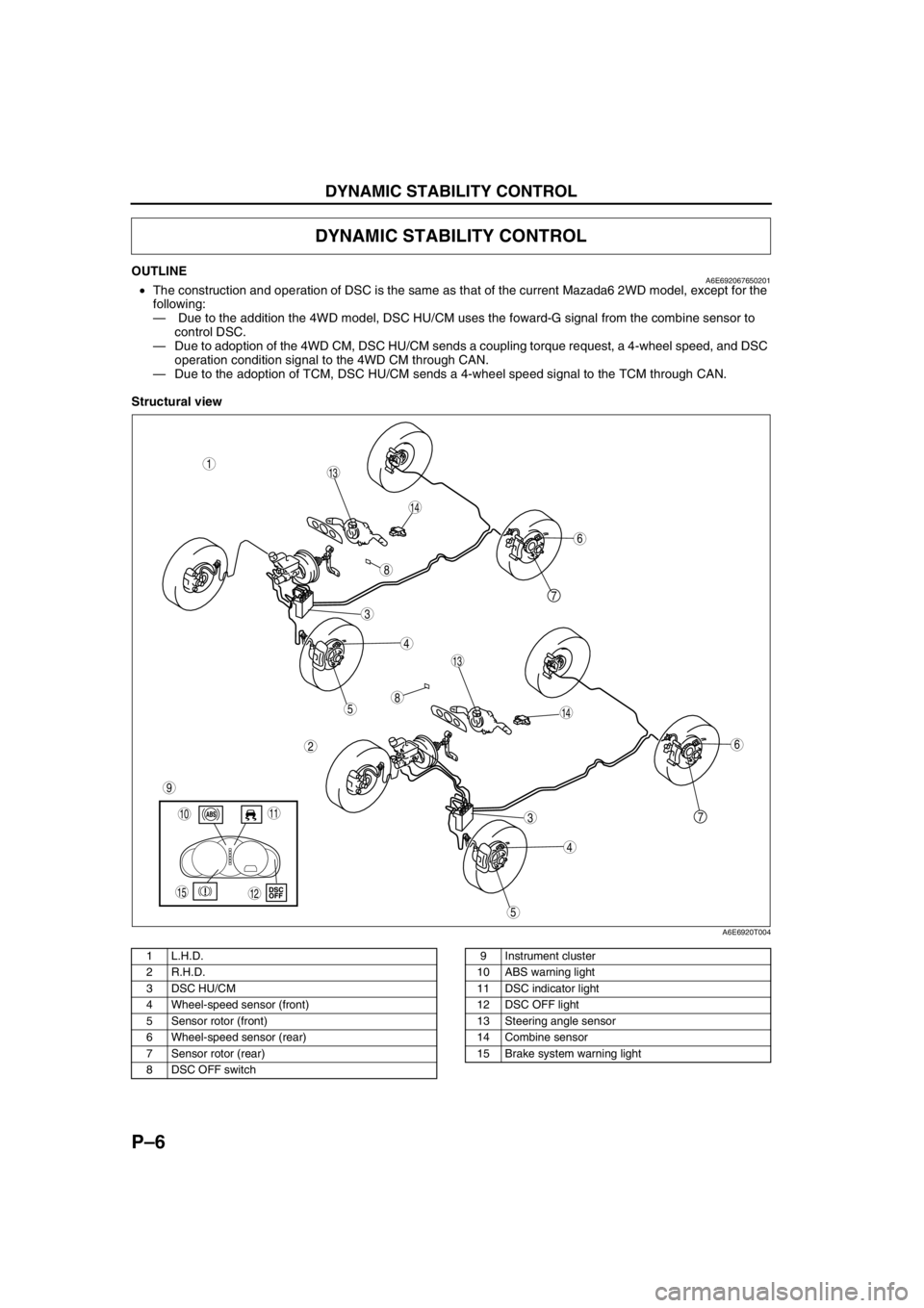

DYNAMIC STABILITY CONTROL

OUTLINEA6E692067650201•The construction and operation of DSC is the same as that of the current Mazada6 2WD model, except for the

following:

— Due to the addition the 4WD model, DSC HU/CM uses the foward-G signal from the combine sensor to

control DSC.

—Due to adoption of the 4WD CM, DSC HU/CM sends a coupling torque request, a 4-wheel speed, and DSC

operation condition signal to the 4WD CM through CAN.

—Due to the adoption of TCM, DSC HU/CM sends a 4-wheel speed signal to the TCM through CAN.

Structural view

.

DYNAMIC STABILITY CONTROL

7

5

4

3

1

2

14

13

6

13

12

5

4

3

7

6

1011

9

14

8

8

15

A6E6920T004

1 L.H.D.

2 R.H.D.

3 DSC HU/CM

4 Wheel-speed sensor (front)

5 Sensor rotor (front)

6 Wheel-speed sensor (rear)

7 Sensor rotor (rear)

8 DSC OFF switch9 Instrument cluster

10 ABS warning light

11 DSC indicator light

12 DSC OFF light

13 Steering angle sensor

14 Combine sensor

15 Brake system warning light

Page 740 of 909

DYNAMIC STABILITY CONTROL

P–7

P

Wiring Diagram

.

9

RF

FL

RR

RL

PCM

G

E

M

I

F

K

H

Q

NJ

P

S

T

V

O

Y

X

W

U

R

L

Z

AC

D

B

AG

AF

AE

AC

AA

AB

C

F

D

A

B

EDSC HU/CM

A

B

C

D

F

1

3

2

8

7

5

4

6

9

9

9

10

11

13

12

15

14

18

17

16

1920

2122

24

23

A6E6921W203

1 IG switch

2SUS 15A fuse

3 ABS 60 A fuse

4 Meter

5 ABS warning light

6 Brake system warning light

7 DSC OFF light

8 DSC indicator light

9CAN driver

10 Battery

11 Cruise actuator

12 DSC OFF switch13 DLC-2

14 CAN-H

15 CAN-L

16 Wheel-speed sensor

17 Combine sensor

18 Steering angle sensor

19 Brake switch

20 Brake light

21 Back-up light switch (MTX only)

22 Back-up light (MTX only)

23 Audio unit, Wiper and washer switch, Car-navigation

unit, Auto leveling control unit

24 TCM, 4WD CM

Page 742 of 909

ON-BOARD DIAGNOSTIC

P–9

P

OUTLINEA6E697043000201•The operation of the on-board diagnostic system for ABS (ABS/TCS) or DSC is the same as that of the current

Mazda6 (GG) L8, LF, L3 engine 2WD model, except for the following. (See Mazda6 Training Manual

3359-1*-02C.)

— Due to the addition of the 4WD model, DTCs and PID data monitor has been added.

—Due to the addition of the MZR-CD (RF Turbo) engine model, the DTC C1119 fail-safe function and the

detection condition have been changed.

Fail-safe Function

Fail-safe function table

*1: When engine speed signal through CAN is out of specification, the light illuminates.*2: When engine speed signal through CAN is out of specification, the system is suspended.*3: When engine speed signal value through CAN is invalid, only brake TCS is available.*4: When fuel injection information through CAN is out of specification or invalid, only brake TCS is available.*5: When engine speed signal value through CAN is invalid, only brake DSC is available.*6: When the engine control system has a malfunction, only brake DSC is available.

PID/DATA Monitor Table

End Of Sie

ON-BOARD DIAGNOSTIC

Malfunc-

tion

locationDTC Fail-safe function

WDS

or

equiva-

lentWarning light illumination condition Control condition

ABS

warning

lightBRAKE

system

warning

light

(when

parking

brake is

released)DSC

(TCS)

OFF lightDSC

(TCS)

indicator

light ABS

controlEBD

controlTCS

controlDSC

controlBrake

assist

control

PCM and/

or engine

speed

signal lineC1119Not

Illuminated Not

Illuminated Not

Illuminated

*1Illuminated Available AvailableAvailable*2, *3, *4Available*2, *5, *6Available

Combine

sensor

(forward-

G) lineC1949

Illuminated Not

Illuminated Illuminated IlluminatedNot

availableAvailable—Not

availableNot

available

C1950

CAN line U2511Not

Illuminated Not

Illuminated Not

Illuminated Illuminated Available Available—Available Available

PID name input/output part Operation/unit

ACCLMTR Accelerometer ACCELERATION

Page 744 of 909

CONVENTIONAL BRAKE SYSTEM

P–11

P

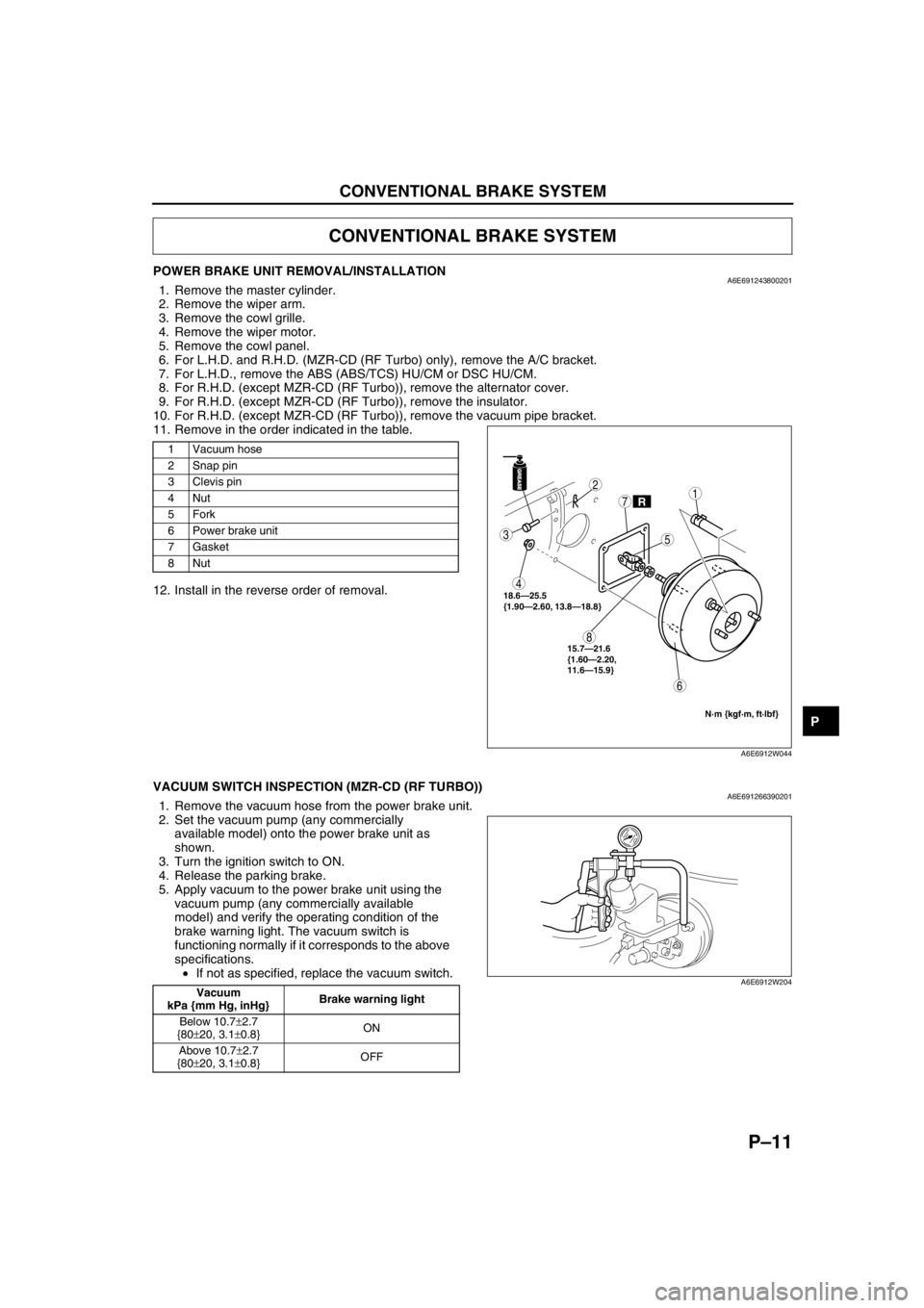

POWER BRAKE UNIT REMOVAL/INSTALLATIONA6E6912438002011. Remove the master cylinder.

2. Remove the wiper arm.

3. Remove the cowl grille.

4. Remove the wiper motor.

5. Remove the cowl panel.

6. For L.H.D. and R.H.D. (MZR-CD (RF Turbo) only), remove the A/C bracket.

7. For L.H.D., remove the ABS (ABS/TCS) HU/CM or DSC HU/CM.

8. For R.H.D. (except MZR-CD (RF Turbo)), remove the alternator cover.

9. For R.H.D. (except MZR-CD (RF Turbo)), remove the insulator.

10. For R.H.D. (except MZR-CD (RF Turbo)), remove the vacuum pipe bracket.

11. Remove in the order indicated in the table.

12. Install in the reverse order of removal.

End Of Sie

VACUUM SWITCH INSPECTION (MZR-CD (RF TURBO))A6E6912663902011. Remove the vacuum hose from the power brake unit.

2. Set the vacuum pump (any commercially

available model) onto the power brake unit as

shown.

3. Turn the ignition switch to ON.

4. Release the parking brake.

5. Apply vacuum to the power brake unit using the

vacuum pump (any commercially available

model) and verify the operating condition of the

brake warning light. The vacuum switch is

functioning normally if it corresponds to the above

specifications.

•If not as specified, replace the vacuum switch.

End Of Sie

CONVENTIONAL BRAKE SYSTEM

1 Vacuum hose

2 Snap pin

3Clevis pin

4Nut

5Fork

6 Power brake unit

7Gasket

8Nut

GREASEGREASE

R

3

4

8

6

2

7

5

1

18.6—25.5

{1.90—2.60, 13.8—18.8}

N·m {kgf·m, ft·lbf}

15.7—21.6

{1.60—2.20,

11.6—15.9}

A6E6912W044

Vacuum

kPa {mm Hg, inHg}Brake warning light

Below 10.7±2.7

{80±20, 3.1±0.8}ON

Above 10.7±2.7

{80±20, 3.1±0.8}OFFA6E6912W204

Page 750 of 909

PARKING BRAKE SYSTEM, DYNAMIC STABILITY CONTROL

P–17

P

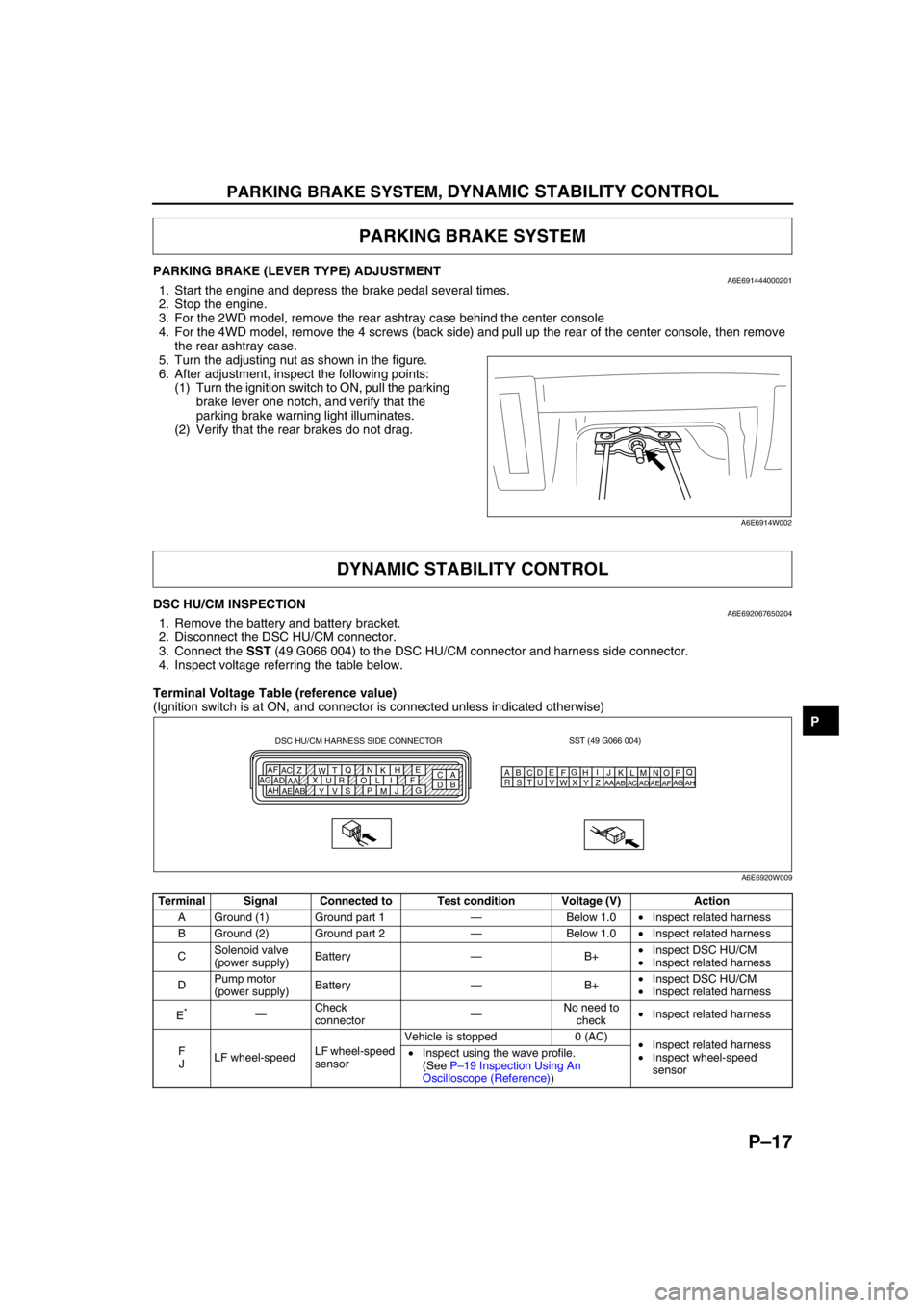

PARKING BRAKE (LEVER TYPE) ADJUSTMENTA6E6914440002011. Start the engine and depress the brake pedal several times.

2. Stop the engine.

3. For the 2WD model, remove the rear ashtray case behind the center console

4. For the 4WD model, remove the 4 screws (back side) and pull up the rear of the center console, then remove

the rear ashtray case.

5. Turn the adjusting nut as shown in the figure.

6. After adjustment, inspect the following points:

(1) Turn the ignition switch to ON, pull the parking

brake lever one notch, and verify that the

parking brake warning light illuminates.

(2) Verify that the rear brakes do not drag.

End Of Sie

DSC HU/CM INSPECTIONA6E6920676502041. Remove the battery and battery bracket.

2. Disconnect the DSC HU/CM connector.

3. Connect the SST (49 G066 004) to the DSC HU/CM connector and harness side connector.

4. Inspect voltage referring the table below.

Terminal Voltage Table (reference value)

(Ignition switch is at ON, and connector is connected unless indicated otherwise)

PARKING BRAKE SYSTEM

A6E6914W002

DYNAMIC STABILITY CONTROL

Terminal Signal Connected to Test condition Voltage (V) Action

A Ground (1) Ground part 1—Below 1.0•Inspect related harness

B Ground (2) Ground part 2—Below 1.0•Inspect related harness

CSolenoid valve

(power supply)Battery—B+•Inspect DSC HU/CM

•Inspect related harness

DPump motor

(power supply)Battery—B+•Inspect DSC HU/CM

•Inspect related harness

E

*—Check

connector—No need to

check•Inspect related harness

F

JLF wheel-speedLF wheel-speed

sensorVehicle is stopped 0 (AC)

•Inspect related harness

•Inspect wheel-speed

sensor •Inspect using the wave profile.

(See P–19 Inspection Using An

Oscilloscope (Reference))

SST (49 G066 004)

AQ

B

CDE

FG

HI

J DSC HU/CM HARNESS SIDE CONNECTOR

A

C E

H

K N Q

T

W Z AC AF

F I L O R U X

AA AD AG

G

J

M P S

V

Y AB AE AHB

DKN

T

WZ

AC

AFLO

RU

XAA

ADAGMP

SV

YAB

AEAH

A6E6920W009

Page 756 of 909

ON-BOARD DIAGNOSTIC

P–23

P

PMPSTAT

(Pump motor output state)ON/OFF•Pump motor is activated:

ON

•Pump motor is deactivated:

OFFInspect DSC HU/CM

—

BRK_FLUID (with DSC only)

(Brake fluid level sensor input)OK/LOW•Brake fluid is above LOW:

OK

•Brake fluid is below LOW:

LOWInspect brake fluid

level.

Inspect brake fluid

level sensor.—

BOO_ABS

(Brake pedal switch input)ON/OFF•Brake pedal is depressed:

ON

•Brake pedal is released:

OFFInspect brake switch.

ABS (ABS/

TCS): Y

DSC: L

ABS_LAMP

(ABS warning light driver

output state)ON/OFF•ABS warning light is

illuminated: ON

•ABS warning light is not

illuminated: OFFInspect ABS warning

light.

—

BRAKE_LMP

(BRAKE system warning light

output state)ON/OFF•BRAKE system warning

light is illuminated: ON

•BRAKE system warning

light is not illuminated: OFFInspect BRAKE

system warning light.

—

ABSRR_O

(Right rear ABS pressure

reduction solenoid valve

output state)ON/OFF•During ABS control: ON/

OFF

(solenoid valve is activated/

deactivated)

•Not ABS control: OFF

(solenoid valve is

deactivated)Internal fault of ABS

(ABS/TCS) or DSC

HU/CM. Replace ABS

(ABS/TCS) or DSC

HU/CM.—

ABSLR_O

(Left rear ABS pressure

reduction solenoid valve

output state)ON/OFF•During ABS or EBD control:

ON/OFF

(solenoid valve is activated/

deactivated)

•Not ABS and EBD control:

OFF

(solenoid valve is

deactivated)Internal fault of ABS

(ABS/TCS) or DSC

HU/CM. Replace ABS

(ABS/TCS) or DSC

HU/CM.—

ABSRF_O

(Right front ABS pressure

reduction solenoid valve

output state)ON/OFF•During ABS control: ON/

OFF

(solenoid valve is activated/

deactivated)

•Not ABS control: OFF

(solenoid valve is

deactivated)Internal fault of ABS

(ABS/TCS) or DSC

HU/CM. Replace ABS

(ABS/TCS) or DSC

HU/CM.—

ABSLF_O

(Left front ABS pressure

reduction solenoid valve

output state)ON/OFF•During ABS control: ON/

OFF

(solenoid valve is activated/

deactivated)

•Not ABS control: OFF

(solenoid valve is

deactivated)Internal fault of ABS

(ABS/TCS) or DSC

HU/CM. Replace ABS

(ABS/TCS) or DSC

HU/CM.—

ABSRR_I

(Right rear ABS pressure

reduction solenoid valve

output state)ON/OFF•During ABS control: ON/

OFF

(solenoid valve is activated/

deactivated)

•Not ABS control: OFF

(solenoid valve is

deactivated)Internal fault of ABS

(ABS/TCS) or DSC

HU/CM. Replace ABS

(ABS/TCS) or DSC

HU/CM.—

ABSLR_I

(Left rear ABS pressure

retention solenoid valve output

state)ON/OFF•During ABS or EBD control:

ON/OFF

(solenoid valve is activated/

deactivated)

•Not ABS and EBD control:

OFF

(solenoid valve is

deactivated)Internal fault of ABS

(ABS/TCS) or DSC

HU/CM. Replace ABS

(ABS/TCS) or DSC

HU/CM.— PID Name

(Definition)Unit/Condition Condition/Specification ActionABS (ABS/

TCS) HU/CM or

DSC HU/CM

terminal

Page 774 of 909

R–12

REAR SUSPENSION

Bracket Installation Note

1. Install the bracket as shown in the figure.

End Of SieREAR SHOCK ABSORBER DISPOSAL (WGN)A6E7416287002021. Lay the shock absorber on a level, horizontal surface.

2. Using a 2—3 mm {0.08—0.12 in} drill bit, drill a

hole in the high-pressure side (area indicated by

A), and allow the gas to escape.

Warning

•The oil in the shock absorber is

pressurized and could spray out. Be sure

to drill slowly and carefully.

3. Using a 2—3 mm {0.08—0.12 in} drill bit, drill a

hole in the low-pressure side (area indicated by

B).

4. Place the shock absorber with the hole drilled in

Step 3 turned downwards. Move the piston rod up

and down several times to drain out the oil.

5. Cut the tube at the end of the shock absorber,

and completely drain the oil out.

6. Properly dispose of the waste oil according to

waste disposal laws.

End Of Sie

106.5—112.5°

A6J74162006

A

A6J74161003

B

A6J74161006

Page 780 of 909

R–18

REAR SUSPENSION

Crossmember component, Differential And Drive Shaft Removal Note

1. Support the differential with a jack, and remove

the nut.

Warning

•Removing the crossmember component,

differential and drive shaft is dangerous.

The crossmember component,

differential and drive shaft could fall and

cause serious injury or death. Verify that

the jack securely supports the differential

lower side.

2. Remove the crossmember component,

differential and drive shaft.

Rear Crossmember Bushing Removal Note

1. Remove the bushing using a screw driver (-),

being careful not to damage the rear

crossmember.

Rear Crossmember Bushing Installation Note

1. Set the bushings as shown in the figure.

JACK

A6E74162012

A6E7416W001

A

B

D

C

A

B

C,D

FRONT

UPPER SIDELOWER SIDE

OVAL

HOLECROSS-

SECTIONAL

VIEW

A6E74162014

Page 789 of 909

S–8

LIFTGATE

LIFTGATE REMOVAL/INSTALLATIONA6E772262010201WGN

Warning

•Removing the stay damper without supporting the liftgate can be dangerous. The liftgate may fall

and injure you. Open the liftgate fully and support it before removing the stay damper.

1. Disconnect the negative battery cable.

2. Remove the liftgate upper trim. (SeeS–23 LIFTGATE UPPER TRIM REMOVAL/INSTALLATION)

3. Disconnect the rear washer hose.

4. Disconnect the vehicle harness and the vehicle

harness connector, attached to the liftgate, from

the liftgate harness connector.

5. Pry away the stay damper's band with a

screwdriver.

6. Pry out the connecting part of the stay damper

and the hinge with a screwdriver to disconnect

them. Then remove the stay damper.

7. Remove the bolts A, then remove the liftgate.

8. To remove the hinge, remove the headliner and

the nut.

LIFTGATE

GROMMET

VEHICLE HARNESS

CONNECTOR LIFTGATE HARNESS

CONNECTORVEHICLE HARNESS

VEHICLE HARNESS

A6E77221101

BAND

STAY

DAMPER

A6E7722W005

Page 795 of 909

S–14

WINDOW GLASS

SIDE WINDOW GLASS REMOVALA6E7738625802011. Apply protective tape along the edge of the body to protect it from damage.

2. Make a hole through the sealant, avoiding pins,

from the inside of the vehicle using an awl.

3. Pass the SST (piano wire) through the hole.

Warning

•Using a SST (piano wire) with bare hands

can cause injury. Always wear gloves

when using a SST (piano wire).

4. Wind each end of the SST (piano wire) around a

bar.

Note

•Use a long sawing action to spread the work

over the whole length of the SST (piano

wire) to prevent it from breaking.

5. Working with another person, saw through the

sealant around the edge of the glass.

6. Remove the side window glass.

End Of Sie

SIDE WINDOW GLASS INSTALLATIONA6E773862580202

Caution

•To prevent the sealant from cracking or the glass from being pushed out by air pressure if a door

is closed, open all of the windows and leave them open until the sealant has hardened.

1. Cut away the old sealant using a razor so that 1—2 mm {0.04—0.07 in} thickness of sealant remains around

the circumference of the frame.

Warning

•Using a razor with bare hands can cause injury. Always wear gloves when using a razor.

2. If the sealant has come off completely in any one place, apply some primer after degreasing, and allow it

approximately 30 minutes to dry. Then put on new sealant to create a 2 mm {0.08 in} layer.

3. Clean and degrease an approximately 50.0 mm {1.97 in} wide strip around the circumference of the glass

and the bonding area on the body.

WINDOW GLASS

PIN

PIN

FASTENER

A6A7738W102

49 0305 870A

PROTECTIVE

TAPE

SEALANT

A6A7738W103

49 0305 870A

A6E7738W021