warning MAZDA 6 2002 Suplement Owners Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 658 of 909

M–28

REAR AXLE

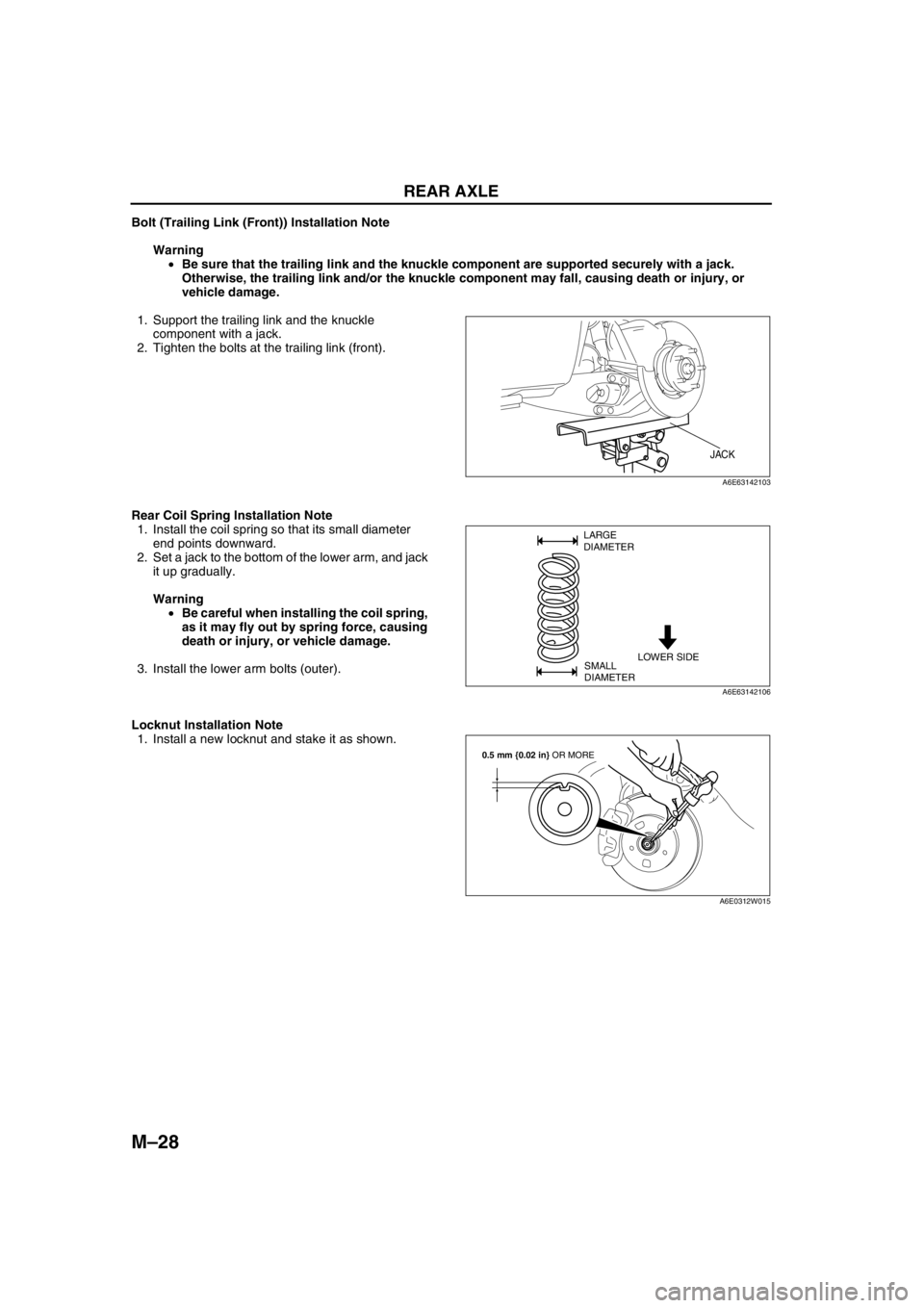

Bolt (Trailing Link (Front)) Installation Note

Warning

•Be sure that the trailing link and the knuckle component are supported securely with a jack.

Otherwise, the trailing link and/or the knuckle component may fall, causing death or injury, or

vehicle damage.

1. Support the trailing link and the knuckle

component with a jack.

2. Tighten the bolts at the trailing link (front).

Rear Coil Spring Installation Note

1. Install the coil spring so that its small diameter

end points downward.

2. Set a jack to the bottom of the lower arm, and jack

it up gradually.

Warning

•Be careful when installing the coil spring,

as it may fly out by spring force, causing

death or injury, or vehicle damage.

3. Install the lower arm bolts (outer).

Locknut Installation Note

1. Install a new locknut and stake it as shown.

End Of Sie

JACK

A6E63142103

LOWER SIDE LARGE

DIAMETER

SMALL

DIAMETER

A6E63142106

0.5 mm {0.02 in} OR MORE

A6E0312W015

Page 682 of 909

M–52

REAR DIFFERENTIAL

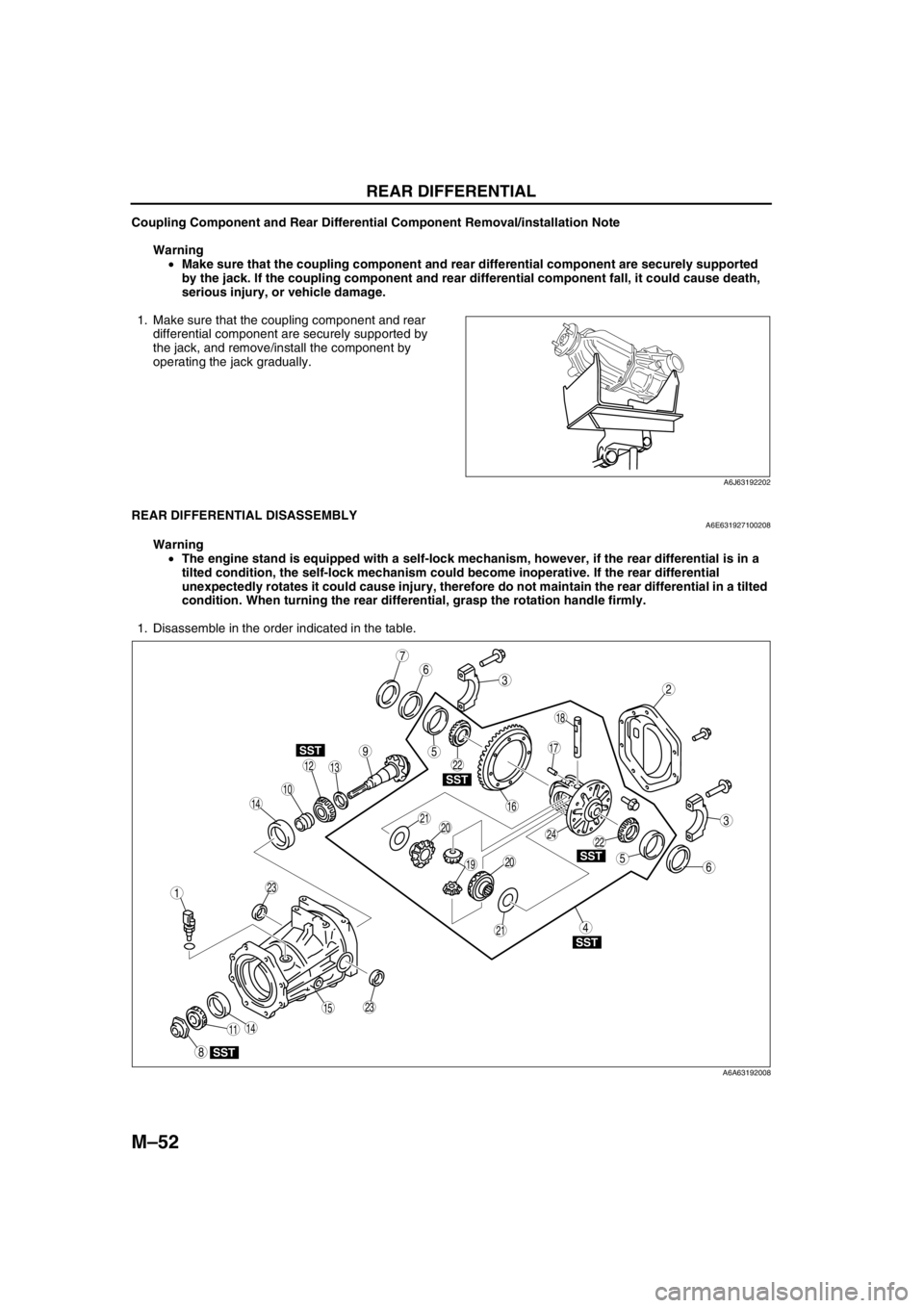

Coupling Component and Rear Differential Component Removal/installation Note

Warning

•Make sure that the coupling component and rear differential component are securely supported

by the jack. If the coupling component and rear differential component fall, it could cause death,

serious injury, or vehicle damage.

1. Make sure that the coupling component and rear

differential component are securely supported by

the jack, and remove/install the component by

operating the jack gradually.

End Of Sie

REAR DIFFERENTIAL DISASSEMBLYA6E631927100208

Warning

•The engine stand is equipped with a self-lock mechanism, however, if the rear differential is in a

tilted condition, the self-lock mechanism could become inoperative. If the rear differential

unexpectedly rotates it could cause injury, therefore do not maintain the rear differential in a tilted

condition. When turning the rear differential, grasp the rotation handle firmly.

1. Disassemble in the order indicated in the table.

.

A6J63192202

9

7

3

10

SST

SST

SST

SST

SST

6

18

14

14

1312

8

5

5

4

3

1

2

19

17

15

16

11

20

2024

23

23

21

21

22

22

6

A6A63192008

Page 686 of 909

M–56

REAR DIFFERENTIAL

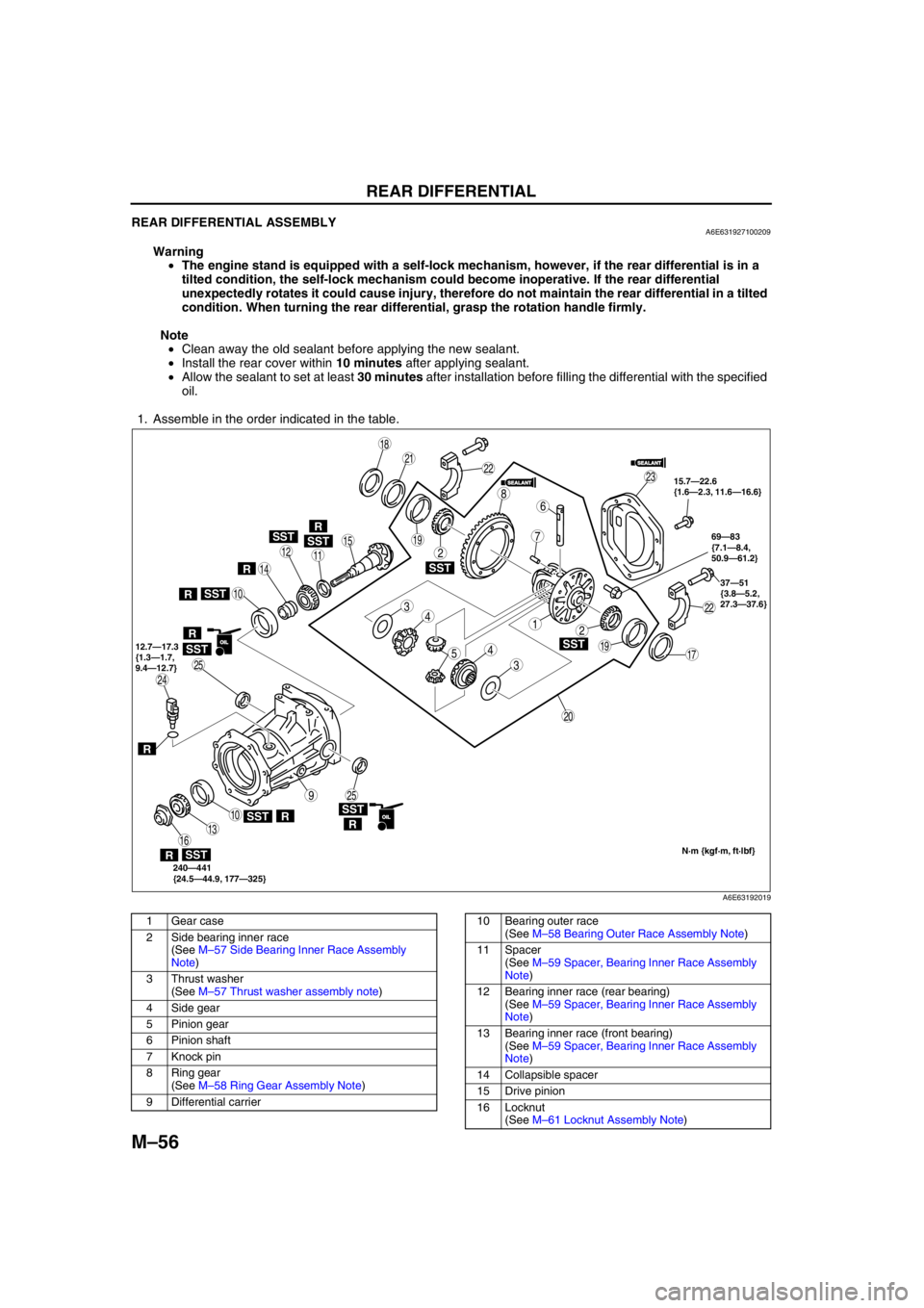

REAR DIFFERENTIAL ASSEMBLYA6E631927100209

Warning

•The engine stand is equipped with a self-lock mechanism, however, if the rear differential is in a

tilted condition, the self-lock mechanism could become inoperative. If the rear differential

unexpectedly rotates it could cause injury, therefore do not maintain the rear differential in a tilted

condition. When turning the rear differential, grasp the rotation handle firmly.

Note

•Clean away the old sealant before applying the new sealant.

•Install the rear cover within 10 minutes after applying sealant.

•Allow the sealant to set at least 30 minutes after installation before filling the differential with the specified

oil.

1. Assemble in the order indicated in the table.

.

SST

SST

SST

SSTSST

SST

SST

9

8

7

54

4

3

3

12

2

10

10

19

19

18

17

15

16

14

13

1112

20

25

25

24

23

21

22

22

R

SST

R

R

R

SSTR

RR

6

SEALANTSEALANT

SEALANTSEALANT

OILOIL

OILOIL

15.7—22.6

{1.6—2.3, 11.6—16.6}

37—51

{3.8—5.2,

27.3—37.6}

240—441

{24.5—44.9, 177—325} 12.7—17.3

{1.3—1.7,

9.4—12.7}69—83

{7.1—8.4,

50.9—61.2}

N·m {kgf·m, ft·lbf}

R

A6E63192019

1 Gear case

2 Side bearing inner race

(See M–57 Side Bearing Inner Race Assembly

Note)

3 Thrust washer

(See M–57 Thrust washer assembly note)

4 Side gear

5 Pinion gear

6Pinion shaft

7 Knock pin

8 Ring gear

(See M–58 Ring Gear Assembly Note)

9 Differential carrier10 Bearing outer race

(See M–58 Bearing Outer Race Assembly Note)

11 Spacer

(See M–59 Spacer, Bearing Inner Race Assembly

Note)

12 Bearing inner race (rear bearing)

(See M–59 Spacer, Bearing Inner Race Assembly

Note)

13 Bearing inner race (front bearing)

(See M–59 Spacer, Bearing Inner Race Assembly

Note)

14 Collapsible spacer

15 Drive pinion

16 Locknut

(See M–61 Locknut Assembly Note)

Page 695 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–65

M

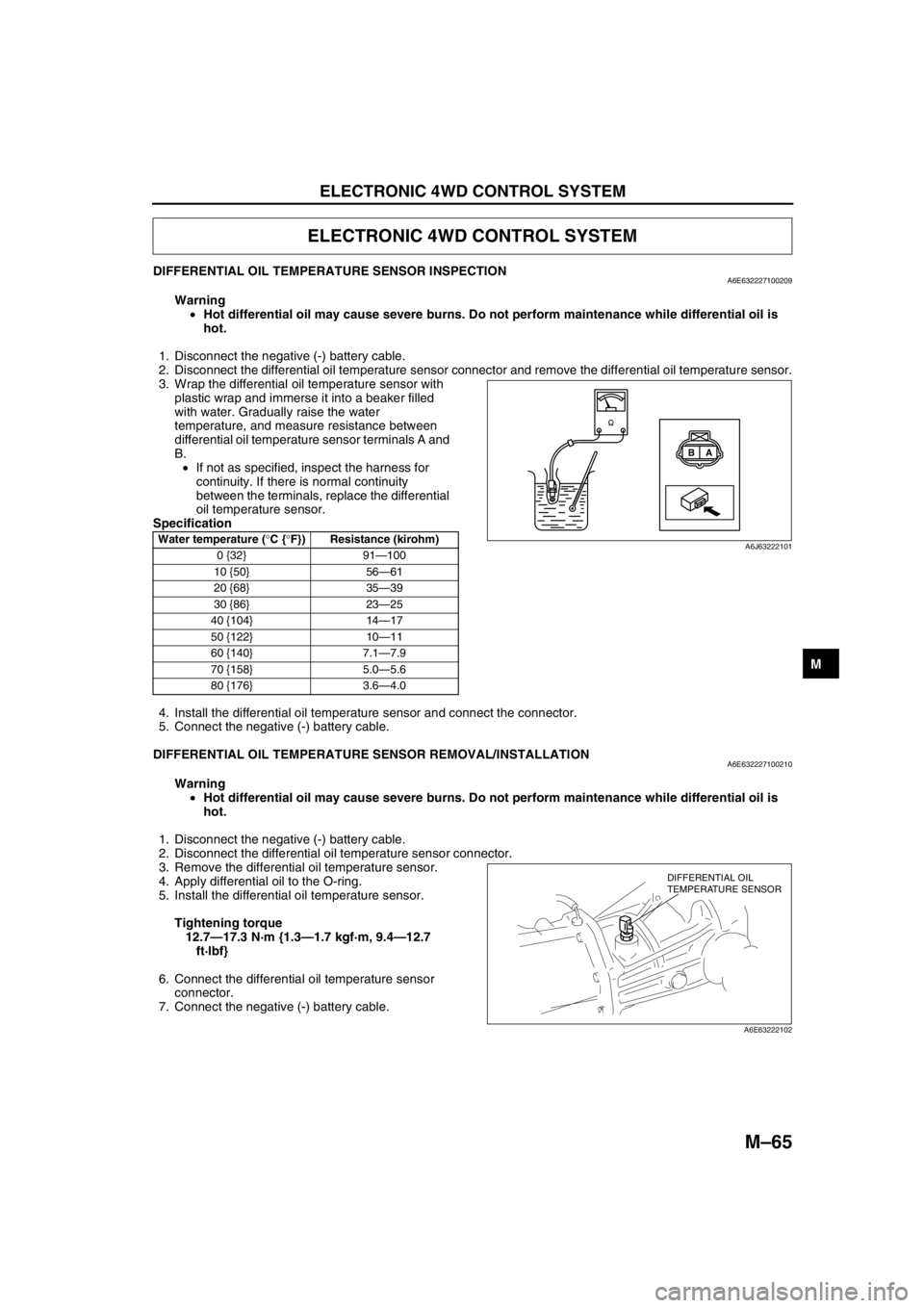

DIFFERENTIAL OIL TEMPERATURE SENSOR INSPECTIONA6E632227100209

Warning

•Hot differential oil may cause severe burns. Do not perform maintenance while differential oil is

hot.

1. Disconnect the negative (-) battery cable.

2. Disconnect the differential oil temperature sensor connector and remove the differential oil temperature sensor.

3. Wrap the differential oil temperature sensor with

plastic wrap and immerse it into a beaker filled

with water. Gradually raise the water

temperature, and measure resistance between

differential oil temperature sensor terminals A and

B.

•If not as specified, inspect the harness for

continuity. If there is normal continuity

between the terminals, replace the differential

oil temperature sensor.

Specification

4. Install the differential oil temperature sensor and connect the connector.

5. Connect the negative (-) battery cable.

End Of Sie

DIFFERENTIAL OIL TEMPERATURE SENSOR REMOVAL/INSTALLATIONA6E632227100210

Warning

•Hot differential oil may cause severe burns. Do not perform maintenance while differential oil is

hot.

1. Disconnect the negative (-) battery cable.

2. Disconnect the differential oil temperature sensor connector.

3. Remove the differential oil temperature sensor.

4. Apply differential oil to the O-ring.

5. Install the differential oil temperature sensor.

Tightening torque

12.7—17.3 N·m {1.3—1.7 kgf·m, 9.4—12.7

ft·lbf}

6. Connect the differential oil temperature sensor

connector.

7. Connect the negative (-) battery cable.

End Of Sie

ELECTRONIC 4WD CONTROL SYSTEM

Water temperature (°C {°F}) Resistance (kirohm)

0 {32} 91—100

10 {50} 56—61

20 {68} 35—39

30 {86} 23—25

40 {104} 14—17

50 {122} 10—11

60 {140} 7.1—7.9

70 {158} 5.0—5.6

80 {176} 3.6—4.0

A B

A6J63222101

DIFFERENTIAL OIL

TEMPERATURE SENSOR

A6E63222102

Page 699 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–69

M

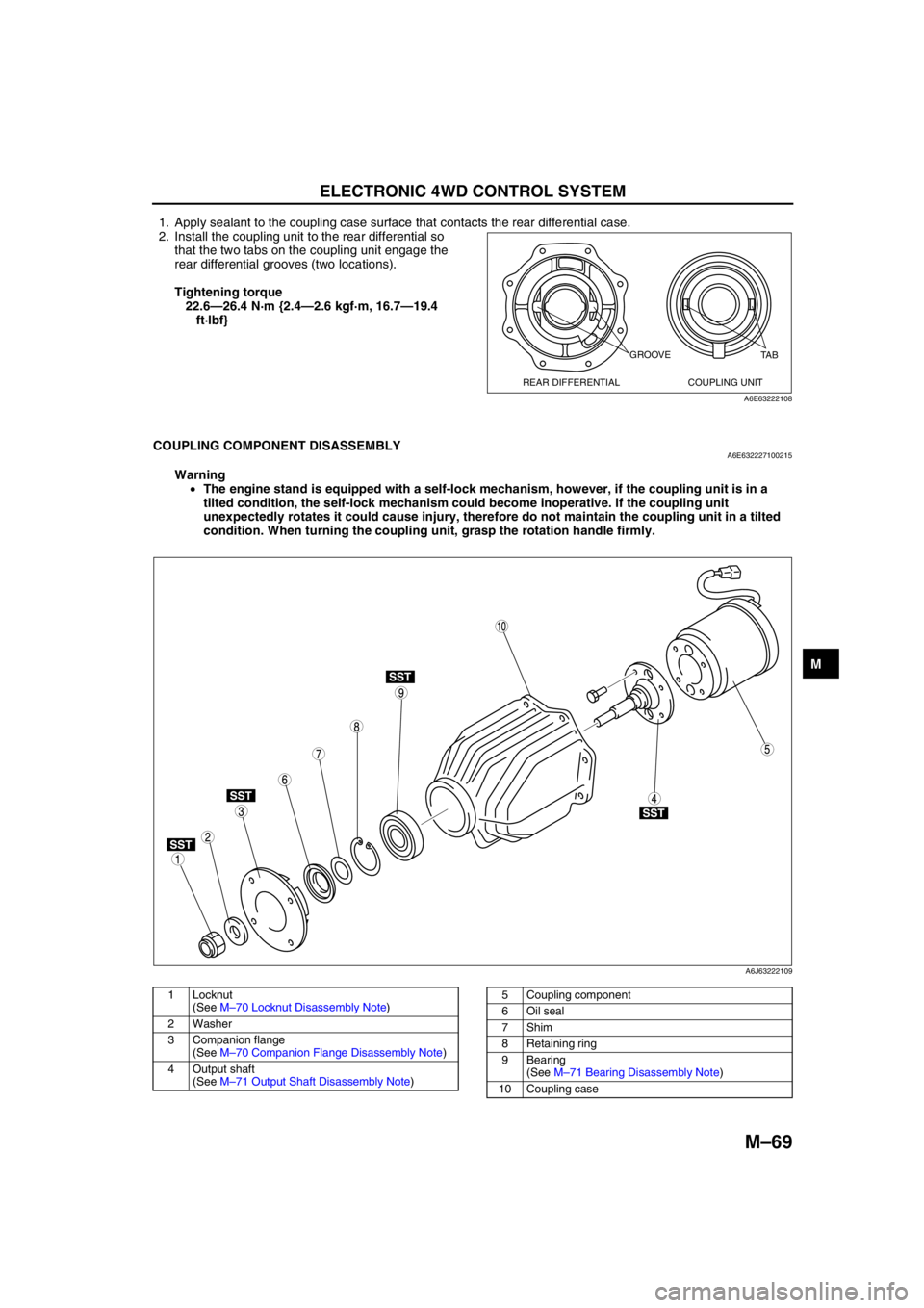

1. Apply sealant to the coupling case surface that contacts the rear differential case.

2. Install the coupling unit to the rear differential so

that the two tabs on the coupling unit engage the

rear differential grooves (two locations).

Tightening torque

22.6—26.4 N·m {2.4—2.6 kgf·m, 16.7—19.4

ft·lbf}

End Of Sie

COUPLING COMPONENT DISASSEMBLYA6E632227100215

Warning

•The engine stand is equipped with a self-lock mechanism, however, if the coupling unit is in a

tilted condition, the self-lock mechanism could become inoperative. If the coupling unit

unexpectedly rotates it could cause injury, therefore do not maintain the coupling unit in a tilted

condition. When turning the coupling unit, grasp the rotation handle firmly.

.

GROOVE

REAR DIFFERENTIAL COUPLING UNITTA B

A6E63222108

SST

SST

SST

SST

9

8

75

4

3

1

2

10

6

A6J63222109

1 Locknut

(See M–70 Locknut Disassembly Note)

2Washer

3 Companion flange

(See M–70 Companion Flange Disassembly Note)

4 Output shaft

(See M–71 Output Shaft Disassembly Note)5 Coupling component

6Oil seal

7Shim

8 Retaining ring

9 Bearing

(See M–71 Bearing Disassembly Note)

10 Coupling case

Page 702 of 909

M–72

ELECTRONIC 4WD CONTROL SYSTEM

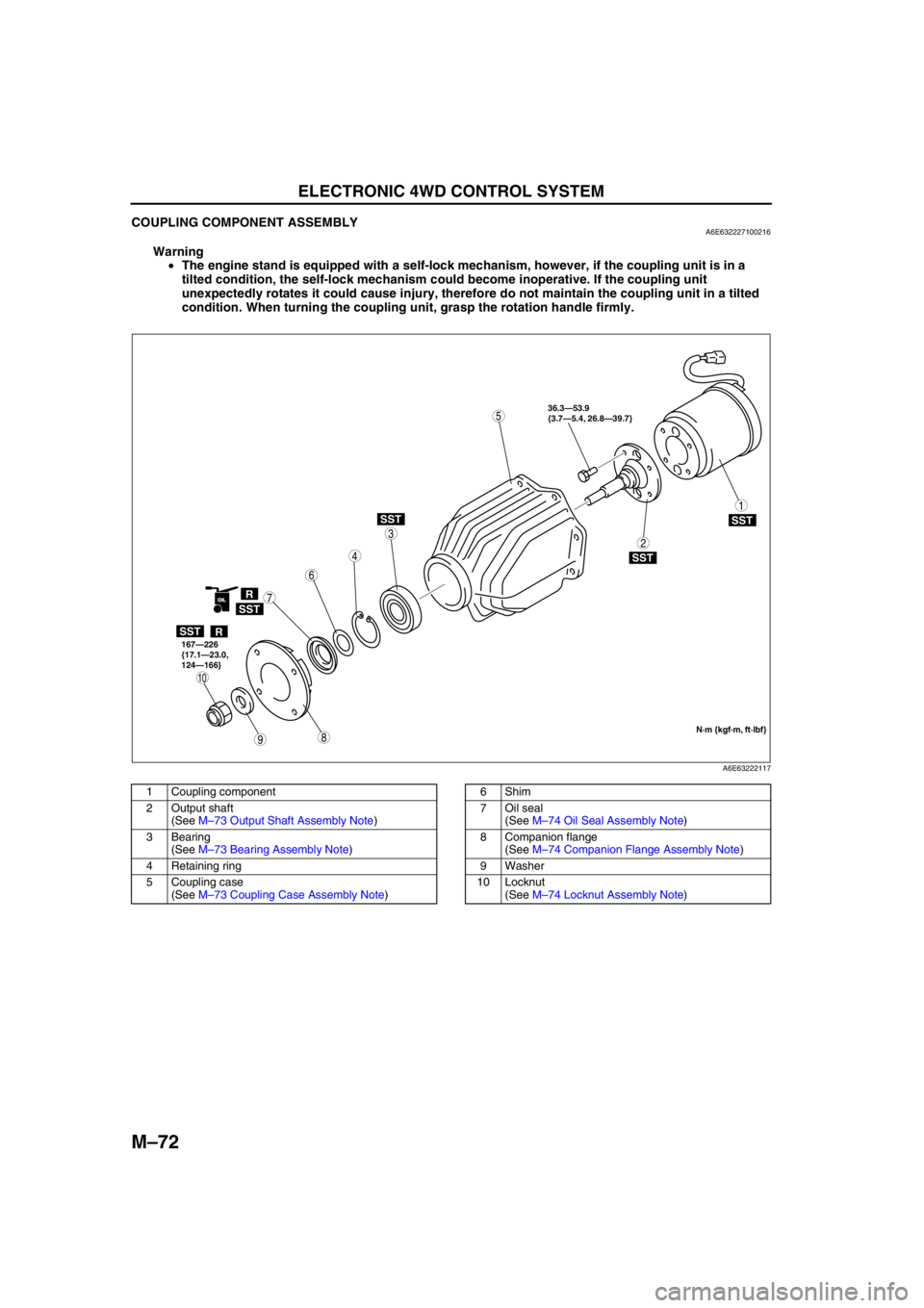

COUPLING COMPONENT ASSEMBLYA6E632227100216

Warning

•The engine stand is equipped with a self-lock mechanism, however, if the coupling unit is in a

tilted condition, the self-lock mechanism could become inoperative. If the coupling unit

unexpectedly rotates it could cause injury, therefore do not maintain the coupling unit in a tilted

condition. When turning the coupling unit, grasp the rotation handle firmly.

.

98

7

5

4

3

1

2

10

6

SST

SST

R

SST

SST

SST

R

OIL

36.3—53.9

{3.7—5.4, 26.8—39.7}

167—226

{17.1—23.0,

124—166}

N·m {kgf·m, ft·lbf}

A6E63222117

1 Coupling component

2 Output shaft

(See M–73 Output Shaft Assembly Note)

3 Bearing

(See M–73 Bearing Assembly Note)

4 Retaining ring

5 Coupling case

(See M–73 Coupling Case Assembly Note)6Shim

7 Oil seal

(See M–74 Oil Seal Assembly Note)

8 Companion flange

(See M–74 Companion Flange Assembly Note)

9Washer

10 Locknut

(See M–74 Locknut Assembly Note)

Page 712 of 909

M–82

TROUBLESHOOTING

FOREWORDA6E638027100202

End Of Sie

SYMPTOM TROUBLESHOOTINGA6E638027100203•Verify the symptoms, and perform troubleshooting according to the appropriate number.

End Of Sie

NO.1 FREQUENT FRONT WHEEL SLIPA6E638027100204

Warning

•During simulation driving, vehicle stability may decrease extremely and cause an accident. Be

sure to perform the simulation test driving in a safe area.

Malfunction vehicle delivered

Questionnaire

Verify malfunction symptoms

Symptom troubleshooting

Verify that malfunctions have been repaired

Troubleshooting completedConfirm all customer problems using a questionnaire.

Confirm malfunction on actual vehicle.

DTC inspection

Inspect for DTCs using WDS or equivalent.

Perform applicable troubleshooting inspection according to

diagnostic index.

A6E63802001

No. Symptom Description

1 Frequent front wheel slip Front wheels slip frequently during acceleration on low-friction road.

2

Tight corner braking effectBrakes seem to be applied during tight cornering while driving very

slowly on paved road.

3 Abnormal noise and/or vibration from

coupling unitThere is abnormal noise and/or vibration from coupling unit during

driving.

1 Frequent front wheel slip

[TROUBLESHOOTING HINTS]

•Tire traction performance is extremely poor for given road friction. (4WD system is normal.)

•Improper wheel alignment (4WD system is normal.)

•Rear differential oil temperature is extremely high (Fail-safe condition)

•Differential oil temperature sensor malfunction (Fail-safe condition)

•Compare slip frequency with another vehicle of the same model (under the same road conditions and tire traction

performance).

•Replace tires with others of the same model and perform test under the same road conditions to determine if the

malfunction was caused by tire traction performance.

•Coupling component malfunction

•4WD solenoid malfunction

Page 725 of 909

ENGINE SPEED SENSING POWER STEERING

N–11

N

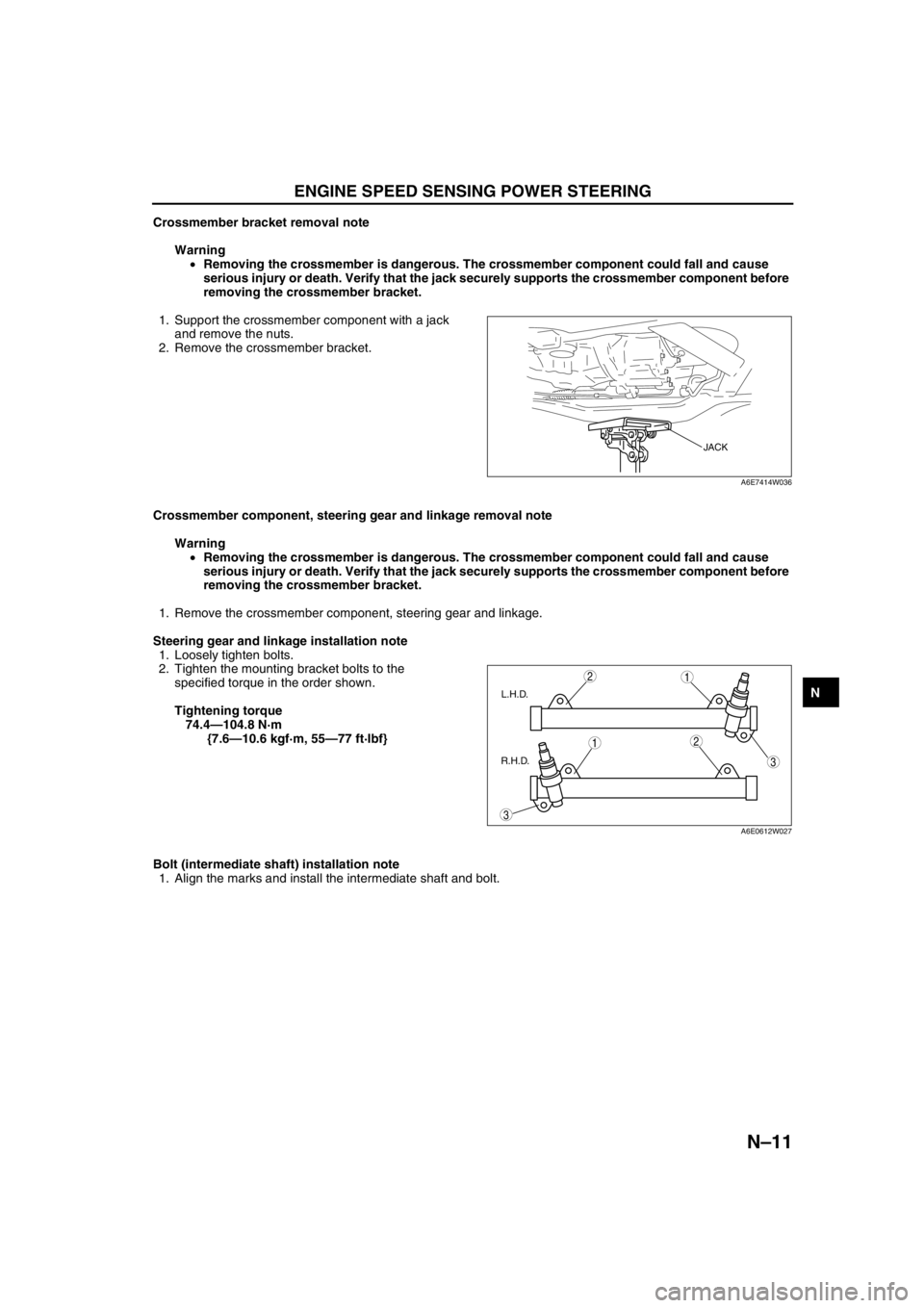

Crossmember bracket removal note

Warning

•Removing the crossmember is dangerous. The crossmember component could fall and cause

serious injury or death. Verify that the jack securely supports the crossmember component before

removing the crossmember bracket.

1. Support the crossmember component with a jack

and remove the nuts.

2. Remove the crossmember bracket.

Crossmember component, steering gear and linkage removal note

Warning

•Removing the crossmember is dangerous. The crossmember component could fall and cause

serious injury or death. Verify that the jack securely supports the crossmember component before

removing the crossmember bracket.

1. Remove the crossmember component, steering gear and linkage.

Steering gear and linkage installation note

1. Loosely tighten bolts.

2. Tighten the mounting bracket bolts to the

specified torque in the order shown.

Tightening torque

74.4—104.8 N·m

{7.6—10.6 kgf·m, 55—77 ft·lbf}

Bolt (intermediate shaft) installation note

1. Align the marks and install the intermediate shaft and bolt.

JACK

A6E7414W036

3

3

1

1

2

2

L.H.D.

R.H.D.

A6E0612W027

Page 737 of 909

P–4

ABS/TCS

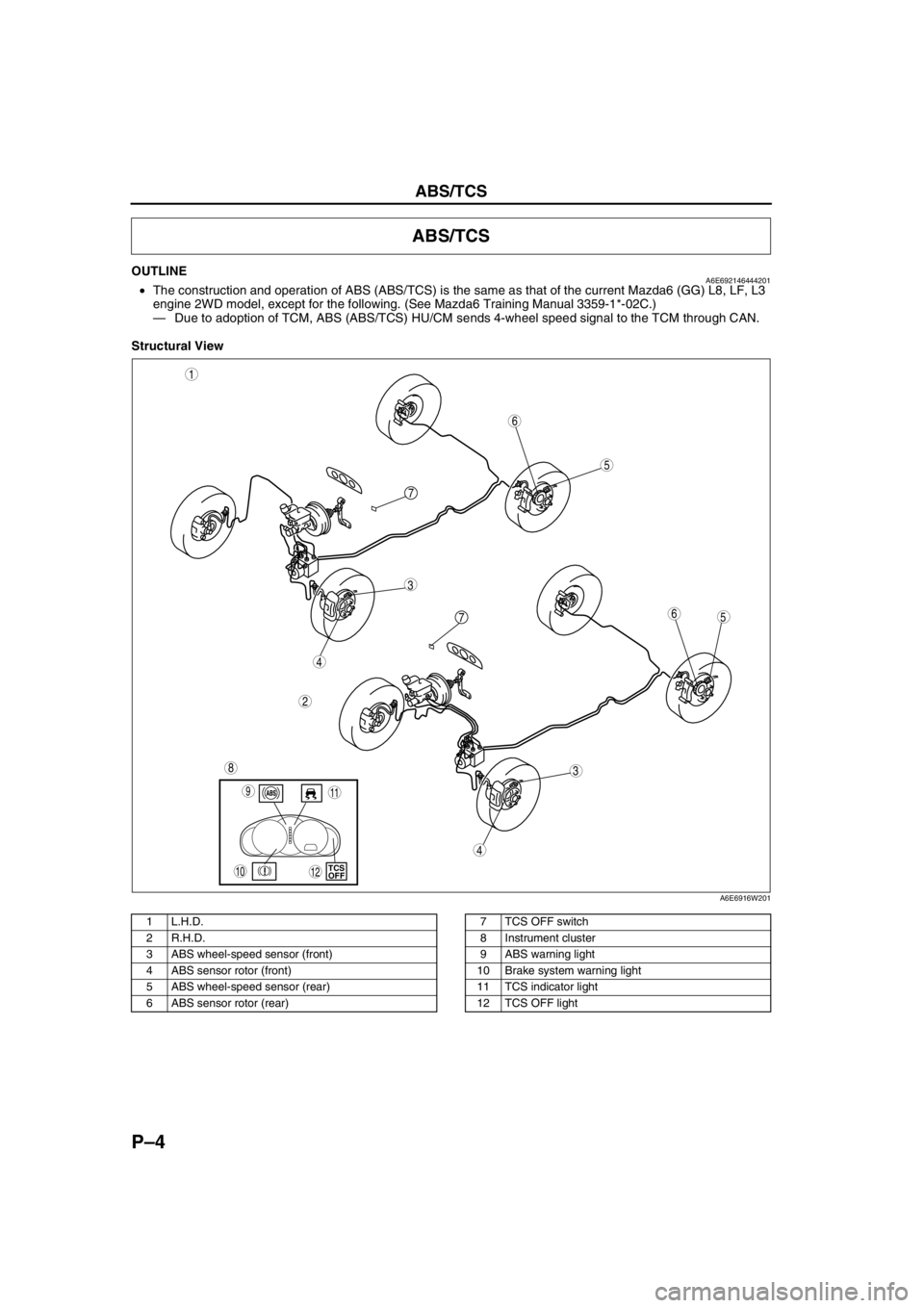

OUTLINEA6E692146444201•The construction and operation of ABS (ABS/TCS) is the same as that of the current Mazda6 (GG) L8, LF, L3

engine 2WD model, except for the following. (See Mazda6 Training Manual 3359-1*-02C.)

—Due to adoption of TCM, ABS (ABS/TCS) HU/CM sends 4-wheel speed signal to the TCM through CAN.

Structural View

.

ABS/TCS

5

3

1

2

6

7

5

3

6

8

4

4

7

9

10TCS

OFF

11

12

A6E6916W201

1 L.H.D.

2 R.H.D.

3 ABS wheel-speed sensor (front)

4 ABS sensor rotor (front)

5 ABS wheel-speed sensor (rear)

6 ABS sensor rotor (rear)7 TCS OFF switch

8 Instrument cluster

9 ABS warning light

10 Brake system warning light

11 TCS indicator light

12 TCS OFF light

Page 738 of 909

ABS/TCS

P–5

P

System Diagram

.

End Of Sie

9

9

8

7

5

43

12

6

18

17

15

16

14

13

11

12

RF

FL

RR

RL

PCMG

E

FI Z

U

D

A

B

C

Y

AC

X

V O

R ADAB AA

ABS/TCS HU/CM

pP

9

10

19

920

A6E6921W201

1 IG switch

2SUS 15 A fuse

3 ABS 60 A fuse

4 Meter

5 ABS warning light

6 Brake system warning light

7 TCS OFF light

8 TCS indicator light

9CAN driver

10 Brake light11 Cruise actuator

12 TCS OFF switch

13 DLC-2

14 CAN-H

15 CAN-L

16 ABS Wheel-speed sensor

17 Battery

18 Brake switch

19 Audio unit, Wiper and washer switch, Car-navigation

unit, Auto leveling control unit

20 TCM, 4WD CM