warning MAZDA 6 2002 Suplement Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 550 of 909

ON-BOARD DIAGNOSTIC

K2–135

K2

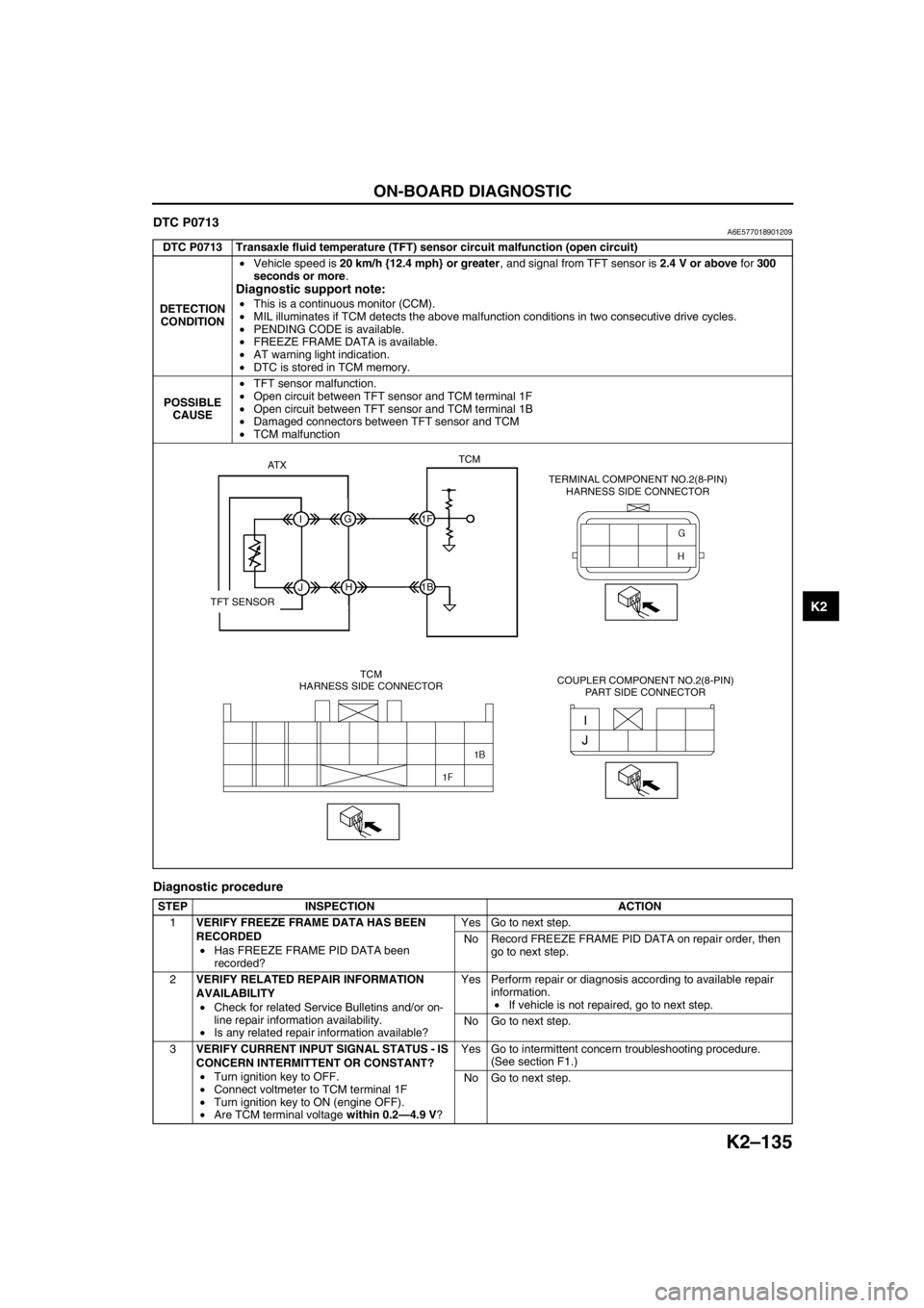

DTC P0713A6E577018901209

Diagnostic procedure

DTC P0713 Transaxle fluid temperature (TFT) sensor circuit malfunction (open circuit)

DETECTION

CONDITION•Vehicle speed is 20 km/h {12.4 mph} or greater, and signal from TFT sensor is 2.4 V or above for 300

seconds or more.

Diagnostic support note:

•This is a continuous monitor (CCM).

•MIL illuminates if TCM detects the above malfunction conditions in two consecutive drive cycles.

•PENDING CODE is available.

•FREEZE FRAME DATA is available.

•AT warning light indication.

•DTC is stored in TCM memory.

POSSIBLE

CAUSE•TFT sensor malfunction.

•Open circuit between TFT sensor and TCM terminal 1F

•Open circuit between TFT sensor and TCM terminal 1B

•Damaged connectors between TFT sensor and TCM

•TCM malfunction

STEP INSPECTION ACTION

1VERIFY FREEZE FRAME DATA HAS BEEN

RECORDED

•Has FREEZE FRAME PID DATA been

recorded?Yes Go to next step.

No Record FREEZE FRAME PID DATA on repair order, then

go to next step.

2VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Bulletins and/or on-

line repair information availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available repair

information.

•If vehicle is not repaired, go to next step.

No Go to next step.

3VERIFY CURRENT INPUT SIGNAL STATUS - IS

CONCERN INTERMITTENT OR CONSTANT?

•Turn ignition key to OFF.

•Connect voltmeter to TCM terminal 1F

•Turn ignition key to ON (engine OFF).

•Are TCM terminal voltage within 0.2—4.9 V?Yes Go to intermittent concern troubleshooting procedure.

(See section F1.)

No Go to next step.

AT XTCM

IG1F

1B

JH

TFT SENSOR

TCM

HARNESS SIDE CONNECTORTERMINAL COMPONENT NO.2(8-PIN)

HARNESS SIDE CONNECTOR

COUPLER COMPONENT NO.2(8-PIN)

PART SIDE CONNECTOR

Page 552 of 909

ON-BOARD DIAGNOSTIC

K2–137

K2

DTC P0715A6E577018901210

DTC P0715 Input/turbine speed sensor circuit malfunction

DETECTION

CONDITION•The following condition is detected twice:

—Input/turbine speed sensor signal is 600 rpm or less while engine speed is 1,500 rpm or greater and

vehicle speed is 40 km/h {24.8 mph} or greater in D range.

Diagnostic support note:

•This is a continuous monitor (CCM).

•MIL illuminates if TCM detects the above malfunction conditions in two consecutive drive cycles.

•PENDING CODE is available.

•FREEZE FRAME DATA is available.

•AT warning light indication.

•DTC is stored in TCM memory.

POSSIBLE

CAUSE•Input/turbine speed sensor malfunction.

•Short to ground between input/turbine speed sensor terminal B and TCM terminal 1N

•Short to ground between input/turbine speed sensor terminal A and TCM terminal 2F

•Open circuit between input/turbine speed sensor terminal B and TCM terminal 1N

•Open circuit between input/turbine speed sensor terminal A and TCM terminal 2F

•Damaged connectors between input/turbine speed sensor and TCM.

•TCM malfunction.

AT X

B

E1NTCM

TCM

HARNESS SIDE CONNECTOR

TERMINAL COMPONENT

NO.2(8-PIN)

HARNESS SIDE CONNECTORCOUPLER COMPONENT

(8-PIN)

PART SIDE CONNECTORINPUT/TURBINE

SPEED SENSOR

HARNESS SIDE CONNECTOR 2F B

A

A

F

INPUT/TURBINE

SPEED SENSOR

Page 554 of 909

ON-BOARD DIAGNOSTIC

K2–139

K2

End Of SieDTC P0720A6E577018901211

10INSPECT INPUT/TURBINE SPEED SENSOR

CONNECTOR FOR POOR CONNECTION

•Disassemble the transaxle.

•Disconnect input/turbine speed sensor

connector.

•Check for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Are terminals okay?Yes Go to next step.

No Repair terminals, then go to Step 12.

11INSPECT INPUT/TURBINE SPEED SENSOR

RESISTANCE

•Measure resistance between input/turbine

speed sensor.

•Is resistance within 513—627 ohms between

input/turbine speed sensor connector terminal

A and B (part side)?Yes Repair or replace coupler component, then go to next step.

No Replace input/turbine speed sensor, then go to next step.

12VERIFY TROUBLESHOOTING OF DTC P0715

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory using WDS or

equivalent.

•Drive vehicle with vehicle speed 40 km/h {25

mph} or above and engine speed 1,500 rpm

or above for 2 second or more

•Repeat Step ii two times.

•Is same DTC present?Yes Replace TCM, then go to next step.

(See K2–96 TCM REMOVAL/INSTALLATION.)

No Go to next step.

13VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See K2–124 AFTER REPAIR PROCEDURE.)

•Is there any DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

DTC P0720 Vehicle speedometer sensor (VSS) malfunction (open/short)

DETECTION

CONDITION•Parking gear rotation detected by VSS is 150 rpm (Vehicle speed: 5—6 km/h) or less while intermediate

sensor signal is 1,400 rpm or greater in D range for 2 second or more.

Diagnostic support note:

•This is a continuous monitor (CCM).

•MIL illuminates if TCM detects the above malfunction conditions in two consecutive drive cycles.

•PENDING CODE is available.

•FREEZE FRAME DATA is available.

•AT warning light indication.

•DTC is stored in TCM memory.

POSSIBLE

CAUSE•Open circuit between vehicle speedometer sensor terminal B and TCM terminal 1M

•Open circuit between vehicle speedometer sensor terminal A and TCM terminal 1V

•Short to ground between vehicle speedometer sensor terminal B and TCM terminal 1M

•Short to ground between vehicle speedometer sensor terminal A and TCM terminal 1V

•Vehicle speedometer sensor malfunction

•Damaged connectors between vehicle speedometer sensor to TCM

•TCM malfunction

Page 557 of 909

K2–142

ON-BOARD DIAGNOSTIC

End Of SieDTC P0740A6E577018901212

Diagnostic procedure

12VERIFY TROUBLESHOOTING OF DTC P0720

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory using WDS or

equivalent.

•Drive vehicle with vehicle speed 40 km/h {25

mph} or above for 2 second or more

•Is same DTC present?Yes Replace TCM, then go to next step.

(See K2–96 TCM REMOVAL/INSTALLATION.)

No Go to next step.

13VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See K2–124 AFTER REPAIR PROCEDURE.)

•Is there any DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

DTC P0740 TCC system malfunction

DETECTION

CONDITION•RPM difference between crankshaft (engine speed signal) and reverse clutch drum (input/turbine speed

sensor signal) exceeds the pre-programmed value.

Diagnostic support note:

•This is continuous monitor (CCM).

•MIL illuminates if TCM detects the above malfunction conditions in two consecutive drive cycles.

•PENDING CODE is available.

•FREEZE FRAME DATA is available.

•AT warning light does not indication.

•DTC is stored in TCM memory.

POSSIBLE

CAUSE•ATF level low.

•Deteriorated ATF.

•TCC solenoid valve and pressure control solenoid stuck.

•Line pressure low.

•Oil pump malfunction.

•Control valve stuck

•Torque convert clutch malfunction

•TCM malfunction.

STEP INSPECTION ACTION

1VERIFY FREEZE FRAME DATA HAS BEEN

RECORDED

•Has FREEZE FRAME PID DATA been

recorded?Yes Go to next step.

No Record FREEZE FRAME PID DATA on repair order, then

go to next step.

2VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Bulletins and/or on-

line repair information availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available repair

information.

•If vehicle is not repaired, go to next step.

No Go to next step.

3CHECK ATF CONDITION

•Turn ignition key to OFF.

•Check ATF condition.

—Clear red: Normal

—Milky: Water mixed in fluid

—Reddish brown: Deteriorated ATF

•Is it okay?

(See K2–78 Automatic Transaxle Fluid (ATF)

Condition Inspection.)Yes Go to next step.

No If ATF color milky or reddish brown, replace ATF, then go to

Step 5.

(See K2–80 AUTOMATIC TRANSAXLE FLUID (ATF)

REPLACEMENT.)

4CHECK ATF LEVEL

•Start engine.

•Warm up ATX.

•Is ATF level within specification?

(See K2–79 Automatic Transaxle Fluid (ATF)

Level Inspection.)Yes Go to next step.

No Adjust ATF level, then go to Step 9.

(See K2–79 Automatic Transaxle Fluid (ATF) Level

Inspection.)

Page 559 of 909

K2–144

ON-BOARD DIAGNOSTIC

DTC P0743A6E577018901213

DTC P0743 Torque converter clutch (TCC) solenoid valve circuit malfunction (open/short)

DETECTION

CONDITION•Open or short in TCC solenoid signal system (while TCM monitors solenoid output voltage, the voltage that

differs from the ON/OFF signal output by CPU in TCM is detected).

Diagnostic support note:

•This is continuous monitor (CCM).

•MIL illuminates if TCM detects the above malfunction condition during first drive cycle.

•PENDING CODE is not available.

•FREEZE FRAME DATA is available.

•AT warning light does not indication.

•DTC is stored in TCM memory.

POSSIBLE

CAUSE•Open circuit between TCC solenoid valve terminal A and TCM terminal 2S

•Short to ground between TCC solenoid valve terminal A and TCM terminal 2S

•Short to power between TCC solenoid valve terminal A and TCM terminal 2S

•TCC solenoid valve malfunction

•Damage connector between TCC solenoid valve and TCM

•TCM malfunction

2PTCM

HARNESS SIDE CONNECTORTERMINAL COMPONENT

NO.1(12-PIN)

HARNESS SIDE CONNECTOR

COUPLER COMPONENT

(10-PIN)

PART SIDE CONNECTORTCC SOLENOID VALVE

HARNESS SIDE CONNECTORAT X

CPU

CPU2S

2PB

JA C

A

B TCM

TCC SOLENOID VALVE

Page 561 of 909

K2–146

ON-BOARD DIAGNOSTIC

End Of SieDTC P0748A6E577018901214

11INSPECT TERMINAL COMPONENT NO.1 (12-

PIN) CIRCUIT FOR SHORT TO POWER

•Turn ignition key to ON (engine OFF).

•Check voltage at terminal component No.1 (12-

pin) terminal H (harness-side).

•Is voltage 0 V?Yes Go to next step.

No Repair or replace harness, then go to Step 13.

12INSPECT TCM CIRCUIT FOR SHORT TO

GROUND

•Turn ignition key to OFF.

•Check continuity between TCM terminal 2S

(harness-side) and body ground.

•Is there any continuity?Yes Repair or replace harness, then go to next step.

No Go to next step.

13VERIFY TROUBLESHOOTING OF DTC P0743

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory using WDS or

equivalent.

•Drive vehicle in D range and make sure that

gears shift smoothly from 1GR to 5GR.

•Is same DTC present?Yes Replace TCM, then go to next step.

(See K2–96 TCM REMOVAL/INSTALLATION.)

No Go to next step.

14VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See K2–124 AFTER REPAIR PROCEDURE.)

•Is there any DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

DTC P0748 Pressure control solenoid circuit malfunction (open/short)

DETECTION

CONDITION•Open or short in pressure control solenoid signal system (while TCM monitors solenoid output voltage, the

voltage that differs from the ON/OFF signal output by CPU in TCM is detected).

Diagnostic support note:

•This is a continuous monitor (CCM).

•MIL does not illuminate.

•PENDING CODE is not available.

•FREEZE FRAME DATA is not available.

•AT warning light indication.

•DTC is stored in TCM memory.

POSSIBLE

CAUSE•Open circuit between pressure control solenoid terminal A and TCM terminal 2Y

•Short to ground between pressure control solenoid terminal A and TCM terminal 2Y

•Short to power between pressure control solenoid terminal A and TCM terminal 2Y

•Pressure control solenoid malfunction

•Damaged connector between pressure control solenoid valve and TCM

•TCM malfunction

Page 564 of 909

ON-BOARD DIAGNOSTIC

K2–149

K2

End Of SieDTC P0751A6E577018901215

Diagnostic procedure

End Of Sie

13VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See K2–124 AFTER REPAIR PROCEDURE.)

•Is there any DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

DTC P0751 Shift solenoid A malfunction (stuck off)

DETECTION

CONDITION•Difference between actual gear ratio and gear ratio set in TCM is large.

Diagnostic support note:

•This is a continuous monitor (CCM).

•MIL illuminates if TCM detects the above malfunction condition.

•PENDING CODE is not available.

•FREEZE FRAME DATA is available.

•AT warning light does not indication.

•DTC is stored in TCM memory.

POSSIBLE

CAUSE•Shift solenoid A malfunction

•Shift valve A stuck

•TCM malfunction

STEP INSPECTION ACTION

1VERIFY FREEZE FRAME DATA HAS BEEN

RECORDED

•Has FREEZE FRAME PID DATA been

recorded?Yes Go to next step.

No Record FREEZE FRAME PID DATA on repair order, then

go to next step.

2VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Bulletins and/or on-

line repair information availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available repair

information.

•If vehicle is not repaired, go to next step.

No Go to next step.

3CHECK FOR DTC

•Turn ignition key to ON (engine OFF).

•Inspect DTC.

•Is DTC outputted?Yes Follow applicable DTC inspection procedure.

No Go to next step.

4CHECK ATF CONDITION

•Turn ignition key to OFF.

•Check ATF condition.

—Transparent red: Normal

—Milky: Water mixed in fluid

—Reddish brown: Deteriorated ATF

•Is it okay?

(See K2–78 Automatic Transaxle Fluid (ATF)

Condition Inspection.)Yes replace control valve body, then go to next step.

No If ATF color milky or reddish brown, reaper or replace ATX,

then go to next step.

5VERIFY TROUBLESHOOTING OF DTC P0751

COMPLETED.

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory using WDS or

equivalent.

•Start engine.

•Warm up ATX.

•Drive vehicle in D range and make sure that

gears shift smoothly from 1GR to 5GR.

•Is same DTC present?Yes Replace TCM, then go to next step.

(See K2–96 TCM REMOVAL/INSTALLATION.)

No Go to next step.

6VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See K2–124 AFTER REPAIR PROCEDURE.)

•Is there any DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed.

Page 565 of 909

K2–150

ON-BOARD DIAGNOSTIC

DTC P0752A6E577018901216

Diagnostic procedure

End Of Sie

DTC P0752 Shift solenoid A malfunction (stuck on)

DETECTION

CONDITION•Difference between actual gear ratio and gear ratio set in TCM is large.

Diagnostic support note:

•This is a continuous monitor (CCM).

•MIL illuminates if TCM detects the above malfunction.

•PENDING CODE is not available.

•FREEZE FRAME DATA is available.

•AT warning light does not indication.

•DTC is stored in TCM memory.

POSSIBLE

CAUSE•Shift solenoid A malfunction

•Shift valve A stuck

•TCM malfunction

STEP INSPECTION ACTION

1VERIFY FREEZE FRAME DATA HAS BEEN

RECORDED

•Has FREEZE FRAME PID DATA been

recorded?Yes Go to next step.

No Record FREEZE FRAME PID DATA on repair order, then

go to next step.

2VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Bulletins and/or on-

line repair information availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available repair

information.

•If vehicle is not repaired, go to next step.

No Go to next step.

3CHECK FOR DTC

•Turn ignition key to ON (engine OFF).

•Inspect DTC.

•Is DTC outputted?Yes Follow applicable DTC inspection procedure.

No Go to next step.

4CHECK ATF CONDITION

•Turn ignition key to OFF.

•Check ATF condition.

—Transparent red: Normal

—Milky: Water mixed in fluid

—Reddish brown: Deteriorated ATF

•Is it okay?

(See K2–78 Automatic Transaxle Fluid (ATF)

Condition Inspection.)Yes replace control valve body, then go to next step.

No If ATF color milky or reddish brown, reaper or replace ATX,

then go to next step.

5VERIFY TROUBLESHOOTING OF DTC P0752

COMPLETED.

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory using WDS or

equivalent.

•Start engine.

•Warm up ATX.

•Drive vehicle in D range and make sure that

gears shift smoothly from 1GR to 5GR.

•Is same DTC present?Yes Replace TCM, then go to next step.

(See K2–96 TCM REMOVAL/INSTALLATION.)

No Go to next step.

6VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See K2–124 AFTER REPAIR PROCEDURE.)

•Is there any DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed.

Page 566 of 909

ON-BOARD DIAGNOSTIC

K2–151

K2

DTC P0753A6E577018901217

DTC P0753 Shift solenoid A circuit malfunction (open/short)

DETECTION

CONDITION•Open or short in shift solenoid A signal system (while TCM monitors solenoid output voltage, the voltage

that differs from the ON/OFF signal output by CPU in TCM is detected).

Diagnostic support note:

•This is a continuous monitor (CCM).

•MIL illuminates if TCM detects the above malfunction condition during first drive cycle.

•PENDING CODE is not available.

•FREEZE FRAME DATA is available.

•AT warning light indication.

•DTC is stored in TCM memory.

POSSIBLE

CAUSE•Open circuit between shift solenoid A terminal A and TCM terminal 2W

•Short to ground between shift solenoid A terminal A and TCM terminal 2W

•Short to power between shift solenoid A terminal A and TCM terminal 2W

•Shift solenoid A malfunction

•Damage connector between shift solenoid A and TCM

•TCM malfunction

CPU

I

K

A

2W

TCM

AT X

TCM

HARNESS SIDE CONNECTOR

TERMINAL COMPONENT

NO.1(12-PIN)

HARNESS SIDE CONNECTORSHIFT SOLENOID A

COUPLER COMPONENT

(10-PIN)

PART SIDE CONNECTORSHIFT SOLENOID A

HARNESS SIDE CONNECTOR

Page 568 of 909

ON-BOARD DIAGNOSTIC

K2–153

K2

End Of Sie

DTC P0756A6E577018901218

Diagnostic procedure

11INSPECT TERMINAL COMPONENT NO.1 (12-

PIN) CIRCUIT FOR SHORT TO POWER

•Turn ignition key to ON (engine OFF).

•Check voltage at terminal component No.1 (12-

pin) terminal I (harness-side).

•Is voltage 0 V?Yes Go to next step.

No Repair or replace harness, then go to Step 13.

12INSPECT TCM CIRCUIT FOR SHORT TO

GROUND

•Turn ignition key to OFF.

•Check continuity between TCM terminal 2W

(harness-side) and body ground.

•Is there any continuity?Yes Repair or replace harness, then go to next step.

No Go to next step.

13VERIFY TROUBLESHOOTING OF DTC P0753

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory using WDS or

equivalent.

•Drive vehicle in D range and make sure that

gears shift smoothly from 1GR to 5GR.

•Is same DTC present?Yes Replace TCM, then go to next step.

(See K2–96 TCM REMOVAL/INSTALLATION.)

No Go to next step.

14VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See K2–124 AFTER REPAIR PROCEDURE.)

•Is there any DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

DTC P0756 Shift solenoid B malfunction (stuck off)

DETECTION

CONDITION•Difference between actual gear ratio and gear ratio set in TCM is large.

Diagnostic support note:

•This is a continuous monitor (CCM).

•MIL illuminates if TCM detects the above malfunction condition.

•PENDING CODE is not available.

•FREEZE FRAME DATA is available.

•AT warning light does not indication.

•DTC is stored in TCM memory.

POSSIBLE

CAUSE•Shift solenoid B malfunction.

•Shift valve B stuck

•TCM malfunction

STEP INSPECTION ACTION

1VERIFY FREEZE FRAME DATA HAS BEEN

RECORDED

•Has FREEZE FRAME PID DATA been

recorded?Yes Go to next step.

No Record FREEZE FRAME PID DATA on repair order, then

go to next step.

2VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Bulletins and/or on-

line repair information availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available repair

information.

•If vehicle is not repaired, go to next step.

No Go to next step.

3CHECK FOR DTC

•Turn ignition key to ON (engine OFF).

•Inspect DTC.

•Is DTC outputted?Yes Follow applicable DTC inspection procedure.

No Go to next step.