air condition MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 570 of 909

ON-BOARD DIAGNOSTIC

K2–155

K2

End Of SieDTC P0758A6E577018901220

5VERIFY TROUBLESHOOTING OF DTC P0757

COMPLETED.

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory using WDS or

equivalent.

•Start engine.

•Warm up ATX.

•Drive vehicle in D range and make sure that

gears shift smoothly from 1GR to 5GR.

•Is same DTC present?Yes Replace TCM, then go to next step.

(See K2–96 TCM REMOVAL/INSTALLATION.)

No Go to next step.

6VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See K2–124 AFTER REPAIR PROCEDURE.)

•Is there any DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

DTC P0758 Shift solenoid B circuit malfunction (open/short)

DETECTION

CONDITION•Open or short in shift solenoid B signal system (while TCM monitors solenoid output voltage, the voltage

that differs from the ON/OFF signal output by CPU in TCM is detected).

Diagnostic support note:

•This is a continuous monitor (CCM).

•MIL illuminates if TCM detects the above malfunction conditions during first drive cycle.

•PENDING CODE is not available.

•FREEZE FRAME DATA is available.

•AT warning light indication.

•DTC is stored in TCM memory.

POSSIBLE

CAUSE•Open circuit between shift solenoid B terminal A and TCM terminal 2T

•Short to ground between shift solenoid B terminal A and TCM terminal 2T

•Short to power between shift solenoid B terminal A and TCM terminal 2T

•Shift solenoid B malfunction

•Damage connector between shift solenoid B and TCM

•TCM malfunction

Page 573 of 909

K2–158

ON-BOARD DIAGNOSTIC

End Of SieDTC P0761A6E577018901221

Diagnostic procedure

13VERIFY TROUBLESHOOTING OF DTC P0758

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory using WDS or

equivalent.

•Drive vehicle in D range and make sure that

gears shift smoothly from 1GR to 5GR.

•Is same DTC present?Yes Replace TCM, then go to next step.

(See K2–96 TCM REMOVAL/INSTALLATION.)

No Go to next step.

14VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See K2–124 AFTER REPAIR PROCEDURE.)

•Is there any DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

DTC P0761 Shift solenoid C malfunction (stuck off)

DETECTION

CONDITION•Difference between actual gear ratio and gear ratio set in TCM is large.

Diagnostic support note:

•This is a continuous monitor (CCM).

•MIL illuminates if TCM detects the above malfunction condition.

•PENDING CODE is not available.

•FREEZE FRAME DATA is available.

•AT warning light does not indication.

•DTC is stored in TCM memory.

POSSIBLE

CAUSE•Shift solenoid C malfunction

•Shift valve C stuck

•TCM malfunction

STEP INSPECTION ACTION

1VERIFY FREEZE FRAME DATA HAS BEEN

RECORDED

•Has FREEZE FRAME PID DATA been

recorded?Yes Go to next step.

No Record FREEZE FRAME PID DATA on repair order, then

go to next step.

2VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Bulletins and/or on-

line repair information availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available repair

information.

•If vehicle is not repaired, go to next step.

No Go to next step.

3CHECK FOR DTC

•Turn ignition key to ON (engine OFF).

•Inspect DTC.

•Is DTC outputted?Yes Follow applicable DTC inspection procedure.

No Go to next step.

4CHECK ATF CONDITION

•Turn ignition key to OFF.

•Check ATF condition.

—Transparent red: Normal

—Milky: Water mixed in fluid

—Reddish brown: Deteriorated ATF

•Is it okay?

(See K2–78 Automatic Transaxle Fluid (ATF)

Condition Inspection.)Yes replace control valve body, then go to next step.

No If ATF color milky or reddish brown, reaper or replace ATX,

then go to next step.

5VERIFY TROUBLESHOOTING OF DTC P0761

COMPLETED.

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory using WDS or

equivalent.

•Start engine.

•Warm up ATX.

•Drive vehicle in D range and make sure that

gears shift smoothly from 1GR to 5GR.

•Is same DTC present?Yes Replace TCM, then go to next step.

(See K2–96 TCM REMOVAL/INSTALLATION.)

No Go to next step.

Page 574 of 909

ON-BOARD DIAGNOSTIC

K2–159

K2

End Of SieDTC P0762A6E577018901222

Diagnostic procedure

End Of Sie

6VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See K2–124 AFTER REPAIR PROCEDURE.)

•Is there any DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

DTC P0762 Shift solenoid C malfunction (stuck on)

DETECTION

CONDITION•Difference between actual gear ratio and gear ratio set in TCM is large.

Diagnostic support note:

•This is continuous monitor (CCM).

•MIL illuminates if TCM detects the above malfunction condition.

•PENDING CODE is not available.

•FREEZE FRAME DATA is available.

•AT warning light does not indication.

•DTC is stored in TCM memory.

POSSIBLE

CAUSE•Shift solenoid C malfunction

•Shift valve C stuck

•TCM malfunction

STEP INSPECTION ACTION

1VERIFY FREEZE FRAME DATA HAS BEEN

RECORDED

•Has FREEZE FRAME PID DATA been

recorded?Yes Go to next step.

No Record FREEZE FRAME PID DATA on repair order, then

go to next step.

2VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Bulletins and/or on-

line repair information availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available repair

information.

•If vehicle is not repaired, go to next step.

No Go to next step.

3CHECK FOR DTC

•Turn ignition key to ON (engine OFF).

•Inspect DTC.

•Is DTC outputted?Yes Follow applicable DTC inspection procedure.

No Go to next step.

4CHECK ATF CONDITION

•Turn ignition key to OFF.

•Check ATF condition.

—Transparent red: Normal

—Milky: Water mixed in fluid

—Reddish brown: Deteriorated ATF

•Is it okay?

(See K2–78 Automatic Transaxle Fluid (ATF)

Condition Inspection.)Yes replace control valve body, then go to next step.

No If ATF color milky or reddish brown, reaper or replace ATX,

then go to next step.

5VERIFY TROUBLESHOOTING OF DTC P0762

COMPLETED.

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory using WDS or

equivalent.

•Start engine.

•Warm up ATX.

•Drive vehicle in D range and make sure that

gears shift smoothly from 1GR to 5GR.

•Is same DTC present?Yes Replace TCM, then go to next step.

(See K2–96 TCM REMOVAL/INSTALLATION.)

No Go to next step.

6VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See K2–124 AFTER REPAIR PROCEDURE.)

•Is there any DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed.

Page 595 of 909

K2–180

ON-BOARD DIAGNOSTIC

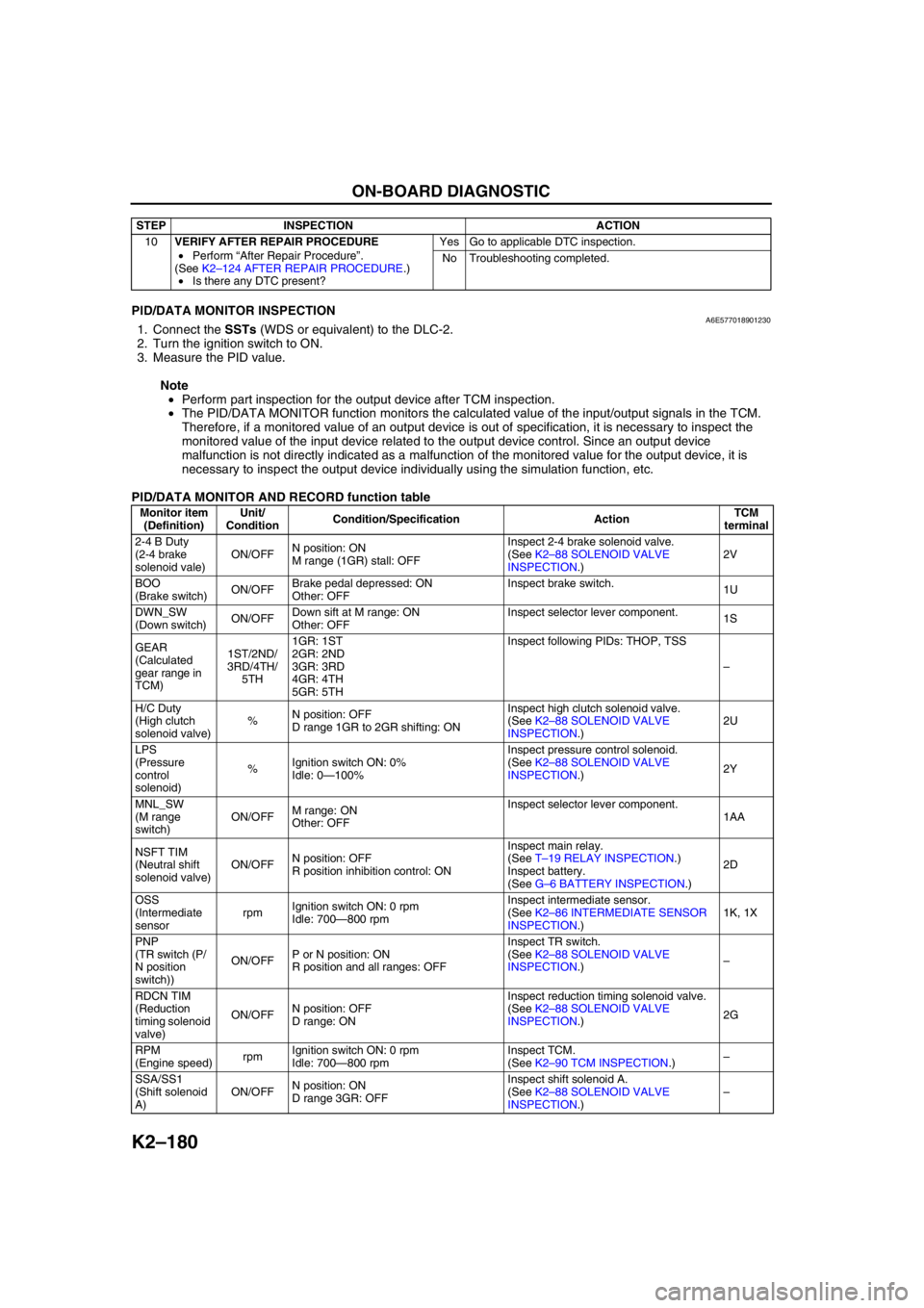

End Of SiePID/DATA MONITOR INSPECTIONA6E5770189012301. Connect the SSTs (WDS or equivalent) to the DLC-2.

2. Turn the ignition switch to ON.

3. Measure the PID value.

Note

•Perform part inspection for the output device after TCM inspection.

•The PID/DATA MONITOR function monitors the calculated value of the input/output signals in the TCM.

Therefore, if a monitored value of an output device is out of specification, it is necessary to inspect the

monitored value of the input device related to the output device control. Since an output device

malfunction is not directly indicated as a malfunction of the monitored value for the output device, it is

necessary to inspect the output device individually using the simulation function, etc.

PID/DATA MONITOR AND RECORD function table

10VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See K2–124 AFTER REPAIR PROCEDURE.)

•Is there any DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

Monitor item

(Definition)Unit/

ConditionCondition/Specification ActionTCM

terminal

2-4 B Duty

(2-4 brake

solenoid vale)ON/OFFN position: ON

M range (1GR) stall: OFFInspect 2-4 brake solenoid valve.

(See K2–88 SOLENOID VALVE

INSPECTION.)2V

BOO

(Brake switch)ON/OFFBrake pedal depressed: ON

Other: OFFInspect brake switch.

1U

DWN_SW

(Down switch)ON/OFFDown sift at M range: ON

Other: OFFInspect selector lever component.

1S

GEAR

(Calculated

gear range in

TCM)1ST/2ND/

3RD/4TH/

5TH1GR: 1ST

2GR: 2ND

3GR: 3RD

4GR: 4TH

5GR: 5THInspect following PIDs: THOP, TSS

–

H/C Duty

(High clutch

solenoid valve)%N position: OFF

D range 1GR to 2GR shifting: ONInspect high clutch solenoid valve.

(See K2–88 SOLENOID VALVE

INSPECTION.)2U

LPS

(Pressure

control

solenoid)%Ignition switch ON: 0%

Idle: 0—100%Inspect pressure control solenoid.

(See K2–88 SOLENOID VALVE

INSPECTION.)2Y

MNL_SW

(M range

switch)ON/OFFM range: ON

Other: OFFInspect selector lever component.

1AA

NSFT TIM

(Neutral shift

solenoid valve)ON/OFFN position: OFF

R position inhibition control: ONInspect main relay.

(See T–19 RELAY INSPECTION.)

Inspect battery.

(See G–6 BATTERY INSPECTION.)2D

OSS

(Intermediate

sensorrpmIgnition switch ON: 0 rpm

Idle: 700—800 rpmInspect intermediate sensor.

(See K2–86 INTERMEDIATE SENSOR

INSPECTION.)1K, 1X

PNP

(TR switch (P/

N position

switch))ON/OFFP or N position: ON

R position and all ranges: OFFInspect TR switch.

(See K2–88 SOLENOID VALVE

INSPECTION.)–

RDCN TIM

(Reduction

timing solenoid

valve)ON/OFFN position: OFF

D range: ONInspect reduction timing solenoid valve.

(See K2–88 SOLENOID VALVE

INSPECTION.)2G

RPM

(Engine speed)rpmIgnition switch ON: 0 rpm

Idle: 700—800 rpmInspect TCM.

(See K2–90 TCM INSPECTION.)–

SSA/SS1

(Shift solenoid

A)ON/OFFN position: ON

D range 3GR: OFFInspect shift solenoid A.

(See K2–88 SOLENOID VALVE

INSPECTION.)–

Page 597 of 909

K2–182

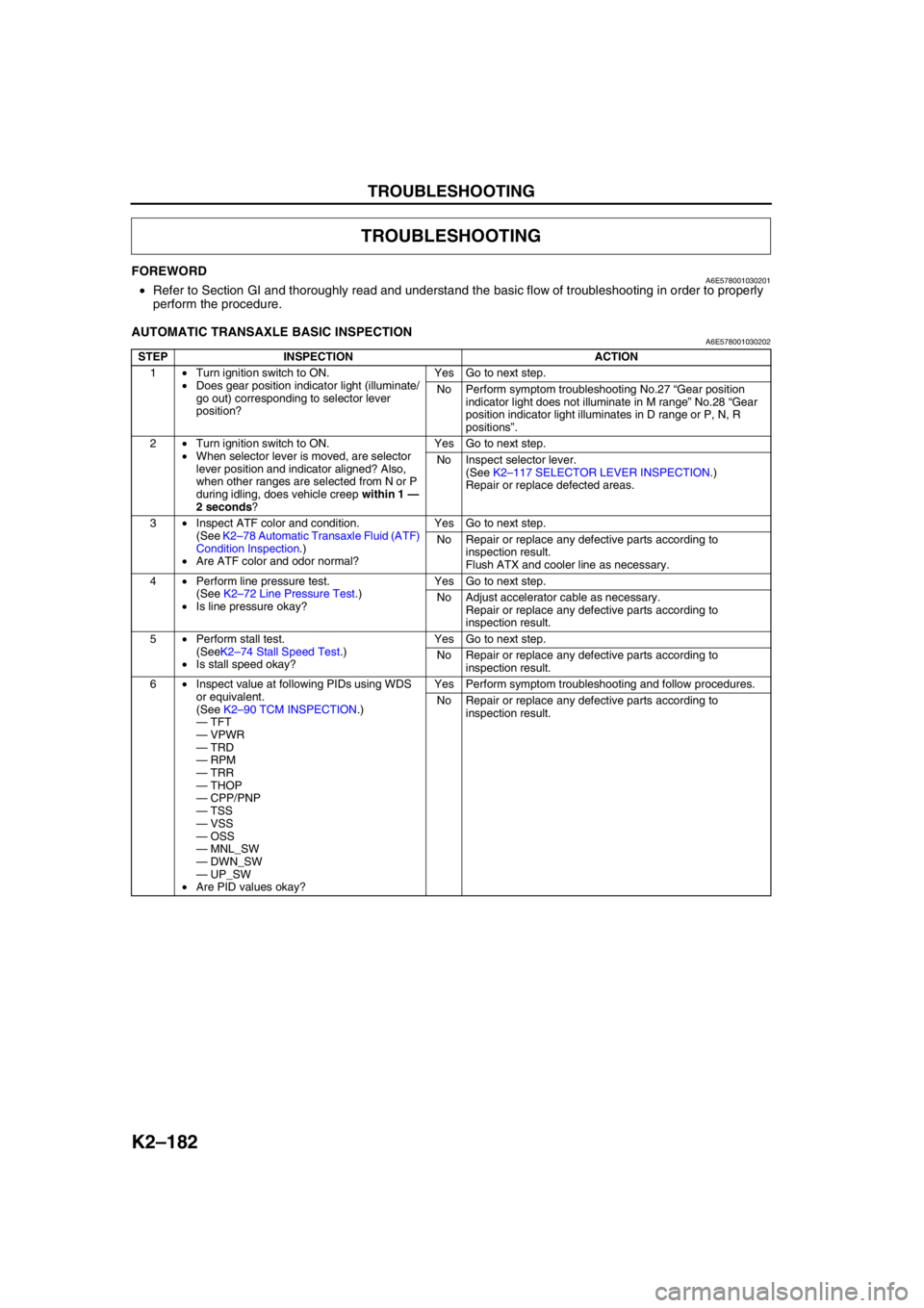

TROUBLESHOOTING

FOREWORDA6E578001030201•Refer to Section GI and thoroughly read and understand the basic flow of troubleshooting in order to properly

perform the procedure.

End Of Sie

AUTOMATIC TRANSAXLE BASIC INSPECTIONA6E578001030202

End Of Sie

TROUBLESHOOTING

STEP INSPECTION ACTION

1•Turn ignition switch to ON.

•Does gear position indicator light (illuminate/

go out) corresponding to selector lever

position?Yes Go to next step.

No Perform symptom troubleshooting No.27 “Gear position

indicator light does not illuminate in M range” No.28 “Gear

position indicator light illuminates in D range or P, N, R

positions”.

2•Turn ignition switch to ON.

•When selector lever is moved, are selector

lever position and indicator aligned? Also,

when other ranges are selected from N or P

during idling, does vehicle creep within 1 —

2 seconds?Yes Go to next step.

No Inspect selector lever.

(See K2–117 SELECTOR LEVER INSPECTION.)

Repair or replace defected areas.

3•Inspect ATF color and condition.

(See K2–78 Automatic Transaxle Fluid (ATF)

Condition Inspection.)

•Are ATF color and odor normal?Yes Go to next step.

No Repair or replace any defective parts according to

inspection result.

Flush ATX and cooler line as necessary.

4•Perform line pressure test.

(See K2–72 Line Pressure Test.)

•Is line pressure okay?Yes Go to next step.

No Adjust accelerator cable as necessary.

Repair or replace any defective parts according to

inspection result.

5•Perform stall test.

(SeeK2–74 Stall Speed Test.)

•Is stall speed okay?Yes Go to next step.

No Repair or replace any defective parts according to

inspection result.

6•Inspect value at following PIDs using WDS

or equivalent.

(See K2–90 TCM INSPECTION.)

—TFT

—VPWR

—TRD

—RPM

—TRR

—THOP

—CPP/PNP

—TSS

—VSS

—OSS

—MNL_SW

—DWN_SW

—UP_SW

•Are PID values okay?Yes Perform symptom troubleshooting and follow procedures.

No Repair or replace any defective parts according to

inspection result.

Page 604 of 909

TROUBLESHOOTING

K2–189

K2

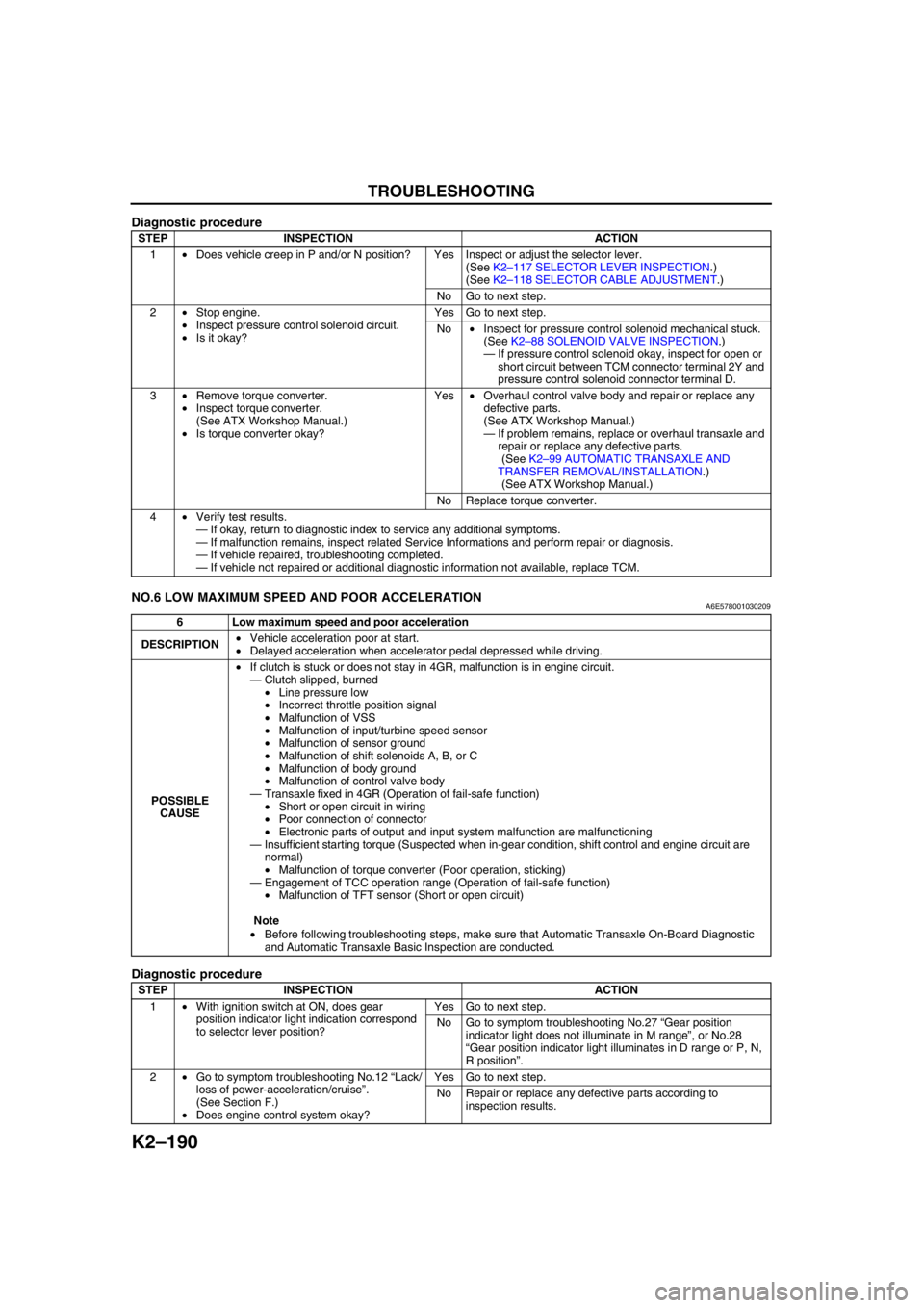

Diagnostic procedure

End Of SieNO.3 VEHICLE MOVES IN P POSITION, OR PARKING GEAR DOES NOT DISENGAGE WHEN P IS

DISENGAGED

A6E578001030206

End Of SieNO.4 EXCESSIVE CREEPA6E578001030207

End Of SieNO.5 NO CREEP AT ALLA6E578001030208

STEP INSPECTION ACTION

1•Does vehicle creep when selector lever

moved slightly in N position?Yes•Overhaul control valve body and repair or replace any

defective parts.

(See ATX Workshop Manual.)

—If problem remains, replace or overhaul transaxle and

repair or replace any defective parts.

(See K2–99 AUTOMATIC TRANSAXLE AND

TRANSFER REMOVAL/INSTALLATION.)

(See ATX Workshop Manual.)

No Inspect and adjust selector lever.

(See K2–117 SELECTOR LEVER INSPECTION.)

(See K2–118 SELECTOR CABLE ADJUSTMENT.)

2•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM.

3 Vehicle moves in P position, or parking gear does not disengage when P is disengaged

DESCRIPTION•Vehicle rolls when on a downward slope and tires do not lock in P position.

•Tires locked when P disengaged, vehicle does not move in D range, and R position when accelerator

pedal depressed, and engine remains in stall condition.

POSSIBLE

CAUSE•Malfunction of parking mechanism (May have effect on noise or shock from transaxle)

•Improper adjustment of selector lever

•If vehicle moves in N position, perform symptom troubleshooting No.2 “Vehicle moves in N position”

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

4 Excessive creep

DESCRIPTION•Vehicle accelerates in D range, and R position without depressing accelerator pedal.

POSSIBLE

CAUSE•Engine idle speed high (transaxle system is not cause of problem)

•Go to symptom troubleshooting No.9 “Fast idle/runs on”

(See Section F.)

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

5 No creep at all

DESCRIPTION•Vehicle does not move in D range, or R position when idling on flat paved road.

POSSIBLE

CAUSE•Either engine output low or there is clutch circuit slippage.

—Clutch burned

•Line pressure low

•Malfunction of shift solenoid A, B, or C

•Malfunction of body ground

•Malfunction of control valve body

—Transaxle fixed in 4GR (Operation of fail-safe function)

•Short or open circuit in wiring

•Poor connection of connector

•Electronic parts of output and input system malfunctioning

—Engine torque is not start

•Malfunction of torque converter

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

Page 605 of 909

K2–190

TROUBLESHOOTING

Diagnostic procedure

End Of SieNO.6 LOW MAXIMUM SPEED AND POOR ACCELERATIONA6E578001030209

Diagnostic procedure

STEP INSPECTION ACTION

1•Does vehicle creep in P and/or N position? Yes Inspect or adjust the selector lever.

(See K2–117 SELECTOR LEVER INSPECTION.)

(See K2–118 SELECTOR CABLE ADJUSTMENT.)

No Go to next step.

2•Stop engine.

•Inspect pressure control solenoid circuit.

•Is it okay?Yes Go to next step.

No•Inspect for pressure control solenoid mechanical stuck.

(See K2–88 SOLENOID VALVE INSPECTION.)

—If pressure control solenoid okay, inspect for open or

short circuit between TCM connector terminal 2Y and

pressure control solenoid connector terminal D.

3•Remove torque converter.

•Inspect torque converter.

(See ATX Workshop Manual.)

•Is torque converter okay?Yes•Overhaul control valve body and repair or replace any

defective parts.

(See ATX Workshop Manual.)

—If problem remains, replace or overhaul transaxle and

repair or replace any defective parts.

(See K2–99 AUTOMATIC TRANSAXLE AND

TRANSFER REMOVAL/INSTALLATION.)

(See ATX Workshop Manual.)

No Replace torque converter.

4•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM.

6 Low maximum speed and poor acceleration

DESCRIPTION•Vehicle acceleration poor at start.

•Delayed acceleration when accelerator pedal depressed while driving.

POSSIBLE

CAUSE•If clutch is stuck or does not stay in 4GR, malfunction is in engine circuit.

—Clutch slipped, burned

•Line pressure low

•Incorrect throttle position signal

•Malfunction of VSS

•Malfunction of input/turbine speed sensor

•Malfunction of sensor ground

•Malfunction of shift solenoids A, B, or C

•Malfunction of body ground

•Malfunction of control valve body

—Transaxle fixed in 4GR (Operation of fail-safe function)

•Short or open circuit in wiring

•Poor connection of connector

•Electronic parts of output and input system malfunction are malfunctioning

—Insufficient starting torque (Suspected when in-gear condition, shift control and engine circuit are

normal)

•Malfunction of torque converter (Poor operation, sticking)

—Engagement of TCC operation range (Operation of fail-safe function)

•Malfunction of TFT sensor (Short or open circuit)

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP INSPECTION ACTION

1•With ignition switch at ON, does gear

position indicator light indication correspond

to selector lever position?Yes Go to next step.

No Go to symptom troubleshooting No.27 “Gear position

indicator light does not illuminate in M range”, or No.28

“Gear position indicator light illuminates in D range or P, N,

R position”.

2•Go to symptom troubleshooting No.12 “Lack/

loss of power-acceleration/cruise”.

(See Section F.)

•Does engine control system okay?Yes Go to next step.

No Repair or replace any defective parts according to

inspection results.

Page 611 of 909

K2–196

TROUBLESHOOTING

NO.15 ENGINE FLARES UP OR SLIPS WHEN ACCELERATING VEHICLEA6E578001030218

End Of SieNO.16 JUDDER UPON TORQUE CONVERTER CLUTCH (TCC) OPERATIONA6E578001030219

End Of SieNO.17 EXCESSIVE SHIFT SHOCK FROM N TO D OR N TO R POSITION/RANGEA6E578001030220

Diagnostic procedure

15 Engine flares up or slips when accelerating vehicle

DESCRIPTION•Engine flares up when accelerator pedal depressed for upshifting.

•Engine flares up suddenly when accelerator pedal depressed for downshifting.

POSSIBLE

CAUSE•Malfunction is basically the same as for No.14 “Engine flares up or slips when upshifting or

downshifting”.

—If conditions for No.14 worsen, malfunction will develop into No.15.

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

16 Judder upon torque converter clutch (TCC) operation

DESCRIPTION•Vehicle jolts when TCC engaged.

POSSIBLE

CAUSE•Poor TCC engagement due to either slippage because TCC piston is stuck or line pressure is low.

Caution

•If the TCC or piston are stuck, inspect them. In addition, inspect the oil cooler for foreign

particles which may have mixed in with the ATF.

—Torque converter clutch piston slipped, burned

•Line pressure low

•Incorrect throttle position signal

•Malfunction of VSS

•Malfunction of input/turbine speed sensor

•Malfunction of sensor ground

•Malfunction of TCC solenoid valve

•Malfunction of control valve body

—Malfunction of torque converter

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

17 Excessive shift shock from N to D or N to R position/range

DESCRIPTION•Strong shock felt when shifting from N to D or N to R position/range at idle.

POSSIBLE

CAUSE•Shift shock may worsen when fail-safe is operating. If no DTC is output, shift shock may worsen due to

poor operation of control valve body or sticking of clutch.

—Clutch burned (N→D: Low clutch, N→R: Reverse clutch or low and reverse brake)

•Line pressure low

•Incorrect throttle position signal

•Malfunction of TFT sensor

•Malfunction of sensor ground

•Misadjustment of throttle cable

•Malfunction of control valve body

—Poor hydraulic operation (Malfunction in range change)

—Idle speed high

—Poor tightening torque of engine mount, exhaust mount

—Line pressure high

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP INSPECTION ACTION

1•Does shift shock occur only when engine

cold?Yes Go to next step.

No Go to Step 3.

2•Inspect TFT sensor and related harness:

vibration, intermittent open/short circuit.

•Is it okay?Yes Go to next step.

No Repair or replace part if necessary.

Page 613 of 909

K2–198

TROUBLESHOOTING

NO.20 NOISE OCCURS AT IDLE WHEN VEHICLE IS STOPPED IN ALL POSITIONS/RANGESA6E578001030223

Diagnostic procedure

End Of SieNO.21 NOISE OCCURS AT IDLE WHEN VEHICLE IS STOPPED IN D RANGE, OR IN R POSITIONA6E578001030224

End Of SieNO.22 NO ENGINE BRAKING IN 1GR POSITION OF M RANGEA6E578001030225

Diagnostic procedure

20 Noise occurs at idle when vehicle is stopped in all positions/ranges

DESCRIPTION•Transaxle noisy in all positions and ranges when vehicle idling.

POSSIBLE

CAUSE•Malfunction is in pressure solenoid or oil pump which causes a high-pitched noise to be emitted from

transaxle at idle.

Note

•If a noise is emitted during shifting only, malfunction is in shift solenoid A, B, or C.

•If a noise is emitted during shifting at certain gears only or during deceleration only, it is gear noise.

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP INSPECTION ACTION

1•Inspect engine condition.

•Is any engine concern (e.g. Rough idle)?Yes Go to appropriate symptom troubleshooting.

(See F1–57 ENGINE SYMPTOM TROUBLESHOOTING.)

No Replace basic inspection and repair or replace any

defective parts according to inspection result.

2•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM.

21 Noise occurs at idle when vehicle is stopped in D range, or in R position

DESCRIPTION•Transaxle noisy in driving ranges when vehicle idling.

POSSIBLE

CAUSE•Although the malfunction is basically the same as No.20 “Noise occurs at idle when vehicle is stopped

in all positions/ranges”, other causes may be selector lever position disparity or TR switch position

disparity.

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

22 No engine braking in 1GR position of M range

DESCRIPTION•Engine speed drops to idle but vehicle coasts when accelerator pedal released during cruising at

medium to high speeds.

•Engine speed drops to idle but vehicle coasts when accelerator pedal released when in M range (1GR)

at low vehicle speed.

POSSIBLE

CAUSE•Clutch slipped, burned (Reduction brake)

—Line pressure low

•Malfunction of VSS

•Malfunction of input/turbine speed sensor

•Malfunction of sensor ground

•Malfunction of control valve body

—M range switch on not judged by TCM (short, or open circuit, poor operation)

•Malfunction of M range switch signal

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP INSPECTION ACTION

1•Inspect TR switch adjustment.

•Does TR switch adjusted properly?

•Select PNP PID.

•Is PNP PID reading okay when selecting

range?Yes Go to next step.

No Adjust TR switch as necessary.

(See K2–83 TRANSAXLE RANGE (TR) SWITCH

ADJUSTMENT.)

Inspect TR switch.

Repair or replace any defective parts.

Page 647 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–17

M

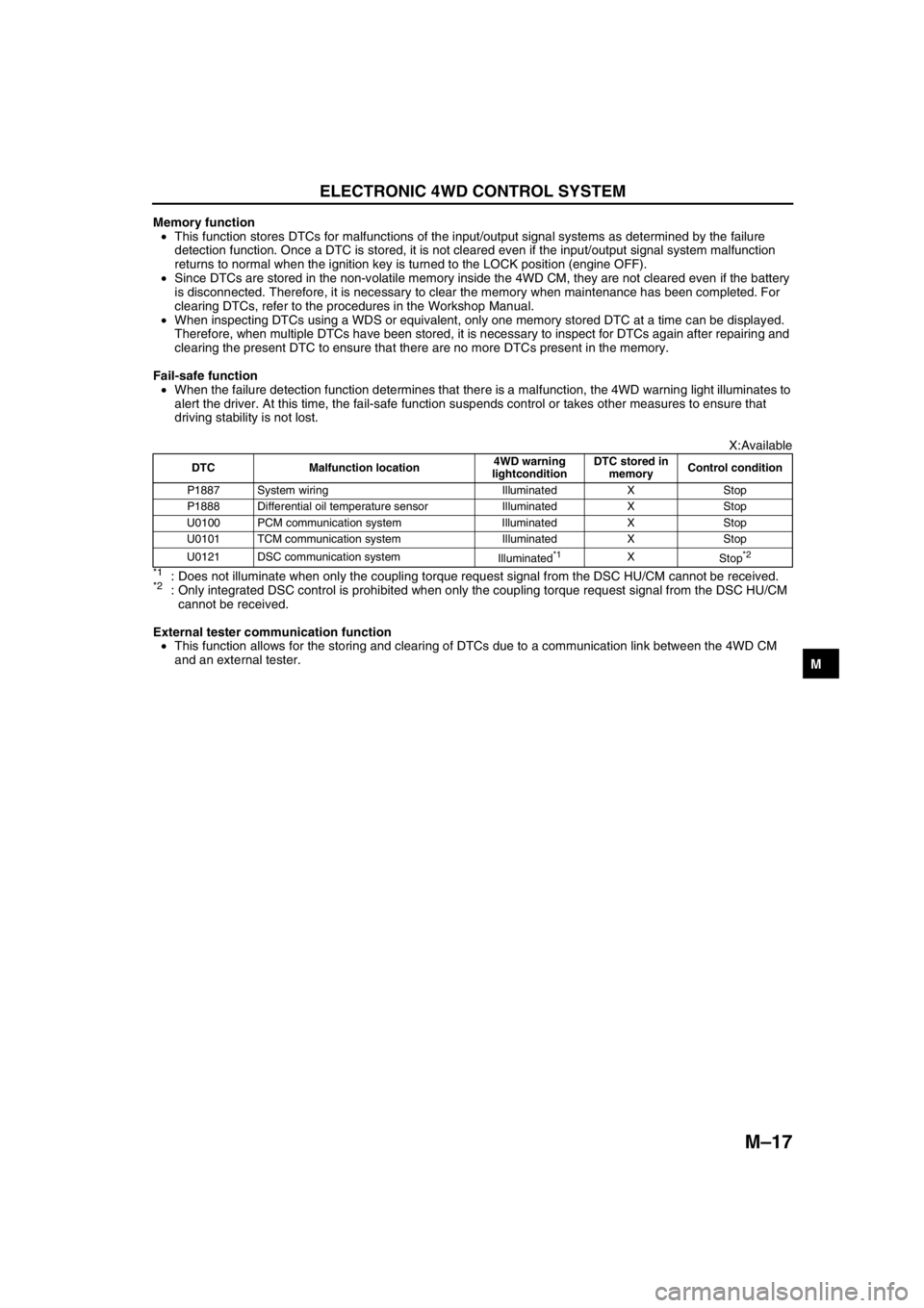

Memory function

•This function stores DTCs for malfunctions of the input/output signal systems as determined by the failure

detection function. Once a DTC is stored, it is not cleared even if the input/output signal system malfunction

returns to normal when the ignition key is turned to the LOCK position (engine OFF).

•Since DTCs are stored in the non-volatile memory inside the 4WD CM, they are not cleared even if the battery

is disconnected. Therefore, it is necessary to clear the memory when maintenance has been completed. For

clearing DTCs, refer to the procedures in the Workshop Manual.

•When inspecting DTCs using a WDS or equivalent, only one memory stored DTC at a time can be displayed.

Therefore, when multiple DTCs have been stored, it is necessary to inspect for DTCs again after repairing and

clearing the present DTC to ensure that there are no more DTCs present in the memory.

Fail-safe function

•When the failure detection function determines that there is a malfunction, the 4WD warning light illuminates to

alert the driver. At this time, the fail-safe function suspends control or takes other measures to ensure that

driving stability is not lost.

X:Available

*1: Does not illuminate when only the coupling torque request signal from the DSC HU/CM cannot be received.*2: Only integrated DSC control is prohibited when only the coupling torque request signal from the DSC HU/CM

cannot be received.

External tester communication function

•This function allows for the storing and clearing of DTCs due to a communication link between the 4WD CM

and an external tester.

End Of Sie

DTC Malfunction location4WD warning

lightconditionDTC stored in

memoryControl condition

P1887 System wiring Illuminated X Stop

P1888 Differential oil temperature sensor Illuminated X Stop

U0100 PCM communication system Illuminated X Stop

U0101 TCM communication system Illuminated X Stop

U0121 DSC communication system

Illuminated

*1X

Stop*2